IEC 60534-8-4:2015

(Main)Industrial-process control valves - Part 8-4: Noise considerations - Prediction of noise generated by hydrodynamic flow

Industrial-process control valves - Part 8-4: Noise considerations - Prediction of noise generated by hydrodynamic flow

IEC 60534-8-4:2015 establishes a method to predict the noise generated in a control valve by liquid flow and the resulting noise level measured downstream of the valve and outside of the pipe. The noise may be generated both by normal turbulence and by liquid cavitation in the valve. Parts of the method are based on fundamental principles of acoustics, fluid mechanics, and mechanics. The method is validated by test data. This third edition cancels and replaces the second edition published 2005. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

a) Hydrodynamic noise is predicted as a function of frequency and

b) Elimination of the acoustic power ratio.

Vannes de régulation des processus industriels - Partie 8-4: Considérations sur le bruit - Prévision du bruit généré par un écoulement hydrodynamique

L'IEC 60534-8-4:(2015) établit une méthode pour prévoir le bruit engendré dans une vanne de régulation par un écoulement liquide et le niveau de bruit mesuré en aval de la vanne et à l'extérieur de la tuyauterie. Le bruit peut être généré à la fois par des turbulences normales et par la cavitation du liquide dans la vanne. Des parties de cette méthode sont basées sur des principes fondamentaux de l'acoustique, de la mécanique et de la mécanique des fluides. Cette méthode est validée par des résultats d'essai. Cette troisième édition annule et remplace la deuxième édition parue en 2005, dont elle constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) Le bruit hydrodynamique est prévu en fonction de la fréquence;

b) Suppression du rapport de puissance acoustique.

General Information

- Status

- Published

- Publication Date

- 14-Sep-2015

- Technical Committee

- SC 65B - Measurement and control devices

- Drafting Committee

- WG 9 - TC 65/SC 65B/WG 9

- Current Stage

- PPUB - Publication issued

- Start Date

- 15-Sep-2015

- Completion Date

- 30-Sep-2015

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60534-8-4:2015 is an international standard developed by the International Electrotechnical Commission (IEC) that addresses noise considerations in industrial-process control valves. Specifically, this part 8-4 of the series provides a method for predicting noise generated by hydrodynamic flow-liquid flow through control valves. It focuses on calculating the noise level downstream of the valve and externally measured outside the pipe wall. The standard takes into account noise caused by both normal turbulence and liquid cavitation within the valve.

This third edition, published in 2015, replaces the 2005 edition and introduces key updates including prediction of hydrodynamic noise as a function of frequency and the removal of the acoustic power ratio parameter.

Key Topics

Hydrodynamic Noise Prediction

The standard establishes a method that predicts noise generated due to the mechanical energy conversion from turbulent fluid flow and cavitation in valves to audible noise levels.Frequency-based Noise Analysis

Noise emissions are predicted across different frequencies rather than as a single aggregated value, allowing more accurate assessment aligned with real-world measurements.Noise Measurement Location

Predictions focus on noise measured 1 meter downstream from the valve and 1 meter away from the pipe’s outer surface, assuming an acoustic free field and ideal straight piping conditions.Fluid Flow Characteristics

Calculations incorporate pressures, pressure ratios, jet velocity, mechanical power, and valve-specific characteristics such as style and trim type.Validated Methodology

The method is validated primarily for water applications, covering valve sizes DN 15 to DN 300 with inlet pressures up to 15 bar and is considered accurate within ±5 dB(A) for typical installations.Exclusions

The standard does not cover noise generated from mechanical vibrations, flashing conditions, unstable flow, or other unpredictable behaviors. It also currently focuses on hydrodynamic noise and does not extend to other fluids beyond water.

Applications

IEC 60534-8-4:2015 is crucial for engineers, designers, and maintenance personnel involved in industrial process control systems that utilize control valves. Typical application areas include:

Industrial Process Automation

Ensuring control valves meet noise emission regulations and occupational health standards.Valve Design and Selection

Supporting valve manufacturers and process engineers in designing low-noise valves and selecting appropriate valve trims and configurations.Occupational Safety

Helping industries comply with noise exposure limits to protect workers around valve installations.Equipment and Pipeline Integrity

Predicting and mitigating noise levels to prevent pipe failure and damage to surrounding equipment caused by excessive hydrodynamic noise.Acoustic Compliance Testing

Providing a standardized prediction methodology to complement or reduce the need for extensive field noise testing.

Related Standards

This standard is part of the broader IEC 60534 series focused on industrial-process control valves. For comprehensive understanding and application, it is often used in conjunction with:

IEC 60534-8-2: Noise Considerations – Measurement of Flow Noise

Provides methods for determining parameters such as flow coefficients essential for noise prediction calculations.IEC 60534-8-3: Noise Considerations – Control Valve Noise and Vibration in Service

Deals with measuring and addressing noise and vibration issues in operational valve installations.Other relevant IEC and ISO standards for acoustics, fluid mechanics, and occupational noise exposure may also be consulted to develop complete noise management strategies.

Keywords: IEC 60534-8-4, industrial process control valves, hydrodynamic noise, valve noise prediction, liquid flow noise, control valve acoustics, cavitation noise, valve design, noise measurement, occupational noise standards, valve trim noise.

