ISO/TS 19880-1:2016

(Main)Gaseous hydrogen — Fuelling stations — Part 1: General requirements

Gaseous hydrogen — Fuelling stations — Part 1: General requirements

ISO/TS 19880-1:2016 recommends the minimum design characteristics for safety and, where appropriate, for performance of public and non-public fuelling stations that dispense gaseous hydrogen to light duty land vehicles (e.g. Fuel Cell Electric Vehicles). NOTE These recommendations are in addition to applicable national regulations and codes, which can prohibit certain aspects of this document. It is applicable to fuelling for light duty hydrogen land vehicles, but it can also be used as guidance for fuelling buses, trams, motorcycles and fork-lift truck applications, with hydrogen storage capacities outside of current published fuelling protocol standards, such as SAE J2601. Residential applications to fuel land vehicles and non-public demonstration fuelling stations are not included in ISO/TS 19880-1:2016. It provides guidance on the following elements of a fuelling station: - hydrogen production/delivery system - delivery of hydrogen by pipeline, trucked in gaseous and/or liquid hydrogen, or metal hydride storage trailers; - on-site hydrogen generators using water electrolysis process or hydrogen generators using fuel processing technologies; - liquid hydrogen storage; - hydrogen purification systems, as applicable; - compression - gaseous hydrogen compression; - pumps and vaporizers; - gaseous hydrogen buffer storage; - pre-cooling device; - gaseous hydrogen dispensers.

Carburant d'hydrogène gazeux — Stations-service — Partie 1: Exigences générales

General Information

- Status

- Withdrawn

- Publication Date

- 29-Jun-2016

- Withdrawal Date

- 29-Jun-2016

- Technical Committee

- ISO/TC 197 - Hydrogen technologies

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 04-Mar-2020

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 12-Feb-2026

- Effective Date

- 16-Jul-2016

- Effective Date

- 28-Sep-2013

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

ISO/TS 19880-1:2016 is a technical specification published by the International Organization for Standardization (ISO). Its full title is "Gaseous hydrogen — Fuelling stations — Part 1: General requirements". This standard covers: ISO/TS 19880-1:2016 recommends the minimum design characteristics for safety and, where appropriate, for performance of public and non-public fuelling stations that dispense gaseous hydrogen to light duty land vehicles (e.g. Fuel Cell Electric Vehicles). NOTE These recommendations are in addition to applicable national regulations and codes, which can prohibit certain aspects of this document. It is applicable to fuelling for light duty hydrogen land vehicles, but it can also be used as guidance for fuelling buses, trams, motorcycles and fork-lift truck applications, with hydrogen storage capacities outside of current published fuelling protocol standards, such as SAE J2601. Residential applications to fuel land vehicles and non-public demonstration fuelling stations are not included in ISO/TS 19880-1:2016. It provides guidance on the following elements of a fuelling station: - hydrogen production/delivery system - delivery of hydrogen by pipeline, trucked in gaseous and/or liquid hydrogen, or metal hydride storage trailers; - on-site hydrogen generators using water electrolysis process or hydrogen generators using fuel processing technologies; - liquid hydrogen storage; - hydrogen purification systems, as applicable; - compression - gaseous hydrogen compression; - pumps and vaporizers; - gaseous hydrogen buffer storage; - pre-cooling device; - gaseous hydrogen dispensers.

ISO/TS 19880-1:2016 recommends the minimum design characteristics for safety and, where appropriate, for performance of public and non-public fuelling stations that dispense gaseous hydrogen to light duty land vehicles (e.g. Fuel Cell Electric Vehicles). NOTE These recommendations are in addition to applicable national regulations and codes, which can prohibit certain aspects of this document. It is applicable to fuelling for light duty hydrogen land vehicles, but it can also be used as guidance for fuelling buses, trams, motorcycles and fork-lift truck applications, with hydrogen storage capacities outside of current published fuelling protocol standards, such as SAE J2601. Residential applications to fuel land vehicles and non-public demonstration fuelling stations are not included in ISO/TS 19880-1:2016. It provides guidance on the following elements of a fuelling station: - hydrogen production/delivery system - delivery of hydrogen by pipeline, trucked in gaseous and/or liquid hydrogen, or metal hydride storage trailers; - on-site hydrogen generators using water electrolysis process or hydrogen generators using fuel processing technologies; - liquid hydrogen storage; - hydrogen purification systems, as applicable; - compression - gaseous hydrogen compression; - pumps and vaporizers; - gaseous hydrogen buffer storage; - pre-cooling device; - gaseous hydrogen dispensers.

