IEC 60749-20-1:2019

(Main)Semiconductor devices - Mechanical and climatic test methods - Part 20-1: Handling, packing, labelling and shipping of surface-mount devices sensitive to the combined effect of moisture and soldering heat

Semiconductor devices - Mechanical and climatic test methods - Part 20-1: Handling, packing, labelling and shipping of surface-mount devices sensitive to the combined effect of moisture and soldering heat

IEC 60749-20-1:2019 applies to all devices subjected to bulk solder reflow processes during PCB assembly, including plastic encapsulated packages, process sensitive devices, and other moisture-sensitive devices made with moisture-permeable materials (epoxies, silicones, etc.) that are exposed to the ambient air.

The purpose of this document is to provide SMD manufacturers and users with standardized methods for handling, packing, shipping, and use of moisture/reflow sensitive SMDs that have been classified to the levels defined in IEC 60749-20. These methods are provided to avoid damage from moisture absorption and exposure to solder reflow temperatures that can result in yield and reliability degradation. By using these procedures, safe and damage-free reflow can be achieved, with the dry packing process, providing a minimum shelf life capability in sealed dry-bags from the seal date. This edition includes the following significant technical changes with respect to the previous edition:

- updates to subclauses to better align the test method with IPC/JEDEC J-STD-033C, including new sections on aqueous cleaning and dry pack precautions;

- addition of two annexes on colorimetric testing of HIC (humidity indicator card) and derivation of bake tables.

Dispositifs à semiconducteurs - Méthodes d'essais mécaniques et climatiques - Partie 20-1: Manipulation, emballage, étiquetage et transport des composants pour montage en surface sensibles à l'effet combiné de l'humidité et de la chaleur de brasage

L'IEC 60749-20-1:2019 s'applique à tous les dispositifs soumis à des procédés de brasage par refusion en masse lors de l'assemblage de la PCB, comprenant les boîtiers plastiques, les dispositifs sensibles aux procédés et les autres dispositifs sensibles à l'humidité fabriqués dans des matériaux perméables à l'humidité (époxydes, silicones, etc.), qui sont exposés à l'air ambiant. L'objet du présent document est de fournir aux fabricants et aux utilisateurs de CMS des méthodes normalisées pour la manipulation, l'emballage, le transport et l'utilisation des CMS sensibles à l'humidité/la refusion qui sont classés selon les niveaux définis dans l'IEC 60749‑20. Ces méthodes sont fournies pour éviter les dommages provoqués par l'absorption d'humidité et l'exposition aux températures de brasage par refusion pouvant donner lieu à une dégradation de rendement et de fiabilité. L'utilisation de ces procédures permet une refusion sûre et ne causant pas de dommages, avec le procédé d'emballage avec dessiccant, ce qui permet une durée minimale de stockage dans des sachets scellés avec dessiccant à compter de la date de scellement. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- mises à jour de certains paragraphes pour mieux aligner la méthode d'essai avec le document IPC/JEDEC J-STD-033C, comprenant de nouvelles sections sur le nettoyage aqueux et les précautions applicables aux emballages avec dessiccant;

- ajout de deux annexes sur les essais colorimétriques des cartes indicatrices d'humidité (HIC) et la détermination des tableaux d'étuvage.

General Information

- Status

- Published

- Publication Date

- 25-Jun-2019

- Technical Committee

- TC 47 - Semiconductor devices

- Drafting Committee

- WG 2 - TC 47/WG 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 26-Jun-2019

- Completion Date

- 05-Jul-2019

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60749-20-1:2019 is an IEC standard that defines standardized handling, packing, labelling and shipping procedures for surface-mount devices (SMDs) that are sensitive to the combined effects of moisture and soldering heat. It applies to all devices exposed to bulk solder reflow during PCB assembly-particularly plastic‑encapsulated, process‑sensitive and other moisture‑permeable materials (epoxies, silicones, etc.). The objective is to prevent moisture-induced damage during reflow that can degrade yield and long‑term reliability.

Key topics and technical requirements

- Scope and applicability: Covers SMDs classified to IEC 60749-20 levels and devices used in mass reflow processes.

- Dry packing (MBBs): Requirements for moisture barrier bags (MBBs), desiccants, sealing, labeling and minimum shelf life from the seal date to enable safe, damage‑free reflow.

- Drying and baking: Approved drying options, bake tables and precautions to remove absorbed moisture prior to sealing or reflow. Annex D provides guidance on derivation of bake tables.

- Floor life and use: Rules for floor life start, clock resetting/pausing, safe storage categories, and reflow categories including limits on multiple reflow passes.

- Inspection and indicators: Incoming bag inspection, humidity indicator cards (HIC) testing and interpretation. Annex C is a normative method for colorimetric testing of HICs.

- Labels and symbols: Standardized MSID (Moisture Sensitive Identification) labels, caution labels and information required on packaging (Annex A).

- Rework and board baking: Guidance on component removal, rework and baking of populated boards (informative Annex B).

- Alignment with industry practices: Updates to align subclauses with IPC/JEDEC J‑STD‑033C, including aqueous cleaning and dry‑pack precautions.

Practical applications and users

Who benefits:

- SMD manufacturers and semiconductor packaging teams

- PCB assemblers and contract manufacturers (CMs)

- Quality, reliability and materials engineers

- Supply chain, packaging, logistics and warehouse personnel

- Failure analysis and board rework technicians

Practical uses:

- Establishing a dry‑pack and shipping process to ensure minimum shelf life and safe reflow

- Creating incoming inspection procedures using HICs

- Determining bake times and storage rules to reset or preserve floor life

- Standardizing labels and documentation for moisture‑sensitive devices in transit

Related standards

- IEC 60749-20 (classification of moisture sensitivity levels)

- IPC/JEDEC J‑STD‑033 (industry practices for moisture/reflow sensitive SMDs)

By following IEC 60749-20-1:2019, organizations can reduce moisture-related assembly failures, standardize handling and packaging practices, and improve yield and reliability for moisture‑sensitive SMDs.

