ISO/IEC 18047-6:2017

(Main)Information technology — Radio frequency identification device conformance test methods — Part 6: Test methods for air interface communications at 860 MHz to 960 MHz

Information technology — Radio frequency identification device conformance test methods — Part 6: Test methods for air interface communications at 860 MHz to 960 MHz

ISO/IEC 18047-6 defines test methods for determining the conformance of radio frequency identification (RFID) devices (tags and interrogators) for item management with the specifications given in ISO/IEC 18000-61, ISO/IEC 18000-62, ISO/IEC 18000-63 and ISO/IEC 18000-64, but does not apply to the testing of conformity with regulatory or similar requirements. The test methods require only that the mandatory functions, and any optional functions which are implemented, are verified. This can, in appropriate circumstances, be supplemented by further, application-specific functionality criteria that are not available in the general case. The interrogator and tag conformance parameters in ISO/IEC 18047-6 are the following: - type-specific conformance parameters including nominal values and tolerances; - parameters that apply directly affecting system functionality and inter-operability. Parameters that are already included in regulatory test requirements are not included in ISO/IEC 18047-6. Unless otherwise specified, the tests in ISO/IEC 18047-6 are intended to be applied exclusively to RFID tags and interrogators defined in ISO/IEC 18000-61, ISO/IEC 18000-62, ISO/IEC 18000-63 and ISO/IEC 18000-64.

Technologies de l'information — Méthodes d'essai de conformité du dispositif d'identification de radiofréquence — Partie 6: Méthodes d'essai pour des communications d'une interface d'air à 860 MHz et jusqu'à 960 MHz

General Information

- Status

- Withdrawn

- Publication Date

- 09-Oct-2017

- Technical Committee

- ISO/IEC JTC 1/SC 31 - Automatic identification and data capture techniques

- Drafting Committee

- ISO/IEC JTC 1/SC 31/WG 4 - Radio communications

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 14-Nov-2025

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 02-Dec-2023

- Effective Date

- 15-Mar-2014

Overview - ISO/IEC 18047-6:2017 (RFID conformance test methods, 860–960 MHz)

ISO/IEC 18047-6:2017 specifies standardized conformance test methods for Radio Frequency Identification (RFID) devices - both tags and interrogators - operating in the UHF band (860 MHz to 960 MHz). It defines how to verify that implemented mandatory functions (and any implemented optional functions) conform to the protocol and air‑interface requirements of ISO/IEC 18000‑61, ‑62, ‑63 and ‑64. The standard is focused on functional and interoperability parameters and does not replace regulatory or spectrum compliance testing.

Key topics and technical requirements

ISO/IEC 18047-6 organizes conformance criteria and test procedures into interrogator and tag test suites. Major technical areas covered include:

- Interrogator tests

- Modulation and demodulation performance

- RF envelope parameters (rise/fall, power-up/power-down)

- Preamble and link timing (T2, T3, T4, etc.)

- Data encoding and decoding

- Tag tests

- Frequency range and link frequency tolerance

- Demodulation capability and backscatter behaviour

- Tag response time, bit rate and duty cycle

- Preamble handling and state storage time

- Link timing parameters (T1–T7) and timing tolerances

- Protocol-related and optional tests

- Memory overrun handling, Kill and Unauthorized Write commands

- Optional features, Battery‑Assisted Passive (BAP) behavior and persistence

- Sensor support and full‑function sensor test procedures

- Test setup and environment

- Default conditions, pre‑conditioning, measurement uncertainty and recommended test apparatus

- Conformance parameter types

- Type‑specific nominal values and tolerances

- Parameters that directly affect system functionality and interoperability

Parameters that duplicate regulatory test requirements are explicitly excluded.

Applications - who uses ISO/IEC 18047-6

- RFID manufacturers validating tag and reader firmware/hardware against ISO/IEC 18000 series air‑interface specs

- Accredited test laboratories performing standardized conformance testing and issuing test reports

- System integrators and procurement teams requiring interoperable RFID components

- Quality assurance and R&D groups during product development and pre‑qualification

- Certification bodies applying consistent test methods for market acceptance (note: not a substitute for regulatory RF compliance)

Related standards

- ISO/IEC 18000‑61, ‑62, ‑63, ‑64 - air‑interface specifications referenced by ISO/IEC 18047‑6

- ISO/IEC 18047 (other parts) - conformance test methods series for RFID

Keywords: ISO/IEC 18047-6, RFID conformance test methods, 860 MHz to 960 MHz, air interface, interrogator tests, tag tests, ISO/IEC 18000-63, UHF RFID testing, BAP, sensor support.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

NYCE

Mexican standards and certification body.

