ISO 19881:2018

(Main)Gaseous hydrogen — Land vehicle fuel containers

Gaseous hydrogen — Land vehicle fuel containers

This document contains requirements for the material, design, manufacture, marking and testing of serially produced, refillable containers intended only for the storage of compressed hydrogen gas for land vehicle operation. These containers a) are permanently attached to the vehicle, b) have a capacity of up to 1 000 l water capacity, and c) have a nominal working pressure that does not exceed 70 MPa. The scope of this document is limited to fuel containers containing fuel cell grade hydrogen according to ISO 14687 for fuel cell land vehicles and Grade A or better hydrogen as per ISO 14687 for internal combustion engine land vehicles. This document also contains requirements for hydrogen fuel containers acceptable for use on-board light duty vehicles, heavy duty vehicles and industrial powered trucks such as forklifts and other material handling vehicles.

Hydrogène gazeux — Réservoirs de carburant pour véhicules terrestres

General Information

- Status

- Withdrawn

- Publication Date

- 17-Oct-2018

- Technical Committee

- ISO/TC 197 - Hydrogen technologies

- Drafting Committee

- ISO/TC 197/WG 18 - Gaseous hydrogen land vehicle fuel tanks and TPRDs

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 13-Jun-2025

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 06-Jun-2022

Overview

ISO 19881:2018 - Gaseous hydrogen - Land vehicle fuel containers sets requirements for the material, design, manufacture, marking and testing of serially produced, refillable containers for compressed hydrogen used in land vehicles. It applies to containers that are permanently attached to the vehicle, have a capacity up to 1 000 L water capacity, and a nominal working pressure not exceeding 70 MPa. The standard covers containers intended for fuel cell grade hydrogen (ISO 14687) and Grade A or better hydrogen for internal combustion engines. It is applicable to light‑duty, heavy‑duty vehicles and industrial powered trucks (e.g., forklifts).

Key technical topics and requirements

ISO 19881 organizes technical requirements across design, materials, manufacture and testing. Major topics include:

Service conditions and categories

Defines standard service conditions, pressure ranges (nominal and maximum), temperature considerations, maximum filling cycles, service life and periodic in‑service inspections.Material qualification and properties

Requirements and tests for metals, aluminum alloys (including sustained load cracking and corrosion tests), nonmetallic liners (Type 4), fibers and resins, and UV resistance of external coatings.Container types and wall thickness

Guidance for Type 1, Type 2, Type 3 and Type 4 containers, liners and composite reinforcement, including stress analysis, stress ratios and hybrid designs.Manufacture and joining methods

Rules for welding, brazing, end closing, mounting/protection, and batch definitions.Testing and inspection

Production, batch and periodic tests such as hydrostatic test, leak test, burst test, cycle (fatigue) testing, design qualification tests (ambient, environmental, extreme temperature cycling, flaw tolerance), and rejection criteria.Safety features and documentation

Pressure relief device requirements, marking, dispatch inspection, records of manufacture and quality assurance procedures.

Practical applications and users

ISO 19881 is intended for:

- Automotive OEMs and system integrators designing hydrogen fuel systems

- Tank and composite container manufacturers

- Component suppliers (liners, bosses, pressure relief devices)

- Test laboratories and certification bodies conducting hydrostatic, burst and cycle tests

- Fleet operators, regulators and safety authorities assessing in‑service inspection and marking compliance

Using ISO 19881 helps ensure safe, reliable and compliant hydrogen fuel tanks for vehicles, supporting hydrogen mobility deployment and regulatory acceptance.

Related standards

- ISO 14687 (Hydrogen - Fuel quality - Product specification)

- Other ISO standards referenced within ISO 19881 for materials and test methods

Keywords: ISO 19881, gaseous hydrogen, land vehicle fuel containers, hydrogen fuel tanks, hydrogen storage, fuel cell hydrogen, 70 MPa, 1000 L, hydrostatic test, burst test.

