IEC 60227-1:2007

(Main)Polyvinyl chloride insulated cables of rated voltages up to and including 450/750 V - Part 1: General requirements

Polyvinyl chloride insulated cables of rated voltages up to and including 450/750 V - Part 1: General requirements

IEC 60227-1:2007 applies to rigid and flexible cables with insulation, and sheath if any, based on polyvinyl chloride, of rated voltages Uo/U up to and including 450/750 V used in power installations of nominal voltage not exceeding 450/750 V a.c. The particular types of cables are specified in IEC 60227-3, IEC 60227-4, etc. The code designations of these types of cables are given in Annex A. The test methods specified in Parts 1, 3, 4, etc. are given in IEC 60227-2, IEC 60332-1-2 and in the relevant parts of IEC 60811. This third edition of IEC 60227-1 cancels and replaces the second edition, published in 1993, amendment 1 (1995) and amendment 2 (1997) The document 20/903/FDIS, circulated to the National Committees as amendment 3, led to the publication of this new edition.

Conducteurs et câbles isolés au polychlorure de vinyle, de tension nominale au plus égale à 450/750 V - Partie 1: Exigences générales

La présente partie de la Norme internationale CEI 60227 s'applique aux conducteurs et câbles souples et rigides ayant une enveloppe isolante, et éventuellement une gaine, à base de polychlorure de vinyle, de tension nominale Uo/U au plus égale à 450/750 V, utilisés dans les installations d'énergie d'une tension nominale ne dépassant pas 450/750 V en courant alternatif. Les types particuliers de conducteurs et câbles sont spécifiés dans les CEI 60227-3, CEI 60227-4, etc. Le code de désignation de ces types de câbles est donné dans l'Annexe A. Les méthodes d'essais spécifiées dans les Parties 1, 3, 4, etc. sont données dans les CEI 60227-2, CEI 60332-1-2 et dans les parties correspondantes de la CEI 60811. Cette troisième édition de la CEI 60227-1 annule et remplace la seconde édition, publiée en 1993, l'amendement 1 (1995) et l'amendement 2 (1997). Le document 20/903/FDIS transmis aux Comités Nationaux comme amendement 3, a conduit à la publication de cette nouvelle édition.

General Information

- Status

- Published

- Publication Date

- 09-Oct-2007

- Technical Committee

- TC 20 - Electric cables

- Drafting Committee

- WG 17 - TC 20/WG 17

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 22-Feb-2024

- Completion Date

- 03-Dec-2021

Relations

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Referred By

EN 61184:2008 - Bayonet lampholders - Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

Overview

IEC 60227-1:2007 is an international standard published by the International Electrotechnical Commission (IEC) that specifies the general requirements for polyvinyl chloride (PVC) insulated cables rated for voltages up to and including 450/750 V. This standard applies to both rigid and flexible cables used in low-voltage power installations, ensuring consistent quality and safety in electrical wiring systems.

The scope of IEC 60227-1 includes insulation and optional sheaths made from PVC for power cables with rated voltages up to 450/750 V a.c. It serves as a foundational document that refers to other parts of the IEC 60227 series for specifications on particular cable types and associated test methods. The standard supports uniformity in cable manufacturing, testing, and application across international markets.

Key Topics

Cable Construction Requirements

The standard defines essential construction elements, including conductor materials, insulation, fillers, inner coverings, and sheaths. It specifies materials, thicknesses, mechanical properties, and electrical resistance criteria to ensure the cable's durability and safety over its operational life.Core Identification

IEC 60227-1 outlines color coding schemes and marking methods for cable cores, facilitating safe and accurate installation. The standard mandates specific colors and numeric identifications for conductors to avoid wiring errors.Marking and Labelling

The standard requires clear, durable markings on cables to indicate origin, type, voltage rating, and other relevant information. This includes provisions on the legibility and longevity of marks to withstand environmental and operational stresses.Test Methods

Test procedures referenced in this standard verify insulation integrity, mechanical strength, flame retardance, and overall cable dimensions. These procedures complement the general requirements and are elaborated in related IEC parts such as IEC 60227-2 and IEC 60332-1-2.Applicable Types of Cables

While IEC 60227-1 covers general requirements, it works alongside other parts like IEC 60227-3, IEC 60227-4, and IEC 60227-5 which specify detailed provisions for types of rigid, sheathed, and flexible cables (including cords).

Applications

IEC 60227-1:2007 is primarily intended for use in:

- Residential, commercial, and industrial power installations requiring low-voltage wiring with voltages up to 450/750 V.

- Manufacturing of rigid and flexible PVC insulated cables ensuring compliance with international quality and safety standards.

- Electrical installation and maintenance professionals who need standardized cables for wiring and repairs within the defined voltage rating.

- Procurement and regulatory compliance to ensure that cables used in constructions meet internationally harmonized quality and safety norms.

This standard supports safe power distribution and electrical connection systems by mandating robust cable design and performance parameters ideal for fixed wiring and flexible cord applications.