Sponsored listings

Frequently Asked Questions

ISO/IEC 18047-6:2017 is a standard published by the International Organization for Standardization (ISO). Its full title is "Information technology — Radio frequency identification device conformance test methods — Part 6: Test methods for air interface communications at 860 MHz to 960 MHz". This standard covers: ISO/IEC 18047-6 defines test methods for determining the conformance of radio frequency identification (RFID) devices (tags and interrogators) for item management with the specifications given in ISO/IEC 18000-61, ISO/IEC 18000-62, ISO/IEC 18000-63 and ISO/IEC 18000-64, but does not apply to the testing of conformity with regulatory or similar requirements. The test methods require only that the mandatory functions, and any optional functions which are implemented, are verified. This can, in appropriate circumstances, be supplemented by further, application-specific functionality criteria that are not available in the general case. The interrogator and tag conformance parameters in ISO/IEC 18047-6 are the following: - type-specific conformance parameters including nominal values and tolerances; - parameters that apply directly affecting system functionality and inter-operability. Parameters that are already included in regulatory test requirements are not included in ISO/IEC 18047-6. Unless otherwise specified, the tests in ISO/IEC 18047-6 are intended to be applied exclusively to RFID tags and interrogators defined in ISO/IEC 18000-61, ISO/IEC 18000-62, ISO/IEC 18000-63 and ISO/IEC 18000-64.

ISO/IEC 18047-6 defines test methods for determining the conformance of radio frequency identification (RFID) devices (tags and interrogators) for item management with the specifications given in ISO/IEC 18000-61, ISO/IEC 18000-62, ISO/IEC 18000-63 and ISO/IEC 18000-64, but does not apply to the testing of conformity with regulatory or similar requirements. The test methods require only that the mandatory functions, and any optional functions which are implemented, are verified. This can, in appropriate circumstances, be supplemented by further, application-specific functionality criteria that are not available in the general case. The interrogator and tag conformance parameters in ISO/IEC 18047-6 are the following: - type-specific conformance parameters including nominal values and tolerances; - parameters that apply directly affecting system functionality and inter-operability. Parameters that are already included in regulatory test requirements are not included in ISO/IEC 18047-6. Unless otherwise specified, the tests in ISO/IEC 18047-6 are intended to be applied exclusively to RFID tags and interrogators defined in ISO/IEC 18000-61, ISO/IEC 18000-62, ISO/IEC 18000-63 and ISO/IEC 18000-64.

ISO/IEC 18047-6:2017 is classified under the following ICS (International Classification for Standards) categories: 35.040 - Information coding; 35.040.50 - Automatic identification and data capture techniques. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/IEC 18047-6:2017 has the following relationships with other standards: It is inter standard links to ISO/IEC 18047-6:2025, ISO/IEC 18047-6:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO/IEC 18047-6:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO/IEC

STANDARD 18047-6

Second edition

2017-10

Information technology — Radio

frequency identification device

conformance test methods —

Part 6:

Test methods for air interface

communications at 860 MHz to 960

MHz

Technologies de l'information — Méthodes d'essai de conformité du

dispositif d'identification de radiofréquence —

Partie 6: Méthodes d'essai pour des communications d'une interface

d'air à 860 MHz et jusqu'à 960 MHz

Reference number

©

ISO/IEC 2017

© ISO/IEC 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO/IEC 2017 – All rights reserved

