ISO/IEC 29102:2015

(Main)Information technology - Office equipment - Method for the determination of ink cartridge photo yield for colour printing with inkjet printers and multi-function devices that contain inkjet printer components

Information technology - Office equipment - Method for the determination of ink cartridge photo yield for colour printing with inkjet printers and multi-function devices that contain inkjet printer components

ISO/IEC 29102:2015 is to provide a method to determine the ink cartridge photo yield of ink-containing cartridges (i.e. integrated ink cartridges and ink cartridges without integrated printheads) for colour photo printing with colour inkjet printers and multifunction devices that contain inkjet printer components. In the case where a cartridge set can be used in multiple printer models, only one yield test needs to be performed as long as the difference between printer models does not impact yield. NOTE A cartridge supplier may choose to use more than one market identifier for a single physical cartridge. In this case only one yield test is required as long as there are no differences in the cartridges other than market identifiers. ISO/IEC 29102:2015 prescribes the following: - the test method that manufacturers, test laboratories, etc. use to determine ink cartridge photo yield; - the method for determination of declared photo yield values from the test results; and - the appropriate method of describing the photo yield of cartridges in documentation supplied to the consumer by the manufacturer. ISO/IEC 29102:2015 is only intended for the determination of ink cartridge photo yield. No other claims can be made from this testing regarding quality, reliability, etc. ISO/IEC 29102:2015 can be used to determine the yield of any cartridge that is used during the printing of the photo test file defined in ISO/IEC 29103. ISO/IEC 29102:2015 is not for use with printers whose minimum printable size is equal to or greater than A3. This International Standard is not intended to measure the yield of photo printing on paper size larger than 4×6, L or A6. In addition, this International Standard is not for use with industrial printers or point of sale printers. It only applies to desktop printing systems.

Technologies de l'information — Équipement de bureau — Méthode d'essai de la détermination du rendement des cartouches d'encre pour l'impression de photographies en couleurs avec des imprimantes à jet d'encre et des dispositifs multi-fonctions contenant des composants d'imprimantes à jet d'encre

General Information

Relations

Frequently Asked Questions

ISO/IEC 29102:2015 is a standard published by the International Organization for Standardization (ISO). Its full title is "Information technology - Office equipment - Method for the determination of ink cartridge photo yield for colour printing with inkjet printers and multi-function devices that contain inkjet printer components". This standard covers: ISO/IEC 29102:2015 is to provide a method to determine the ink cartridge photo yield of ink-containing cartridges (i.e. integrated ink cartridges and ink cartridges without integrated printheads) for colour photo printing with colour inkjet printers and multifunction devices that contain inkjet printer components. In the case where a cartridge set can be used in multiple printer models, only one yield test needs to be performed as long as the difference between printer models does not impact yield. NOTE A cartridge supplier may choose to use more than one market identifier for a single physical cartridge. In this case only one yield test is required as long as there are no differences in the cartridges other than market identifiers. ISO/IEC 29102:2015 prescribes the following: - the test method that manufacturers, test laboratories, etc. use to determine ink cartridge photo yield; - the method for determination of declared photo yield values from the test results; and - the appropriate method of describing the photo yield of cartridges in documentation supplied to the consumer by the manufacturer. ISO/IEC 29102:2015 is only intended for the determination of ink cartridge photo yield. No other claims can be made from this testing regarding quality, reliability, etc. ISO/IEC 29102:2015 can be used to determine the yield of any cartridge that is used during the printing of the photo test file defined in ISO/IEC 29103. ISO/IEC 29102:2015 is not for use with printers whose minimum printable size is equal to or greater than A3. This International Standard is not intended to measure the yield of photo printing on paper size larger than 4×6, L or A6. In addition, this International Standard is not for use with industrial printers or point of sale printers. It only applies to desktop printing systems.

ISO/IEC 29102:2015 is to provide a method to determine the ink cartridge photo yield of ink-containing cartridges (i.e. integrated ink cartridges and ink cartridges without integrated printheads) for colour photo printing with colour inkjet printers and multifunction devices that contain inkjet printer components. In the case where a cartridge set can be used in multiple printer models, only one yield test needs to be performed as long as the difference between printer models does not impact yield. NOTE A cartridge supplier may choose to use more than one market identifier for a single physical cartridge. In this case only one yield test is required as long as there are no differences in the cartridges other than market identifiers. ISO/IEC 29102:2015 prescribes the following: - the test method that manufacturers, test laboratories, etc. use to determine ink cartridge photo yield; - the method for determination of declared photo yield values from the test results; and - the appropriate method of describing the photo yield of cartridges in documentation supplied to the consumer by the manufacturer. ISO/IEC 29102:2015 is only intended for the determination of ink cartridge photo yield. No other claims can be made from this testing regarding quality, reliability, etc. ISO/IEC 29102:2015 can be used to determine the yield of any cartridge that is used during the printing of the photo test file defined in ISO/IEC 29103. ISO/IEC 29102:2015 is not for use with printers whose minimum printable size is equal to or greater than A3. This International Standard is not intended to measure the yield of photo printing on paper size larger than 4×6, L or A6. In addition, this International Standard is not for use with industrial printers or point of sale printers. It only applies to desktop printing systems.

