ISO 11960:2020

(Main)Petroleum and natural gas industries — Steel pipes for use as casing or tubing for wells

Petroleum and natural gas industries — Steel pipes for use as casing or tubing for wells

This document specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material. By agreement between the purchaser and manufacturer, this document can also be applied to other plain-end pipe sizes and wall thicknesses. This document is applicable to the following connections: — short round thread casing (SC); — long round thread casing (LC); — buttress thread casing (BC); — non-upset tubing (NU); — external upset tubing (EU); — integral-joint tubing (IJ). NOTE 1 For further information, see API Spec 5B. For such connections, this document specifies the technical delivery conditions for couplings and thread protection. NOTE 2 Supplementary requirements that can optionally be agreed for enhanced leak resistance connections (LC) are given in A.9 SR22. This document can also be applied to tubulars with connections not covered by ISO or API standards. This document is applicable to products including the following grades of pipe: H40, J55, K55, N80, L80, C90, R95, T95, P110, C110 and Q125. This document is not applicable to threading requirements. NOTE 3 Dimensional requirements on threads and thread gauges, stipulations on gauging practice, gauge specifications, as well as, instruments and methods for inspection of threads are given in API Spec 5B.

Industries du pétrole et du gaz naturel — Tubes d'acier utilisés comme tubes de cuvelage ou tubes de production dans les puits

Le présent document spécifie les conditions de livraison techniques relatives aux tubes en acier (tubes de cuvelage, tubes de production et joints de tube courts), tubes-ébauches pour manchon, matériaux pour manchons et matériaux pour accessoires. Par accord entre l'acheteur et le fabricant, le présent document peut également être appliqué à d'autres tailles de tubes à extrémités lisses et à d'autres épaisseurs de paroi. Le présent document s'applique aux raccordements suivants: — tubes de cuvelage à filetage rond court (SC); — tubes de cuvelage à filetage rond long (LC); — tubes de cuvelage à filetage trapézoïdal buttress (BC); — tubes de production sans refoulement (NU); — tubes de production avec refoulement externe (EU); — tubes de production à filetage intégral (IJ). NOTE 1 Pour plus d'informations, voir l'API Spec 5B. Pour ces raccordements, le présent document spécifie des conditions de livraison techniques pour les manchons et la protection des filetages. NOTE 2 Des exigences supplémentaires, qui peuvent optionnellement faire l'objet d'un accord pour des raccordements à résistance renforcée aux fuites (LC), sont données en A.9 SR22. Le présent document peut également être appliqué à des tubes ayant des raccordements non couverts par les normes ISO ou API. Le présent document est applicable aux produits comprenant les grades de tubes suivants: H40, J55, K55, N80, L80, C90, R95, T95, P110, C110 et Q125. Le présent document ne s'applique pas aux exigences de filetage. NOTE 3 Les exigences dimensionnelles sur les filetages et les calibres de filetage, les dispositions sur la pratique du calibrage, les spécifications de calibrage, de même que les instruments et les modes opératoires de contrôle des filets sont donnés dans l'API Spec 5B.

General Information

- Status

- Published

- Publication Date

- 30-Mar-2020

- Technical Committee

- ISO/TC 67/SC 5 - Casing, tubing and drill pipe

- Drafting Committee

- ISO/TC 67/SC 5/WG 1 - Casing, tubing and drill pipe

- Current Stage

- 9060 - Close of review

- Completion Date

- 02-Sep-2030

Relations

- Effective Date

- 12-Feb-2026

- Effective Date

- 20-Jan-2018

Overview

ISO 11960:2020 - Petroleum and natural gas industries - Steel pipes for use as casing or tubing for wells - defines the technical delivery conditions for steel pipes, coupling stock, coupling material and accessory material used as casing, tubing and pup joints in oil and gas wells. The sixth edition (2020) covers a wide range of pipe grades (H40, J55, K55, N80, L80, C90, R95, T95, P110, C110, Q125) and common field connections (SC, LC, BC, NU, EU, IJ). By purchaser–manufacturer agreement it can be extended to other plain-end sizes and non‑standard connections.

Key topics and requirements

ISO 11960:2020 focuses on the practical, quality and inspection requirements for well tubulars without specifying thread dimensions (see API Spec 5B for gauging and thread dimensions). Major technical topics include:

- Material and metallurgical requirements: chemical composition, grain size and hardenability for specific grades.

- Mechanical properties: tensile properties, yield/elongation and statistical tensile testing for selected grades.

- Toughness and impact testing: Charpy V-notch test requirements, specimen hierarchy, test temperatures and statistical impact testing.

- Hardness control: maximum hardness, hardness variation and process control for higher grades.

- Heat treatment and manufacturing processes: requirements for quenching/tempering, straightening, welding and processes that require validation.

- Corrosion and sulfide stress cracking (SSC): SSC testing provisions and selection guidance for susceptible grades.

- Dimensional and physical tolerances: diameter, wall thickness, mass, length, straightness, end finishes and defect disposition.

- Couplings and thread protection: delivery conditions for couplings, coupling stock and thread protection for the listed connections.

- Traceability and serialization: marking and traceability requirements, especially for higher strength grades.

Applications and users

ISO 11960 is essential for stakeholders in the upstream oil and gas sector who require consistent, auditable specifications for tubulars:

- Pipe manufacturers and foundries - to set production processes, heat treatment and inspection regimes.

- Oil & gas operators and drilling contractors - to specify purchase requirements for casing and tubing.

- Procurement and quality assurance teams - to verify delivery, traceability and conformance.

- Inspection and testing laboratories - to perform tensile, Charpy, hardness and SSC testing in accordance with standard requirements.

- Coupling and accessory suppliers - for compatibility with coupling stock, thread protection and accessory materials.

Related standards

- API Spec 5B - thread dimensions, gauging practice and thread inspection methods (ISO 11960 excludes threading requirements and references API 5B).

- ANSI/NACE TM0177 - referenced for additional SSC testing methods and guidance.

Keywords: ISO 11960:2020, steel casing, tubing specifications, well casing standards, oil and gas tubulars, API Spec 5B, Charpy V-notch, sulfide stress cracking, pipe grades P110, casing couplings.

Buy Documents

ISO 11960:2020 - Petroleum and natural gas industries -- Steel pipes for use as casing or tubing for wells

ISO 11960:2020 - Petroleum and natural gas industries — Steel pipes for use as casing or tubing for wells Released:3/31/2020

ISO 11960:2020 - Industries du pétrole et du gaz naturel — Tubes d'acier utilisés comme tubes de cuvelage ou tubes de production dans les puits Released:7/12/2024

REDLINE ISO 11960:2020 - Industries du pétrole et du gaz naturel — Tubes d'acier utilisés comme tubes de cuvelage ou tubes de production dans les puits Released:7/12/2024

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

ISO 11960:2020 is a standard published by the International Organization for Standardization (ISO). Its full title is "Petroleum and natural gas industries — Steel pipes for use as casing or tubing for wells". This standard covers: This document specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material. By agreement between the purchaser and manufacturer, this document can also be applied to other plain-end pipe sizes and wall thicknesses. This document is applicable to the following connections: — short round thread casing (SC); — long round thread casing (LC); — buttress thread casing (BC); — non-upset tubing (NU); — external upset tubing (EU); — integral-joint tubing (IJ). NOTE 1 For further information, see API Spec 5B. For such connections, this document specifies the technical delivery conditions for couplings and thread protection. NOTE 2 Supplementary requirements that can optionally be agreed for enhanced leak resistance connections (LC) are given in A.9 SR22. This document can also be applied to tubulars with connections not covered by ISO or API standards. This document is applicable to products including the following grades of pipe: H40, J55, K55, N80, L80, C90, R95, T95, P110, C110 and Q125. This document is not applicable to threading requirements. NOTE 3 Dimensional requirements on threads and thread gauges, stipulations on gauging practice, gauge specifications, as well as, instruments and methods for inspection of threads are given in API Spec 5B.

This document specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material. By agreement between the purchaser and manufacturer, this document can also be applied to other plain-end pipe sizes and wall thicknesses. This document is applicable to the following connections: — short round thread casing (SC); — long round thread casing (LC); — buttress thread casing (BC); — non-upset tubing (NU); — external upset tubing (EU); — integral-joint tubing (IJ). NOTE 1 For further information, see API Spec 5B. For such connections, this document specifies the technical delivery conditions for couplings and thread protection. NOTE 2 Supplementary requirements that can optionally be agreed for enhanced leak resistance connections (LC) are given in A.9 SR22. This document can also be applied to tubulars with connections not covered by ISO or API standards. This document is applicable to products including the following grades of pipe: H40, J55, K55, N80, L80, C90, R95, T95, P110, C110 and Q125. This document is not applicable to threading requirements. NOTE 3 Dimensional requirements on threads and thread gauges, stipulations on gauging practice, gauge specifications, as well as, instruments and methods for inspection of threads are given in API Spec 5B.

ISO 11960:2020 is classified under the following ICS (International Classification for Standards) categories: 75.180.10 - Exploratory, drilling and extraction equipment; 77.140.75 - Steel pipes and tubes for specific use. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 11960:2020 has the following relationships with other standards: It is inter standard links to EN ISO 11960:2021, ISO 11960:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 11960:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 11960