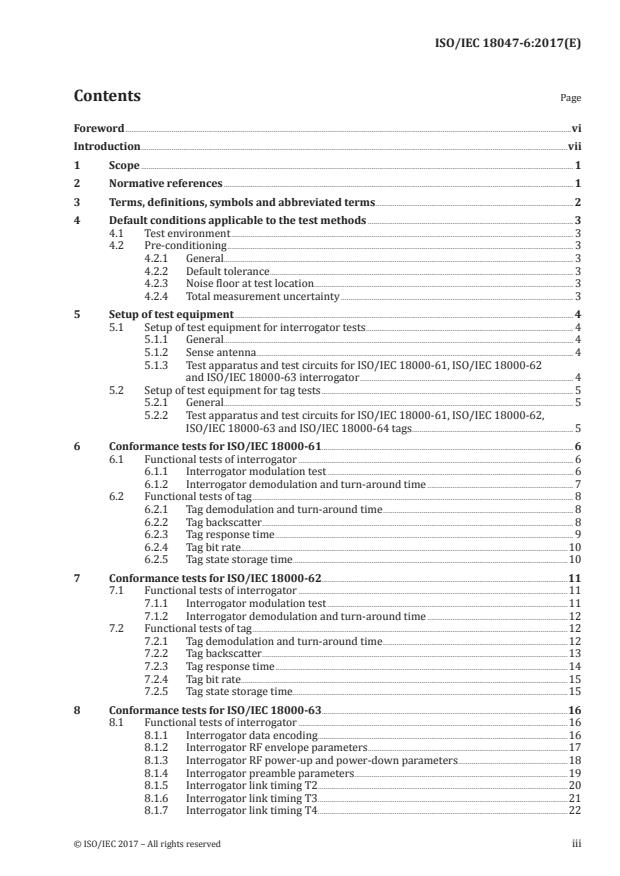

Contents Page

Foreword .vi

Introduction .vii

1 Scope . 1

2 Normative references . 1

3 Terms, definitions, symbols and abbreviated terms . 2

4 Default conditions applicable to the test methods . 3

4.1 Test environment . 3

4.2 Pre-conditioning . 3

4.2.1 General. 3

4.2.2 Default tolerance . 3

4.2.3 Noise floor at test location. 3

4.2.4 Total measurement uncertainty . 3

5 Setup of test equipment . 4

5.1 Setup of test equipment for interrogator tests . 4

5.1.1 General. 4

5.1.2 Sense antenna. 4

5.1.3 Test apparatus and test circuits for ISO/IEC 18000-61, ISO/IEC 18000-62

and ISO/IEC 18000-63 interrogator . 4

5.2 Setup of test equipment for tag tests . 5

5.2.1 General. 5

5.2.2 Test apparatus and test circuits for ISO/IEC 18000-61, ISO/IEC 18000-62,

ISO/IEC 18000-63 and ISO/IEC 18000-64 tags . 5

6 Conformance tests for ISO/IEC 18000-61. 6

6.1 Functional tests of interrogator . 6

6.1.1 Interrogator modulation test . 6

6.1.2 Interrogator demodulation and turn-around time . 7

6.2 Functional tests of tag . 8

6.2.1 Tag demodulation and turn-around time . 8

6.2.2 Tag backscatter . 8

6.2.3 Tag response time . 9

6.2.4 Tag bit rate . .10

6.2.5 Tag state storage time . .10

7 Conformance tests for ISO/IEC 18000-62.11

7.1 Functional tests of interrogator .11

7.1.1 Interrogator modulation test .11

7.1.2 Interrogator demodulation and turn-around time .12

7.2 Functional tests of tag .12

7.2.1 Tag demodulation and turn-around time .12

7.2.2 Tag backscatter .13

7.2.3 Tag response time .14

7.2.4 Tag bit rate . .15

7.2.5 Tag state storage time . .15

8 Conformance tests for ISO/IEC 18000-63.16

8.1 Functional tests of interrogator .16

8.1.1 Interrogator data encoding .16

8.1.2 Interrogator RF envelope parameters .17

8.1.3 Interrogator RF power-up and power-down parameters .18

8.1.4 Interrogator preamble parameters.19

8.1.5 Interrogator link timing T2 .20

8.1.6 Interrogator link timing T3 .21

8.1.7 Interrogator link timing T4 .22

© ISO/IEC 2017 – All rights reserved iii

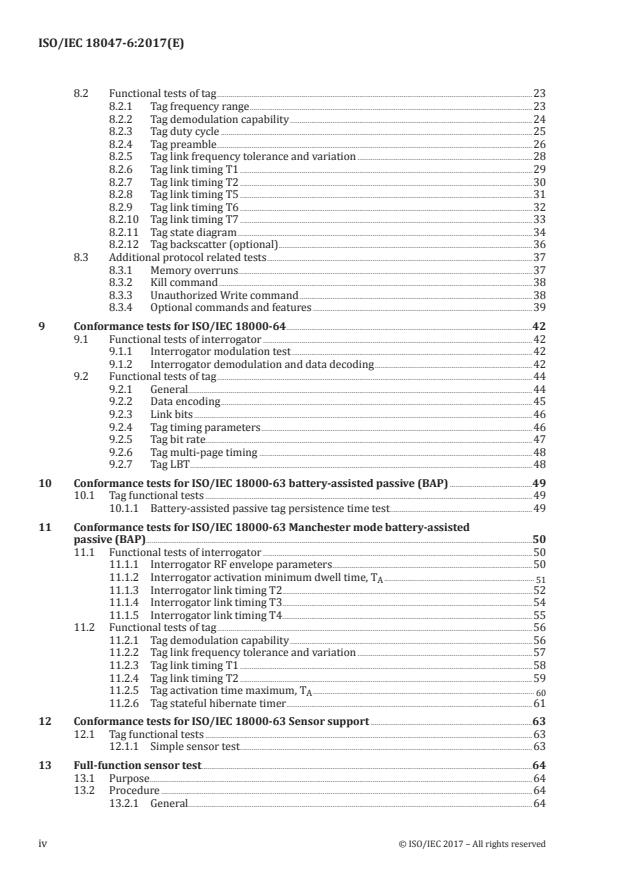

8.2 Functional tests of tag .23

8.2.1 Tag frequency range .23

8.2.2 Tag demodulation capability .24

8.2.3 Tag duty cycle .25

8.2.4 Tag preamble .26

8.2.5 Tag link frequency tolerance and variation .28

8.2.6 Tag link timing T1 .29

8.2.7 Tag link timing T2 .30

8.2.8 Tag link timing T5 .31

8.2.9 Tag link timing T6 .32

8.2.10 Tag link timing T7 .33

8.2.11 Tag state diagram .34

8.2.12 Tag backscatter (optional) .36

8.3 Additional protocol related tests .37

8.3.1 Memory overruns.37

8.3.2 Kill command .38

8.3.3 Unauthorized Write command .38

8.3.4 Optional commands and features .39

9 Conformance tests for ISO/IEC 18000-64.42

9.1 Functional tests of interrogator .42

9.1.1 Interrogator modulation test .42

9.1.2 Interrogator demodulation and data decoding .42

9.2 Functional tests of tag .44

9.2.1 General.44

9.2.2 Data encoding .45

