ISO 13705:2001

(Main)Petroleum and natural gas industries - Fired heaters for general refinery service

Petroleum and natural gas industries - Fired heaters for general refinery service

Industries du pétrole et du gaz naturel — Réchauffeurs à brûleurs pour usage général dans les raffineries

General Information

Relations

Frequently Asked Questions

ISO 13705:2001 is a standard published by the International Organization for Standardization (ISO). Its full title is "Petroleum and natural gas industries - Fired heaters for general refinery service". This standard covers: Petroleum and natural gas industries - Fired heaters for general refinery service

Petroleum and natural gas industries - Fired heaters for general refinery service

ISO 13705:2001 is classified under the following ICS (International Classification for Standards) categories: 75.180.20 - Processing equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 13705:2001 has the following relationships with other standards: It is inter standard links to ISO/R 64:1958, ISO 13705:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO 13705:2001 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 13705

First edition

2001-12-15

Petroleum and natural gas industries —

Fired heaters for general refinery service

Industries du pétrole et du gaz naturel — Réchauffeurs à brûleurs pour

usage général dans les raffineries

Reference number

©

ISO 2001

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this

file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this

area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2001

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's member body

in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

ii © ISO 2001 – All rights reserved

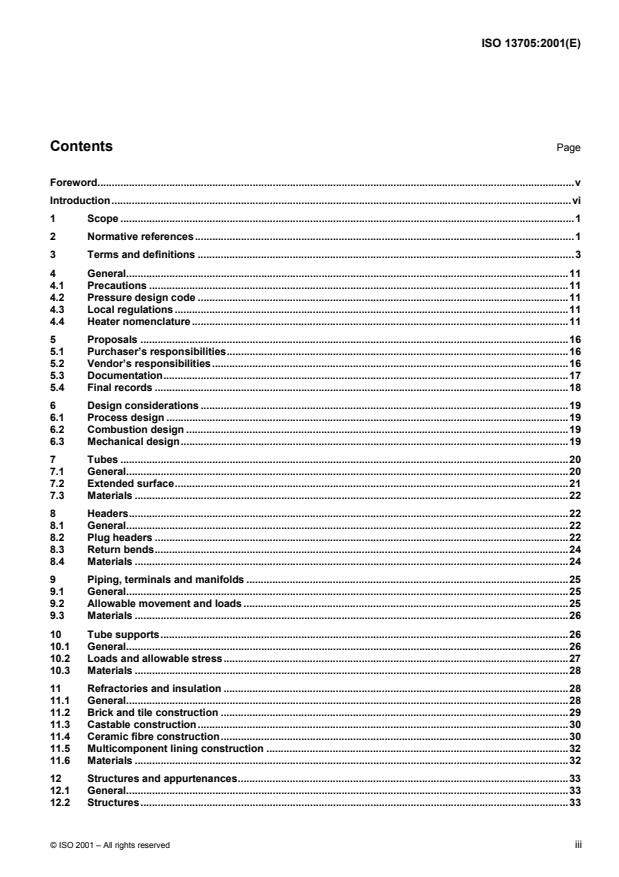

Contents Page

Foreword.v

Introduction.vi

1 Scope .1

2 Normative references.1

3 Terms and definitions .3

4 General.11

4.1 Precautions .11

4.2 Pressure design code .11

4.3 Local regulations .11

4.4 Heater nomenclature.11

5 Proposals .16

5.1 Purchaser’s responsibilities.16

5.2 Vendor’s responsibilities.16

5.3 Documentation.17

5.4 Final records .18

6 Design considerations .19

6.1 Process design .19

6.2 Combustion design .19

6.3 Mechanical design.19

7 Tubes .20

7.1 General.20

7.2 Extended surface.21

7.3 Materials .22

8 Headers.22

8.1 General.22

8.2 Plug headers .22

8.3 Return bends.24

8.4 Materials .24

9 Piping, terminals and manifolds .25

9.1 General.25

9.2 Allowable movement and loads .25

9.3 Materials .26

10 Tube supports.26

10.1 General.26

10.2 Loads and allowable stress.27

10.3 Materials .28

11 Refractories and insulation .28

11.1 General.28

11.2 Brick and tile construction .29

11.3 Castable construction.30

11.4 Ceramic fibre construction.30

11.5 Multicomponent lining construction .32

11.6 Materials .32

12 Structures and appurtenances.33

12.1 General.33

12.2 Structures.33

12.3 Header boxes, doors and ports.34

12.4 Ladders, platforms and stairways.34

12.5 Materials .35

13 Stacks, ducts and breeching.36

13.1 General.36

13.2 Design considerations .36

13.3 Design methods.38

13.4 Static design.38

13.5 Wind-induced vibration design .39

13.6 Materials .40

14 Burners and auxiliary equipment.40

14.1 Burners .40

14.2 Sootblowers .44

14.3 Fans and drivers .45

14.4 Dampers and damper controls.45

15 Instrument and auxiliary connections.46

15.1 Flue gas and air.46

15.2 Process fluid temperature .47

15.3 Auxiliary connections .47

15.4 Tube skin thermocouples .48

15.5 Access to connections.48

16 Shop fabrication and field erection.48

16.1 General.48

16.2 Structural steel fabrication .48

16.3 Coil fabrication.50