Sixth edition

2020-03

Petroleum and natural gas

industries — Steel pipes for use as

casing or tubing for wells

Industries du pétrole et du gaz naturel — Tubes d'acier utilisés

comme cuvelage ou tubes de production dans les puits

Reference number

©

ISO 2020

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

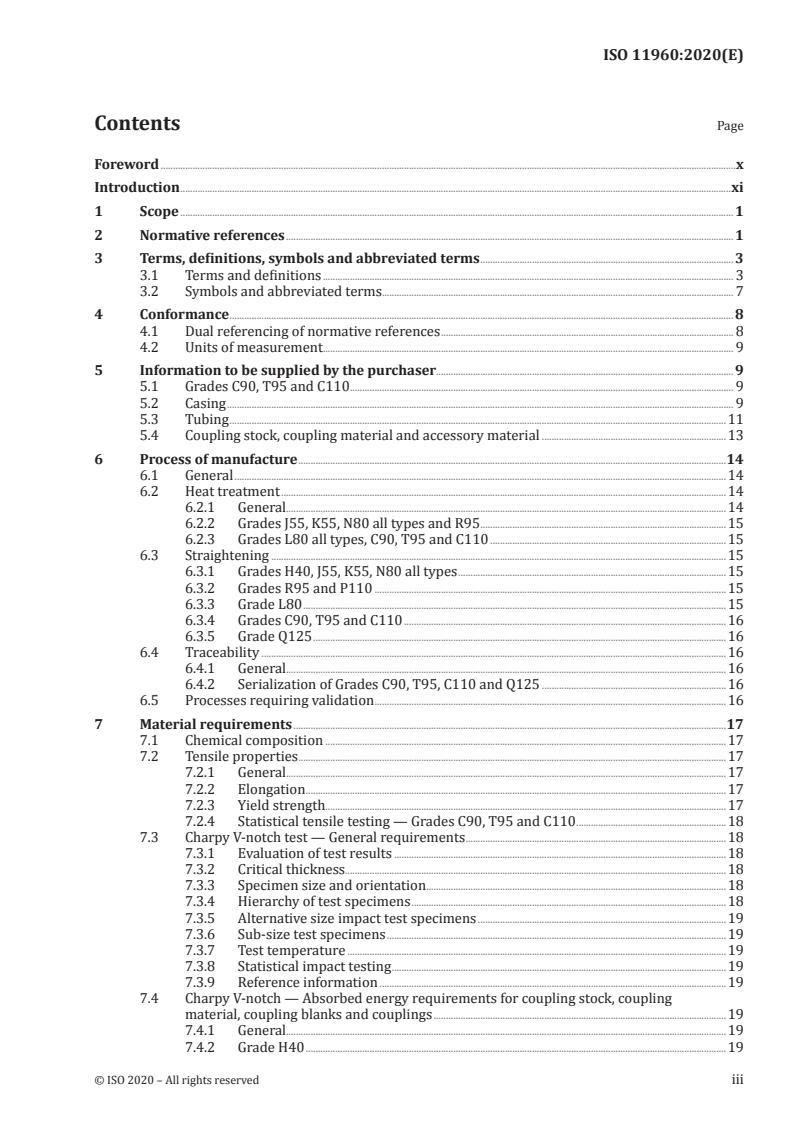

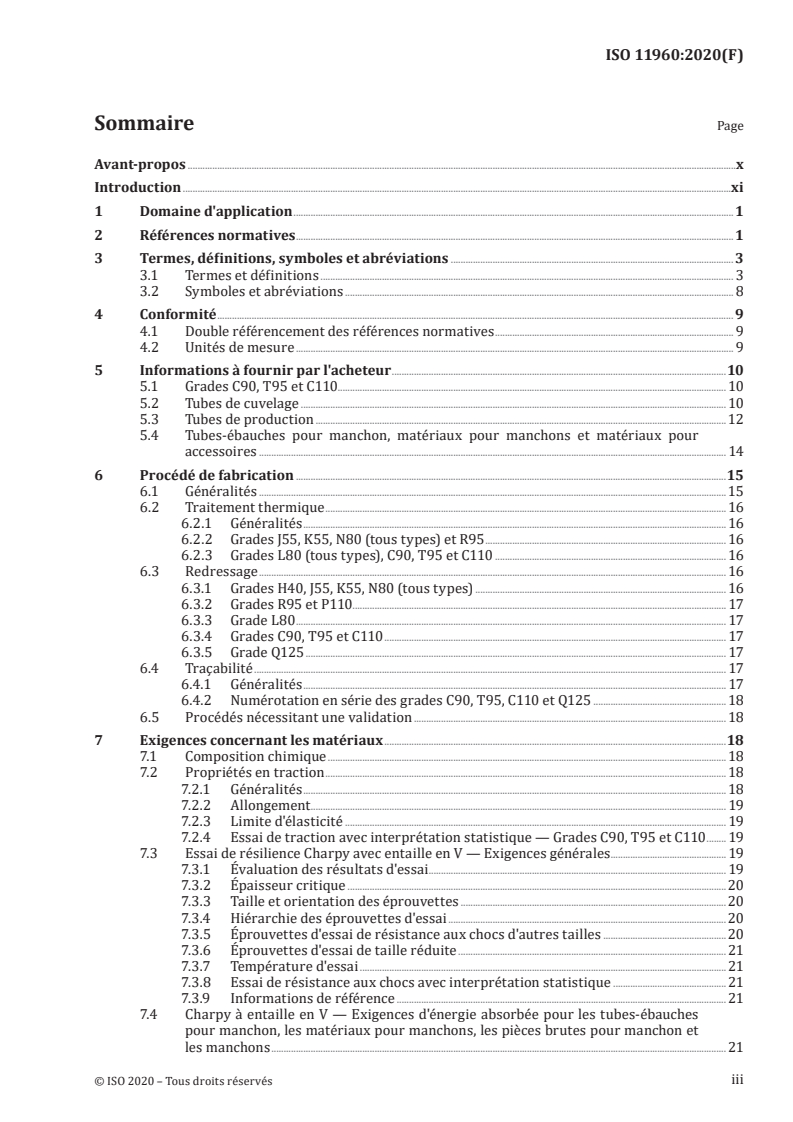

Contents Page

Foreword .x

Introduction .xi

1 Scope . 1

2 Normative references . 1

3 Terms, definitions, symbols and abbreviated terms . 3

3.1 Terms and definitions . 3

3.2 Symbols and abbreviated terms. 7

4 Conformance . 8

4.1 Dual referencing of normative references . 8

4.2 Units of measurement . . 9

5 Information to be supplied by the purchaser. 9

5.1 Grades C90, T95 and C110 . 9

5.2 Casing . 9

5.3 Tubing .11

5.4 Coupling stock, coupling material and accessory material .13

6 Process of manufacture .14

6.1 General .14

6.2 Heat treatment .14

6.2.1 General.14

6.2.2 Grades J55, K55, N80 all types and R95 .15

6.2.3 Grades L80 all types, C90, T95 and C110 .15

6.3 Straightening .15

6.3.1 Grades H40, J55, K55, N80 all types .15

6.3.2 Grades R95 and P110 .15

6.3.3 Grade L80 .15

6.3.4 Grades C90, T95 and C110 .16

6.3.5 Grade Q125 .16

6.4 Traceability .16

6.4.1 General.16

6.4.2 Serialization of Grades C90, T95, C110 and Q125 .16

6.5 Processes requiring validation .16

7 Material requirements .17

7.1 Chemical composition .17

7.2 Tensile properties .17

7.2.1 General.17

7.2.2 Elongation .17

7.2.3 Yield strength . . .17

7.2.4 Statistical tensile testing — Grades C90, T95 and C110 .18

7.3 Charpy V-notch test — General requirements .18

7.3.1 Evaluation of test results .18

7.3.2 Critical thickness.18

7.3.3 Specimen size and orientation .18

7.3.4 Hierarchy of test specimens .18

7.3.5 Alternative size impact test specimens .19

7.3.6 Sub-size test specimens .19

7.3.7 Test temperature .19

7.3.8 Statistical impact testing .19

7.3.9 Reference information .19

7.4 Charpy V-notch — Absorbed energy requirements for coupling stock, coupling

material, coupling blanks and couplings .19

7.4.1 General.19

7.4.2 Grade H40 .19

7.4.3 Grades J55 and K55 for API threads . .19

7.4.4 Grades N80 all Types, R95, L80 all Types, C90, T95, P110 and Q125 for

API threads .20

7.4.5 Special end-finish .20

7.5 Charpy V-notch — Absorbed energy requirements for pipe . .20

7.5.1 Grades H40, J55 and K55 .20

7.5.2 Grades N80 all Types, R95, L80, C90, T95 and P110 .20

7.5.3 Grades C110 and Q125 .21

7.5.4 Test specimen .21

7.5.5 Testing conditions .22

7.6 Charpy V-notch — Absorbed energy requirements for accessory material .22

7.6.1 Accessory material — General .22

7.6.2 Accessory material for accessories with internal API threads except

integral tubing connections .22

7.6.3 Accessory material for accessories with internal special end-finish

tapered interference-type threads .22

7.6.4 Accessory material for accessories with external threads .22

7.6.5 Accessory material for accessories with either integral tubing connections

or internal special end-finish connections that do not have thread interference 22

