ISO/IEC 29158:2020

(Main)Information technology — Automatic identification and data capture techniques — Direct Part Mark (DPM) Quality Guideline

Information technology — Automatic identification and data capture techniques — Direct Part Mark (DPM) Quality Guideline

This document is an engineering document intended for verifier manufacturers and application specification developers. This document describes modifications to the symbol quality methodology defined in ISO/IEC 15415 and a symbology specification. It defines alternative illumination conditions, some new terms and parameters, modifications to the measurement and subsequent grading of certain parameters and the reporting of the grading results. This document was developed to assess the symbol quality of direct marked parts, where the mark is applied directly to the surface of the item and the reading device is a two-dimensional imager. When application specifications allow, this method is also potentially applicable to symbols produced by other methods. This is appropriate when direct part marked (DPM) symbols and non-DPM symbols are being scanned in the same scanning environment. The symbol grade is reported as a DPM grade rather than as an ISO/IEC 15415 grade.

Technologies de l'information — Techniques automatiques d'identification et de capture de données — Ligne directrice de qualité du marquage direct sur pièce (DPM)

General Information

- Status

- Withdrawn

- Publication Date

- 13-Dec-2020

- Technical Committee

- ISO/IEC JTC 1/SC 31 - Automatic identification and data capture techniques

- Drafting Committee

- ISO/IEC JTC 1/SC 31/WG 1 - Data carrier

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 25-Mar-2025

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 03-Jun-2023

- Effective Date

- 05-Nov-2015

Overview - ISO/IEC 29158:2020 (Direct Part Mark Quality Guideline)

ISO/IEC 29158:2020 is an engineering guideline for assessing the image-based quality of Direct Part Mark (DPM) symbols captured by two-dimensional imagers. Intended primarily for verifier manufacturers and application specification developers, it adapts the symbol quality methodology in ISO/IEC 15415 to address the unique optical and surface characteristics of DPM marks (e.g., dot peen, laser, ink‑jet, electro‑chemical etch). The standard defines alternative illumination conditions, new terms and parameters, modified measurement and grading methods, and reporting conventions - producing a DPM grade rather than an ISO/IEC 15415 grade.

Key Technical Topics and Requirements

- Scope & Purpose

- Engineering guidance for imaging-based verification of marks applied directly to part surfaces.

- Predictive of scanner performance in DPM environments where specular reflection and disconnected dots occur.

- Methodology Changes from ISO/IEC 15415

- Modified measurement and grading routines tailored for DPM symbol characteristics.

- Reporting of results as a DPM grade.

- Lighting and Camera Configurations

- Defines multiple illumination setups: perpendicular coaxial (90°), diffuse off‑axis (D), directional lighting patterns (four-, two-, one‑direction), and tilted coaxial lighting (TCL) with tilted camera positions to manage specular highlights.

- Image Acquisition and Optimization

- Procedures for camera position, focus, depth of field, system response adjustment, and reflectance calibration.

- Quality Metrics and Grading

- Parameters and grading processes include cell contrast (CC), cell module modulation (CM / CMOD), minimum reflectance (Rmin), and fixed pattern damage (FPD).

- Inclusion of continuous grading and expanded grading levels for minimum reflectance.

- Verification Workflow

- Steps to obtain test images, apply a reference decode algorithm, compute reflectance histograms, and produce reproducible grading reports.

Practical Applications and Who Uses It

- Primary users:

- Verifier manufacturers implementing DPM-capable quality tools.

- Application specification developers who define acceptance criteria for DPM in production and inspection processes.

- Systems integrators and quality engineers deploying DPM scanning solutions.

- Practical uses:

- Standardizing verification of DPM Data Matrix and other matrix symbologies when marks are directly applied to part surfaces.

- Ensuring consistent verifier behavior in mixed scanning environments (DPM and non‑DPM).

- Informing imaging hardware selection, lighting design, and acceptance thresholds for manufacturing inspection.

Related Standards

- ISO/IEC 15415 - Matrix symbology print quality methodology (baseline referenced and modified by ISO/IEC 29158).

- ISO/IEC TR 29158:2011 - Earlier technical report superseded by this first edition (ISO/IEC 29158:2020).

Keywords: ISO/IEC 29158:2020, Direct Part Mark, DPM quality guideline, DPM grade, verifier manufacturers, two-dimensional imager, tilted coaxial lighting, ISO/IEC 15415, cell contrast, minimum reflectance.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

NYCE

Mexican standards and certification body.