Buy Documents

IEC 60749-20-1:2019 RLV - Semiconductor devices - Mechanical and climatic test methods - Part 20-1: Handling, packing, labelling and shipping of surface-mount devices sensitive to the combined effect of moisture and soldering heat Released:6/26/2019 Isbn:9782832271247

IEC 60749-20-1:2019 - Semiconductor devices - Mechanical and climatic test methods - Part 20-1: Handling, packing, labelling and shipping of surface-mount devices sensitive to the combined effect of moisture and soldering heat Released:6/26/2019 Isbn:9782832270431

Frequently Asked Questions

IEC 60749-20-1:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Semiconductor devices - Mechanical and climatic test methods - Part 20-1: Handling, packing, labelling and shipping of surface-mount devices sensitive to the combined effect of moisture and soldering heat". This standard covers: IEC 60749-20-1:2019 applies to all devices subjected to bulk solder reflow processes during PCB assembly, including plastic encapsulated packages, process sensitive devices, and other moisture-sensitive devices made with moisture-permeable materials (epoxies, silicones, etc.) that are exposed to the ambient air. The purpose of this document is to provide SMD manufacturers and users with standardized methods for handling, packing, shipping, and use of moisture/reflow sensitive SMDs that have been classified to the levels defined in IEC 60749-20. These methods are provided to avoid damage from moisture absorption and exposure to solder reflow temperatures that can result in yield and reliability degradation. By using these procedures, safe and damage-free reflow can be achieved, with the dry packing process, providing a minimum shelf life capability in sealed dry-bags from the seal date. This edition includes the following significant technical changes with respect to the previous edition: - updates to subclauses to better align the test method with IPC/JEDEC J-STD-033C, including new sections on aqueous cleaning and dry pack precautions; - addition of two annexes on colorimetric testing of HIC (humidity indicator card) and derivation of bake tables.

IEC 60749-20-1:2019 applies to all devices subjected to bulk solder reflow processes during PCB assembly, including plastic encapsulated packages, process sensitive devices, and other moisture-sensitive devices made with moisture-permeable materials (epoxies, silicones, etc.) that are exposed to the ambient air. The purpose of this document is to provide SMD manufacturers and users with standardized methods for handling, packing, shipping, and use of moisture/reflow sensitive SMDs that have been classified to the levels defined in IEC 60749-20. These methods are provided to avoid damage from moisture absorption and exposure to solder reflow temperatures that can result in yield and reliability degradation. By using these procedures, safe and damage-free reflow can be achieved, with the dry packing process, providing a minimum shelf life capability in sealed dry-bags from the seal date. This edition includes the following significant technical changes with respect to the previous edition: - updates to subclauses to better align the test method with IPC/JEDEC J-STD-033C, including new sections on aqueous cleaning and dry pack precautions; - addition of two annexes on colorimetric testing of HIC (humidity indicator card) and derivation of bake tables.

IEC 60749-20-1:2019 is classified under the following ICS (International Classification for Standards) categories: 31.080.01 - Semiconductor devices in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60749-20-1:2019 has the following relationships with other standards: It is inter standard links to IEC 60749-20-1:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60749-20-1:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60749-20-1 ®

Edition 2.0 2019-06

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Semiconductor devices – Mechanical and climatic test methods –

Part 20-1: Handling, packing, labelling and shipping of surface-mount devices

sensitive to the combined effect of moisture and soldering heat

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60749-20-1 ®

Edition 2.0 2019-06

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Semiconductor devices – Mechanical and climatic test methods –

Part 20-1: Handling, packing, labelling and shipping of surface-mount devices

sensitive to the combined effect of moisture and soldering heat

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.080.01 ISBN 978-2-8322-7124-7