ISO/TS 19880-1:2016 is classified under the following ICS (International Classification for Standards) categories: 43.060.40 - Fuel systems; 71.100.20 - Gases for industrial application. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/TS 19880-1:2016 has the following relationships with other standards: It is inter standard links to EN 17127:2018, ISO 19880-1:2020, ISO/TS 20100:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO/TS 19880-1:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 19880-1

First edition

2016-07-01

Gaseous hydrogen — Fuelling

stations —

Part 1:

General requirements

Carburant d’hydrogène gazeux — Stations-service —

Partie 1: Exigences générales

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

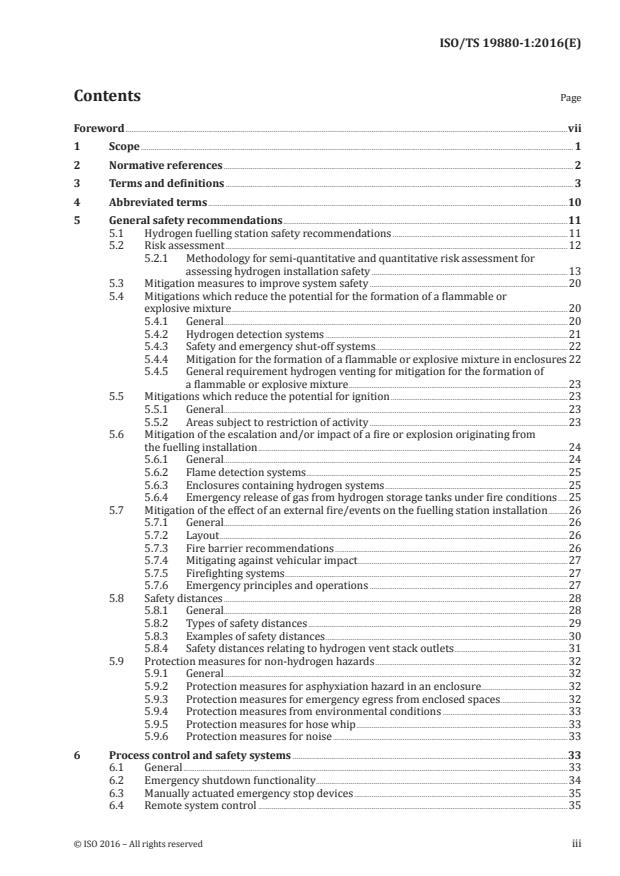

Contents Page

Foreword .vii

1 Scope . 1

2 Normative references . 2

3 Terms and definitions . 3

4 Abbreviated terms .10

5 General safety recommendations .11

5.1 Hydrogen fuelling station safety recommendations .11

5.2 Risk assessment .12

5.2.1 Methodology for semi-quantitative and quantitative risk assessment for

assessing hydrogen installation safety .13

5.3 Mitigation measures to improve system safety .20

5.4 Mitigations which reduce the potential for the formation of a flammable or

explosive mixture .20

5.4.1 General.20

5.4.2 Hydrogen detection systems .21

5.4.3 Safety and emergency shut-off systems . .22

5.4.4 Mitigation for the formation of a flammable or explosive mixture in enclosures 22

5.4.5 General requirement hydrogen venting for mitigation for the formation of

a flammable or explosive mixture .23

5.5 Mitigations which reduce the potential for ignition .23

5.5.1 General.23

5.5.2 Areas subject to restriction of activity .23

5.6 Mitigation of the escalation and/or impact of a fire or explosion originating from

the fuelling installation .24

5.6.1 General.24

5.6.2 Flame detection systems .25

5.6.3 Enclosures containing hydrogen systems .25

5.6.4 Emergency release of gas from hydrogen storage tanks under fire conditions .25

5.7 Mitigation of the effect of an external fire/events on the fuelling station installation .26

5.7.1 General.26

5.7.2 Layout .26

5.7.3 Fire barrier recommendations .26

5.7.4 Mitigating against vehicular impact .27

5.7.5 Firefighting systems .27

5.7.6 Emergency principles and operations .27

5.8 Safety distances .28

5.8.1 General.28

5.8.2 Types of safety distances .29

5.8.3 Examples of safety distances .30

5.8.4 Safety distances relating to hydrogen vent stack outlets .31

5.9 Protection measures for non-hydrogen hazards .32

5.9.1 General.32

5.9.2 Protection measures for asphyxiation hazard in an enclosure.32

5.9.3 Protection measures for emergency egress from enclosed spaces .32

5.9.4 Protection measures from environmental conditions .33

5.9.5 Protection measures for hose whip .33

5.9.6 Protection measures for noise .33

