ISO/TR 12489:2013

(Main)Petroleum, petrochemical and natural gas industries — Reliability modelling and calculation of safety systems

Petroleum, petrochemical and natural gas industries — Reliability modelling and calculation of safety systems

ISO/TR 12489:2013 aims to close the gap between the state-of-the-art and the application of probabilistic calculations for the safety systems of the petroleum, petrochemical and natural gas industries. It provides guidelines for reliability and safety system analysts and the oil and gas industries. The elementary approaches (e.g. PHA, HAZID, HAZOP, FMECA) are out of the scope of ISO/TR 12489:2013. Yet they are of utmost importance as their results provide the input information essential to properly undertake the implementation of the approaches described in ISO/TR 12489:2013: analytical formulae, Boolean approaches (reliability block diagrams, fault trees, event trees, etc.), Markov graphs and Petri nets. ISO/TR 12489:2013 is focused on probabilistic calculations of random failures and, therefore, the non-random failures are out of the scope even if, to some extent, they are partly included into the reliability data collected from the field.

Pétrole, pétrochimie et gaz naturel — Modélisation et calcul fiabilistes des systèmes de sécurité

General Information

- Status

- Published

- Publication Date

- 04-Nov-2013

- Technical Committee

- ISO/TC 67 - Materials, equipment and offshore structures for petroleum, petrochemical and natural gas industries

- Drafting Committee

- ISO/TC 67/WG 4 - Reliability Engineering and technology

- Current Stage

- 6060 - International Standard published

- Start Date

- 05-Nov-2013

- Completion Date

- 31-May-2014

Overview

ISO/TR 12489:2013 - Petroleum, petrochemical and natural gas industries - Reliability modelling and calculation of safety systems - is a Technical Report that provides guidance to close the gap between state-of-the‑art methods and practical application of probabilistic calculations for safety systems in oil & gas. It focuses on modelling and calculation of random failures in safety systems (including safety instrumented systems), and describes analytical and computational approaches rather than prescribing mandatory design rules.

Key topics

ISO/TR 12489:2013 covers a broad set of reliability modelling and calculation topics, including:

- Modelling frameworks and an analysis workflow for reliability and safety-calculation tasks.

- Approaches for probabilistic calculation:

- Analytical formulae (low-demand/on‑demand mode)

- Boolean approaches: Reliability Block Diagrams (RBD), Fault Tree Analysis (FTA), Event Trees and sequence modelling

- Markov models (multiphase Markovian analysis)

- Petri nets for complex sequential and concurrent behaviours

- Monte Carlo simulation techniques

- Failure classification, safe vs. unsafe failures, dependent and common‑cause failures, and human factors considerations.

- Reliability data: sources, collection, required parameters, and handling of numerical uncertainty.

- Typical application examples (single channel, dual channel, redundant architectures, multiple safety systems, emergency depressurization).

- Extensive informative annexes on modelling details, common‑cause failures, human factors, and numerical uncertainty handling.

Note: elementary hazard analysis methods (PHA, HAZID, HAZOP, FMECA) and non‑random failures are out of scope, although their outputs feed the probabilistic analyses discussed.

Practical applications

ISO/TR 12489:2013 is aimed at enabling robust probabilistic assessment of safety systems to support:

- Safety integrity evaluations and SIL assessments for safety instrumented systems (SIS)

- Quantitative risk assessment (QRA) and consequence analysis

- Design verification of redundant and multi‑layer safety architectures

- Reliability-centered maintenance planning and test interval optimization

- Assessing effects of dependent and common‑cause failures on system safety

Who should use it

- Reliability and safety engineers in the petroleum, petrochemical and natural gas industries

- Process safety analysts, asset integrity and maintenance managers

- Consultants performing probabilistic safety assessments (PSA), FTA or reliability modelling

- Regulators and auditors seeking guidance on probabilistic calculation methods

Related standards

ISO/TR 12489:2013 complements other ISO/TC 67 reliability standards such as ISO 14224 (reliability and maintenance data collection) and ISO 20815 (production assurance and reliability management), providing targeted guidance for probabilistic modelling of safety systems.

Keywords: ISO/TR 12489:2013, reliability modelling, safety systems, petroleum, petrochemical, natural gas, probabilistic calculations, fault tree, reliability block diagram, Markov, Petri net, Monte Carlo, common cause failures.

