IEC 61508-6:2010

(Main)Functional safety of electrical/electronic/programmable electronic safety-related systems - Part 6: Guidelines on the application of IEC 61508-2 and IEC 61508-3 (see Functional Safety and IEC 61508)

Functional safety of electrical/electronic/programmable electronic safety-related systems - Part 6: Guidelines on the application of IEC 61508-2 and IEC 61508-3 (see Functional Safety and IEC 61508)

Looking for deeper insights? Check out IEC 61508:2010 CMV, which includes commented versions of Parts 1 to 7 of IEC 61508. These commented versions highlight the changes made from previous editions and provide explanations from a world-leading expert on the reasons behind the most significant changes.

IEC 61508-6:2010 contains information and guidelines on IEC 61508-2 and IEC 61508 3. Annex A gives a brief overview of the requirements of IEC 61508-2 and IEC 61508-3 and sets out the functional steps in their application. Annex B gives an example technique for calculating the probabilities of hardware failure and should be read in conjunction with 7.4.3 and Annex C of IEC 61508-2 and Annex D. Annex C gives a worked example of calculating diagnostic coverage and should be read in conjunction with Annex C of IEC 61508-2. Annex D gives a methodology for quantifying the effect of hardware-related common cause failures on the probability of failure. Annex E gives worked examples of the application of the software safety integrity tables specified in Annex A of IEC 61508-3 for safety integrity levels 2 and 3. This second edition cancels and replaces the first edition published in 1998. This edition constitutes a technical revision. It has been subject to a thorough review and incorporates many comments received at the various revision stages.

This publication is of high relevance for Smart Grid.

Sécurité fonctionnelle des systèmes électriques / électroniques / électroniques programmables relatifs à la sécurité - Partie 6: Lignes directrices pour l'application de la CEI 61508-2 et de la CEI 61508-3

La CEI 61508-6:2010 contient des informations et lignes directrices sur la CEI 61508-2 et la CEI 61508-3. L'Annexe A présente un bref aperçu des exigences de la CEI 61508-2 et de la CEI 61508-3 et établit les étapes fonctionnelles de leur application. L'Annexe B donne une technique servant d'exemple pour le calcul des probabilités de défaillance du matériel; il convient de la lire conjointement au 7.4.3 et à l'Annexe C de la CEI 61508-2, et à l'Annexe D. L'Annexe C donne un exemple élaboré de calcul de la couverture de diagnostic; il convient de la lire conjointement avec l'Annexe C de la CEI 61508-2. L'Annexe D donne une méthodologie de quantification de l'effet des défaillances de cause commune relatives au matériel sur la probabilité de défaillance. L'Annexe E donne des exemples d'application des tableaux d'intégrité de sécurité du logiciel spécifiés dans l'Annexe A de la CEI 61508-3 pour les niveaux 2 et 3 d'intégrité de sécurité. Cette deuxième édition annule et remplace la première édition publiée en 1998 dont elle constitue une révision technique. Elle a fait l'objet d'une révision approfondie et intègre de nombreux commentaires reçus lors des différentes phases de révision.

General Information

- Status

- Published

- Publication Date

- 29-Apr-2010

- Technical Committee

- SC 65A - System aspects

- Current Stage

- PPUB - Publication issued

- Start Date

- 30-Apr-2010

- Completion Date

- 15-Apr-2010

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Referred By

EN 764-7:2002 - Pressure equipment - Part 7: Safety systems for unfired pressure equipment - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 05-Sep-2023

Overview

IEC 61508-6:2010 is a critical international standard published by the International Electrotechnical Commission (IEC) that addresses the functional safety of electrical, electronic, and programmable electronic (E/E/PE) safety-related systems. As Part 6 of the IEC 61508 series, this standard provides comprehensive guidelines on the practical application of IEC 61508-2 and IEC 61508-3, which focus on hardware and software requirements respectively. The second edition of IEC 61508-6 represents a technical revision with enhanced explanations and updates, aiming to support engineers and safety professionals in implementing effective safety systems.

Key Topics

IEC 61508-6:2010 covers several vital aspects of functional safety related to E/E/PE systems:

Application Guidelines for IEC 61508-2 and IEC 61508-3

Annex A offers an overview of the essential requirements and functional steps in applying the hardware (Part 2) and software (Part 3) standards.Hardware Failure Probability Calculations

Annex B details example techniques for evaluating the probabilities of hardware failure. It provides methods for calculating failure rates, taking into account diverse system configurations like 1oo1, 1oo2, and 2oo3 architectures, essential for reliability and safety assessments.Diagnostic Coverage and Safe Failure Fraction

Annex C presents worked examples illustrating how to calculate diagnostic coverage and safe failure fractions, crucial metrics to measure how effectively failures are detected and managed.Common Cause Failures Methodology

Annex D explains methods to quantify the impact of hardware-related common cause failures (CCF), which are key to understanding correlated failures in redundant systems.Software Safety Integrity Applications

Annex E showcases practical examples applying software safety integrity level tables from IEC 61508-3, illustrating how to meet SIL 2 and SIL 3 requirements.Updated Technical Revisions

Incorporates significant adjustments and clarifications from the previous 1998 edition to enhance usability and align with the evolving functional safety ecosystem.