Sponsored listings

Frequently Asked Questions

ISO/IEC 29158:2020 is a standard published by the International Organization for Standardization (ISO). Its full title is "Information technology — Automatic identification and data capture techniques — Direct Part Mark (DPM) Quality Guideline". This standard covers: This document is an engineering document intended for verifier manufacturers and application specification developers. This document describes modifications to the symbol quality methodology defined in ISO/IEC 15415 and a symbology specification. It defines alternative illumination conditions, some new terms and parameters, modifications to the measurement and subsequent grading of certain parameters and the reporting of the grading results. This document was developed to assess the symbol quality of direct marked parts, where the mark is applied directly to the surface of the item and the reading device is a two-dimensional imager. When application specifications allow, this method is also potentially applicable to symbols produced by other methods. This is appropriate when direct part marked (DPM) symbols and non-DPM symbols are being scanned in the same scanning environment. The symbol grade is reported as a DPM grade rather than as an ISO/IEC 15415 grade.

This document is an engineering document intended for verifier manufacturers and application specification developers. This document describes modifications to the symbol quality methodology defined in ISO/IEC 15415 and a symbology specification. It defines alternative illumination conditions, some new terms and parameters, modifications to the measurement and subsequent grading of certain parameters and the reporting of the grading results. This document was developed to assess the symbol quality of direct marked parts, where the mark is applied directly to the surface of the item and the reading device is a two-dimensional imager. When application specifications allow, this method is also potentially applicable to symbols produced by other methods. This is appropriate when direct part marked (DPM) symbols and non-DPM symbols are being scanned in the same scanning environment. The symbol grade is reported as a DPM grade rather than as an ISO/IEC 15415 grade.

ISO/IEC 29158:2020 is classified under the following ICS (International Classification for Standards) categories: 35.040 - Information coding; 35.040.50 - Automatic identification and data capture techniques. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/IEC 29158:2020 has the following relationships with other standards: It is inter standard links to ISO/IEC 29158:2025, ISO/IEC TR 29158:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO/IEC 29158:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO/IEC

STANDARD 29158

First edition

2020-12

Information technology — Automatic

identification and data capture

techniques — Direct Part Mark (DPM)

Quality Guideline

Technologies de l'information — Techniques automatiques

d'identification et de capture de données — Ligne directrice de

qualité du marquage direct sur pièce (DPM)

Reference number

©

ISO/IEC 2020

© ISO/IEC 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO/IEC 2020 – All rights reserved

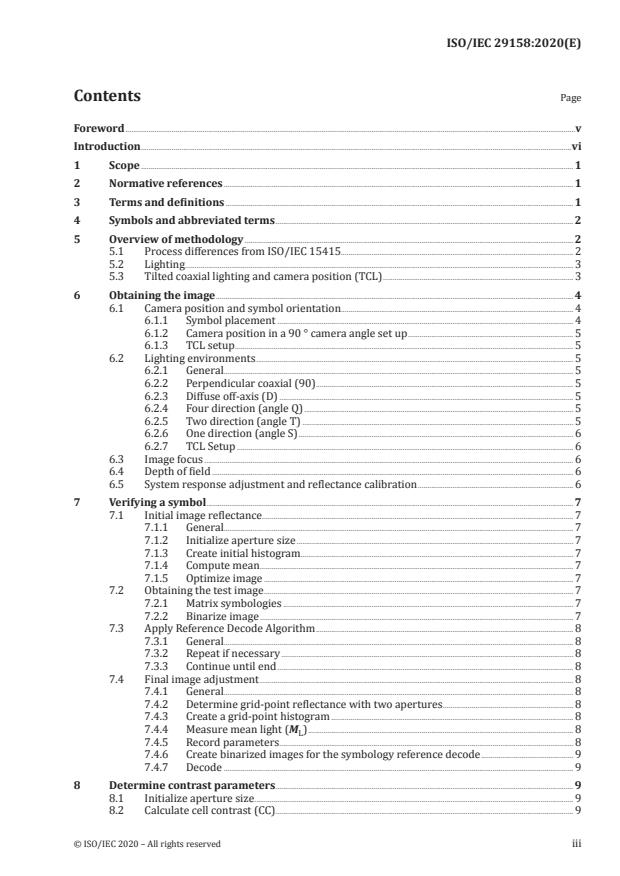

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols and abbreviated terms . 2