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

ISO/TR 12489:2013 is a technical report published by the International Organization for Standardization (ISO). Its full title is "Petroleum, petrochemical and natural gas industries — Reliability modelling and calculation of safety systems". This standard covers: ISO/TR 12489:2013 aims to close the gap between the state-of-the-art and the application of probabilistic calculations for the safety systems of the petroleum, petrochemical and natural gas industries. It provides guidelines for reliability and safety system analysts and the oil and gas industries. The elementary approaches (e.g. PHA, HAZID, HAZOP, FMECA) are out of the scope of ISO/TR 12489:2013. Yet they are of utmost importance as their results provide the input information essential to properly undertake the implementation of the approaches described in ISO/TR 12489:2013: analytical formulae, Boolean approaches (reliability block diagrams, fault trees, event trees, etc.), Markov graphs and Petri nets. ISO/TR 12489:2013 is focused on probabilistic calculations of random failures and, therefore, the non-random failures are out of the scope even if, to some extent, they are partly included into the reliability data collected from the field.

ISO/TR 12489:2013 aims to close the gap between the state-of-the-art and the application of probabilistic calculations for the safety systems of the petroleum, petrochemical and natural gas industries. It provides guidelines for reliability and safety system analysts and the oil and gas industries. The elementary approaches (e.g. PHA, HAZID, HAZOP, FMECA) are out of the scope of ISO/TR 12489:2013. Yet they are of utmost importance as their results provide the input information essential to properly undertake the implementation of the approaches described in ISO/TR 12489:2013: analytical formulae, Boolean approaches (reliability block diagrams, fault trees, event trees, etc.), Markov graphs and Petri nets. ISO/TR 12489:2013 is focused on probabilistic calculations of random failures and, therefore, the non-random failures are out of the scope even if, to some extent, they are partly included into the reliability data collected from the field.

ISO/TR 12489:2013 is classified under the following ICS (International Classification for Standards) categories: 75.180.01 - Equipment for petroleum and natural gas industries in general; 75.200 - Petroleum products and natural gas handling equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/TR 12489:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 12489