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

ISO 19881:2018 is a standard published by the International Organization for Standardization (ISO). Its full title is "Gaseous hydrogen — Land vehicle fuel containers". This standard covers: This document contains requirements for the material, design, manufacture, marking and testing of serially produced, refillable containers intended only for the storage of compressed hydrogen gas for land vehicle operation. These containers a) are permanently attached to the vehicle, b) have a capacity of up to 1 000 l water capacity, and c) have a nominal working pressure that does not exceed 70 MPa. The scope of this document is limited to fuel containers containing fuel cell grade hydrogen according to ISO 14687 for fuel cell land vehicles and Grade A or better hydrogen as per ISO 14687 for internal combustion engine land vehicles. This document also contains requirements for hydrogen fuel containers acceptable for use on-board light duty vehicles, heavy duty vehicles and industrial powered trucks such as forklifts and other material handling vehicles.

This document contains requirements for the material, design, manufacture, marking and testing of serially produced, refillable containers intended only for the storage of compressed hydrogen gas for land vehicle operation. These containers a) are permanently attached to the vehicle, b) have a capacity of up to 1 000 l water capacity, and c) have a nominal working pressure that does not exceed 70 MPa. The scope of this document is limited to fuel containers containing fuel cell grade hydrogen according to ISO 14687 for fuel cell land vehicles and Grade A or better hydrogen as per ISO 14687 for internal combustion engine land vehicles. This document also contains requirements for hydrogen fuel containers acceptable for use on-board light duty vehicles, heavy duty vehicles and industrial powered trucks such as forklifts and other material handling vehicles.

ISO 19881:2018 is classified under the following ICS (International Classification for Standards) categories: 43.060.40 - Fuel systems; 71.100.20 - Gases for industrial application. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 19881:2018 has the following relationships with other standards: It is inter standard links to ISO 19881:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 19881:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 19881