Applications

IEC 61508-6:2010 is applicable in diverse industries where functional safety and reliability of electronic safety-related systems are paramount, including:

Industrial Automation and Control Systems

Ensuring machinery and process control systems operate safely under programmable electronic controls.Smart Grid Technologies

Supporting reliable and safe operation of smart electrical grids by managing safety integrity levels and failure probabilities of protection devices.Automotive and Transportation Systems

Enhancing safety features implemented via embedded electronic systems controlling brakes, steering, and collision avoidance.Railway Signaling and Control

Assuring fail-safe design and operation of electronic signaling systems.Process Industries (Chemical, Oil & Gas, Pharmaceuticals)

Safeguarding against hazardous failures in critical control and safety instrumented systems (SIS).

Professionals use the guidelines to:

- Conduct detailed safety integrity assessments

- Calculate hardware and software failure probabilities

- Model diagnostic capabilities and manage common cause failures

- Design and validate functional safety to achieve required SIL levels

Related Standards

IEC 61508-6 integrates closely with and extends the following standards in the IEC 61508 series and beyond:

- IEC 61508-1: Framework, definitions, and general requirements for functional safety

- IEC 61508-2: Hardware requirements for safety-related systems

- IEC 61508-3: Software requirements for safety-related systems

- IEC 61508-4 to IEC 61508-7: Additional parts covering supporting processes and sector-specific applications

- Industry-specific functional safety standards such as IEC 62061 (machinery safety), IEC 61511 (process industry) and IEC 61850 (power utility communications including Smart Grid)

Utilizing IEC 61508-6 enables organizations to effectively interpret and apply hardware and software safety requirements, ensuring compliance and promoting reliable system design in accordance with the global functional safety best practices.

This guideline-rich standard is essential for engineers and safety managers aiming to optimize safety-related system design, verification, and validation, supporting safer operation of programmable electronic systems in critical industrial applications worldwide.

IEC 61508-6:2010 - Functional safety of electrical/electronic/programmable electronic safety-related systems - Part 6: Guidelines on the application of IEC 61508-2 and IEC 61508-3 (see <a href="http://www.iec.ch/functionalsafety">Functional Safety and IEC 61508</a>)

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

IEC 61508-6:2010 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Functional safety of electrical/electronic/programmable electronic safety-related systems - Part 6: Guidelines on the application of IEC 61508-2 and IEC 61508-3 (see Functional Safety and IEC 61508)". This standard covers: Looking for deeper insights? Check out IEC 61508:2010 CMV, which includes commented versions of Parts 1 to 7 of IEC 61508. These commented versions highlight the changes made from previous editions and provide explanations from a world-leading expert on the reasons behind the most significant changes. IEC 61508-6:2010 contains information and guidelines on IEC 61508-2 and IEC 61508 3. Annex A gives a brief overview of the requirements of IEC 61508-2 and IEC 61508-3 and sets out the functional steps in their application. Annex B gives an example technique for calculating the probabilities of hardware failure and should be read in conjunction with 7.4.3 and Annex C of IEC 61508-2 and Annex D. Annex C gives a worked example of calculating diagnostic coverage and should be read in conjunction with Annex C of IEC 61508-2. Annex D gives a methodology for quantifying the effect of hardware-related common cause failures on the probability of failure. Annex E gives worked examples of the application of the software safety integrity tables specified in Annex A of IEC 61508-3 for safety integrity levels 2 and 3. This second edition cancels and replaces the first edition published in 1998. This edition constitutes a technical revision. It has been subject to a thorough review and incorporates many comments received at the various revision stages. This publication is of high relevance for Smart Grid.