5 Overview of methodology . 2

5.1 Process differences from ISO/IEC 15415. 2

5.2 Lighting . 3

5.3 Tilted coaxial lighting and camera position (TCL) . 3

6 Obtaining the image . 4

6.1 Camera position and symbol orientation. 4

6.1.1 Symbol placement . 4

6.1.2 Camera position in a 90 ° camera angle set up . 5

6.1.3 TCL setup . 5

6.2 Lighting environments . 5

6.2.1 General. 5

6.2.2 Perpendicular coaxial (90) . 5

6.2.3 Diffuse off-axis (D) . 5

6.2.4 Four direction (angle Q) . 5

6.2.5 Two direction (angle T) . 5

6.2.6 One direction (angle S) . 6

6.2.7 TCL Setup . 6

6.3 Image focus . 6

6.4 Depth of field . 6

6.5 System response adjustment and reflectance calibration . 6

7 Verifying a symbol . 7

7.1 Initial image reflectance. 7

7.1.1 General. 7

7.1.2 Initialize aperture size . 7

7.1.3 Create initial histogram. 7

7.1.4 Compute mean . 7

7.1.5 Optimize image . 7

7.2 Obtaining the test image . 7

7.2.1 Matrix symbologies . 7

7.2.2 Binarize image . 7

7.3 Apply Reference Decode Algorithm . 8

7.3.1 General. 8

7.3.2 Repeat if necessary . 8

7.3.3 Continue until end . 8

7.4 Final image adjustment . 8

7.4.1 General. 8

7.4.2 Determine grid-point reflectance with two apertures . 8

7.4.3 Create a grid-point histogram . 8

7.4.4 Measure mean light (M ) . 8

L

7.4.5 Record parameters . . 8

7.4.6 Create binarized images for the symbology reference decode . 9

7.4.7 Decode . 9

8 Determine contrast parameters . 9

8.1 Initialize aperture size . 9

8.2 Calculate cell contrast (CC) . 9

© ISO/IEC 2020 – All rights reserved iii

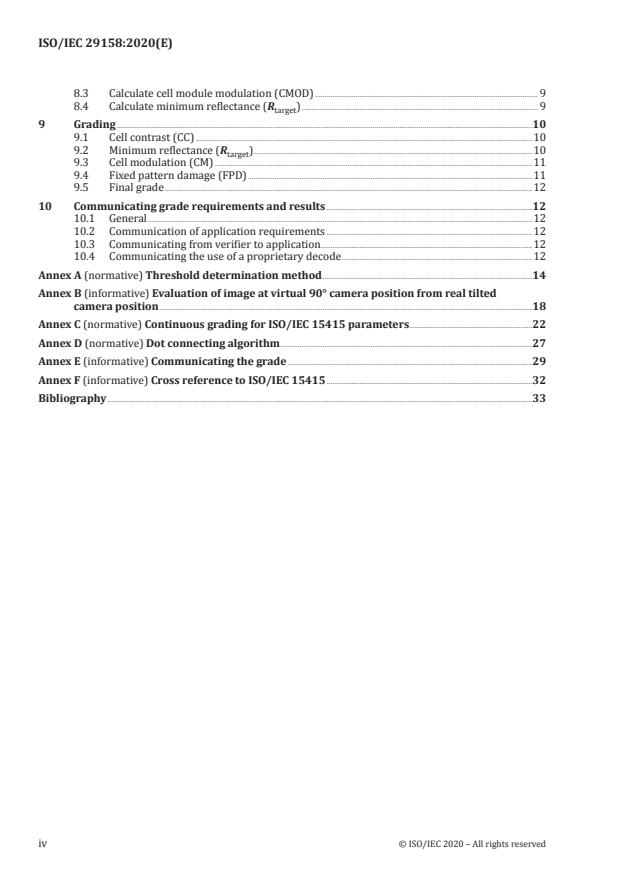

8.3 Calculate cell module modulation (CMOD) . 9

8.4 Calculate minimum reflectance (R ) . 9

target

9 Grading .10

9.1 Cell contrast (CC) .10

9.2 Minimum reflectance (R ) .10

target

9.3 Cell modulation (CM) .11

9.4 Fixed pattern damage (FPD) .11

9.5 Final grade .12

10 Communicating grade requirements and results .12

10.1 General .12

10.2 Communication of application requirements .12

10.3 Communicating from verifier to application .12

10.4 Communicating the use of a proprietary decode .12

Annex A (normative) Threshold determination method .14

Annex B (informative) Evaluation of image at virtual 90° camera position from real tilted

camera position .18

Annex C (normative) Continuous grading for ISO/IEC 15415 parameters .22

Annex D (normative) Dot connecting algorithm .27

Annex E (informative) Communicating the grade .29

Annex F (informative) Cross reference to ISO/IEC 15415 .32

Bibliography .33

iv © ISO/IEC 2020 – All rights reserved

Foreword

ISO (the International Organization for Standardization) and IEC (the International Electrotechnical

Commission) form the specialized system for worldwide standardization. National bodies that

are members of ISO or IEC participate in the development of International Standards through

technical committees established by the respective organization to deal with particular fields of

technical activity. ISO and IEC technical committees collaborate in fields of mutual interest. Other

international organizations, governmental and non-governmental, in liaison with ISO and IEC, also

take part in the work.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for

the different types of document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject

of patent rights. ISO and IEC shall not be held responsible for identifying any or all such patent

rights. Details of any patent rights identified during the development of the document will be in the

Introduction and/or on the ISO list of patent declarations received (see www .iso .org/ patents) or the

IEC list of patent declarations received (see https:// patents .iec .c).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.