16.4 Painting and galvanizing.50

16.5 Refractories and insulation .51

16.6 Field erection.51

17 Inspection, examination and testing.52

17.1 General.52

17.2 Weld examination .52

17.3 Castings examination.53

17.4 Examination of other components.54

17.5 Testing .54

Annex A (informative) Equipment data sheets.56

Annex B (informative) Purchaser's checklist .85

Annex C (informative) Proposed shop assembly conditions .89

Annex D (normative) Stress curves for use in the design of tube support elements.91

Annex E (normative) Centrifugal fans for fired heater systems.107

Annex F (informative) Air preheat systems for fired process heaters.122

Annex G (informative) Measurement of thermal efficiency of fired process heaters .175

Annex H (informative) Stack design.222

Bibliography .232

iv © ISO 2001 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO

member bodies). The work of preparing International Standards is normally carried out through ISO technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

Draft International Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this International Standard may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

International Standard ISO 13705 was prepared by Technical Committee ISO/TC 67, Materials, equipment and

offshore structures for petroleum and natural gas industries, Subcommittee SC 6, Processing equipment and

systems.

Annexes D and E form a normative part of this International Standard. Annexes A, B, C, F, G and H are for

information only.

Introduction

This International Standard is based on API standard 560, second edition, September 1995.

Users of this International Standard should be aware that further or differing requirements may be needed for

individual applications. This International Standard is not intended to inhibit a vendor from offering, or the purchaser

from accepting, alternative equipment or engineering solutions for the individual application. This may be

particularly applicable where there is innovative or developing technology. Where an alternative is offered, the

vendor should identify any variations from this International Standard and provide details.

In International Standards, the SI system of units is used. Where practical in this International Standard, US

Customary units are included in brackets for information.

A bullet (zzzz) at the beginning of a clause or subclause indicates that either a decision is required or further

information is to be provided by the purchaser. This information should be indicated on data sheets (see examples

in annex A) or stated in the enquiry or purchase order. Decisions should be indicated on a check list (see example

in annex B).

vi © ISO 2001 – All rights reserved

INTERNATIONAL STANDARD ISO 13705:2001(E)

Petroleum and natural gas industries — Fired heaters for general

refinery service

1 Scope

This International Standard specifies requirements and gives recommendations for the design, materials,

fabrication, inspection, testing, preparation for shipment, and erection of fired heaters, air preheaters, fans and

burners for general refinery service.

2 Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of

this International Standard. For dated references, subsequent amendments to, or revisions of, any of these

publications do not apply. However, parties to agreements based on this International Standard are encouraged to

investigate the possibility of applying the most recent editions of the normative documents indicated below. For

undated references, the latest edition of the normative document referred to applies. Members of ISO and IEC

maintain registers of currently valid International Standards.