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

BSMI (Bureau of Standards, Metrology and Inspection)

Taiwan's standards and inspection authority.

Sponsored listings

Frequently Asked Questions

IEC 60534-8-4:2015 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Industrial-process control valves - Part 8-4: Noise considerations - Prediction of noise generated by hydrodynamic flow". This standard covers: IEC 60534-8-4:2015 establishes a method to predict the noise generated in a control valve by liquid flow and the resulting noise level measured downstream of the valve and outside of the pipe. The noise may be generated both by normal turbulence and by liquid cavitation in the valve. Parts of the method are based on fundamental principles of acoustics, fluid mechanics, and mechanics. The method is validated by test data. This third edition cancels and replaces the second edition published 2005. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) Hydrodynamic noise is predicted as a function of frequency and b) Elimination of the acoustic power ratio.

IEC 60534-8-4:2015 establishes a method to predict the noise generated in a control valve by liquid flow and the resulting noise level measured downstream of the valve and outside of the pipe. The noise may be generated both by normal turbulence and by liquid cavitation in the valve. Parts of the method are based on fundamental principles of acoustics, fluid mechanics, and mechanics. The method is validated by test data. This third edition cancels and replaces the second edition published 2005. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) Hydrodynamic noise is predicted as a function of frequency and b) Elimination of the acoustic power ratio.

IEC 60534-8-4:2015 is classified under the following ICS (International Classification for Standards) categories: 17.140.20 - Noise emitted by machines and equipment; 23.060.40 - Pressure regulators; 25.040.40 - Industrial process measurement and control. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60534-8-4:2015 has the following relationships with other standards: It is inter standard links to IEC 60534-8-4:2005/COR1:2006, IEC 60534-8-4:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60534-8-4:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60534-8-4 ®

Edition 3.0 2015-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Industrial-process control valves –

Part 8-4: Noise considerations – Prediction of noise generated by hydrodynamic

flow

Vannes de régulation des processus industriels –

Partie 8-4: Considérations sur le bruit – Prévisions du bruit généré par un

écoulement hydrodynamique

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 15

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 60 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

15 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 60 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60534-8-4 ®

Edition 3.0 2015-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Industrial-process control valves –

Part 8-4: Noise considerations – Prediction of noise generated by hydrodynamic

flow

Vannes de régulation des processus industriels –

Partie 8-4: Considérations sur le bruit – Prévisions du bruit généré par un

écoulement hydrodynamique

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 17.140.20; 23.060.40; 25.040.40 ISBN 978-2-8322-2879-1