This document was prepared by Joint Technical Committee ISO/TC JTC 1, Information Technology,

Subcommittee SC 31, Automatic identification and data capture techniques.

This first edition cancels and replaces ISO/IEC TR 29158:2011, which has been technically revised.

The main changes compared to the previous edition are as follows:

— inclusion of continuous grading;

— expanded grading levels for minimum reflectance (R );

target

— inclusion of a tilted lighting and camera position;

— reorganized proposed lighting options.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

© ISO/IEC 2020 – All rights reserved v

Introduction

Direct Part Marking (DPM) is a technology whereby, generally, an item is physically altered to produce

two different surface conditions. This alteration can be accomplished by various means including, but

not limited to, dot peen, laser mark, ink jetting, and electro-chemical etch. The area of the alteration

is called "the mark." The area that includes the mark and background as a whole, when containing a

pattern defined by a bar code symbology specification, is called "a symbol."

When light illuminates a symbol, it reflects differently depending on whether it impinges on the

background of the part or on the physical alteration. In most non-DPM bar code scanning environments,

light is reflected off a smooth surface that has been coloured to produce two different diffuse reflected

states. The DPM environment generally does not fit this model because the two different reflected

states depend on at least one of the states having material oriented to the lighting such that the angle

of incidence is equal to the angle of reflection. Sometimes the material so oriented produces a specular

(mirror like) reflectance that results in a signal that is orders of magnitude greater than the signal from

diffuse reflectance.

In addition, from the scanner point-of-view, some marking and printing methods generate dots and are

not capable of producing smooth lines. This is important for symbologies such as Data Matrix, which

is specified to contain smooth continuous lines, but can be marked with disconnected dots in DPM

applications.

Current specifications for matrix symbologies and two-dimensional print quality are not exactly suited

to reading situations that have either specular reflection or unconnected dots or both. Additionally,

symbologies specified to consist of smooth continuous lines may appear with unconnected dots. This

is intended to act as a bridge between the existing specifications and the DPM environment in order

to provide a standardized image-based measurement method for DPM that is predictive of scanner

performance.

As with all symbology and quality standards, it is the responsibility of the application to define the

appropriate parameters of this guideline for use in conjunction with a particular application.

vi © ISO/IEC 2020 – All rights reserved

INTERNATIONAL STANDARD ISO/IEC 29158:2020(E)

Information technology — Automatic identification and

data capture techniques — Direct Part Mark (DPM) Quality

Guideline

1 Scope

This document is an engineering document intended for verifier manufacturers and application

specification developers.

This document describes modifications to the symbol quality methodology defined in ISO/IEC 15415

and a symbology specification. It defines alternative illumination conditions, some new terms and

parameters, modifications to the measurement and subsequent grading of certain parameters and the

reporting of the grading results.

This document was developed to assess the symbol quality of direct marked parts, where the mark is

applied directly to the surface of the item and the reading device is a two-dimensional imager.

When application specifications allow, this method is also potentially applicable to symbols produced

by other methods. This is appropriate when direct part marked (DPM) symbols and non-DPM symbols

are being scanned in the same scanning environment. The symbol grade is reported as a DPM grade

rather than as an ISO/IEC 15415 grade.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO/IEC 15415, Information technology — Automatic identification and data capture techniques — Bar

code symbol print quality test specification — Two-dimensional symbols

ISO/IEC 19762, Information technology — Automatic identification and data capture (AIDC) techniques —

Harmonized vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO/IEC 19762 and ISO/IEC 15415

and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

reference symbol

high-contrast printed calibration card for which results are traceable back to national or international

standards and for which the supplier supplies a calibration certificate

3.2

stick

line segment comprised of image pixels that is used to connect areas of the same colour that are near to

each other

© ISO/IEC 2020 – All rights reserved 1

4 Symbols and abbreviated terms

CM cell modulation

CC cell contrast

CMOD cell module modulation

FPD fixed pattern damage

M mean of the grid-centre point histogram of the dark elements

D

M mean of the grid-centre point histogram of the light elements

L

M mean of the light lobe from a histogram of the calibrated standard

Lcal

M mean of the light lobe from the final grid-point histogram of the symbol under test

Ltarget

R reported reflectance value, R , from a calibration standard

cal max

R measured percent reflectance of the light elements of the symbol under test relative to the

target

calibrated standard

NOTE R is graded and reported as the parameter named “Minimum Reflectance”.

target

S system response parameters (such as exposure and/or gain) used to create an image of the