Related Standards

IEC 60227-1 aligns with and references several complementary international standards and IEC parts to deliver a comprehensive framework for PVC insulated cables, such as:

- IEC 60227-2: Test methods for PVC insulated cables.

- IEC 60227-3: Specifications for non-sheathed cables for fixed wiring.

- IEC 60227-4: Specifications for sheathed cables for fixed wiring.

- IEC 60227-5: Guidelines for flexible cables (cords).

- IEC 60228: Conductors of insulated cables.

- IEC 60332-1-2: Flame propagation tests for cables.

- IEC 60811 series: Common test methods for insulating and sheathing materials of electric cables.

Together, these standards ensure comprehensive technical requirements from material selection and testing to performance and safety validations, facilitating international uniformity in electrical cable manufacturing and use.

Keywords: IEC 60227-1, PVC insulated cables, low voltage cables, flexible cables, rigid cables, electrical cable standards, 450/750 V cables, power installation wiring, cable marking, cable testing, IEC cable standards.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60227-1:2007 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Polyvinyl chloride insulated cables of rated voltages up to and including 450/750 V - Part 1: General requirements". This standard covers: IEC 60227-1:2007 applies to rigid and flexible cables with insulation, and sheath if any, based on polyvinyl chloride, of rated voltages Uo/U up to and including 450/750 V used in power installations of nominal voltage not exceeding 450/750 V a.c. The particular types of cables are specified in IEC 60227-3, IEC 60227-4, etc. The code designations of these types of cables are given in Annex A. The test methods specified in Parts 1, 3, 4, etc. are given in IEC 60227-2, IEC 60332-1-2 and in the relevant parts of IEC 60811. This third edition of IEC 60227-1 cancels and replaces the second edition, published in 1993, amendment 1 (1995) and amendment 2 (1997) The document 20/903/FDIS, circulated to the National Committees as amendment 3, led to the publication of this new edition.

IEC 60227-1:2007 applies to rigid and flexible cables with insulation, and sheath if any, based on polyvinyl chloride, of rated voltages Uo/U up to and including 450/750 V used in power installations of nominal voltage not exceeding 450/750 V a.c. The particular types of cables are specified in IEC 60227-3, IEC 60227-4, etc. The code designations of these types of cables are given in Annex A. The test methods specified in Parts 1, 3, 4, etc. are given in IEC 60227-2, IEC 60332-1-2 and in the relevant parts of IEC 60811. This third edition of IEC 60227-1 cancels and replaces the second edition, published in 1993, amendment 1 (1995) and amendment 2 (1997) The document 20/903/FDIS, circulated to the National Committees as amendment 3, led to the publication of this new edition.

IEC 60227-1:2007 is classified under the following ICS (International Classification for Standards) categories: 29.060.20 - Cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60227-1:2007 has the following relationships with other standards: It is inter standard links to EN 60598-2-20:2010, EN IEC 60934:2019, EN IEC 62368-1:2020, EN 60702-1:2002/A1:2015, EN 60838-1:2017, EN IEC 60598-1:2024, EN 62841-3-12:2019, EN 61558-2-7:2007, EN 62841-2-21:2019, EN IEC 62368-1:2024, EN 61184:2008, EN 60730-1:2011, EN 60320-3:2014/A1:2021, EN IEC 61058-2-1:2021, EN 60598-2-2:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60227-1:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60227-1

Edition 3.0 2007-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Polyvinyl chloride insulated cables of rated voltages up to and including

450/750 V –

Part 1: General requirements

Conducteurs et câbles isolés au polychlorure de vinyle, de tension nominale au

plus égale à 450/750 V –

Partie 1: Exigences générales

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60227-1

Edition 3.0 2007-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Polyvinyl chloride insulated cables of rated voltages up to and including