ISO/IEC 29102:2015 is classified under the following ICS (International Classification for Standards) categories: 37.100.10 - Reproduction equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/IEC 29102:2015 has the following relationships with other standards: It is inter standard links to ISO/IEC 29102:2023, ISO/IEC 29102:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO/IEC 29102:2015 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

INTERNATIONAL ISO/IEC

STANDARD 29102

Second edition

2015-08-15

Information technology — Office

equipment — Method for the

determination of ink cartridge

photo yield for colour printing with

inkjet printers and multi-function

devices that contain inkjet printer

components

Technologies de l’information — Équipement de bureau — Méthode

d’essai de la détermination du rendement des cartouches d’encre pour

l’impression de photographies en couleurs avec des imprimantes à jet

d’encre et des dispositifs multi-fonctions contenant des composants

d’imprimantes à jet d’encre

Reference number

©

ISO/IEC 2015

© ISO/IEC 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO/IEC 2015 – All rights reserved

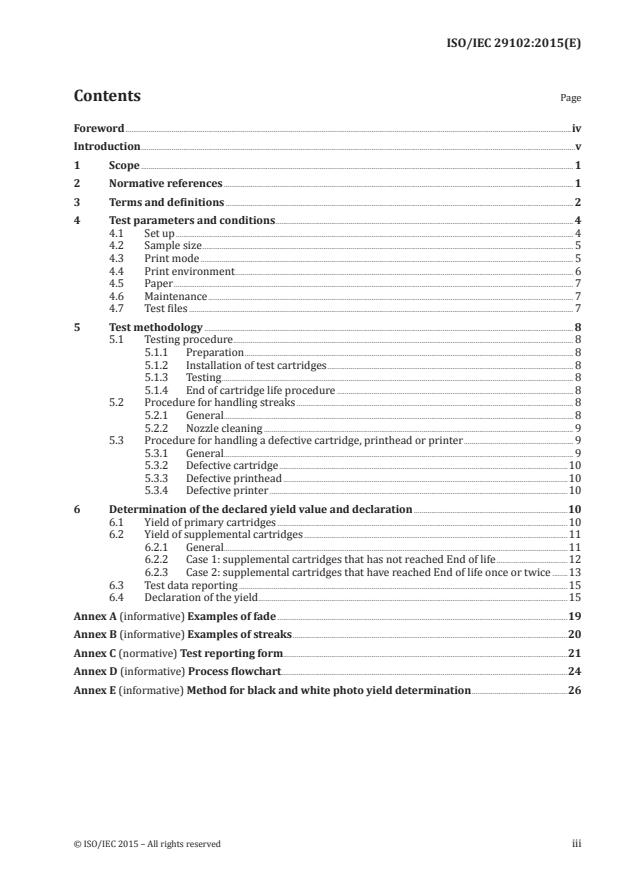

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Test parameters and conditions . 4

4.1 Set up . 4

4.2 Sample size . 5

4.3 Print mode . 5

4.4 Print environment . 6

4.5 Paper . 7

4.6 Maintenance . 7

4.7 Test files . 7

5 Test methodology . 8

5.1 Testing procedure . 8

5.1.1 Preparation . 8

5.1.2 Installation of test cartridges . 8

5.1.3 Testing . 8

5.1.4 End of cartridge life procedure . 8

5.2 Procedure for handling streaks . 8

5.2.1 General. 8

5.2.2 Nozzle cleaning . 9

5.3 Procedure for handling a defective cartridge, printhead or printer . 9

5.3.1 General. 9

5.3.2 Defective cartridge .10

5.3.3 Defective printhead .10

5.3.4 Defective printer .10

6 Determination of the declared yield value and declaration .10

6.1 Yield of primary cartridges .10

6.2 Yield of supplemental cartridges .11

6.2.1 General.11

6.2.2 Case 1: supplemental cartridges that has not reached End of life .12

6.2.3 Case 2: supplemental cartridges that have reached End of life once or twice .13

6.3 Test data reporting .15

6.4 Declaration of the yield .15

Annex A (informative) Examples of fade .19

Annex B (informative) Examples of streaks .20

Annex C (normative) Test reporting form .21

Annex D (informative) Process flowchart.24

Annex E (informative) Method for black and white photo yield determination .26

© ISO/IEC 2015 – All rights reserved iii

Foreword

ISO (the International Organization for Standardization) and IEC (the International Electrotechnical