7.6.6 Critical thickness for accessory material and special end-finish material .22

7.7 Maximum hardness .23

7.7.1 Grades L80 all types, C90, T95 and C110 .23

7.7.2 Grade Q125 — All products .23

7.8 Hardness variation — Grades C90, T95, C110 and Q125 .23

7.9 Process control — Grades C90, T95, C110 and Q125 . .23

7.10 Hardenability — Minimum percentage martensite for quenched and tempered

products .24

7.10.1 Grade L80 Type 1 .24

7.10.2 Grades C90 and T95 .24

7.10.3 Grade C110.24

7.10.4 All grades except Grades L80, C90, T95 and C110 .24

7.11 Grain size — Grades C90, T95 and C110 .25

7.12 Surface condition — Grade L80 13Cr .25

7.13 Flattening — Electric-welded pipe .25

7.14 Sulfide stress cracking test — Grades C90, T95 and C110 .25

7.14.1 General guidance .25

7.14.2 Test and retest requirements and recommendations .25

7.14.3 Test sample selection and location .26

7.14.4 Test solution.26

7.14.5 Minimum SSC requirements .27

7.14.6 Invalidation of tests .28

7.14.7 Additional testing provisions for ANSI/NACE TM0177-2016 Method D .28

8 Dimensions, masses, tolerances, product ends and defects.28

8.1 Labels and sizes .28

8.2 Dimensions and masses .28

8.3 Diameter .29

8.3.1 Measurement and design .29

8.3.2 Requirements .29

8.4 Wall thickness .29

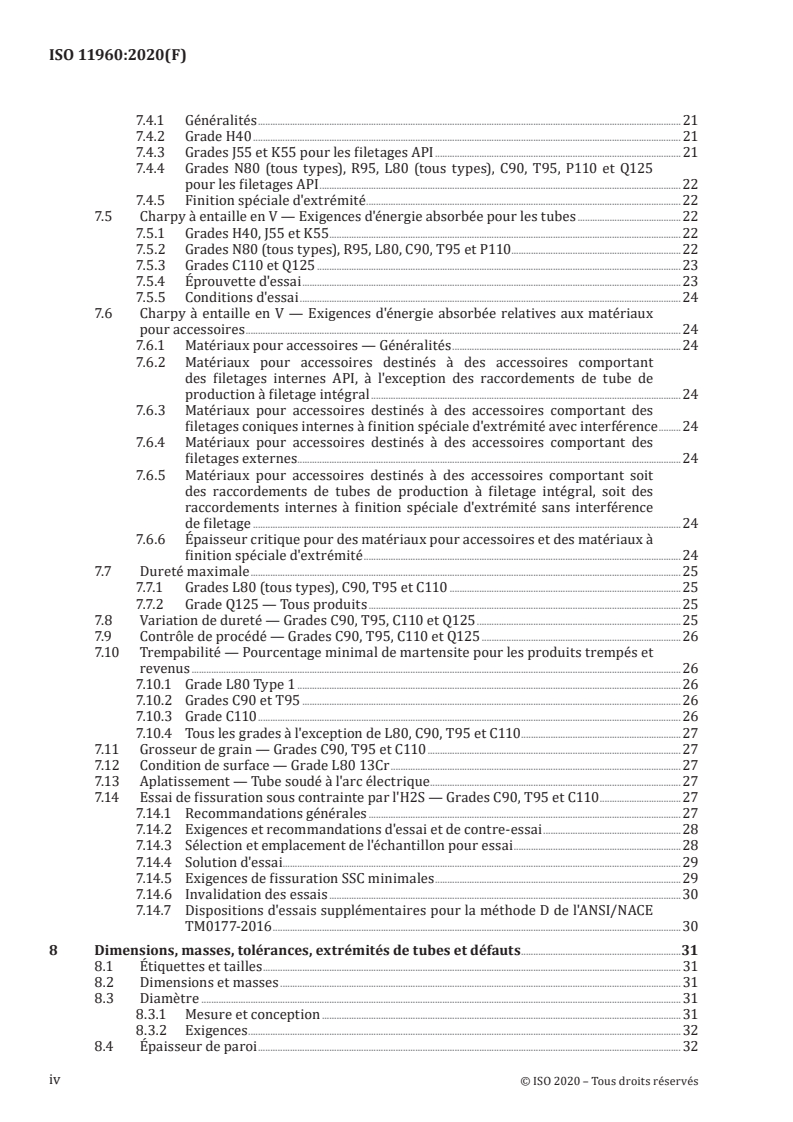

8.5 Mass .29

8.6 Length .30

8.7 Casing jointers .30

8.8 Height and trim of electric-weld flash .30

8.8.1 Trimming electric-weld flash .30

8.8.2 Grades H40, J55, K55, N80 all types, R95, and L80 Type 1 .30

8.8.3 Grades P110 and Q125 .31

8.8.4 Disposition .31

8.9 Straightness .31

iv © ISO 2020 – All rights reserved

8.9.1 Pipe .31

8.9.2 Coupling stock, coupling material and accessory material .31

8.10 Drift requirements .31

8.11 Tolerances on dimensions and masses .32

8.11.1 Outside diameter .32

8.11.2 Wall thickness .32

8.11.3 Mass .32

8.11.4 Inside diameter .33

8.11.5 Upset dimensions .33

8.11.6 Extended length upsets .33

8.12 Product ends .33

8.12.1 Plain-end pipe .33

8.12.2 Product with API threads .33

8.12.3 Rounded nose .33

8.12.4 Threading .33

8.12.5 Special end finish .34

8.13 Defects .34

8.13.1 Pipe and accessory made from pipe .34

8.13.2 Accessory material not made from pipe, coupling stock and coupling material.34

8.13.3 Process control plan.35

8.14 Coupling make-up and thread protection.35

8.14.1 All Grades except Q125 .35

8.14.2 Grade Q125 .35

9 Couplings .35

9.1 General requirements .35

9.2 Alternative grades or heat treatments .36

9.3 Mechanical properties .36

9.4 Dimensions and tolerances .36

9.4.1 All Grades except Q125 .36

9.4.2 Grade Q125 .37

9.5 Regular couplings .37

9.6 Special-clearance couplings — All Grades except Q125 .37

9.7 Combination couplings .37

9.8 Seal-ring couplings .37

9.9 Special-bevel tubing regular couplings — All Grades .37

9.10 Threading — Couplings .38

9.11 Surface inspection .38

9.12 Measurement of imperfections .38

9.13 Repair and removal of imperfections and defects .39

9.14 Thread surface treatment — Grade Q125 .39

9.15 Couplings and coupling blank protection — Grades C90, T95, C110 and Q125 .39

10 Inspection and testing .39

10.1 Test equipment .39

10.2 Lot definition for testing of mechanical properties .39

10.2.1 Grades H40, J55, K55, N80 all types, L80 Type 1, R95 and P110 —

Coupling stock, coupling material and pipe (except pup joints heat-

treated after cutting to blank or individual length) .39

10.2.2 Grades L80 13Cr, C90, T95, C110 and Q125 — Coupling stock, coupling

material and pipe (except pup joints heat-treated after cutting to blank or

individual length) .39

10.2.3 Coupling blanks, pup joints or accessory material heat-treated after

cutting to blank or individual length .40

10.3 Testing of chemical composition .40

10.3.1 Heat analyses .40

10.3.2 Product analyses .40

10.3.3 Test method .40

10.3.4 Recheck of product analyses — All Grades .41

10.4 Tensile tests .41

10.4.1 Stress-relief temperature — All grades .41

10.4.2 Heat-control tensile tests — All Grades except Q125 .41

10.4.3 Frequency of testing and location of test specimen — Casing and tubing .41

10.4.4 Frequency of testing and test specimen location — Coupling stock,

coupling material, coupling blanks, pup joints and accessory material .41

10.4.5 Test specimens — General .42

10.4.6 Test specimens — Additional requirements for coupling blanks, coupling

stock coupling material and pup joint and accessory materials — Grades

C110 and Q125 .42

10.4.7 Test method .42

10.4.8 Invalidation of tests .43

10.4.9 Retests — All products (except coupling blanks, coupling stock, coupling

material, pup joints or accessory material) — Grades C90, T95, C110 and

Q125 .43

10.4.10 Retests — Coupling blanks, coupling stock, coupling material, pup joints

or accessory material in Grades C90, T95, C110 and Q125 .43

10.5 Flattening test .43

10.5.1 General requirement for testing .43

10.5.2 Frequency of testing .43

10.5.3 Test specimens.44

10.5.4 Test method for Grades H40, J55, K55, N80 all types, R95, and L80 Type 1 .44

10.5.5 Test method for Grade P110 pipe and Grade Q125 casing .44

10.5.6 Invalidation of tests .44

10.5.7 Retests .44

10.6 Hardness test .44

10.6.1 Frequency of testing — General .44

10.6.2 Frequency of testing — Heat-control tests — Grade L80.45

10.6.3 Frequency of testing — Grade L80 .45

10.6.4 Frequency of testing and test specimen location — Non-upset pipe —

Grades C90, T95 and C110 .45

10.6.5 Frequency of testing and test specimen location — Upset pipe —

Grades C90 and T95 .45

10.6.6 Frequency of testing and test specimen location — Coupling blanks,

coupling stock, coupling material, pup joints and accessory material —

Grades C90, T95 and C110 .45

10.6.7 Frequency of testing — Grade Q125 .46

10.6.8 Test specimens.46

10.6.9 Test method .46

10.6.10 Invalidation of tests .48

10.6.11 Periodic checks of hardness-testing machines .48

10.6.12 Verification of hardness-testing machines and indenters.48

10.6.13 Retests — Grade L80 .49

10.6.14 Retests — Grades C90, T95 and C110 products except for coupling blanks,

pup joints or accessory material heat-treated after cutting to individual

lengths.49

10.6.15 Retests — Grades C90, T95 and C110 coupling blanks, pup joints or

accessory material heat-treated after cutting to individual lengths .50

10.6.16 Retests — Grade Q125 — General .50

10.6.17 Retests — Grade Q125 — Casing, coupling stock and coupling material .50

10.6.18 Retests — Grade Q125 — Coupling blanks, pup joints and accessory material .50

10.6.19 Rejected lots — Grades L80 all types, C90, T95, C110 and Q125 .50

10.7 Impact test .50

10.7.1 Sampling —Grades J55 and K55 .50

10.7.2 Sampling — Grades N80 all types, R95, L80, C90, T95, C110 and P110 .50

10.7.3 Sampling and test specimen location — Grade Q125 .51

10.7.4 Test specimens.51

10.7.5 Test method .51

vi © ISO 2020 – All rights reserved

10.7.6 Invalidation of tests .51

10.7.7 Retest of a length — All Grades .51

10.7.8 Replacement of a reject length — All Grades .52

10.7.9 Multiple length rejection — Grade Q125 .52

10.8 Grain size determination — Grades C90, T95 and C110 .52

10.8.1 Sampling.52

10.8.2 Test method .52

10.9 Hardenability — Grades C90, T95 and C110 .52

10.10 Sulfide stress-cracking test — Grades C90, T95 and C110 .52

10.11 Metallographic evaluation — All EW Grades .52

10.12 Hydrostatic tests .53

10.12.1 Hydrostatic test procedures .53

10.12.2 Hydrostatic test requirements .53

10.12.3 Test pressure calculation .54

10.13 Dimensional testing .55

10.13.1 General.55

10.13.2 Diameter measurement .55

10.13.3 Diameter retests .55

10.13.4 Wall thickness measurement .56

10.13.5 Drift test.56

10.13.6 Length measurement .56

10.13.7 Mass (weight) determination .56

10.13.8 Straightness evaluation .57

10.13.9 Internal upset inspection .57

10.14 Visual inspection .57

10.14.1 General.57

10.14.2 Pipe body, coupling stock and coupling material (excluding pipe ends) .58

10.14.3 Pipe ends.58

10.14.4 Disposition .58

10.15 Non-destructive examination (NDE) .58

10.15.1 General.58

10.15.2 NDE personnel .59

10.15.3 Reference standards .59

10.15.4 NDE system capability records .59

10.15.5 Pipe body or coupling stock inspection — General .60

10.15.6 Full-body, full-length NDE of casing and tubing — Grades H40, J55, K55,

N80 all types, L80 and R95 .60

10.15.7 Full-body, full-length NDE of casing and tubing — Grade P110 to A.8 SR16 .60

10.15.8 Full-body, full-length NDE of casing and tubing — Grade P110 and

Grade P110 to A.8 SR16 and A.2 SR2 .61

10.15.9 Full-body, full-length NDE of casing and tubing — Grades L80 13Cr, C90,

T95, C110 and Q125 .61

10.15.10 .

NDE of the weld seam of welded pipe .61

10.15.11 .

...