Looking for deeper insights? Check out IEC 61508:2010 CMV, which includes commented versions of Parts 1 to 7 of IEC 61508. These commented versions highlight the changes made from previous editions and provide explanations from a world-leading expert on the reasons behind the most significant changes. IEC 61508-6:2010 contains information and guidelines on IEC 61508-2 and IEC 61508 3. Annex A gives a brief overview of the requirements of IEC 61508-2 and IEC 61508-3 and sets out the functional steps in their application. Annex B gives an example technique for calculating the probabilities of hardware failure and should be read in conjunction with 7.4.3 and Annex C of IEC 61508-2 and Annex D. Annex C gives a worked example of calculating diagnostic coverage and should be read in conjunction with Annex C of IEC 61508-2. Annex D gives a methodology for quantifying the effect of hardware-related common cause failures on the probability of failure. Annex E gives worked examples of the application of the software safety integrity tables specified in Annex A of IEC 61508-3 for safety integrity levels 2 and 3. This second edition cancels and replaces the first edition published in 1998. This edition constitutes a technical revision. It has been subject to a thorough review and incorporates many comments received at the various revision stages. This publication is of high relevance for Smart Grid.

IEC 61508-6:2010 is classified under the following ICS (International Classification for Standards) categories: 25.040.40 - Industrial process measurement and control. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61508-6:2010 has the following relationships with other standards: It is inter standard links to EN ISO 22734-1:2025, EN ISO 25197:2012, EN ISO 4126-5:2004, EN ISO 25197:2018, EN 764-7:2002, CR 13694:1999, EN ISO 13577-4:2022, EN ISO 16904:2016, EN ISO 18497:2018, CEN/CLC/TR 17602-80-01:2021, EN ISO 16924:2018, EN ISO 20257-2:2021, IEC 61508-6:2000. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61508-6:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61508-6 ®

Edition 2.0 2010-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Functional safety of electrical/electronic/programmable electronic safety-related

systems –

Part 6: Guidelines on the application of IEC 61508-2 and IEC 61508-3

Sécurité fonctionnelle des systèmes électriques/électroniques/électroniques

programmables relatifs à la sécurité –

Partie 6: Lignes directrices pour l'application de la CEI 61508-2 et de la

CEI 61508-3

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61508-6 ®

Edition 2.0 2010-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Functional safety of electrical/electronic/programmable electronic safety-related