– 2 – IEC 60749-20-1:2019 RLV © IEC:2019

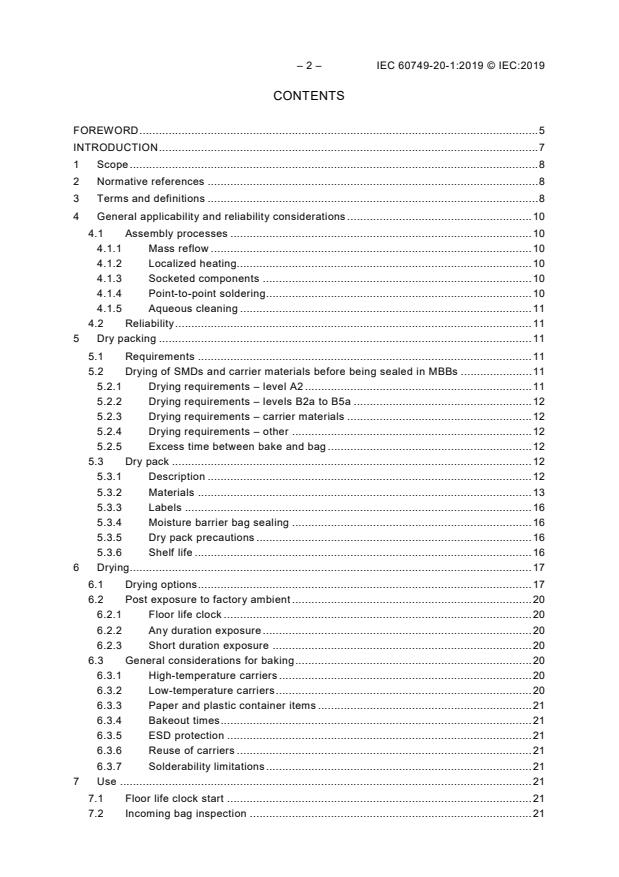

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 8

4 General applicability and reliability considerations . 10

4.1 Assembly processes . 10

4.1.1 Mass reflow . 10

4.1.2 Localized heating. 10

4.1.3 Socketed components . 10

4.1.4 Point-to-point soldering . 11

4.1.5 Aqueous cleaning . 11

4.2 Reliability . 11

5 Dry packing . 11

5.1 Requirements . 11

5.2 Drying of SMDs and carrier materials before being sealed in MBBs . 11

5.2.1 Drying requirements – level A2 . 11

5.2.2 Drying requirements – levels B2a to B5a . 12

5.2.3 Drying requirements – carrier materials . 12

5.2.4 Drying requirements – other . 12

5.2.5 Excess time between bake and bag . 12

5.3 Dry pack . 12

5.3.1 Description . 12

5.3.2 Materials . 13

5.3.3 Labels . 16

5.3.4 Moisture barrier bag sealing . 17

5.3.5 Dry pack precautions . 17

5.3.6 Shelf life . 17

6 Drying. 17

6.1 Drying options . 17

6.2 Post exposure to factory ambient . 22

6.2.1 Floor life clock . 22

6.2.2 Any duration exposure . 22

6.2.3 Short duration exposure . 22

6.3 General considerations for baking . 22

6.3.1 High-temperature carriers . 22

6.3.2 Low-temperature carriers . 22

6.3.3 Paper and plastic container items . 23

6.3.4 Bakeout times . 23

6.3.5 ESD protection . 23

6.3.6 Reuse of carriers . 23

6.3.7 Solderability limitations . 23

7 Use . 23

7.1 Floor life clock start . 23

7.2 Incoming bag inspection . 23

7.2.1 Upon receipt . 23

7.2.2 Component inspection . 24

7.3 Floor life . 24

7.4 Safe storage . 24

7.4.1 Safe storage categories . 24

7.4.2 Dry pack . 24

7.4.3 Shelf life . 24

7.4.4 Dry atmosphere cabinet . 25

7.5 Reflow . 25

7.5.1 Reflow categories . 25

7.5.2 Opened MBB . 25

7.5.3 Reflow temperature extremes . 25

7.5.4 Additional thermal profile parameters. 25

7.5.5 Multiple reflow passes . 26

7.5.6 Maximum reflow passes . 26

7.6 Drying indicators . 26

7.6.1 Drying requirements . 26

7.6.2 Excess humidity in the dry pack . 26

7.6.3 Floor life or ambient temperature/humidity exceeded . 27

7.6.4 Level B6 SMDs . 27

Annex A (normative) Symbol and labels for moisture-sensitive devices . 28

A.1 Object . 28

A.2 Symbol and labels. 28

A.2.1 "Moisture-sensitive" symbol . 28

A.2.2 Moisture-sensitive identification (MSID) label . 28

A.2.3 Moisture-sensitive caution labels . 28

Annex B (informative) Board rework . 32

B.1 Component removal, rework and remount . 32

B.1.1 Removal precautions . 32

B.1.2 Removal for failure analysis . 32

B.1.3 Removal and remount . 32

B.2 Baking of populated boards. 32

Annex C (normative) Test method for humidity indicator cards used with electronic

component packaging . 33

C.1 HIC testing method . 33

C.2 Testing apparatus . 33

C.3 Testing procedure . 33

C.4 Data analysis . 34

Annex D (informative) Derivation of bake tables . 35

Annex E (informative) Derating due to factory environmental conditions . 37

Bibliography . 41

Figure 1 – Typical dry pack configuration for moisture-sensitive SMDs

in shipping tubes . 13

Figure 2 – Example humidity indicator cards . 16

Figure A.1 – Moisture-sensitive symbol (example) . 28

Figure A.2 – MSID label (example) . 28

Figure A.3 – Information label for level A1 or B1 (example) . 29

– 4 – IEC 60749-20-1:2019 RLV © IEC:2019

Figure A.4 – Moisture-sensitive caution label for level A2 (example) . 29

Figure A.5 – Moisture-sensitive caution label for levels B2-B5a (example) . 30

Figure A.6 – Moisture-sensitive caution label for level B6 (example) . 31

Figure D.1 –Typical moisture concentration over time . 35

Table 1 – Dry packing requirements . 11

Table 2 –Typical HIC spot compliance . 15

Table 3 – Reference conditions for drying mounted or unmounted SMDs (user bake:

floor life begins counting at time = 0 after bake) – Level 2. 18

Table 4 – Reference conditions for drying mounted or unmounted SMDs (user bake:

floor life begins counting at time = 0 after bake) – Levels B2, B2a to B5a . 20

Table 5 – Default baking times used prior to dry-pack that were exposed to conditions

≤ 60 % RH (supplier bake: MET = 24 h) . 21

Table 6 – Resetting or pausing the ‘floor life’ clock at user site . 21

Table 7 – Moisture classification level and floor life . 24

Table C.1 – HIC spot compliance . 33

Table E.1 – Recommended equivalent total floor life (days) for level A2 at 20 °C, 25 °C,

30 °C and 35 °C for ICs with novolac, biphenyl and multifunctional epoxies (reflow at

same temperature at which component was classified) . 38

Table E.2 – Recommended equivalent total floor life (days) for levels B2a to B5a at

20 °C, 25 °C, 30 °C and 35 °C for ICs with novolac, biphenyl and multifunctional

epoxies (reflow at same temperature at which component was classified) . 39

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SEMICONDUCTOR DEVICES –

MECHANICAL AND CLIMATIC TEST METHODS –

Part 20-1: Handling, packing, labelling and shipping of surface-mount

devices sensitive to the combined effect of moisture and soldering heat

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

– 6 – IEC 60749-20-1:2019 RLV © IEC:2019

This second edition cancels and replaces the first edition published in 2009. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) updates to subclauses to better align the test method with IPC/JEDEC J-STD-033C,

including new sections on aqueous cleaning and dry pack precautions;

b) addition of two annexes on colorimetric testing of HIC (humidity indicator card) and

derivation of bake tables.

The text of this standard is based on the following documents:

FDIS Report on voting

47/2565/FDIS 47/2579/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60749 series, published under the general title Semiconductor

devices – Mechanical and climatic test methods, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

INTRODUCTION

The advent of surface-mount devices (SMDs) introduced a new class of quality and reliability

concerns regarding package damage "cracks and delamination" from the solder reflow

process. This document describes the standardized levels of floor life exposure for

moisture/reflow-sensitive SMDs along with the handling, packing and shipping requirements

necessary to avoid moisture/reflow-related failures. IEC 60749-20 defines the classification

procedure and Annex A of this document defines the labelling requirements.

Moisture from atmospheric humidity enters permeable packaging materials by diffusion.

Assembly processes used to solder SMDs to printed circuit boards (PCBs) expose the entire

package body to temperatures higher than 200 °C. During solder reflow, the combination of

rapid moisture expansion, materials mismatch, and material interface degradation can result

in package cracking and/or delamination of critical interfaces within the package.

The solder reflow processes of concern are convection, convection/IR, infrared (IR), vapour

phase (VPR) and hot air rework tools. The use of assembly processes that immerse the

component body in molten solder are not recommended for most SMDs.

This first edition of IEC 60749-20-1 is based principally on IPC/JEDEC J-STD-033 and the

permission to use this standard is gratefully acknowledged. It is also based on contributing

documents from various national committees.

Typical solder reflow processes of concern for all devices are infrared (IR), convection/IR,

convection, vapour phase reflow (VPR), hot air rework tools, and wave solder, including full

immersion.

Non-semiconductor devices can exhibit additional process sensitivities beyond moisture

sensitivity such as thermal sensitivity, flux sensitivity, or cleaning process sensitivity.

___________

Refer to Bibliography.

– 8 – IEC 60749-20-1:2019 RLV © IEC:2019

SEMICONDUCTOR DEVICES –

MECHANICAL AND CLIMATIC TEST METHODS –

Part 20-1: Handling, packing, labelling and shipping of surface-mount

devices sensitive to the combined effect of moisture and soldering heat

1 Scope

This part of IEC 60749 applies to all non-hermetic SMD packages which are subjected to

reflow solder processes and devices subjected to bulk solder reflow processes during PCB

assembly, including plastic encapsulated packages, process sensitive devices, and other

moisture-sensitive devices made with moisture-permeable materials (epoxies, silicones, etc.)

that are exposed to the ambient air.

The purpose of this document is to provide SMD manufacturers and users with standardized

methods for handling, packing, shipping, and use of moisture/reflow sensitive SMDs that have

been classified to the levels defined in IEC 60749-20. These methods are provided to avoid

damage from moisture absorption and exposure to solder reflow temperatures that can result

in yield and reliability degradation. By using these procedures, safe and damage-free reflow

can be achieved, with the dry packing process, providing a minimum shelf life capability in

sealed dry-bags from the seal date.