INTERNATIONAL ISO

STANDARD 11960

Sixth edition

2020-03

Petroleum and natural gas

industries — Steel pipes for use as

casing or tubing for wells

Industries du pétrole et du gaz naturel — Tubes d'acier utilisés

comme cuvelage ou tubes de production dans les puits

Reference number

©

ISO 2020

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

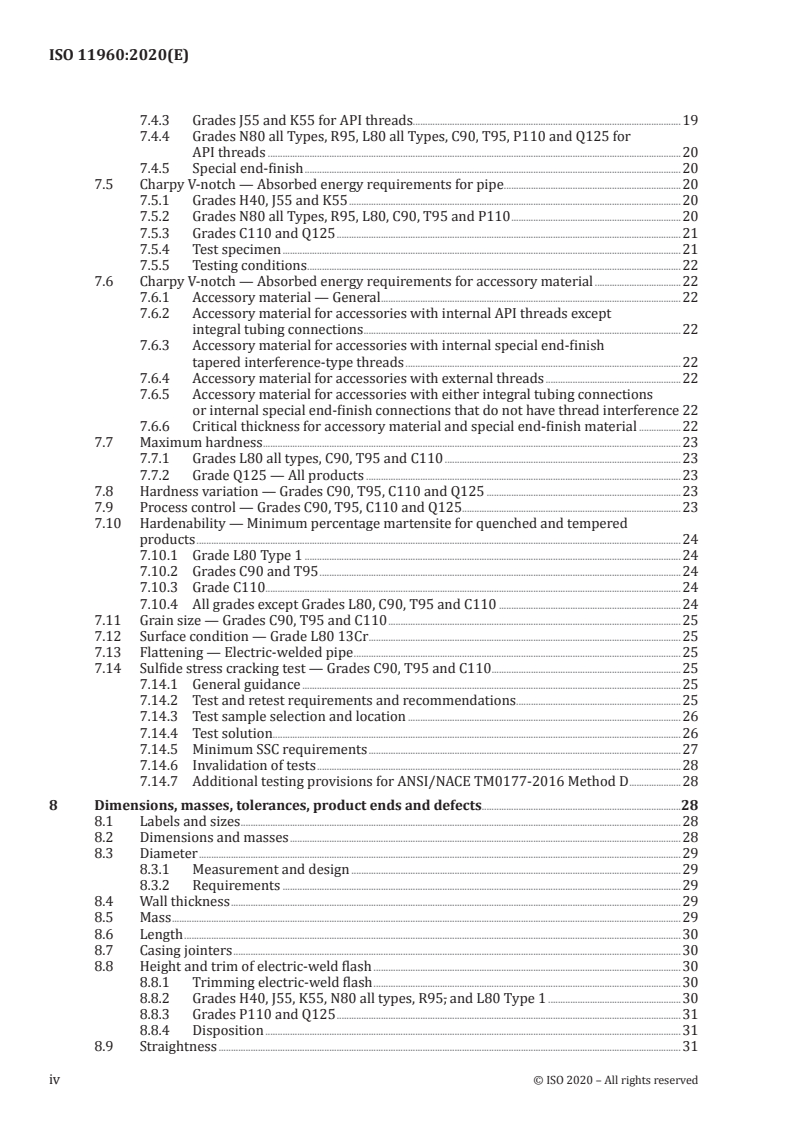

Contents Page

Foreword .x

Introduction .xi

1 Scope . 1

2 Normative references . 1

3 Terms, definitions, symbols and abbreviated terms . 3

3.1 Terms and definitions . 3

3.2 Symbols and abbreviated terms. 7

4 Conformance . 8

4.1 Dual referencing of normative references . 8

4.2 Units of measurement . . 9

5 Information to be supplied by the purchaser. 9

5.1 Grades C90, T95 and C110 . 9

5.2 Casing . 9

5.3 Tubing .11

5.4 Coupling stock, coupling material and accessory material .13

6 Process of manufacture .14

6.1 General .14

6.2 Heat treatment .14

6.2.1 General.14

6.2.2 Grades J55, K55, N80 all types and R95 .15

6.2.3 Grades L80 all types, C90, T95 and C110 .15

6.3 Straightening .15

6.3.1 Grades H40, J55, K55, N80 all types .15

6.3.2 Grades R95 and P110 .15

6.3.3 Grade L80 .15

6.3.4 Grades C90, T95 and C110 .16

6.3.5 Grade Q125 .16

6.4 Traceability .16

6.4.1 General.16

6.4.2 Serialization of Grades C90, T95, C110 and Q125 .16

6.5 Processes requiring validation .16

7 Material requirements .17

7.1 Chemical composition .17

7.2 Tensile properties .17

7.2.1 General.17

7.2.2 Elongation .17

7.2.3 Yield strength . . .17

7.2.4 Statistical tensile testing — Grades C90, T95 and C110 .18

7.3 Charpy V-notch test — General requirements .18

7.3.1 Evaluation of test results .18

7.3.2 Critical thickness.18

7.3.3 Specimen size and orientation .18

7.3.4 Hierarchy of test specimens .18

7.3.5 Alternative size impact test specimens .19

7.3.6 Sub-size test specimens .19

7.3.7 Test temperature .19

7.3.8 Statistical impact testing .19

7.3.9 Reference information .19

7.4 Charpy V-notch — Absorbed energy requirements for coupling stock, coupling

material, coupling blanks and couplings .19

7.4.1 General.19

7.4.2 Grade H40 .19

7.4.3 Grades J55 and K55 for API threads . .19

7.4.4 Grades N80 all Types, R95, L80 all Types, C90, T95, P110 and Q125 for

API threads .20

7.4.5 Special end-finish .20

7.5 Charpy V-notch — Absorbed energy requirements for pipe . .20

7.5.1 Grades H40, J55 and K55 .20

7.5.2 Grades N80 all Types, R95, L80, C90, T95 and P110 .20

7.5.3 Grades C110 and Q125 .21

7.5.4 Test specimen .21

7.5.5 Testing conditions .22

7.6 Charpy V-notch — Absorbed energy requirements for accessory material .22

7.6.1 Accessory material — General .22

7.6.2 Accessory material for accessories with internal API threads except

integral tubing connections .22

7.6.3 Accessory material for accessories with internal special end-finish

tapered interference-type threads .22

7.6.4 Accessory material for accessories with external threads .22

7.6.5 Accessory material for accessories with either integral tubing connections

or internal special end-finish connections that do not have thread interference 22

