ISO/FDIS 13679

(Main)Petroleum and natural gas industries — Procedures for testing casing and tubing connections

Petroleum and natural gas industries — Procedures for testing casing and tubing connections

Industries du pétrole et du gaz naturel — Modes opératoires d'essai des connexions pour tubes de cuvelage et de production

General Information

- Status

- Withdrawn

- Technical Committee

- ISO/TC 67/SC 5 - Casing, tubing and drill pipe

- Current Stage

- 5098 - Project deleted

- Start Date

- 28-May-2018

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 12-Feb-2026

- Effective Date

- 15-Apr-2008

ISO/FDIS 13679 - Petroleum and natural gas industries -- Procedures for testing casing and tubing connections

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

ISO/FDIS 13679 is a draft published by the International Organization for Standardization (ISO). Its full title is "Petroleum and natural gas industries — Procedures for testing casing and tubing connections". This standard covers: Petroleum and natural gas industries — Procedures for testing casing and tubing connections

Petroleum and natural gas industries — Procedures for testing casing and tubing connections

ISO/FDIS 13679 is classified under the following ICS (International Classification for Standards) categories: 75.180.10 - Exploratory, drilling and extraction equipment; 75.200 - Petroleum products and natural gas handling equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/FDIS 13679 has the following relationships with other standards: It is inter standard links to FprEN ISO 13679, ISO 13679:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO/FDIS 13679 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

FINAL

INTERNATIONAL ISO/FDIS

DRAFT

STANDARD 13679

ISO/TC 67/SC 5

Petroleum and natural gas industries —

Secretariat: JISC

Procedures for testing casing and tubing

Voting begins on:

connections

2011-09-15

Voting terminates on:

Industries du pétrole et du gaz naturel — Modes opératoires d'essai des

2011-11-15

connexions pour tubes de cuvelage et de production

Please see the administrative notes on page iii

RECIPIENTS OF THIS DRAFT ARE INVITED TO

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPORT-

ING DOCUMENTATION.

IN ADDITION TO THEIR EVALUATION AS

Reference number

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO-

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN-

DARDS TO WHICH REFERENCE MAY BE MADE IN

©

ISO 2011

NATIONAL REGULATIONS.

Copyright notice

This ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user's country, neither this ISO draft nor any extract from it may be

reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic,

photocopying, recording or otherwise, without prior written permission being secured.

Requests for permission to reproduce should be addressed to either ISO at the address below or ISO's

member body in the country of the requester.

ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii © ISO 2011 – All rights reserved

ISO/CEN PARALLEL PROCESSING

This final draft has been developed within the International Organization for Standardization (ISO), and

processed under the ISO-lead mode of collaboration as defined in the Vienna Agreement. The final draft

was established on the basis of comments received during a parallel enquiry on the draft.

This final draft is hereby submitted to the ISO member bodies and to the CEN member bodies for a parallel

two-month approval vote in ISO and formal vote in CEN.

Positive votes shall not be accompanied by comments.

Negative votes shall be accompanied by the relevant technical reasons.

In accordance with the provisions of Council Resolution 15/1993, this document is circulated in the

English language only.

