IEC 61000-4-4:2004

(Main)Electromagnetic compatibility (EMC) - Part 4-4: Testing and measurement techniques - Electrical fast transient/burst immunity test

Electromagnetic compatibility (EMC) - Part 4-4: Testing and measurement techniques - Electrical fast transient/burst immunity test

Establishes a common and reproducible reference for evaluating the immunity of electrical and electronic equipment when subjected to electrical fast transient/bursts on supply, signal, control and earth ports. The test method documented in this part of IEC 61000-4 describes a consistent method to assess the immunity of an equipment or system against a defined phenomenon. The standard defines: - test voltage waveform; - range of test levels; - test equipment; - verification procedures of test equipment; - test set-up; - test procedure. The standard gives specifications for laboratory and post-installation tests. The contents of the corrigenda of August 2006 and June 2007 have been included in this copy.

Compatibilité électromagnétique (CEM) - Partie 4-4: Techniques d'essai et de mesure - Essais d'immunité aux transitoires électriques rapides en salves

Etablit une référence commune et reproductible dans le but d'évaluer l'immunité des matériels électriques et électroniques, quand ils sont soumis aux transitoires électriques rapides en salves sur les accès d'alimentation, de signal, de commande et de terre. La méthode d'essai documentée dans cette partie de la CEI 61000-4 décrit une méthode cohérente dans le but d'évaluer l'immunité d'un matériel ou système vis-à-vis d'un phénomène défini. Cette norme définit: - la forme d'onde de l'essai en tension; - la gamme des niveaux d'essais; - le matériel d'essai; - les procédures de vérification du matériel d'essai; - l'installation d'essai; - la procédure d'essai. Cette norme donne des spécifications pour les essais menés en laboratoire et les essais in situ réalisés sur le matériel dans l'installation finale. Le contenu des corrigenda d'août 2006 et juin 2007 a été pris en considération dans cet exemplaire. -

General Information

- Status

- Published

- Publication Date

- 07-Jul-2004

- Technical Committee

- SC 77B - High frequency phenomena

- Drafting Committee

- WG 11 - TC 77/SC 77B/WG 11

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 30-Apr-2012

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61000-4-4:2004 - "Electromagnetic compatibility (EMC) - Part 4-4: Testing and measurement techniques - Electrical fast transient/burst immunity test" is a basic EMC publication that establishes a common, reproducible reference for evaluating the immunity of electrical and electronic equipment to electrical fast transients/bursts (EFT/B). The second edition (2004), including corrigenda from 2006 and 2007, defines the test waveform, ranges of test levels, required test equipment and verification procedures, and both laboratory and post-installation test set-ups and procedures. The standard clarifies simulator specifications and test criteria and specifies that only common-mode injection is required.

Key Topics and Requirements

- Test purpose: Assess immunity of equipment under test (EUT) to repetitive electrical fast transient/burst events on supply, signal, control and earth ports.

- Defined test elements:

- Test voltage waveform and general pulse characteristics (as the reference phenomenon).

- Range of test levels to be applied (see standard for level selection).

- Test equipment requirements, including burst generators, coupling/decoupling networks (CDNs) for a.c./d.c. mains, and capacitive coupling clamps for common-mode coupling.

- Verification procedures for calibrating and confirming generator and CDN performance.

- Test set-up options for laboratory type tests and for post-installation (on-site) tests.

- Test procedures and evaluation criteria and required content of the test report.

- Injection mode: Common-mode coupling is specified as the required injection method.

- Scope of application: Applies to supply, signal, control and protective earth ports; includes both type (laboratory) testing and post-installation verification.

Practical Applications - Who Uses IEC 61000-4-4

- EMC test laboratories performing conformity and type testing for products subject to EFT/B immunity requirements.

- Electronic and electrical equipment manufacturers designing for EMC-power supplies, control systems, communications equipment, industrial automation and medical devices.

- Compliance engineers and product committees using the standard to set product-specific immunity levels and performance criteria.

- Installation and maintenance teams conducting post-installation immunity checks in the field.

Using IEC 61000-4-4 helps identify vulnerabilities to fast transients (switching, arcing, relay contact bounce) and validates mitigation such as filtering, shielding, grounding and surge suppression.

Related Standards

- IEC 61000 series (EMC framework) - Part 1.. Part 2.. Part 3.. Part 5..

- IEC 60050-161 (IEV Chapter 161: EMC) - terminology used by this standard.

- IEC Guide 107 - guidance on basic EMC publications and product committee responsibilities.

Keywords: IEC 61000-4-4, EMC, electrical fast transient, burst immunity test, EFT/B, burst generator, coupling/decoupling network, capacitive coupling clamp, EMI testing, immunity testing.

Buy Documents

IEC 61000-4-4:2004 - Electromagnetic compatibility (EMC) - Part 4-4: Testing and measurement techniques - Electrical fast transient/burst immunity test Released:7/8/2004

IEC 61000-4-4:2004 - Compatibilité électromagnétique (CEM) - Partie 4-4: Techniques d'essai et de mesure - Essais d'immunité aux transitoires électriques rapides en salves Released:7/8/2004

IEC 61000-4-4:2004 - Electromagnetic compatibility (EMC) - Part 4-4: Testing and measurement techniques - Electrical fast transient/burst immunity test Released:7/8/2004 Isbn:2831875676

IEC 61000-4-4:2004+AMD1:2010 CSV - Electromagnetic compatibility (EMC) - Part 4-4: Testing and measurement techniques - Electrical fast transient/burst immunity test Released:3/30/2011 Isbn:9782889124121

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC 61000-4-4:2004 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electromagnetic compatibility (EMC) - Part 4-4: Testing and measurement techniques - Electrical fast transient/burst immunity test". This standard covers: Establishes a common and reproducible reference for evaluating the immunity of electrical and electronic equipment when subjected to electrical fast transient/bursts on supply, signal, control and earth ports. The test method documented in this part of IEC 61000-4 describes a consistent method to assess the immunity of an equipment or system against a defined phenomenon. The standard defines: - test voltage waveform; - range of test levels; - test equipment; - verification procedures of test equipment; - test set-up; - test procedure. The standard gives specifications for laboratory and post-installation tests. The contents of the corrigenda of August 2006 and June 2007 have been included in this copy.