450/750 V –

Part 1: General requirements

Conducteurs et câbles isolés au polychlorure de vinyle, de tension nominale au

plus égale à 450/750 V –

Partie 1: Exigences générales

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

S

CODE PRIX

ICS 29.060.20 ISBN 2-8318-9339-9

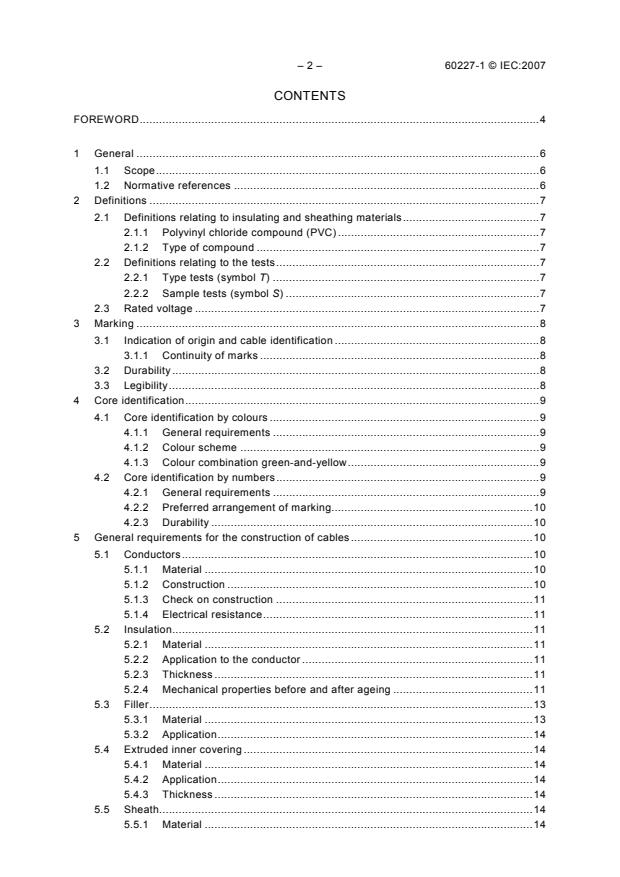

– 2 – 60227-1 © IEC:2007

CONTENTS

FOREWORD.4

1 General .6

1.1 Scope.6

1.2 Normative references .6

2 Definitions .7

2.1 Definitions relating to insulating and sheathing materials.7

2.1.1 Polyvinyl chloride compound (PVC) .7

2.1.2 Type of compound .7

2.2 Definitions relating to the tests.7

2.2.1 Type tests (symbol T) .7

2.2.2 Sample tests (symbol S) .7

2.3 Rated voltage .7

3 Marking .8

3.1 Indication of origin and cable identification .8

3.1.1 Continuity of marks .8

3.2 Durability .8

3.3 Legibility.8

4 Core identification.9

4.1 Core identification by colours .9

4.1.1 General requirements .9

4.1.2 Colour scheme .9

4.1.3 Colour combination green-and-yellow.9

4.2 Core identification by numbers.9

4.2.1 General requirements .9

4.2.2 Preferred arrangement of marking.10

4.2.3 Durability .10

5 General requirements for the construction of cables.10

5.1 Conductors.10

5.1.1 Material .10

5.1.2 Construction .10

5.1.3 Check on construction .11

5.1.4 Electrical resistance.11

5.2 Insulation.11

5.2.1 Material .11

5.2.2 Application to the conductor .11

5.2.3 Thickness .11

5.2.4 Mechanical properties before and after ageing .11

5.3 Filler.13

5.3.1 Material .13

5.3.2 Application.14

5.4 Extruded inner covering .14

5.4.1 Material .14

5.4.2 Application.14

5.4.3 Thickness .14

5.5 Sheath.14

5.5.1 Material .14

60227-1 © IEC:2007 – 3 –

5.5.2 Application.14

5.5.3 Thickness .15

5.5.4 Mechanical properties before and after ageing .15

5.6 Tests on completed cables .17

5.6.1 Electrical properties .17

5.6.2 Overall dimensions .18

5.6.3 Mechanical strength of flexible cables .19

5.6.4 Flame retardance.19

6 Guide to use of the cables .19

Annex A (normative) Code designation .20

Table 1 – Requirements for the non-electrical tests for polyvinyl chloride (PVC)

insulation .12

Table 2 – Requirements for the non-electrical test for polyvinyl chloride (PVC) sheaths.16

Table 3 – Requirements for electrical tests for PVC insulated cables .18

– 4 – 60227-1 © IEC:2007

INTERNATIONAL ELECTROTECHNICAL COMMISSION

–––––––––––

POLYVINYL CHLORIDE INSULATED CABLES

OF RATED VOLTAGES UP TO AND

INCLUDING 450/750 V –

Part 1: General requirements

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60227-1 has been prepared by IEC technical committee 20: Electric

cables.

This third edition of IEC 60227-1 cancels and replaces the second edition, published in 1993,

amendment 1 (1995) and amendment 2 (1997) The document 20/903/FDIS, circulated to the

National Committees as amendment 3, led to the publication of this new edition.

60227-1 © IEC:2007 – 5 –

The text of this standard is based on the second edition, its amendments 1 and 2, and the

following documents:

FDIS Report on voting

20/903/FDIS 20/910/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until the

maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 60227-1 © IEC:2007

POLYVINYL CHLORIDE INSULATED CABLES

OF RATED VOLTAGES UP TO AND

INCLUDING 450/750 V –

Part 1: General requirements

1 General

1.1 Scope

This part of International Standard IEC 60227 applies to rigid and flexible cables with

insulation, and sheath if any, based on polyvinyl chloride, of rated voltages U /U up to and

o

including 450/750 V used in power installations of nominal voltage not exceeding

450/750 V a.c.

NOTE For some types of flexible cables the term cord is used.

The particular types of cables are specified in IEC 60227-3, IEC 60227-4, etc. The code

designations of these types of cables are given in Annex A.

The test methods specified in Parts 1, 3, 4, etc. are given in IEC 60227-2, IEC 60332-1-2 and

in the relevant parts of IEC 60811.

