ISO/IEC 18050:2006

(Main)Information technology — Office equipment — Print quality attributes for machine readable Digital Postage Marks

Information technology — Office equipment — Print quality attributes for machine readable Digital Postage Marks

ISO/IEC 18050:2006 specifies two methodologies for the measurement of specific print quality attributes of two-dimensional bar code symbols printed within the requirements of Digital Postage Marks. One of these methodologies is applicable to multi-row bar code symbologies and the other to two-dimensional matrix symbologies. ISO/IEC 18050:2006 defines methods for grading print quality attributes and deriving an overall assessment of symbol quality. In addition, it gives information on possible causes of deviation from optimum grades so as to assist users and postal operators in taking appropriate corrective action. ISO/IEC 18050:2006 applies only to those two-dimensional symbologies for which a reference decode algorithm has been defined, and provides an indicative read rate for limiting mean parameter values. The methodologies can be applied partially or wholly to other similar symbologies.

Technologies de l'information — Équipement de bureau — Attributs d'impression qualité pour les timbres postaux numériques lisibles par machine

General Information

- Status

- Published

- Publication Date

- 16-Feb-2006

- Technical Committee

- ISO/IEC JTC 1/SC 28 - Office equipment

- Drafting Committee

- ISO/IEC JTC 1/SC 28 - Office equipment

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 15-Dec-2021

- Completion Date

- 14-Feb-2026

Overview

ISO/IEC 18050:2006 - Information technology - Office equipment - Print quality attributes for machine readable Digital Postage Marks - defines standardized methods to measure and grade the print quality of two‑dimensional bar code symbols used as Digital Postage Marks (DPM). It provides two tailored measurement methodologies: one for multi‑row symbologies (e.g., PDF417) and one for two‑dimensional matrix symbologies (e.g., Data Matrix). The standard helps estimate read rates, identify causes of poor print quality, and guide corrective actions for reliable machine reading in postal applications.

Key topics and technical requirements

- Measurement methodology: Adapts the ISO/IEC 15415 approach to DPMs, specifying how to measure symbol attributes that affect readability.

- Two methodologies: Separate procedures for multi‑row and matrix symbologies to reflect differences in structure and scanning behavior.

- Grading scheme: Defines attribute grading levels (criticality grades 0–4) and a method to derive an overall symbol quality grade from multiple scans.

- Verification requirements: Requirements for verification equipment, optical geometry, light sources, and measuring apertures tailored to DPMs.

- Quiet zone and additional parameters: Guidance on margins and other parameters that influence decoding success.

- Printing system qualification: Test procedures and annexed guidance for qualifying printers and substrates for reliable DPM production.

- Diagnostic guidance: Informative annexes describe likely causes of low grades (contrast, modulation, defects, print growth, grid non‑uniformity) and recommended checks.

- Scope limitations: Applies to two‑dimensional symbologies with a defined reference decode algorithm; provides indicative read rates for limiting mean parameter values and may be partially applied to similar symbologies.

Practical applications and users

ISO/IEC 18050:2006 is intended for:

- Postal operators and carriers seeking reliable automated validation of postage marks and high read rates during sorting and processing.

- Mailers and print service providers who generate postage marks and need to ensure compliance and process control.

- Printing equipment manufacturers (inkjet, laser, thermal, direct thermal) who design and qualify systems for DPM production.

- Barcode verification and AIDC vendors who develop validation tools and decoding hardware/software.

- Quality engineers and test labs using standardized procedures to qualify substrates, inks, and production processes for consistent machine readability.

Related standards

- ISO/IEC 15415 (print quality measurement methodology for two‑dimensional symbols) - referenced and adapted for DPMs.

- UPU S‑28 (postal symbology recommendations) - commonly related for postal implementations.

Keywords: ISO/IEC 18050:2006, Digital Postage Marks, print quality, two‑dimensional bar code, PDF417, Data Matrix, barcode grading, postal automation, verification.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

NYCE

Mexican standards and certification body.

Sponsored listings

Frequently Asked Questions

ISO/IEC 18050:2006 is a standard published by the International Organization for Standardization (ISO). Its full title is "Information technology — Office equipment — Print quality attributes for machine readable Digital Postage Marks". This standard covers: ISO/IEC 18050:2006 specifies two methodologies for the measurement of specific print quality attributes of two-dimensional bar code symbols printed within the requirements of Digital Postage Marks. One of these methodologies is applicable to multi-row bar code symbologies and the other to two-dimensional matrix symbologies. ISO/IEC 18050:2006 defines methods for grading print quality attributes and deriving an overall assessment of symbol quality. In addition, it gives information on possible causes of deviation from optimum grades so as to assist users and postal operators in taking appropriate corrective action. ISO/IEC 18050:2006 applies only to those two-dimensional symbologies for which a reference decode algorithm has been defined, and provides an indicative read rate for limiting mean parameter values. The methodologies can be applied partially or wholly to other similar symbologies.