7.6.6 Critical thickness for accessory material and special end-finish material .22

7.7 Maximum hardness .23

7.7.1 Grades L80 all types, C90, T95 and C110 .23

7.7.2 Grade Q125 — All products .23

7.8 Hardness variation — Grades C90, T95, C110 and Q125 .23

7.9 Process control — Grades C90, T95, C110 and Q125 . .23

7.10 Hardenability — Minimum percentage martensite for quenched and tempered

products .24

7.10.1 Grade L80 Type 1 .24

7.10.2 Grades C90 and T95 .24

7.10.3 Grade C110.24

7.10.4 All grades except Grades L80, C90, T95 and C110 .24

7.11 Grain size — Grades C90, T95 and C110 .25

7.12 Surface condition — Grade L80 13Cr .25

7.13 Flattening — Electric-welded pipe .25

7.14 Sulfide stress cracking test — Grades C90, T95 and C110 .25

7.14.1 General guidance .25

7.14.2 Test and retest requirements and recommendations .25

7.14.3 Test sample selection and location .26

7.14.4 Test solution.26

7.14.5 Minimum SSC requirements .27

7.14.6 Invalidation of tests .28

7.14.7 Additional testing provisions for ANSI/NACE TM0177-2016 Method D .28

8 Dimensions, masses, tolerances, product ends and defects.28

8.1 Labels and sizes .28

8.2 Dimensions and masses .28

8.3 Diameter .29

8.3.1 Measurement and design .29

8.3.2 Requirements .29

8.4 Wall thickness .29

8.5 Mass .29

8.6 Length .30

8.7 Casing jointers .30

8.8 Height and trim of electric-weld flash .30

8.8.1 Trimming electric-weld flash .30

8.8.2 Grades H40, J55, K55, N80 all types, R95, and L80 Type 1 .30

8.8.3 Grades P110 and Q125 .31

8.8.4 Disposition .31

8.9 Straightness .31

iv © ISO 2020 – All rights reserved

8.9.1 Pipe .31

8.9.2 Coupling stock, coupling material and accessory material .31

8.10 Drift requirements .31

8.11 Tolerances on dimensions and masses .32

8.11.1 Outside diameter .32

8.11.2 Wall thickness .32

8.11.3 Mass .32

8.11.4 Inside diameter .33

8.11.5 Upset dimensions .33

8.11.6 Extended length upsets .33

8.12 Product ends .33

8.12.1 Plain-end pipe .33

8.12.2 Product with API threads .33

8.12.3 Rounded nose .33

8.12.4 Threading .33

8.12.5 Special end finish .34

8.13 Defects .34

8.13.1 Pipe and accessory made from pipe .34

8.13.2 Accessory material not made from pipe, coupling stock and coupling material.34

8.13.3 Process control plan.35

8.14 Coupling make-up and thread protection.35

8.14.1 All Grades except Q125 .35

8.14.2 Grade Q125 .35

9 Couplings .35

9.1 General requirements .35

9.2 Alternative grades or heat treatments .36

9.3 Mechanical properties .36

9.4 Dimensions and tolerances .36

9.4.1 All Grades except Q125 .36

9.4.2 Grade Q125 .37

9.5 Regular couplings .37

9.6 Special-clearance couplings — All Grades except Q125 .37

9.7 Combination couplings .37

9.8 Seal-ring couplings .37

9.9 Special-bevel tubing regular couplings — All Grades .37

9.10 Threading — Couplings .38

9.11 Surface inspection .38

9.12 Measurement of imperfections .38

9.13 Repair and removal of imperfections and defects .39

9.14 Thread surface treatment — Grade Q125 .39

9.15 Couplings and coupling blank protection — Grades C90, T95, C110 and Q125 .39

10 Inspection and testing .39

10.1 Test equipment .39

10.2 Lot definition for testing of mechanical properties .39

10.2.1 Grades H40, J55, K55, N80 all types, L80 Type 1, R95 and P110 —

Coupling stock, coupling material and pipe (except pup joints heat-

treated after cutting to blank or individual length) .39

10.2.2 Grades L80 13Cr, C90, T95, C110 and Q125 — Coupling stock, coupling

material and pipe (except pup joints heat-treated after cutting to blank or

individual length) .39

10.2.3 Coupling blanks, pup joints or accessory material heat-treated after

cutting to blank or individual length .40

10.3 Testing of chemical composition .40

10.3.1 Heat analyses .40

10.3.2 Product analyses .40

10.3.3 Test method .40

10.3.4 Recheck of product analyses — All Grades .41

10.4 Tensile tests .41

10.4.1 Stress-relief temperature — All grades .41

10.4.2 Heat-control tensile tests — All Grades except Q125 .41

10.4.3 Frequency of testing and location of test specimen — Casing and tubing .41

10.4.4 Frequency of testing and test specimen location — Coupling stock,

coupling material, coupling blanks, pup joints and accessory material .41

10.4.5 Test specimens — General .42

10.4.6 Test specimens — Additional requirements for coupling blanks, coupling

stock coupling material and pup joint and accessory materials — Grades

C110 and Q125 .42

10.4.7 Test method .42

10.4.8 Invalidation of tests .43

10.4.9 Retests — All products (except coupling blanks, coupling stock, coupling

material, pup joints or accessory material) — Grades C90, T95, C110 and

Q125 .43

10.4.10 Retests — Coupling blanks, coupling stock, coupling material, pup joints

or accessory material in Grades C90, T95, C110 and Q125 .43

10.5 Flattening test .43

10.5.1 General requirement for testing .43

10.5.2 Frequency of testing .43

10.5.3 Test specimens.44

10.5.4 Test method for Grades H40, J55, K55, N80 all types, R95, and L80 Type 1 .44

10.5.5 Test method for Grade P110 pipe and Grade Q125 casing .44

10.5.6 Invalidation of tests .44

10.5.7 Retests .44

10.6 Hardness test .44

10.6.1 Frequency of testing — General .44

10.6.2 Frequency of testing — Heat-control tests — Grade L80.45

10.6.3 Frequency of testing — Grade L80 .45

10.6.4 Frequency of testing and test specimen location — Non-upset pipe —

Grades C90, T95 and C110 .45

10.6.5 Frequency of testing and test specimen location — Upset pipe —

Grades C90 and T95 .45

10.6.6 Frequency of testing and test specimen location — Coupling blanks,

coupling stock, coupling material, pup joints and accessory material —

Grades C90, T95 and C110 .45

10.6.7 Frequency of testing — Grade Q125 .46

10.6.8 Test specimens.46

10.6.9 Test method .46

10.6.10 Invalidation of tests .48

10.6.11 Periodic checks of hardness-testing machines .48

10.6.12 Verification of hardness-testing machines and indenters.48

10.6.13 Retests — Grade L80 .49

10.6.14 Retests — Grades C90, T95 and C110 products except for coupling blanks,

pup joints or accessory material heat-treated after cutting to individual

lengths.49

10.6.15 Retests — Grades C90, T95 and C110 coupling blanks, pup joints or

accessory material heat-treated after cutting to individual lengths .50

10.6.16 Retests — Grade Q125 — General .50

10.6.17 Retests — Grade Q125 — Casing, coupling stock and coupling material .50

10.6.18 Retests — Grade Q125 — Coupling blanks, pup joints and accessory material .50

10.6.19 Rejected lots — Grades L80 all types, C90, T95, C110 and Q125 .50

10.7 Impact test .50

10.7.1 Sampling —Grades J55 and K55 .50

10.7.2 Sampling — Grades N80 all types, R95, L80, C90, T95, C110 and P110 .50

10.7.3 Sampling and test specimen location — Grade Q125 .51

10.7.4 Test specimens.51

10.7.5 Test method .51

vi © ISO 2020 – All rights reserved

10.7.6 Invalidation of tests .51

10.7.7 Retest of a length — All Grades .51

10.7.8 Replacement of a reject length — All Grades .52

10.7.9 Multiple length rejection — Grade Q125 .52

10.8 Grain size determination — Grades C90, T95 and C110 .52

10.8.1 Sampling.52

10.8.2 Test method .52

10.9 Hardenability — Grades C90, T95 and C110 .52

10.10 Sulfide stress-cracking test — Grades C90, T95 and C110 .52

10.11 Metallographic evaluation — All EW Grades .52

10.12 Hydrostatic tests .53

10.12.1 Hydrostatic test procedures .53

10.12.2 Hydrostatic test requirements .53

10.12.3 Test pressure calculation .54

10.13 Dimensional testing .55

10.13.1 General.55

10.13.2 Diameter measurement .55

10.13.3 Diameter retests .55

10.13.4 Wall thickness measurement .56

10.13.5 Drift test.56

10.13.6 Length measurement .56

10.13.7 Mass (weight) determination .56

10.13.8 Straightness evaluation .57

10.13.9 Internal upset inspection .57

10.14 Visual inspection .57

10.14.1 General.57

10.14.2 Pipe body, coupling stock and coupling material (excluding pipe ends) .58

10.14.3 Pipe ends.58

10.14.4 Disposition .58

10.15 Non-destructive examination (NDE) .58

10.15.1 General.58

10.15.2 NDE personnel .59

10.15.3 Reference standards .59

10.15.4 NDE system capability records .59

10.15.5 Pipe body or coupling stock inspection — General .60

10.15.6 Full-body, full-length NDE of casing and tubing — Grades H40, J55, K55,

N80 all types, L80 and R95 .60

10.15.7 Full-body, full-length NDE of casing and tubing — Grade P110 to A.8 SR16 .60

10.15.8 Full-body, full-length NDE of casing and tubing — Grade P110 and

Grade P110 to A.8 SR16 and A.2 SR2 .61

10.15.9 Full-body, full-length NDE of casing and tubing — Grades L80 13Cr, C90,

T95, C110 and Q125 .61

10.15.10 .

NDE of the weld seam of welded pipe .61

10.15.11 .

...

NORME ISO

INTERNATIONALE 11960

Sixième édition

2020-03

Industries du pétrole et du gaz

naturel — Tubes d'acier utilisés

comme tubes de cuvelage ou tubes de

production dans les puits

Petroleum and natural gas industries — Steel pipes for use as casing

or tubing for wells

Numéro de référence

DOCUMENT PROTÉGÉ PAR COPYRIGHT

© ISO 2020

Tous droits réservés. Sauf prescription différente ou nécessité dans le contexte de sa mise en œuvre, aucune partie de cette

publication ne peut être reproduite ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique,

y compris la photocopie, ou la diffusion sur l’internet ou sur un intranet, sans autorisation écrite préalable. Une autorisation peut

être demandée à l’ISO à l’adresse ci-après ou au comité membre de l’ISO dans le pays du demandeur.

ISO copyright office

Case postale 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Genève

Tél.: +41 22 749 01 11

E-mail: copyright@iso.org

Web: www.iso.org

Publié en Suisse

ii

Sommaire Page

Avant-propos .x

Introduction .xi

1 Domaine d'application .1

2 Références normatives .1

3 Termes, définitions, symboles et abréviations . 3

3.1 Termes et définitions . 3

3.2 Symboles et abréviations . 8

4 Conformité . 9

4.1 Double référencement des références normatives . 9

4.2 Unités de mesure . 9

5 Informations à fournir par l'acheteur .10

5.1 Grades C90, T95 et C110. 10

5.2 Tubes de cuvelage . 10

5.3 Tubes de production .12

5.4 Tubes-ébauches pour manchon, matériaux pour manchons et matériaux pour

accessoires . 14

6 Procédé de fabrication .15

6.1 Généralités . 15

6.2 Traitement thermique . 16

6.2.1 Généralités . 16

6.2.2 Grades J55, K55, N80 (tous types) et R95 . 16

6.2.3 Grades L80 (tous types), C90, T95 et C110 . 16

6.3 Redressage . 16

6.3.1 Grades H40, J55, K55, N80 (tous types) . 16

6.3.2 Grades R95 et P110. 17

6.3.3 Grade L80 . 17

6.3.4 Grades C90, T95 et C110 . 17

6.3.5 Grade Q125 . 17

6.4 Traçabilité . 17

6.4.1 Généralités . 17

6.4.2 Numérotation en série des grades C90, T95, C110 et Q125 . 18

6.5 Procédés nécessitant une validation . 18

7 Exigences concernant les matériaux .18

7.1 Composition chimique . 18

7.2 Propriétés en traction . 18

7.2.1 Généralités . 18

7.2.2 Allongement . 19

7.2.3 Limite d'élasticité . 19

7.2.4 Essai de traction avec interprétation statistique — Grades C90, T95 et C110 . 19

7.3 Essai de résilience Charpy avec entaille en V — Exigences générales . 19

7.3.1 Évaluation des résultats d'essai . 19

7.3.2 Épaisseur critique .20

7.3.3 Taille et orientation des éprouvettes . 20

7.3.4 Hiérarchie des éprouvettes d'essai . 20

7.3.5 Éprouvettes d'essai de résistance aux chocs d'autres tailles .20

7.3.6 Éprouvettes d'essai de taille réduite . 21

7.3.7 Température d'essai . 21

7.3.8 Essai de résistance aux chocs avec interprétation statistique . 21

7.3.9 Informations de référence . 21

7.4 Charpy à entaille en V — Exigences d'énergie absorbée pour les tubes-ébauches

pour manchon, les matériaux pour manchons, les pièces brutes pour manchon et

les manchons . 21

iii

7.4.1 Généralités . 21

7.4.2 Grade H40 . 21

7.4.3 Grades J55 et K55 pour les filetages API . 21

7.4.4 Grades N80 (tous types), R95, L80 (tous types), C90, T95, P110 et Q125

pour les filetages API . 22

7.4.5 Finition spéciale d'extrémité . 22

7.5 Charpy à entaille en V — Exigences d'énergie absorbée pour les tubes .22

7.5.1 Grades H40, J55 et K55 . 22

7.5.2 Grades N80 (tous types), R95, L80, C90, T95 et P110 . .22

7.5.3 Grades C110 et Q125 . 23

7.5.4 Éprouvette d'essai .23

7.5.5 Conditions d'essai . 24

7.6 Charpy à entaille en V — Exigences d'énergie absorbée relatives aux matériaux

pour accessoires . 24

7.6.1 Matériaux pour accessoires — Généralités . 24

7.6.2 Matériaux pour accessoires destinés à des accessoires comportant

des filetages internes API, à l'exception des raccordements de tube de

production à filetage intégral . 24

7.6.3 Matériaux pour accessoires destinés à des accessoires comportant des

filetages coniques internes à finition spéciale d'extrémité avec interférence . 24