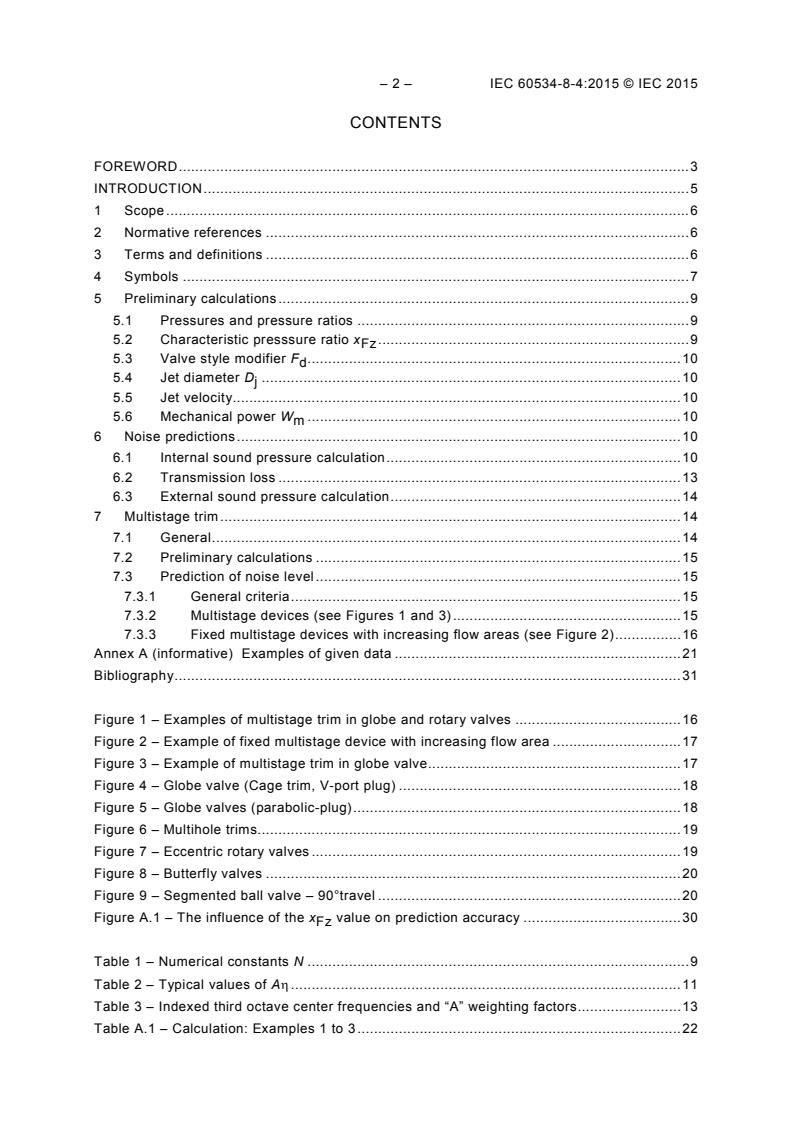

– 2 – IEC 60534-8-4:2015 © IEC 2015

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Symbols . 7

5 Preliminary calculations . 9

5.1 Pressures and pressure ratios . 9

5.2 Characteristic presssure ratio x . 9

Fz

5.3 Valve style modifier F . 10

d

5.4 Jet diameter D . 10

j

5.5 Jet velocity. 10

5.6 Mechanical power W . 10

m

6 Noise predictions . 10

6.1 Internal sound pressure calculation . 10

6.2 Transmission loss . 13

6.3 External sound pressure calculation . 14

7 Multistage trim . 14

7.1 General . 14

7.2 Preliminary calculations . 15

7.3 Prediction of noise level . 15

7.3.1 General criteria . 15

7.3.2 Multistage devices (see Figures 1 and 3) . 15

7.3.3 Fixed multistage devices with increasing flow areas (see Figure 2) . 16

Annex A (informative) Examples of given data . 21

Bibliography . 31

Figure 1 – Examples of multistage trim in globe and rotary valves . 16

Figure 2 – Example of fixed multistage device with increasing flow area . 17

Figure 3 – Example of multistage trim in globe valve . 17

Figure 4 – Globe valve (Cage trim, V-port plug) . 18

Figure 5 – Globe valves (parabolic-plug) . 18

Figure 6 – Multihole trims. 19

Figure 7 – Eccentric rotary valves . 19

Figure 8 – Butterfly valves . 20

Figure 9 – Segmented ball valve – 90°travel . 20

Figure A.1 – The influence of the x value on prediction accuracy . 30

Fz

Table 1 – Numerical constants N . 9

Table 2 – Typical values of Aη . 11

Table 3 – Indexed third octave center frequencies and “A” weighting factors. 13

Table A.1 – Calculation: Examples 1 to 3 . 22

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

INDUSTRIAL-PROCESS CONTROL VALVES –

Part 8-4: Noise considerations –

Prediction of noise generated by hydrodynamic flow

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60534-8-4 has been prepared by subcommittee 65B: Measurement

and control devices , of IEC technical committee 65: Industrial-process measurement, control

and automation.

This third edition cancels and replaces the second edition published 2005. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Hydrodynamic noise is predicted as a function of frequency.

b) Elimination of the acoustic power ratio

– 4 – IEC 60534-8-4:2015 © IEC 2015

The text of this standard is based on the following documents:

FDIS Report on voting

65B/1005/FDIS 65B/1017/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60534 series, published under the general title Industrial-process

control valves, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

INTRODUCTION

It is valuable to predict the noise levels that will be generated by valves. Safety requirements,

such as the occupational health standards require that human exposure to noise be limited.

There is also data indicating that noise levels above certain levels could lead to pipe failure or

affect associated equipment. See IEC 60534-8-3. Earlier hydrodynamic noise standards relied

on manufacturer test data and were neither generic nor as complete as desired. The method

can be used with all conventional control valve styles including globe, butterfly, cage type,

eccentric rotary, and modified ball valves.

A valve restricts flow by converting pressure energy into turbulence, heat and mechanical

pressure waves in the fluid contained within the valve body and piping. A small portion of this

mechanical vibration is converted into acoustical energy. Most of the noise is retained within

the piping system with only a small portion passing through the pipe wall downstream of the

valve. Calculation of the mechanical energy involved is straightforward. The difficulties arise

from determining first the acoustic efficiency of the mechanical energy to noise conversion

and then the noise attenuation caused by the pipe wall.

This part of IEC 60534 considers only noise generated by normal turbulence and liquid

cavitation. It does not consider any noise that might be generated by mechanical vibrations,

flashing conditions, unstable flow patterns, or unpredictable behaviour. In the typical

installation, very little noise travels through the wall of the control valve body. The noise

predicted is that which would be measured at the standard measuring point of 1 m

downstream of the valve and 1 m away from the outer surface of the pipe in an acoustic free

field. Ideal straight piping is assumed. Since an acoustic free field is seldom encountered in

industrial installations, this prediction cannot guarantee actual results in the field.

This prediction method has been validated with test results based on water covering a

majority of control valve types, in the DN 15 to DN 300 size range, at inlet pressures up to

15 bar. However, some types of low noise valves may not be covered. This method is

considered accurate within ± 5 dB(A), for most cases, if based on tested values of x using

FZ

the method from IEC 60534-8-2. The applicability of this method for fluids other than water is

not known at this time.

