ISO 7186:2011

(Main)Ductile iron products for sewerage applications

Ductile iron products for sewerage applications

ISO 7186:2011 specifies the requirements and test methods applicable to ductile iron pipes, fittings, accessories and their joints for the construction of drains and sewers outside buildings: - to convey surface water (e.g. rainwater), domestic waste water and/or certain types of industrial effluents, either in separate systems or in combined systems; - operating without pressure (gravity sewers) or with positive or negative pressure; - for installation below or above ground. ISO 7186:2011 contains specifications for materials, dimensions and tolerances, mechanical properties and standard coatings of pipes, fittings and accessories. It also gives performance requirements for all components including joints. ISO 7186:2011 is applicable to pipes, fittings and accessories cast by any type of foundry process or manufactured by fabrication of cast components, as well as corresponding joints, in the size range DN 80 to DN 2600 inclusive. It is applicable to pipes, fittings and accessories which are manufactured with socketed, flanged or spigot ends (joint design and gasket shape are outside the scope of ISO 7186:2011) and normally delivered internally and externally coated.

Produits en fonte ductile pour l'assainissement

General Information

- Status

- Published

- Publication Date

- 07-Jul-2011

- Technical Committee

- ISO/TC 5/SC 2 - Cast iron pipes, fittings and their joints

- Drafting Committee

- ISO/TC 5/SC 2 - Cast iron pipes, fittings and their joints

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 18-Mar-2024

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 15-Apr-2008

Overview

ISO 7186:2011 - Ductile iron products for sewerage applications defines requirements and test methods for ductile iron pipes, fittings, accessories and their joints used in drains and sewers outside buildings. The standard covers components for gravity, pressure (positive), and vacuum (negative) sewers and for installation both below and above ground. It applies to cast or fabricated ductile iron components in the size range DN 80 to DN 2600, normally delivered with internal and external coatings.

Key topics and technical requirements

- Scope and applications: Conveyance of surface water (rainwater), domestic wastewater and certain industrial effluents in separate or combined systems; use in gravity, pressure and vacuum sewers.

- Materials and mechanical properties: Requirements for ductile iron materials and mechanical testing (e.g., tensile tests, Brinell hardness) to verify material performance.

- Dimensions and tolerances: Standardized dimensions, laying lengths and tolerances for socketed, flanged or spigot ends (note: joint design and gasket shape are outside ISO 7186’s scope).

- Pressure classification: New pressure-based classification system introduced in this edition, linking minimum wall thickness to allowable operating pressure.

- Coatings and linings: Specifications for standard internal and external coatings/linings and references to informative annexes on external/internal protection.

- Performance criteria: Leaktightness of pipeline components and joints, diametral stiffness of pipes, chemical resistance to effluents, and abrasion resistance.

- Test methods and type testing: Defined factory and type tests, including works leaktightness tests for pressure/vacuum, diametral stiffness testing, chemical and abrasion resistance tests and test frequencies.

- Size range and joint types: Applicable to DN 80–DN 2600; components may be socketed, flanged or spigot.

Practical applications and intended users

ISO 7186 is essential for:

- Municipal engineers, wastewater utility managers and sewer system designers specifying ductile iron pipelines.

- Manufacturers, foundries and fabricators producing pipes, fittings and accessories for sewerage systems.

- Contractors and inspectors responsible for installation, quality assurance and site testing.

- Test laboratories performing mechanical, leaktightness and durability testing. Using ISO 7186 helps ensure compatibility, reliable joint performance, long-term durability and suitability for specific hydraulic and chemical conditions encountered in sewerage projects.

Related standards

- ISO 2531 (ductile iron pipes for water applications)

- ISO 10804 (restrained joint systems for ductile iron pipelines)

- EN 1092-2, ISO 7005-2 (cast iron flanges) These referenced standards complement ISO 7186 when specifying flanges, jointing systems and wider ductile iron pipeline requirements.

Keywords: ISO 7186:2011, ductile iron pipes, sewerage applications, ductile iron fittings, leaktightness, diametral stiffness, DN 80–DN 2600, pressure classification, sewer standards.

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

ISO 7186:2011 is a standard published by the International Organization for Standardization (ISO). Its full title is "Ductile iron products for sewerage applications". This standard covers: ISO 7186:2011 specifies the requirements and test methods applicable to ductile iron pipes, fittings, accessories and their joints for the construction of drains and sewers outside buildings: - to convey surface water (e.g. rainwater), domestic waste water and/or certain types of industrial effluents, either in separate systems or in combined systems; - operating without pressure (gravity sewers) or with positive or negative pressure; - for installation below or above ground. ISO 7186:2011 contains specifications for materials, dimensions and tolerances, mechanical properties and standard coatings of pipes, fittings and accessories. It also gives performance requirements for all components including joints. ISO 7186:2011 is applicable to pipes, fittings and accessories cast by any type of foundry process or manufactured by fabrication of cast components, as well as corresponding joints, in the size range DN 80 to DN 2600 inclusive. It is applicable to pipes, fittings and accessories which are manufactured with socketed, flanged or spigot ends (joint design and gasket shape are outside the scope of ISO 7186:2011) and normally delivered internally and externally coated.