First edition

2018-10

Gaseous hydrogen — Land vehicle fuel

containers

Hydrogène gazeux — Réservoirs de carburant pour véhicules

terrestres

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

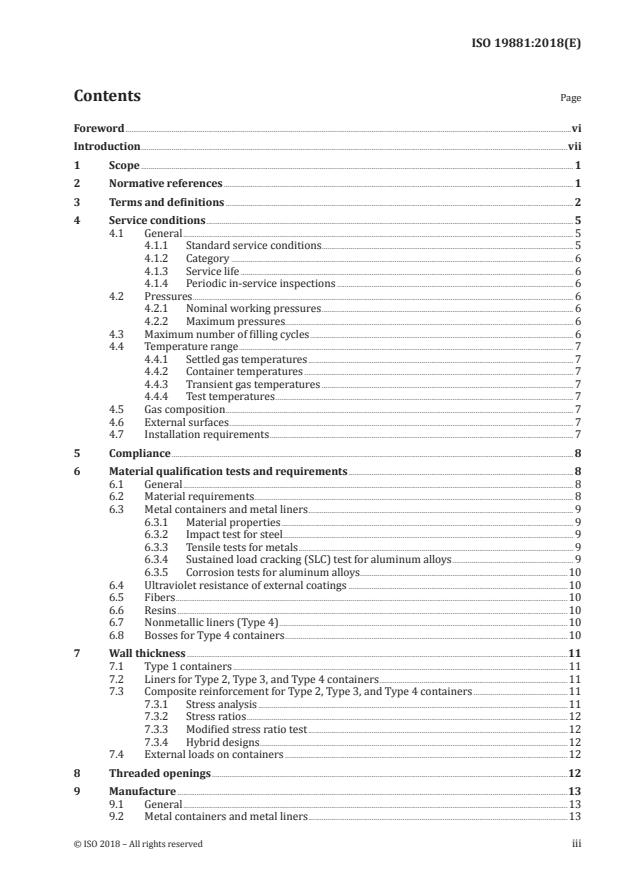

Contents Page

Foreword .vi

Introduction .vii

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Service conditions . 5

4.1 General . 5

4.1.1 Standard service conditions. 5

4.1.2 Category . 6

4.1.3 Service life . 6

4.1.4 Periodic in-service inspections . 6

4.2 Pressures . 6

4.2.1 Nominal working pressures . 6

4.2.2 Maximum pressures. 6

4.3 Maximum number of filling cycles . 6

4.4 Temperature range . 7

4.4.1 Settled gas temperatures . 7

4.4.2 Container temperatures . 7

4.4.3 Transient gas temperatures . 7

4.4.4 Test temperatures . 7

4.5 Gas composition . 7

4.6 External surfaces . 7

4.7 Installation requirements . 7

5 Compliance . 8

6 Material qualification tests and requirements . 8

6.1 General . 8

6.2 Material requirements. 8

6.3 Metal containers and metal liners . 9

6.3.1 Material properties . 9

6.3.2 Impact test for steel . 9

6.3.3 Tensile tests for metals . 9

6.3.4 Sustained load cracking (SLC) test for aluminum alloys . 9

6.3.5 Corrosion tests for aluminum alloys .10

6.4 Ultraviolet resistance of external coatings .10

6.5 Fibers .10

6.6 Resins .10

6.7 Nonmetallic liners (Type 4) .10

6.8 Bosses for Type 4 containers .10

7 Wall thickness .11

7.1 Type 1 containers .11

7.2 Liners for Type 2, Type 3, and Type 4 containers .11

7.3 Composite reinforcement for Type 2, Type 3, and Type 4 containers .11

7.3.1 Stress analysis .11

7.3.2 Stress ratios .12

7.3.3 Modified stress ratio test .12

7.3.4 Hybrid designs .12

7.4 External loads on containers .12

8 Threaded openings .12

9 Manufacture .13

9.1 General .13

9.2 Metal containers and metal liners .13

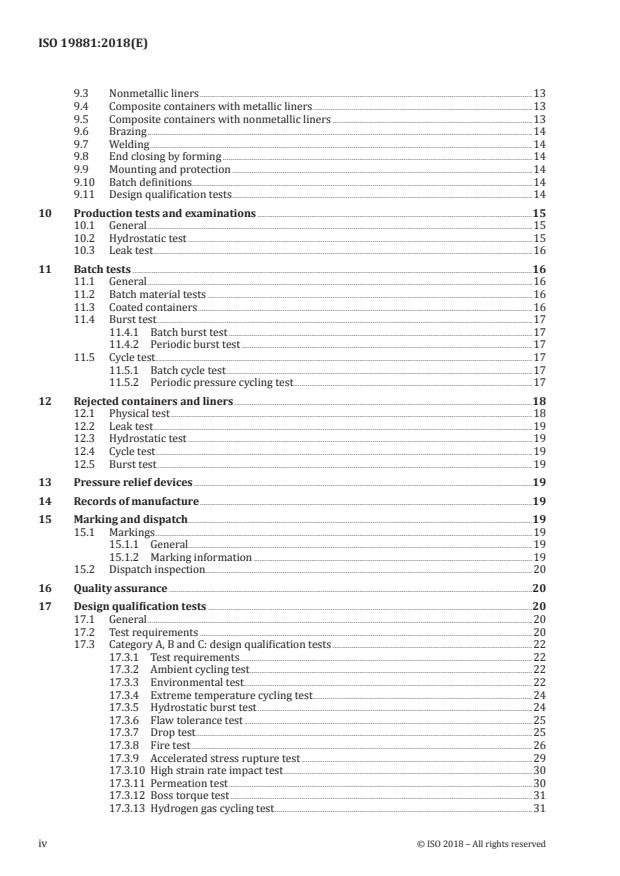

9.3 Nonmetallic liners .13

9.4 Composite containers with metallic liners .13

9.5 Composite containers with nonmetallic liners .13

9.6 Brazing .14

9.7 Welding .14

9.8 End closing by forming .14

9.9 Mounting and protection .14

9.10 Batch definitions .14

9.11 Design qualification tests .14

10 Production tests and examinations .15

10.1 General .15

10.2 Hydrostatic test .15

10.3 Leak test .16

11 Batch tests .16

11.1 General .16

11.2 Batch material tests .16

11.3 Coated containers .16

11.4 Burst test .17

11.4.1 Batch burst test .17

11.4.2 Periodic burst test .17

11.5 Cycle test .17

11.5.1 Batch cycle test .17

11.5.2 Periodic pressure cycling test .17

12 Rejected containers and liners .18

12.1 Physical test .18

12.2 Leak test .19

12.3 Hydrostatic test .19

12.4 Cycle test .19

12.5 Burst test .19

13 Pressure relief devices .19

14 Records of manufacture .19

15 Marking and dispatch .19

15.1 Markings .19

15.1.1 General.19

15.1.2 Marking information .19

15.2 Dispatch inspection .20

16 Quality assurance .20

17 Design qualification tests .20

17.1 General .20

17.2 Test requirements .20

17.3 Category A, B and C: design qualification tests .22

17.3.1 Test requirements .22

17.3.2 Ambient cycling test . .22

17.3.3 Environmental test.22

17.3.4 Extreme temperature cycling test .24

17.3.5 Hydrostatic burst test .24

17.3.6 Flaw tolerance test .25

17.3.7 Drop test .25

17.3.8 Fire test .26

17.3.9 Accelerated stress rupture test .29

17.3.10 High strain rate impact test .30

17.3.11 Permeation test .30

17.3.12 Boss torque test .31

17.3.13 Hydrogen gas cycling test .31

iv © ISO 2018 – All rights reserved

17.3.14 Leak before break test .32

17.4 Change of design .32

17.5 Category B: design qualification tests .35

17.5.1 General test requirements .35

17.5.2 Ambient cycling test . .35

17.5.3 Hydrostatic burst test .35

17.5.4 Container test for performance durability .35