– 6 – IEC 60534-8-4:2015 © IEC 2015

INDUSTRIAL-PROCESS CONTROL VALVES –

Part 8-4: Noise considerations –

Prediction of noise generated by hydrodynamic flow

1 Scope

This part of IEC 60534 establishes a method to predict the noise generated in a control valve

by liquid flow and the resulting noise level measured downstream of the valve and outside of

the pipe. The noise may be generated both by normal turbulence and by liquid cavitation in

the valve. Parts of the method are based on fundamental principles of acoustics, fluid

mechanics, and mechanics. The method is validated by test data.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60534-1, Industrial-process control valves – Part 1: Control valve terminology and

general considerations

IEC 60534-2-3, Industrial-process control valves – Part 2-3: Flow capacity – Test procedures

IEC 60534-8-2, Industrial-process control valves – Part 8-2: Noise considerations –

Laboratory measurement of noise generated by hydrodynamic flow through control valves

IEC 60534-8-3, Industrial-process control valves – Part 8-3: Noise considerations – Control

valve aerodynamic noise prediction method

3 Terms and definitions

For the purpose of this document, all of the terms and definitions given in IEC 60534 series

and the following apply:

3.1

acoustical efficiency η

ratio of the stream power converted into sound power propagating downstream to the stream

power of the mass flow

3.2

fluted vane butterfly valve

butterfly valve which has flutes (grooves) on the face(s) of the disk. These flutes are intended

to shape the flow stream without altering the seating line or seating surface

3.3

independent flow passage

flow passage where the exiting flow is not affected by the exiting flow from adjacent flow

passages

3.4

peak frequency f

p

frequency at which the internal sound pressure is maximum

3.5

valve style modifier F

d

ratio of the hydraulic diameter of a single flow passage to the diameter of a circular orifice,

the area of which is equivalent to the sum of areas of all identical flow passages at a given

travel

4 Symbols

Symbol Description Unit

A(f) Frequency dependent A-weighting value dBA (ref P )

o

A Valve correction factor for acoustic efficiency Dimensionless

η

(see Table 2)

c Speed of sound in liquid m/s

c Speed of sound in air at standard conditions = 343 m/s

a

c Speed of sound in pipe (for steel pipe 5 000) m/s

S

C Flow coefficient (K and C ) Various

v v

(see IEC 60534-1)

C Flow coefficient (K and C ) at rated travel Various

R v v

(see IEC 60534-1)

C Flow coefficents of n stages (i=1…n) in a multistage valve Various

i

(K and C ) (see IEC 60534-1)

v v

C Flow coefficent of last stage in a multistage valve (K and Various

n v

C ) (see IEC 60534-1)

v

D Internal pipe diameter m

i

D Jet diameter m

j

D Nominal valve size m

d Multihole trim hole diameter m

H

d Seat or orifice diameter m

o

F Frequency distribution function (cavitating) Dimensionless

cav

F Valve style modifier Dimensionless

d

F Liquid pressure recovery factor of a valve without Dimensionless

L

attached fittings

F

Liquid pressure recovery factor of the last throttling stage Dimensionless

Ln

F Frequency distribution function (turbulent) Dimensionless

turb

f

Frequency Hz

f Cutoff frequency Hz

c

f

Octave band frequency Hz

ji

f Ring frequency Hz

r

f

Internal peak sound frequency (turbulent) Hz

p,turb

f Internal peak sound frequency (cavitating) Hz

p,cav

K Differential pressure ratio of incipient choked flow Dimensionless

c

3 2

(approximately in the range of F to F )

L L

L External sound pressure level 1 m from pipe wall dB (ref P )

pe,1m o

– 8 – IEC 60534-8-4:2015 © IEC 2015

Symbol Description Unit

L A-weighted external sound pressure level 1 m from pipe dBA (ref P )

pAe,1m o

wall

L A-weighted external sound pressure level 1 m from pipe dBA (ref P )

pAe,1m,i o

wall of stage i (number i from 1…n) in multistage valve

with n stages

L Internal sound pressure level at pipe wall dB (ref P )

pi o

Mass flow rate kg/s

m

n Number of stages in multistage trim Dimensionless

N Numerical constants (see Table 1) Various

N Number of independent and identical flow passages in Dimensionless

o

valve trim or throttling stage

P Pa

Reference pressure = 1 × 10

a

–5

P

Reference sound pressure = 2 × 10 Pa

o

p Valve inlet absolute pressure Pa

p Valve outlet absolute pressure Pa

p Inlet absolute pressure of stage i (number i from 1…n) in Pa

1,i

multistage valve with n stages

p Outlet absolute pressure of stage i (number i from 1…n) in Pa

2,i

multistage valve with n stages

p Vapour pressure of liquid Pa

v

Pressure differential Pa

∆p

∆p Pressure differential for U calculation Pa

c vc

St Strouhal number for peak frequency calculation Dimensionless

p

t Pipe wall thickness m

S

TL Transmission loss dB

TL Transmission loss at ring frequency f dB

fr r

U Vena contracta velocity m/s

vc

W Sound power of noise created by valve flow which W

a

propagates downstream

W Mechanical stream power W

m

x Differential pressure ratio Dimensionless

F

x Differential pressure ratio of incipient cavitation noise with Dimensionless

Fz

inlet pressure of 6 × 10 Pa

x Differential pressure ratio corrected for inlet pressure Dimensionless

Fzp1

η Acoustic efficiency factor (turbulent) Dimensionless

turb

Acoustic efficiency factor (cavitating) Dimensionless

η

cav

Acoustic efficiency factor of pipe wall Dimensionless

η

s

Density of liquid kg/m

ρ

ρ Density of air = 1,293 kg/m

a

Density of pipe material (= 7 800 for steel) kg/m

ρ

S

Table 1 – Numerical constants N

Flow coefficent

Constant K C

v v

–3 –3

N

4,9 × 10 4,6 × 10

N 1 1,17

5 Preliminary calculations

5.1 Pressures and pressure ratios

There are several pressures and pressure ratios needed in the noise prediction procedure.