Commission) form the specialized system for worldwide standardization. National bodies that are

members of ISO or IEC participate in the development of International Standards through technical

committees established by the respective organization to deal with particular fields of technical

activity. ISO and IEC technical committees collaborate in fields of mutual interest. Other international

organizations, governmental and non-governmental, in liaison with ISO and IEC, also take part in the

work. In the field of information technology, ISO and IEC have established a joint technical committee,

ISO/IEC JTC 1.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for

the different types of document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject

of patent rights. ISO and IEC shall not be held responsible for identifying any or all such patent

rights. Details of any patent rights identified during the development of the document will be in the

Introduction and/or on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT), see the following URL: Foreword — Supplementary information.

The committee responsible for this document is ISO/IEC JTC 1, Information technology, Subcommittee

SC 28, Office equipment.

This second edition cancels and replaces the first edition (ISO/IEC 29102:2011), of which it constitutes

a minor revision.

iv © ISO/IEC 2015 – All rights reserved

Introduction

The scope of this International Standard is limited to evaluation of ink cartridge photo yield of ink-

containing cartridges (i.e. integrated ink cartridges and ink cartridges without integrated printheads)

for colour photo printing with colour inkjet printers. This International Standard can be applied to

colour inkjet printers having an interface to a computer as well as colour inkjet printers that cannot

be connected to a computer. This International Standard can also be applied to the inkjet printer

component of any multifunctional device that has a digital input printing path, including multi-function

devices that contain inkjet printer components. Both liquid and solid ink products can be tested using

this International Standard.

The cartridge photo yields of primary cartridges are determined by an end of life judgment, or signalled

with either of two phenomena: fade, caused by depletion of ink in the cartridge, or automatic printing

stop, caused by an Ink Out detection function. The cartridge photo yields of supplemental cartridges are

estimated. It is envisioned that one of the uses of this International Standard will be for the calculation

of cost per page (CPP). While this International Standard measures a portion of this cost, it is not used

as the sole component of CPP calculation. Additional factors need to be considered for accurate CPP

calculations.

© ISO/IEC 2015 – All rights reserved v

INTERNATIONAL STANDARD ISO/IEC 29102:2015(E)

Information technology — Office equipment — Method for

the determination of ink cartridge photo yield for colour

printing with inkjet printers and multi-function devices

that contain inkjet printer components

1 Scope

The purpose of this International Standard is to provide a method to determine the ink cartridge photo

yield of ink-containing cartridges (i.e. integrated ink cartridges and ink cartridges without integrated

printheads) for colour photo printing with colour inkjet printers and multifunction devices that contain

inkjet printer components. In the case where a cartridge set can be used in multiple printer models,

only one yield test needs to be performed as long as the difference between printer models does not

impact yield.

NOTE A cartridge supplier may choose to use more than one market identifier for a single physical cartridge.

In this case only one yield test is required as long as there are no differences in the cartridges other than market

identifiers.

This International Standard prescribes the following:

— the test method that manufacturers, test laboratories, etc. use to determine ink cartridge photo

yield;

— the method for determination of declared photo yield values from the test results; and

— the appropriate method of describing the photo yield of cartridges in documentation supplied to the

consumer by the manufacturer.

This International Standard is only intended for the determination of ink cartridge photo yield. No

other claims can be made from this testing regarding quality, reliability, etc.

This International Standard can be used to determine the yield of any cartridge that is used during the

printing of the photo test file defined in ISO/IEC 29103.

This International Standard is not for use with printers whose minimum printable size is equal to or

greater than A3. This International Standard is not intended to measure the yield of photo printing on

paper size larger than 4×6, L or A6. In addition, this International Standard is not for use with industrial

printers or point of sale printers. It only applies to desktop printing systems.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO/IEC 29103, Information technology — Office equipment — Colour photo test pages for measurement of

ink cartridge yield for colour photo printing

ISO/IEC 24711, Method for the determination of ink cartridge yield for colour inkjet printers and multi-

function devices that contain printer components

© ISO/IEC 2015 – All rights reserved 1

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

fade

phenomenon in which a significant colour change occurs due to ink depletion

Note 1 to entry: If a printer exhibits fade, a five minute pause is allowed to provide for recovery of the ink delivery

system and printing can continue. If fade appears on the next page, then the cartridge is judged at end of life and

the additional page printed after the five minute pause is not counted in the yield calculation. If fade does not

appear on the next page, then printing can continue until the next fade or ink out is encountered.