17.5.5 Container test for expected on-road performance .37

17.6 Category C: design qualification conditions and limitations .37

17.6.1 Marking information .37

17.6.2 Material tests for steel containers and liners .37

17.6.3 Material tests for aluminum alloy containers and liners .37

17.7 Qualification test results .38

Annex A (informative) Visual inspection .39

Annex B (informative) Non-destructive examination .40

Annex C (informative) Records of manufacture .42

Annex D (informative) Design qualification test rationale .45

Bibliography .53

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/iso/foreword .html.

This document was prepared by Technical Committee TC 197, Hydrogen technologies.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

vi © ISO 2018 – All rights reserved

Introduction

The purpose of this document is to promote the implementation of hydrogen powered land vehicles

through the creation of performance based testing requirements for compressed hydrogen fuel

containers. The successful commercialization of hydrogen land vehicle technologies requires

standards pertaining to fueling stations, vehicle fuel system components and the global homologation

of standards requirements for technologies with the same end use. This will allow manufacturers to

achieve economies of scale in production through the ability to manufacture one product for global use.

This document is based on the CSA Standard ANSI/HGV 2-2014.

INTERNATIONAL STANDARD ISO 19881:2018(E)

Gaseous hydrogen — Land vehicle fuel containers

1 Scope

This document contains requirements for the material, design, manufacture, marking and testing of

serially produced, refillable containers intended only for the storage of compressed hydrogen gas for

land vehicle operation. These containers

a) are permanently attached to the vehicle,

b) have a capacity of up to 1 000 l water capacity, and

c) have a nominal working pressure that does not exceed 70 MPa.

The scope of this document is limited to fuel containers containing fuel cell grade hydrogen according

to ISO 14687 for fuel cell land vehicles and Grade A or better hydrogen as per ISO 14687 for internal

combustion engine land vehicles. This document also contains requirements for hydrogen fuel

containers acceptable for use on-board light duty vehicles, heavy duty vehicles and industrial powered

trucks such as forklifts and other material handling vehicles.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 148-1, Metallic materials — Charpy pendulum impact test — Part 1: Test method

ISO 306, Plastics — Thermoplastic Materials — Determination of Vicat Softening Temperature (VST)

ISO 7866:2012, Gas cylinders — Refillable seamless aluminium alloy gas cylinders — Design, construction

and testing

ISO 9809-1:2010, Gas cylinders — Refillable seamless steel gas cylinders — Design, construction and

testing — Part 1: Quenched and tempered steel cylinders with tensile strength less than 1 100 MPa

ISO 9809-2:2010, Gas cylinders — Refillable seamless steel gas cylinders — Design, construction and

testing — Part 2: Quenched and tempered steel cylinders with tensile strength greater than or equal to

1 100 MPa

ISO 11439:2013, Gas cylinders — High pressure cylinders for the on-board storage of natural gas as a fuel

for automotive vehicles

ISO 19078:2013, Gas cylinders — Inspection of the cylinder installation, and requalification of high pressure

cylinders for the on-board storage of natural gas as a fuel for automotive vehicles

ISO 19882, Gaseous hydrogen — Thermally activated pressure relief devices for compressed hydrogen

vehicle fuel containers

ASTM D638, Standard Test Method for Tensile Properties of Plastics

ASTM D2344/D2344M-00, Standard Test Method for Short-Beam Strength of Polymer Matrix Composite