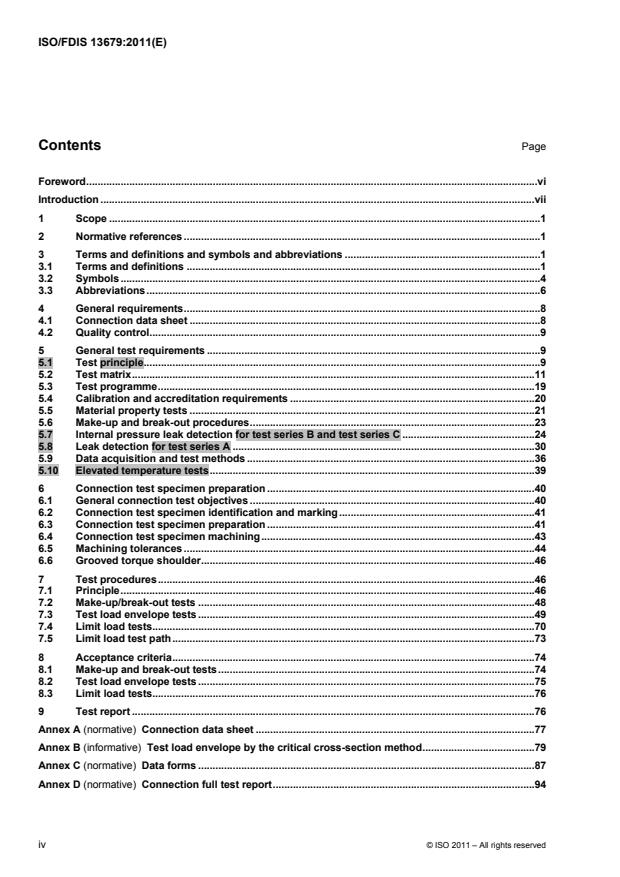

Contents Page

Forew ord .vi

Introduction .vii

1 Scope .1

2 Normative references .1

3 Terms and definitions and symbols and abbreviations .1

3.1 Terms and definitions .1

3.2 Symbols .4

3.3 Abbreviations .6

4 General requirements .8

4.1 Connection data sheet .8

4.2 Quality control .9

5 General test requirements .9

5.1 Test principle .9

5.2 Test matrix .11

5.3 Test programme .19

5.4 Calibration and accreditation requirements .20

5.5 Material property tests .21

5.6 Make-up and break-out procedures .23

5.7 Internal pressure leak detection for test series B and test series C .24

5.8 Leak detection for test series A .30

5.9 Data acquisition and test methods .36

5.10 Elevated temperature tests .39

6 Connection test specimen preparation .40

6.1 General connection test objectives .40

6.2 Connection test specimen identification and marking .41

6.3 Connection test specimen preparation .41

6.4 Connection test specimen machining .43

6.5 Machining tolerances .44

6.6 Grooved torque shoulder .46

7 Test procedures .46

7.1 Principle .46

7.2 Make-up/break-out tests .48

7.3 Test load envelope tests .49

7.4 Limit load tests .70

7.5 Limit load test path .73

8 Acceptance criteria .74

8.1 Make-up and break-out tests .74

8.2 Test load envelope tests .75

8.3 Limit load tests .76

9 Test report .76

Annex A (normative) Connection data sheet .77

Annex B (informative) Test load envelope by the critical cross-section method .79

Annex C (normative) Data forms .87

Annex D (normative) Connection full test report .94

iv © ISO 2011 – All rights reserved

Annex E (normative) Calculations for pipe body load envelope and examples of load schedules

for each test series . 98

Annex F (informative) Frame load range determination . 118

Annex G (informative) Connection product line qualification . 119

Annex H (informative) Special application testing . 126

Annex I (informative) Rationale for design basis. 132

Annex J (informative) Independent seal testing of connections with metal-to-metal and resilient

seals . 135

Annex K (informative) Summary of changes to ISO 13679:2002 as of April 2011 . 138

Bibliography . 143

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 13679 was prepared by Technical Committee ISO/TC 67, Materials, equipment and offshore structures

for petroleum, petrochemical and natural gas industries, Subcommittee SC 5, Casing, tubing and drill pipe.

This second edition cancels and replaces the first edition (ISO 13679:2002). Refer to Annex K for a listing of

the parts of this document that have been technically revised.

vi © ISO 2011 – All rights reserved

Introduction

This International Standard is part of a process to provide reliable tubing and casing connections for the oil

and natural gas industry which are fit for purpose. It has been developed based on improvements to

API RP 5C5 and proprietary test procedures, with input from leading users, manufacturers and testing

consultants from around the world. This International Standard represents the knowledge of many years of

testing and qualification experiences.

The validation of connection test load envelope and failure limit loads is relevant to design of tubing and

casing for the oil and natural gas industries. Tubing and casing are subject to loads which include internal

pressure, external pressure, axial tension, axial compression, bending torsion, transverse forces and

temperature changes. The magnitude and combination of these loads result in various pipe body and

connection failure modes. Although pipe body test and limit loads are well understood in general, the same

cannot be stated for the connection. These failure modes and loads are generally different and often less than

that of the pipe. Consequently, experimental validation is required.