First edition

2013-11-01

Petroleum, petrochemical and natural

gas industries — Reliability modelling

and calculation of safety systems

Pétrole, pétrochimie et gaz naturel — Modélisation et calcul

fiabilistes des systèmes de sécurité

Reference number

©

ISO 2013

© ISO 2013

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2013 – All rights reserved

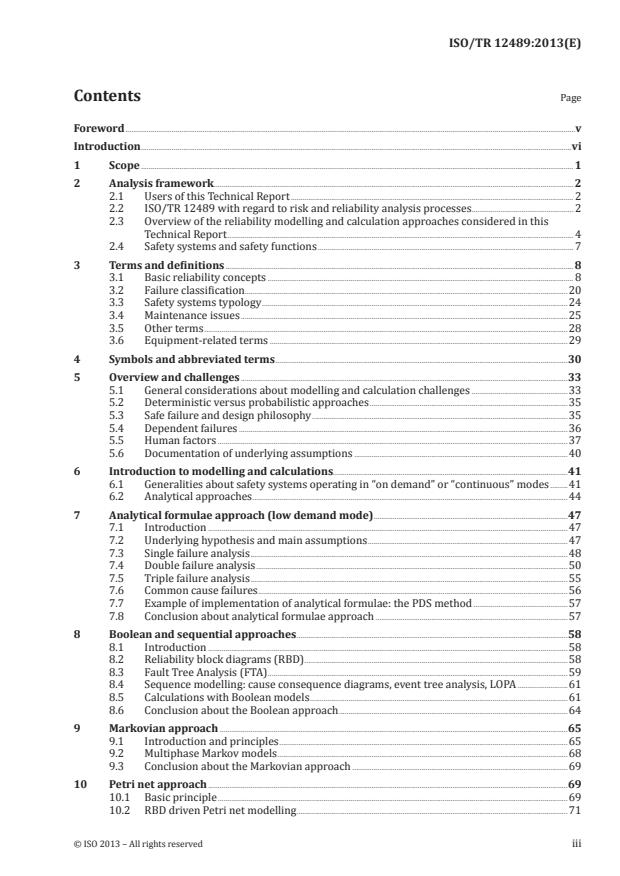

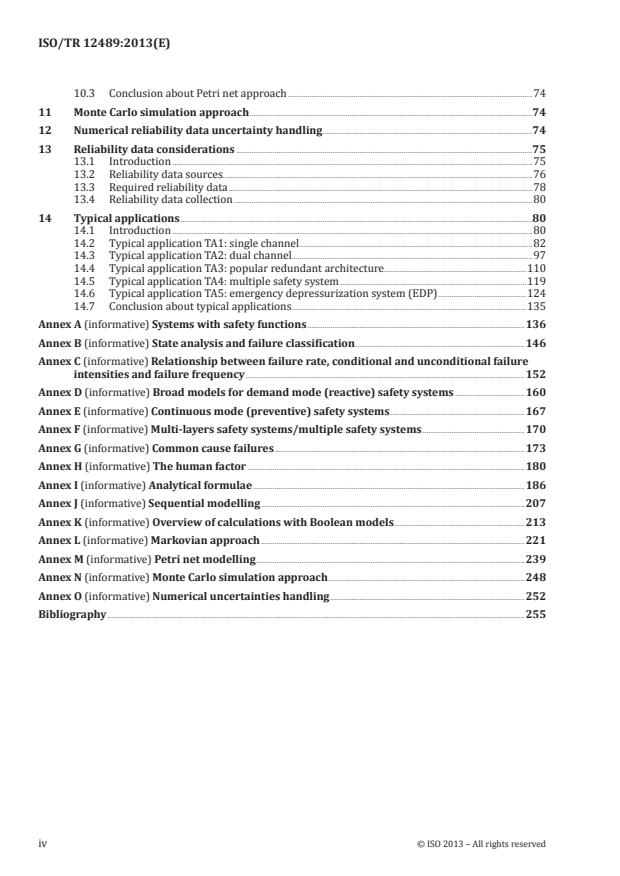

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Analysis framework . 2

2.1 Users of this Technical Report . 2

2.2 ISO/TR 12489 with regard to risk and reliability analysis processes . 2

2.3 Overview of the reliability modelling and calculation approaches considered in this

Technical Report . 4

2.4 Safety systems and safety functions . 7

3 Terms and definitions . 8

3.1 Basic reliability concepts . 8

3.2 Failure classification.20

3.3 Safety systems typology .24

3.4 Maintenance issues .25

3.5 Other terms .28

3.6 Equipment-related terms .29

4 Symbols and abbreviated terms .30

5 Overview and challenges .33

5.1 General considerations about modelling and calculation challenges .33

5.2 Deterministic versus probabilistic approaches .35

5.3 Safe failure and design philosophy .35

5.4 Dependent failures .36

5.5 Human factors .37

5.6 Documentation of underlying assumptions .40

6 Introduction to modelling and calculations.41

6.1 Generalities about safety systems operating in “on demand” or “continuous” modes .41

6.2 Analytical approaches .44

7 Analytical formulae approach (low demand mode) .47

7.1 Introduction .47

7.2 Underlying hypothesis and main assumptions .47

7.3 Single failure analysis .48

7.4 Double failure analysis .50

7.5 Triple failure analysis .55

7.6 Common cause failures .56

7.7 Example of implementation of analytical formulae: the PDS method .57

7.8 Conclusion about analytical formulae approach .57

8 Boolean and sequential approaches .58

8.1 Introduction .58

8.2 Reliability block diagrams (RBD) .58

8.3 Fault Tree Analysis (FTA) .59

8.4 Sequence modelling: cause consequence diagrams, event tree analysis, LOPA .61

8.5 Calculations with Boolean models .61

8.6 Conclusion about the Boolean approach .64

9 Markovian approach .65

9.1 Introduction and principles .65

9.2 Multiphase Markov models .68

9.3 Conclusion about the Markovian approach .69

10 Petri net approach .69

10.1 Basic principle .69

10.2 RBD driven Petri net modelling .71

10.3 Conclusion about Petri net approach .74

11 Monte Carlo simulation approach .74

12 Numerical reliability data uncertainty handling .74

13 Reliability data considerations .75

13.1 Introduction .75

13.2 Reliability data sources.76

13.3 Required reliability data .78

13.4 Reliability data collection .80

14 Typical applications .80

14.1 Introduction .80

14.2 Typical application TA1: single channel .82

14.3 Typical application TA2: dual channel .97

14.4 Typical application TA3: popular redundant architecture .110

14.5 Typical application TA4: multiple safety system .119

14.6 Typical application TA5: emergency depressurization system (EDP) .124

14.7 Conclusion about typical applications .135

Annex A (informative) Systems with safety functions .136

Annex B (informative) State analysis and failure classification .146

Annex C (informative) Relationship between failure rate, conditional and unconditional failure

intensities and failure frequency .152

Annex D (informative) Broad models for demand mode (reactive) safety systems .160