Materials and Their Laminates

ASTM D3359, Standard Test Methods for Measuring Adhesion by Tape Test

ASTM D3418, Standard Test Method for Transition Temperatures and Enthalpies of Fusion and

Crystallization of Polymers by Differential Scanning Calorimetry

ASTM D4138, Standard Practices for Measurement of Dry Film Thickness of Protective Coating Systems by

Destructive, Cross Sectioning Means

ASTM D4814, Standard Specification for Automotive Spark-Ignition Engine Fuel

ASTM D7091, Standard Practice for Nondestructive Measurement of Fry Film Thickness of Nonmagnetic

Coatings Applied to Ferrous Metals and Nonmagnetic, Nonconductive Coatings Applied to Non-Ferrous Metals

ASTM E8/E8M, Standard Test Methods for Tension Testing of Metallic Materials

ASTM E23, Standard Test Methods for Notched Bar Impact Testing of Metallic Materials

ASTM G154-12, Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for

Exposure of Nonmetallic Materials

CGA C-1-2009, Methods for Pressure Testing Compressed Gas Cylinders

CGA C-6.4, Methods for External Visual Inspection of Natural Gas Vehicle (NGV) and Hydrogen Gas Vehicle

(HGV) Fuel Containers and Their Installations

SAE J2579: 2013, Standard for Fuel Systems in Fuel Cell and Other Hydrogen Vehicles

SAE J2601, Fueling Protocols for Light Duty Gaseous Hydrogen Surface Vehicles

UN GTR No. 13, UN Global Technical Regulation on Hydrogen and Fuel Cell Vehicles

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https: //www .iso .org/obp

— IEC Electropedia: available at https: //www .electropedia .org/

3.1

autofrettage

pressure application procedure, used in manufacturing composite containers with metal liners (3.14),

which strains the liner (3.14) past its yield point sufficiently to cause permanent plastic deformation

that results in the liner (3.14) having residual compressive stresses and the fibers having residual

tensile stresses at zero internal pressure

3.2

burst pressure

highest pressure reached in a container during a burst test

3.3

composite

filament and resin system

3.4

container category

unique class of containers that are intended for a specific usage

2 © ISO 2018 – All rights reserved

3.4.1

Category A

class of containers that are intended to be used in light duty and heavy duty land vehicle applications,

regardless of the potential for further qualification to the UN GTR No. 13 for hydrogen and fuel cell

vehicles

3.4.2

Category B

class of Type 4 (3.5.4) containers of 70 MPa nominal working pressure that are intended to be further

qualified in accordance with the UN GTR No. 13 for hydrogen and fuel cell vehicles with a gross vehicle

mass of 4 536 kg or less

3.4.3

Category C

class of containers that are intended to be used on hydrogen powered industrial trucks

3.5 Container type

3.5.1

Type 1

metal container

3.5.2

Type 2

container which contains a metal liner (3.14) reinforced with a resin impregnated continuous filament

(hoop-wrapped)

Note 1 to entry: See 3.11.

3.5.3

Type 3

container which contains a metal liner (3.14) reinforced with a resin impregnated continuous filament

(fully-wrapped)

Note 1 to entry: See 3.10.

3.5.4

Type 4

container which contains a resin impregnated continuous filament with a nonmetallic liner (3.14) (all

composite)

Note 1 to entry: See 3.3.

3.6

design family

group of containers consisting of one fully qualified design and variations on that design that comply

with Table 6

3.7

destroyed

in a state of alteration which makes a container physically unusable for its purpose

3.8

dry hydrogen

hydrogen which meets or exceeds the quality level in ISO 14687

3.9

fold

place where two material flows meet in such a manner as to create a sharp visual groove

3.10

full-wrapped

reinforced by a composite (3.3) material applied over the entire liner (3.14) including the domes

3.11

hoop-wrapped

reinforced by a composite (3.3) material applied in a substantially circumferential pattern over the

cylindrical portion of the liner (3.14) so that the filament does not transmit any significant stresses in a

direction parallel to the container longitudinal axis

3.12

leakage

release of contents through a defect or crack

3.13

leak test gas

gas for testing leaks that consists of dry hydrogen (3.8), dry helium or blends that contain these gases at

a detectable level

Note 1 to entry: Use leak test gas in 9.3.