ISO 7186:2011 specifies the requirements and test methods applicable to ductile iron pipes, fittings, accessories and their joints for the construction of drains and sewers outside buildings: - to convey surface water (e.g. rainwater), domestic waste water and/or certain types of industrial effluents, either in separate systems or in combined systems; - operating without pressure (gravity sewers) or with positive or negative pressure; - for installation below or above ground. ISO 7186:2011 contains specifications for materials, dimensions and tolerances, mechanical properties and standard coatings of pipes, fittings and accessories. It also gives performance requirements for all components including joints. ISO 7186:2011 is applicable to pipes, fittings and accessories cast by any type of foundry process or manufactured by fabrication of cast components, as well as corresponding joints, in the size range DN 80 to DN 2600 inclusive. It is applicable to pipes, fittings and accessories which are manufactured with socketed, flanged or spigot ends (joint design and gasket shape are outside the scope of ISO 7186:2011) and normally delivered internally and externally coated.

ISO 7186:2011 is classified under the following ICS (International Classification for Standards) categories: 77.140.80 - Iron and steel castings; 93.030 - External sewage systems. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 7186:2011 has the following relationships with other standards: It is inter standard links to ISO 7186:1996. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 7186:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 7186

Third edition

2011-07-15

Ductile iron products for sewerage

applications

Produits en fonte ductile pour l'assainissement

Reference number

©

ISO 2011

© ISO 2011

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2011 – All rights reserved

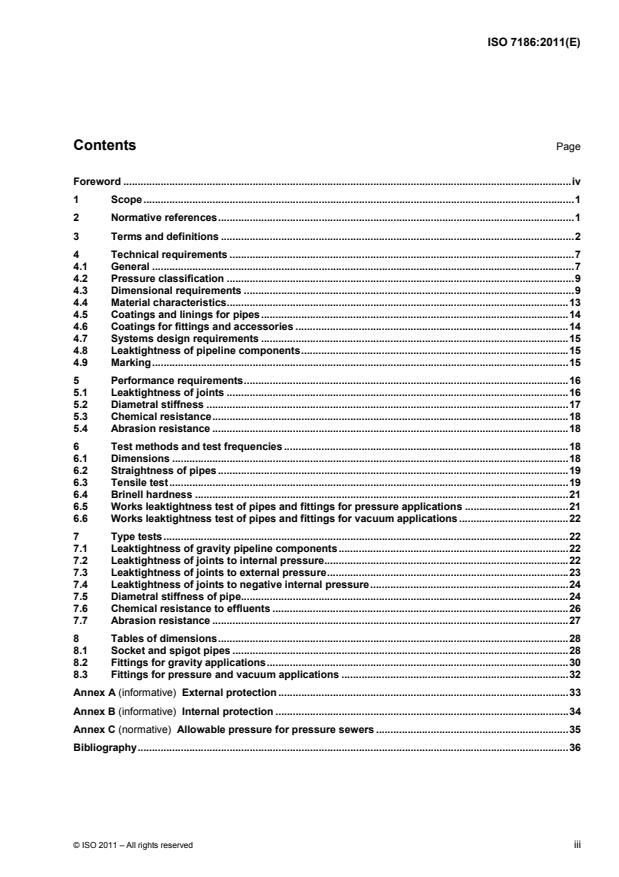

Contents Page

Foreword .iv

1 Scope.1

2 Normative references.1

3 Terms and definitions .2

4 Technical requirements .7

4.1 General .7

4.2 Pressure classification .9

4.3 Dimensional requirements .9

4.4 Material characteristics.13

4.5 Coatings and linings for pipes.14

4.6 Coatings for fittings and accessories .14

4.7 Systems design requirements .15

4.8 Leaktightness of pipeline components.15

4.9 Marking.15

5 Performance requirements.16

5.1 Leaktightness of joints .16

5.2 Diametral stiffness .17

5.3 Chemical resistance.18

5.4 Abrasion resistance .18

6 Test methods and test frequencies .18

6.1 Dimensions .18

6.2 Straightness of pipes .19

6.3 Tensile test.19

6.4 Brinell hardness .21

6.5 Works leaktightness test of pipes and fittings for pressure applications .21

6.6 Works leaktightness test of pipes and fittings for vacuum applications .22

7 Type tests.22

7.1 Leaktightness of gravity pipeline components.22

7.2 Leaktightness of joints to internal pressure.22

7.3 Leaktightness of joints to external pressure.23

7.4 Leaktightness of joints to negative internal pressure.24

7.5 Diametral stiffness of pipe.24

7.6 Chemical resistance to effluents .26

7.7 Abrasion resistance .27

8 Tables of dimensions.28

8.1 Socket and spigot pipes .28

8.2 Fittings for gravity applications.30

8.3 Fittings for pressure and vacuum applications .32

Annex A (informative) External protection .33

Annex B (informative) Internal protection .34

Annex C (normative) Allowable pressure for pressure sewers .35

Bibliography.36

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 7186 was prepared by Technical Committee ISO/TC 5, Ferrous metal pipes and metallic fittings,

Subcommittee SC 2, Cast iron pipes, fittings and their joints.