They are given below.

The differential pressure ratio x for liquids depends on the pressure difference p -p and the

F 1 2

difference of the inlet pressure p and the vapour pressure p .

1 v

p − p

1 2

x = (1)

F

p − p

1 v

The differential pressure for beginning choked flow is approximately F (p –p ). Some

L 1 v

calculations are based on the following pressure differential:

Δp = lower of (p − p ) or F (p − p ) (2)

c 1 2 L 1 v

For low differential pressure ratios, the noise is mainly generated by turbulence. If x exceeds

F

x cavitation noise overlays the turbulent noise. At x = 1, cavitation noise has a second

z F,p1 F

minimum and for x > 1, in the flashing region, there is a very gradual increase in sound level

F

as x increases above x = 1.

F F

5.2 Characteristic presssure ratio x

Fz

The valve specific characteristic pressure ratio x can be measured with dependency on the

Fz

valve travel according to IEC 60534-8-2. It should not be confused with K , the value at which

c

choked flow caused by cavitation starts. It identifies the pressure ratio at which the cavitation

is acoustically detected. The value of x depends on the valve and closure member type and

Fz

the specific flow capacity.

Alternatively, the value of x can be estimated from equations (3), (4), and (5). Calculations

Fz

of hydrodynamic noise based on equation (3), (4) and (5) can create uncertainties as

illustrated in Annex A. Figures 4 to 9 include typical curves of x for different control valve

Fz

types. Both equation (3a) and Figures 4 to 9 are based on an inlet pressure of 6 × 10 Pa. If a

different inlet pressure is required, then the x value shall be corrected using equation (5).

Fz

0,90

(3)

XFz = for valve types except multihole trims

C

1+ 3 F

d

N34 F

L

XFz = for multihole trims (4)

N0 dH

4,5 + 1650

FL

NOTE N is a numerical constant, the values of which account for the specific flow coefficient (K or C ) used.

34 v v

– 10 – IEC 60534-8-4:2015 © IEC 2015

is obtained by testing at an inlet pressure of 6 × 10 Pa, then the tested value shall

When x

Fz

be corrected for the actual inlet pressure using the following equation and using x in place

Fzp1

of x :

Fz

0,125

6 x 10

x = x

(5)

Fzp1 Fz

p

5.3 Valve style modifier F

d

The valve style modifier depends on the valve and closure member type and on the flow

coefficient C (see IEC 60534-2-3).

5.4 Jet diameter D

j

The jet diameter D can be predicted as in IEC 60534-8-3 per the following equation:

j

D = N F C F (6)

j 14 d L

5.5 Jet velocity

The vena contracta flow velocity, used in calculating the mechanical power, is determined as

follows:

1 2 ∆p

c

U (7)

=

vc

F ρ

L L

5.6 Mechanical power W

m

The mechanical energy dissipated in the valve orifice is determined from the following

equation:

2 2

m U F

vc L

(8)

W =

m

6 Noise predictions

6.1 Internal sound pressure calculation

from 5.6 converted to valve internal noise and

The portion of the mechanical power W

m

radiated into the downstream pipe is a function of the acoustic efficiency η.

For turbulent conditions defined here where (x ≤ x ):

F Fzp1

W = η W (9)

a turb m

For cavitating conditions defined here where (x < x < 1):

Fzp1 F

W = (η +η )W (10)

a turb cav m

For turbulent flow due to the relatively low fluid velocity U the valve is considered a

vc

–4

monopole source with an acoustical efficiency of approximately 10 at U = c (see

vc 1

reference [1] ). The acoustic efficiency factor for turbulent flow is calculated as follows using

A from Table 2:

η

A U

vc

η = 10 (11)

turb

c

Table 2 – Typical values of A

η

Valve or fitting A

η

Globe, parabolic plug –4,6

Globe, V-port plug –4,6

Globe, ported cage design –4,6

Globe, multihole drilled plug or cage –4,6

Butterfly, eccentric –4,3

Butterfly, swing-through (centered shaft), to 70° –4,3

Butterfly, fluted vane, to 70° –4,3

Butterfly, 60° flat disk –4,3

Eccentric rotary plug –4,6

Segmented ball 90° –4,6

Drilled hole plate fixed resistance –4,6

Expanders –4,0

Additional noise is produced as cavitation begins. Cavitation is the second part of a two-part

process. Vapour bubbles develop when the pressure at a point is lower than the vapour

pressure of the fluid at that point. This occurs at the vena contracta or point of maximum

velocity and minimum pressure in the valve. The second part of this process is the collapse of

these vapour bubbles as the fluid pressure rises above the vapour pressure as the vapour

leaves the point of minimum pressure. The energy which created the bubbles is returned to

the flowing fluid in the form of a high intensity jet as the bubble collapses. This can cause

noise and serious damage. The process of cavitation, the energies involved, the reasons that

water is one of the most destructive liquids, and why some other liquids cause less damage is

part of current hydraulic research.