Rcal

calibration standard

S system response parameters (such as exposure and/or gain) used to create an image of the

Rtarget

symbol under test

T threshold created using a histogram of the defined grey scale pixel values in a circular area

20 times the aperture size in diameter, centred on the image centre using the algorithm

defined in Annex A

T threshold created using the histogram of the reference grey scale image pixel values at

each intersection point of the grid using the method defined in Annex A

T current minimum threshold in the calculation of the optimal threshold according Annex A

min

T current maximum threshold in the calculation of the optimal threshold according Annex A

max

TCL tilted coaxial lighting and camera position

5 Overview of methodology

5.1 Process differences from ISO/IEC 15415

All parameters in the symbology and print quality specifications apply except for:

— a different method for setting the image contrast;

— a different method for creating the binary image;

— a new method for choosing the aperture size;

— an image pre-process methodology for joining disconnected modules in a symbol (where applicable);

— a different process for determining the modulation and reflectance margin parameter renamed cell

modulation (CM);

2 © ISO/IEC 2020 – All rights reserved

— a different process for determining the symbol contrast parameter which has been renamed cell

contrast (CC);

— a different process for computing FPD;

— A new parameter called minimum reflectance (R ).

target

Axial nonuniformity, grid nonuniformity and unused error correction are applied with their continuous

grading grades as defined in Annex C, so long as ISO/IEC 15415 does not provide information on

continuous grading for these parameters. If/when ISO/IEC 15415 does provide continuous grading

on these parameters, that information will be used. This document explains how to both specify and

report quality grades in a manner complementary to, yet distinct from, the method in ISO/IEC 15415.

NOTE Annex F gives a cross reference comparison of this document to ISO/IEC15415.

5.2 Lighting

Lighting environments shall be reported according to 6.2 and 10.2. The lighting environment(s) shall be

selected by the application standard in consideration of the properties of the mark and the requirements

of the reading equipment and environment of the application.

5.3 Tilted coaxial lighting and camera position (TCL)

TCL is useful for DPM applications that use a geometrical mark which is peened, drilled or carved into a

surface. Reading camera and unidirectional illumination are located at a coaxial position with a known

fixed tilt angle and object rotation angle and position.

To read dot-peened codes, there are multiple reading setups possible. This document defines several

camera and lighting setups in order to address various dot peen geometries.

This specific TCL environment is focussing on the system response of the mark (e.g. the image a camera

[2]

sees). SAE Standard AS9132 takes a different approach to specify the mark geometry.

Figure 1 illustrates the setup. The essential parameter is the camera reading angle. Typical camera

reading angles include 30°, 45° or 60° in relation to the plane of the mark.

NOTE 1 The camera angle is defined in a compatible way to the lighting angle of ISO/IEC 15415:2011, Figure 3.

NOTE 2 Within the dot peen industry, it is common to specify the stylus angle which is twice the camera angle

given in Figure 1.

NOTE 3 In practice, the condition "coaxial lighting" may be implemented by an approximate setup like a high

distance ring. The light angle tolerance of ±3° should be respected.

© ISO/IEC 2020 – All rights reserved 3

Key

c camera and coaxial lighting

m light beam in mark is reflected to camera

o light beam outside mark is reflected away

α camera reading angle

p peened mark

M marked object

Figure 1 — Tilted coaxial lighting and camera setup

This setup is referenced by the abbreviation "TCL" in the following text.

It is not feasible to grade this setup with a camera angle of 90°. The result will not be significant for this

application, as other features of the marked object are measured.

Note that a general-purpose verifier device may not cover this application, as it requires a special

construction.

6 Obtaining the image

6.1 Camera position and symbol orientation

6.1.1 Symbol placement

Camera to object position is described in this subclause. By default, the horizontal and vertical axis of

the symbol are parallel to a line formed by the edge of the image sensor within ±3° (i.e. nominally no

rotation). This symbol orientation should be maintained unless an application specification requires

or allows a different orientation. An application specification may specify a different symbol rotation.

Since the symbol rotation is determined after decoding, the actual rotation angle should be reported

so that the setup can be reproduced easily. In applications in which the rotation angle is specified, the

rotation angle shall be reported to confirm conformance to specified requirements.

The part is placed such that the symbol is in the centre of the field of view.

4 © ISO/IEC 2020 – All rights reserved

6.1.2 Camera position in a 90 ° camera angle set up

The camera is positioned such that the plane of the image sensor is parallel to the plane of the symbol

area. This is identical to a 90° camera angle.

6.1.3 TCL setup

Within the TCL setup, camera and symbol position differs in the following points.

— The camera is positioned in the camera angle defined by the application.

— The raw image is geometrically transformed to correspond to a test image with a virtual camera

position with a 90° camera angle, as described in Annex B.