This third edition cancels and replaces the second edition (ISO 7186:1996), which has been technically

revised. A new classification system for pipes and fittings based on pressure is introduced with minimum wall

thickness determined by allowable operating pressure.

iv © ISO 2011 – All rights reserved

INTERNATIONAL STANDARD ISO 7186:2011(E)

Ductile iron products for sewerage applications

1 Scope

This International Standard specifies the requirements and test methods applicable to ductile iron pipes,

fittings, accessories and their joints for the construction of drains and sewers outside buildings:

⎯ to convey surface water (e.g. rainwater), domestic waste water and/or certain types of industrial effluents,

either in separate systems or in combined systems;

⎯ operating without pressure (gravity sewers) or with positive or negative pressure;

⎯ for installation below or above ground.

1)

NOTE In this International Standard, all pressures are relative pressures expressed in bar .

This International Standard contains specifications for materials, dimensions and tolerances, mechanical

properties and standard coatings of pipes, fittings and accessories. It also gives performance requirements for

all components including joints.

This International Standard is applicable to pipes, fittings and accessories cast by any type of foundry process

or manufactured by fabrication of cast components, as well as corresponding joints, in the size range DN 80 to

DN 2600 inclusive.

It is applicable to pipes, fittings and accessories which are

⎯ manufactured with socketed, flanged or spigot ends (joint design and gasket shape are outside the scope

of this International Standard), and

⎯ normally delivered internally and externally coated.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 2531, Ductile iron pipes, fittings, accessories and their joints for water applications

ISO 4016, Hexagon head bolts — Product grade C

ISO 4034, Hexagon nuts — Product grade C

ISO 4633, Rubber seals — Joint rings for water supply, drainage and sewerage pipelines — Specification for

materials

ISO 6506-1, Metallic materials — Brinell hardness test — Part 1: Test method

1) 100 kPa = 1 bar = 0,1 MPa; 1 MPa = 1 N/mm .

ISO 7005-2, Metallic flanges — Part 2: Cast iron flanges

ISO 7091, Plain washers — Normal series — Product grade C

ISO 10804, Restrained joint systems for ductile iron pipelines — Design rules and type testing

EN 1092-2, Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories,

PN designated — Part 2: Cast iron flanges

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

ductile iron

type of cast iron used for pipes, fittings and accessories in which graphite is present primarily in spheroidal

form

[ISO 2531:2009, definition 3.8]

3.2

pipe

casting of uniform bore, with straight axis, having either socket, spigot or flanged ends

NOTE This does not apply to flanged sockets, flanged spigots and collars, which are classified as fittings.

[ISO 2531:2009, definition 3.22]

3.3

fitting

casting other than a pipe, which allows pipeline deviation, change of direction or bore

NOTE Flanged sockets, flanged spigots and collars are also classified as fittings.

[ISO 2531:2009, definition 3.9]

3.4

accessory

any casting other than a pipe or fitting, which is used in a pipeline

EXAMPLE 1 Glands and bolts for mechanical flexible joints.

EXAMPLE 2 Glands, bolts and locking rings or segments for restrained joints.

[ISO 2531:2009, definition 3.1]

3.5

inspection chamber

component of a discharge system, of a drain or of a sewer providing access from the ground surface for

inspection and maintenance equipment

3.6

manhole

component of a sewer of sufficient size to provide access from the ground surface for inspection and

maintenance operations by personnel and equipment

2 © ISO 2011 – All rights reserved

3.7

flange

end of a pipe or fitting, extending perpendicular to its axis, with bolt holes equally spaced on a circle

NOTE A flange can be fixed (e.g. integrally cast, screwed-on or welded-on) or adjustable. An adjustable flange

comprises a ring, in one or several parts bolted together, which bears on an end joint hub and can be freely rotated around

the barrel axis before jointing.

[ISO 2531:2009, definition 3.10]

3.8

spigot

male end of a pipe or fitting

[ISO 2531:2009, definition 3.26]

3.9

spigot end

maximum insertion depth of the spigot, L , plus 50 mm

i

[ISO 2531:2009, definition 3.27]

See Figure 5.

3.10

socket

female end of a pipe or fitting to make the connection with the spigot of the next component

[ISO 2531:2009, definition 3.25]

3.11

gasket

sealing component of a joint

[ISO 2531:2009, definition 3.13]

3.12

joint

connection between the ends of pipes and/or fittings in which a gasket is used to effect a seal

[ISO 2531:2009, definition 3.15]

3.13

flexible joint

joint providing significant angular deflection and movement parallel and/or perpendicular to the pipe axis

[ISO 2531:2009, definition 3.12]

3.14

push-in flexible joint

flexible joint assembled by pushing the spigot through the gasket into the socket of the mating component

[ISO 2531:2009, definition 3.23]

3.15

mechanical flexible joint

flexible joint in which sealing is obtained by applying pressure to the gasket by mechanical means, e.g. a

gland

[ISO 2531:2009, definition 3.18]

3.16

restrained joint

joint in which a means is provided to prevent separation of the assembled joint

[ISO 2531:2009, definition 3.24]

3.17

flanged joint

joint between two flanged ends

[ISO 2531:2009, definition 3.11]

3.18

nominal size

DN

alphanumeric designation of size for components of a pipework system, which is used for reference purposes

NOTE 1 It comprises the letters DN followed by a dimensionless whole number, which is indirectly related to the

physical size, in millimetres, of the bore or outside diameter of the end connections.