9.2.3 Link bits .46

9.2.4 Tag timing parameters .46

9.2.5 Tag bit rate . .47

9.2.6 Tag multi-page timing .48

9.2.7 Tag LBT .48

10 Conformance tests for ISO/IEC 18000-63 battery-assisted passive (BAP) .49

10.1 Tag functional tests .49

10.1.1 Battery-assisted passive tag persistence time test .49

11 Conformance tests for ISO/IEC 18000-63 Manchester mode battery-assisted

passive (BAP).50

11.1 Functional tests of interrogator .50

11.1.1 Interrogator RF envelope parameters .50

11.1.2 Interrogator activation minimum dwell time, T .

A 51

11.1.3 Interrogator link timing T2 .52

11.1.4 Interrogator link timing T3 .54

11.1.5 Interrogator link timing T4 .55

11.2 Functional tests of tag .56

11.2.1 Tag demodulation capability .56

11.2.2 Tag link frequency tolerance and variation .57

11.2.3 Tag link timing T1 .58

11.2.4 Tag link timing T2 .59

11.2.5 Tag activation time maximum, T .

A 60

11.2.6 Tag stateful hibernate timer .61

12 Conformance tests for ISO/IEC 18000-63 Sensor support .63

12.1 Tag functional tests .63

12.1.1 Simple sensor test .63

13 Full-function sensor test .64

13.1 Purpose .64

13.2 Procedure .64

13.2.1 General.64

iv © ISO/IEC 2017 – All rights reserved

Annex A (informative) Test measurement site .65

Annex B (normative) Command coding for conformance tests for the different types of ISO/

IEC 18000-6 .77

Annex C (normative) Technical performance of the generic electronic test instruments .78

Annex D (normative) Tag emulator .79

Annex E (informative) Measurement examples .81

Bibliography .82

© ISO/IEC 2017 – All rights reserved v

Foreword

ISO (the International Organization for Standardization) and IEC (the International Electrotechnical

Commission) form the specialized system for worldwide standardization. National bodies that are

members of ISO or IEC participate in the development of International Standards through technical

committees established by the respective organization to deal with particular fields of technical

activity. ISO and IEC technical committees collaborate in fields of mutual interest. Other international

organizations, governmental and non-governmental, in liaison with ISO and IEC, also take part in the

work. In the field of information technology, ISO and IEC have established a joint technical committee,

ISO/IEC JTC 1.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for

the different types of document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject

of patent rights. ISO and IEC shall not be held responsible for identifying any or all such patent

rights. Details of any patent rights identified during the development of the document will be in the

Introduction and/or on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/IEC JTC 1, Information technology,

Subcommittee SC 31, Automatic identification and data capture techniques.

This second edition cancels and replaces the first edition (ISO/IEC 18047-6:2012), which has been

technically revised.