6 Process control and safety systems .33

6.1 General .33

6.2 Emergency shutdown functionality .34

6.3 Manually actuated emergency stop devices .35

6.4 Remote system control .35

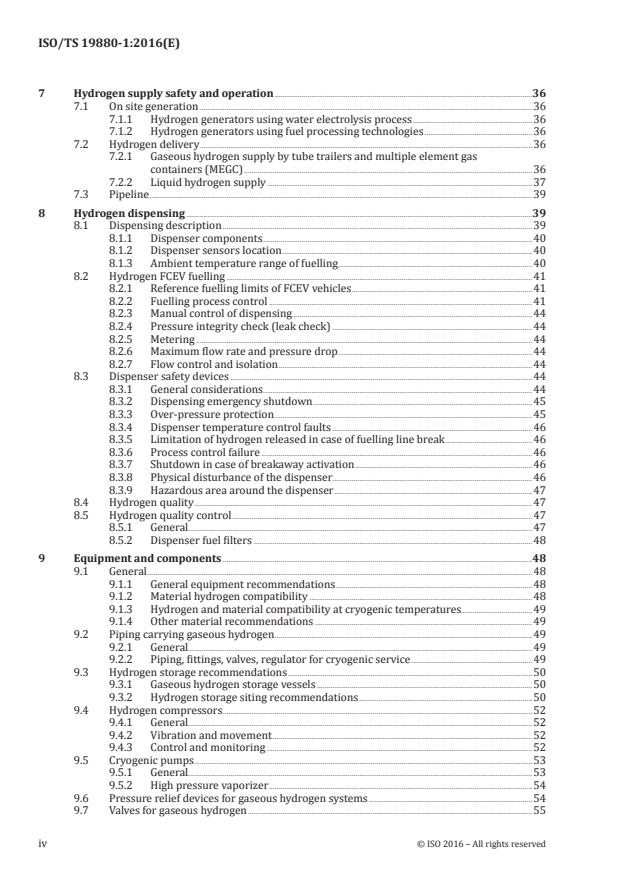

7 Hydrogen supply safety and operation .36

7.1 On site generation .36

7.1.1 Hydrogen generators using water electrolysis process .36

7.1.2 Hydrogen generators using fuel processing technologies .36

7.2 Hydrogen delivery .36

7.2.1 Gaseous hydrogen supply by tube trailers and multiple element gas

containers (MEGC) .36

7.2.2 Liquid hydrogen supply .37

7.3 Pipeline .39

8 Hydrogen dispensing .39

8.1 Dispensing description .39

8.1.1 Dispenser components .40

8.1.2 Dispenser sensors location .40

8.1.3 Ambient temperature range of fuelling .40

8.2 Hydrogen FCEV fuelling .41

8.2.1 Reference fuelling limits of FCEV vehicles .41

8.2.2 Fuelling process control .41

8.2.3 Manual control of dispensing.44

8.2.4 Pressure integrity check (leak check) .44

8.2.5 Metering .44

8.2.6 Maximum flow rate and pressure drop .44

8.2.7 Flow control and isolation .44

8.3 Dispenser safety devices .44

8.3.1 General considerations .44

8.3.2 Dispensing emergency shutdown .45

8.3.3 Over-pressure protection .45

8.3.4 Dispenser temperature control faults .46

8.3.5 Limitation of hydrogen released in case of fuelling line break .46

8.3.6 Process control failure .46

8.3.7 Shutdown in case of breakaway activation .46

8.3.8 Physical disturbance of the dispenser .46

8.3.9 Hazardous area around the dispenser .47

8.4 Hydrogen quality .47

8.5 Hydrogen quality control .47

8.5.1 General.47

8.5.2 Dispenser fuel filters .48

9 Equipment and components .48

9.1 General .48

9.1.1 General equipment recommendations .48

9.1.2 Material hydrogen compatibility .48

9.1.3 Hydrogen and material compatibility at cryogenic temperatures.49

9.1.4 Other material recommendations .49

9.2 Piping carrying gaseous hydrogen .49

9.2.1 General.49

9.2.2 Piping, fittings, valves, regulator for cryogenic service .49

9.3 Hydrogen storage recommendations .50

9.3.1 Gaseous hydrogen storage vessels .50

9.3.2 Hydrogen storage siting recommendations .50

9.4 Hydrogen compressors .52

9.4.1 General.52

9.4.2 Vibration and movement .52

9.4.3 Control and monitoring .52

9.5 Cryogenic pumps .53

9.5.1 General.53

9.5.2 High pressure vaporizer .54

9.6 Pressure relief devices for gaseous hydrogen systems .54

9.7 Valves for gaseous hydrogen .55

iv © ISO 2016 – All rights reserved

9.8 Instruments for gaseous hydrogen .55

9.9 Filters for gaseous hydrogen .55

9.10 Dispensers .56

9.10.1 Location and protection of dispensers .56

9.10.2 Fuelling pad .56

9.10.3 Dispenser system design .56

9.10.4 Dispenser fuelling assembly .58

9.11 Hose assembly .60

9.11.1 Rated operating conditions .60

9.11.2 Hose assembly design .60

9.11.3 Hose assembly type testing and production testing .60