NOTE 2 Adapted from ISO 6708:1995, definition 2.1.

3.19

nominal pressure

PN

numerical designation, which is a convenient rounded number, used for reference purposes

NOTE 1 All components of the same nominal size, DN, designated by the same PN number have compatible mating

dimensions.

NOTE 2 Adapted from ISO 7268.

3.20

leaktightness test pressure

pressure applied to a component during manufacturing in order to ensure its leaktightness

3.21

allowable operating pressure

PFA

maximum internal pressure, excluding surge, that a component can safely withstand in permanent service

[ISO 2531:2009, definition 3.2]

3.22

allowable maximum operating pressure

PMA

maximum internal pressure, including surge, which a component can safely withstand in service

NOTE Adapted from ISO 2531:2009, definition 3.17.

4 © ISO 2011 – All rights reserved

3.23

allowable site test pressure

PEA

maximum hydrostatic pressure that a newly installed component can withstand for a relatively short duration,

when either fixed above ground level or laid and backfilled underground, in order to measure the integrity and

tightness of the pipeline

NOTE This test pressure is different from the system test pressure which is related to the design pressure of the

pipeline.

[ISO 2531:2009, definition 3.3]

3.24

diametral stiffness of a pipe

characteristic of a pipe allowing it to resist diametral deflection under loading

[ISO 2531:2009, definition 3.7]

3.25

discharge system

system of pipes, fittings, accessories and joints used to collect and drain waste water and rainwater from a

building

NOTE It comprises discharge pipes, stack ventilation pipes and rainwater downpipes, installed within the limits of a

building or attached to the building.

3.26

drain

system of pipes, fittings, accessories and joints installed outside the limits of a building in order to connect the

discharge system of the building to a sewer or a septic tank

3.27

sewer

pipeline designed to collect waste water and rainwater from buildings and surface water and to convey them

to the point of disposal or treatment

3.28

gravity sewer

sewer operating normally under free flowing conditions

3.29

pumping sewer

pressure sewer

sewer (or section of a sewer) operating under positive pressure

3.30

vacuum sewer

sewer operating under negative pressure

3.31

combined sewer

sewer collecting together rainwater, surface water and waste water

3.32

separate sewer system

sewerage system which collects waste water separately from surface water

3.33

batch

quantity of castings from which a sample may be taken for testing purposes during manufacture

[ISO 2531:2009, definition 3.4]

3.34

type test

proof-of-design test, which is done once and is repeated only after change of design

[ISO 2531:2009, definition 3.29]

3.35

laying length

L

e

length by which a pipeline progresses when an additional pipe is installed

NOTE 1 For socket and spigot pipes, it is equal to the total length of the pipe, L , minus the maximum spigot insertion

tot

depth, L , as given by the manufacturer and as shown in Figure 5. For flanged pipes, it is equal to the total length of the

i

pipe.

NOTE 2 It is expressed in metres.

NOTE 3 Adapted from ISO 2531:2009, definition 3.16.

3.36

standardized length

length of pipe barrel and fitting body or branch

NOTE 1 For socket and spigot pipes, it is designated L (l for branches). For flanged pipes, and fittings, it is

u u

designated L (l for branches). See Figure 5 and ISO 2531.

NOTE 2 For flanged pipes and fittings, the standardized length L (l for branches) is equal to the total length. For

socketed pipes and fittings, the standardized length L (l for branches) is equal to the total length minus the depth of

u u

socket, as indicated in the manufacturer's handbooks.

NOTE 3 Adapted from ISO 2531:2009, definition 3.28

3.37

ovality

out-of-roundness of a pipe section, equal to Equation (1):

A − A

()

100 (1)

A + A

()

where

A is the maximum axis, in millimetres;

A is the minimum axis, in millimetres.

[ISO 2531:2009, definition 3.21]

6 © ISO 2011 – All rights reserved

3.38

deviation

amount by which the design length may differ from the standardized length of a pipe or a fitting

NOTE 1 Pipes and fittings are designed to a length selected in the range of standard length plus or minus the deviation

(see Table 3); they are manufactured to this length plus or minus the tolerance given in Table 4.

NOTE 2 Adapted from ISO 2531:2009, definition 3.6.

3.39

component

any product defined as an element of a pipeline, such as a pipe, fitting or accessory

[ISO 2531:2009, definition 3.5]

See 3.2, 3.3 and 3.4.

3.40

hoop stress

σ

stress in a pipe or fitting under pressure, acting tangentially to the perimeter of a transverse section

[ISO 2531:2009, definition 3.14]

4 Technical requirements

4.1 General

4.1.1 Pipes, fittings and accessories

Thicknesses, lengths and coatings are specified in 4.3.2, 4.3.3, and 4.5 and 4.6, respectively. Where, by

agreement between the manufacturer and the purchaser, pipes and fittings with different lengths, thicknesses

and/or coatings, and other types of fittings than those given in 8.2 and 8.3, are supplied in accordance with

this International Standard, they shall comply with all the other requirements of this International Standard.

This includes pipes and fittings manufactured to national standards and regulations.

The standard nominal sizes DN of pipes and fittings are the following:

80, 100, 125, 150, 200, 250, 300, 350, 400, 450, 500, 600, 700, 800, 900, 1000, 1100, 1200, 1400, 1500,

1600, 1800, 2000, 2200, 2400, 2600.