systems –

Part 6: Guidelines on the application of IEC 61508-2 and IEC 61508-3

Sécurité fonctionnelle des systèmes électriques/électroniques/électroniques

programmables relatifs à la sécurité –

Partie 6: Lignes directrices pour l'application de la CEI 61508-2 et de la

CEI 61508-3

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

XE

CODE PRIX

ICS 25.040.40 ISBN 978-2-88910-529-8

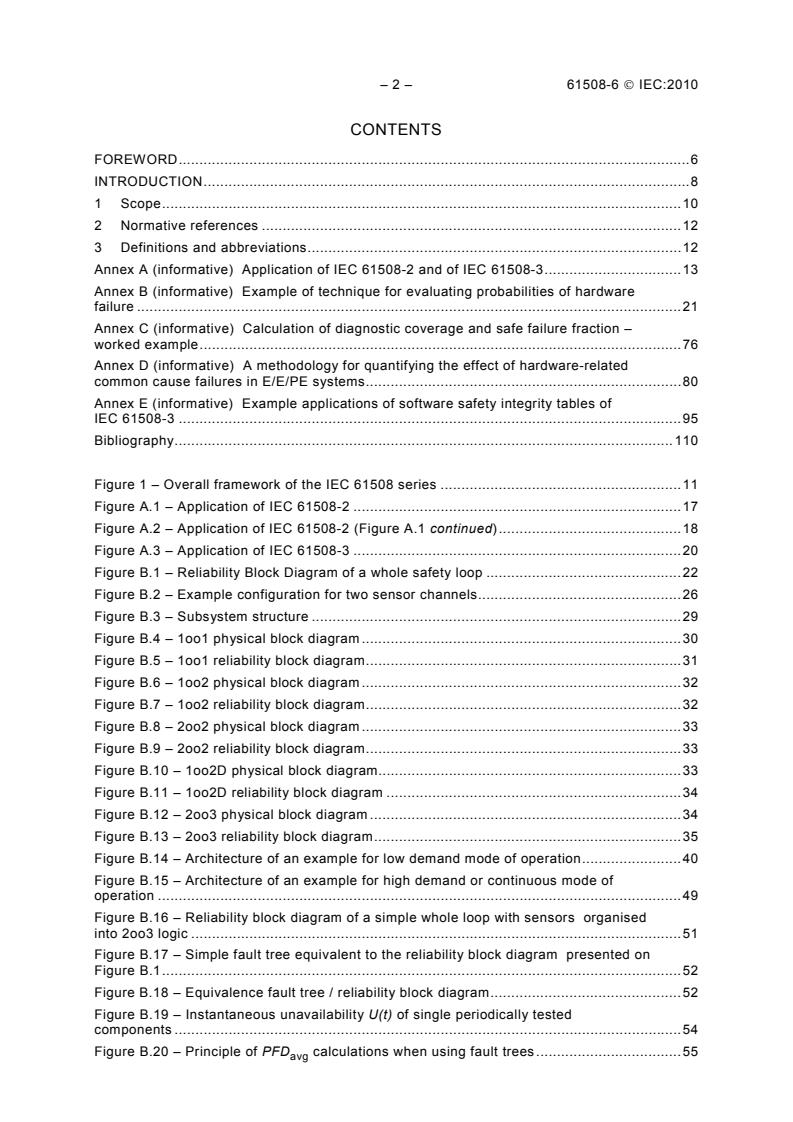

– 2 – 61508-6 © IEC:2010

CONTENTS

FOREWORD.6

INTRODUCTION.8

1 Scope.10

2 Normative references .12

3 Definitions and abbreviations.12

Annex A (informative) Application of IEC 61508-2 and of IEC 61508-3.13

Annex B (informative) Example of technique for evaluating probabilities of hardware

failure .21

Annex C (informative) Calculation of diagnostic coverage and safe failure fraction –

worked example.76

Annex D (informative) A methodology for quantifying the effect of hardware-related

common cause failures in E/E/PE systems.80

Annex E (informative) Example applications of software safety integrity tables of

IEC 61508-3 .95

Bibliography.110

Figure 1 – Overall framework of the IEC 61508 series .11

Figure A.1 – Application of IEC 61508-2 .17

Figure A.2 – Application of IEC 61508-2 (Figure A.1 continued).18

Figure A.3 – Application of IEC 61508-3 .20

Figure B.1 – Reliability Block Diagram of a whole safety loop .22

Figure B.2 – Example configuration for two sensor channels.26

Figure B.3 – Subsystem structure .29

Figure B.4 – 1oo1 physical block diagram .30

Figure B.5 – 1oo1 reliability block diagram.31

Figure B.6 – 1oo2 physical block diagram .32

Figure B.7 – 1oo2 reliability block diagram.32

Figure B.8 – 2oo2 physical block diagram .33

Figure B.9 – 2oo2 reliability block diagram.33

Figure B.10 – 1oo2D physical block diagram.33

Figure B.11 – 1oo2D reliability block diagram .34

Figure B.12 – 2oo3 physical block diagram .34

Figure B.13 – 2oo3 reliability block diagram.35

Figure B.14 – Architecture of an example for low demand mode of operation.40

Figure B.15 – Architecture of an example for high demand or continuous mode of

operation .49

Figure B.16 – Reliability block diagram of a simple whole loop with sensors organised

into 2oo3 logic .51

Figure B.17 – Simple fault tree equivalent to the reliability block diagram presented on

Figure B.1.52

Figure B.18 – Equivalence fault tree / reliability block diagram.52

Figure B.19 – Instantaneous unavailability U(t) of single periodically tested

components .54

Figure B.20 – Principle of PFD calculations when using fault trees.55

avg

61508-6 © IEC:2010 – 3 –

Figure B.21 – Effect of staggering the tests .56

Figure B.22 – Example of complex testing pattern .56

Figure B.23 – Markov graph modelling the behaviour of a two component system .58

Figure B.24 – Principle of the multiphase Markovian modelling .59

Figure B.25 – Saw-tooth curve obtained by multiphase Markovian approach.60

Figure B.26 – Approximated Markovian model .60

Figure B.27 – Impact of failures due to the demand itself.61

Figure B.28 – Modelling of the impact of test duration.61

Figure B.29 – Multiphase Markovian model with both DD and DU failures.62

Figure B.30 – Changing logic (2oo3 to 1oo2) instead of repairing first failure.63

Figure B.31 – "Reliability" Markov graphs with an absorbing state .63

Figure B.32 – "Availability" Markov graphs without absorbing states .65

Figure B.33 – Petri net for modelling a single periodically tested component.66

Figure B.34 – Petri net to model common cause failure and repair resources.69

Figure B.35 – Using reliability block diagrams to build Petri net and auxiliary Petri net

for PFD and PFH calculations .70

Figure B.36 – Simple Petri net for a single component with revealed failures and

repairs .71

Figure B.37 – Example of functional and dysfunctional modelling with a formal

language.72

Figure B.38 – Uncertainty propagation principle.73

Figure D.1 – Relationship of common cause failures to the failures of individual

channels .82

Figure D.2 – Implementing shock model with fault trees.93

Table B.1 – Terms and their ranges used in this annex (applies to 1oo1, 1oo2, 2oo2,