The main changes compared to the previous edition are as follows:

— Tag demodulation test setup now includes a monostatic setup with the use of a circulator;

— new tests for Tag link timings T5, T6 and T7 (defined in ISO/IEC 18000-63:2015 and related to

delayed and in-process tag reply); and

— new tests related to ISO/IEC 18000-63:2015 like Tag memory overruns, Kill command, unauthorized

write commands and optional commands that involve C-flag, ResponseBuffer, security features and

untraceability.

vi © ISO/IEC 2017 – All rights reserved

Introduction

ISO/IEC 18000 series defines the air interfaces for radio frequency identification (RFID) devices

used in item management applications. ISO/IEC 18000-61, ISO/IEC 18000-62, ISO/IEC 18000-63 and

ISO/IEC 18000-64 define the air interface for these devices operating at frequencies from 860 MHz to

960 MHz.

ISO/IEC 18047 series provides test methods for conformance with the various parts of the

ISO/IEC 18000 series.

Each part of ISO/IEC 18047 contains all measurements required to be made on a product in order to

establish whether it conforms to the corresponding part of ISO/IEC 18000. For this document, each

interrogator and each tag needs to support at least one of the types A or B or C or D.

NOTE Test methods for interrogator and tag performance are covered by ISO/IEC 18046 series.

Clause 5 describes all necessary conformance tests for ISO/IEC 18000-61.

Clause 6 describes all necessary conformance tests for ISO/IEC 18000-62.

Clause 7 describes all necessary conformance tests for ISO/IEC 18000-63.

Clause 8 describes all necessary conformance tests for ISO/IEC 18000-64.

Clause 9 describes all necessary conformance tests for ISO/IEC 18000-63:2015, Clause 7.

Clause 10 describes all necessary conformance tests for ISO/IEC 18000-63:2015, 7.5.

© ISO/IEC 2017 – All rights reserved vii

INTERNATIONAL STANDARD ISO/IEC 18047-6:2017(E)

Information technology — Radio frequency identification

device conformance test methods —

Part 6:

Test methods for air interface communications at 860 MHz

to 960 MHz

1 Scope

This document defines test methods for determining the conformance of radio frequency identification

(RFID) devices (tags and interrogators) for item management with the specifications given in

ISO/IEC 18000-61, ISO/IEC 18000-62, ISO/IEC 18000-63 and ISO/IEC 18000-64, but does not apply to

the testing of conformity with regulatory or similar requirements.

The test methods require only that the mandatory functions, and any optional functions which are

implemented, are verified. This can, in appropriate circumstances, be supplemented by further,

application-specific functionality criteria that are not available in the general case.

The interrogator and tag conformance parameters in this document are the following:

— type-specific conformance parameters including nominal values and tolerances;

— parameters that apply directly affecting system functionality and inter-operability.

Parameters that are already included in regulatory test requirements are not included in this document.

Unless otherwise specified, the tests in this document are intended to be applied exclusively to

RFID tags and interrogators defined in ISO/IEC 18000-61, ISO/IEC 18000-62, ISO/IEC 18000-63 and

ISO/IEC 18000-64.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO/IEC 18000-61:2012, Information technology — Radio frequency identification for item management —

Part 61: Parameters for air interface communications at 860 MHz to 960 MHz Type A

ISO/IEC 18000-62:2012, Information technology — Radio frequency identification for item management —

Part 62: Parameters for air interface communications at 860 MHz to 960 MHz Type B

ISO/IEC 18000-63:2015, Information technology — Radio frequency identification for item management —

Part 63: Parameters for air interface communications at 860 MHz to 960 MHz Type C

ISO/IEC 18000-64, Information technology — Radio frequency identification for item management —

Part 64: Parameters for air interface communications at 860 MHz to 960 MHz Type D

ISO/IEC 19762, Information technology — Automatic identification and data capture (AIDC) techniques —

Harmonized vocabulary

© ISO/IEC 2017 – All rights reserved 1

3 Terms, definitions, symbols and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO/IEC 19762 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.2 Symbols

For the purposes of this document, the symbols given in ISO/IEC 19762 and the following apply.

D modulation depth of data coding pulse

d distance between the interrogator and test antenna

d distance between test antenna and DUT tag

d distance between the interrogator antenna and sense antenna

s

d interrogator antenna to tag distance

T,IA

d measurement antenna to tag distance

T,MA

d distance between the interrogator antenna and tag emulator

TE

G gain of interrogator antenna

IA

G gain of measurement antenna

MA

Icir isolation of a circulator

K calibration factor

L maximum interrogator antenna dimension

M modulation index

P delivered power at the carrier frequency

I

P measured power at the carrier frequency

M

T fall time

f

T rise time

r

2 © ISO/IEC 2017 – All rights reserved

3.3 Abbreviated terms

For the purposes of this document, the abbreviated terms given in ISO/IEC 19762 and the following apply.