9.11.4 Venting hose assembly . .60

9.12 Fuelling connector (nozzle) general design and assembly .61

9.12.1 General design and assembly .61

9.12.2 Depressurization of nozzles .61

9.13 Hose breakaway device general design and assembly .61

9.13.1 Rated operating conditions .61

9.13.2 Breakaway durability .61

9.14 Gaseous hydrogen vent systems .61

9.14.1 General.61

9.14.2 Piping design .61

9.14.3 Flame arrestors .62

9.14.4 Vent outlet .62

9.14.5 Maximum flow rate calculation .62

9.14.6 Piping diameter and exit velocity .63

9.14.7 Maximum pressure drop .63

9.15 Pneumatics .63

9.16 Hydrogen purifier .63

10 Electrical safety .64

10.1 General .64

10.1.1 Overview of electrical hazards.64

10.1.2 Components .65

10.1.3 Site interconnections to and/or between equipment assemblies .65

10.1.4 Electrical grounding .65

10.1.5 Lightning protection .65

10.2 Hazardous areas (potentially explosive atmospheres) .66

10.2.1 General.66

10.2.2 Protection requirements for electrical equipment within hazardous

(classified) areas .66

10.2.3 Other equipment in hazardous (classified) areas .67

10.2.4 Areas adjacent to hazardous areas .67

10.2.5 Protection from ignition due to accumulation of static charge .67

10.3 Electromagnetic compatibility and interference (EMC) .68

10.3.1 General.68

10.3.2 Industrial (EMC) environments .68

10.3.3 Residential, commercial, and light-industrial (EMC) environments.68

11 Markings .69

11.1 General .69

11.2 Warning signs .69

11.3 Functional identification .70

11.4 Marking of equipment (data plate) .70

11.5 Reference designations .71

11.6 Emergency contact information .71

12 Technical documentation .72

12.1 General .72

12.2 Information to be provided .72

12.3 Recommendations applicable to all documentation .73

12.4 Installation documents .73

12.4.1 General.73

12.4.2 Installation documentation for hazardous (classified) areas .74

12.4.3 Venting .74

12.4.4 Seismic documentation .74

12.4.5 Handling and lifting documentation .75

12.5 Overview diagrams and function diagrams .75

12.6 Circuit diagrams .75

12.7 Flow (P&ID) diagrams .75

12.8 Fuelling station operating manual .76

12.9 Hydrogen fuelling station dispenser operation instructions .76

12.10 Maintenance manual .76

12.11 Service manual .76

12.12 Parts list .76

12.13 Technical file .77

13 Station inspection and tests .77

13.1 General .77

13.2 Minimum hydrogen fuelling station acceptance inspection .78

13.2.1 General.78

13.2.2 Minimum hydrogen fuelling station acceptance testing .78

13.2.3 Pressure test .79

13.2.4 Leak test .79

13.2.5 Electrical testing .80

13.2.6 Communications test .81

13.2.7 Safety and performance functional testing of the hydrogen fueling station .81

13.3 Minimum periodic hydrogen fuelling station inspection and test .82

Annex A (informative) Safety distances definition and basic principles .87