1oo2D, 1oo3 and 2oo3) .27

Table B.2 – Average probability of failure on demand for a proof test interval of six

months and a mean time to restoration of 8 h .36

Table B.3 – Average probability of failure on demand for a proof test interval of one

year and mean time to restoration of 8 h.37

Table B.4 – Average probability of failure on demand for a proof test interval of two

years and a mean time to restoration of 8 h .38

Table B.5 – Average probability of failure on demand for a proof test interval of

ten years and a mean time to restoration of 8 h .39

Table B.6 – Average probability of failure on demand for the sensor subsystem in the

example for low demand mode of operation (one year proof test interval and

8 h MTTR) .40

Table B.7 – Average probability of failure on demand for the logic subsystem in the

example for low demand mode of operation (one year proof test interval and

8 h MTTR) .41

Table B.8 – Average probability of failure on demand for the final element subsystem

in the example for low demand mode of operation (one year proof test interval and

8 h MTTR) .41

Table B.9 – Example for a non-perfect proof test .42

Table B.10 – Average frequency of a dangerous failure (in high demand or continuous

mode of operation) for a proof test interval of one month and a mean time to

restoration of 8 h .45

– 4 – 61508-6 © IEC:2010

Table B.11 – Average frequency of a dangerous failure (in high demand or continuous

mode of operation) for a proof test interval of three month and a mean time to

restoration of 8 h .46

Table B.12 – Average frequency of a dangerous failure (in high demand or continuous

mode of operation) for a proof test interval of six month and a mean time to restoration

of 8 h .Error! Bookmark not defined.

Table B.13 – Average frequency of a dangerous failure (in high demand or continuous

mode of operation) for a proof test interval of one year and a mean time to restoration

of 8 h .Error! Bookmark not defined.

Table B.14 – Average frequency of a dangerous failure for the sensor subsystem in the

example for high demand or continuous mode of operation (six month proof test

interval and 8 h MTTR) .49

Table B.15 – Average frequency of a dangerous failure for the logic subsystem in the

example for high demand or continuous mode of operation (six month proof test

interval and 8 h MTTR) .50

Table B.16 – Average frequency of a dangerous failure for the final element subsystem

in the example for high demand or continuous mode of operation (six month proof test

interval and 8 h MTTR) .50

Table C.1 – Example calculations for diagnostic coverage and safe failure fraction .78

Table C.2 – Diagnostic coverage and effectiveness for different elements .79

Table D.1 – Scoring programmable electronics or sensors/final elements .88

Table D.2 – Value of Z – programmable electronics .89

Table D.3 – Value of Z – sensors or final elements .89

Table D.4 – Calculation of β or β .90

int D int

Table D.5 – Calculation of β for systems with levels of redundancy greater than 1oo2 .91

Table D.6 – Example values for programmable electronics .92

Table E.1 – Software safety requirements specification .96

Table E.2 – Software design and development – software architecture design .97

Table E.3 – Software design and development – support tools and programming

language.98

Table E.4 – Software design and development – detailed design .99

Table E.5 – Software design and development – software module testing and

integration .100

Table E.6 – Programmable electronics integration (hardware and software). 100

Table E.7 – Software aspects of system safety validation .101

Table E.8 – Modification .101

Table E.9 – Software verification .102

Table E.10 – Functional safety assessment .102

Table E.11 – Software safety requirements specification . 104

Table E.12 – Software design and development – software architecture design .104

Table E.13 – Software design and development – support tools and programming

language.105

Table E.14 – Software design and development – detailed design .106

Table E.15 – Software design and development – software module testing and

integration .106

Table E.16 – Programmable electronics integration (hardware and software). 107

Table E.17 – Software aspects of system safety validation . 108

Table E.18 – Modification .108

61508-6 © IEC:2010 – 5 –

Table E.19 – Software verification .109

Table E.20 – Functional safety assessment .109

– 6 – 61508-6 © IEC:2010

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FUNCTIONAL SAFETY OF ELECTRICAL/ELECTRONIC/

PROGRAMMABLE ELECTRONIC SAFETY-RELATED SYSTEMS –

Part 6: Guidelines on the application

of IEC 61508-2 and IEC 61508-3

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61508-6 has been prepared by subcommittee 65A: System

aspects, of IEC technical committee 65: Industrial-process measurement, control and

automation.

This second edition cancels and replaces the first edition published in 2000. This edition

constitutes a technical revision.

This edition has been subject to a thorough review and incorporates many comments received

at the various revision stages.

61508-6 © IEC:2010 – 7 –

The text of this standard is based on the following documents:

FDIS Report on voting

65A/553/FDIS 65A/577/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 61508 series, published under the general title Functional safety

of electrical / electronic / programmable electronic safety-related systems, can be found on

the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 8 – 61508-6 © IEC:2010

INTRODUCTION

Systems comprised of electrical and/or electronic elements have been used for many years to

perform safety functions in most application sectors. Computer-based systems (generically

referred to as programmable electronic systems) are being used in all application sectors to

perform non-safety functions and, increasingly, to perform safety functions. If computer

system technology is to be effectively and safely exploited, it is essential that those

responsible for making decisions have sufficient guidance on the safety aspects on which to

make these decisions.

