ISO 11424:2017

(Main)Rubber hoses and tubing for air and vacuum systems for internal-combustion engines — Specification

Rubber hoses and tubing for air and vacuum systems for internal-combustion engines — Specification

ISO 11424:2017 specifies requirements for rubber hoses and tubing for use in the various air and vacuum systems found on internal combustion engines. This document does not cover hoses used for direct power-brake actuation in trucks and trailers, nor for air intakes and ducting within the passenger compartment. The highest-temperature hoses are generally used for turbocharger applications. All hoses and tubing remain serviceable down to −40°C. NOTE Although the term vacuum is generally used, in reality the application is one of reduced air pressure used for the purposes of actuation or monitoring of the various engine-system components. The air carried by the tubing or hoses may be clean and free of contaminants but may also contain oil, fuel and their vapours as contamination, due to the particular installation and application.

Tuyaux et tubes en caoutchouc pour systèmes d'aération et à vide des moteurs à combustion interne — Spécifications

General Information

- Status

- Withdrawn

- Publication Date

- 22-Feb-2017

- Technical Committee

- ISO/TC 45/SC 1 - Rubber and plastics hoses and hose assemblies

- Drafting Committee

- ISO/TC 45/SC 1/WG 2 - Automotive hoses

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 20-Jul-2023

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 28-Jan-2023

- Effective Date

- 04-Nov-2015

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

ISO 11424:2017 is a standard published by the International Organization for Standardization (ISO). Its full title is "Rubber hoses and tubing for air and vacuum systems for internal-combustion engines — Specification". This standard covers: ISO 11424:2017 specifies requirements for rubber hoses and tubing for use in the various air and vacuum systems found on internal combustion engines. This document does not cover hoses used for direct power-brake actuation in trucks and trailers, nor for air intakes and ducting within the passenger compartment. The highest-temperature hoses are generally used for turbocharger applications. All hoses and tubing remain serviceable down to −40°C. NOTE Although the term vacuum is generally used, in reality the application is one of reduced air pressure used for the purposes of actuation or monitoring of the various engine-system components. The air carried by the tubing or hoses may be clean and free of contaminants but may also contain oil, fuel and their vapours as contamination, due to the particular installation and application.

ISO 11424:2017 specifies requirements for rubber hoses and tubing for use in the various air and vacuum systems found on internal combustion engines. This document does not cover hoses used for direct power-brake actuation in trucks and trailers, nor for air intakes and ducting within the passenger compartment. The highest-temperature hoses are generally used for turbocharger applications. All hoses and tubing remain serviceable down to −40°C. NOTE Although the term vacuum is generally used, in reality the application is one of reduced air pressure used for the purposes of actuation or monitoring of the various engine-system components. The air carried by the tubing or hoses may be clean and free of contaminants but may also contain oil, fuel and their vapours as contamination, due to the particular installation and application.

ISO 11424:2017 is classified under the following ICS (International Classification for Standards) categories: 27.020 - Internal combustion engines; 83.140.30 - Plastics pipes and fittings for non fluid use; 83.140.40 - Hoses. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 11424:2017 has the following relationships with other standards: It is inter standard links to ISO 11424:2023, ISO 11424:1996. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 11424:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 11424

Second edition

2017-02

Rubber hoses and tubing for air

and vacuum systems for internal-

combustion engines — Specification

Tuyaux et tubes en caoutchouc pour systèmes d’aération et à vide des

moteurs à combustion interne — Spécifications

Reference number

©

ISO 2017

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

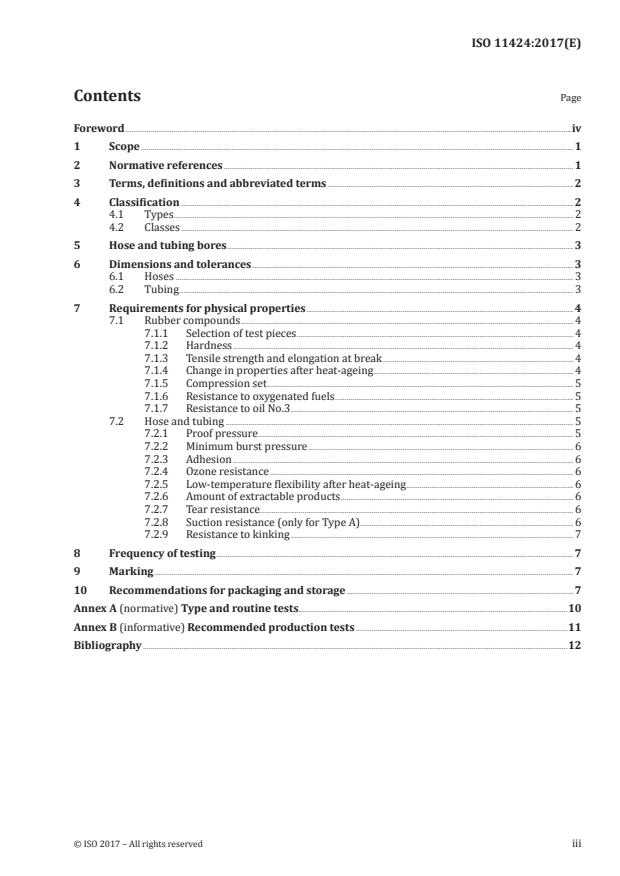

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms, definitions and abbreviated terms . 2