Note 2 to entry: For examples of fade, please consult Annex A.

Note 3 to entry: In some printer systems, fade can occur prematurely due to the way that ink is provided to the

printing system.

Note 4 to entry: It can be helpful to use the first photo test suite print samples from the first cartridge set for

colour comparison.

Note 5 to entry: A blue light source (such as a blue LED) can be used to help in the detection of yellow fade.

3.2

streak

thin lines of colour that appear in test images

Note 1 to entry: Streaks differ from fade in the width.

Note 2 to entry: If streaks occur in two or more out of four consecutive test pages, then a streak removal operation

is required.

Note 3 to entry: Streaks can appear due to a number of reasons; thermal issues and clogged nozzles being two of

the main causes. Comparisons are made using the phenomenon sample provided in Annex B.

3.3

streak removal operation

procedure used to restore the print performance by removing streaks

Note 1 to entry: It is often called a nozzle cleaning operation.

Note 2 to entry: If streaks are observed in two or more out of four consecutive test pages, first the printer can

be left idle for five minutes. Then an additional four pages are printed. If the streaks are still observed, then a

streak removal operation is conducted according to the latest printer manufacturer documentation. Due to the

significant amount of ink that is used for cleaning, the maximum permissible number of times that the streak

removal operation can be used on a given cartridge is prescribed in 5.2.1. All test pages printed during this

process will be included in the page count for determining the yield.

3.4

printhead alignment operation

function that aligns newly installed printheads

Note 1 to entry: If it is mandatory according to the latest printer manufacturer documentation, this operation

is performed during testing. The pages used in the alignment procedure are not counted in the measurement of

yield.

3.5

ink low

warning generated by the printing system when it has determined that the amount of ink is such that a

cartridge change may be required soon

Note 1 to entry: It does not indicate that the system is out of ink.

2 © ISO/IEC 2015 – All rights reserved

3.6

ink out

signal generated by the printing system when the usable ink in the system is depleted and the printer

stops printing

3.7

end of life

condition determined by one of two mechanisms: fade (3.1) or ink out (3.6)

Note 1 to entry: For cartridges containing multiple colour inks, end of life is defined when the first colour exhibits

fade or ink out. In the event that the printer can continue printing after ink out is reported, the cartridge will still

be considered at end of life.

3.8

end of testing

point of time when all of primary cartridges are consumed three times per printer under testing

3.9

photo test suite

series of pages defined in ISO/IEC 29103 that are printed as separate jobs

3.10

individual cartridge photo yield

number of pages printed between cartridge installation and end of life

3.11

declared cartridge photo yield

at or below the lower 90 % confidence bound of the mean

Note 1 to entry: 90 % confidence bound of the mean is prescribed in 6.1 and 6.2.

3.12

primary cartridge

major contributing cartridge for ink consumption

Note 1 to entry: The minimum number of primary cartridges to be tested for different printing systems is

prescribed in 4.2. Cartridges that reach end of life (3.7) first are classified as primary cartridges. They should be

consumed at least three times per printer at end of testing (3.8).

Note 2 to entry: Colour inkjet printers commonly utilize a set of different colour inks to improve quality of photo

images. The number of different colour inks ranges from three to more than 10. Ink usages of different colours

are not designed to be uniform. In order to maintain testing time and cost at a reasonable level, the definition of

primary cartridges is introduced in this International Standard.

3.13

supplemental cartridge

cartridge that is not classified as primary cartridge

Note 1 to entry: The determination of yield for supplemental cartridges is made according to the procedure

prescribed in 6.2.

3.14

proxy cartridge

primary cartridge to be utilized for estimating yield of supplemental cartridges (3.13)

Note 1 to entry: The definition of proxy cartridges is prescribed in 6.2.

3.15

photo paper

coated paper for photo printing

© ISO/IEC 2015 – All rights reserved 3

3.16

content type selection

selection that specifies the content for printing

Note 1 to entry: Examples include photo and document. This can be selected by the user or in some cases by the

printing system based on the automatic media detection.

3.17

paper media selection

selection that specifies the type of media

Note 1 to entry: This can be selected by the user and/or by the automatic media detection.