— The symbol rotation angle needs to be specified by the application and shall be respected by ± 5°.

6.2 Lighting environments

6.2.1 General

The lighting environment is specified by the application. This shall include a direction specifier or an

angle or both. The format is an extension of the angle specifier used in ISO/IEC 15415. Several examples

are given in the following subclauses.

6.2.2 Perpendicular coaxial (90)

The symbol is illuminated with diffuse light such that the specular reflection from the entire field of

view is nominally uniform.

6.2.3 Diffuse off-axis (D)

A diffusely reflecting dome is illuminated from below so that the reflected light falls non-directionally

on the part and does not cast defined shadows. This is commonly used for reading curved parts. The

angle specifier shall be D.

This lighting is also called dome lighting.

6.2.4 Four direction (angle Q)

Light is aimed at the part at the given angle ±3° from the plane of the surface of the symbol from four

sides such that the lines describing the centre of the beams from opposing pairs of lights are co-planar

and the planes at right angles to each other. One lighting plane is aligned to be parallel to the line formed

by a horizontal edge of the image sensor to within ±5°. The lighting shall illuminate the entire symbol

area with nominally uniform energy. The angle specifier shall be angle "Q".

EXAMPLE 45Q (angle equal to 45°) or 30Q (angle equal to 30°).

6.2.5 Two direction (angle T)

Light is aimed at the part at the given angle ±3° from two sides. The light may be incident from either of

the two possible orientations with respect to the symbol. The lighting plane is aligned to be parallel to

the line formed by one edge of the image sensor to within ±5°. The lighting shall illuminate the entire

symbol area with nominally uniform energy. The angle specifier shall be angle "T".

EXAMPLE 45T (angle equal to 45°) or 30T (angle equal to 30°).

Since there are two possible orientations in this setup (above and below, and left and right) the

particular orientation actually used should be reported. The reporting method may be to indicate the

location of the lights with respect to the symbol such as “north-south” when the light is incident from

© ISO/IEC 2020 – All rights reserved 5

above and below the natural “top” and “bottom” of a symbol. The orientation of a symbol is known after

decoding and related to the normal orientation of a symbol as specified in its symbology specification

(e.g. a Data Matrix symbol’s natural orientation has the solid borders on left and bottom, and for QR

code the normal orientation has finder patterns in the upper left, lower left and upper right corners but

not lower right corner.)

6.2.6 One direction (angle S)

Light is aimed at the part at the given angle ±3° from one side. The light may be incident from any

of the four possible orientations with respect to the symbol. The plane perpendicular to the symbol

surface containing the centre of the beam is aligned to be parallel to the line formed by one edge of

the image sensor to within ±5°. The lighting shall illuminate the entire symbol area with nominally

uniform energy. The angle specifier shall be angle S. Since there are four possible orientations in this

setup, the particular orientation of the incident illumination should be reported based on the symbol

orientation determined after decoding, with respect to the symbol’s normal orientation (see 6.2.5). For

example, if a symbol is upside down, and the illumination is incident from below the symbol, such that

the illumination is actually oriented toward the “top” of the symbol, then the incident light should be

reported as “North”.

EXAMPLE 45S (angle equal to 45°) or 30S (angle equal to 30°).

6.2.7 TCL Setup

TCL setup uses coaxial light at the camera reading angle. Light is aimed at the camera reading angle with

a tolerance of ±3°. The lighting shall illuminate the entire symbol area with nominally uniform energy.

Typical lighting setups are 30° (30CS), 45° (45CS) or 60° (60CS). The angle specification has an added

"C" to indicate the coaxial camera position.

NOTE A camera angle of 90° is not a TCL setup (not tilted). In consequence, a specification of "(90CS)" is not

allowed.

6.3 Image focus

The camera is adjusted such that the symbol is in best focus.

6.4 Depth of field

Non-planar surfaces or a TCL setup may require a depth of field range. The condition given in

ISO/IEC 15415:2015, 7.3.3 should be fulfilled for the whole depth of field range.

6.5 System response adjustment and reflectance calibration

System response recording is a task performed prior to the use of an instrument. It shall be repeated in

regular intervals together with the regular adjustment of an instrument.

Capture an image of the reference symbol (test code on a calibration card, see 3.1). On such a card,

a symbol which achieves a SC grade of 4 shall be used. Using an aperture size of 80 % in relation to

the test code module size, sample the centre of every element in the symbol including quiet zone and

and set the system response so that the mean of the light elements is in the range of 70 % to 86 %,

nominally 78 %, of the maximum grey scale, and the black level (no light) is nominally equal to zero.