The stiffness and allowable diametral deflection of ductile iron pipes are those given in Table 11.

The pressures PFA, PMA and PEA (see 3.21, 3.22 and 3.23) for pressure sewers are those indicated in

Annex C.

NOTE Where designed, installed, operated and maintained with due regard to the factors described in Annexes A

and B, ductile iron pipes, fittings, accessories and their joints maintain their functional characteristics over their service life,

due to time-independent material properties and high factors of safety.

4.1.2 Surface condition and repairs

Pipes, fittings and accessories shall be free from defects and surface imperfections which can impair their

compliance with the requirements of Clauses 4 and 5.

Where necessary, pipes and fittings may be repaired by the manufacturer, for example by welding, to remove

surface imperfections and localized defects, which do not affect the entire wall thickness, provided the

repaired pipes and fittings comply with all the requirements of Clauses 4 and 5.

4.1.3 Types of joints and interconnection

4.1.3.1 General

Joint design and gasket shapes are beyond the scope of this International Standard.

Rubber gasket materials shall conform to the requirements of ISO 4633 for sewerage applications. Where

materials other than rubber are necessary (e.g. high-temperature flanged joints), they shall conform to the

appropriate International Standards.

4.1.3.2 Flanged joints

Flanged joints shall be designed such that they can be attached to flanges whose dimensions and tolerances

comply with ISO 7005-2 or EN 1092-2. This ensures interconnection between all flanged components (pipes,

fittings, valves, etc.) of the same DN and PN and adequate joint performance. Bolts and nuts shall comply, as

a minimum, with the requirements of ISO 4016 and ISO 4034, property class 4.6. Where washers are required

they shall comply with ISO 7091.

In addition, each type of flanged joint shall be designed to meet the performance requirements as specified in

ISO 2531.

Although it does not affect interconnection, the manufacturer's handbook shall indicate whether products

contained therein are normally delivered with fixed or loose flanges.

4.1.3.3 Flexible joints

Pipes and fittings with flexible joints shall be in accordance with 4.3.1.1 for their spigot external diameters, DE,

and their tolerances. This provides the possibility of interconnection between components equipped with

different types of flexible joints. In addition, each type of flexible joint shall be designed to meet the

performance requirements of 5.1.

For interconnection with certain types of joints operating within a tighter tolerance range on DE, the

manufacturer's guidance should be followed as to the means of ensuring adequate joint performance up to the

highest pressures (e.g. measurement and selection of external diameter).

For interconnection with existing pipelines, which can have external diameters not in accordance with 4.3.1.1,

the manufacturer's guidance should be followed as to the appropriate means of interconnection (e.g.

adaptors).

4.1.3.4 Restrained joints

Restrained joints for ductile iron pipelines shall be designed in accordance with ISO 10804. Their spigot

external diameters, DE, and their tolerances shall comply with 4.3.1.1.

4.1.4 Colour identification

Pipes and fittings for sewers and drains shall be identified externally by a specific colour (see national

standard). Identification is possible by various means, e.g. external paint, polyethylene sleeving or a warning

tape.

NOTE This is to allow easy identification of installed sewers and drains and to avoid mistaking with pipelines for

water and gas supply.

8 © ISO 2011 – All rights reserved

4.2 Pressure classification

4.2.1 General

Depending on the manner by which the surface water or sewerage is transported, the sewerage system can

be classified as a pressure sewer or a gravity sewer and, accordingly, flexibly jointed pipeline systems can be

classified as pressure pipes/fittings or gravity pipes/fittings.

The allowable pressures within a pipeline system shall be limited to the lowest pressure classification

component within the system.

Components with flanged joints shall be classified by the PN number of the flange.

Pressure pipes can be used in gravity pipeline systems.

4.2.2 Gravity pipes

Gravity pipes are designed for gravity sewer applications. Their normal service, internal and external

pressures are defined in Table 6.

4.2.3 Pressure pipes

Pressure pipes are designed for pressure sewer applications and are classified by the allowable operating

pressure (PFA), prefixed by a letter C.

Allowable pipeline pressures relationships are as follows:

a) allowable operating pressure (PFA) = (C), in bar;

b) maximum allowable operating pressure (PMA) = 1,20 × (PFA), in bar;

c) allowable site test pressure (PEA) = (1,20 × PFA) + 5, in bar.

The pressure pipes shall be selected from the preferred pressure classes C25, C30 and C40 as defined in

ISO 2531. Their normal service internal and external pressures are defined in Table 6.

Other pressure classes, specified in ISO 2531, may be used if applicable.

The allowable pressures within a pipeline system shall be limited to the lowest pressure classification

component within the system.

4.3 Dimensional requirements

4.3.1 Diameter

4.3.1.1 External diameter

Table 12 gives the values of the external diameter DE of the spigot end of pipes and fittings, when measured

circumferentially using a circumferential tape in accordance with 6.1.1. The positive tolerance is +1 mm and

applies to all pressure classes of pipes and also to flanged spigot fittings.

The negative tolerance depends on the design of each type of joint and can be as specified in national

standards, or, when not so specified, in the manufacturer's handbook, for the type of joint and the nominal

size considered.