3.14

liner

inner gas tight container or gas container to which the overwrap is applied

3.15

maximum fueling pressure

MFP

maximum pressure applied to a compressed system during fueling

Note 1 to entry: The maximum fueling pressure is 125 % of the nominal working pressure (3.18).

3.16

minimum required burst pressure

minimum burst pressure (3.2) that is to be met during a burst test and which is needed to demonstrate

the required stress ratio (3.26)

3.17

normal cubic centimeter

Ncc

dry gas that occupies a volume of 1 cm at a temperature of 273,15 K (0 °C) and an absolute pressure of

101,325 kPa (1 atm)

3.18

nominal working pressure

container pressure, as specified by the container manufacturer, at a uniform gas temperature of 15 °C

and full gas content

3.19

permanently attached

intended to remain fixed to a particular vehicle for the lifetime of the container or vehicle, whichever

comes first

3.20

permeation

diffusion of the gaseous contents to the atmosphere at a molecular level, by means of pores or

molecular gaps

4 © ISO 2018 – All rights reserved

3.21 Pressures

3.21.1

autofrettage pressure

pressure to which a container is taken with the intent of yielding the liner (3.14) or inner surface of the

container

Note 1 to entry: The autofrettage operation is considered to be part of the manufacturing operation and is

conducted prior to proof testing.

3.21.2

fill pressure

pressure attained at the actual time of filling

Note 1 to entry: Fill pressure varies according to the gas temperature in the container, which is dependent on

the filling parameters and the ambient conditions. The maximum fill pressure should not exceed 125 % of the

nominal working pressure (3.18).

3.21.3

hydrostatic pressure

pressure to which a container is taken during acceptance testing

Note 1 to entry: See 17.3.5.

3.22

pressure relief device

PRD

device that, when activated under specified performance conditions, is used to vent the container

contents

3.23

rejectable damage

damage as outlined in ISO 19078 or CGA C-6.4 and in agreement with the container manufacturer's

recommendations

3.24

rupture

sudden and unstable damage propagation in the structural components of the container resulting in

loss of contents

3.25

settled temperature

uniform gas temperature after any change in the temperature caused by filling has dissipated

3.26

stress ratio

minimum ultimate strength of the fiber, as determined in pressure container burst tests, divided by the

stress in the fiber at the nominal working pressure (3.18)

4 Service conditions

4.1 General

4.1.1 Standard service conditions

The standard service conditions specified herein are provided as a basis for the design, manufacture,

inspection, testing and approval of containers that are to be mounted permanently on vehicles and

used to store compressed hydrogen for use as a fuel on-board the vehicles. Containers are intended to

be installed on vehicles in accordance with SAE J2578, SAE J2579, IEC 62282-4-101, UN GTR No. 13, or

other equivalent standards.

4.1.2 Category

Category A, Category B and Category C containers are intended to provide a sufficient level of safety for

the intended application, but test methods and records are different.

4.1.3 Service life

The service life for the containers shall be specified by the container manufacturer. The specified life

shall not be less than 10 years or greater than 25 years as defined in 4.3.

4.1.4 Periodic in-service inspections

Any requirements and procedures for periodic re-qualification by inspection or testing during the

service life shall be specified by the container or vehicle manufacturer on the basis of use under the

service conditions specified herein. For containers that require periodic re-qualification by inspection

or testing, the container label shall identify this requirement according to Clause 15. Guidance on

periodic inspection is included in Annex A.

4.2 Pressures

4.2.1 Nominal working pressures

This document applies to containers that have a nominal working pressure, as specified by the container

manufacturer, of 25 MPa, 35 MPa, 50 MPa or 70 MPa at 15 °C, hereinafter referred to in this document

as the following:

a) “H25” — 25 MPa;

b) “H35” — 35 MPa;

c) “H50” — 50 MPa;

d) “H70” — 70 MPa.

4.2.2 Maximum pressures

Containers are designed to be filled to a pressure not exceeding any of the following conditions:

a) A pressure that would settle to the nominal working pressure at a settled temperature of 15 °C. The

fill pressure shall be temperature compensated to prevent pressures from exceeding the maximum

pressures that are defined.

b) Normally up to 125 % of the nominal working pressure immediately after filling, regardless of the

gas temperature, and infrequently up to 150 % under dispenser fault conditions.