The validation of test and limit loads requires testing at the extremes of performance parameters to these

defined loads. Testing at the extremes of the performance parameters assures that the production population

that falls within these limits meets or exceeds the performance of the test population. Thread connection

performance parameters include dimensional tolerances, mechanical properties, surface treatment, make-up

torque and the type and amount of thread compound. For typical proprietary connections, worst-case

tolerances are known and defined in this International Standard. For other connections designs, analysis is

required to define worst-case tolerance combinations.

It is necessary that users of this International Standard be aware that further or differing requirements can be

needed for individual applications. This International Standard is not intended to inhibit a vendor from offering,

or a purchaser from accepting, alternate equipment or engineering solutions for the individual application. This

is particularly applicable when there is innovative or developing technology. Where an alternative is offered, it

is the responsibility of the vendor to identify any variations from this International Standard and provide details.

This International Standard consists of the following major parts. Based on manufacturer's supplied data

specified in Annex A and/or calculations in Annex B, tests are conducted in accordance with Clauses 4 to 8

and reported on the data forms given in Annex C. Annex D lists all the information that it is necessary to

provide in the full test report. Annex E provides methodology for calculating and examples of pipe body load

envelopes, the test load envelope and the test load points. Annex F gives an example of a load frame

calibration. Annex G gives considerations for possible connection product line qualifications. Annex H

provides guidelines for supplemental tests that can be used for special applications. Annex I gives the design

rationale for this International Standard. Annex J gives requirements for connections that contain both a metal-

to-metal seal and a resilient seal that are tested separately. Annex K is a summary of changes to

ISO 13679:2002.

For specific applications that are not evaluated by the tests herein, supplementary tests can be appropriate. It

is necessary that the user and manufacturer discuss well applications and limitations of the connection being

considered.

Representatives of users and/or other third party personnel are encouraged to monitor the tests. ISO 13679

covers the testing of connections for the most commonly encountered well conditions. Not all possible service

scenarios are included. For example, the presence of a corrosive fluid, which can influence the service

performance of a connection, is not considered.

This International Standard includes various provisions. These are identified by the use of certain verbal

forms:

SHALL is used to indicate requirements that strictly need to be followed in order to conform to this

International Standard and from which no deviation is permitted.

SHOULD is used to indicate that among several possibilities one is recommended as particularly suitable,

without mentioning or excluding others, or that a certain course of action is preferred but not necessarily

required, or that (in the negative form) a certain possibility or course of action is deprecated but not

prohibited.

MAY is used to indicate a course of action permissible within the limits of the document.

CAN is used to indicate statements of possibility and capability, whether material, physical or causal.

In addition, for Standard International (SI) units, the thousands separator is a space and the decimal separator

is a comma. For United States Customary (USC) units, the thousands separator is a comma and the decimal

separator is a period.

The “Highlighting in gray change-identification system” and the “Summary of changes” shown in informative

Annex K identify sections of this document where committee-agreed changes (additions, modifications, and/or

deletions) affecting the performance of the product(s) or the technical requirement(s) applicable to the

product(s) have been made from the previous edition of this International Standard. While efforts have been

made to ensure the accuracy and consistency of the application of the change-identification system, the user

of this International Standard is both encouraged to consider the totality of the technical content of this

International Standard rather than those changes identified, and is ultimately responsible for recognizing any

differences between this and previous editions of the International Standard.