ISO 8501-1, Preparation of steel substrates before application of paints and related products — Visual assessment

of surface cleanliness — Part 1: Rust grades and preparation grades of uncoated steel substrates and of steel

substrates after overall removal of previous coatings

ISO 13704, Petroleum and natural gas industries — Calculation of heater-tube thickness in petroleum refineries

1)

EN 10025 , Hot rolled products of non-alloy structural steels — Technical delivery conditions

2)

AFBMA Standard 9 , Load ratings and fatigue life for ball bearings

3)

AMCA 99-2404-78 , Drive arrangements for centrifugal fans

AMCA 201, Fans and systems

AMCA 210, Laboratory methods of testing fans for aerodynamic performance rating

4)

ASME B17.1 , Keys and keyseats

ASME B31.3, Process piping

ASME Boiler and pressure vessel code, Section VIII, Rules for construction of pressure vessels

5)

ASTM A 36 , Standard specification for carbon structural steel

1) European Committee for Standardization (CEN), Rue de Stassart 36, B-1050 Brussels, Belgium.

th

2) Anti-Friction Bearing Manufacturers Association, 1200 19 Street NW, Suite 300, Washington, DC 20036-2412, USA.

3) Air Movement and Control Assocation, 30 West University Drive, Arlington Heights, IL 60004, USA.

4) American Society of Mechanical Engineers, 3 Park Avenue, New York, NY 10017, USA.

5) American Society for Testing and Materials, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, USA.

ASTM A 105, Standard specification for carbon steel forgings for piping applications

ASTM A 123, Standard specification for zinc (hot-dip galvanized) coatings on iron and steel products

ASTM A 143, Standard practice for safeguarding against embrittlement of hot-dip galvanized structural steel

products and procedure for detecting embrittlement

ASTM A 153, Standard specification for zinc coating (hot-dip) on iron and steel hardware

ASTM A 161, Standard specification for seamless low-carbon and carbon-molybdenum steel still tubes for refinery

service

ASTM A 181, Standard specification for carbon steel forgings, for general-purpose piping

ASTM A 182, Standard specification for forged or rolled alloy-steel pipe flanges, forged fittings, and valves and

parts for high-temperature service

ASTM A 192, Standard specification for seamless carbon steel boiler tubes for high-pressure service

ASTM A 193, Standard specification for alloy-steel and stainless steel bolting materials for high-temperature

service

ASTM A 194, Standard specification for carbon and alloy steel nuts for bolts for high-pressure or high-temperature

service, or both

ASTM A 209, Standard specification for seamless carbon-molybdenum alloy-steel boiler and superheater tubes

ASTM A 210, Standard specification for seamless medium-carbon steel boiler and superheater tubes

ASTM A 213, Standard specification for seamless ferritic and austenitic alloy-steel boiler, superheater and heat-

exchanger tubes

ASTM A 216, Standard specification for steel castings, carbon, suitable for fusion welding, for high-temperature

service

ASTM A 217, Standard specification for steel castings, martensitic stainless and alloy, for pressure-containing

parts, suitable for high-temperature service

ASTM A 234, Standard specification for piping fittings of wrought carbon steel and alloy steel for moderate and high

temperature service

ASTM A 240, Standard specification for heat-resisting chromium and chromium-nickel stainless steel plate, sheet,

and strip for pressure vessels

ASTM A 242, Standard specification for high-strength low-alloy structural steel

ASTM A 283, Standard specification for low and intermediate tensile strength carbon steel plates

ASTM A 297, Standard specification for steel castings, iron-chromium and iron-chromium-nickel, heat resistant, for

general application

ASTM A 307, Standard specification for carbon steel bolts and studs, 60 000 psi tensile strength

ASTM A 320, Standard specification for alloy steel bolting materials for low-temperature service

ASTM A 325, Standard specification for structural bolts, steel, heat treated, 120/105 ksi minimum tensile strength

ASTM A 351, Standard specification for castings, austenitic, austenitic-ferritic (duplex), for pressure-containing

parts

ASTM A 384, Standard practice for safeguarding against warpage and distortion during hot-dip galvanizing of steel

assemblies

2 © ISO 2001 – All rights reserved

ASTM A 385, Standard practice for providing high-quality zinc coatings (hot-dip)