1.2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60173, Colours of the cores of flexible cables and cords

IEC 60227-2, Polyvinyl chloride insulated cables of rated voltage up to and including

450/750 V – Part 2: Test methods

IEC 60227-3, Polyvinyl chloride insulated cables of rated voltage up to and including

450/750 V – Part 3: Non-sheathed cables for fixed wiring

IEC 60227-4, Polyvinyl chloride insulated cables of rated voltage up to and including

450/750 V – Part 4: Sheathed cables for fixed wiring

IEC 60227-5, Polyvinyl chloride insulated cables of rated voltages up to and including

450/750 V – Part 5: Flexible cables (cords)

IEC 60228, Conductors of insulated cables

IEC 60332-1-2, Tests on electric and optical fibre cables under fire conditions – Part 1-2: Test

for vertical flame propagation for a single insulated wire or cable – Procedure for 1 kW pre-

mixed flame

IEC 60811-1-1, Common test methods for insulating and sheathing materials of electric

cables and optical cables – Part 1: Methods for general application –Measuring of thickness

and overall dimensions – Tests for determining the mechanical properties

60227-1 © IEC:2007 – 7 –

IEC 60811-1-2, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section Two: Thermal ageing methods

IEC 60811-1-4, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section Four: Tests at low temperature

IEC 60811-3-1, Common test methods for insulating and sheathing materials of electric

cables – Part 3: Methods specific to PVC compounds – Section One: Pressure test at high

temperature – Tests for resistance to cracking

IEC 60811-3-2, Common test methods for insulating and sheathing materials of electric

cables – Part 3: Methods specific to PVC compounds – Section Two: Loss of mass test –

Thermal stability tests

IEC 62440, Electric cables – Guide to use for cables with a rated voltage not exceeding

450/750V

2 Definitions

For the purpose of this standard the following definitions shall apply.

2.1 Definitions relating to insulating and sheathing materials

2.1.1 Polyvinyl chloride compound (PVC)

Combination of materials suitably selected, proportioned and treated, of which the

characteristic constituent is the plastomer polyvinyl chloride or one of its copolymers. The

same term also designates compounds containing both polyvinyl chloride and certain of its

polymers.

2.1.2 Type of compound

The category in which a compound is placed according to its properties, as determined by

specific tests. The type designation is not directly related to the composition of the compound.

2.2 Definitions relating to the tests

2.2.1 Type tests (symbol T)

Tests required to be made before supplying a type of cable covered by this standard on a

general commercial basis in order to demonstrate satisfactory performance characteristics to

meet the intended application. These tests are of such a nature that, after they have been

made, they need not be repeated unless changes are made in the cable materials or design

which might change the performance characteristics.

2.2.2 Sample tests (symbol S)

Tests made on samples of completed cable or components taken from a completed cable,

adequate to verify that the finished product meets the design specifications.

2.3 Rated voltage

The rated voltage of a cable is the reference voltage for which the cable is designed and which

serves to define the electrical tests.

___________

In preparation.

– 8 – 60227-1 © IEC:2007

The rated voltage is expressed by the combination of two values U /U, expressed in volts:

o

U being the r.m.s. value between any insulated conductor and "earth" (metal covering of the

o

cable or the surrounding medium);

U being the r.m.s. value between any two-phase conductors of a multicore cable or of a

system of single-core cables.

In an alternating current system, the rated voltage of a cable shall be at least equal to the

nominal voltage of the system for which it is intended.

This condition applies both to the value U and to the value U.

o

In a direct current system, the nominal voltage of the system shall be not higher than 1,5 times

the rated voltage of the cable.

NOTE The operating voltage of a system may permanently exceed the nominal voltage of such a system by 10 %.

A cable can be used at a 10 % higher operating voltage than its rated voltage if the latter is at least equal to the

nominal voltage of the system.

3 Marking

3.1 Indication of origin and cable identification

Cables shall be provided with an indication of the manufacturer, which shall be either an

identification thread or a repetitive marking of the manufacturer's name or trade-mark.

Cables for use at a conductor temperature exceeding 70 °C shall also be marked either with

the code designation or with the maximum conductor temperature.

Marking may be by printing or by reproduction in relief on or in the insulation or sheath.

3.1.1 Continuity of marks

Each specified mark shall be regarded as continuous if the distance between the end of the

mark and the beginning of the next identical mark does not exceed

– 550 mm if the marking is on the outer sheath of the cable;

– 275 mm if the marking is

a) on the insulation of an unsheathed cable;

b) on the insulation of a sheathed cable;

c) on a tape within a sheathed cable.

3.2 Durability

Printed markings shall be durable. Compliance with this requirement shall be checked by the

test given in 1.8 of IEC 60227-2.

3.3 Legibility

All markings shall be legible.

The colours of the identification threads shall be easy to recognize or easily made

recognizable, if necessary, by cleaning with petrol or other suitable solvent.