BLF backscatter-link frequency (BLF = 1/T = DR/TRcal)

pri

DUT device under test

RCS radar cross-section

ΔRCS change in radar cross-section

RBW resolution bandwidth

VBW video bandwidth

4 Default conditions applicable to the test methods

4.1 Test environment

Unless otherwise specified, testing shall take place in an environment of temperature (23 ± 3) °C and of

non-condensing humidity from 40 % to 60 %.

4.2 Pre-conditioning

4.2.1 General

The interrogators and tags to be tested shall be conditioned to the test environment for a period of 24 h

before testing.

4.2.2 Default tolerance

Unless otherwise specified, a default tolerance of ±5 % shall be applied to the quantity values given

to specify the characteristics of the test equipment (e.g. linear dimensions) and the test method

procedures (e.g. test equipment adjustments).

4.2.3 Noise floor at test location

Noise floor at test location shall be measured for at least 1 min with the spectrum analyser using the

same conditions as for the measurement of the DUT.

The maximum of the measured noise amplitude measured in a 10 kHz bandwidth shall be −60 dB from

0,5 GHz to 2 GHz and −90 dBm around the frequency of the main signal of the tag backscatter signal.

Special attention has to be given to spurious emissions, e.g. insufficiently shielded computer monitors.

The electromagnetic test conditions of the measurements shall be checked by performing the

measurements with and without a tag in the field.

4.2.4 Total measurement uncertainty

The total measurement uncertainty for each quantity determined by these test methods shall be stated

in the test report.

NOTE Basic information is given in ISO/IEC Guide 98-3.

© ISO/IEC 2017 – All rights reserved 3

5 Setup of test equipment

5.1 Setup of test equipment for interrogator tests

5.1.1 General

The DUT shall be an interrogator including an antenna.

All conformance measurements and setups shall be done in an anechoic chamber as defined in Annex A.

All measurements shall be done at one of the test frequencies in Table 1.

Table 1 — Test frequencies

Test carrier frequency Comment

866 MHz Recommended for tests under European regulations

915 MHz Recommended for tests under Japan, Korean, Australian or US regulations

NOTE With the test frequencies specified in Table 1, all frequencies of the entire band from 860 MHz to

930 MHz are within ±2,9 % of one of the test frequencies. All practically used frequencies in the frequency bands

860 MHz to 870 MHz, 900 MHz to 930 MHz are within ±1,7 % of the test frequencies.

5.1.2 Sense antenna

Where applicable, tests shall be carried out using a sense antenna, which shall be a substantially non-

reactive, non-radiating load of 50 Ω equipped with an antenna connector. The voltage standing wave

ratio (VSWR) at the 50 Ω connector shall not be greater than 2 : 1 over the frequency range of the

measurement.

5.1.3 Test apparatus and test circuits for ISO/IEC 18000-61, ISO/IEC 18000-62 and

ISO/IEC 18000-63 interrogator

5.1.3.1 Interrogator modulation test setup

For this test, the sense antenna shall always be placed and orientated for optimum field strength

reception in the direction of the major power radiation of the DUT interrogator antenna according to

Figure 1 at a distance, d , of 0,8 m to 1,1 m.

s

Figure 1 — Interrogator modulation test setup

5.1.3.2 Interrogator demodulation and turn-around time test setup

For this test, the tag emulator as defined in Annex D shall be placed and orientated for optimum field

strength reception in the direction of the major power radiation of the DUT interrogator antenna

according to Figure 2 at a distance, d , of 0,8 m to 1,1 m.

TE

4 © ISO/IEC 2017 – All rights reserved

Figure 2 — Interrogator demodulation and turn-around test setup

5.2 Setup of test equipment for tag tests

5.2.1 General

The DUT shall be a tag including all means in order to be capable to communicate with an interrogator.

When tests require use of an interrogator, this shall be a measurement equipment that fulfills the

requirements in order to act as interrogator and in particular it shall support the minimum tag response

to interrogator command turn-around time.

All conformance measurements and setups shall be done in an anechoic chamber as defined in Annex A.

All measurements shall be done at one of the test frequencies in Table 1.