ISO/IEC 18050:2006 specifies two methodologies for the measurement of specific print quality attributes of two-dimensional bar code symbols printed within the requirements of Digital Postage Marks. One of these methodologies is applicable to multi-row bar code symbologies and the other to two-dimensional matrix symbologies. ISO/IEC 18050:2006 defines methods for grading print quality attributes and deriving an overall assessment of symbol quality. In addition, it gives information on possible causes of deviation from optimum grades so as to assist users and postal operators in taking appropriate corrective action. ISO/IEC 18050:2006 applies only to those two-dimensional symbologies for which a reference decode algorithm has been defined, and provides an indicative read rate for limiting mean parameter values. The methodologies can be applied partially or wholly to other similar symbologies.

ISO/IEC 18050:2006 is classified under the following ICS (International Classification for Standards) categories: 35.040 - Information coding; 35.040.50 - Automatic identification and data capture techniques. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/IEC 18050:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO/IEC

STANDARD 18050

First edition

2006-02-15

Information technology — Office

equipment — Print quality attributes for

machine readable Digital Postage Marks

Technologies de l'information — Équipement de bureau — Attributs

d'impression qualité pour les timbres postaux numériques lisibles par

machine

Reference number

©

ISO/IEC 2006

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO/IEC 2006

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO/IEC 2006 – All rights reserved

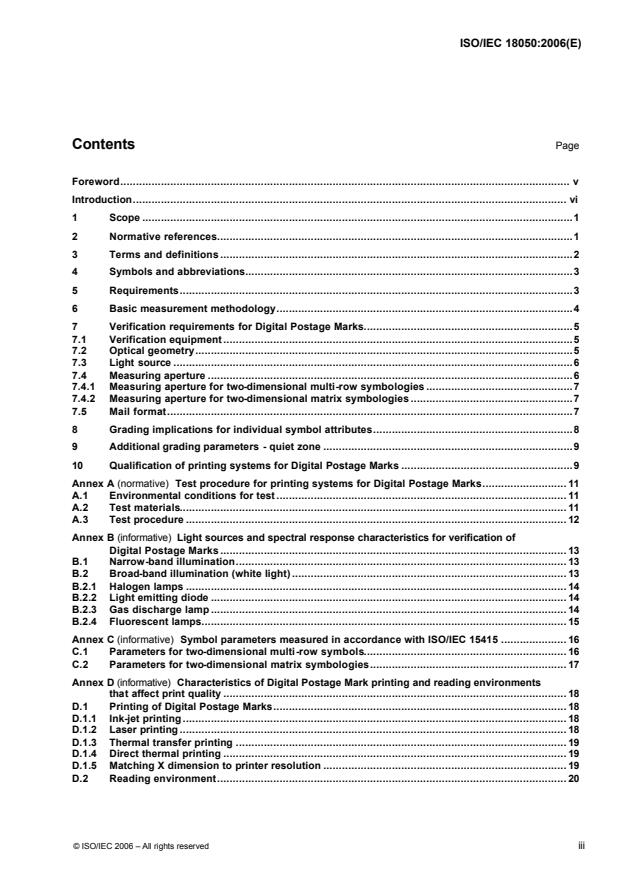

Contents Page

Foreword. v

Introduction. vi

1 Scope .1

2 Normative references.1

3 Terms and definitions .2

4 Symbols and abbreviations.3

5 Requirements.3

6 Basic measurement methodology.4

7 Verification requirements for Digital Postage Marks.5

7.1 Verification equipment .5

7.2 Optical geometry.5

7.3 Light source .6

7.4 Measuring aperture .6

7.4.1 Measuring aperture for two-dimensional multi-row symbologies .7

7.4.2 Measuring aperture for two-dimensional matrix symbologies .7

7.5 Mail format.7

8 Grading implications for individual symbol attributes.8

9 Additional grading parameters - quiet zone .9

10 Qualification of printing systems for Digital Postage Marks .9

Annex A (normative) Test procedure for printing systems for Digital Postage Marks. 11

A.1 Environmental conditions for test . 11

A.2 Test materials. 11

A.3 Test procedure . 12

Annex B (informative) Light sources and spectral response characteristics for verification of

Digital Postage Marks . 13

B.1 Narrow-band illumination. 13

B.2 Broad-band illumination (white light) . 13

B.2.1 Halogen lamps . 14

B.2.2 Light emitting diode . 14

B.2.3 Gas discharge lamp . 14

B.2.4 Fluorescent lamps. 15

Annex C (informative) Symbol parameters measured in accordance with ISO/IEC 15415 . 16