Two test conditions, method A and method B, are specified in the soldering heat test of

IEC 60749-20. For method A, moisture soak conditions are specified on the assumption that

moisture content inside the moisture barrier bag is less than 30 % RH. For method B,

moisture soaking conditions are specified on the assumption that manufacturer’s exposure

time (MET) does not exceed 24 h and the moisture content inside the moisture barrier bag is

less than 10 % RH. In an actual handling environment, SMDs tested by method A are

permitted to absorb moisture up to 30 % RH, and SMDs tested by method B are permitted to

absorb moisture up to 10 % RH. This document specifies the handling conditions for SMDs

subjected to the above test conditions.

NOTE Hermetic SMD packages are not moisture sensitive and do not require moisture precautionary handling.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60749-20, Semiconductor devices – Mechanical and climatic test methods – Part 20:

Resistance of plastic-encapsulated SMDs to the combined effect of moisture and soldering

heat

IEC 60749-30, Semiconductor devices – Mechanical and climatic test methods – Part 30:

Preconditioning of non-hermetic surface mount devices prior to reliability testing

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

active desiccant

desiccant that is either fresh (new) or has been baked according to the manufacturer’s

recommendations to renew it to original specifications

3.2

bar code label

label that gives information in a code consisting of parallel bars and spaces, each of various

specific widths

Note 1 to entry: For the purposes of this document, the bar code label is on the lowest level shipping container

and includes information that describes the product, e.g. part number, quantity, lot information, supplier

identification, and moisture-sensitivity level etc.

3.3

mass reflow

reflow of a number of components with simultaneous attachment by an infrared (IR),

convection/IR, convection, or vapour phase reflow (VPR) process

3.4

carrier

container that directly holds components such as a tray, tube, or tape and reel

3.5

desiccant

absorbent material used to maintain a low relative humidity

3.6

floor life

allowable time period for a moisture-sensitive device, after removal from a moisture barrier

bag, dry storage or dry bake and before the solder reflow process

3.7

humidity indicator card

HIC

card on which a moisture-sensitive chemical is applied in such a way that it will make a

significant, perceptible change in colour (hue), typically from blue (dry) to pink (wet) when the

indicated relative humidity is exceeded

card printed with a moisture-sensitive chemical (cobalt bromide) that changes from blue to

pink in the presence of water vapour

Note 1 to entry: The HIC is packed inside the moisture-barrier bag, along with a desiccant, to aid in determining

the level of moisture to which the moisture-sensitive devices have been subjected.

Note 2 to entry: This note applies to the French language only.

3.8

manufacturer’s exposure time

MET

maximum time after bake that the component manufacturer requires to process components

prior to bag seal, and that also includes the maximum time allowed at the distributor for

having the bag open to split out smaller shipments

Note 1 to entry: This note applies to the French language only.

– 10 – IEC 60749-20-1:2019 RLV © IEC:2019

3.9

moisture barrier bag

MBB

bag designed to restrict the transmission of water vapour and used to pack moisture-sensitive

devices

storage bag manufactured with a flexible laminated vapour barrier film that restricts the

transmission of water vapour

Note 1 to entry: This note applies to the French language only.

3.10

rework

removal of a component for scrap, reuse, or failure analysis; replacement of an attached

component; or heating and repositioning of a previously attached component

3.11

shelf-life

maximum storage period for a dry-packed moisture-sensitive device in an unopened moisture

barrier bag (MBB) to avoid exceeding the specified interior bag ambient humidity

3.12

surface-mount device

SMD

plastic-encapsulated surface-mount devices made with moisture-permeable materials

Note 1 to entry: For the purposes of this document, the term "SMD" is limited as indicated in the above definition.

3.13

solder reflow

solder attachment process in which previously applied solder or solder paste is melted to

attach a component to the printed circuit board

3.14

water vapour transmission rate

WVTR

measure of the permeability of plastic film or metallized plastic film material to moisture

4 General applicability and reliability considerations

4.1 Assembly processes

4.1.1 Mass reflow

This document applies to mass solder reflow assembly by convection, convection/IR, infrared

(IR), and vapour phase (VPR), processes. It does not apply to mass solder reflow processes

that immerse the component bodies in molten solder (e.g. wave soldering bottom mounted

components). Such processes are not allowed for many SMDs and are not covered by the

component qualifications standards used as a basis for this document.

4.1.2 Localized heating

This document also applies to moisture-sensitive SMDs that are removed or attached singly

by local ambient heating, i.e. "hot air rework". See Annex B.

4.1.3 Socketed components

This document does not apply to SMDs that are socketed and not exposed to solder reflow

temperatures. Such SMDs are not at risk and do not require moisture precautionary handling.

4.1.4 Point-to-point soldering

This document does not apply to SMDs in which only the leads are heated to reflow the solder,

e.g. hand-soldering, hot bar attach of gull-wing leads, and through hole by wave soldering.

The heat absorbed by the SMD body from such operations is typically much lower than that

for mass surface mount reflow or hot air rework, and moisture precautionary measures are

typically not needed.

4.1.5 Aqueous cleaning

For non-cavity SMDs, typical short-term aqueous cleaning processes will not impact the floor

life (internal moisture content). Special consideration should be given to non-hermetic cavity

packages.

4.2 Reliability

The methods set forth in this specification ensure that an adequate SMD reliability can be

achieved during and after the PCB assembly operation, when the SMDs are evaluated and

verified by IEC 60749-20 and/or by IEC 60749-30, together with environmental reliability

testing.

This specification does not address or ensure solder joint reliability of attached components.

5 Dry packing

5.1 Requirements

Dry packing requirements for the various moisture sensitivity levels are shown in Table 1. The

levels are determined in accordance with IEC 60749-20 and/or IEC 60749-30, together with

reliability testing. As a minimum, all materials used in dry packing should conform to relevant

national packaging material standards for ESD-sensitive items.

Table 1 – Dry packing requirements

a

Level Dry before MBB Desiccant MSID label Caution label

bag

A1 or B1 Optional Optional Optional Not required Not required if classified at

220 °C to 225 °C

b

Required if classified at other

than 220 °C to 225 °C

A2 or B2 Optional Required Required Required Required

B2a-B5a Required Required Required Required Required

B6 Optional Optional Optional Required Required

a

MSID = moisture-sensitive identification label.

b

A "Caution" label is not required if level and reflow temperature are given, in human readable form, on the

barcode label attached to the lowest level shipping container.

5.2 Drying of SMDs and carrier materials before being sealed in MBBs

5.2.1 Drying requirements – level A2

Packing of the SMDs classified as Level A2 into MBBs shall be carried out within one week

under the environmental condition below 30 °C/60 % RH after moulding, burn-in, or bake.

MET is not specified for Level A2 SMDs.