The system response is the nominally linear relationship between the reflectivity of the target and the

pixel intensity values in the image as a result of several factors (e.g. shutter speed, imager sensitivity,

f-stop, gain, illumination intensity). This procedure requires the ability to adjust at least one of these

factors in order to adjust the system response.

Record the system response as the reference system response (S ) and record M .

Rcal Lcal

NOTE This procedure is not used for lighting configuration 90.

6 © ISO/IEC 2020 – All rights reserved

7 Verifying a symbol

7.1 Initial image reflectance

7.1.1 General

The reference grey scale image is created by the following steps.

7.1.2 Initialize aperture size

The minimum and maximum X-dimensions should be specified by the application standard and used

by the verifier in this and subsequent steps. Set the aperture to 0,5 of the minimum X-dimension of the

application and apply it to the image to create a reference grey scale image.

7.1.3 Create initial histogram

Create a histogram of the reference grey scale pixel values in a circular area 20 times the aperture size

in diameter, centred on the image centre, and find the Threshold, T , using the algorithm defined in

Annex A.

The threshold divides the histogram into two portions: a portion below the threshold which contains

dark pixels and a portion above the threshold which contains light pixels (called the “light lobe”).

NOTE If the circular area of 20 times of the aperture size is larger than the field of view of a real device, then

the area is limited by the field of view.

7.1.4 Compute mean

Compute the mean of the light lobe.

7.1.5 Optimize image

Adjust the system response by taking new images and repeating steps 7.1.2 and 7.1.3 until the mean of

the light elements is 78 % reflectance of the maximum grey scale. A tolerance of ±8 is acceptable for the

mean value of the light elements. This results in a range from 70 % to 86 % for system response.

7.2 Obtaining the test image

7.2.1 Matrix symbologies

Matrix symbologies are specified in different appearances. Some are specified to consist of separate,

unconnected dots. The reference decode of such symbologies takes care of handling these separated

dots. Other symbologies are specified to consist of continuous connected matrix cells. Some marking

technologies are not capable of producing such symbols with smooth, continuous lines. Therefore,

they appear also with unconnected dots (e.g. if marked by a dot peen process). In this specific case the

code image is pre-processed to connect the unconnected dots (see Annex D). After this pre-process the

standard reference decode algorithm is applied.

Once the grid of the symbol is determined, the location information is transferred to the evaluation of

the reference grey scale image and subsequent processing occurs using the reference grey scale image.

7.2.2 Binarize image

Compute a reference grey scale image using the current aperture size. Using T , binarize the entire image.

© ISO/IEC 2020 – All rights reserved 7

7.3 Apply Reference Decode Algorithm

7.3.1 General

Attempt to find and process the symbol using the symbology Reference Decode Algorithm and the

current aperture size.

If a dot code symbol is detected for which no dot reference decode algorithm exists apply the dot

connecting algorithm in Annex D. On a successful attempt, go to 7.4.

NOTE Where a symbology has a reference decode algorithm that operates successfully on nominally

disconnected modules (e.g., “dot” codes) the process of connecting modules is inappropriate. With these

symbologies, if the application of the Reference Decode Algorithm fails then go to 7.3.2 (not Annex D).

7.3.2 Repeat if necessary

If the decode attempt fails, increase the aperture size by 1/10th of the X dimension range allowed in the

application and go to 7.2.1. Stop if the aperture size exceeds the largest X dimension.

7.3.3 Continue until end

Continue until the symbol is successfully decoded or all aperture sizes are tested. If the symbol is not

decoded, the symbol grade is Zero.

7.4 Final image adjustment

7.4.1 General

This procedure uses only the nominal centres of modules to create a highly bi-modal histogram of the

symbol reflectance states.

7.4.2 Determine grid-point reflectance with two apertures

Re-compute the reference grey scale image using two new aperture sizes equal to 0.5 and 0.8 of the

measured average grid spacing. Perform the following calculations and grading for both apertures.

7.4.3 Create a grid-point histogram

Create a histogram of the reference grey scale image pixel values at each intersection point of the grid

determined from the decode and find T using the algorithm defined in Annex A.

7.4.4 Measure mean light (M )

L

Measure the mean light of the grid-centre point histogram. If it is 78 % (reflectance) of the maximum

grey scale (e.g. 255 for an 8-bit image) then retain the values for mean dark (M ) and mean light. A

D

tolerance of ±8 is acceptable for the mean light reflectance value. This results in a range from 70 % to

86 % for mean light.

If not, adjust the system response and go to 7.4.2.

NOTE The measurement algorithm for mean light (M ) and mean dark (M ) is described in Annex A.

L D

7.4.5 Record parameters

Set M equal to mean light (M ). Record the system response as S . Record the new T .