7.6.4 Matériaux pour accessoires destinés à des accessoires comportant des

filetages externes. 24

7.6.5 Matériaux pour accessoires destinés à des accessoires comportant soit

des raccordements de tubes de production à filetage intégral, soit des

raccordements internes à finition spéciale d'extrémité sans interférence

de filetage . 24

7.6.6 Épaisseur critique pour des matériaux pour accessoires et des matériaux à

finition spéciale d'extrémité . 24

7.7 Dureté maximale . 25

7.7.1 Grades L80 (tous types), C90, T95 et C110 . 25

7.7.2 Grade Q125 — Tous produits . 25

7.8 Variation de dureté — Grades C90, T95, C110 et Q125 . 25

7.9 Contrôle de procédé — Grades C90, T95, C110 et Q125 . 26

7.10 Trempabilité — Pourcentage minimal de martensite pour les produits trempés et

revenus . 26

7.10.1 Grade L80 Type 1 . 26

7.10.2 Grades C90 et T95 . 26

7.10.3 Grade C110 . 26

7.10.4 Tous les grades à l'exception de L80, C90, T95 et C110 . 27

7.11 Grosseur de grain — Grades C90, T95 et C110 . 27

7.12 Condition de surface — Grade L80 13Cr . 27

7.13 Aplatissement — Tube soudé à l'arc électrique . 27

7.14 Essai de fissuration sous contrainte par l'H2S — Grades C90, T95 et C110 . 27

7.14.1 Recommandations générales . 27

7.14.2 Exigences et recommandations d'essai et de contre-essai .28

7.14.3 Sélection et emplacement de l'échantillon pour essai .28

7.14.4 Solution d'essai.29

7.14.5 Exigences de fissuration SSC minimales .29

7.14.6 Invalidation des essais .30

7.14.7 Dispositions d'essais supplémentaires pour la méthode D de l'ANSI/NACE

TM0177-2016 .30

8 Dimensions, masses, tolérances, extrémités de tubes et défauts .31

8.1 Étiquettes et tailles . 31

8.2 Dimensions et masses . 31

8.3 Diamètre . 31

8.3.1 Mesure et conception . 31

8.3.2 Exigences . 32

8.4 Épaisseur de paroi . 32

iv

8.5 Masse . 32

8.6 Longueur . 32

8.7 Tronçons courts de tube de cuvelage . 33

8.8 Hauteur et ébavurage du bourrelet de soudure à l'arc électrique . 33

8.8.1 Ébavurage du bourrelet de soudure à l'arc électrique . 33

8.8.2 Grades H40, J55, K55, N80 (tous types), R95 et L80 Type 1 .33

8.8.3 Grades P110 et Q125 .33

8.8.4 Disposition .34

8.9 Rectitude .34

8.9.1 Tubes .34

8.9.2 Tubes-ébauches pour manchon, matériaux pour manchons et matériaux

pour accessoires .34

8.10 Exigences en matière de calibrage .34

8.11 Tolérances sur les dimensions et les masses .34

8.11.1 Diamètre extérieur .34

8.11.2 Épaisseur de paroi . 35

8.11.3 Masse . 35

8.11.4 Diamètre intérieur . 36

8.11.5 Dimensions du refoulement.36

8.11.6 Refoulements de longueurs étendues .36

8.12 Extrémités du produit . .36

8.12.1 Tube à extrémités lisses .36

8.12.2 Produit avec des filetages API .36

8.12.3 Extrémité arrondie . 36

8.12.4 Filetage . 37

8.12.5 Finition spéciale d'extrémité . 37

8.13 Défauts . 37

8.13.1 Tubes et accessoires réalisés à partir de tubes . 37

8.13.2 Matériaux pour accessoires non réalisés à partir de tubes, tubes-ébauches

pour manchon et matériaux pour manchons . 37

8.13.3 Plan de contrôle de procédé .38

8.14 Vissage du manchon et protection des filetages .38

8.14.1 Tous les grades à l'exception de Q125 .38

8.14.2 Grade Q125 .38

9 Manchons .39

9.1 Exigences générales .39

9.2 Autres grades ou traitements thermiques . 39

9.3 Propriétés mécaniques .40

9.4 Dimensions et tolérances .40

9.4.1 Tous les grades à l'exception de Q125 .40

9.4.2 Grade Q125 .40

9.5 Manchons normaux .40

9.6 Manchons à encombrement réduit — Tous les grades à l'exception de Q125 .40

9.7 Manchons de combinaison .40

9.8 Manchons à bagues d'étanchéité . 41

9.9 Manchons de tubes de production à chanfrein spécial — Tous les grades. 41

9.10 Filetage — Manchons . 41

9.11 Contrôle de surface . 41

9.12 Mesurage des imperfections . 42

9.13 Réparation et élimination des imperfections et des défauts . 42

9.14 Traitement de surface du filetage — Grade Q125 . 42

9.15 Protection des manchons et des pièces brutes pour manchon — Grades C90, T95,

C110 et Q125 . 42

10 Contrôle et essais.43

10.1 Équipement d'essai . 43

10.2 Définition des lots pour les essais de propriétés mécaniques . 43

v

10.2.1 Grades H40, J55, K55, N80 (tous types), L80 Type 1, R95 et P110 — Tubes-

ébauches pour manchon, matériaux pour manchons et tubes à l'exception

des joints de tube courts ayant fait l'objet d'un traitement thermique après

découpe en flan ou à longueur individuelle) . 43

10.2.2 Grades L80 13Cr, C90, T95, C110 et Q125 — Tubes-ébauches pour manchon,

matériaux pour manchons et tubes (à l'exception des joints de tube courts

ayant fait l'objet d'un traitement thermique après découpe en flan ou à

longueur individuelle) . 43

10.2.3 Pièces brutes pour manchon, joints de tube courts ou matériaux pour

accessoires ayant fait l'objet d'un traitement thermique après découpe en

flan ou à longueur individuelle . 43

10.3 Essai de composition chimique .44

10.3.1 Analyses de coulées .44

10.3.2 Analyses sur produits .44

10.3.3 Méthode d'essai .44

10.3.4 Contre-essais des analyses sur produits — Tous les grades .44

10.4 Essais de traction . 45

10.4.1 Température de détente — Tous les grades . 45

10.4.2 Essais de traction de contrôle de coulée — Tous les grades à l'exception de

Q125 . 45

10.4.3 Fréquence d'essai et emplacement des éprouvettes d'essai — Tubes de

cuvelage et tubes de production . 45

10.4.4 Fréquence d'essai et emplacement des éprouvettes d'essai — Tubes-

ébauches pour manchon, matériaux pour manchons, pièces brutes pour

manchon, joints de tube courts et matériaux pour accessoires . 45

10.4.5 Éprouvettes d'essai — Généralités .46

10.4.6 Éprouvettes d'essai — Exigences supplémentaires pour les pièces brutes

pour manchon, les tubes-ébauches pour manchon, les matériaux pour

manchons et les joints de tube courts et les matériaux pour accessoires —

Grades C110 et Q125 .46

10.4.7 Méthode d'essai . 47

10.4.8 Invalidation des essais . 47

10.4.9 Contre-essais — Tous les produits (à l'exception des pièces brutes

pour manchon, des tubes-ébauches pour manchon, des matériaux pour

manchons, des joints de tube courts ou des matériaux pour accessoires) —

Grades C90, T95, C110 et Q125) . 47

10.4.10 Contre-essais — Pièces brutes pour manchon, tubes-ébauches pour

manchon, matériaux pour manchons, joints de tube courts ou matériaux

pour accessoires dans les grades C90, T95, C110 et Q125 . 47

10.5 Essai d'aplatissement .48

10.5.1 Exigence générale pour l'essai.48

10.5.2 Fréquence d'essai .48

10.5.3 Éprouvettes d'essai .48

10.5.4 Méthode d'essai pour les grades H40, J55, K55, N80 (tous types), R95 et

L80 Type 1 .48

10.5.5 Méthode d'essai pour un tube en grade P110 et un tube de cuvelage en

grade Q125 .48

10.5.6 Invalidation des essais .48

10.5.7 Contre-essais .49

10.6 Essai de dureté .49

10.6.1 Fréquence d'essai — Généralités .49

10.6.2 Fréquence d'essai — Essais de contrôle de coulée — Grade L80 .49

10.6.3 Fréquence d'essai — Grade L80 .49

10.6.4 Fréquence d'essai et emplacement de l'éprouvette d'essai — Tube sans

refoulement — Grades C90, T95 et C110 .49

10.6.5 Fréquence d'essai et emplacement d'éprouvette d'essai — Tube avec

refoulement — Grades C90 et T95 .50

vi

10.6.6 Fréquence d'essai et emplacement des éprouvettes d'essai — Pièces brutes

pour manchon, tubes-ébauches pour manchon, matériaux pour manchons,

joints de tube courts et matériaux pour accessoires — Grades C90, T95 et

C110. 50

10.6.7 Fréquence d'essai — Grade Q125 .50

10.6.8 Éprouvettes d'essai . 51

10.6.9 Méthode d'essai . 51

10.6.10 Invalidation des essais . 53

10.6.11 Contrôles périodiques de machines d'essai de dureté .53

10.6.12 Vérification des machines d'essai de dureté et des pénétrateurs.54

10.6.13 Contre-essais — Grade L80 .54

10.6.14 Contre-essais — Produits en grades C90, T95 et C110 à l'exception des

pièces brutes pour manchon, des joints de tube courts ou des matériaux

pour accessoires ayant fait l'objet d'un traitement thermique après

découpe à des longueurs individuelles . 55

10.6.15 Contre-essais — Pièces brutes pour manchon, joints de tube courts ou

matériaux pour accessoires en grades C90, T95 et C110 ayant fait l'objet

d'un traitement thermique après découpe en longueurs individuelles.55

10.6.16 Contre-essais — Grade Q125 — Généralités . 55

10.6.17 Contre-essais — Grade Q125 — Tubes de cuvelage, tubes-ébauches pour

manchon et matériaux pour manchons . 55

10.6.18 Contre-essais — Grade Q125 — Pièces brutes pour manchon, joints de

tube courts et matériaux pour accessoires .56

10.6.19 Lots rejetés — Grades L80 (tous types), C90, T95, C110 et Q125 .56

10.7 Essai de résistance aux chocs .56

10.7.1 Échantillonnage — Grades J55 et K55 .56

10.7.2 Échantillonnage — Grades N80 (tous types), R95, L80, C90, T95, C110 et

P110 .56

10.7.3 Échantillonnage et emplacement des éprouvettes d'essai — Grade Q125 .56

10.7.4 Éprouvettes d'essai .56

10.7.5 Méthode d'essai . 57

10.7.6 Invalidation des essais . 57

10.7.7 Contre-essai d'une longueur — Tous les grades . 57

10.7.8 Remplacement d'une longueur rejetée — Tous les grades . 57

10.7.9 Rejet de plusieurs longueurs — Grade Q125 . 57

10.8 Détermination de la grosseur des grains — Grades C90, T95 et C110 . 57

10.8.1 Échantillonnage. 57

10.8.2 Méthode d'essai .58

10.9 Trempabilité — Grades C90, T95 et C110 .58

10.10 Essai de fissuration sous contrainte par l'H2S — Grades C90, T95 et C110 .58

10.11 Évaluation métallographique — Tous les grades soudés à l'arc électrique .58