In addition, the ovality (see 3.37) of the spigot end of pipes and fittings shall

⎯ remain within the tolerances on DE for DN 80 to DN 200, and

⎯ not exceed 1 % of DE for DN 250 to DN 600 or 2 % for DN > 600.

The manufacturer's recommendations should be followed with respect to the necessity and means of ovality

correction; certain types of flexible joints can accept the maximum ovality without the need for spigot re-

rounding prior to jointing.

4.3.1.2 Internal diameter

The nominal values of the internal diameters of centrifugally cast pipes, expressed in millimetres, are

approximately equal to the numbers indicating their nominal size, DN.

4.3.2 Wall thickness

4.3.2.1 Pipes with flexible joints

4.3.2.1.1 Gravity pipes

The minimum wall thickness for gravity pipes shall be as given in Table 12.

The minimum wall thickness, e , is equal to the nominal wall thickness, e , minus 1 mm for DN 80 to

min nom

DN 300 and minus 1,2 mm for DN 350.

4.3.2.1.2 Pressure pipes

The minimum wall thickness, e , and shall be not less than 3 mm and shall be determined using

min

Equation (2):

PFA××SF DE

e = (2)

min

20R+×PFA SF

()

m

where:

e is the minimum pipe wall thickness, in millimetres;

min

PFA is the allowable operating pressure, in bar;

SF is the safety factor for PFA (= 3);

DE is the nominal pipe external diameter (see Table 12), in millimetres;

R is the minimum tensile strength of ductile iron, in megapascals (R = 420 MPa; see Table 5).

m m

NOTE Equation (2) is derived from Barlow's equation, i.e. hoop stress, σ = PD/2t (see 3.40).

For pressure pipes centrifugally cast, the minimum wall thickness, e , shall not be less than 3 mm. The

min

nominal wall thickness, e , is equal to the minimum wall thickness, e , plus (1,3 + 0,001 DN).

nom min

For pressure pipes not centrifugally cast, the minimum wall thickness, e , shall not be less than 4,7 mm. The

min

nominal wall thickness, e , is equal to the minimum wall thickness, e , plus (2,3 + 0,001 DN).

nom min

10 © ISO 2011 – All rights reserved

4.3.2.2 Flanged pipe

Flanged pipe shall be classified by PN number. The pressure class of the barrel of the flanged pipes shall be

equal to or greater than a value, in bar, equal to the PN of the flanges. The pressure class of the flanged pipe

barrel to be used for fabricated flanged pipe shall be as indicated in 8.2 for weld-on flanges, screwed-on

flanges and integrally cast flanges.

NOTE Pipe threads are regarded as loss of wall thickness.

4.3.2.3 Fittings

4.3.2.3.1 Fittings for gravity applications

The iron wall thickness of fittings for gravity applications is defined by the manufacturer. The thickness shall

be equal to or greater than those of pipes of the same DN.

4.3.2.3.2 Fittings for pressure applications

Fittings for pressure application shall be in accordance with 8.3.

4.3.3 Length

4.3.3.1 Socket and spigot pipes

The standardized lengths of socket and spigot pipes shall be as given in Table 1.

Table 1 — Standardized lengths of socket and spigot pipes

Dimensions in metres

a

DN Standardized lengths, L

u

80 to 600 4 or 5 or 5,5 or 6 or 9

700 and 800 4 or 5,5 or 6 or 7 or 9

900 to 2600 4 or 5 or 5,5 or 6 or 7 or 8,15 or 9

NOTE Not all the standardized lengths are available in all countries.

a

See 3.36.

The manufacturer's design lengths, L (see 3.36), shall be within a deviation of ±250 mm of the lengths given

u

in Table 1 and shall be given in their handbook. The actual length, L , shall be measured in accordance

u

with 6.1.3 and shall not differ from the manufacturer's design length by more than the tolerance given in

Table 4. Of the total number of socket and spigot pipes being supplied in each diameter, the percentage of

shorter pipes shall not exceed 10 %.

NOTE 1 Pipes cut for test purposes can be excluded from the 10 % limitation and treated as full length pipes.

NOTE 2 When pipes are ordered on a meterage basis, the manufacturer can determine the required quantity of pipes

to be supplied by the summation of the measured individual pipe laying lengths.

4.3.3.2 Flanged pipes

The lengths of flanged pipes shall be as given in Table 2. Other lengths are available by agreement between

the manufacturer and the purchaser.

Table 2 — Standardized lengths of flanged pipes

Dimensions in metres

a

Type of pipe DN Standardized lengths, L

With cast-on flanges 80 to 2600 0,5 or 1 or 2 or 3

80 to 500 2 or 3 or 4 or 5

With screwed-on or welded-on flanges 600 to 1000 2 or 3 or 4 or 5 or 6

1100 to 2600 4 or 5 or 6 or 7

a

See 3.36.

4.3.3.3 Fittings

Fittings for gravity applications shall be in conformity with 8.2.

Fittings for pressure applications shall be supplied in conformity with ISO 2531.