This International Standard sets out a generic approach for all safety lifecycle activities for

systems comprised of electrical and/or electronic and/or programmable electronic (E/E/PE)

elements that are used to perform safety functions. This unified approach has been adopted

in order that a rational and consistent technical policy be developed for all electrically-based

safety-related systems. A major objective is to facilitate the development of product and

application sector international standards based on the IEC 61508 series.

In most situations, safety is achieved by a number of systems which rely on many

technologies (for example mechanical, hydraulic, pneumatic, electrical, electronic,

programmable electronic). Any safety strategy must therefore consider not only all the

elements within an individual system (for example sensors, controlling devices and actuators)

but also all the safety-related systems making up the total combination of safety-related

systems. Therefore, while this International Standard is concerned with E/E/PE safety-related

systems, it may also provide a framework within which safety-related systems based on other

technologies may be considered.

It is recognized that there is a great variety of applications using E/E/PE safety-related

systems in a variety of application sectors and covering a wide range of complexity, hazard

and risk potentials. In any particular application, the required safety measures will be

dependent on many factors specific to the application. This International Standard, by being

generic, will enable such measures to be formulated in future product and application sector

international standards and in revisions of those that already exist.

This International Standard

– considers all relevant overall, E/E/PE system and software safety lifecycle phases (for

example, from initial concept, though design, implementation, operation and maintenance

to decommissioning) when E/E/PE systems are used to perform safety functions;

– has been conceived with a rapidly developing technology in mind; the framework is

sufficiently robust and comprehensive to cater for future developments;

– enables product and application sector international standards, dealing with E/E/PE

safety-related systems, to be developed; the development of product and application

sector international standards, within the framework of this standard, should lead to a high

level of consistency (for example, of underlying principles, terminology etc.) both within

application sectors and across application sectors; this will have both safety and economic

benefits;

– provides a method for the development of the safety requirements specification necessary

to achieve the required functional safety for E/E/PE safety-related systems;

– adopts a risk-based approach by which the safety integrity requirements can be

determined;

– introduces safety integrity levels for specifying the target level of safety integrity for the

safety functions to be implemented by the E/E/PE safety-related systems;

NOTE 2 The standard does not specify the safety integrity level requirements for any safety function, nor does it

mandate how the safety integrity level is determined. Instead it provides a risk-based conceptual framework and

example techniques.

– sets target failure measures for safety functions carried out by E/E/PE safety-related

systems, which are linked to the safety integrity levels;

61508-6 © IEC:2010 – 9 –

– sets a lower limit on the target failure measures for a safety function carried out by a

single E/E/PE safety-related system. For E/E/PE safety-related systems operating in

– a low demand mode of operation, the lower limit is set at an average probability of a

–5

dangerous failure on demand of 10 ;

– a high demand or a continuous mode of operation, the lower limit is set at an average

–9 –1

frequency of a dangerous failure of 10 [h ];

NOTE 3 A single E/E/PE safety-related system does not necessarily mean a single-channel architecture.

NOTE 4 It may be possible to achieve designs of safety-related systems with lower values for the target safety

integrity for non-complex systems, but these limits are considered to represent what can be achieved for relatively

complex systems (for example programmable electronic safety-related systems) at the present time.

– sets requirements for the avoidance and control of systematic faults, which are based on

experience and judgement from practical experience gained in industry. Even though the

probability of occurrence of systematic failures cannot in general be quantified the

standard does, however, allow a claim to be made, for a specified safety function, that the

target failure measure associated with the safety function can be considered to be

achieved if all the requirements in the standard have been met;

– introduces systematic capability which applies to an element with respect to its confidence

that the systematic safety integrity meets the requirements of the specified safety integrity

level;

– adopts a broad range of principles, techniques and measures to achieve functional safety

for E/E/PE safety-related systems, but does not explicitly use the concept of fail safe.

However, the concepts of “fail safe” and “inherently safe” principles may be applicable and

adoption of such concepts is acceptable providing the requirements of the relevant

clauses in the standard are met.

– 10 – 61508-6 © IEC:2010

FUNCTIONAL SAFETY OF ELECTRICAL/ELECTRONIC/

PROGRAMMABLE ELECTRONIC SAFETY-RELATED SYSTEMS –

Part 6: Guidelines on the application

of IEC 61508-2 and IEC 61508-3

1 Scope

1.1 This part of IEC 61508 contains information and guidelines on IEC 61508-2 and

IEC 61508-3.

– Annex A gives a brief overview of the requirements of IEC 61508-2 and IEC 61508-3 and

sets out the functional steps in their application.