60227-1 © IEC:2007 – 9 –

4 Core identification

Each core shall be identified as follows:

– in cables having up to and including five cores by colour, see 4.1;

– in cables having more than five cores by number, see 4.2.

NOTE The colour scheme, and in particular the scheme for rigid multicore cables, is under consideration.

4.1 Core identification by colours

4.1.1 General requirements

Identification of the cores of a cable shall be achieved by the use of coloured insulation or

other suitable method.

Each core of a cable shall have only one colour, except the core identified by a combination of

the colours green-and-yellow.

The colours green and yellow,when not in combination, shall not be used for any multicore

cable.

NOTE The colours red and white should preferably be avoided.

4.1.2 Colour scheme

The preferred colour scheme for flexible cables and single-core cables is:

– single-core cable: no preferred colour scheme;

– two-core cable: no preferred colour scheme;

– three-core cable: either green-and-yellow, blue, brown,

or, brown, black, grey

– four-core cable: either green-and-yellow, brown, black, grey,

or blue, brown, black, grey

– five-core cable: either green-and-yellow, blue, brown, black, grey,

or blue, brown, black, grey, black.

The colours shall be clearly identifiable and durable. Durability shall be checked by the test

given in 1.8 of IEC 60227-2.

4.1.3 Colour combination green-and-yellow

The distribution of the colours for the core coloured green-and-yellow shall comply with the

following condition (which is in accordance with IEC 60173): for every 15 mm length of core,

one of these colours shall cover at least 30 % and not more than 70 % of the surface of the

core, the other colour covering the remainder.

NOTE Information on the use of the colours green-and-yellow and blue.

It is understood that the colours green and yellow, when they are combined as specified above, are recognized

exclusively as a means of identification of the core intended for use as earth connection or similar protection, and

that the colour blue is intended for the identification of the core intended to be connected to neutral. If, however,

there is no neutral, blue can be used to identify any core except the earthing or protective conductor.

4.2 Core identification by numbers

4.2.1 General requirements

The insulation of the cores shall be of the same colour and numbered sequentially, except for

the core coloured green-and-yellow, if one is included.

– 10 – 60227-1 © IEC:2007

The green-and-yellow core, if any, shall comply with the requirement of 4.1.3 and shall be in

the outer layer.

The numbering shall start by number 1 in the inner layer.

The numbers shall be printed in arabic numerals on the outer surfaces of the cores. All the

numbers shall be of the same colour, which shall contrast with the colour of the insulation. The

numerals shall be legible.

4.2.2 Preferred arrangement of marking

The numbers shall be repeated, at regular intervals along the core, consecutive numbers being

inverted in relation to each other.

When the number is a single numeral, a dash shall be placed underneath it. If the number

consists of two numerals, these shall be disposed one below the other and a dash placed

below the lower numeral. The spacing d between consecutive numbers shall not exceed

50 mm.

The arrangement of the marks is shown in the figure below.

d d

IEC 2008/07

4.2.3 Durability

Printed numerals shall be durable. Compliance with this requirement shall be checked by the

test given in 1.8 of IEC 60227-2.

5 General requirements for the construction of cables

5.1 Conductors

5.1.1 Material

The conductors shall consist of annealed copper, except for the wires of tinsel cords, for which

a copper alloy may be used. The wires may be plain or tinned.

5.1.2 Construction

The maximum diameters of the wires of flexible conductors – other than the conductors of

tinsel cords – and the minimum number of the wires of rigid conductors shall be in accordance

with IEC 60228.

The classes of the conductors relevant to the various types of cables are given in the particular

specifications (see IEC 60227-3, IEC 60227-4, etc.).

Conductors of cables for fixed installations shall be circular solid, circular stranded or

compacted circular stranded conductors.

For tinsel cords each conductor shall comprise a number of strands or groups of strands,

twisted together, each strand being composed of one or more flattened wires of copper or

copper alloy, helically wound on a thread of cotton, polyamide or similar material.

60227-1 © IEC:2007 – 11 –

5.1.3 Check on construction

Compliance with the requirements of 5.1.1 and 5.1.2, including the requirements of IEC 60228,

shall be checked by inspection and by measurement.

5.1.4 Electrical resistance

For cables – other than tinsel cords – the resistance of each conductor at 20 °C shall be in

accordance with the requirements of IEC 60228 for the given class of the conductor.

Compliance shall be checked by the test given in 2.1 of IEC 60227-2.

5.2 Insulation

5.2.1 Material

The insulation shall be polyvinyl chloride compound of the type specified for each type of cable

in the particular specifications (see IEC 60227-3, IEC 60227-4, etc.).

Type PVC/C in the case of cables for fixed installation.

Type PVC/D in the case of flexible cables.

Type PVC/E in the case of heat-resistant cables for internal wiring.

The test requirements for these compounds are specified in Table 1.

The maximum operating temperatures for cables insulated with any of the above types of

compound and covered by the particular specifications (see IEC 60227-3, IEC 60227-4, etc.)

are given in those publications.