Table 3 — Permissible deviations on lengths of fittings

Dimensions in metres

Type of fitting DN Deviation

Flanged sockets

80 to 1200 ±25

Flanged spigots

1400 to 2600 ±35

Collars, tapers

+50

80 to 1200

−25

Tees

+75

1400 to 2600

−35

Bends 90° (1/4) 80 to 2600 ±(15 + 0,03 DN)

Bends 45° (1/8) 80 to 2600 ±(10 + 0,025 DN)

80 to 1200 ±(10 + 0,02 DN)

Bends 22°30' (1/16) and 11°15' (1/32)

1400 to 2600 ±(10 + 0,025 DN)

Fittings for gravity applications 80 to 2600 ±(15 + 0,03 DN)

4.3.3.4 Tolerances on lengths

The tolerances on lengths shall be as given in Table 4.

Table 4 — Tolerances on lengths

Dimensions in metres

Type of casting Tolerance

−30

Socket and spigot pipes (full length or shortened)

+70

Fittings for socketed joints ±20

a

Pipes and fittings for flanged joints ±10

a

By agreement between the manufacturer and the purchaser, smaller tolerances are possible, but not less than ±3 mm for DN ≤ 600

and ±4 mm for DN > 600.

12 © ISO 2011 – All rights reserved

4.3.4 Straightness of pipes

Pipes shall be straight, with a maximum deviation of 0,125 % of their length.

The verification of this requirement is normally carried out by visual inspection, but in case of doubt or in

dispute, the deviation shall be measured in accordance with 6.2.

4.3.5 Inspection chambers

Inspection chambers shall be manufactured either as an integral item or by site assembly of a bottom part and

a vertical part.

Normal access sizes shall be the following: 250, 300, 400, 600 mm.

The leaktightness of inspection chambers shall be in conformity with 4.8.

4.3.6 Manholes

Manholes are composed of a vertical part of DN ≥ 800, a bottom plate, a top plate capable of receiving a

frame and a manhole cover, and 2 or more inlets/outlets fixed to the vertical part.

The number and location of the inlets/outlets shall preserve the hydraulic continuity inside the manhole.

The leaktightness of manholes shall be in conformity with 4.8.

4.4 Material characteristics

4.4.1 Tensile properties

Pipes, fittings and accessories made of ductile iron shall have the tensile properties shown in Table 5.

During the manufacturing process, the manufacturer shall carry out suitable tests to verify these tensile

properties; such tests may be either

a) a batch sampling system whereby samples are obtained from the pipe spigot or, for fittings, from samples

cast separately or integrally with the casting concerned (test bars shall be machined from these samples

and tensile tested according to 6.3), or

b) a system of process control testing (e.g. non-destructive), by which a positive correlation can be

demonstrated with the tensile properties specified in Table 5; testing verification procedures shall be

based on the use of comparator samples having known and verifiable properties. This system of testing

shall be supported by tensile testing in accordance with 6.3.

Table 5 — Tensile properties

Minimum tensile strength

Minimum percent elongation after fracture

R

A

m

Type of casting

MPa %

DN 80 to DN 2600 DN 80 to DN 1000 DN 1100 to DN 2600

Pipes centrifugally cast 420 10 7

Pipes not centrifugally cast,

420 5 5

fittings and accessories

By agreement between the manufacturer and the purchaser, the 0,2 % proof stress (R ) may be measured. It shall be

p02

not less than: 270 MPa when A ≥ 12 % for DN 80 to DN 1000 or A ≥ 10 % for DN > 1000; 300 MPa in other cases.

For centrifugally cast pipes of DN 80 to DN 1000 and having a design minimum wall thickness of 10 mm or greater, the

minimum elongation after fracture shall be 7 %.

4.4.2 Brinell hardness

The hardness of the various components shall be such that they can be cut, tapped, drilled and/or machined

with standard tools. In case of dispute, the hardness shall be measured according to 6.4.

The Brinell hardness shall not exceed 230 HBW for centrifugally cast pipes and 250 HBW for non-centrifugally

cast pipes, fittings and accessories. For components manufactured by welding, a higher Brinell hardness is

allowed in the heat-affected zone of the weld.

4.5 Coatings and linings for pipes

4.5.1 General

Pipes shall be normally delivered internally and externally coated.

4.5.2 External coatings

Ductile iron pipeline systems can be installed in a wide range of external operating environments. These

environments can be characterized according to their aggressivity. For relevant factors, see A.1.

Coatings specified by relevant International Standards are available as specified in A.2. Other coatings are

also available.

Except for the pipes intended only for the transportation of rainwater, domestic waste water in pressure

applications, or non-septic domestic sewerage, the surfaces which can come into contact with the effluents

(internal surface of the socket and external surface of the spigot end) shall be coated with a special coating,

whose chemical resistance should be in conformity with 5.3.

4.5.3 Internal linings

Ductile iron pipeline systems can be used to convey surface water, domestic waste water and/or certain types

of industrial effluents. These internal effluents can be characterized according to their aggressivity. Relevant

factors to be considered are given in B.1.

Linings specified by relevant International Standards are available as specified in B.2. Other linings are also

available.

Except for the pipes intended only for the transportation of rainwater, domestic waste water in pressure

applications, or non-septic domestic sewerage, the chemical resistance should be in conformity with 5.3, and

the abrasion resistance should be in conformity with 5.4.

4.6 Coatings for fittings and accessories

4.6.1 General

Fittings and accessories shall be normally delivered internally and externally coated.