ASTM A 387, Standard specification for pressure vessel plates, alloy steel, chromium-molybdenum

ASTM A 403, Standard specification for wrought austenitic stainless steel piping fittings

ASTM A 447, Standard specification for steel castings, chromium-nickel-iron alloy (25-12 class), for high-

temperature service

ASTM A 560, Standard specification for castings, chromium-nickel alloy

ASTM A 572, Standard specification for high-strength, low alloy columbium-vanadium structural steel

ASTM A 608, Standard specification for centrifugally cast iron-chromium-nickel high-alloy tubing for pressure

application at high temperatures

ASTM B 366, Standard specification for factory-made wrought nickel and nickel alloy fittings

ASTM B 407, Standard specification for nickel-iron-chromium alloy seamless pipe and tube

ASTM B 564, Standard specification for nickel alloy forgings

ASTM B 633, Standard specification for electrodeposited coatings of zinc on iron and steel

ASTM C 27, Standard classification of fireclay and high-alumina refractory brick

ASTM C 155, Standard classification of insulating firebrick

ASTM C 332, Standard specification for lightweight aggregates for insulating concrete

ASTM C 401, Standard classification of alumina and alumina-silicate castable refractories

ASTM C 612, Standard specification for mineral fiber block and board thermal insulation

6)

AWS D1.1, Structural welding code — Steel

AWS D14.6-96, Specification for welding of rotating elements of equipment

7)

MSS SP-55 , Quality standard for steel castings for valves, flanges and fittings, and other piping components —

Visual method

8)

NFPA 70 , National electrical code

3 Terms and definitions

For the purposes of this International Standard, the following terms and definitions apply.

NOTE Terms and definitions related to centrifugal fans are given in annex E.

3.1

air heater

air preheater

heat transfer apparatus through which combustion air is passed and heated by a medium of higher temperature,

such as the combustion products, steam or other fluid

6) American Welding Society, 550 NW Le Jeune Road, Miami, FL 33126, USA.

7) Manufacturers Standardization Society, 127 Park Street NE, Vienna, VA 22180, USA.

8) National Fire Protection Association, 1 Batterymarch Park, Quincy, MA 02269-9101, USA.

3.2

anchor

tieback

metallic or refractory device that holds the refractory or insulation in place

3.3

arch

flat or sloped portion of the heater radiant section opposite the floor

3.4

atomizer

device used to reduce liquid fuel to a fine mist

3.5

backup layer

refractory layer behind the hot face layer

3.6

balanced draught heater

heater which uses forced-draught fans to supply combustion air and uses induced fans to remove flue gases

3.7

breeching

heater section where flue gases are collected after the last convection coil for transmission to the stack or the outlet

ductwork

3.8

bridgewall

gravity wall

wall which separates two adjacent heater zones

3.9

bridgewall temperature

temperature of flue gas leaving the radiant section

3.10

burner

device which introduces fuel and air into a heater at the desired velocities, turbulence and concentration to

establish and maintain proper ignition and combustion

NOTE Burners are classified by the type of fuel fired, such as oil, gas, or a combination of gas and oil, which may be

designated as “dual fuel” or “combination”.

3.11

butterfly damper

single-blade damper which pivots about its centre

3.12

casing

metal plate used to enclose the fired heater

3.13

castable

insulating concrete poured or gunned in place to form a rigid refractory shape or structure

3.14

ceramic fibre

fibrous refractory insulation composed primarily of silica and alumina

NOTE Applicable forms include blanket, board, module, rigidized blanket, and vacuum-formed shapes.

4 © ISO 2001 – All rights reserved

3.15

convection section

portion of the heater in which the heat is transferred to the tubes primarily by convection

3.16

corbel

projection from the refractory surface generally used to prevent flue gas bypassing the tubes of the convection

section if they are on a staggered pitch

3.17

corrosion allowance

additional material thickness added to allow for material loss due to corrosion

3.18

corrosion rate

rate of reduction in the material thickness due to chemical attack from the process fluid or flue gas or both

NOTE Corrosion rate is expressed in millimetres per year (mils per year).