Reference [3] includes a mathematical model for the sound power of a cavitating jet. The

calculation noise prediction model includes the fact that cavitation occurs in a turbulent flow

field because at any point the static pressure varies randomly with time and that there is the

probability that at some instant the pressure falls below the threshold pressure (i.e. nearly the

vapour pressure). They define the average duration of a pressure minimum with values lower

than the threshold pressure. This depends on the peak frequency of turbulent noise. Together

with a constant velocity bubble-growth model, the radius of the most-frequently occurring

cavitation bubbles can be estimated. After these bubbles have grown to a certain size, they

collapse in the collapse time, which determines the peak frequency of the cavitation noise.

In the cavitation region (x ≤ x ≤ 1), this modified theoretical model (see reference [2]) for

Fzp1 F

cavitating jets combined with many test results for validation leads to the following acoustical

efficiency factor equation.

0,5

1− x

p − p 1 Fzp1 x

1 2 F 1,5

(12)

η = 0,32 η exp(5x ) (x − x )

cav turb Fzp1 F Fzp1

∆p x 1− x x

c Fzp1 F Fzp1

___________

Numbers in square brackets refer to the bibliography.

η

– 12 – IEC 60534-8-4:2015 © IEC 2015

where “exp(x)” represents the constant e raised to the power of the object x.

The internal sound pressure level L is calculated as follows:

pi

3,2 x 10 W ρ c

a 1 1

L = 10 log (13)

pi 10

D

i

where the appropriate value for W is from equation (9) or (10), depending on whether

a

turbulent or cavitating flow, is used.

Using equations (14) and (15), the internal sound pressure level can be predicted at each

third octave center frequency, f , as given in Table 3.

i

≤ x ):

For turbulent conditions (x

F Fzp1

L (f ) = L + F (f ) (14)

pi i pi turb i

For cavitating conditions (x < x < 1):

Fzp1 F

η η

turb 0,1F (f ) cav 0,1F (f )

turb i cav i

L (f ) = L + 10 log 10 + 10 (15)

pi i pi 10

ηturb +ηcav ηturb +ηcav

3 −1

1 f f

i i

F (f ) = − 8 −10 log + (16)

turb i 10

4 f f

p,turb p,turb

1,5 −1,5

1 f f

i i

F (f ) = − 9 −10 log + (17)

cav i 10

4 f f

p,cav p,cav

Table 3 – Indexed third octave center frequencies and “A” weighting factors

Index, i Third octave “A” weighting Index, i Third octave “A” weighting

center factor center factor

frequency frequency

f ∆L (f ) f ∆L (f )

i A i i A i

(Hz) (dB) (Hz) (dB)

1 12,5 –63,4 18 630 –1,9

2 16* –56,7 19 800 –0,8

3 20 –50,5 20 1 000* 0

4 25 –44,7 21 1 250 0,6

5 31,5* –39,4 22 1 600 1,0

6 40 –34,6 23 2 000* 1,2

7 50 –30,2 24 2 500 1,3

8 63* –26,2 25 3 150 1,2

9 80 –22,5 26 4 000* 1,0

10 100 –19,1 27 5 000 0,5

11 125* –16,1 28 6 300 –0,1

12 160 –13,4 29 8 000* –1,1

13 200 –10,9 30 10 000 –2,5

14 250* –8,6 31 12 500 –4,3

15 315 –6,6 32 16 000* –6,6

16 400 –4,8 33 20 000 –9,3

17 500* –3,2

* Octave center frequencies (octave center frequencies could be used in place of third octave center

frequencies, but of course the corresponding index numbers would be changed. If octave bands are used,

the constant 8 in equation (12) should be replaced by 3 and the constant 9 in equation (13) should be

replaced by 4.)

The peak frequencies are different for turbulent and cavitating flow. The turbulent peak

frequency can be calculated as in IEC 60534-8-3 as follows:

U

vc

f = St (18)

p,turb p

D

j

0,57

2 0,75

0,036 F C Fd 1

L

St = (19)

p

1,5

p − p

N x D d 1 v

34 Fzp1 0

The following equation determines the peak frequency in the cavitation region [2,3,8].

2,5

x

1− x

Fzp1

F

f = 6 f (20)

p,cav p,turb

1− x x

Fzp1 F

6.2 Transmission loss

As in IEC 60534-8-3 for aerodynamic flow, the following frequencies are needed to calculate

the transmission loss.

– 14 – IEC 60534-8-4:2015 © IEC 2015

The ring frequency with c as the velocity of sound in the pipe (5 000 m/s for steel) is given

s

by:

c

S

f = (21)

r

π D

i

The reference minimum transmission loss for f = f can be predicted from the following

r

equation (see reference [4] in the Bibliography):

c ρ t

S S S

TL = −10 −10 log (22)

fρ 10

c ρ D

a a i

The transmission loss at given frequencies f is determined as follows:

i

(23)

TL(f ) = TL + ∆TL(f )

i fr i

1,5

f f

r i

∆TL(f ) = −20 log + (24)

i 10

f f

i r

6.3 External sound pressure calculation

The external sound pressure level spectrum at a distance of 1 m from the pipe wall can be

calculated from the internal sound-pressure level spectrum and the transmission losses.