– Annex B gives an example technique for calculating the probabilities of hardware failure

and should be read in conjunction with 7.4.3 and Annex C of IEC 61508-2 and Annex D.

– Annex C gives a worked example of calculating diagnostic coverage and should be read in

conjunction with Annex C of IEC 61508-2.

– Annex D gives a methodology for quantifying the effect of hardware-related common

cause failures on the probability of failure.

– Annex E gives worked examples of the application of the software safety integrity tables

specified in Annex A of IEC 61508-3 for safety integrity levels 2 and 3.

1.2 IEC 61508-1, IEC 61508-2, IEC 61508-3 and IEC 61508-4 are basic safety publications,

although this status does not apply in the context of low complexity E/E/PE safety-related

systems (see 3.4.3 of IEC 61508-4). As basic safety publications, they are intended for use by

technical committees in the preparation of standards in accordance with the principles

contained in IEC Guide 104 and ISO/IEC Guide 51. IEC 61508-1, IEC 61508-2, IEC 61508-3

and IEC 61508-4 are also intended for use as stand-alone publications. The horizontal safety

function of this international standard does not apply to medical equipment in compliance with

the IEC 60601 series.

1.3 One of the responsibilities of a technical committee is, wherever applicable, to make use

of basic safety publications in the preparation of its publications. In this context, the

requirements, test methods or test conditions of this basic safety publication will not apply

unless specifically referred to or included in the publications prepared by those technical

committees.

1.4 Figure 1 shows the overall framework of the IEC 61508 series and indicates the role that

IEC 61508-6 plays in the achievement of functional safety for E/E/PE safety-related systems.

61508-6 © IEC:2010 – 11 –

Technical Requirements Other Requirements

Part 4

Part 1

Definitions &

Development of the overall

abbreviations

safety requirements

(concept, scope, definition,

hazard and risk analysis)

7.1 to 7.5

Part 5

Example of methods

for the determination Part 1

of safety integrity Documentation

levels Clause 5 &

Part 1

Annex A

Allocation of the safety requirements

to the E/E/PE safety-related systems

7.6

Part 1

Management of

functional safety

Clause 6

Part 1

Specification of the system safety

requirements for the E/E/PE

safety-related systems

Part 1

Functional safety

7.10 assessm ent

Clause 8

Part 6

Guidelines for the

application of

Parts 2 & 3

Part 2 Part 3

Realisation phase Realisation phase

for E/E/PE for safety-related

safety-related software

systems

Part 7

Overview of

techniques and

measures

Part 1

Installation, commissioning

& safety validation of E/E/PE

safety-related systems

7.13 - 7.14

Part 1

Operation, maintenance,repair,

modification and retrofit,

decommissioning or disposal of

E/E/PE safety-related systems

7.15 - 7.17

Figure 1 – Overall framework of the IEC 61508 series

– 12 – 61508-6 © IEC:2010

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 61508-2:2010, Functional safety of electrical/electronic/programmable electronic safety-

related systems – Part 2: Requirements for electrical/electronic/programmable electronic

safety-related systems

IEC 61508-3:2010, Functional safety of electrical/electronic/programmable electronic safety-

related systems – Part 3: Software requirements

IEC 61508-4:2010, Functional safety of electrical/electronic/programmable electronic safety-

related systems – Part 4: Definitions and abbreviations

3 Definitions and abbreviations

For the purposes of this document, the definitions and abbreviations given in IEC 61508-4

apply.

61508-6 © IEC:2010 – 13 –

Annex A

(informative)

Application of IEC 61508-2 and of IEC 61508-3

A.1 General

Machinery, process plant and other equipment may, in the case of malfunction (for example

by failures of electrical, electronic and/or programmable electronic devices), present risks to

people and the environment from hazardous events such as fires, explosions, radiation

overdoses, machinery traps, etc. Failures can arise from either physical faults in the device

(for example causing random hardware failures), or from systematic faults (for example

human errors made in the specification and design of a system cause systematic failure under

some particular combination of inputs), or from some environmental condition.

IEC 61508-1 provides an overall framework based on a risk approach for the prevention

and/or control of failures in electro-mechanical, electronic, or programmable electronic

devices.

The overall goal is to ensure that plant and equipment can be safely automated. A key

objective of this standard is to prevent:

– failures of control systems triggering other events, which in turn could lead to danger (for

example fire, release of toxic materials, repeat stroke of a machine, etc.); and

– undetected failures in protection systems (for example in an emergency shut-down

system), making the systems unavailable when needed for a safety action.