– 12 – IEC 60749-20-1:2019 RLV © IEC:2019

MBBs may be opened for a short period of time (less than 1 h) and re-closed provided that

the HIC indicates a humidity of less than 30 % RH and provided that the desiccant is replaced

with fresh desiccant. When the MBB is next opened, as long as the HIC indicates below

30 % RH, the duration time of the previous MBB’s opening may be disregarded. Thus, if the

HIC indicates below 30 % RH when MBB is opened, the floor life is not dependent on the

duration time of the MBB's opening, and is 168 h at 30 °C/70 % RH.

5.2.2 Drying requirements – levels B2a to B5a

SMDs classified from Levels B2a through to B5a shall be dried (see Clause 6) prior to being

sealed in MBBs. The period between drying and sealing shall not exceed the MET less the

time allowed for distributors to open the bags and repack parts. If the supplier’s actual MET is

more than the default 24 h, then the actual time shall be used. If the distributor practice is to

repack the MBBs with active desiccant, then this time does not need to be subtracted from the

MET.

5.2.3 Drying requirements – carrier materials

The materials from which carriers (such as trays, tubes, reels, etc.) are made can affect the

moisture level when placed in the MBB. Therefore, the effect of these materials shall be

compensated for by baking or, if required, adding additional desiccant in the MBB to ensure

the shelf life of the SMDs (see 6.3).

5.2.4 Drying requirements – other

Suppliers may use the drying effect of normal in-line processes such as post-mould cure,

marking cure, and burn-in to reduce the bake time. An equivalency evaluation is

recommended to ensure that high-temperature processing maintains moisture weight gain to

an acceptable level. The total weight gain for the SMD at the time it is sealed in the MBB shall

not exceed the moisture gain of that SMD starting dry and then being exposed to

30 °C/60 % RH for MET h (less the time for distributors).

5.2.5 Excess time between bake and bag

If the allowable time between bake and bag is exceeded, the SMDs shall be redried in

accordance with Clause 6.

5.3 Dry pack

5.3.1 Description

A dry pack consists of desiccant material and a humidity indicator card (HIC) sealed with the

SMDs and their carriers inside a moisture barrier bag (MBB). A representative dry pack

configuration is shown in Figure 1.

Figure 1 – Typical dry pack configuration for moisture-sensitive

SMDs in shipping tubes

5.3.2 Materials

5.3.2.1 Moisture barrier bag (MBB)

The moisture barrier bag shall meet relevant national standard requirements for flexibility,

ESD protection, mechanical strength, and puncture resistance. The bags shall be heat-

sealable. The water vapour transmission rate (WVTR) shall be ≤ 0,03 g/m in 24 h at 40 °C

after flex testing in accordance with relevant national standards governing flex durability of

flexible barrier materials. The WVTR is measured using relevant national standards governing

water vapour transmission rate through plastic film and sheeting using a modulated infrared

sensor.

5.3.2.2 Desiccant

The desiccant material shall comply with relevant national standards governing activated

desiccants used for the static dehumidification of packaging bags. Desiccant shall be dustless,

non-corrosive, and absorbent to amounts specified in the standard. The desiccant shall be

packaged in moisture-permeable bags. The amount of desiccant used, per moisture barrier

bag, shall be based on the bag surface area and WVTR in order to maintain an interior

relative humidity in the MBB of less than 30 % at 25 °C for SMD classification A2 and less

than 10 % at 25 °C for SMDs classified from Levels B2a to B5a.

For comparison between various desiccant types, certain specifications adopted the "UNIT"

as the basic unit of measure of quantity for desiccant material. A UNIT of desiccant is defined

as the amount that will absorb a minimum of 2,85 g of water vapour at 20 % RH and 25 °C. To

meet the dry pack requirements of this document, the amount of water vapour that a UNIT of

desiccant can absorb at 10 % RH and 25 °C must shall be known.

When the desiccant capacity at 10 % RH and 25 °C is known, the following equation should

be used.

U = (0,003 × M × WVTR × A)/D (1)

where

U = amount of desiccant in UNITS;

M = shelf life desired in months;

WVTR = water vapour transmission rate in g/m in 24 h;

– 14 – IEC 60749-20-1:2019 RLV © IEC:2019

A = total surface area of the MBB in m ;

D = amount of water in grams, that a UNIT of desiccant will absorb at 10 % RH and 25 °C.

When the desiccant capacity at 10 % RH and 25 °C is not known, the quantity needed can be

estimated using the following simplified equation.

U = 8 × A (2)

where

U = amount of desiccant in UNITS;

A = total surface area of the MBB in m .

NOTE If trays, tubes, reels, foam end caps, etc., are placed in the bag without baking, additional desiccant will be

required to absorb the moisture contained in these materials.

If it is desired to minimize the amount of desiccant used for dry-packing level 2 components, a

value of D based on the amount of water in grams that a UNIT of desiccant will absorb at

60 % RH and 25 °C should be used in the formula. This value can be obtained from the

desiccant manufacturer. When this option is used, it can be verified that, when the component

was classified in accordance with IEC 60749-20, it has achieved full saturation during

moisture soak.

No moisture-absorbing material (e.g. trays, tubes, reels, foam end caps) should be placed in

the dry bag without baking. Any such material that is included increases the amount of

desiccant needed to meet the calculated shelf life (see 7.4.2) by an amount based on the

moisture content of the material. This can be determined by weighing a representative

quantity of material known to be at equilibrium with the manufacturing environment, baking to

a new constant weight, and subtracting the final from the initial weight. Additional UNIT(s) of

desiccant, based on 10 % RH at 25 °C, should be added to absorb the amount of water, in

grams, egressed from the packing materials (dunnage) after baking.

5.3.2.3 Desiccant handling and storage

Desiccant capacity decreases rapidly when exposed to 30 °C/60 % RH. Therefore, the

desiccant should remain in the manufacturer’s container or stored in a dry cabinet at < 5 %

RH until use. When dry packing, the desiccant shall be removed from the storage container

just prior to placing it into the MBB and sealing the MBB.

5.3.2.4 Humidity indicator card (HIC)

The HIC shall comply with relevant national standards governing chemically impregnated

humidity indicator cards. For level A2, the HIC shall have a sensitivity value of 30 % RH,

which may be indicated by colour dots with sensitivity values of 20 % RH, 30 % RH, 40 % RH.

For SMDs classified from Levels B2a through to B5a, as a minimum, the HIC shall have 3

colour dots with sensitivity values of 5 % RH, 10 % RH, 60 % RH. The spots shall indicate the

humidity with a significant and perceptible change in colour (hue) as indicated in Table 2. Hue

shall be tested using the test method in Annex C. The colours shall be described in writing on

the card. HIC reuse is not allowed if the 60 % spot has changed colour. Reuse is not allowed,

owing to loss of accuracy of the 5 % and 10 % spot chemistry, if the 60 % spot has changed

colour. It is not required to reuse the same HIC from the MBB if the MBB is to be resealed; a

fresh HIC may be used.