3.19

crossover

interconnecting piping between any two heater-coil sections

3.20

damper

device for introducing a variable resistance in order to regulate the flow of flue gas or air

3.21

direct air preheater

heat exchanger which transfers heat directly between the flue gas and the combustion air

NOTE A regenerative air preheater uses heated rotating elements and a recuperative design uses stationary tubes, plates,

or cast iron elements to separate the two heating media.

3.22

draught

negative pressure (vacuum) of the air and/or flue gas measured at any point in the heater

3.23

draught loss

pressure drop (including buoyancy effect) through duct conduits or across tubes and equipment in air and flue gas

systems

3.24

duct

conduit for air or flue gas flow

3.25

fuel efficiency

total heat absorbed divided by the total input of heat derived from the combustion of fuel only (lower heating value

basis)

NOTE This definition excludes sensible heat of the fuels and applies to the net amount of heat exported from the unit.

3.26

thermal efficiency

total heat absorbed divided by the total input of heat derived from the combustion of fuel (h ) plus sensible heats

L

from air, fuel and any atomizing medium

3.27

erosion

reduction in material thickness due to mechanical attack from a fluid

3.28

excess air

amount of air above the stoichiometric requirement for complete combustion

NOTE Excess air is expressed as a percentage.

3.29

extended surface

heat-transfer surface in the form of fins or studs attached to the heat-absorbing surface

3.30

extension ratio

ratio of total outside exposed surface to the outside surface of the bare tube

3.31

flue gas

gaseous product of combustion including excess air

3.32

forced-draught heater

heater for which combustion air is supplied by a fan or other mechanical means

3.33

fouling allowance

factor to allow for a layer of residue that increases pressure drop

NOTE 1 This residue is usually a build-up of coke or scale on the inner surface of a coil.

NOTE 2 The fouling allowance is used in calculating the fouled pressure drop.

3.34

fouling resistance

factor used to calculate the overall heat transfer coefficient

NOTE The inside fouling resistance is used to calculate the maximum metal temperature for design. The external fouling

resistance is used to compensate the loss of performance due to deposits on the external surface of the tubes or extended

surface.

3.35

header

return bend

cast or wrought fitting shaped in a 180° bend and used to connect two or more tubes

3.36

header box

internally insulated structural compartment, separated from the flue-gas stream, which is used to enclose a number

of headers or manifolds

NOTE Access is afforded by means of hinged doors or removable panels.

3.37

heat absorption

total heat absorbed by the coils, excluding any combustion-air preheat

6 © ISO 2001 – All rights reserved

3.38

average heat flux density

heat absorbed divided by the exposed heating surface of the coil section

NOTE Average flux density for an extended-surface tube is indicated on a bare surface basis with extension ratio noted.

3.39

maximum heat flux density

maximum local rate of heat transfer in the coil section

3.40

total heat release

heat liberated from the specified fuel, using the lower heating value of the fuel

3.41

volumetric heat release

heat released divided by the net volume of the radiant section, excluding the coils and refractory dividing walls

3.42

higher heating value

h

H

gross heating value

total heat obtained from the combustion of a specified fuel at 15 °C (60 °F)

3.43

lower heating value

h

L

net heating value

higher heating value minus the latent heat of vaporization of the water formed by combustion of hydrogen in the

fuel

3.44

hot face layer

refractory layer exposed to the highest temperatures in a multilayer or multicomponent lining

3.45

hot face temperature

temperature of the refractory surface in contact with the flue gas or heated combustion air

NOTE The hot face temperature is used to determine refractory or insulation thickness and heat transmitted.

3.46

indirect air preheater

fluid-to-air heat transfer device

NOTE The heat transfer can be accomplished by using a heat-transfer fluid, process stream or utility stream which has

been heated by the flue gas or other means. A heat pipe air preheater uses a vaporizing/condensing fluid to transfer heat

between the flue gas and air.