3.18

print quality level selection

user selection that specifies the various levels of printed image quality and enhancement

Note 1 to entry: Examples include normal, best or highest.

Note 2 to entry: Some printers might not have all of the selections specified in 3.16, 3.17 and 3.18 available.

4 Test parameters and conditions

4.1 Set up

Place the printer on a horizontal surface and set up the printer according to the installation guide

provided in the printer user’s manual. If a printer has the capability to use both PC connection and

another method of data input for photo printing, the PC connection shall be used for testing. If a printer

does not have PC connection capability, the method of delivering photo test page suite to printer and

printing procedure shall be included in the test report. Use the most recent printer driver available

from the manufacturer’s website or the supplied driver with the printer. The driver version shall be

specified on the test report. Cartridge installation shall be completed following the instructions in the

cartridge installation guide. If there is a contradiction between the printer and cartridge manuals for the

cartridge installation, the cartridge manual will take precedence except if changes are recommended

for printer or driver settings.

At the start of the test, all printers shall be set up using a set of priming cartridges to ensure that the

ink used in testing is primarily for printing, not for initial priming/cleaning. After the printer is set

up according to the manufacturer’s instructions, the priming cartridges shall be used to print until

consistent images are generated. The priming cartridges shall be removed and replaced with new

cartridges that will be used for testing yield. The pages printed during priming operation will be

included in the test report. But, those pages are not counted towards yield. Even if required by the

printer, printhead alignment does not have to be performed on the priming cartridges. The replacement

of the priming cartridges with the first set of test cartridges may be done all at once or staggered

individually. If done all at once, all test cartridges begin with photo test suite number 1 and continue

until end of life. If the staggered start method is used, the test suite number shall be tracked separately

for each cartridge. The test start method shall be included in the test report.

Print quality level selection shall be at factory pre-set configuration for the printer and default installed

condition for the driver and shall be included in the test report. Any user selectable ink conservation

modes, (for example, draft mode) shall be disabled during testing. If content type selection to photo is

available on the printer, it shall be set to photo and included in the test report.

Paper media selection shall be set to photo paper. In case of multiple choices are available for photo

paper setting, selection made for testing shall be included in the test report. If user selectable automatic

media detection is available on the printer, it shall be disabled to make sure the same ink amount to be

consumed for different media. If automatic media detection is used, it shall be noted on the test report.

If these settings cannot be verified, then testing shall occur with automatic media detection on. If the

printer and driver settings differ, then the driver defaults shall be used.

4 © ISO/IEC 2015 – All rights reserved

Any scaling to ensure that the photo test suite is printed correctly shall be based on printer system

or driver. To facilitate automated testing, the photo test suite may be pre-generated using the printer

driver. This is often accomplished using a print to file command. This method is only valid if it does not

affect the measured yield. If a pre-generated file is used, it shall be noted on the test report.

4.2 Sample size

Colour inkjet printers commonly utilize different colour inks and/or overlays to improve quality of

photo images. Number of different colour inks/overlays for colour photo printing is quite diverse. Some

of the printers may utilize more than 10 different colour inks/overlays. Ink usages of different colours

are not designed to be uniform. In order to maintain testing time and cost at reasonable level, major

contributing cartridges are defined as primary cartridges in this International Standard. The rest of

cartridges are regarded as supplemental cartridges. During testing, cartridges that reach end of life

first are classified as primary cartridges.

The minimum number of primary cartridges to be tested is determined based on the number of

cartridges utilized for printing system. Inkjet cartridges are designed in two common styles, single

colour and multi-colour contained cartridges. The number of cartridges may be smaller than the

number of colour inks/overlays. The minimum number of primary cartridges for various printing

system is listed in Table 1.

Primary cartridges shall reach end of life at least three times on each of the printers tested. Regardless

of the minimum number of primary cartridges specified in Table 1, all of the cartridges depleted three

or more times on all tested printers shall be treated as primary cartridges. The minimum number

of printers for testing is three. For example, if the number of primary cartridges is three, at least 27

cartridges shall be tested. (3 primary cartridges × 3 cartridges to reach end of life × 3 printers)

To represent yield variations due to cartridge and printer manufacturing tolerances, it is acceptable

that additional engines and/or cartridges be used in testing.

Table 1 — Minimum number of primary cartridges

The Minimum Number

Printer system

of Primary Cartridges

1 cartridge system 1

2 cartridge system 1

3 cartridge system 2

4 cartridge system 3

6 cartridge system 3

7 or more cartridge system 3

When testing additional printers and primary cartridges above the minimum, an effort shall be made

to test an equal number of primary cartridges on each printer. For example, if an additional printer

were to be tested for 3 primary cartridges, then the minimum number of cartridges to be tested would

be 36 (3 primary cartridges × 3 cartridges to reach end of life × 4 printers).