C.1 Parameters for two-dimensional multi-row symbols. 16

C.2 Parameters for two-dimensional matrix symbologies. 17

Annex D (informative) Characteristics of Digital Postage Mark printing and reading environments

that affect print quality . 18

D.1 Printing of Digital Postage Marks. 18

D.1.1 Ink-jet printing . 18

D.1.2 Laser printing . 18

D.1.3 Thermal transfer printing . 19

D.1.4 Direct thermal printing . 19

D.1.5 Matching X dimension to printer resolution . 19

D.2 Reading environment. 20

© ISO/IEC 2006 – All rights reserved iii

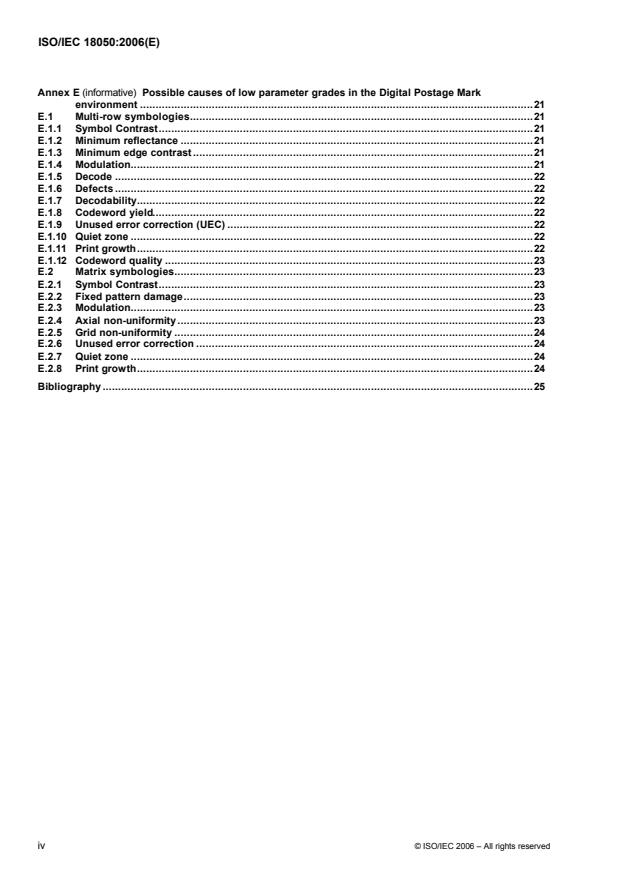

Annex E (informative) Possible causes of low parameter grades in the Digital Postage Mark

environment .21

E.1 Multi-row symbologies.21

E.1.1 Symbol Contrast.21

E.1.2 Minimum reflectance .21

E.1.3 Minimum edge contrast .21

E.1.4 Modulation.21

E.1.5 Decode .22

E.1.6 Defects .22

E.1.7 Decodability.22

E.1.8 Codeword yield.22

E.1.9 Unused error correction (UEC) .22

E.1.10 Quiet zone .22

E.1.11 Print growth.22

E.1.12 Codeword quality .23

E.2 Matrix symbologies.23

E.2.1 Symbol Contrast.23

E.2.2 Fixed pattern damage.23

E.2.3 Modulation.23

E.2.4 Axial non-uniformity .23

E.2.5 Grid non-uniformity .24

E.2.6 Unused error correction .24

E.2.7 Quiet zone .24

E.2.8 Print growth.24

Bibliography .25

iv © ISO/IEC 2006 – All rights reserved

Foreword

ISO (the International Organization for Standardization) and IEC (the International Electrotechnical

Commission) form the specialized system for worldwide standardization. National bodies that are members of

ISO or IEC participate in the development of International Standards through technical committees

established by the respective organization to deal with particular fields of technical activity. ISO and IEC

technical committees collaborate in fields of mutual interest. Other international organizations, governmental

and non-governmental, in liaison with ISO and IEC, also take part in the work. In the field of information

technology, ISO and IEC have established a joint technical committee, ISO/IEC JTC 1.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of the joint technical committee is to prepare International Standards. Draft International

Standards adopted by the joint technical committee are circulated to national bodies for voting. Publication as

an International Standard requires approval by at least 75 % of the national bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO and IEC shall not be held responsible for identifying any or all such patent rights.

ISO/IEC 18050 was prepared by Joint Technical Committee ISO/IEC JTC 1, Information technology,

Subcommittee SC 28, Office equipment.

v

© ISO/IEC 2006 – All rights reserved

Introduction

Digital Postage Marks (or franking marks), sometimes abbreviated to DPM, are used to evidence the payment

of postage and/or other fees related to services requested by mailers. Digital Postage Marks are represented

by symbols imprinted on the envelope, the label or the insert. Digital Postage Marks produced by different

vendors’ systems are generated with a variety of symbols and graphical images. The symbologies used for

these images are primarily two-dimensional bar codes of both multi-row (PDF417) and matrix types (e.g. Data

Matrix), as specified in UPU standard S 28. However, postal operators may also use other symbologies, e.g.