Annex E (informative) Continuous mode (preventive) safety systems .167

Annex F (informative) Multi-layers safety systems/multiple safety systems .170

Annex G (informative) Common cause failures .173

Annex H (informative) The human factor .180

Annex I (informative) Analytical formulae .186

Annex J (informative) Sequential modelling .207

Annex K (informative) Overview of calculations with Boolean models.213

Annex L (informative) Markovian approach .221

Annex M (informative) Petri net modelling.239

Annex N (informative) Monte Carlo simulation approach .248

Annex O (informative) Numerical uncertainties handling .252

Bibliography .255

iv © ISO 2013 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of any

patent rights identified during the development of the document will be in the Introduction and/or on

the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 67, Materials, equipment and offshore structures

for petroleum, petrochemical and natural gas industries.

This first edition of ISO/TR 12489 belongs of the family of reliability related standards developed

by ISO/TC 67:

— ISO 14224, Petroleum, petrochemical and natural gas industries — Collection and exchange of reliability

and maintenance data for equipment

— ISO 20815, Petroleum, petrochemical and natural gas industries — Production assurance and

reliability management

Introduction

Safety systems have a vital function in petroleum, petrochemical and natural gas industries where

safety systems range from simple mechanical safety devices to safety instrumented systems.

They share three important characteristics which make them difficult to handle:

1) They should be designed to achieve good balance between safety and production. This implies a

high probability of performing the safety action as well as a low frequency of spurious actions.

2) Some of their failures are not revealed until relevant periodic tests are performed to detect and

repair them.

3) A given safety system rarely works alone. It generally belongs to a set of several safety systems (so-

called multiple safety systems) working together to prevent accidents.

Therefore improving safety may be detrimental to dependability and vice versa. These two aspects

should therefore, ideally, be handled at the same time by the same reliability engineers. However, in

reality they are generally considered separately and handled by different persons belonging to different

departments. Moreover this is encouraged by the international safety standards, which exclude

dependability from their scopes, and the international dependability (see 3.1.1) standard, which excludes

safety from theirs. This may lead to dangerous situations (e.g. safety system disconnected because of

too many spurious trips) as well as high production losses.

The proof of the conservativeness of probabilistic calculations of safety systems is generally required

by safety authorities. Unfortunately, managing the systemic dependencies introduced by the periodic

tests to obtain conservative results implies mathematical difficulties which are frequently ignored. The

impact is particularly noticeable for redundant safety systems and multiple safety systems. Awareness

of these challenges is important for reliability engineers as well as safety managers and decision makers,

utilizing reliability analytical support.

Most of the methods and tools presently applied in reliability engineering have been developed since

the 1950s before the emergence of personal computers when only pencil and paper were available. At

that time the reliability pioneers could only manage simplified models and calculations but this has

completely changed because of the tremendous improvement in the computation means achieved over

the past 30 years. Nowadays, models and calculations which were once impossible are carried out

with a simple laptop computer. Flexible (graphical) models and powerful algorithms based on sound

mathematics are now available to handle “industrial size” systems (i.e. many components with complex

interactions). This allows the users to focus on the analysis of the systems and assessment of results,

rather than on the calculations themselves. All the approaches described in this Technical Report have

been introduced in the petroleum, petrochemical and natural gas industries as early as the 1970s where

they have proven to be very effective. They constitute the present time state-of-the-art in reliability

calculations. Nevertheless some of them have not been widely disseminated in this sector although

they can be of great help for reliability engineers to overcome the problems mentioned above. This is

particularly true when quantitative reliability or availability requirements need confirmation and/or

when the objective of the reliability study lay beyond the scope of the elementary approaches.

The present document is a “technical” report and its content is obviously “technical”. Nevertheless, it

only requires a basic knowledge in probabilistic calculation and mathematics and any skilled reliability

engineer should have no difficulties in using it.

vi © ISO 2013 – All rights reserved

TECHNICAL REPORT ISO/TR 12489:2013(E)

Petroleum, petrochemical and natural gas industries —

Reliability modelling and calculation of safety systems

1 Scope

This Technical Report aims to close the gap between the state-of-the-art and the application of probabilistic

calculations for the safety systems of the petroleum, petrochemical and natural gas industries. It provides

guidelines for reliability and safety system analysts and the oil and gas industries to:

• understand the correct meaning of the definitions used in the reliability field;