5.2.2 Application to the conductor

The insulation shall be so applied that it fits closely on the conductor, but for cables other than

tinsel cords, it shall be possible to remove it without damage to the insulation itself, to the

conductor or to the tin coating if any. Compliance shall be checked by inspection and by

manual test.

5.2.3 Thickness

The mean value of the thickness of insulation shall be not less than the specified value for

each type and size of cable shown in the tables of the particular specifications (IEC 60227-3,

IEC 60227-4, etc.).

However, the thickness at any place may be less than the specified value provided that the

difference does not exceed 0,1 mm + 10 % of the specified value.

Compliance shall be checked by the test given in 1.9 of IEC 60227-2.

5.2.4 Mechanical properties before and after ageing

The insulation shall have adequate mechanical strength and elasticity within the temperature

limits to which it may be exposed in normal use.

Compliance shall be checked by carrying out the tests specified in Table 1.

The applicable test methods and the results to be obtained are specified in Table 1.

– 12 – 60227-1 © IEC:2007

Table 1 – Requirements for the non-electrical tests for polyvinyl chloride (PVC)

insulation

1 2 3 4 5 6 7

Reference Test Unit Type of component Test method

No. described in

PVC/C PVC/D PVC/E IEC subclause

1 Tensile strength and 60811-1-1 9.1

elongation at break

1.1 Properties in the state as

delivered

1.1.1 Values to be obtained for the

tensile strength:

– median, min. N/mm 12,5 10,0 15,0

1.1.2 Values to be obtained for the

elongation at break:

– median, min. % 125 150 150

1.2 Properties after ageing in air 60811-1-2 8.1.3.1

oven and and

60811-1-1 9.1

1.2.1 Ageing conditions:

– temperature °C 80 ± 2 80 ± 2 135 ± 2

– duration of treatment h 7 × 24 7 × 24 10 × 24

1.2.2 Values to be obtained for the

tensile strength:

– median, min. N/mm 12,5 10,0 15,0

1)

±20 ±20 ±25

– variation , max. %

1.2.3 Values to be obtained for the

elongation at break:

– median, min. % 125 150 150

1)

– variation , max. % ±20 ±20 ±25

2 Loss of mass test 60811-3-2 8.1

2.1 Ageing conditions:

– temperature °C 80 ± 2 80 ± 2 115 ± 2

– duration of treatment h

7 × 24 7 × 24 10 × 24

2.2 Values to be obtained for the

loss of mass, max. 2,0 2,0 2,0

mg/cm

2)

3 Compatibility test

3.1 Ageing conditions °C 80 ± 2 80 ± 2 100 ± 2 60811-1-2 8.1.4

h 7 × 24 7 × 24 10 × 24

3.2 Mechanical properties after As in references

ageing Nos. 1.2.2 and 1.2.3

Values to be obtained

4 60811-3-1 9.1

Heat shock test

4.1 Test conditions:

– temperature °C 150 ± 2 150 ± 2 150 ± 2

– duration of treatment h 1 1 1

4.2 Results to be obtained Absence of cracks

1)

Variation: difference between the median value after ageing and the median value without ageing, expressed as

a percentage of the latter.

2)

If applicable, see 5.3.1.

60227-1 © IEC:2007 – 13 –

Table 1 (continued)

1 2 3 4 5 6 7

Reference Test Unit Type of component Test method

No. described in

PVC/C PVC/D PVC/E IEC subclause

5 60811-3-1 8.1

Pressure test at high

temperature

5.1 Test conditions:

– force exercised by the blade See 8.1.4 of IEC 60811-3-1

– duration of heating under See 8.1.5 of IEC 60811-3-1

load

– temperature

°C 80 ± 2 70 ± 2 90 ± 2

5.2 Results to be obtained:

– median of the depth of

penetration, max. % 50 50 50

6 Bending test at low 60811-1-4 8.1

temperature

6.1 Test conditions:

1)

°C –15 ± 2 –15 ± 2 –15 ± 2

– temperature

– period of application of low See 8.1.4 and 8.1.5 of IEC 60811-1-4

temperature

6.2 Results to be obtained Absence of cracks

7 Elongation test at low 60811-1-4 8.3

temperature

7.1 Test conditions:

1)

– temperature °C –15 ± 2 –15 ± 2 –

– period of application of low See 8.3.4 and 8.3.5 of IEC 60811-1-4

temperature

7.2 Result to be obtained:

– elongation without break, % 20 20 –

min.

8 Impact test at low 60811-1-4 8.5

2)

temperature

8.1 Test conditions:

1)

– temperature °C –15 ± 2 –15 ± 2 –

– period of application of low See 8.5.5 of IEC 60811-1-4

temperature

– mass of hammer See 8.5.4 of IEC 60811-1-4

See 8.5.6 of IEC 60811-1-4

8.2 Results to be obtained

9 60811-3-2 9

Thermal stability test

9.1 Test conditions:

– temperature °C – – 200 ± 0,5

9.2 Result to be obtained:

– mean value of the thermal

stability time, min. min – – 180

1)

Due to climatic conditions, national standards may require a lower test temperature to be used.