IEC 61508-1 requires that a hazard and risk analysis at the process/machine level is carried

out to determine the amount of risk reduction necessary to meet the risk criteria for the

application. Risk is based on the assessment of both the consequence (or severity) and the

frequency (or probability) of the hazardous event.

IEC 61508-1 further requires that the amount of risk reduction established by the risk analysis

is used to determine if one or more safety-related systems are required and what safety

functions (each with a specified safety integrity) they are needed for.

IEC 61508-2 and IEC 61508-3 take the safety functions and safety integrity requirements

allocated to any system, designated as a E/E/PE safety-related system, by the application of

IEC 61508-1 and establish requirements for safety lifecycle activities which:

– are to be applied during the specification, design and modification of the hardware and

software; and

– focus on means for preventing and/or controlling random hardware and systematic failures

(the E/E/PE system and software safety lifecycles) .

—————————

Systems necessary for functional safety and containing one or more electrical (electro-mechanical), electronic

or programmable electronic (E/E/PE) devices are designated as E/E/PE safety-related systems and include all

equipment necessary to carry out the required safety function (see 3.5.1 of IEC 61508-4).

Safety integrity is specified as one of four discrete levels. Safety integrity level 4 is the highest and safety

integrity level 1 the lowest (see 3.5.4 and 3.5.8 of IEC 61508-4).

To enable the requirements of this standard to be clearly structured, a decision was made to order the

requirements using a development process model in which each stage follows in a defined order with little

iteration (sometimes referred to as a waterfall model). However, it is stressed that any lifecycle approach can

be used provided a statement of equivalence is given in the safety plan for the project (see Clause 7 of

IEC 61508-1).

– 14 – 61508-6 © IEC:2010

IEC 61508-2 and IEC 61508-3 do not give guidance on which level of safety integrity is

appropriate for a given required tolerable risk. This decision depends upon many factors,

including the nature of the application, the extent to which other systems carry out safety

functions and social and economic factors (see IEC 61508-1 and IEC 61508-5).

The requirements of IEC 61508-2 and IEC 61508-3 include:

– the application of measures and techniques , which are graded against the safety integrity

level, for the avoidance of systematic failures by preventative methods; and

– the control of systematic failures (including software failures) and random hardware

failures by design features such as fault detection, redundancy and architectural features

(for example diversity).

In IEC 61508-2, assurance that the safety integrity target has been satisfied for dangerous

random hardware failures is based on:

– hardware fault tolerance requirements (see Tables 2 and 3 of IEC 61508-2); and

– the diagnostic coverage and frequency of proof tests of subsystems and components, by

carrying out a reliability analysis using appropriate data.

In both IEC 61508-2 and IEC 61508-3, assurance that the safety integrity target has been

satisfied for systematic failures is gained by:

– the correct application of safety management procedures;

– the use of competent staff;

– the application of the specified safety lifecycle activities, including the specified

techniques and measures ; and

– an independent functional safety assessment .

The overall goal is to ensure that remaining systematic faults, commensurate with the safety

integrity level, do not cause a failure of the E/E/PE safety-related system.

IEC 61508-2 has been developed to provide requirements for achieving safety integrity in the

hardware of the E/E/PE safety-related systems including sensors and final elements.

Techniques and measures against both random hardware failures and systematic hardware

failures are required. These involve an appropriate combination of fault avoidance and failure

control measures as indicated above. Where manual action is needed for functional safety,

requirements are given for the operator interface. Also diagnostic test techniques and

measures, based on software and hardware (for example diversity), to detect random

hardware failures are specified in IEC 61508-2.

IEC 61508-3 has been developed to provide requirements for achieving safety integrity for the

software – both embedded (including diagnostic fault detection services) and application

software. IEC 61508-3 requires a combination of fault avoidance (quality assurance) and fault

tolerance approaches (software architecture), as there is no known way to prove the absence

of faults in reasonably complex safety-related software, especially the absence of

specification and design faults. IEC 61508-3 requires the adoption of such software

—————————

The required techniques and measures for each safety integrity level are shown in the tables in Annexes A

and B of IEC 61508-2 and IEC 61508-3.

Systematic failures cannot usually be quantified. Causes include: specification and design faults in hardware

and software; failure to take account of the environment (for example temperature); and operation-related faults

(for example poor interface).

Alternative measures to those specified in the standard are acceptable provided justification is documented

during safety planning (see Clause 6 of IEC 61508-1).

Independent assessment does not always imply third party assessment (see Clause 8 of IEC 61508-1).

Including fixed built-in software or software equivalents (also called firmware), such as application-specific

integrated circuits.

61508-6 © IEC:2010 – 15 –

engineering principles as: top down design; modularity; verification of each phase of the

development lifecycle; verified software modules and software module libraries; and clear

documentation to facilitate verification and validation. The different levels of software require

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...