• identify

— the safety systems which may be concerned,

— the difficulties encountered when dealing with reliability modelling and calculation of

safety systems,

— the relevant probabilistic parameters to be considered;

• be informed of effective solutions overcoming the encountered difficulties and allowing to undertake

the calculations of relevant probabilistic parameters;

• obtain sufficient knowledge of the principles and framework (e.g. the modelling power and

limitations) of the well-established approaches currently used in the reliability field:

[1][2][13]

— analytical formulae;

— Boolean:

[4]

• reliability block diagrams;

[5]

• fault trees;

[8] [10] [9]

— sequential: event trees, cause consequence diagrams and LOPA;

[6]

— Markovian;

[7]

— Petri nets;

• obtain sufficient knowledge of the principles of probabilistic evaluations:

[1][2][3]

— analytical calculations (e.g. performed on Boolean or Markovian models);

[7]

— and Monte Carlo simulation (e.g. performed on Petri nets );

• select an approach suitable with the complexity of the related safety system and the reliability study

which is undertaken;

• handle safety and dependability (e.g. for production assurance purpose, see 3.1.1) within the same

reliability framework.

The elementary approaches (e.g. PHA, HAZID, HAZOP, FMECA) are out of the scope of this Technical

Report. Yet they are of utmost importance and ought to be applied first as their results provide the input

information essential to properly undertake the implementation of the approaches described in this

Technical Report: analytical formulae, Boolean approaches (reliability block diagrams, fault trees, event

trees, etc.), Markov graphs and Petri nets.

This Technical Report is focused on probabilistic calculations of random failures and, therefore, the non-

[14]

random (i.e. systematic failures as per the international reliability vocabulary IEV 191 ) failures are out

of the scope even if, to some extent, they are partly included into the reliability data collected from the field.

2 Analysis framework

2.1 Users of this Technical Report

This Technical Report is intended for the following users, in a role defining the scope of work of reliability

models (customer or decision-maker), executing reliability analysis or as a risk analyst using these

calculations:

• Installation/Plant/Facility: operating facility staff, e.g. safety, maintenance and engineering personnel.

• Owner/Operator/Company: reliability staff or others analysing or responsible for reliability

studies for safety related equipment located in company facilities.

• Industry: groups of companies collaborating to enhance reliability of safety systems and safety

functions. The use of this Technical Report supports “reliability analytical best practices” for the

[54]

benefit of societal risk management in accordance with ISO 26000 .

• Manufacturers/Designers: users having to document the reliability of their safety equipment.

• Authorities/Regulatory bodies: enforcers of regulatory requirements which can quote these

guidelines to enhance quality and resource utilization.

• Consultant/Contractor: experts and contractors/consultants undertaking reliability modelling

and probabilistic calculation studies.

• University bodies: those having educational roles in society and experts that might improve

methods on these matters.

• Research institutions: experts that might improve reliability modelling and probabilistic

calculation methods.

2.2 ISO/TR 12489 with regard to risk and reliability analysis processes

When a safety system has been designed using good engineering practice (i.e. applying the relevant

regulations, standards, rules and technical and safety requirements) it is expected to work properly.

After that a reliability analysis is usually undertaken in order to evaluate its probability of failure and,

if needed, identify how it can be improved to reach some safety targets.

2 © ISO 2013 – All rights reserved

With regards to, e.g.,

Risk management

safety, environment,

production,

operations, etc.

Risk assessment

Risk analysis

Reliability analysis

ISO TR

A

Fig.2

Modelling

& calculations

B

Fig.2

Figure 1 — ISO/TR 12489 within the framework of risk management

Relevant interdisciplinary communication and a good understanding of the safety system life cycle are

required to have qualified inputs and correct result interpretations. Applying this Technical Report also

[16]

requires interaction and compliance with other standards such as ISO 20815 (production assurance),

[15] [29] 28]

ISO 14224 (reliability data collection) or ISO 17776 and ISO 31000[ (risk management). As

shown in Figure 1, this Technical Report contributes to the risk management process which encompasses

both safety and production (dependability, cf. 3.1.1) aspects and involves different stages such as risk

assessment and risk analysis. More precisely, this Technical Report contributes to the probabilistic part

(reliability analysis) of the risk analysis stage.

[16]

NOTE ISO 20815 gives further information on reliability/availability in a production assurance

[15]

perspective, while ISO 14224 which is devoted to reliability data collection is another fundamental reference

[29]

for both safety and production within our industries (within ISO/TC67 business arena). ISO 17776 and

[28]

ISO 31000 are devoted to risk management.