2)

If specified in the particular specifications (IEC 60227-3, IEC 60227-4, etc.).

5.3 Filler

5.3.1 Material

Unless otherwise specified in the particular specifications (IEC 60227-3, IEC 60227-4, etc.), the

fillers shall be composed of one of the following or of any combination of the following:

– a compound based on unvulcanized rubber of plastics; or

– natural or synthetic textiles; or

– paper.

– 14 – 60227-1 © IEC:2007

When the filler is composed of unvulcanized rubber, there shall be no harmful interactions

between its constituents and the insulation and/or the sheath. Compliance with this

requirement shall be checked by the test given in 8.1.4 of IEC 60811-1-2.

5.3.2 Application

For each type of cable, the particular specifications (IEC 60227-3, IEC 60227-4, etc.) specify

whether that cable includes fillers or whether the sheath or inner covering may penetrate

between the cores, thus forming a filling.

The fillers shall fill the spaces between the cores giving the assembly a practically circular

shape. The fillers shall not adhere to the cores. The assembly of cores and fillers may be held

together by a film or tape.

5.4 Extruded inner covering

5.4.1 Material

Unless otherwise specified in the particular specifications (IEC 60227-4, etc.), the extruded

inner covering shall be composed of a compound based on unvulcanized rubber or plastics.

Where the inner covering is composed of unvulcanized rubber, there shall be no harmful

interactions between its constituents and the insulation and/or the sheath.

Compliance with this requirement shall be checked by the test given in 8.1.4 of IEC 60811-1-2.

5.4.2 Application

The extruded inner covering shall surround the cores and may penetrate the spaces between

them giving the assembly a practical circular shape. The extruded inner covering shall not

adhere to the cores.

For each type of cable, the particular specifications (IEC 60227-4, etc.) indicate whether that

cable includes an extruded inner covering or not, or whether the outer sheath may penetrate

between the cores, thus forming a filling.

5.4.3 Thickness

Unless otherwise specified in the particular specifications (IEC 60227-4, etc.), no measurement

is required for the extruded inner covering.

5.5 Sheath

5.5.1 Material

The sheath shall be polyvinyl chloride compound of the type specified for each type of cable in

the particular specifications (see IEC 60227-4, etc.):

– type PVC/ST4 in the case of cables for fixed installations;

– type PVC/ST5 in the case of flexible cables;

− type PVC/ST9 in case of oil-resistant flexible cables;

– type PVC/ST10 in the case of cables sheathed with a 90° polyvinyl chloride compound.

The test requirements for these compounds are specified in Table 2.

5.5.2 Application

The sheath shall be extruded in a single layer:

60227-1 © IEC:2007 – 15 –

a) on the core, in the case of single-core cables;

b) on the assembly of cores and fillers or inner covering, if any, in the case of other cables.

The sheath shall not adhere to the cores. A separator, consisting of a film or tape, may be

placed under the sheath.

In certain cases, indicated in the particular specifications (IEC 60227-4, etc.), the sheath may

penetrate into the spaces between the cores, thus forming a filling (see 5.4.2).

5.5.3 Thickness

The mean value of the thickness shall not be less than the specified value for each type and

size of cable shown in the tables of the particular specifications (IEC 60227-4, etc.).

However, the thickness at any place may be less than the specified value provided that the

difference does not exceed 0,1 mm + 15 % of the specified value, unless otherwise specified.

Compliance shall be checked by the test given in 1.10 of IEC 60227-2.

5.5.4 Mechanical properties before and after ageing

The sheath shall have adequate mechanical strength and elasticity within the temperature

limits to which it may be exposed in normal use.

Compliance shall be checked by carrying out the tests specified in Table 2.

The applicable test values and the results to be obtained are specified in Table 2.

– 16 – 60227-1 © IEC:2007

Table 2 – Requirements for the non-electrical test for polyvinyl chloride (PVC) sheaths

1 2 3 4 5 6 7 8

Reference Test Unit Test method

Type of compound

No. described in

PVC/ PVC/ PVC/ PVC/ IEC clause/

ST4 ST5 ST9 ST10 subclause

1 Tensile strength and elongation 60811-1-1 9.2

at break

1.1 Properties in the state as delivered

1.1.1 Values to be obtained for the tensile

strength:

– median, min. N/mm 12,5 10,0 10,0 10, 0

1.1.2 Values to be obtained for the

elongation at break

– median, min. % 125 150 150 150

1.2 Properties after ageing in the air oven 60811-1-2 8.1

1.2.1 Ageing conditions: 60811-1-1 9.2

– temperature °C 80 ± 2 80 ± 2 80 ± 2 135 ± 2

– duration of treatment h 7 × 24 7 × 24 7 × 24 10 × 24

1.2.2 Values to be obtained for the tensile

strength:

– median, min. N/mm 12,5 10,0 10,0 10,0

1)

– variation , max. % ±20 ±20 ±20 ±25

1.2.3 Values to be obtained for the

elongation at break:

150 150

– median, min. % 125 150

1)

±25

– variation , max. % ±20 ±20 ±20

2 Loss of mass test 60811-3-2 8.2

2.1 Ageing conditions:

– temperature °C As in reference No. 1.2.1 115 ± 2

– duration of treatment h 10 × 24

2.2 Values to be obtained for the loss of mg/cm 2,0 2,0 2,0 2,0

mass, max.