Annex B (informative) Proposal for hydrogen fuelling verification of the SAE J2601

fuelling protocol .93

Annex C (informative) Example matrices for guidance for hydrogen quality control .104

Annex D (informative) Pressure level definitions for the compressed hydrogen storage

system and fuelling station dispensers.112

Annex E (informative) Examples of vehicular impact protection measures .113

Bibliography .115

vi © ISO 2016 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the World Trade Organization (WTO)

principles in the Technical Barriers to Trade (TBT) see the following URL: Foreword – Supplementary

information.

The committee responsible for this document is ISO/TC 197, Hydrogen technologies.

ISO/TS 19880-1 has been prepared with the ultimate goal of developing an International Standard and

it replaces ISO/TS 20100:2008, on the same subject, which was withdrawn in 2015.

A list of all parts in the ISO 19880 series can be found on the ISO website.

viii © ISO 2016 – All rights reserved

TECHNICAL SPECIFICATION ISO/TS 19880-1:2016(E)

Gaseous hydrogen — Fuelling stations —

Part 1:

General requirements

1 Scope

This document recommends the minimum design characteristics for safety and, where appropriate,

for performance of public and non-public fuelling stations that dispense gaseous hydrogen to light duty

land vehicles (e.g. Fuel Cell Electric Vehicles).

NOTE These recommendations are in addition to applicable national regulations and codes, which can

prohibit certain aspects of this document.

This document is applicable to fuelling for light duty hydrogen land vehicles, but it can also be used as

guidance for fuelling buses, trams, motorcycles and fork-lift truck applications, with hydrogen storage

capacities outside of current published fuelling protocol standards, such as SAE J2601.

Residential applications to fuel land vehicles and non-public demonstration fuelling stations are not

included in this Technical Specification.

This Technical Specification provides guidance on the following elements of a fuelling station (see

Figure 1 and Figure 2):

— hydrogen production/delivery system

— delivery of hydrogen by pipeline, trucked in gaseous and/or liquid hydrogen, or metal hydride

storage trailers;

— on-site hydrogen generators using water electrolysis process or hydrogen generators using fuel

processing technologies;

— liquid hydrogen storage;

— hydrogen purification systems, as applicable;

— compression

— gaseous hydrogen compression;

— pumps and vaporizers;

— gaseous hydrogen buffer storage;

— pre-cooling device;

— gaseous hydrogen dispensers.

Figure 1 — Example of typical elements in a hydrogen fuelling station, including the

hydrogen supply

Figure 2 — Image of an example hydrogen fuelling station

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

There are no normative references in this document.