When such a process is undertaken, the usual steps are the following:

a) Defining the objective of the study and system boundaries in order to identify the limits of the

process and the safety system(s) to be analysed.

b) Functioning analysis to understand how the safety system works.

c) Dysfunctioning analysis to understand how the safety system may fail:

1) risk identification and establishment of the safety targets;

2) elementary analyses (e.g. HAZOP, FMEA, etc.);

3) common cause failures identification.

d) Modelling and calculations:

1) Modelling:

i) functioning and dysfunctioning modelling

ii) common cause/ Common mode failures modelling

2) Qualitative analysis;

3) Quantitative analysis (if qualitative analysis is not sufficient).

e) Discussion with field specialists and redesign if improvements are needed.

f) Final results (weak points, failure contributors, failure probabilities, interpretation,

specifications, etc.).

The present Technical Report is focused on the steps written in bold and underlined characters:

modelling and calculations [step d)] and final results of interest [step f)]. Nevertheless, step d) and

consequently f) can be achieved only if the steps a), b) and c) and consequently e) have been properly

undertaken first. Therefore in this Technical Report it is supposed that the limits of the safety system

and the objective of the study have been properly identified [step a)], that the analyst has acquired a

sound understanding about the functioning [step b)] and dysfunctioning of the safety system under

study, that the relevant risk identification and the safety targets have been properly established [and c)]

and that field specialists have been invited to give their advice in due time [step e)] to ensure that the

final results are close to real life feedback.

This Technical Report also suggests the safety systems and safety functions typically requiring such

reliability analysis support in order to utilize resources effectively. See Annex A.

2.3 Overview of the reliability modelling and calculation approaches considered in this

Technical Report

Figure 2 gives an overview of the approaches selected for the purpose of this Technical Report and

provides some guidelines to select them when the level in difficulty and complexity increases.

4 © ISO 2013 – All rights reserved

From

A

"reliability analysis"

(Figure 1)

N Y

Need for

quantitative results ?

Strong

N

Y

dependencies ?

(see NOTE 2)

N Y

Repairable

components ?

Y N

Constant Y N

transition rates ?

Weak

Y N

dependencies ?

(see NOTE 2)

N Y

Large number

N Y

N Y

of states ?

Y N

Relevance of

series-parallel model ?

Ch.7

Ch.9 Ch.10

Ch.8

Analytical

RBD Fault Tree Markov models Petri net

Formulae

Ch.8 Ch.10

Fault tree driven

Qualitative or

RBD driven Formal

Markov models

semi quantitative

Petri nets languages

approaches

Analytical calculations

(outside the scope

of ISO TR 12489)

Monte Carlo simulation

Increasing complexity

To

B

"reliability analysis"

(Figure 1)

NOTE 1 The questions on the left hand side can be used as guidelines to choose an adequate approach to study

a given safety system.

NOTE 2 Systems without dependencies do not really exist in the real world but the dependencies may have

a negligible impact (weak dependencies) or a strong impact (strong dependencies) on the probability of failure.

An example of weak dependency is the use of a single repair team for a topside periodically tested component

(because the repair time is negligible compared to the MFDT (Mean Fault Detection Time, see 3.1.35). An example

of strong dependency is when a stand-by component starts when another fails.

NOTE 3 “Series-parallel model” refers to a popular model found in numerous text books which uses only series

[4]

and parallel structures to model the logic of the systems, for example, reliability block diagrams .

NOTE 4 The arrow from “Markov” to “Analytical Formulae” through “fault tree” and “RBD” highlights the fact

[4][5] [6]

that the analytical formulae are obtained through models mixing Boolean and Markov models.

Figure 2 — Overview of reliability modelling and calculation approaches currently used

Other criteria can be used to classify the reliability modelling and calculation approaches:

• the accuracy of results (approximated or exact);

• conservativeness of the results (pessimistic or optimistic);

• the nature of the calculations (analytical or Monte Carlo simulation);

• the nature of the modelling (static or dynamic);

• the user friendliness (graphical or non graphical);

• the input data which can be made available;

• the possibility to update the model after several years by someone else.

The various approaches currently used in reliability engineering have different characteristics

(strengths and limitations). It is important for the selection and use of these approaches to be aware of

their limitations and conservativeness:

[1][2][13]

a) Analytical formulae: analytical methods which provide approximated suitable

results when used skilfully. They are useful for quick calculations but the underlying limits and

approximations often limit their application to systems of limited complexity. This also limits their

application to systems where sequence-dependent failures or other time-dependent failures, such

as desynchronized testing (see 3.4.10), are not important contributors to the overall performance.