4 Classification . 2

4.1 Types. 2

4.2 Classes . 2

5 Hose and tubing bores . 3

6 Dimensions and tolerances . 3

6.1 Hoses . 3

6.2 Tubing . 3

7 Requirements for physical properties . 4

7.1 Rubber compounds . 4

7.1.1 Selection of test pieces . 4

7.1.2 Hardness . 4

7.1.3 Tensile strength and elongation at break . 4

7.1.4 Change in properties after heat-ageing . 4

7.1.5 Compression set . 5

7.1.6 Resistance to oxygenated fuels . 5

7.1.7 Resistance to oil No.3 . 5

7.2 Hose and tubing . 5

7.2.1 Proof pressure . 5

7.2.2 Minimum burst pressure . 6

7.2.3 Adhesion . 6

7.2.4 Ozone resistance . 6

7.2.5 Low-temperature flexibility after heat-ageing . 6

7.2.6 Amount of extractable products . 6

7.2.7 Tear resistance . 6

7.2.8 Suction resistance (only for Type A). 6

7.2.9 Resistance to kinking . 7

8 Frequency of testing . 7

9 Marking . 7

10 Recommendations for packaging and storage . 7

Annex A (normative) Type and routine tests .10

Annex B (informative) Recommended production tests .11

Bibliography .12

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity assessment,

as well as information about ISO’s adherence to the World Trade Organization (WTO) principles in the

Technical Barriers to Trade (TBT) see the following URL: www . i so .org/ iso/ foreword .html

This document was prepared by Technical Committee ISO/TC 45, Rubber and rubber products,

Subcommittee SC 1, Hoses (rubber and plastics).

This second edition cancels and replaces the first edition (ISO 11424:1996), which has been technically

revised.

The main changes are the following:

— in 6.2, inside diameter (ID) for each nominal bore has been included;

— requirement on frequency of testing has been added in Clause 8;

— requirement to mark nominal bore of the hose or tubing has been added in Clause 9;

— recommendations for packaging and storage have been added in Clause 10;

— Annex A and Annex B have been added.

iv © ISO 2017 – All rights reserved

INTERNATIONAL STANDARD ISO 11424:2017(E)

Rubber hoses and tubing for air and vacuum systems for

internal-combustion engines — Specification

1 Scope

This document specifies requirements for rubber hoses and tubing for use in the various air and vacuum

systems found on internal combustion engines. This document does not cover hoses used for direct

power-brake actuation in trucks and trailers, nor for air intakes and ducting within the passenger

compartment. The highest-temperature hoses are generally used for turbocharger applications. All

hoses and tubing remain serviceable down to −40°C.

NOTE Although the term vacuum is generally used, in reality the application is one of reduced air pressure

used for the purposes of actuation or monitoring of the various engine-system components. The air carried by

the tubing or hoses may be clean and free of contaminants but may also contain oil, fuel and their vapours as

contamination, due to the particular installation and application.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 37:2011, Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties

ISO 48, Rubber, vulcanized or thermoplastic — Determination of hardness (hardness between 10 IRHD and

100 IRHD)

ISO 188, Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests

ISO 815-1:2014, Rubber, vulcanized or thermoplastic — Determination of compression set — Part 1: At

ambient or elevated temperatures

ISO 1402, Rubber and plastics hoses and hose assemblies — Hydrostatic testing

ISO 1629, Rubber and latices — Nomenclature

ISO 1817:2015, Rubber, vulcanized or thermoplastic — Determination of the effect of liquids

ISO 3302-1, Rubber — Tolerances for products — Part 1: Dimensional tolerances

ISO 4671, Rubber and plastics hoses and hose assemblies — Methods of measurement of the dimensions of

hoses and the lengths of hose assemblies

ISO 7233:2016, Rubber and plastics hoses and hose assemblies — Determination of resistance to vacuum

ISO 7326, Rubber and plastics hoses — Assessment of ozone resistance under static conditions

ISO 8033, Rubber and plastics hoses — Determination of adhesion between components

ISO 8330, Rubber and plastics hoses and hose assemblies — Vocabulary

ISO 10619-1:2011, Rubber and plastics hoses and tubing — Measurement of flexibility and stiffness —

Part 1: Bending tests at ambient temperature

ISO 10619-2:2011, Rubber and plastics hoses and tubing — Measurement of flexibility and stiffness —

Part 2: Bending tests at sub-ambient temperatures

ISO 19013-1:2005, Rubber hoses and tubing for fuel circuits for internal combustion engines —

Specification — Part 1: Diesel fuels

3 Terms, definitions and abbreviated terms

For the purposes of this document, the terms and definitions given in ISO 8330 and the abbreviated

terms given in ISO 1629 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http:// www .electropedia .org/

— ISO Online browsing platform: available at http:// www .iso .org/ obp

4 Classification

4.1 Types

Type A — internally reinforced hose with a working pressure up to 0,3 MPa (3 bar).

Type B — homogeneous tube with a working pressure up to 0,12 MPa (1,2 bar).

4.2 Classes

Class 1 — Long-term working temperature up to 70 °C; maximum working temperature up to 100 °C.

Not recommended for applications where resistance to oils, fuel and their vapours is required.

NOTE 1 Typically, styrene-butadiene rubber (SBR) can be used.

Class 2 — Long-term working temperature up to 100 °C; maximum working temperature up to 125 °C.

Resistant to oils and their vapours.

NOTE 2 Typically, chloroprene rubber (CR) can be used.

Class 3 — Long-term working temperature up to 100 °C, maximum working temperature up to 125 °C.

Resistant to oils, fuels and their vapours.

NOTE 3 Typically, acrylonitrile-butadiene rubber (NBR) can be used.

Class 4 — Long-term working temperature up to 125 °C, maximum working temperature u

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...