OCR or 4-state codes for these purposes. The two-dimensional bar code symbologies offer advantages for

the machine-readable representation of data strings of the order of 80 or more bytes in length, due to their

high information density characteristics.

Public postal operators and private carriers have a high interest in automatically reading and validating these

marks, preferably at high speed. These symbols must be read reliably by postal processing equipment. The

highest practicable read rate is desired by users of such equipment in order to ensure efficient automation of

this process, and any shortfall in the read rate may have as its consequence a loss of revenue to the operator.

This International Standard has been designed to customize the generic method of measuring the print quality

of two-dimensional bar code symbols to the needs of the postal application and to recommend appropriate

print quality levels that should contribute to the achievement of the read rates desired by the authorities

responsible for validation of the Digital Postage Marks and by postal operators; it is also intended to provide

guidelines for printing machine readable Digital Postage Marks on mail items. This International Standard will

provide mailers, postal operators and their suppliers with a practical, quantitative and objective way to

measure and communicate to each other basic print quality parameters of machine readable Digital Postage

Marks. Since all attributes do not contribute uniformly to the readability of a Digital Postage Mark, this

International Standard identifies five levels of criticality for an attribute (graded 0 to 4, in ascending order of

quality), and a grading scheme that assesses the overall symbol quality based on averaging the results of

multiple scans.

The International Standard may be used in the following ways:

• It allows an estimate to be made of the readability of a Digital Postage Mark without actually submitting it

to any postal validation and the qualification of said symbol as acceptable or not acceptable for readability

purposes.

• It allows an estimate to be made of the quality levels potentially achievable by a printing system with

particular substrates.

•

It provides a tool for process control in the operation of Digital Postage Mark printing systems.

This International Standard applies the measurement methodology defined in ISO/IEC 15415 for print quality

attributes that tend to influence the readability of two-dimensional bar codes. This methodology is derived

from a view of the current state-of-the-art in two-dimensional bar code scanning technologies.

Yet, such a state-of-the-art is not a perfectly defined concept. First, it is likely to evolve with time towards

improved recognition capabilities. Second, an automatic identification and data capture system is always the

result of a compromise between recognition power and cost. This is why this International Standard is

expressed in the form of guidelines rather than prescriptions. However, it is not technically possible to define

guidelines concerning solely the printing of Digital Postage Marks without taking into account the

manufacturing of the mail item as a whole. The readability of the Digital Postage Mark is a function not only of

the inherent quality of printing, i.e. the interaction of the ink, substrate and printing mechanism together with

the effects of the shape of the mail-piece and its transport through the printing system on the production of the

mark, but also of the effects of environmental and handling factors in transit between the production point and

the point at which it is to be read. For example, the symbol contrast of Digital Postage Marks is not only that

provided by the printer/paper combination under defined illumination conditions. It also results from a variety

v i

© ISO/IEC 2006 – All rights reserved

of other factors among which the covering of the mail item or the material of the transparent window through

which the Digital Postage Mark may be seen. As a consequence, the guidelines described in this

International Standard apply to the Digital Postage Mark blocks of fully assembled mail items. It is the

responsibility of the users of this International Standard to achieve compliance with the guidelines by

controlling the effects of the physical elements resulting in the relevant attributes.

The guidelines are primarily a tool for predicting the level of Digital Postage Mark readability with respect to

current scanning technologies, and compliance with them should result in a high level of Digital Postage Mark

readability. The guidelines are aimed at facilitating the relations between postal operators and customers,

vendors of mail generation and printing equipment and suppliers of mail reading and sorting equipment. In

particular, equipment vendors need firm and precise guidance in designing print systems and formats for

machine readability. Therefore, a quantitative specification of print quality is critical to the development of

products that meet the needs of mailers and postal operators.

vii

© ISO/IEC 2006 – All rights reserved

INTERNATIONAL STANDARD ISO/IEC 18050:2006(E)

Information technology — Office equipment — Print quality

attributes for machine readable Digital Postage Marks

1 Scope

This International Standard:

specifies a methodology for the measurement of defined print quality attributes of Digital Postage Marks

in the form of two-dimensional bar code symbols on mail-pieces,

defines methods for grading the results of these measurements and deriving an overall symbol quality

grade as a guide to estimating the readability of the Digital Postage Marks,

provides guidelines for printing and gives information on possible causes of deviation from high grades to

assist users in taking appropriate corrective action,

defines a test procedure for the assessment of printing systems for the production of Digital Postage

Marks.