Analytical formulae are generally obtained from underlying Boolean and/or Markovian models.

b) Boolean models: static and graphical models supporting analytical calculations. “Reliability block

[4] [5]

diagrams” (RBD) and fault trees (FT) belong to Boolean models. To some extent, the sequential

[8] [9] [10]

approaches event trees (ET) , LOPA or cause consequence diagrams can also be associated

with Boolean models. These approaches provide clear and understandable models for large or

complex systems. Boolean models are limited to “two-state” systems (working, failed) and handling

of time evolution requires a high level of understanding in probabilistic calculations.

[6]

c) Markovian models : dynamic and graphical models supporting analytical calculations and

modelling of sequence-dependent or time-dependent failures. A Markovian model is a “state-

transition” model limited to exponentially distributed events. The combinatory explosion of the

number of system states limits this approach to small (simple or complex) systems with few states.

The impact of approximations performed to deal with larger systems is often difficult to evaluate.

Boolean and Markovian approaches can be mixed to model large systems when weak dependencies

between the components are involved. This can be achieved by implementing the fault tree driven

Markov models (see Figure 2).

[7]

d) Petri nets : dynamic and graphical models supporting Monte Carlo simulation to provide

statistical results associated with their confidence intervals. A Petri net is a “state-transition” model

handling any kind of probabilistic distributions. Time-, state- or sequence-dependent failures can

be modelled explicitly. The size of the model is linear with regard to the number of components.

This makes possible the modelling of very large complex systems. The Monte Carlo simulation

computation time increases when low probability events are calculated but probabilities of failure

−5

as low as 10 over one year can be handled with modern personal computers. For large safety

systems, the Petri net may become difficult to handle. The use of the RBD driven PN overcomes this

difficulty (see Figure 2).

[11][12]

e) Formal languages : dynamic models used to generate analytical models (e.g. Markovian

models or fault trees, when possible) or used directly for Monte Carlo simulation. The other

characteristics are same as Petri nets except that computations may be slower. They are just

mentioned but they are outside the scope of this Technical Report.

Except for bullet e), more details can be found in Clauses 7 to 10. All these models can be mathematically

described in terms of “finite states automata” (i.e. a mathematical state machine with a finite number of

discrete states). The system behaviour can be modelled more and more rigorously when going from a)

to e) but, of course, every approach can be used to model simple safety systems.

Figure 2 gives advice to the analyst to select the relevant approach in order to optimize the design of

a safety system and meet some reliability targets. This choice depends on the safety function, purpose

and complexity the analyst has to face. When several approaches are relevant, the analyst may choose

his favourite.

A warning may be raised here: using a software package as a black box or a formula as a magic recipe

is likely to lead to inaccurate, often non-conservative, results. In all cases the reliability engineers

should be aware of the limitations of the tools that they are using and they should have a minimum

understanding of the mathematics behind the calculations and a good knowledge of the nature of the

results that they obtain (unreliability, point unavailability, average unavailability, frequency, etc.), of the

6 © ISO 2013 – All rights reserved

conservativeness and of the associated uncertainties. Without adequate understanding of the software

tool, erroneous results can be obtained through its misuse.

Table 1 — Road map of ISO/TR 12489

Topic Reference to main report Reference to annexes

(sub)clause

I- General issues

a) Terms and definitions 3, 4 -

b) General analytical overview 5, 6 B, C, D, E, F

c) Human factors 5.5 H

d) Common cause 5.4.2 G

e) Monte Carlo simulation 11 N

f) Uncertainty 12 O

g) Reliability data 13 -

h) Systems with safety functions 2.4 A

II- Approaches

a) Analytical formulae 7 I

b) Boolean 8 K

- Reliability Block Diagram 8.2

- Fault Tree 8.3

- Sequence modelling 8.4 J

c) Markovian 9 L

d) Petri net 10 M

III- Examples 14 -

IV- Bibliography End of ISO/TR 12489 -

It is important that the reliability methods and application of those, including the available input data

are adapted to the life cycle phase. Uncertainty handling is further addressed in Clause 12.

The human factor is addressed in 5.5 and Annex H in terms of the quantification of the reliability of

human performed tasks. This inclusion is intended to support assessment of the pros and cons of

including human tasks with the potential for failure in safety systems.

Table 1 gives a road map for these issues and the supporting annexes and supplement Figure 2.