3.47

induced-draught heater

heater which uses a fan to remove flue gases and maintain a negative pressure in the heater to induce combustion

air without a forced-draught fan

3.48

jump over

interconnecting pipework within a heater coil section

3.49

louvre damper

damper consisting of several blades, each of which pivots about its centre and is linked to the other blades for

simultaneous operation

3.50

manifold

chamber for the collection and distribution of fluid to or from multiple parallel flow paths

3.51

metal fibre reinforcement

stainless steel needles added to castable for improved toughness and durability

3.52

monolithic lining

single-component lining system

3.53

mortar

refractory material preparation used for laying and bonding refractory bricks

3.54

multicomponent lining

refractory system consisting of two or more layers of different refractory types

NOTE Examples of refractory types are castable and ceramic fibre.

3.55

multilayer lining

refractory system consisting of two or more layers of the same refractory type

3.56

natural-draught heater

heater in which a stack effect induces the combustion air and removes the flue gases

3.57

normal heat release

design heat absorption of the heater divided by the calculated fuel efficiency

3.58

pass

stream

flow circuit consisting of one or more tubes in series

3.59

pilot

small burner that provides ignition energy to light the main burner

3.60

plenum

windbox

chamber surrounding the burners that is used to distribute air to the burners or reduce combustion noise

3.61

plug header

cast return bend provided with one or more openings for the purpose of inspection or mechanical tube cleaning

8 © ISO 2001 – All rights reserved

3.62

pressure design code

recognized pressure vessel standard specified or agreed by the purchaser

EXAMPLE ASME Boiler and Pressure Vessel Code, Section VIII.

3.63

pressure drop

difference between the inlet and the outlet static pressures between termination points, excluding the static

differential head

3.64

primary air

portion of the total combustion air that first mixes with the fuel

3.65

protective coating

corrosion-resistant material applied to a metal surface

EXAMPLE Coating on casing plates behind porous refractory materials to protect against sulfur in the flue gases.

3.66

radiant section

portion of the heater in which heat is transferred to the tubes primarily by radiation

3.67

radiation loss

setting loss

heat lost to the surroundings from the casing of the heater and the ducts and auxiliary equipment (when heat

recovery systems are used)

3.68

secondary air

air supplied to the fuel to supplement primary air

3.69

setting

heater casing, brickwork, refractory and insulation, including the tiebacks

3.70

shield section

shock section

tubes that shield the remaining convection-section tubes from direct radiation

3.71

sootblower

device used to remove soot or other deposits from heat-absorbing surfaces in the convection section

NOTE Steam is normally the medium used for soot blowing.

3.72

stack

vertical conduit used to discharge flue gas to the atmosphere

3.73

strake

spoiler

metal attachment to a stack which can prevent the formation of von Karman vortices that can cause wind-induced

vibration

3.74

structural design code

structural design standard specified or agreed by the purchaser

EXAMPLES ICBO Uniform Building Code, ASCE standards, AISC Specification for design, fabrication and erection of

structural steel for buildings.

3.75

target wall

re-radiating wall

vertical refractory firebrick wall which is exposed to direct flame impingement on one or both sides

3.76

temperature allowance

number of degrees Celsius (Fahrenheit) to be added to the process fluid temperature to account for flow

maldistribution and operating unknowns

NOTE The temperature allowance is added to the calculated maximum tube-metal temperature or the equivalent tube-metal

temperature to obtain the design metal temperature

3.77

terminal

flanged or welded connection to or from the coil providing for inlet and outlet of fluids

3.78

tube guide

device used with vertical tubes to restrict horizontal movement while allowing the tube to expand axially

3.79

tube retainer

device used to restrain horizontal radiant tubes from lifting off the intermediate tube supports during operation

3.80

tube support

tube sheet

device used to support tubes

3.81

vapour barrier

metallic foil placed between layers of refractory as a barrier to flue gas flow

10 © ISO 2001 – All rights reserved

4 General

4.1 Precautions

Care shall be excercised when using certain materials in the construction of fired heater components, in particular

those where a dust hazard may be experienced. Manufacturer’s recommendations and local and national safety

requirements shall be followed in all cases.

4.2 Pressure design code

z The pressure design code shall be specified or agreed by the purchaser. Pressure components shall comply with

the pressure design code and the supplemental requirements in this International Standard.