Examples of HIC are shown in Figures 2a) and 2b).

5.3.2.5 HIC paper

White blotting paper made from fibrous, cellulosic material, with a minimum basis weight of,

255 g/m2 shall be used for HICs.

5.3.2.6 Visual defects

HICs shall be free from defects including missing spots, tears, improperly located spots, and

indicating colour overrunning the black circles.

5.3.2.7 Preservation

HICs shall be stored in accordance with the manufacturer’s recommendation prior to insertion

in the MBB. At a minimum, the 10 % spot shall indicate dry when the cards are removed from

the original container.

Table 2 –Typical HIC spot compliance

Indication at Indication at Indication at Indication at Indication at Indication at

2 % RH 5 % RH 10 % RH 55 % RH 60 % RH 65 % RH

environment environment environment environment environment environment

5 % spot Blue Lavender Pink Pink Pink Pink

(dry) (spot value) (wet) (wet) (wet) (wet)

change ≤7 %

hue

10 % spot Blue Blue Lavender Pink Pink Pink

(dry) (dry) (spot value) (wet) (wet) (wet)

change

≤10 % hue

60 % spot Blue Blue Blue Blue Lavender Pink

(dry) (dry) (dry) (dry) (spot value) (wet)

change

≤10 % hue

NOTE Other colour schemes can be used.

– 16 – IEC 60749-20-1:2019 RLV © IEC:2019

Below 30 % RH can be confirmed by comparison of a colour (lavender).

a) Example of humidity indicator card for level A2

b) Example of humidity indicator card for levels B2a to B5a

Figure 2 – Example humidity indicator cards

5.3.3 Labels

5.3.3.1 Labels – Moisture sensitive identification

Labels relevant to the dry pack process are the moisture-sensitive identification (MSID) label

and the caution label as specified in Annex A (see Figures A.2 to A.5). The MSID label shall

be affixed to the lowest-level shipping container that contains the MBB. The caution label

shall be affixed to the outside surface of the MBB. The caution label includes fields for the

moisture classification level in accordance with IEC 60749-20; the peak package body

temperature allowed during reflow soldering (the classification temperature); the floor life; and

the bag seal date. If the calculated shelf life is greater than 12 months, item # 1 of the caution

label shall be changed accordingly.

5.3.3.2 Labels – Level B6 requirements

Level B6 parts not shipped in MBBs s

...

IEC 60749-20-1 ®

Edition 2.0 2019-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Semiconductor devices – Mechanical and climatic test methods –

Part 20-1: Handling, packing, labelling and shipping of surface-mount devices

sensitive to the combined effect of moisture and soldering heat

Dispositifs à semiconducteurs – Méthodes d'essais mécaniques et climatiques –

Partie 20-1: Manipulation, emballage, étiquetage et transport des composants

pour montage en surface sensibles à l'effet combiné de l'humidité et de la

chaleur de brasage

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 60749-20-1 ®

Edition 2.0 2019-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Semiconductor devices – Mechanical and climatic test methods –

Part 20-1: Handling, packing, labelling and shipping of surface-mount devices

sensitive to the combined effect of moisture and soldering heat

Dispositifs à semiconducteurs – Méthodes d'essais mécaniques et climatiques –

Partie 20-1: Manipulation, emballage, étiquetage et transport des composants

pour montage en surface sensibles à l'effet combiné de l'humidité et de la

chaleur de brasage

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.080.01 ISBN 978-2-8322-7043-1

– 2 – IEC 60749-20-1:2019 © IEC:2019

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 8

4 General applicability and reliability considerations . 10

4.1 Assembly processes . 10

4.1.1 Mass reflow . 10

4.1.2 Localized heating. 10

4.1.3 Socketed components . 10

4.1.4 Point-to-point soldering . 10

4.1.5 Aqueous cleaning . 11

4.2 Reliability . 11

5 Dry packing . 11

5.1 Requirements . 11

5.2 Drying of SMDs and carrier materials before being sealed in MBBs . 11

5.2.1 Drying requirements – level A2 . 11

5.2.2 Drying requirements – levels B2a to B5a . 12

5.2.3 Drying requirements – carrier materials . 12

5.2.4 Drying requirements – other . 12

5.2.5 Excess time between bake and bag . 12

5.3 Dry pack . 12

5.3.1 Description . 12

5.3.2 Materials . 13

5.3.3 Labels . 16

5.3.4 Moisture barrier bag sealing . 16

5.3.5 Dry pack precautions . 16

5.3.6 Shelf life . 16

6 Drying. 17

6.1 Drying options . 17

6.2 Post exposure to factory ambient . 20

6.2.1 Floor life clock . 20

6.2.2 Any duration exposure . 20

6.2.3 Short duration exposure . 20

6.3 General considerations for baking . 20

6.3.1 High-temperature carriers . 20

6.3.2 Low-temperature carriers . 20

6.3.3 Paper and plastic container items . 21

6.3.4 Bakeout times . 21

6.3.5 ESD protection . 21

6.3.6 Reuse of carriers . 21

6.3.7 Solderability limitations . 21

7 Use . 21

7.1 Floor life clock start . 21

7.2 Incoming bag inspection . 21

7.2.1 Upon receipt . 21

7.2.2 Component inspection . 22

7.3 Floor life . 22

7.4 Safe storage . 22

7.4.1 Safe storage categories . 22

7.4.2 Dry pack . 22

7.4.3 Shelf life . 22

7.4.4 Dry atmosphere cabinet . 22

7.5 Reflow . 23

7.5.1 Reflow categories . 23

7.5.2 Opened MBB . 23

7.5.3 Reflow temperature extremes . 23

7.5.4 Additional thermal profile parameters. 23

7.5.5 Multiple reflow passes . 23

7.5.6 Maximum reflow passes . 24

7.6 Drying indicators . 24

7.6.1 Drying requirements . 24

7.6.2 Excess humidity in the dry pack . 24

7.6.3 Floor life or ambient temperature/humidity exceeded . 25

7.6.4 Level B6 SMDs . 25

Annex A (normative) Symbol and labels for moisture-sensitive devices . 26

A.1 Object . 26

A.2 Symbol and labels. 26

A.2.1 Moisture-sensitive symbol . 26

A.2.2 Moisture-sensitive identification (MSID) label . 26

A.2.3 Moisture-sensitive caution labels . 26

Annex B (informative) Board rework . 30

B.1 Component removal, rework and remount . 30

B.1.1 Removal precautions . 30

B.1.2 Removal for failure analysis . 30

B.1.3 Removal and remount . 30

B.2 Baking of populated boards. 30

Annex C (normative) Test method for Humidity Indicator Card used with electronic

component packaging . 31

C.1 HIC testing method . 31

C.2 Testing apparatus . 31

C.3 Testing procedure . 31

C.4 Data analysis . 32

Annex D (informative) Derivation of bake tables . 33

Annex E (informative) Derating due to factory environmental conditions . 35

Bibliography . 39

Figure 1 – Typical dry pack configuration for moisture-sensitive SMDs in shipping