ISO/CS expressly disclaims any liability or responsibility for loss or damage resulting from inappropriate use of

this International Standard based on inaccuracy of the “change-identification” system.

viii © ISO 2011 – All rights reserved

FINAL DRAFT INTERNATIONAL STANDARD ISO/FDIS 13679:2011(E)

Petroleum and natural gas industries — Procedures for testing

casing and tubing connections

1 Scope

This International Standard specifies tests to perform to determine the galling tendency, sealing performance

and structural integrity of casing and tubing connections. The words “casing” and “tubing” apply to the service

application and not to the diameter of the pipe.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 3183, Petroleum and natural gas industries — Steel pipe for pipeline transportation systems

ISO/TR 10400:2007, Petroleum and natural gas industries — Equations and calculations for the properties of

casing, tubing, drill pipe and line pipe used as casing or tubing

ISO 11960, Petroleum and natural gas industries — Steel pipes for use as casing or tubing for wells

ISO 13680, Petroleum and natural gas industries — Corrosion-resistant alloy seamless tubes for use as

casing, tubing and coupling stock — Technical delivery conditions

API TR 5C3, Technical report on equations and calculations for casing, tubing, and line pipe used as casing or

tubing; and performance properties tables for casing and tubing)

ANSI/API Spec 5L, Specification for Line Pipe

3 Terms and definitions and symbols and abbreviations

3.1 Terms and definitions

For the purposes of this document, the following terms, definitions, symbols and abbreviated terms apply.

3.1.1

100 % pipe body load envelope

diagram containing the extremes of pipe body performance based on actual properties

NOTE Pipe body performance is also known as VME yield. See ISO/TR 10400 (API TR 5C3) for collapse.

3.1.2

ambient temperature

actual current temperature of the test lab environment at the time of testing

3.1.3

axial-pressure load diagram

plot of axial load versus pressure showing pipe and/or connection test load envelope or limit load extremes

3.1.4

connection

one pin and its adjoining coupling side or integral box

3.1.5

connection leak

leak that occurs across a connection.

NOTE See 8.2 for pressure sealing acceptance criteria.

3.1.6

diametrical interference

outer diameter of the inner member minus the inner diameter of the outer member

3.1.7

failure load

load at which the pipe body or connection fails catastrophically as in an axial separation, a rupture, large

permanent deformation (e.g. buckling or collapse) or loss of sealing integrity

3.1.8

galling

form of surface damage resulting from cold welding of contacting material surfaces followed by tearing of the

metal during further sliding/rotation

NOTE There are several degrees of galling used for repair and reporting purposes as defined in 8.1.

3.1.9

interference

amount of geometric overlap of mating members created by the design and tolerances of the members

3.1.10

leak

leakage

passage of contained test medium outside of the containment space whether in the equipment or the

connection

3.1.11

light galling

galling that can be repaired by the use of abrasive paper

3.1.12

limit load

load combination extreme (axial load and/or pressure) that defines the failure conditions for the connection or

load combination resulting in large permanent deformation (such as buckling) prior to catastrophic failure

3.1.13

lot

lengths of pipe with the same specified dimensions and grade from the same heat of steel that are

heat-treated as part of a continuous operation (or batch)

3.1.14

material test coupon

cylinder of material from the tested pipe and/or coupling stock from which tensile test specimens are cut

3.1.15

metal-to-metal seal

seal or sealing system that relies on intimate and usually high contact stress of mating metal surfaces to

achieve a seal

NOTE The thread compound can affect, both beneficially and detrimentally, the performance of a metal seal.

2 © ISO 2011 – All rights reserved

3.1.16

moderate galling

galling that can be repaired by the use of fine files and abrasive paper

3.1.17

mother joint

length of pipe or coupling stock from which short lengths are cut for machining connection test specimens

3.1.18

multiple seal

sealing system having more than one independent barrier, with each barrier forming a seal

3.1.19

pipe string

pipe body and the connection

3.1.20

pup joint

short pipe length usually with threaded ends

3.1.21

resilient seal

seal or sealing system that relies on entrapment of a seal ring within a machined groove in the connection (e.g.

in the thread-form, on a seal area, etc.) to achieve a seal

3.1.22

seal

pressure barrier to prevent the passage of the test medium

3.1.23

seal ovality

maximum seal diameter minus the minimum seal diameter divided by the average seal diameter multiplied

by 100

NOTE Seal ovality shall be reported as a percentage.