10.12 Épreuves hydrauliques .58

10.12.1 Procédures d'épreuve hydraulique .58

10.12.2 Exigences d'épreuve hydraulique . 59

10.12.3 Calcul de la pression d'essai .60

10.13 Contrôle dimensionnel . 61

10.13.1 Généralités . 61

10.13.2 Mesurage du diamètre . 61

10.13.3 Contre-mesures du diamètre . 61

10.13.4 Mesurage de l'épaisseur de paroi . 62

10.13.5 Essai de calibrage . 62

10.13.6 Mesurage de la longueur .63

10.13.7 Détermination de la masse (poids) .63

10.13.8 Évaluation de la rectitude .63

10.13.9 Contrôle du refoulement interne.63

10.14 Contrôle visuel .64

10.14.1 Généralités .64

vii

10.14.2 Corps de tube, de tube-ébauche pour manchon et de matériaux pour

manchons (à l'exclusion des extrémités de tubes) .64

10.14.3 Extrémités de tubes . .64

10.14.4 Disposition .

...

ISO/TC 67/SC 5

Date: 2024-06-13

ISO/TC 67/SC 5

Secrétariat:

Sixième édition

2020-03

Industries du pétrole et du gaz naturel — Tubes d'acier utilisés

comme tubes de cuvelage ou tubes de production dans les puits

Petroleum and natural gas industries — Steel pipes for use as casing or tubing for wells

Type du document: Norme internationale

Sous-type du document:

Stade du document: (60) Publication

Langue du document: F

ISO 11960:2020(F)

DOCUMENT PROTÉGÉ PAR COPYRIGHT

Tous droits réservés. Sauf prescription différente ou nécessité dans le contexte de sa mise en œuvreoeuvre, aucune

partie de cette publication ne peut être reproduite ni utilisée sous quelque forme que ce soit et par aucun procédé,

électronique ou mécanique, y compris la photocopie, ou la diffusion sur l’internet ou sur un intranet, sans

autorisation écrite préalable. Une autorisation peut être demandée à l’ISO à l’adresse ci-après ou au comité membre

de l’ISO dans le pays du demandeur.

ISO Copyright Officecopyright office

Case PostaleCP 401 • • Ch. de Blandonnet 8

CH-1214 Vernier, GenèveGeneva

Tél.: Phone: + 41 22 749 01 11

E-mail: copyright@iso.org

Web: www.iso.org

Website: www.iso.org

Publié en Suisse

ii © ISO 2024 – Tous droits réservés

ii © ISO 2020 – Tous droits réservés

ISO 11960:2020(F)

Sommaire Page

Avant-propos . xxi

Introduction . xxiii

1 Domaine d'application . 1

2 Références normatives . 1

3 Termes, définitions, symboles et abréviations . 4

3.1 Termes et définitions . 4

3.2 Symboles et abréviations . 9

4 Conformité . 10

4.1 Double référencement des références normatives . 10

4.2 Unités de mesure . 10

5 Informations à fournir par l'acheteur. 11

5.1 Grades C90, T95 et C110 . 11

5.2 Tubes de cuvelage . 11

5.3 Tubes de production . 14

5.4 Tubes-ébauches pour manchon, matériaux pour manchons et matériaux pour accessoires . 17

6 Procédé de fabrication . 18

6.1 Généralités . 18

6.2 Traitement thermique . 18

6.2.1 Généralités . 18

6.2.2 Grades J55, K55, N80 (tous types) et R95 . 19

6.2.3 Grades L80 (tous types), C90, T95 et C110 . 19

6.3 Redressage . 19

6.3.1 Grades H40, J55, K55, N80 (tous types) . 19

6.3.2 Grades R95 et P110 . 19

6.3.3 Grade L80 . 19

6.3.4 Grades C90, T95 et C110 . 20

6.3.5 Grade Q125 . 20

6.4 Traçabilité . 20

6.4.1 Généralités . 20

6.4.2 Numérotation en série des grades C90, T95, C110 et Q125 . 20

6.5 Procédés nécessitant une validation . 21

7 Exigences concernant les matériaux . 21

7.1 Composition chimique . 21

7.2 Propriétés en traction . 21

7.2.1 Généralités . 21

ISO 11960:2020(F)

7.2.2 Allongement . 21

7.2.3 Limite d'élasticité . 22

7.2.4 Essai de traction avec interprétation statistique — Grades C90, T95 et C110 . 22

7.3 Essai de résilience Charpy avec entaille en V — Exigences générales . 22

7.3.1 Évaluation des résultats d'essai . 22

7.3.2 Épaisseur critique . 23

7.3.3 Taille et orientation des éprouvettes . 23

7.3.4 Hiérarchie des éprouvettes d'essai . 23

7.3.5 Éprouvettes d'essai de résistance aux chocs d'autres tailles . 23

7.3.6 Éprouvettes d'essai de taille réduite . 24

7.3.7 Température d'essai . 24

7.3.8 Essai de résistance aux chocs avec interprétation statistique . 24

7.3.9 Informations de référence . 24

7.4 Charpy à entaille en V — Exigences d'énergie absorbée pour les tubes-ébauches pour manchon,

les matériaux pour manchons, les pièces brutes pour manchon et les manchons . 24

7.4.1 Généralités . 24

7.4.2 Grade H40. 24

7.4.3 Grades J55 et K55 pour les filetages API . 24

7.4.4 Grades N80 (tous types), R95, L80 (tous types), C90, T95, P110 et Q125 pour les filetages API

7.4.5 Finition spéciale d'extrémité . 25

7.5 Charpy à entaille en V — Exigences d'énergie absorbée pour les tubes . 25

7.5.1 Grades H40, J55 et K55 . 25

7.5.2 Grades N80 (tous types), R95, L80, C90, T95 et P110 . 26

7.5.3 Grades C110 et Q125 . 26

7.5.4 Éprouvette d'essai . 27

7.5.5 Conditions d'essai . 27

7.6 Charpy à entaille en V — Exigences d'énergie absorbée relatives aux matériaux pour accessoires

7.6.1 Matériaux pour accessoires — Généralités . 27

7.6.2 Matériaux pour accessoires destinés à des accessoires comportant des filetages internes API, à

l'exception des raccordements de tube de production à filetage intégral . 27

7.6.3 Matériaux pour accessoires destinés à des accessoires comportant des filetages coniques

internes à finition spéciale d'extrémité avec interférence . 27

7.6.4 Matériaux pour accessoires destinés à des accessoires comportant des filetages externes . 27

7.6.5 Matériaux pour accessoires destinés à des accessoires comportant soit des raccordements de

tubes de production à filetage intégral, soit des raccordements internes à finition spéciale d'extrémité

sans interférence de filetage . 28

iv © ISO 2024 – Tous droits réservés

iv © ISO 2020 – Tous droits réservés

ISO 11960:2020(F)

7.6.6 Épaisseur critique pour des matériaux pour accessoires et des matériaux à finition spéciale

d'extrémité . 28

7.7 Dureté maximale . 28

7.7.1 Grades L80 (tous types), C90, T95 et C110 . 28

7.7.2 Grade Q125 — Tous produits . 29

7.8 Variation de dureté — Grades C90, T95, C110 et Q125 . 29

7.9 Contrôle de procédé — Grades C90, T95, C110 et Q125 . 29

7.10 Trempabilité — Pourcentage minimal de martensite pour les produits trempés et revenus . 29

7.10.1 Grade L80 Type 1 . 29

7.10.2 Grades C90 et T95 . 30

7.10.3 Grade C110 . 30

7.10.4 Tous les grades à l'exception de L80, C90, T95 et C110 . 30

7.11 Grosseur de grain — Grades C90, T95 et C110 . 30

7.12 Condition de surface — Grade L80 13Cr . 31

7.13 Aplatissement — Tube soudé à l'arc électrique . 31

7.14 Essai de fissuration sous contrainte par l'H2S — Grades C90, T95 et C110 . 31

7.14.1 Recommandations générales . 31

7.14.2 Exigences et recommandations d'essai et de contre-essai . 31

7.14.3 Sélection et emplacement de l'échantillon pour essai . 32

7.14.4 Solution d'essai . 32

7.14.5 Exigences de fissuration SSC minimales . 33

7.14.6 Invalidation des essais . 34

7.14.7 Dispositions d'essais supplémentaires pour la méthode D de l'ANSI/NACE TM0177-2016 . 34

8 Dimensions, masses, tolérances, extrémités de tubes et défauts . 34

8.1 Étiquettes et tailles . 34

8.2 Dimensions et masses . 34

8.3 Diamètre . 35

8.3.1 Mesure et conception . 35

8.3.2 Exigences . 35

8.4 Épaisseur de paroi . 36

8.5 Masse . 36

8.6 Longueur. 36

8.7 Tronçons courts de tube de cuvelage . 37

8.8 Hauteur et ébavurage du bourrelet de soudure à l'arc électrique . 37

8.8.1 Ébavurage du bourrelet de soudure à l'arc électrique . 37

8.8.2 Grades H40, J55, K55, N80 (tous types), R95 et L80 Type 1 . 37

8.8.3 Grades P110 et Q125 . 37

ISO 11960:2020(F)