D + 2 t + 2

i S

L (f ) = L (f ) +TL(f ) −10 log (25)

pe,1m i pi i i 10

D + 2 t

i S

Finally, the overall A-weighted sound pressure level at a distance of 1 m from the pipe wall

can be calculated by:

L (f )+ ∆L (f )

pe,1m i A i

L = 10·log 10

pAe,1m 10 ∑ (26)

i=1

where:

f = third octave band center frequency

i

L (f ) = internal sound pressure level at frequency f

pi i i

TL(f ) = transmission loss at frequency f

i i

∆L (f ) = “A” weighting factor at frequency fi (see Table 3)

A i

7 Multistage trim

7.1 General

Clause 8 is applicable to valves with trims having more than one stage. Although it uses

much of the same procedures as in the previous clauses, it is separated because these trims

require special consideration.

It is assumed that the rated flow coefficients C of the n stages (i =1.n) are known by the

i

values of

manufacturer. The numbering of stages occurs in the direction of flow. The x

Fzp1,i

each stage for such a trim have to be stated by the manufacturer or they can be taken from

Figures 4 to 9 for single-stage configurations. This is the same with the F and F values.

d,i L,i

7.2 Preliminary calculations

The following calculations for pressure assume choking does not occur in any stage.

The inlet pressure ahead of each stage (i = 1 . n) can be approximated as follows:

(27)

p = p i = 1

1,i 1

p − p

1 2

p = p − i = 2.n (28)

1,i 1,i−1

(C /C)

i−1

The outlet pressure behind each stage (i = 1 . n) can be approximated as follows:

p = p i = 1.n −1 (29)

2,i 1,i+1

p = p i = n (30)

2,i 2

The jet diameter of each stage opening according to equation (6) is:

(31)

D = N F C F

j,i 14 d,i i L,i

The valve style modifier F for the first and last stages are F (first stage) and F (last

d d,1 d,n

stage). These values depend on the valve and closure member type and on the value of C

i

(IEC 60534-8-3).

The differential pressure ratio x for each stage according to equation (1) is:

F,i

p − p

1,i 2,i

x = i = 1.n (32)

F,i

p − p

1,i v

7.3 Prediction of noise level

7.3.1 General criteria

Calculations for turbulent noise apply when x ≤ x ; otherwise, use applicable equations

F,i Fzp1,i

for cavitation.

7.3.2 Multistage devices (see Figures 1 and 3)

Determine the x values for each stage using Figures 4 to 9. Calculate L for each

Fzp1,i pAe,1m,i

stage using Clauses 5 to 7 and equation (33) using the appropriate input from equations (27)

to (32) for each stage. Add up the total sound level as follows:

n

0,1LpAe,1m,i

(33)

L = 10 log 10

pAe,1m 10 ∑

i =1

Proceed to calculate the internal and external frequency profile using f from the first and last

p

stages.

– 16 – IEC 60534-8-4:2015 © IEC 2015

7.3.3 Fixed multistage devices with increasing flow areas (see Figure 2)

Experimental evidence indicates that most of the sound power in stages ahead of the last

stage is attenuated within the flow path. It is, therefore, sufficient to calculate only the sound

generated by jets eminating from the last stage; thus:

:

a) Calculate ∆p

c

∆p = lesser of p − p or x (p − p ) (34)

c 1,n 2 Fzp1,n 1,n v

b) The valve style modifier F depends on the number of uniform outlet passages at the last

d

stage and can be estimated using the F value stated by the manufacturer or from

d

equation (35).

F = (35)

d

N

o

where

N is the number of uniform openings within the last stage.

o

Calculate D using equation (31) with C as the flow coefficient of the exit stage.

j,n n

d can be estimated from equation d = 5,2 N C . (36)

o 34 n

o

c) Calculate the velocity and the mechanical power from equations (7) and (8) using ∆p

c

(equation (2)) of the last stage and F instead of F .

Ln L

d) Calculate the turbulent sound power from equation (9) and the cavitation sound power

from equation (10), except use ∆p from equation (33) and use p from equation (23)

c 1,n

instead of p . Calculate η from equation (11), except use U of the last stage (see

1 turb vc

item c) above).

e) Calculate L from equations (13) to (18), except use the jet velocity and D of the last

pi j

stage. For f , use C and F instead of C and F .

p,cav n Ln L

f) Calculate the transmission loss using equations (21) to (24).

g) Proceed to calculate the external sound pressure level using equations (25) and (26),

from the last stage (see item e) above.

except use f

p

C

n

C

n

p p

n 2

p p p

1 n 2

p

Globe Rotary

IEC

Figure 1 – Examples of multistage trim in globe and rotary valves

C

n

p

p

n

p

IEC

Figure 2 – Example of fixed multistage device with increasing flow area

IEC

Figure 3 – Example of multistage trim in globe valve

– 18 – IEC 60534-8-4:2015 © IEC 2015

IEC

Figure 4 – Globe valve (Cage trim, V-port plug)

IEC

Figure 5 – Globe valves (parabolic-plug)

IEC

Figure 6 – Multihole trims

IEC

Figure 7 – Eccentric rotary valves

– 20 – IEC 60534-8-4:2015 © IEC 2015

IEC

Figure 8 – Butterfly valves

IEC

Figure 9 – Segmented ball valve – 90°travel

Annex A

(informative)