3.1.24

severe galling

galling that cannot be repaired by the use of fine files and abrasive paper

3.1.25

single seal

one barrier or multiple barriers that cannot be physically differentiated in their function

3.1.26

specimen

two connections with a shared coupling or one integral connection

3.1.27

test load envelope

extremes of loads (axial load, pressure, bending) based on actual measured mechanical properties and

dimension of the specimen for a specific temperature to which the connection has been or will be tested in

accordance with this International Standard

3.1.28

thread lot

all products manufactured on a given machine during a continuous production cycle that is not interrupted by

a catastrophic tool failure or injurious machine malfunction (excluding worn tools or minor tool breakage), tool

holder change (except rough boring bar) or any other malfunction of either threading equipment or inspection

gauges

3.1.29

thread seal

seal or sealing system that relies on intimate fitting of the thread-form and usually entrapment of the thread

compound within the thread-form to achieve a seal

3.1.30

VME stress

equivalent stress based on the von Mises-Hencky minimum distortion energy criterion

3.2 Symbols

a

A cycles in test series A at ambient temperature using gas for internal pressure and liquid for external

pressure. For CAL I-E, either gas or liquid shall be used.

e

A cycles in test series A at 180 °C (356 °F) for CAL III and CAL IV using gas for internal pressure and

liquid for external pressure

a

B cycles in test series B, without bending, at ambient temperature with gas for CAL II through CAL IV;

with gas or water for CAL I-E; with water for CAL I

a

B cycles in test series B, with bending, at ambient temperature with gas for CAL II through CAL IV; with

b

gas or water for CAL I-E; with water for CAL I

e

B cycles in test series B, with bending, at 180 °C (356 °F) using gas for CAL III-Ambient A, CAL III, and

b

CAL IV; at 135 °C (275 °F) for CAL II using gas

C compressive axial force

D specified pipe outside diameter or measured average outside diameter of a specimen used for axial

load or pressure load

D inside diameter

i

D outside diameter

o

D effective dogleg severity, expressed in degrees per thirty metres

leg

d maximum pipe D

wall i

E error in load frame calibration

r

E error in load frame calibration, expressed in percent

rp

F failure

F total axial force, tension or compression (sum of applied loads: F , F , F )

a b i CEPL

F bending equivalent axial force

b

F test load envelope compression load at 0 pressure (uniaxial compression)

c

F capped-end pressure load acting on the connection

CEPL

F actual load frame axial force, tension or compression

f

F indicated load frame axial force, tension or compression

i

F 95 % of pipe body tension or compression yield load at 0 pressure (uniaxial load)

p

4 © ISO 2011 – All rights reserved

F TLE tension load at 0 pressure (uniaxial tension)

t

F specified minimum material yield strength

ymn

I moment of inertia

I maximum design interference between thread or seal members, resulting from pin and box diameter

max

specification and tolerances

I minimum design interference between thread or seal members, resulting from pin and box diameter

min

specification and tolerances

I range of design interference between thread or seal members, equal to I minus I

range max min

k , k geometric variable

i o

K minimum of (t /t) or 0,95

wall ac

p collapse rating for specified OD, specified wall thickness and specified specimen yield strength (see

c

ISO/TR 10400:2007,Clause 8)

P TLE pressure at 0 axial load (uniaxial internal pressure)

d

p internal pressure

i

p internal pressure with bending

ib

p high internal pressure

ih

p normalized internal test pressure

in

p low internal pressure

il

p external pressure

o

p external pressure with bending

ob

p normalized external test pressure

on

q actual leak rate to be reported

ac

q maximum connection leak rate that is acceptable during a test hold period

max

q observed leak rate

o

R radius of curvature of the pipe body at the axis of the pipe

t specified pipe wall thickness

t minimum measured wall thickness

ac

t average measured wall for the specimen used for axial load calculations

ave

T tension axial force

leak detection system efficiency

lds

stress

axial stress without bending

a

axial stress with bending

ab

axial stress due to bending

b

axial compressive yield strength if available or otherwise axial tensile yield strength

c

actual measured minimum yield strength of the specimen or the source mother tube

e

hoop (tangential) stress

h

hoop (tangential) stress at outside diameter

ho

radial (normal) stress

r

radial (normal) stress at outside diameter

ro

transverse tensile yield strength if available or otherwise axial tensile yield strength

t

defined transverse compressive yield strength if available or otherwise axial tensile yield strength