2.4 Safety systems and safety functions

Numerous safety systems are implemented in the petroleum, petrochemical and natural gas industries.

They range from very simple to very complex systems, used on-demand or in continuous mode of operation.

Table A.1 gives a non-exhaustive list of safety systems and safety functions which may require reliability

modelling in the petroleum, petrochemical and natural gas industries. It has been built in relationship

[15]

with the taxonomy developed in the ISO 14224 standard and covers either safety systems (taxonomy

level 5) or other systems with safety function(s). A summary is given below:

A. Emergency/process shutdown (split in A.1 and A.2)

B. Fire and gas detection

C. Fire water

D. Fire-fighting

E. Process control

F. Public alarm

G. Emergency preparedness systems

H. Marine equipment

I. Electrical and Telecommunication

J. Other utilities

K. Drilling and Wells

L. Subsea

[15]

NOTE A to G are covered as safety and control systems in Table A.3 of ISO 14224 . The list has been extended

from H to L to give a broader coverage.

This Technical Report provides a number of reliability modelling and calculation approaches large

enough to cope with any kind of safety system like those identified in Table A.1. They can be used when

the objectives of the reliability studies lay beyond the scope of the elementary approaches (e.g. PHA,

HAZID, HAZOP, FMECA .) and selected according to Figure 2.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

NOTE 1 Since their introduction more than 50 years ago, the core concepts of the reliability engineering field

have been used and adapted for various purposes. Over time this has caused “semantic” drifts and most of the

terms have various meanings. They have become so polysemic now that it is necessary to define them accurately

to avoid confusion, even when they seem well known.

NOTE 2 The terms are divided into:

— 3.1 Basic reliability concepts

— 3.2 Failure classification

— 3.3 Safety systems typology

— 3.4 Maintenance issues

— 3.5 Other terms

— 3.6 Equipment related terms

Textual definitions are provided as well as, when this is possible, the corresponding mathematical formulae which

leave less place to interpretation. Notes are added when clarifications are useful.

3.1 Basic reliability concepts

3.1.1

dependability

ability to perform as and when required

Note 1 to entry: Dependability is mainly business oriented.

8 © ISO 2013 – All rights reserved

Note 2 to entry: IEC/TC 56 which is the international “dependability” technical committee deals with reliability,

availability, maintainability and maintenance support. More than 80 dependability standards have been published

[14]

by the IEC/TC56. In particular, it is in charge of the international vocabulary related to those topics (IEV 191 )

and also of the methods used in the reliability field (e.g. FMEA, HAZOP, reliability block diagrams, fault trees,

Markovian approach, event tree, Petri nets).

Note 3 to entry: The production availability is an extension, for production systems, of the classical dependability

[16]

measures. This term is defined in the ISO 20815 standard which deals with production assurance and relates

to systems and operations associated with drilling, processing and transport of petroleum, petrochemical and

[16]

natural gas. The relationship between production-assurance terms can be found in Figure G.1 of ISO 20815 .

[SOURCE: IEC 60050 −191]

3.1.2

safety integrity

ability of a safety instrumented system to perform the required safety instrumented functions as and

when required

Note 1 to entry: This definition is equivalent to the dependability of the SIS (Safety Instrumented System) with

regard to the required safety instrumented function. Dependability, being often understood as an economical

rather a safety concept, has not been used to avoid confusion.

Note 2 to entry: The term “integrity” is used to point out that a SIS aims to protect the integrity of the operators

as well as of the process and its related equipment from hazardous events.

3.1.3

SIL

Safety Integrity Level

discrete level (one out of four) for specifying the safety integrity requirements of the safety instrumented

functions to be allocated to the safety instrumented systems

Note 1 to entry: Safety integrity level 4 is related to the highest level of safety integrity; safety integrity level 1

has the lowest.

Note 2 to entry: The safety integrity level is a requirement about a safety instrumented function. The higher

the safety integrity level, the higher the probability that the required safety instrumented function (SIF) will be

carried out upon a real demand.

[2]

Note 3 to entry: This term differs from the definition in IEC 61508–4 to reflect differences in process

sector terminology.

3.1.4

safe state

state of the process when safety is achieved

Note 1 to entry: Some states are safer than others (see Figures B.1, B.2 and B.3) and in going from a potentially

hazardous condition to the final safe state, or in going from the nominal safe condition to a potentially hazardous

condition, the process may have to go through a number of intermediate safe-states.

Note 2 to entry: For some situ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...