When testing cartridges for a commercially available product, it is recommended that cartridges and

printers be procured from various sources, or sampled from different production lots. The printers and

cartridges shall be within their useful life as stated in their user’s manual.

4.3 Print mode

Colour inkjet printers commonly need to service the printing system after a number of prints, or when

the device has been powered down or not used for a given amount of time. This servicing uses ink that

could have been used to print additional photos. It is realized that customers do not normally print in

a continuous fashion. But, the yield test will be run in semi-continuous simplex printing to decrease

© ISO/IEC 2015 – All rights reserved 5

testing time and increase the repeatability of the testing process. Each photo test page shall be printed

as a separate print job. This allows for some intra-job servicing and calibration to take place.

Additional pauses may take place due to paper refills and idle time due to end of work days, but pauses

are not required. All print settings shall be documented in the test report to sufficient level to allow

testing to be reproduced by a third party.

NOTE Depending on printing conditions, the yield experienced by a given user may vary significantly from

the yield measured by this test method.

If a printer has capability to print both borderless and bordered, photo test suite shall be printed

without border. If borderless printing is not allowed for a printer under testing, photo test suite can be

printed with border. It shall be noted in test report. Any scaling to ensure that the photo test suite is

printed correctly shall be based on printer system or driver.

4.4 Print environment

The temperature can have a profound effect on test results. For this reason, the test shall be carried out

according to the following test conditions:

Temperature: Testing room average 23,0 °C ±2 °C

Readings to be made with a running average of 1 hour with readings recorded at least every 15 minutes,

all running average temperatures are to be between 20,0 °C and 26,0 °C.

An example of the calculation of the temperature is shown in Table 2 for temperature readings taken on

15-min intervals for the testing of one cartridge.

Table 2 — Running temperature calculation example

Testing Room

t t t t t t t t t t t t Average

1 2 3 4 5 6 7 8 9 10 11 12

Temperature t 24,0 23,4 20,5 24,2 23,6 22,0 25,5 24,7 22,1 20,8 22,0 23,5 23,0

i

Running Average

T N/A N/A N/A 23,0 22,9 22,6 23,8 24,0 23,6 23,3 22,4 22,1

i

Running Average T = (t +t +t +t )/4

i i-3 i-2 i-1 i

Testing Room Average = (t +t + … +t )/12

1 2 12

From these formulae, the testing room average would be 23,0 °C, the maximum running average reading 24,0 °C and the

minimum running average reading 22,1 °C. These values can be found highlighted in the table of temperature measurements.

It shall be noted that the testing room average for temperature are averages of all measurements, not the running averages.

Humidity shall be within the range recommended by the manufacturer for operating the device.

Environmental conditions shall be included in the test report. The maximum and minimum running

averages for temperature shall be reported for each cartridge tested. Please see Annex C for test

reporting form.

All materials shall be temperature acclimated to the test room environment. Prior to testing, the printer,

paper and cartridges shall be acclimated to the above conditions. Before acclimation, packaging and

shipping materials shall be opened with care to prevent damage to the cartridges during acclimation.

Paper may be acclimated in the ream wrapper.

Any water condensation shall be avoided when printer, paper and cartridges are carried in the test

environment

6 © ISO/IEC 2015 – All rights reserved

4.5 Paper

The paper utilized in this test represents photo paper. If photo paper is tested, it shall conform to the

printer’s list of approved photo papers for colour photo printing. If automatic media detection can be

disabled and yield results are not affected by the type of paper, plain paper that shall conform to the

printer’s list of approved papers can be utilized for testing to reduce the cost for testing. If automatic

media detection cannot be disabled, tester shall utilize photo paper.

Size of paper used in this test shall be 4×6, L or A6 size. It is recommended that the test will be performed

with 4×6 sized paper if it can be utilized for a printer under testing. But, if a printer under testing is not

capable of printing on 4×6 sized paper and/or L or A6 is of dominant paper size in the nation, L or A6

sized paper can be utilized for testing. Tester may use larger sized paper only if yield results are not

affected by the size of paper.

The paper manufacturer, manufacturer’s paper model and/or code, and size for the paper that is

actually used in the test shall be noted on the report. When available, weight for the paper is actually

used shall be noted on the report.

4.6 Maintenance

Printer maintenance shall be performed according to the printer and cartridge user’s manual.