These provisions apply to the Digital Postage Mark blocks as they appear on fully produced mail items when

remitted to postal operators, including the characteristics resulting from operations other than printing per se

that affect their appearance to a mail processing system (covering, inserts into transparent window envelopes,

affixed Digital Postage Mark labels).

This International Standard does not define the qualification tests or sampling requirements necessary to

determine the practical feasibility of any specific read rate.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO/IEC 15415:2004, Information technology – Automatic identification and data capture techniques – Bar code

print quality test specification – Two-dimensional symbols

ISO/IEC 15416:2000, Information technology – Automatic identification and data capture techniques – Bar

code print quality test specification – Linear symbols

ISO/IEC 15419:2001, Information technology – Automatic identification and data capture techniques – Bar

code digital imaging and printing performance testing

ISO/IEC 15426-2:2005, Information technology – Automatic identification and data capture techniques – Bar

code verifier conformance specification – Part 2: Two-dimensional symbols.

EN 1556:1996, Bar coding – Terminology.

© ISO/IEC 2006 – All rights reserved

Universal Postal Union (UPU) standard S-28, Communication of Postal Information using Two-dimensional

Symbols

UPU standard S-36, Digital Postage Marks: Applications, Security and Design

UPU standard S-44-1, Colour and Durability Attributes of Franking Marks

3 Terms and definitions

For the purposes of this International Standard, the terms and definitions given in ISO/IEC 15415, ISO/IEC

15416, EN 1556 and the following apply:

3.1

broad-band

descriptive of illumination in which the spectral distribution of the light is wide, with a bandwidth in excess of

200 nm at the 50% power level.

3.2

mail format

form taken by a finished mail-piece or other carrier of a Digital Postage Mark, e.g. envelope with or without

contents, or flat sheet of paper

3.3

narrow-band

descriptive of illumination in which the spectral power distribution is concentrated in a narrow band of

wavelengths, with a bandwidth of less than 200 nm at the 50% power level.

3.4

overall symbol grade

measure of symbol quality calculated as arithmetic mean of scan grades from a number of individual scans of

the symbol

3.5

read rate

percentage representing the number of items carrying digital postage marks that have been successfully read,

out of all such items attempted to be read in a given period.

3.6

scan grade

result of the assessment of a single scan of a symbol, derived by taking the lowest grade achieved for any

measured parameter in that scan.

3.7

spectral response characteristic

integral response of the reading system, a function of wavelength across the spectral region of interest and

calculated for each wavelength as the product of the intensity of light emitted, the transmission characteristic

of any filters or coatings used, and the response of the sensor element at that wavelength.

3.8

validation

technical process by which the authenticity, data integrity and uniqueness of a Digital Postage Mark are

confirmed or denied.

3.9

verification

technical process by which a bar code symbol is measured to determine its conformance with the specification

for that symbol.

© ISO/IEC 2006 – All rights reserved

3.10

verifier

device used to measure and analyse quality attributes of a bar code symbol such as element and quiet zone

dimensions, reflectances, and other aspects against a standard to which the bar code symbol should conform

4 Symbols and abbreviations

dpi dots per inch (25.4 mm)

dpmm dots per millimetre

°K degrees Kelvin

UEC Unused Error Correction

X nominal width of a narrow element (bar code) or of a module (matrix code)

Y nominal height of an element (bar code)

5 Requirements

The print quality requirement for a Digital Postage Mark, when measured in accordance with ISO/IEC 15415

and the following clauses, is expressed in the form:

grade/aperture/light/angle, where:

"grade" is the overall symbol grade, i.e. the arithmetic mean to one decimal place of the scan reflectance

profile or scan grades,

NOTE where the value is followed by an asterisk it indicates that there are extremes of reflectance in the symbol

surroundings which may potentially interfere with reading

"aperture" is the aperture reference number (from ISO/IEC 15416 for linear scanning techniques, or the

diameter in thousandths of an inch (to the nearest thousandth) of the synthetic aperture defined in

ISO/IEC 15415),

"light" defines the illumination: a numeric value indicates the peak light wavelength in nanometres (for

narrow-band illumination); the alphabetic character W indicates that the symbol has been measured with

broad-band illumination (sometimes referred to as "white light" although the terms are not directly

equivalent) the spectral response characteristics of which must imperatively be defined or have their

source specification clearly referenced.

"angle" is an additional parameter defining the angle of incidence (relative to the plane of the symbol) of

the illumination. It shall be included in the reporting of the overall symbol grade when the angle of

incidence is other than 45°. Its absence indicates that the angle of incidence is 45°.