tc

von Mises equivalent stress

v

axial tensile yield strength

y

3.3 Abbreviations

A connection A end

B connection B end

AMYS actual minimum yield strength

CAL connection assessment level

CCS critical cross-section

CCW counter-clockwise direction around the test load envelope

cm /min cubic centimetres per minute

cm /s cubic centimetres per second

CW clockwise direction around the test load envelope

CEPL capped end pressure load (tension) at the designated pressure

CEYP capped end yield pressure

CRA corrosion-resistant alloy

EUE external upset end

FEA finite element analysis

FMU final make-up specimen condition

H high thread or seal interference range

H/H maximum specified amount of thread compound / maximum specified torque value in Figures 1 to 6;

and maximum thread interference / maximum seal interference

H/L maximum specified amount of thread compound / minimum specified torque value and in Figures 1

to 6; maximum thread interference / minimum seal interference

IJ integral joint

kN kiloNewton

6 © ISO 2011 – All rights reserved

kips 1 000 pound-force

ksi 1 000 pound-force per square inch

lb pound-force

L low thread or seal interference range

L/H minimum specified amount of thread compound / maximum specified torque value

LL limit load

LL1 limit load test path 1

LL2 limit load test path 2

LL3 limit load test path 3

LL4 limit load test path 4

LL5 limit load test path 5

LP load point

M/B make-up/break-out

MBG make-up/break-out galling test specimen condition

MC mechanical cycle

MPa megapascal

MT material test coupon

MTC metal seal threaded and coupled connection

MTM metal-to-metal seal

MU make-up

OCTG oil country tubular goods

PBVME pipe body von Mises envelope

PBY pipe body yield

PEL pressure end load

psi pound-force per square inch

psig pound-force per square inch gauge

PF-BS pin fast taper - box slow taper

PS-BF pin slow taper - box fast taper

PTFE polytetrafluoroethylene

r/min revolutions per minute

RS resilient seal

SMYS specified minimum yield strength

SRG seal ring groove

Std standard

TC thermal cycle

TLE test load envelope

TS-A test series A

TS-B test series B

TS-C test series C

TSC thread sealing connection

T&C threaded and coupled

VME von Mises equivalent stress

XH extreme maximum high thread or seal interference range

XL extreme minimum low thread or seal interference range

4 General requirements

4.1 Connection data sheet

Prior to beginning a test, the manufacturer shall provide a connection data sheet for the product stating its

intended connection assessment level, its geometry, and claimed performance properties in terms of tension,

compression, internal pressure, external pressure, bending, and torque (see Table A.1 for the connection data

sheet). The manufacturer shall provide a drawing, which is representative of the cross-sectional area of the

connection. The manufacturer shall also provide the following in graphical form (VME plot): 100 % pipe body

load envelope, 95 % pipe body load envelope (or as otherwise agreed to between user and manufacturer),

and claimed test load envelope and should quantify limit loads (see 7.4 and 7.5). The manufacturer's own

method of calculation should be used to derive the claimed test load envelope and to calculate the test loads.

Performance data or the method described in Annex B may be used.

Annex B has been provided as a means by which a manufacturer or user may estimate the test load envelope

using a connection performance model based on capacities of specific critical cross-sections in the connection.

The manufacturer should define as completely as possible the limit loads for each connection. A user may

also make an independent estimate of the limit loads. Limit loads shall be greater than the test load envelope.

It is critical that the combined load capacity described by the test load envelope be defined near and

throughout the conditions where the dominant load sensitivity of the connection can change from pressure to

axial force and/or bending or vice versa.

Since casing and tubing connection designs and the resultant performance can vary widely, no overall

requirement for the minimum number of values in a tabular data format can be mandated. However, it is

expected that approximately 10 combined load values of pressure and axial force per quadrant should be

sufficient to define the test and limit loads. If a connection design exhibits changes in load sensitivities, the

loads at which the changes in load sensitivity occur shall be provided.

In the calculation of both pipe body and connection load capacities, it is the intent of this International

Standard to test the specimens to as high a load or combination of loads as safely practical.