4.7 Test files

The test image suite used shall be as specified in ISO/IEC 29103. The test shall be conducted using the

most recent official electronic test image suite as the input. The most recent official file can be located at

(http://www.iso.org/jtc1/sc28). Failure to use the exact file specifications will invalidate test results.

OS provided photo printing tool (for example, Windows photo printing wizard) will be used to send

photo test suite to the printer. The method used for connection between the host computer and the

printer shall be recorded on the test report. For automated testing, a pre-generated print file can be

used if the results are equivalent to direct printing methods. This will be recorded on the test report.

The version of the test file, the printer driver version and OS provided photo printing tool version and

type will be included in the test report. Before starting the test, a sample file set shall be printed to

check the image and ensure the proper size.

NOTE There are often several OS provided photo printing tools available; each version can have an impact

on the yield results.

To reduce test variability due to other programs, it is recommended that test file generation be

conducted on a printer with a “clean” install of the Operating System (OS) with only the printer driver

and any test control software installed. Testing has shown that old installed drivers from the same

or different printers can affect the yield results. To aid in counting and tracking pages, a header or

footer can be added to the photo test page suite. Every attempt shall be made to reduce the size of this

addition to minimize the effect on calculated yield. If this information is included in the photo test suite,

it shall be documented in the test report.

The host computer environment such as OS, RAM size, CPU type and application software may affect

the yield test results, the computer environment recommended by the printer’s user manual shall be

used for the test. All of this information shall be recorded on the test report. Test file shall be printed

without any border if a printer has capability to print both borderless and bordered. If a printer under

testing is incapable of borderless printing, test file can be printed with border. In case of bordered

printing for testing, it shall be noted in test report. Any scaling to ensure that the photo test suite is

printed correctly shall be based on printer system or driver.

© ISO/IEC 2015 – All rights reserved 7

5 Test methodology

5.1 Testing procedure

5.1.1 Preparation

a) Install at least three printers following the user’s manual.

b) Install a priming cartridge into the printers.

c) Using priming cartridge, print until consistent images are generated.

d) Remove each priming cartridge.

5.1.2 Installation of test cartridges

a) Remove all packaging material from a new complete set of cartridges to be tested and weigh each

cartridge individually to within 0,01 g and record the weight. Install these cartridges based on the

cartridge installation guide.

If there is a contradiction between the printer and cartridge manuals for the cartridge installation,

the cartridge manual will take precedence except if changes are recommended for printer or driver

settings.

b) If the printer has a mandatory printhead alignment operation, it will be conducted according to the

printer manual.

Pages printed for head alignment operation will not be counted in the measured yield.

5.1.3 Testing

a) Begin test and start tracking the number of test photos printed on each test cartridge.

b) When end of life is reached on any cartridge, execute the End of cartridge life procedure according

to 5.1.4. End of life shall be determined as prescribed in 3.7.

c) Repeat steps 5.1.3 a) and b) until all of primary cartridges that are prescribed in 4.2 reach End

of life at least three times. When the last primary cartridge reaches end of life, record individual

cartridge yield for the depleted primary cartridge. Remove the depleted primary cartridge and

all supplemental cartridges. When yields of supplemental cartridges are determined using proxy

cartridges as specified in 6.2, weigh the removed cartridges and record in the report.

d) Repeat steps 5.1.2 to 5.1.4 for all of printers under testing. (At least three printers should be tested

as prescribed in 4.2.

5.1.4 End of cartridge life procedure

a) Record individual cartridge yield for the depleted cartridge.

b) Remove the depleted cartridge, weigh and record the final weight. Replace depleted cartridge with

new cartridge. Measure its weight and record as in step 5.1.2.

5.2 Procedure for handling streaks

5.2.1 General

If streaks are observed as described in 3.2, a streak removal operation (as defined in 3.3) shall be

performed according to the printer user’s manual. The page count and streaking colour will be recorded

in test report.

8 © ISO/IEC 2015 – All rights reserved

5.2.2 Nozzle cleaning

a) Nozzle cleaning strength

If nozzle cleaning operation has the option of multiple cleaning strengths, the procedure indicated

in the printer manual for resolving streaking will be followed. Use of a light and a strong cleaning

procedure will count as one nozzle cleaning operation. Any cleaning pages printed during the

nozzle cleaning operation will not be counted in the yield calculation.

b) Permissible limited number of nozzle cleaning operation

Nozzle cleaning operation will consume ink. This may affect yield test results. To reduce the

influence of this operation, the maximum number of user initiated cleaning operations for a single

cartridge is limited as shown in the list below. If the estimated yield for primary cartridges is

equal to or less than 400 pages, the nozzle cleaning operations are allowed up to three times. If the

estimated yield is greater than 400 pages, the maximum number of nozzle cleaning operation is

incremented by one for every additional 150 pages.