2)

3 Compatibility test 60811-1-2 8.1.4

3.1 Ageing conditions:

– temperature °C As in reference No. 1.2.1 100 ± 2

– duration of treatment h 10 × 24

3.2 Mechanical properties after ageing As in references Nos. 1.2.2

Values to be obtained and 1.2.3

4 Heat shock test 60811-3-1 9.2

4.1 Test conditions:

– temperature °C 150 ± 2 150 ± 2 150 ± 2 150 ± 2

– duration of treatment h 1 1 1 1

4.2 Result to be obtained Absence of cracks

1)

Variation: difference between the median value after ageing and the median value without ageing, expressed as a

percentage of the latter.

2)

Only applicable when called up by the particular cable standard, see also 5.3.1.

60227-1 © IEC:2007 – 17 –

Table 2 (continued)

1 2 3 4 5 6 7 8

Reference Test Unit Test method described

Type of compound

No. in

PVC/ PVC/ PVC/ PVC/ IEC clause/

ST4 ST5 ST9 ST10 subclause

5 Pressure test at high temperature 60811-3-1 8.2

5.1 Test conditions:

– force exercised by the blade 60811-3-1 8.2.4

– duration of heating under load h 60811-3-1 8.2.5

– temperature °C 80 ± 2 70 ± 2 70 ± 2 90 ± 2

5.2 Results to be obtained:

– median of the depth of penetration, % 50 50 50 50

max.

6 Bending test at low temperature 60811-1-4 8.2

6.1 Test conditions:

1)

– temperature °C –15 ± 2 –15 ± 2 –15 ± 2 –15 ± 2

– period of application of h 60811-1-4 8.2.3

low temperature

6.2 Results to be obtained Absence of cracks

7 Elongation test at low temperature 60811-1-4 8.4

7.1 Test conditions:

1)

– temperature °C –15 ± 2 –15 ± 2 –15 ± 2 –15 ± 2

– period of application of h 60811-1-4 8.4.4

low temperature and

8.4.5

7.2 Result to be obtained:

– elongation without break, min. % 20 20 20 20

8 Impact test at low temperature 60811-1-4 8.5

8.1 Test conditions:

1)

– temperature °C –15 ± 2 –15 ± 2 –15 ± 2 –15 ± 2

60811-1-4 8.5.5

– period of application of h

low temperature

– mass of hammer 60811-1-4 8.5.4

8.2 Result to be obtained 60811-1-4 8.5.6

9 Mechanical properties after 60811-2-1 10

immersion in mineral oil

9.1 Test conditions:

– temperature of oil °C – – 90 ± 2 –

– duration of immersion in oil h – – 24 –

9.1.1 Value to be obtained for the tensile

strength:

2)

– variation max. % – – ±30 –

9.1.2 Value to be obtained for the

2)

elongation at break:

– variation max. % – – ±30 –

10 Minimum thermal stability at 200 °C min

– – – 180 60811-3-2

1)

Due to climatic conditions, national standards may require the use of a lower test temperature.

2)

Variation is the difference between the median value after ageing and the median value without ageing, expressed as a

percentage of the latter.

5.6 Tests on completed cables

5.6.1 Electrical properties

The cables shall have adequate dielectric strength and insulation resistance.

Compliance shall be checked by carrying out the tests specified in Table 3.

The test methods and the results to be obtained are specified in Table 3.

– 18 – 60227-1 © IEC:2007

Table 3 – Requirements for electrical tests for PVC insulated cables

1 2 3 4 5 6 7

Reference Test Unit Rated voltage of cables Test method

No. described in

300/ 300/ 450/ IEC subclause

300 V 500 V 750 V

1 Measurement of the resistance 60227-2 2.1

of conductors

1.1 Values to be obtained, max. See IEC 60228 and particular

specifications

(IEC 60227-3, IEC 60227-4,

etc.)

2 Voltage test on completed 60227-2 2.2

cables

2.1 Test conditions:

– minimum length of the m 10 10 10

sample

– minimum period of

immersion in water h 1 1 1

– temperature of the water °C 20 ± 5 20 ± 5 20 ± 5

2.2 Voltage applied (a.c.) V 2 000 2 000 2 500

2.3 Duration of each application of

voltage, min. min 5 5 5

2.4 Results to be obtained No breakdown

3 Voltage test on cores 60227-2 2.3

3.1 Test conditions:

– length of sample m 5 5 5

– minimum period of h 1 1 1

immersion in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...