5.2.2 Test apparatus and test circuits for ISO/IEC 18000-61, ISO/IEC 18000-62, ISO/IEC 18000-

63 and ISO/IEC 18000-64 tags

5.2.2.1 Tag demodulation and turn-around time test setup

For this test, the tag shall be placed and oriented for optimum field strength reception in the direction

of the major power radiation of the interrogator.

a) Bistatic setup b) Monostatic setup

Figure 3 — Tag demodulation test setup

5.2.2.2 Tag backscatter test setup

For this test, two different setups may be used.

In a first one [see Figure 3 a)], the test interrogator antenna setup (the interrogator may alternately

also be realized with a signal generator according Annex C) shall consist of a set of two mechanically

assembled antennas specifically designed to reduce the signal coupling between each other. One shall

be used as interrogator antenna while the second shall be used as measurement antenna and shall be

© ISO/IEC 2017 – All rights reserved 5

connected either to a spectrum analyser or to an oscilloscope as specified in Annex C. The tag under

test shall be placed at this focal point and oriented for optimum field strength reception. The distances

between the tag and the antennas are d and d , respectively [see Figure 3 a)].

T,IA T,MA

The tag backscatter test setup parameters are defined in Table 2.

Table 2 — Tag backscatter setup parameters

Symbol Name Description

d Interrogator antenna to tag distance 0,8 m to 1,1 m

T,IA

d Measurement antenna to tag distance 0,8 m to 1,1 m

T,MA

G Gain of interrogator antenna The maximum 3 dB beam width shall be ±35°

IA

G Gain of measurement antenna The maximum 3 dB beam width shall be ±35°

MA

Icir Isolation of the circulator The minimum isolation of the circulator shall be 20 dB

In a second one [see Figure 3 b)], the test interrogator antenna setup (the interrogator may alternately

also be realized with a signal generator according Annex C) shall consist of a single antenna specifically

designed to transmit the signal from the interrogator and to receive the signal backscattered from the

tag under test. This antenna shall be connected to the interrogator and to either a spectrum analyser or

an oscilloscope as specified in Annex C via a circulator. The tag under test shall be oriented for optimum

field strength reception. The distance between the tag and the antenna is d [see Figure 3 b)].

T,IA

The tag backscatter test setup parameters are defined in Table 2.

5.2.2.3 Tag response time

The setup for this test shall be as described in 5.2.2.1.

5.2.2.4 Tag bit rate accuracy test setup

The setup for this test shall be as described in 5.2.2.1.

5.2.2.5 Tag state storage time test setup

The setup for this test shall be as described in 5.2.2.1.

6 Conformance tests for ISO/IEC 18000-61

6.1 Functional tests of interrogator

6.1.1 Interrogator modulation test

6.1.1.1 Test objective

The objective of this test is to verify that the interrogator provides the appropriate modulation

waveform required for operation of tags.

6.1.1.2 Test procedure

The interrogator shall transmit an Init_round_all command at the maximum power of the selected

carrier frequency for testing.

In case the interrogator is intended for operation of non-overlapping RF bands, then this test shall be

done for each RF band.

6 © ISO/IEC 2017 – All rights reserved

A digital oscilloscope as specified in Annex C and the sense antenna shall be used to record the

waveform provided by the interrogator.

6.1.1.3 Test report

The test report shall give the measured values of the parameters according to Table 3. The pass/fail

condition is determined whether the measured values are within the requirements as specified in

ISO/IEC 18000-61. Furthermore, the DUT and the sense antenna orientation and position, as well as the

used interrogator output power, and the used operation frequency shall be recorded.

Table 3 — Measurements to be made

Parameter Conditions

D Default modulation operation mode

T Default modulation operation mode

apr

T Default modulation operation mode

apf

6.1.2 Interrogator demodulation and turn-around time

6.1.2.1 Test objective

The objectives of this test are to verify whether the interrogator is capable of

— demodulating signals from the tags, and

— receiving the data transmitted by the tag emulator after the minimum specified turn-around time.

6.1.2.2 Test procedure

The interrogator shall transmit an Init_round_all command (see B.1.1) at the maximum power of the

selected carrier frequency for testing.

After the command provided by the interrogator has been sent and after the minimum turn-around

time, a tag emulator as specified in Annex D shall transmit a typical response to the Init_round_all

command at a minimum ΔRCS specified in ISO/IEC 18000-61. The tag emulator does not need to

demodulate the command, but shall only detect its end to respond after the minimum turn-around time.

When the interrogator is intended for operation of non-overlapping RF bands, this test shall be done for

each RF band.

Measurements shall be done for both the minimum and maximum tag response data rate, i.e. the turn-

around time from interrogator command to tag response.