In view of the close correlation between print quality and reading performance, where maximum reading

performance is critical, a Digital Postage Mark represented by a two-dimensional bar code symbol should

achieve a minimum overall symbol grade of 2,8 under the following measurement conditions:

aperture diameter 0,25 mm (reference number 10), in the case of a Digital Postage Mark in the form of a

two-dimensional multi-row bar code symbol, or

aperture diameter 0,40 mm (reference number 16), in the case of a Digital Postage Mark in the form of a

two-dimensional matrix symbol,

© ISO/IEC 2006 – All rights reserved

and

peak wavelength of 660 nm in the case of a Digital Postage Mark intended to be read under narrow-band

illumination, or

light reference W, together with the specification of the spectral response characteristics used or a

reference to a source of this specification, in the case of a Digital Postage Mark intended to be read under

broad-band illumination.

NOTE The aperture reference number represents the nominal diameter, in thousandths of an inch, of the measuring

aperture. For multi-row symbologies, ISO/IEC 15415 specifies that its diameter is to be determined by the application

specification; see 7.4.1. For matrix symbols, the measuring aperture diameter is a function of the symbol X dimension;

see 7.4.2.

In either case the angle of incidence of the light shall be 45°.

These would be expressed as, for example,

2,8/16/W (with the spectral response specification, or an appropriate reference) for a Digital Postage Mark in

the form of a two-dimensional matrix symbol intended for reading in broad-band light, or

2,8/10/660 for a Digital Postage Mark in the form of a multi-row bar code symbol intended to be read in

narrow-band (visible red) light with a peak wavelength of 660 nm.

The illumination conditions used for verification shall imperatively be specified or clearly referenced with the

verification results.

In order to allow for the effect of less easily controllable substrates, where a somewhat lower read rate may

result (for example with Digital Postage Mark symbols printed on relatively low-reflectance substrates that are

unable to meet the preferred symbol contrast requirements), the overall symbol grade requirement may be

reduced to 1,8 provided that all measured parameters except Symbol Contrast are consistent with the

requirements of the higher grade of 2,8. A minimum overall symbol grade of 1,8 governed by any of the

measured parameters would probably lead to a further reduction in read rate performance. See clause 8 for

details, and Annex C for a description of the measurement parameters.

While the above grades are recommended as the minima to ensure an adequate read rate, postal operators

may determine their minimum recommended grades corresponding to the particular reading requirements of

their environment or to the read rate which they require.

6 Basic measurement methodology

Digital Postage Marks shall be measured according to the methodology defined in ISO/IEC 15415 for the type

of symbology concerned, either two-dimensional multi-row symbologies (e.g. PDF417 as defined in ISO/IEC

15438) or two-dimensional matrix symbologies (e.g. DataMatrix as defined in ISO/IEC 16022). The print

quality requirements specified in ISO/IEC 15438 and ISO/IEC 16022, and in similar symbology standards,

which were published prior to the development of the generic methodologies defined in ISO/IEC 15415 shall

not be applied to the evaluation of Digital Postage Marks.

NOTE For two-dimensional multi-row symbols, ISO/IEC 15415 adapts (and supplements) the methodology for the

print quality assessment of linear bar code symbols defined in ISO/IEC 15416. For matrix symbols, the methodology of

ISO/IEC 15415 requires the capture of a two-dimensional grey-scale image of the symbol to be verified, under defined and

controlled illumination conditions, and the processing of the image to analyse its specified parameters. ISO/IEC 15415

defines the reference optical arrangement to be used for measurement, and the symbol attributes to be measured (see

Annex C for a list of the measured parameters for each type of symbol). ISO/IEC 15415 requires to be read in conjunction

with the International Standard or other equivalent formal specification of the symbology concerned and in particular

makes use of the reference decode algorithm defined in that specification as a common, standard basis for evaluation. It

assigns grades on a five-step scale to each of the parameters; there are four passing grades, from 4 to 1 in descending

order of quality, and one failing grade of 0. It provides for multiple scans of the symbol in different positions in order to

derive an average assessment of the symbol, and defines an overall grading scheme that takes account of the individual

4 © ISO/IEC 2006 — All rights reserved

parameters and the results from individual scans. It provides for applications to determine the minimum grade for

acceptability for that application. It also allows for applications to establish additional parameters. In the case of Digital

Postage Marks, the quiet zone is an additional graded parameter (see clause 9), and the spectral response characteristics

of the system by which the Digital Postage Mark is intended to be read require to be specified.

In each scan of the symbol a number of parameters is measured and graded, and the scan is given a scan

grade, which is equal to the lowest grade obtained for any parameter in that scan; the overall symbol grade in

accordance with ISO/IEC 15415 is the arithmetic mean, to one decimal place, of the scan grades. However,

for the purposes of this International Standard, if any scan grade is 0, the overall symbol grade shall also be

regarded as 0. In this event it may be appropriate to perform the verification process a second time to

eliminate the possibility of a random or transient incident having affected one of the scans.