tubes . 12

Figure 2 – Example humidity indicator cards . 15

Figure A.1 – Moisture-sensitive symbol (example) . 26

Figure A.2 – MSID label (example) . 26

Figure A.3 – Information label for level A1 or B1 (example) . 27

– 4 – IEC 60749-20-1:2019 © IEC:2019

Figure A.4 – Moisture-sensitive caution label for level A2 (example) . 27

Figure A.5 – Moisture-sensitive caution label for levels B2-B5a (example) . 28

Figure A.6 – Moisture-sensitive caution label for level B6 (example) . 29

Figure D.1 –Typical moisture concentration over time . 33

Table 1 – Dry packing requirements . 11

Table 2 –Typical HIC spot compliance . 15

Table 3 – Reference conditions for drying mounted or unmounted SMDs (user bake:

floor life begins counting at time = 0 after bake) – Level 2. 17

Table 4 – Reference conditions for drying mounted or unmounted SMDs (user bake:

floor life begins counting at time = 0 after bake) – Levels B2, B2a to B5a . 18

Table 5 – Default baking times used prior to dry-pack that were exposed to conditions

≤60 % RH (supplier bake: MET = 24 h) . 19

Table 6 – Resetting or pausing the ‘floor life’ clock at user site . 19

Table 7 – Moisture classification level and floor life . 22

Table C.1 – HIC spot compliance: . 31

Table E.1 – Recommended equivalent total floor life (days) for level A2 at 20 °C, 25 °C,

30 °C and 35 °C for ICs with novolac, biphenyl and multifunctional epoxies (reflow at

same temperature at which component was classified) . 36

Table E.2 – Recommended equivalent total floor life (days) for levels B2a to B5a at

20 °C, 25 °C, 30 °C and 35 °C for ICs with novolac, biphenyl and multifunctional

epoxies (reflow at same temperature at which component was classified) . 37

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SEMICONDUCTOR DEVICES –

MECHANICAL AND CLIMATIC TEST METHODS –

Part 20-1: Handling, packing, labelling and shipping of surface-mount

devices sensitive to the combined effect of moisture and soldering heat

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This second edition cancels and replaces the first edition published in 2009. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) updates to subclauses to better align the test method with IPC/JEDEC J-STD-033C,

including new sections on aqueous cleaning and dry pack precautions;

b) addition of two annexes on colorimetric testing of HIC (humidity indicator card) and

derivation of bake tables.

– 6 – IEC 60749-20-1:2019 © IEC:2019

The text of this standard is based on the following documents:

FDIS Report on voting

47/2565/FDIS 47/2579/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60749 series, published under the general title Semiconductor

devices – Mechanical and climatic test methods, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

INTRODUCTION

The advent of surface-mount devices (SMDs) introduced a new class of quality and reliability

concerns regarding package damage "cracks and delamination" from the solder reflow

process. This document describes the standardized levels of floor life exposure for

moisture/reflow-sensitive SMDs along with the handling, packing and shipping requirements

necessary to avoid moisture/reflow-related failures. IEC 60749-20 defines the classification

procedure and Annex A of this document defines the labelling requirements.

Moisture from atmospheric humidity enters permeable packaging materials by diffusion.

Assembly processes used to solder SMDs to printed circuit boards (PCBs) expose the entire

package body to temperatures higher than 200 °C. During solder reflow, the combination of

rapid moisture expansion, materials mismatch, and material interface degradation can result

in package cracking and/or delamination of critical interfaces within the package.

Typical solder reflow processes of concern for all devices are infrared (IR), convection/IR,

convection, vapour phase reflow (VPR), hot air rework tools, and wave solder, including full

immersion.

Non-semiconductor devices can exhibit additional process sensitivities beyond moisture

sensitivity such as thermal sensitivity, flux sensitivity, or cleaning process sensitivity.

– 8 – IEC 60749-20-1:2019 © IEC:2019

SEMICONDUCTOR DEVICES –

MECHANICAL AND CLIMATIC TEST METHODS –

Part 20-1: Handling, packing, labelling and shipping of surface-mount

devices sensitive to the combined effect of moisture and soldering heat

1 Scope

This part of IEC 60749 applies to all devices subjected to bulk solder reflow processes during

PCB assembly, including plastic encapsulated packages, process sensitive devices, and other

moisture-sensitive devices made with moisture-permeable materials (epoxies, silicones, etc.)

that are exposed to the ambient air.

The purpose of this document is to provide SMD manufacturers and users with standardized

methods for handling, packing, shipping, and use of moisture/reflow sensitive SMDs that have

been classified to the levels defined in IEC 60749-20. These methods are provided to avoid

damage from moisture absorption and exposure to solder reflow temperatures that can result

in yield and reliability degradation. By using these procedures, safe and damage-free reflow

can be achieved, with the dry packing process, providing a minimum shelf life capability in

sealed dry-bags from the seal date.

Two test conditions, method A and method B, are specified in the soldering heat test of

IEC 60749-20. For method A, moisture soak conditions are specified on the assumption that

moisture content inside the moisture barrier bag is less than 30 % RH. For method B,

moisture soaking conditions are specified on the assumption that manufacturer’s exposure

time (MET) does not exceed 24 h and the moisture content inside the moisture barrier bag is

less than 10 % RH. In an actual handling environment, SMDs tested by method A are

permitted to absorb moisture up to 30 % RH, and SMDs tested by method B are permitted to

absorb moisture up to 10 % RH. This document specifies the handling conditions for SMDs

subjected to the above test conditions.

NOTE Hermetic SMD packages are not moisture sensitive and do not require moisture precautionary handling.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60749-20, Semiconductor devices – Mechanical and climatic test methods – Part 20:

Resistance of plastic-encapsulated SMDs to the combined effect of moisture and soldering

heat

IEC 60749-30, Semiconductor devices – Mechanical and climatic test methods – Part 30:

Preconditioning of non-hermetic surface mount devices prior to reliability testing

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

active desiccant

desiccant that is either fresh (new) or has been baked according to the manufacturer’s

recommendations to renew it to original specifications

3.2

bar code label

label that gives information in a code consisting of parallel bars and spaces, each of various

specific widths

Note 1 to entry: For the purposes of this document, the bar code label is on the lowest level shipping container

and includes information that describes the product, e.g. part number, quantity, lot information, supplier

identification, moisture-sensitivity level.