4.3 Local regulations

z The vendor shall comply with the applicable local rules and regulations specified by the purchaser.

4.4 Heater nomenclature

In a fired heater, heat liberated by the combustion of fuels is transferred to fluids contained in tubular coils within an

internally insulated enclosure. The type of heater is normally described by the structural configuration, radiant tube

coil configuration, and burner arrangement. Some examples of structural configurations are cylindrical, box, cabin

and multicell box. Examples of radiant tube coil configurations include vertical, horizontal, helical and arbor.

Examples of burner arrangements include upfired, downfired and wallfired. The wallfired arrangement can be

further classified as sidewall, endwall and multilevel.

Figure 1 illustrates some typical heater types.

Figure 2 illustrates typical burner arrangements.

Various combinations of Figures 1 and 2 can be used. For example, Figure 1 c) can employ burner arrangements

as in Figure 2 a), b) or c) Similarly, Figure 1 d) can employ burner arrangements as in Figure 2 a) or d).

Figure 3 shows typical components. Figures 4, 5 and 6 show typical combustion-air preheat systems.

a) Box heater with arbor coil b) Cylindrical heater with helical coil c) Cabin heater with horizontal

tube coil

d) Box heater with vertical tube coil e) Cylindrical heater with vertical coil f) Box heater with horizontal

tube coil

Figure 1 — Typical heater types

12 © ISO 2001 – All rights reserved

a) Upfired b) Endwall-fired

c) Sidewall-fired d) Sidewall-fired multi-level

Figure 2 — Typical burner arrangements (elevation view)

Key

1 Access door 7 Convection section 13 Header box 19 End tube sheet

2 Arch 8 Corbel 14 Radiant section 20 Pier

3 Breeching 9 Crossover 15 Shield section 21 Stack/duct

4 Bridgewall 10 Tubes 16 Observation door 22 Platform

5 Burner 11 Extended surface 17 Tube support 23 Process in

6 Casing 12 Return bend 18 Refractory lining 24 Process out

Figure 3 — Heater components

14 © ISO 2001 – All rights reserved

Key

1 Fired heater

2 Air

3 Air preheater

4 Induced-draught fan

5 Flue gas

6 Forced-draught fan

7 Separate stack (alternative)

Figure 4 — Air preheat system using regenerative, recuperative or heat pipe unit

Key

1 Flue gas

2 Induced-draught fan

3 Fired heater

4 Air

5 Air preheater

6 Forced-draught fan

7 Heat medium

Figure 5 — System using indirect closed system air preheater with mechanical circulation

Key

1 Fired heater

2 Air

3 Air preheater

4 Forced-draught fan

5 Process or utility stream

Figure 6 — External heat source for air preheating

5 Proposals

5.1 Purchaser’s responsibilities

5.1.1 The purchaser’s enquiry shall include data sheets, check list, and other applicable information outlined

herein. This information shall include any special requirements or exceptions to this International Standard.

5.1.2 The purchaser is responsible for the correct process specification to enable the vendor to prepare the fired

heater design. The purchaser should complete, as a minimum, those items on the data sheet that are designated

by an asterisk (*).

5.1.3 The purchase order shall state clearly the vendor’s scope of work and extent of supply.

z 5.1.4 The purchaser’s enquiry shall specify the number of copies of drawings, data sheets, specifications, data

reports, operating manuals, installation instructions, spare parts lists, and other data to be supplied by the vendor,

as required by 5.3 and 5.4.

5.2 Vendor’s responsibilities

The vendor’s proposal shall include:

a) for each heater, completed ISO data sheets for fired heater and associated equipment (see examples in

annex A);

b) an outline drawing showing firebox dimensions, burner layout and clearances, arrangement of tubes,

platforms, ducting, stack, breeching, air pre-heater and fans;

c) a full definition of the extent of shop assembly (format given in annex C may be used), including the number,

size and mass of prefabricated parts and the number of field welds;

16 © ISO 2001 – All rights reserved

d) a detailed description of any exceptions to the specified requirements;

z e) a completed noise data sheet if the data sheet is supplied by the purchaser;

f) curves for heaters in vaporizing

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...