8.8.4 Disposition . 38

8.9 Rectitude . 38

8.9.1 Tubes . 38

8.9.2 Tubes-ébauches pour manchon, matériaux pour manchons et matériaux pour accessoires . 38

8.10 Exigences en matière de calibrage . 38

8.11 Tolérances sur les dimensions et les masses . 38

8.11.1 Diamètre extérieur . 38

8.11.2 Épaisseur de paroi . 39

8.11.3 Masse . 39

8.11.4 Diamètre intérieur . 40

8.11.5 Dimensions du refoulement . 40

8.11.6 Refoulements de longueurs étendues . 40

8.12 Extrémités du produit . 40

8.12.1 Tube à extrémités lisses . 40

8.12.2 Produit avec des filetages API . 40

8.12.3 Extrémité arrondie . 40

8.12.4 Filetage . 41

8.12.5 Finition spéciale d'extrémité . 41

8.13 Défauts . 41

8.13.1 Tubes et accessoires réalisés à partir de tubes . 41

8.13.2 Matériaux pour accessoires non réalisés à partir de tubes, tubes-ébauches pour manchon et

matériaux pour manchons . 42

8.13.3 Plan de contrôle de procédé . 42

8.14 Vissage du manchon et protection des filetages . 42

8.14.1 Tous les grades à l'exception de Q125 . 42

8.14.2 Grade Q125 . 43

9 Manchons . 43

9.1 Exigences générales . 43

9.2 Autres grades ou traitements thermiques . 43

9.3 Propriétés mécaniques . 44

9.4 Dimensions et tolérances. 44

9.4.1 Tous les grades à l'exception de Q125 . 44

9.4.2 Grade Q125 . 44

9.5 Manchons normaux . 44

9.6 Manchons à encombrement réduit — Tous les grades à l'exception de Q125 . 44

9.7 Manchons de combinaison . 45

9.8 Manchons à bagues d'étanchéité . 45

vi © ISO 2024 – Tous droits réservés

vi © ISO 2020 – Tous droits réservés

ISO 11960:2020(F)

9.9 Manchons de tubes de production à chanfrein spécial — Tous les grades . 45

9.10 Filetage — Manchons . 45

9.11 Contrôle de surface . 45

9.12 Mesurage des imperfections . 46

9.13 Réparation et élimination des imperfections et des défauts . 46

9.14 Traitement de surface du filetage — Grade Q125 . 47

9.15 Protection des manchons et des pièces brutes pour manchon — Grades C90, T95, C110 et Q125

10 Contrôle et essais . 47

10.1 Équipement d'essai . 47

10.2 Définition des lots pour les essais de propriétés mécaniques . 47

10.2.1 Grades H40, J55, K55, N80 (tous types), L80 Type 1, R95 et P110 — Tubes-ébauches pour

manchon, matériaux pour manchons et tubes à l'exception des joints de tube courts ayant fait l'objet d'un

traitement thermique après découpe en flan ou à longueur indivduelle) . 47

10.2.2 Grades L80 13Cr, C90, T95, C110 et Q125 — Tubes-ébauches pour manchon, matériaux pour

manchons et tubes (à l'exception des joints de tube courts ayant fait l'objet d'un traitement thermique

après découpe en flan ou à longueur individuelle) . 47

10.2.3 Pièces brutes pour manchon, joints de tube courts ou matériaux pour accessoires ayant fait

l'objet d'un traitement thermique après découpe en flan ou à longueur individuelle . 48

10.3 Essai de composition chimique . 48

10.3.1 Analyses de coulées . 48

10.3.2 Analyses sur produits . 48

10.3.3 Méthode d'essai . 49

10.3.4 Contre-essais des analyses sur produits — Tous les grades . 49

10.4 Essais de traction . 49

10.4.1 Température de détente — Tous les grades . 49

10.4.2 Essais de traction de contrôle de coulée — Tous les grades à l'exception de Q125 . 49

10.4.3 Fréquence d'essai et emplacement des éprouvettes d'essai — Tubes de cuvelage et tubes de

production . 50

10.4.4 Fréquence d'essai et emplacement des éprouvettes d'essai — Tubes-ébauches pour manchon,

matériaux pour manchons, pièces brutes pour manchon, joints de tube courts et matériaux pour

accessoires . 50

10.4.5 Éprouvettes d'essai — Généralités . 50

10.4.6 Éprouvettes d'essai — Exigences supplémentaires pour les pièces brutes pour manchon, les

tubes-ébauches pour manchon, les matériaux pour manchons et les joints de tube courts et les matériaux

pour accessoires — Grades C110 et Q125 . 51

10.4.7 Méthode d'essai . 51

10.4.8 Invalidation des essais . 52

ISO 11960:2020(F)

10.4.9 Contre-essais — Tous les produits (à l'exception des pièces brutes pour manchon, des tubes-

ébauches pour manchon, des matériaux pour manchons, des joints de tube courts ou des matériaux pour

accessoires) — Grades C90, T95, C110 et Q125) . 52

10.4.10 Contre-essais — Pièces brutes pour manchon, tubes-ébauches pour manchon, matériaux

pour manchons, joints de tube courts ou matériaux pour accessoires dans les grades C90, T95, C110 et

Q125 52

10.5 Essai d'aplatissement . 52

10.5.1 Exigence générale pour l'essai . 52

10.5.2 Fréquence d'essai . 53

10.5.3 Éprouvettes d'essai . 53

10.5.4 Méthode d'essai pour les grades H40, J55, K55, N80 (tous types), R95 et L80 Type 1 . 53

10.5.5 Méthode d'essai pour un tube en grade P110 et un tube de cuvelage en grade Q125 . 53

10.5.6 Invalidation des essais . 53

10.5.7 Contre-essais . 53

10.6 Essai de dureté . 54

10.6.1 Fréquence d'essai — Généralités . 54

10.6.2 Fréquence d'essai — Essais de contrôle de coulée — Grade L80 . 54

10.6.3 Fréquence d'essai — Grade L80 . 54

10.6.4 Fréquence d'essai et emplacement de l'éprouvette d'essai — Tube sans refoulement — Grades

C90, T95 et C110 . 54

10.6.5 Fréquence d'essai et emplacement d'éprouvette d'essai — Tube avec refoulement — Grades

C90 et T95. 55

10.6.6 Fréquence d'essai et emplacement des éprouvettes d'essai — Pièces brutes pour manchon,

tubes-ébauches pour manchon, matériaux pour manchons, joints de tube courts et matériaux pour

accessoires — Grades C90, T95 et C110 . 55

10.6.7 Fréquence d'essai — Grade Q125 . 55

10.6.8 Éprouvettes d'essai . 55

10.6.9 Méthode d'essai . 56

10.6.10 Invalidation des essais . 58

10.6.11 Contrôles périodiques de machines d'essai de dureté . 58

10.6.12 Vérification des machines d'essai de dureté et des pénétrateurs . 59

10.6.13 Contre-essais — Grade L80 . 60

10.6.14 Contre-essais — Produits en grades C90, T95 et C110 à l'exception des pièces brutes pour

manchon, des joints de tube courts ou des matériaux pour accessoires ayant fait l'objet d'un traitement

thermique après découpe à des longueurs individuelles . 60

10.6.15 Contre-essais — Pièces brutes pour manchon, joints de tube courts ou matériaux pour

accessoires en grades C90, T95 et C110 ayant fait l'objet d'un traitement thermique après découpe en

longueurs individuelles . 60

10.6.16 Contre-essais — Grade Q125 — Généralités . 60

viii © ISO 2024 – Tous droits réservés

viii © ISO 2020 – Tous droits réservés

ISO 11960:2020(F)

10.6.17 Contre-essais — Grade Q125 — Tubes de cuvelage, tubes-ébauches pour manchon et

matériaux pour manchons . 61

10.6.18 Contre-essais — Grade Q125 — Pièces brutes pour manchon, joints de tube courts et

matériaux pour accessoires . 61

10.6.19 Lots rejetés — Grades L80 (tous types), C90, T95, C110 et Q125 . 61

10.7 Essai de résistance aux chocs . 61

10.7.1 Échantillonnage — Grades J55 et K55 . 61

10.7.2 Échantillonnage — Grades N80 (tous types), R95, L80, C90, T95, C110 et P110 . 61

10.7.3 Échantillonnage et emplacement des éprouvettes d'essai — Grade Q125 . 61

10.7.4 Éprouvettes d'essai . 62

10.7.5 Méthode d'essai . 62

10.7.6 Invalidation des essais . 62

10.7.7 Contre-essai d'une longueur — Tous les grades . 62

10.7.8 Remplacement d'une longueur rejetée — Tous les grades . 62

10.7.9 Rejet de plusieurs longueurs — Grade Q125 . 63

10.8 Détermination de la grosseur des grains — Grades C90, T95 et C110 . 63

10.8.1 Échantillonnage . 63

10.8.2 Méthode d'essai . 63

10.9 Trempabilité — Grades C90, T95 et C110 . 63

10.10 Essai de fissuration sous contrainte par l'H2S — Grades C90, T95 et C110 . 63

10.11 Évaluation métallographique — Tous les grades soudés à l'arc électrique . 64

10.12 Épreuves hydrauliques . 64

10.12.1 Procédures d'épreuve hydraulique . 64

10.12.2 Exigences d'épreuve hydraulique . 65

10.12.3 Calcul de la pression d'essai . 65

10.13 Contrôle dimensionnel . 66

10.13.1 Généralités . 66

10.13.2 Mesurage du diamètre . 66

10.13.3 Contre-mesures du diamètre. 67

10.13.4 Mesurage de l'épaisseur de paroi . 67

10.13.5 Essai de calibrage . 68

10.13.6 Mesurage de la longueur . 68

10.13.7 Détermination de la masse (poids) . 69

10.13.8 Évaluation de la rectitude . 69

10.13.9 Contrôle du refoulement interne . 69

10.14 Contrôle visuel. 70

10.14.1 Généralités . 70

ISO 11960:2020(F)

10.14.2 Corps de tube, de tube-ébauche pour manchon et de matériaux pour manchons (à l'exclusion

des extrémités de tubes) . 70

10.14.3 Extrémités de tubes . 70

10.14.4 Disposition . 70

10.15 Contrôle non destructif (CND) . 70

10.15.1 Généralités . 70

10.15.2 Personnel pour les CND . 71

10.15.3 Étalons de référence. 71

10.15.4 Enregistrements de capacités des systèmes de CND . 72

10.15.5 Contrôle des corps de tube ou des tubes-ébauches pour manchon — Généralités . 73

10.15.6 CND sur corps complet et en pleine longueur des tubes de cuvelage et des tubes de

production — Grades H40, J55, K55, N80 (tous types), L80 et R95 . 73

10.15.7 CND sur corps complet et en pleine longueur des tubes de cuvelage et des tubes de

production — Grade P110 pour A.8 SR16 . 73

10.15.8 CND sur corps complet et en pleine longueur des tubes de cuvelage et des tubes de

production — Grade P110 et grade P110 pour A.8 SR16 et A.2 SR2 .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...