4.3 Maximum number of filling cycles

Containers are designed to be filled to pressures not exceeding the requirements of 4.2.2, as follows:

a) Category A:

For a maximum of 750 times the service life of the container in years for a minimum of 10 years and

a maximum of 25 years.

b) Category B:

For a maximum of 5 500, 7 500, or 11 000 for a 15 year service life.

6 © ISO 2018 – All rights reserved

c) Category C:

For a maximum of 1 125 times the service life of the container in years for a minimum of 10 years

and a maximum of 25 years.

NOTE 1 Refer to D.3, D.4, and D.5 for the rationale on container fill cycles.

NOTE 2 Containers are expected to be removed from service when the service life used in the design

qualification has expired, consistent with the labelling requirements in Clause 15.

4.4 Temperature range

4.4.1 Settled gas temperatures

Settled temperature of the gas in containers may vary from −40 °C to 85 °C.

4.4.2 Container temperatures

The temperature of the container materials may vary from −40 °C to 85 °C.

4.4.3 Transient gas temperatures

Transient gas temperatures (temperatures that would be insufficient to change the bulk temperature

of the liner material) during filling and discharge may vary beyond the limits described in 4.4.1.

Containers qualified to meet this document shall be capable of being filled safely utilizing SAE J2601

fueling protocol or an equivalent fueling protocol.

4.4.4 Test temperatures

Unless otherwise specified, all tests shall be conducted at an ambient temperature of 20 °C ± 5 °C.

4.5 Gas composition

Containers made according to this document are designed to be used with hydrogen fuel complying with

ISO 14687 or SAE J2719. Containers made according to this document can also be used for hydrogen

road vehicles with hydrogen fuel (Type I Grade A) complying with ISO 14687.

4.6 External surfaces

Container external surfaces shall be designed to be resistant to environmental conditions outlined

in 17.3.3.

4.7 Installation requirements

The container manufacturer shall provide information to the vehicle manufacturer or system integrator

as necessary to support proper installation in the vehicle.

The vehicle manufacturer or system integrator shall be responsible for the protection of the container,

container valves, pressure relief devices and connections as required.

If this protection is mounted to the container, the design and method of attachment shall be approved

by the container manufacturer. Factors to be considered include the ability of the container to support

the transferred impact loads and the effect of local stiffening on container stresses and fatigue life.

Containers shall be protected from accidental cargo spillage and from mechanical damage. This

document contains no requirements for container integrity in a vehicle collision. Container locations

and mountings should be designed to provide adequate impact protection to prevent container failure

in a collision.

5 Compliance

Compliance shall be required in all details, without exception. If there is evidence of a fault in carrying

out a test or an error in measurement, another test shall be performed. If the results of this test are

satisfactory, the results of the prior test shall not be a basis for rejection.

6 Material qualification tests and requirements

6.1 General

All structural materials shall be traceable to their original manufacturer's certified test reports. The

materials shall be of uniform quality. Materials not in compliance with the original manufacturer's

design specifications are not authorized.

Table 1 summarizes specific material tests that are required herein subsequently.

Table 1 — Material tests

Container type

Material tests Clause Material type

1 2 3 4

Impact test 6.3.2 Steel • • • •

Tensile test 6.3.3 Metals • • • •

Sustained load cracking test 6.3.4 Aluminum • • • •

Corrosion test 6.3.5 Aluminum • • • •

Ultraviolet resistance test 6.4 External coatings • • • •

Shear strength test 6.6 Resins • • •

Glass transition temperature test 6.6 Resins • • •

Tensile test 6.7 Nonmetallic liners •

Softening temperature test 6.7 Nonmetallic liners •

Tensile test 9.3 Nonmetallic liner welds •

6.2 Material requirements

Materials normally in contact with hydrogen shall be determined to be acceptable in hydrogen service,

with the consideration of hydrogen embrittlement and hydrogen accelerated fatigue. The performance

tests cannot guarantee that all cases and conditions of hydrogen service will be validated, so it is

still incumbent on the container manufacturer to carefully screen materials of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...