In the event that unanticipated events result in deviations to the detailed requirements and or procedures,

such deviations shall be clearly identified in the documentation and test report.

8 © ISO 2011 – All rights reserved

4.2 Quality control

All quality control procedures for the manufacturing of test specimens shall be documented and shall be

consistent with procedures used for connections manufactured for well service. The connection manufacturer

shall ensure that the connections manufactured for the purpose of these design verification tests are of the

same design and manufactured to the same dimensions and extremes of tolerances (see 6.5) as those

supplied for well service. The connection manufacturer shall issue a declaration of conformity (see

ISO/IEC Guide 22 for an example). The manufacturer shall provide the process control plan. This process

control plan shall include the product drawing number(s) and associated revision level(s) as well as the

procedure number and the associated revision levels for all applicable sub-tier documents (manufacturing,

gauge calibration, gauging procedure, surface treatment, thread compound [type and quantity, or other

amount indicators], make-up procedures, etc.). These procedures and any others determined necessary to

provide a consistent product for well service shall be used during manufacturing of all test specimens

(see A.4).

5 General test requirements

5.1 Test principle

5.1.1 Overview

Connection performance data are generated by testing. Passing the tests demonstrates conformance of the

connection to a specified level of assessment. Test failures can result in a revision of the connection design or

a revision of the test loads or limit loads. In the first case (connection redesign), the testing shall be repeated.

In the second case (test load revision), the individual test specimens shall be retested unless the tests

conform to the revised performance envelope.

Six test programmes, known as connection assessment levels (CAL), are presented. The increasingly

arduous test programs are developed to provide means to assess connection performance to satisfy the

variety of service requirements that have been driven by well design. These test programs increase in rigor by

increasing the number of test parameters and test specimens.

The test programmes do not include all possible service scenarios. For example, the presence of a corrosive

fluid that can influence the service performance of a connection is not considered and is beyond the scope of

this International Standard.

The user of this International Standard shall specify the connection assessment level required based on the

requirements for the particular service intended. Users of the connection should be familiar with the defined

connection test rigor, the performance limits and limit loads. The connection assessment levels (CAL) are

defined as follows:

a) Connection assessment level IV (5 specimens) — most testing rigor

CAL IV is the most rigorous test plan. CAL IV test matrix exposes the connection to cyclical test loads

including internal pressure, external pressure, tension, compression and bending at ambient and elevated

temperature. CAL IV test conditions subject the connection to extensive thermal cycling, with

approximately 83 h of cumulative exposure to gas loading conditions at an elevated temperature of

180 °C (356 °F). Limit load tests are performed to failure in three quadrants of the axial-pressure load

diagram.

b) Connection assessment level III (5 specimens) — significant testing rigor

CAL III is a rigorous test plan of significance. As with CAL IV, CAL III test matrix exposes the connection

to cyclical test loads including internal pressure, external pressure, tension, compression and bending at

ambient and elevated temperature. CAL III test conditions subject connections to less severe thermal

cycling levels than CAL IV. Elevated temperature requirements are maintained at 180 °C (356 °F);

however, cumulative exposure time is reduced to approximately 45 h. Limit loads tests are performed in

quadrant I on two separate specimens.

c) Connection assessment level III-Ambient A (5 specimens) — less significant testing rigor

CAL III-Ambient A is a less significant testing plan than CAL III. As with CAL III, CAL III-Ambient A test

matrix exposes the connection to cyclical test loads including internal pressure, external pressure, tension,

compression and bending at ambient and elevated temperature; however, external pressure testing is

conducted only at ambient temperature. Elevated temperature requirements are maintained at 180 °C

(356 °F); however, cumulative exposure time is reduced to approximately 34 h. Limit loads tests are

performed in quadrant I on two separate specimens.

d) Connection assessment level II (3 specimens) — moderate testing rigor

CAL II is a moderate rigor test plan. The CAL II test matrix exposes the connection to cyclical test loads

including internal pressure, tension, compression and bending at ambient and elevated temperature.