2 © ISO 2016 – All rights reserved

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1

accessory

device with an operational function

3.2

authority having jurisdiction

AHJ

organization, office or individual responsible for approving a facility along with an equipment, an

installation or a procedure

3.3

bleed venting

expiration or inspiration of air or gas from, or to, one side of a diaphragm of any accessory, component,

or equipment such as a valve, pressure regulator or switch

3.4

breakaway device

device installed on a dispensing hose that separates when a given pull force is applied and closes the flow

of hydrogen to prevent gas leakage and protect the dispenser from damage from vehicles driving away

3.5

buffer storage tanks

pressurized tanks, which can be located between a hydrogen generator and a compressor for an even

flow of gas to the compressor or between the compressor and dispenser for accumulation of pressurized

gas supply for vehicle fuelling

3.6

control system

system which responds to input signals from the process and/or from an operator and generates output

signals causing the process to operate in the desired manner

Note 1 to entry: A separate safety instrumented system (SIS), typically with a greater reliability than the more

basic process control system (BPCS), may be required, according to the manufacturer’s risk assessment, to

respond solely to safety critical alarms. Further information is provided in IEC 61508 and 61511.

3.7

connector

joined assembly of nozzle and receptacle which permits the transfer of hydrogen

[SOURCE: ISO 17268:2012, 3.1]

3.8

dispenser

parts of the pressurised-gas fuelling station via which the pressurised gas is dispensed to vehicles

Note 1 to entry: As an example, the dispenser may include a dispenser cabinet, gas flow meter, a fueling hose and

fueling nozzle attachments.

3.9

dispenser cabinet

protective housing that encloses process piping and may also enclose measurement, control and

ancillary dispenser equipment

3.10

dispensing system

system comprising all equipment necessary to carry out the vehicle fuelling operation, downstream of

the hydrogen supply system

3.11

enclosure

protective housing that may enclose, or partially enclose, equipment in order to protect it from the

environment, provide noise attenuation, or provide safety to the areas surrounding the equipment

3.12

frequency

rate of occurrence of events, e.g., how many time the event occurs in a specified time or number of

opportunities

3.13

fail-safe

design feature that ensures that safe operating conditions are maintained in the event of a malfunction

of control devices or an interruption of a supply source

3.14

fitting

connector used to join any pressure retaining components in the system

3.15

forecourt

surfaced area where vehicle dispensing operations are conducted including the fuelling pad and any

area underneath a canopy

3.16

fuel temperature

temperature of the hydrogen fuel, measured less than 1 m upstream of the dispenser hose breakaway

3.17

fuelling assembly

part of the dispenser providing the interface between the hydrogen fuelling station and the vehicle

- an assembly consisting of a breakaway device, a hose(s), a nozzle and connectors between these

components

3.18

fuelling hose

flexible conduit used for dispensing gaseous hydrogen to vehicles through a fuelling nozzle

3.19

fuelling pad

area adjacent to the hydrogen dispensers, where customers park their vehicles for fuelling

3.20

fuelling station

facility for the dispensing of compressed hydrogen vehicle fuel, often referred to as a hydrogen fuelling

station (HRS) or hydrogen filling station, including the supply of hydrogen, and hydrogen compression,

storage and dispensing systems

3.21

standalone

independent facility for the dispensing of compressed hydrogen only

Note 1 to entry: This is a type of fuelling station (3.20).

4 © ISO 2016 – All rights reserved

3.22

integrated

facility for the dispensing of compressed hydrogen integrated into an existing, or new build,

conventional fuelling station

Note 1 to entry: This is a type of fuelling station (3.20).

3.23

fuelling station operator

person or organisation responsible for the safe operation, maintenance and housekeeping of the

fuelling station

3.24

guard

part of a machine specially used to provide protection by means of a physical barrier

Note 1 to entry: Depending on its construction, a guard may be called casing, cover, screen, door, enclosed

guard, etc.

3.25

harm

physical injury or damage to the health of people, or damage to property or the environment

[SOURCE: ISO/IEC Guide 51:2014, 3.1]

3.26

harmonised standard

European standard devel

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...