Table 3 — Maximum number of nozzle cleaning operations allowed

Estimated cartridge yield Number of nozzle cleaning operation

Up to 400 pages 3 times

Up to 550 pages 4 times

Up to 700 pages 5 times

Up to 850 pages 6 times

Up to 1 000 pages 7 times

Up to 1 150 pages 8 times

Up to 1 300 pages 9 times

Up to 1 450 pages 10 times

In addition to the maximum number of nozzle cleaning operation, one more additional cleaning

operation can be tried. If a Fade occurs or an Ink Out is signalled on this additional cleaning

operation, the yield data are still valid and the data can be used in the final yield calculation. If

a Fade or Ink Out does not occur during the cleaning operation, the cartridge shall be replaced

with new one regardless of streak condition. The cartridge will be considered defective for having

excessive streaks and the yield data are not valid. The cartridge removed for this reason will be

recorded in the test report as a failed cartridge due to excessive streaking.

c) If the nozzle cleaning operation cannot be limited to individual colour

If nozzle cleaning operation cannot be limited to the cartridge that is streaking, all other cartridges

under testing will also use ink during the cleaning process. For this reason, if a nozzle clean

operation affects all cartridges in a printing system, any cleaning operation performed will be

counted against all cartridges. If more than the specified cleaning operations are performed on a

cartridge under test, that cartridge will be removed from testing even though it was not the cause

of the streaks. Cartridges removed for this reason will be recorded on the test report as removed

due to excessive cleaning. These cartridges shall not be used in the calculation of yield.

5.3 Procedure for handling a defective cartridge, printhead or printer

5.3.1 General

During testing, a failure of the cartridge, printhead or printer may occur. This will be handled as

described below: Cartridge failures are defined as occurrences of problems that would result in

replacement of the ink cartridge before End of life. Examples of this could be excessive nozzle clogging

(for integrated printheads), excessive ink leakage, and/or structural failure, etc. Printhead failures are

© ISO/IEC 2015 – All rights reserved 9

usually indicated by excessive, non-cleanable streaking or other non-resolvable print quality defects in

systems where the printheads can be replaced. Printer failures are defined as non-user clearable errors

that prevent normal printer operation from occurring. An example of this might be the failure of the

paper feed mechanism or excessive streaking on a non-replaceable printhead. All defective cartridges,

printheads and printers will be recorded on the testing report along with reason for failure.

5.3.2 Defective cartridge

In the case of a defective cartridge, the number of the last photo test suite printed and reason for failure

will be recorded on the report. The cartridge will then be replaced with a new cartridge and the testing

continued. If the printer has a mandatory printhead alignment operation, it will be conducted according

to the printer manual. For the purposes of yield calculation, the defective cartridge will not be used.

When a defective cartridge is encountered, the yield data of all the cartridges installed in the printer

cannot be used for yield calculation unless it can be proven that those data would not be affected by

the defective cartridge or the streak removal operation conducted immediately following the cartridge

replacement. This justification will be noted in the test report.

5.3.3 Defective printhead

In the case of a defective printhead, the printhead shall be replaced as specified in the printer user’s

manual. For the purposes of yield calculation, all cartridges that were in the printer at the time of the

failure will not be used in calculation of the final yield. After replacement of the printhead, the printer

shall be set up using a set of priming cartridges as specified in 4.1. A new set of cartridges shall be

weighed and installed for subsequent testing. On the report, the number of the last photo test suite

printed for each cartridge using the defective printhead will be recorded. A note will be made that all

cartridges were replaced due to printhead failure. If the printer has a mandatory printhead alignment

operation, it will be conducted according to the printer manual. If the printhead is not user replaceable,

refer to 5.3.3.

5.3.4 Defective printer

In the case of a defective printer, the printer shall be repaired or replaced. After repair/replacement of

the printer, the printer shall be set up using a set of priming cartridges as specified in 4.1. Then, new

cartridges shall be installed for subsequent testing. If the printer has a mandatory printhead alignment

operation, it will be conducted according to the printer manual. On the report, the number of the last

photo test suite printed by the cartridges in the defective printer will be recorded and it shall be noted

that the cartridges were replaced due to printer failure. The failure of the printer will be noted and the

replacement printer serial number recorded. The yield data obtained before printer failure cannot be

used for yield calculation unless it can be proved that the printer failure did not affect the previously

tested cartridges. This justification will be recorded in the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...