The overall symbol grades are only meaningful when reported in conjunction with additional parameters

defined in the application specification: the measuring aperture size, the illumination (peak wavelength or

spectral response characteristic), and the angle of incidence of the illumination.

7 Verification requirements for Digital Postage Marks

7.1 Verification equipment

Instruments to be used for the verification of Digital Postage Marks shall comply with the requirements of

ISO/IEC 15426-2. These devices provide a standardised means of measurement of two-dimensional bar

code symbols to enable consistent and repeatable measurements of symbol quality to be made. Their basic

configuration is intended to replicate a bar code reading device that uses image capture and processing

techniques, as is likely to be the case with mail processing equipment. ISO/IEC 15415 defines a reference

optical arrangement for reflectance measurements, with the results of which the reflectance measurements

obtained by a verifier should correlate. There is however no requirement that its construction should follow

the reference arrangement. The specification of certain components of the device, described in the following

sub-clauses, shall be matched to the defined requirements of the application in which the bar code symbols

are intended to be used. The instrument shall be calibrated before use in accordance with the manufacturer's

instructions.

For the verification of Digital Postage Mark symbols, the image capture component of the equipment should

preferably be a camera, and associated illumination, of the same type and spectral response characteristics

as the equipment expected to be used for operational reading of the mail-piece(s) to be verified, with a

mechanism, of a similar nature to that expected to be used, to transport the mail-pieces past the

measurement window.

If equipment precisely matching the spectral response characteristics of the mail processing equipment

expected to be used is not available, a device complying with the general requirements of ISO/IEC 15415 and

ISO/IEC 15426-2 shall be used with a light source covering the spectral band indicated for the ink colour in

question in UPU S-44-1. It should be noted that in this case the reflectance measurements (of ink and paper)

recorded may differ from those perceived by the operational mail processing equipment and the results should

be taken as indicative rather than predictive of the symbol contrast perceived by the specific mail processor.

7.2 Optical geometry

ISO/IEC 15415 defines a default geometry for print quality assessment of two-dimensional symbols. This

consists of two elements. The first element is an annular light source, or a set of individual light sources

arranged in a circle, giving flood incident illumination which is uniform across the sample area. The light

source(s) shall be concentric with the sample area and shall lie in a plane parallel to that of the sample area,

at a height which will allow incident light to fall on the centre of the sample area at an angle of 45° to its plane.

The second component is a light collection device, the optical axis of which is perpendicular to the sample

area and passes through its centre, and which focuses an image of the test symbol on a light-sensitive array.

This arrangement is appropriate for the measurement of the diffusely reflected light from the surface of a mail-

piece and shall be used for the verification of Digital Postage Marks; another arrangement may be used if its

results can be correlated with those obtained by the use of the default geometry.

© ISO/IEC 2006 – All rights reserved

7.3 Light source

The apparent reflectance of a sample area to a scanner or verifier is primarily a function of:

the response of the ink and substrate to the illumination (its absorption or reflection of incident light at

different wavelengths), and

the spectral response characteristics of the reading system, which in turn depend on:

the spectral distribution of the illumination (the intensity of light of different wavelengths emitted

across the spectrum)

the spectral characteristics of any filters in the optical path (the transmittance of light of different

wavelengths)

the spectral response of the photosensitive elements of the image capture device (their sensitivity at

different wavelengths)

When the light is not monochromatic, the apparent reflectance is the integrated response across the image

capture device's spectral band.

The illumination conditions used by mail processing systems generally require broad-band light (of various

colour temperatures, and the spectral response characteristics of the specific equipment may, therefore,

differ) to capture not only the image of the Digital Postage Mark but also the images of the address block and

other information which are not covered by this International Standard. Hand-held reading equipment for

Digital Postage Marks may have a narrow-band red light source.

Ink specifications for the Digital Postage Mark are defined in UPU standard S-44-1. For a given ink, its

reflectance will vary widely with different light sources. The ink reflectance will also depend on the ink

coverage, which is determined principally by the print mechanism. UPU standard S-44-1 indicates the

reference spectral bands and the desirable contrast levels within these for the various ink colours on a range

of backgrounds. It also describes the use of a default set of spectral characteristics for the assessment of

reflectances, which may be correlated with those of a specific type of reading equipment by the use of an

appropriate correction factor. Individual postal operators may define the colours permitted in their territory.

The substrates used may be of a variety of materials and colours, and their reflectances will also vary widely

with the light source.

It is therefore essential, in order to maximise the correlation between reflectance values as measured by a

verifier and their appearance to reading and mail processing equipment, that the spectral response

characteristics of the two types of equipment should match as closely as practicable. The print quality of a

Digital Postage Mark should be measured under the same spectral response conditions as are used in the

mail processing equipment expected to be used. Because the spectral response characteristics of different

equipment specified by postal operators may vary, the verifier shall either have the capability to change the

light source or image capture component, or have its particular set of spectral response characteristics clearly

identified.