External pressure is evaluated only at ambient temperature and has a reduced number of cycles. Internal

pressure testing temperatures are limited to 135 °C (275 °F). Connection test samples are subjected to

elevated temperature testing conditions for approximately 16 h. A limit load test is performed in quadrant I

on one specimen.

e) Connection assessment level I-E (2 specimens) — less testing rigor

CAL I-E is a reduced rigor test plan that may utilize liquid or gas as an internal pressurization medium. All

testing is conducted at ambient temperature with one test specimen exposed to internal pressure testing

under tension and compression loading and bending. External pressure is evaluated at ambient

temperature and has a reduced number of cycles. Limit load test is performed in quadrant I on one

specimen.

f) Connection assessment level I (2 specimens) — least testing rigor

CAL I is the least rigorous test. CAL I exposes the connection to internal pressure testing performed with

liquid under tension and compression loading at ambient temperature. External pressure loading and

bending are not included. The limit load test is performed in quadrant I on one specimen.

5.1.2 Previous tests

Connections previously tested to prior versions of this International Standard shall retain the CAL test class to

which they were successfully tested. The test protocol used and the date of the test protocol used shall be

stated in the test report. See Annex D for reporting format.

Connection test data obtained from tests performed prior to the establishment of this International Standard

may also be used as part of a design verification process or application test sequence, provided that parties to

agreements based on this International Standard can agree such tests were substantially conducted to the

technical and documentation requirements of this International Standard and that they give comparable

results.

5.1.3 Abbreviated tests and deviations

Some of the tests herein, rather than the complete test programme, may be adequate to verify suitability for

specific applications when experience and related test data, for example on other sizes, are available.

Deviations to the tests specified herein are acceptable, provided

a) the planned deviations are clearly documented in advance;

b) there is clear agreement between the parties involved;

c) the deviations are clearly identified in the full test report.

A discussion of product line qualification and use of interpolation and extrapolation considerations is provided

in Annex G. More stringent acceptance requirements, sensitivity requirements and/or more extended

informative data may be agreed by the user and manufacturer.

10 © ISO 2011 – All rights reserved

5.2 Test matrix

Table 1 shows a matrix relating the connection assessment level to the relevant total number of test

specimens, their identification numbers and the relevant tests. Figures 1 to 6 are a summary of the each CAL

test programme and should be read and followed from the top down. When testing multiple specimens in

series, the applied test loads shall be determined using the lowest strength specimen.

Table 1 — Test matrix — Test series and specimen identification numbers

Series A Series B Series C

Internal test

4 quadrants 2 quadrants Thermal cycling

Bake and pressure

Connection

with with

elevated medium

Thermal/pressure and tension

assessment

mechanical mechanical

temperature

cycling

level

cycles cycles

tests (external is

(see 7.3.5)

liquid)

(see 7.3.3) (see 7.3.4)

Bending required

At ambient and

10 thermal with pressure/tension

at ambient and

IV elevated

elevated

5 mechanical cycles at ≤ 35 °C (95 °F)

temperature

temperatures

180 °C (356 °F) Gas

Total number of

Specimens Specimens

Specimens

specimens

1,2,3,4

1, 2, 3, 4 1, 2, 3, 4

Bending required

At ambient and

10 thermal with pressure/tension

at ambient and

III elevated

elevated

5 mechanical cycles at ≤ 35 °C (95 °F)

temperature

temperatures

180 °C (356 °F) Gas

Total number of

Specimen

Specimens Specimens

specimens

1,2,3,4 1, 2

Bending required

10 thermal with pressure/tension

At ambient at ambient and

III-Ambient A

temperature elevated

5 mechanical cycles at ≤ 35 °C (95 °F) 180 °C (356 °F) Gas

temperatures

Total number of

Specimen

Specimens Specimens

specimens — —

1,2,3,4 1, 2

Bending required

At ambient

at ambient and

temperature

II

elevated

Not applicable

(reduced cycles)

temperature

135 °C (275 °F) Gas

Total number of

Specimen Specimens

specimens

1 1, 4

I-E At ambient

Bending required

temperature

at ambient

Bake-out not

temperature

(reduced cycles) required

Not applicable Gas or liquid

ambient

Specimen Specimen

Total number of

specimens 2

1 1

Bending n

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...