4.6.2 External coatings

Ductile iron pipeline systems can be installed in a wide range of external operating environments. These

environments can be characterized according to their aggressivity. For relevant factors, see A.1.

Coatings specified by relevant International Standards are available as specified in A.3. Other coatings are

available.

14 © ISO 2011 – All rights reserved

Except for the fittings and accessories intended only for the transportation of rainwater, domestic waste water

in pressure applications, or non-septic domestic sewerage, the surfaces which can come into contact with the

effluents (internal surfaces of the socket and external surface of the spigot end) shall be coated with a special

coating, whose chemical resistance should be in conformity with 5.3.

4.6.3 Internal linings

Ductile iron pipeline systems can be used to convey surface water, domestic waste water and/or certain types

of industrial effluents. These internal effluents can be characterized according to their aggressivity. Relevant

factors for consideration are given in B.1.

Linings specified by relevant International Standards are available as specified in B.4. Other linings are also

available.

Except for the fittings and accessories intended only for the transportation of rainwater, domestic waste water

in pressure applications, or non-septic domestic sewerage, the chemical resistance should be in conformity

with 5.3, and the abrasion resistance should be in conformity with 5.4.

4.7 Systems design requirements

Installed sewer systems constructed with ductile iron components in conformity with this International

Standard shall be leaktight to the pressures given in Table 6, depending on the way in which they are normally

operated.

Table 6 — Operating pressure of sewer system

Internal pressure External pressure

Type of operation

bar bar

Continuous Occasional Continuous

Gravity sewer 0 to 0,5 2 1

Pressure sewer See PFA in Annex C See PMA in Annex C 1

Vacuum sewer −0,5 −0,8 1

This applies under all normal service conditions, including foreseeable external loads and joint movements

(both angular and radial).

4.8 Leaktightness of pipeline components

Ductile iron pipes, fittings, inspection chambers and manholes shall be leaktight when used under the

conditions for which they are designed (see 4.7).

When tested according to 6.5, pipes and fittings for positive pressure applications shall exhibit no visible

leakage, sweating or any other sign of failure.

When tested according to 7.1, pipes and fittings for gravity applications shall exhibit no visible leakage,

sweating or any other sign of failure.

When tested according to 6.6, pipes and fittings for vacuum applications shall exhibit no visible leakage,

sweating or any other sign of failure.

4.9 Marking

All pipes and fittings shall be durably and legibly marked and shall bear at least the following indications:

a) a reference to this International Standard, i.e. ISO 7186;

b) the manufacturer's name or mark;

c) identification of the year of manufacture;

d) identification as ductile iron;

e) the DN;

f) the PN rating of flanges, if applicable;

g) identification of the application (gravity or pressure).

List items b) to f) shall be cast-on or cold stamped. List items a) and g) can be applied by any method, e.g.

painted on the castings.

5 Performance requirements

5.1 Leaktightness of joints

5.1.1 General

All flexible joints for ductile iron pipes and components shall be designed in compliance with the requirements

of 5.1. If the design has been tested and documented by the manufacturer and successfully used for a

minimum of 10 years, the performance of a type test as specified in 5.1.2 for internal pressure, as specified

in 5.1.3 for external pressure and as specified in 5.1.4 for negative internal pressure is only required for

significant changes in design, which could adversely affect the performance of the joint.

Joint designs shall be type tested to demonstrate leaktightness to both internal and external pressure under

the most unfavourable conditions of casting tolerances and joint movements.

There shall be a type test for at least one DN for each of the groupings given in Table 7. One DN is

representative of a grouping when the performances are based on the same design parameters throughout

the size range.

Table 7 — DN groupings for type tests

DN groupings 80 to 250 300 to 600 700 to 1000 1100 to 2000 2200 to 2600

Preferred DN in each grouping 200 400 800 1600 2400

If a grouping covers products of different designs and/or manufactured by different processes, the grouping

shall be subdivided.

If, for a manufacturer, a grouping contains only one DN, this DN may be considered as part of the adjacent

grouping provided that it is of identical design and manufactured by the same process.

The type tests shall be carried out in the configuration of maximum design radial gap between the

components to be jointed (smallest spigot together with largest socket).

In the type test, the maximum gap shall be equal to the maximum design radial gap with a tolerance of % .

−5

The internal socket diameter may be machined to achieve this, even if the resulting diameter is slightly outside

the normal manufacturing tolerance.

All joints shall be performance tested with a spigot having an average iron wall thickness (over a distance of

two times DN, in millimetres, from the spigot face) equal to the specified minimum value for the pipe for which

+10

the joint is designed, % . It is permissible to machine the spigot of the pipe bore to achieve the required

thickness.

Restrained flexible joints shall be designed and tested in accordance with ISO 10804.

16 © ISO 2011 – All rights reserved

5.1.2 Positive internal pressure

The leaktightness of joints to positive internal pressure shall be tested as specified in 7.2; the joints shall

exhibit no visible leakage during 2 h, in the two following positions:

a) joint aligned and subjected to a shear: the shear force across the joint, expressed in newtons, shall not be

less than 30 times DN;

b) joint deflected: the test angular deflection shall be the maximum allowable deflection indicated in the

manufacturer's handbook, but not less than 3°30' for DN 80 to DN 300

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...