Annex B describes the spectral response characteristics of a number of common types of light source used for

the reading of Digital Postage Marks.

7.4 Measuring aperture

The shape and dimensions of the measuring aperture shall be specified.

NOTE This is necessary in order that defects in the symbol are not given exaggeratedly high or unjustifiably low

importance, and secondly in order to maximise the measured contrast between dark and light elements. Defects include

voids in low reflectance areas and extraneous specks in high reflectance areas, which will tend to decrease the

modulation of the area by bringing the reflectance of the area closer to the Global Threshold (the midpoint between the

highest and lowest reflectances in the symbol, used to binarise the image into dark and light areas). These goals are

© ISO/IEC 2006 – All rights reserved

achieved by specifying a circular aperture whose diameter is somewhat smaller than the width of the smallest element that

may require to be recognised by the reference decode algorithm.

The measuring aperture may be either a real physical aperture in the optical path of the verifier or a virtual one

achieved by applying a mathematical process to integrate the reflectance values from a number of adjoining

pixels in the image capture device.

7.4.1 Measuring aperture for two-dimensional multi-row symbologies

For Digital Postage Mark symbols in the form of a two-dimensional multi-row symbol, complying with UPU

standard S28, with a minimum X dimension of 0,38 mm, the measuring aperture shall be a circular aperture of

diameter 0,250 mm (aperture reference number 10, as defined in ISO/IEC 15416).

NOTE ISO/IEC 15416 indicates that this aperture is appropriate for symbols with X dimensions up to 0,63 mm, but it

also states that the aperture to be used for verification shall be the aperture appropriate for the smallest X dimension

permitted by the application.

7.4.2 Measuring aperture for two-dimensional matrix symbologies

ISO/IEC 15415 defines the measuring aperture for these symbols as a circular aperture, synthesised from the

individual image pixels, 0,8X in diameter (based on the smallest X dimension specified for the application),

and specifies that the resolution of the verifier shall be sufficient to ensure that the parameter grading results

are consistent irrespective of the rotation of the symbol. For Digital Postage Mark symbols in the form of a

two-dimensional matrix symbol, complying with UPU standard S28, which specifies an X dimension of

0,508 mm or more, an aperture of 0,40 mm diameter (reference number 16) is appropriate in accordance with

ISO/IEC 15415.

NOTE Experience has shown that the imaging system used for verification may require an effective linear resolution

of 6 to 8 pixels per module (corresponding to 11,8 to 15,7 pixels per mm for an X dimension of 0,508 mm), or 30 to 60

pixels per module on an area basis, to provide the required consistency of results. Annex D.2 indicates that current mail

processing systems typically use a resolution of approx 8 to 10 pixels per mm for reading.

7.5 Mail format

The form in which the Digital Postage Mark is verified depends on the purpose for which it is being measured

and the point in the entire mailing process at which it is measured. As a general principle, the capabilities of

the production system dictate the highest quality that can be achieved, and the introduction of other factors

(substrate materials, filling of envelopes, window envelopes or overwraps, handling in transit etc.) will tend to

reduce symbol quality, and allowance must be made for this when setting quality levels.

For testing the performance of printing equipment it will normally be sufficient to test symbols printed on to a

flat substrate, in order to minimise the effect of external variables.

For process control of symbol production it is appropriate to verify the symbol on the mail-piece in the form in

which it emerges from the printing system.

For predicting whether the readability of the Digital Postage Mark is likely to reach an acceptable level it is

appropriate to verify the symbol on the finished mail-piece in the form in which it is presented to the postal

service, or received at the mail processing point.

In the cases of process control and the prediction of readability of a complete mail piece, it may be desirable

to allow for the influence of factors such as the geometrical distortions caused by contents of the mail-piece,

the optical effects of window materials or film wraps through which the Digital Postage Mark has to be read,

and the effects of environmental conditions and handling while it is in transit.

These factors lead to the recommendation that the symbol quality at the point of production should, wherever

possible, be higher than the minimum required for acceptable readability at the point of reading, to allow for

possible degradation by these factors.

© ISO/IEC 2006 – All rights reserved

Annex D discusses a number of factors related to the printing and scanning process that may impact on

symbol quality.

8 Grading implications for individual symbol attributes

The minimum overall symbol grades specified in section 5 are based on averaging the profile (or scan) grades

of multiple scans of a symbol, which are in turn based on the lowest grade for any parameter in each scan. It

is not possible, therefore, to define a set of threshold values which must be exceeded for all parameters in

every scan. However, it is possible to suggest, for guidance, that the average value of each individual

param

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...