Ltarget L Rtarget 2

8 © ISO/IEC 2020 – All rights reserved

7.4.6 Create binarized images for the symbology reference decode

If the dot connecting algorithm in Annex D is to be used in this step 7.4.7, then set the stick size to the

average grid spacing and apply the dot connecting algorithm using T on the new reference grey scale

image to create the final binarized image. Otherwise, binarize using T .

7.4.7 Decode

Decode the final binary image using the steps of 7.3 through 7.4.7 using the symbology reference decode

algorithm without applying the dot connecting algorithm.

If the dot connecting algorithm is applicable to the symbology, repeat the decode and the following

steps with dot connecting algorithm applied.

NOTE The Data Matrix reference decode algorithm contains a process of searching for clock tracks and

quiet zones using minimum and maximum values of transition counts, which thus shall be taken from these two

different binarized images separately.

Recalculate T using the grid centres of this decode.

8 Determine contrast parameters

8.1 Initialize aperture size

Calculate the following parameters using the T value and grid centres of 7.4.7.

8.2 Calculate cell contrast (CC)

Calculate CC using Formula (1), referencing the algorithm found in Annex A:

C = (M – M ) / M (1)

c Ltarget D Ltarget

where C is the cell contrast (CC).

c

8.3 Calculate cell module modulation (CMOD)

Calculate CMOD using the Formula (2):

If (R < T ) then C = (T - R) / (T - M ) Else C = (R - T ) / (M - T) (2)

2 MOD 2 2 D MOD 2 Ltarget 2

where

R is the measured reflectance of the cell;

C is the cell module modulation (CMOD).

MOD

8.4 Calculate minimum reflectance (R )

target

Calculate Minimum Reflectance (R ) using Formula (3):

target

R = R x (S / S ) x (M / M) (3)

target cal Rcal Rtarget Ltarget Lcal

When the lighting is "/90" (specular reflectance), S and M are not defined. See 9.2.

LRCal Lcal

© ISO/IEC 2020 – All rights reserved 9

9 Grading

9.1 Cell contrast (CC)

The grade levels for cell contrast grading are given in Table 1.

Table 1 — Grade levels of cell contrast

CC

Grade

%

≥30 4.0

25 3.0

20 2.0

15 1.0

<=10 0.0

The grade shall be computed as a linearly interpolated value, rounded to the nearest 0.1 in between

grade levels.

For example, a Cell Contrast Value of 21 % gets a grade of 2.2 and a Cell Contrast value of 13 % gets a

grade of 0,6.

The grade may be evaluated from the cell contrast value using Formulae (4), (5) and (6):

C ≥ 30 %: Grade = 4.0 (4)

c

10 % < C < 30 %: Grade = round10( (20 × C ) − 2) (5)

c c

C ≤ 10 %: Grade = 0.0 (6)

c

where C is the cell contrast (CC).

c

See Annex C.4 for a definition of the round10() function.

NOTE With an 8-bit grey scale sensor, 15 % is equal to a difference of 30 grey scale values.

9.2 Minimum reflectance (R )

target

The grade levels for minimum reflectance grading are given in Table 2.

Table 2 — Grade levels of minimum reflectance

R

target

Grade

%

≥20 4.0

15 3.5

10 2.5

5 1.5

=0 0.0

The grade shall be computed as a linearly interpolated value, rounded to the nearest 0.1 in between

grade levels.

For example, a R Value of 13 % gets a grade of 3.1 and a R value of 3 % gets a grade of 0.9.

target target

10 © ISO/IEC 2020 – All rights reserved

The continuous grade may be evaluated from the minimum reflectance value using Formulae (7), (8),

(9), (10) and (11):

R ≥ 20 %: Grade = 4.0 (7)

target

15 % ≤ R < 20 %: Grade = round10(10 × R + 2) (8)

target target

5 % ≤ R < 15 %: Grade = round10(20 × R + 0,5) (9)

target target

0 % < R < 5 %: Grade = round10(30 × R) (10)

target target

R = 0 %: Grade 0.0 (11)

target

See Annex C.4 for a definition of the round10() function.

When the lighting is "/90", R is not determined. R is then either not reported or reported as

target target

n/a (not applicable).

9.3 Cell modulation (CM)

The ISO/IEC 15415 Modulation and Reflectance Margin parameters are replaced with CM.

CM calculation follows the method for modulation of ISO/IEC 15415, with the following modifications.

— The value CMOD defined in 8.3 of this document is used instead of the ISO/IEC 15415 value MOD.

— The grade level for CMOD is identical to the grades given by the formula in ISO/IEC 15415 and set to

0 if the module is decoded as error.

Continuous grading as described in Annex C shall be applied to "MOD or MARGIN" and "UEC", as long as

ISO/IEC 15415 does not implement continuous grading. For CMOD continuous grading applies a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...