In case the interrogator is designed for shorter communication distances, then the distance d may be

TE

decreased and the actual used value shall be mentioned in test report.

The interrogator (digital) demodulator shall accept the tag response including verification of the CRC.

6.1.2.3 Test report

The test report shall contain the tag emulator distance to the interrogator and the ΔRCS value setup in

the tag emulator. Furthermore, also the set up turn-around time from the tag emulator, the DUT and

the tag emulator orientation and position, as well as the used interrogator output power and the used

operation frequency shall be recorded.

© ISO/IEC 2017 – All rights reserved 7

6.2 Functional tests of tag

6.2.1 Tag demodulation and turn-around time

6.2.1.1 Test objective

The objectives of this test are to verify whether the tag is capable of

— demodulating signals from the interrogator, and

— receiving the data transmitted by the interrogator after the minimum specified response to

command turn-around time.

6.2.1.2 Test procedure

The test interrogator shall transmit an Init_round_all (see B.1.1) command.

The tag (DUT) shall receive the command provided by the interrogator and shall provide an appropriate

response. After complete reception of the tag response, the interrogator shall generate a Next_slot

command within the minimum specified turn-around time between tag response and interrogator

command.

Measurements shall be done by verifying that the tag detects the command appropriately by means of

evaluation of its response. Measurements shall be done at P = 1,2 P .

I I,min

In case the interrogator is designed for shorter communication distances, then the distance d may be

TE

decreased and the actual used value shall be mentioned in test report.

The test shall be seen as successful when it could be shown that the tag sent the correct response for

both commands including verification of the CRC.

The interrogator waveform shall contain the setup of the waveform for the respective types according

to Table 4.

Table 4 — Setup of waveforms

Setup number Setup description Parameter setting

A-1 Minimum modulation depth D = D

min

A-2 Medium modulation depth D = (D + D )/2

max min

A-3 Maximum modulation depth D = D

max

6.2.1.3 Test report

The test result shall be recorded as successful or unsuccessful. The test report shall contain the tag

distance to the interrogator. Furthermore, also the setup turn-around time from the tag response to

interrogator command, the DUT and the interrogator orientation and position, as well as the used

interrogator output power and the used operation frequency shall be recorded.

6.2.2 Tag backscatter

6.2.2.1 Test objective

The objective of this test is to verify that the tag provides the appropriate modulation waveform and

backscatter strength required to be successfully detected and received by the interrogator.

Measurements are carried out in an anechoic chamber either in bistatic antennas configuration as

shown in Figure 3 a) with the tag positioned in the far field of the transmit antenna or in monostatic

antenna configuration [see Figure 3 b)].

8 © ISO/IEC 2017 – All rights reserved

6.2.2.2 Test procedure

Measurements shall be done with power P , where P is the minimum power allowing the DUT

I,min I,min

tag activation.

A vector signal analyser as specified in Annex C shall be used to record the quadrature baseband

voltages I and Q versus time.

Test setup shall be calibrated to determine antennas gain and mismatch, circulator isolation and

insertion loss and also cables loss, to be taken into account for all power measurements.

The delta radar cross-section measurement procedure is as follows.

1) The signal generator shall be set to the required test frequency.

2) The signal generator amplitude shall be set to a value that allows the DUT tag activation.

3) Using the power meter, determine the power at the entrance of the transmit antenna, P , which is

e

defined as the average power measured over at least 100 µs period during the continuous wave

signal following the signal generator command.

4) The signal analyser shall be set to measure the quadrature baseband I and Q power versus time

with a sampling rate of at least 5 Msps.

5) With the tag placed in the anechoic chamber, the analyser shall be set to capture the complex IQ

power for at least during 10 symbols of tag reply.

6) Calculate the difference of power from the DUT tag backscattering according to Formula (1):

2 2

ΔP ()rms =⋅ II− +−QQ (1)

() ()

tag rr,,10 rr,,10

2Z

where

Z is the wave resistance of the measurement equipment and is usually 50 Ω.

7) Calculate the ΔRCS of the DUT tag using Formula (2):

ΔP

4πd 4π

tag

ΔRCS= (2)

P GG⋅ λ

e 00tr

6.2.2.3 Test report

The test report shall give the measured values of ΔRCS. The pass/fail condition is determined whether

the measured values are within the requirements as specified in ISO/IEC 18000-61 and the evaluated

ΔRCS is at least above the value from ISO/IEC 18000-61. Furthermore, the DUT and the interrogator

orientation and position, as well as the used interrogator output power and the used operation

frequency shall be recorded.

6.2.3 Tag response time

6.2.3.1 Tes

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...