Examples of given data

Valve

Single seat globe valve (no multihole trim) installed flow to open

Valve size: DN 100

Nominal valve size: d = 100 mm = 0,1 m

Rated C : C = 195

v vR

Required C : C = 90

v v

Seat diameter: d : 100 mm = 0,1 m

o

Liquid pressure recovery factor: F = 0,92

L

Valve style modifier: F = 0,42

d

Pipe

Inlet nominal pipe size: DN 100

Outlet nominal pipe size: DN 100

Internal pipe diameter: D = 107,1 mm = 0,1071 m

i

Pipe wall thickness: t = 3,6 mm = 0,0036 m

p

Speed of sound in pipe: c = 5 000 m/s

s

Density of pipe material: ρ = 7 800 kg/m

s

Other

Speed of sound in air: c = 343 m/s

a

ρ = 1,293 kg/m

Density of air:

a

Table A.1 provides calculation examples for the given data and three different flow rates.

– 22 – IEC 60534-8-4:2015 © IEC 2015

Table A.1 – Calculation: Examples 1 to 3

Example 1 Example 2 Example 3

Medium: water

Mass flow rate

m = 30 kg/s m = 40 kg/s m = 40 kg/s

Valve inlet absolute pressure p = 10 bar = p = 10 bar = p = 10 bar =

1 1 1

6 6 6

1,0 × 10 Pa 1,0 × 10 Pa 1,0 × 10 Pa

Valve outlet absolute pressure

p = 8 bar = p = 6,5 bar = p = 6,5 bar =

2 2 2

5 5 5

8,0 × 10 Pa 6,5 × 10 Pa 6,5 × 10 Pa

3 3 3

Vapour pressure of liquid

p = 2,32 × 10 Pa p = 2,32 × 10 Pa p = 2,32 × 10 Pa

v v v

3 3 3

Density of liquid

ρ = 997 kg/m ρ = 997 kg/m ρ = 997 kg/m

1 1 1

Speed of sound in liquid c = 1 400 m/s c = 1 400 m/s c = 1 400 m/s

1 1 1

(1) Differential pressure ratio x = 0,200 5 x = 0,350 8 x = 0,350 8

F F F

p − p

1 2

x =

F

p − p

1 v

(2) Pressure differential for U calculation x (p – p ) = x (p – p ) = x (p – p ) =

vc F 1 v F 1 v F 1 v

5 5 5

2,0 × 10 Pa 3,5 × 10 Pa 3,5 × 10 Pa

p = lower of (p − p ) or F (p − p )

c 1 2 L 1 v

2 2 2

F (p – p ) = F (p – p ) = F (p – p ) =

L 1 v L 1 v L 1 v

5 5 5

8,44 × 10 Pa 8,44 × 10 Pa 8,44 × 10 Pa

5 5 5

⇒ ∆p = 2,0 × 10 ⇒ ∆p = 3,5 × 10 ⇒ ∆p = 3,5 × 10

c c c

Pa Pa Pa

(3) Differential pressure ratio of incipient cavitation C = C = 90 C = C = 90

Calculation with

v v

noise

X = x + 0,1

Fz Fz

0,90

XFz =

N = 1,17 N = 1,17

From example 2

34 34

C

1+ 3 F

d

⇒ x = 0,254 3 ⇒ x = 0,254 3 ⇒ x = 0,354 3

N34 F Fz Fz Fz

L

(4) Differential pressure ratio corrected for inlet x = 0,238 6 x = 0,238 6 x = 0,332 4

Fzp1 Fzp1 Fzp1

pressure

0,125

6 x 10

x = x

Fzp1 Fz

p

(6) Jet diameter C = C = 90 C = C = 90 C = C = 90

v v v

N = 0,004 6 N = 0,004 6 N = 0,004 6

D = N F C F 14 14 14

j 14 d L

⇒ D = 0,017 58 m ⇒ D = 0,017 58 m ⇒ D = 0,017 58 m

j j j

(7) Vena contracta velocity U = 21,772 m/s U = 28,801 m/s U = 28,801 m/s

vc vc vc

1 2 ∆p

c

U =

vc

F ρ

L L

(8) Mechanical stream power W = 6 018,05 W W = 14 042,1 W W = 14 042,1 W

m m m

2 2

m U F

vc L

W =

m

Flow conditions

∆p = p – p = ∆p = p – p = ∆p = p – p =

1 2 1 2 1 2

5 5 5

2 × 10 Pa 3,5 × 10 Pa 3,5 × 10 Pa

∆p < x (p – ∆p > x (p – ∆p > x (p –

Fzp1 1 Fzp1 1 Fzp1 1

5 5 5

p ) = 2,38 × 10 p ) = 2,38 × 10 p ) = 3,32 × 10

v v v

Pa Pa Pa

⇒ Turbulent ⇒Cavitating ⇒ Cavitating

– – –

(11) Acoustic efficiency factor (turbulent) η = 3,906 × 10 η = 5,168 × 10 η = 5,168 × 10

turb turb turb

7 7 7

U

A

vc

A = –4,6 A = –4,6 A = –4,6

η = 10

turb η η η

c

1

– –

(12) Acoustic efficiency factor (cavitating)

η = 3,121 × 10 η

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...