3.3

mass reflow

reflow of a number of components with simultaneous attachment by an infrared (IR),

convection/IR, convection, or vapour phase reflow (VPR) process

3.4

carrier

container that directly holds components such as a tray, tube, or tape and reel

3.5

desiccant

absorbent material used to maintain a low relative humidity

3.6

floor life

allowable time period for a moisture-sensitive device, after removal from a moisture barrier

bag, dry storage or dry bake and before the solder reflow process

3.7

humidity indicator card

HIC

card printed with a moisture-sensitive chemical (cobalt bromide) that changes from blue to

pink in the presence of water vapour

Note 1 to entry: The HIC is packed inside the moisture-barrier bag, along with a desiccant, to aid in determining

the level of moisture to which the moisture-sensitive devices have been subjected.

Note 2 to entry: This note applies to the French language only.

3.8

manufacturer’s exposure time

MET

maximum time after bake that the component manufacturer requires to process components

prior to bag seal, and that also includes the maximum time allowed at the distributor for

having the bag open to split out smaller shipments

Note 1 to entry: This note applies to the French language only.

3.9

moisture barrier bag

MBB

storage bag manufactured with a flexible laminated vapour barrier film that restricts the

transmission of water vapour

– 10 – IEC 60749-20-1:2019 © IEC:2019

Note 1 to entry: This note applies to the French language only.

3.10

rework

removal of a component for scrap, reuse, or failure analysis; replacement of an attached

component; or heating and repositioning of a previously attached component

3.11

shelf-life

maximum storage period for a dry-packed moisture-sensitive device in an unopened moisture

barrier bag (MBB) to avoid exceeding the specified interior bag ambient humidity

3.12

surface-mount device

SMD

plastic-encapsulated surface-mount devices made with moisture-permeable materials

Note 1 to entry: For the purposes of this document, the term "SMD" is limited as indicated in the above definition.

3.13

solder reflow

solder attachment process in which previously applied solder or solder paste is melted to

attach a component to the printed circuit board

3.14

water vapour transmission rate

WVTR

measure of the permeability of plastic film or metallized plastic film material to moisture

4 General applicability and reliability considerations

4.1 Assembly processes

4.1.1 Mass reflow

This document applies to mass solder reflow assembly by convection, convection/IR, infrared

(IR), and vapour phase (VPR), processes. It does not apply to mass solder reflow processes

that immerse the component bodies in molten solder (e.g. wave soldering bottom mounted

components). Such processes are not allowed for many SMDs and are not covered by the

component qualifications standards used as a basis for this document.

4.1.2 Localized heating

This document also applies to moisture-sensitive SMDs that are removed or attached singly

by local ambient heating, i.e. "hot air rework". See Annex B.

4.1.3 Socketed components

This document does not apply to SMDs that are socketed and not exposed to solder reflow

temperatures. Such SMDs are not at risk and do not require moisture precautionary handling.

4.1.4 Point-to-point soldering

This document does not apply to SMDs in which only the leads are heated to reflow the solder,

e.g. hand-soldering, hot bar attach of gull-wing leads, and through hole by wave soldering.

The heat absorbed by the SMD body from such operations is typically much lower than that

for mass surface mount reflow or hot air rework, and moisture precautionary measures are

typically not needed.

4.1.5 Aqueous cleaning

For non-cavity SMDs, typical short-term aqueous cleaning processes will not impact the floor

life (internal moisture content). Special consideration should be given to non-hermetic cavity

packages.

4.2 Reliability

The methods set forth in this specification ensure that an adequate SMD reliability can be

achieved during and after the PCB assembly operation, when the SMDs are evaluated and

verified by IEC 60749-20 and/or by IEC 60749-30, together with environmental reliability

testing.

This specification does not address or ensure solder joint reliability of attached components.

5 Dry packing

5.1 Requirements

Dry packing requirements for the various moisture sensitivity levels are shown in Table 1. The

levels are determined in accordance with IEC 60749-20 and/or IEC 60749-30, together with

reliability testing. As a minimum, all materials used in dry packing should conform to relevant

national packaging material standards for ESD-sensitive items.

Table 1 – Dry packing requirements

a

Level Dry before MBB Desiccant MSID label Caution label

bag

A1 or B1 Optional Optional Optional Not required Not required if classified at

220 °C to 225 °C

b

Required if classified at other

than 220 °C to 225 °C

A2 or B2 Optional Required Required Required Required

B2a-B5a Required Required Required Required Required

B6 Optional Optional Optional Required Required

a

MSID = moisture-sensitive identification label.

b

A "Caution" label is not required if level and reflow temperature are given, in human readable form, on the

barcode label attached to the lowest level shipping container.

5.2 Drying of SMDs and carrier materials before being sealed in MBBs

5.2.1 Drying requirements – level A2

Packing of the SMDs classified as Level A2 into MBBs shall be carried out within one week

under the environmental condition below 30 °C/60 % RH after moulding, burn-in, or bake.

MET is not specified for Level A2 SMDs.

MBBs may be opened for a short period of time (less than 1 h) and re-closed provided that

the HIC indicates a humidity of less than 30 % RH and provided that the desiccant is replaced

with fresh desiccant. When the MBB is next opened, as long as the HIC indicates below

30 % RH, the duration time of the previous MBB’s opening may be disregarded. Thus, if the

HIC indicates below 30 % RH when MBB is opened, the floor life is not dependent on the

duration time of the MBB's opening, and is 168 h at 30 °C/70 % RH.

– 12 – IEC 60749-20-1:2019 © IEC:2019

5.2.2 Drying requirements – levels B2a to B5a

SMDs classified from Levels B2a through to B5a shall be dried (see Clause 6) prior to being

sealed in MBBs. The period between drying and sealing shall not exceed the MET less the

time allowed for distributors to open the bags and repack parts. If the supplier’s actual MET is

more than the default 24 h, then the actual time shall be used. If the distributor practice is to

repack the MBBs with active desiccant, then this time does not need to be subtracted from the

MET.

5.2.3 Drying requirements – carrier materials

The materials from which carriers (such as trays, tubes, reels) are made can affect the

moisture level when placed in the MBB. Therefore, the effect of these materials shall be

compensated for by baking or, if required, adding additional desiccant in the MBB to ensure

the shelf life of the SMDs (see 6.3).

5.2.4 Drying requirements – other

Suppliers may use the drying effect of normal in-line processes such as post-mould cure,

marking cure, and burn-in to reduce the bake time. An equivalency evaluation is

recommended to ensure that high-temperature processing maintains moisture weight gain to

an acceptable level. The total weight gain for the SMD at the time it is sealed in the MBB shall

not exceed the moisture gain of that SMD starting dry and then being exposed to

30 °C/60 % RH for MET h (less the time for distributors).

5.2.5 Excess time between bake and bag

If the allowable time between bake and bag is exceeded, the SMDs shall be redried in

accordance with Clause 6.

5.3 Dry pack

5.3.1 Description

A dry pack consists of desiccant material and a humidity indicator card (HIC) sealed with the

SMDs and their carriers inside a moisture barrier bag (MBB). A representative dry pack