Establishes a common and reproducible reference for evaluating the immunity of electrical and electronic equipment when subjected to electrical fast transient/bursts on supply, signal, control and earth ports. The test method documented in this part of IEC 61000-4 describes a consistent method to assess the immunity of an equipment or system against a defined phenomenon. The standard defines: - test voltage waveform; - range of test levels; - test equipment; - verification procedures of test equipment; - test set-up; - test procedure. The standard gives specifications for laboratory and post-installation tests. The contents of the corrigenda of August 2006 and June 2007 have been included in this copy.

IEC 61000-4-4:2004 is classified under the following ICS (International Classification for Standards) categories: 33.100.20 - Immunity. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61000-4-4:2004 has the following relationships with other standards: It is inter standard links to IEC 61000-4-4:2004/AMD1:2010, IEC 61000-4-4:2004/COR1:2006, IEC 61000-4-4:2004/COR2:2007, IEC 61000-4-4:2012, IEC 61000-4-4:1995/AMD1:2000, IEC 61000-4-4:1995/AMD2:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61000-4-4:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 61000-4-4

Second edition

2004-07

BASIC EMC PUBLICATION

Electromagnetic compatibility (EMC) –

Part 4-4:

Testing and measurement techniques –

Electrical fast transient/burst immunity test

This English-language version is derived from the original

bilingual publication by leaving out all French-language

pages. Missing page numbers correspond to the French-

language pages.

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 61000-4-4

Second edition

2004-07

BASIC EMC PUBLICATION

Electromagnetic compatibility (EMC) –

Part 4-4:

Testing and measurement techniques –

Electrical fast transient/burst immunity test

” IEC 2004 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical,

including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale V

International Electrotechnical Commission

ɆɟɠɞɭɧɚɪɨɞɧɚɹɗɥɟɤɬɪɨɬɟɯɧɢɱɟɫɤɚɹɄɨɦɢɫɫɢɹ

For price, see current catalogue

61000-4-4 © IEC:2004 – 3 –

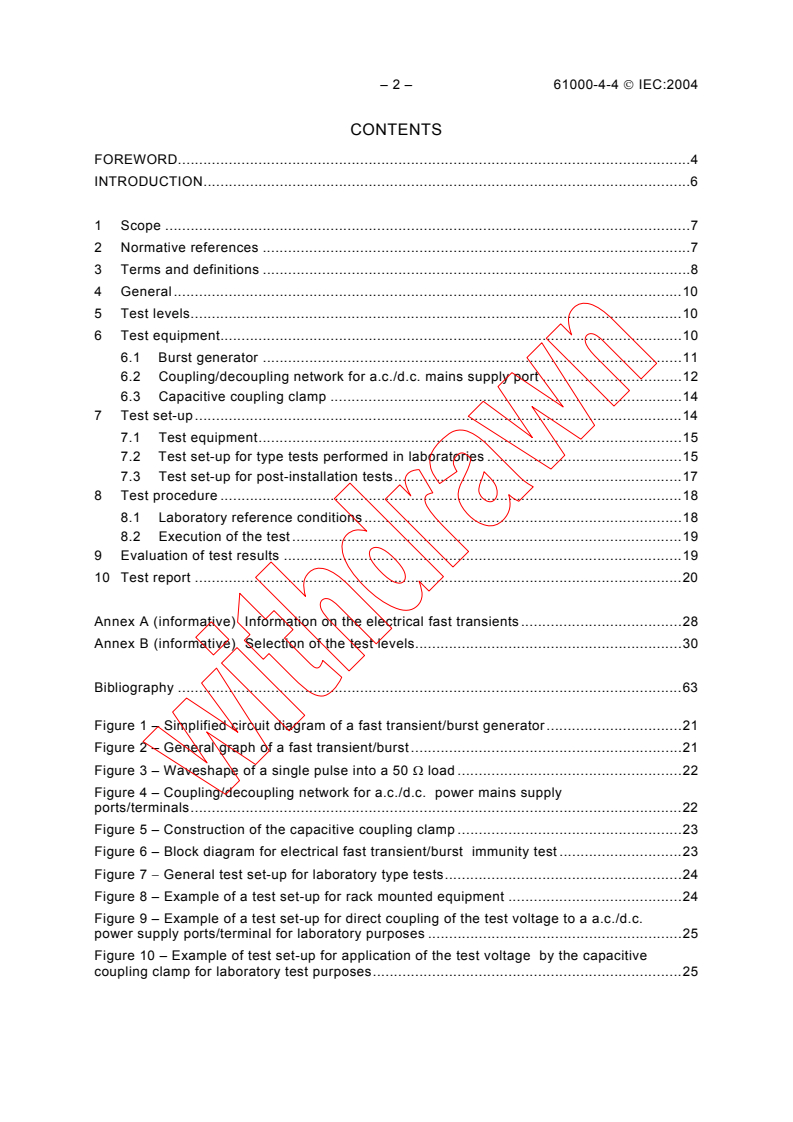

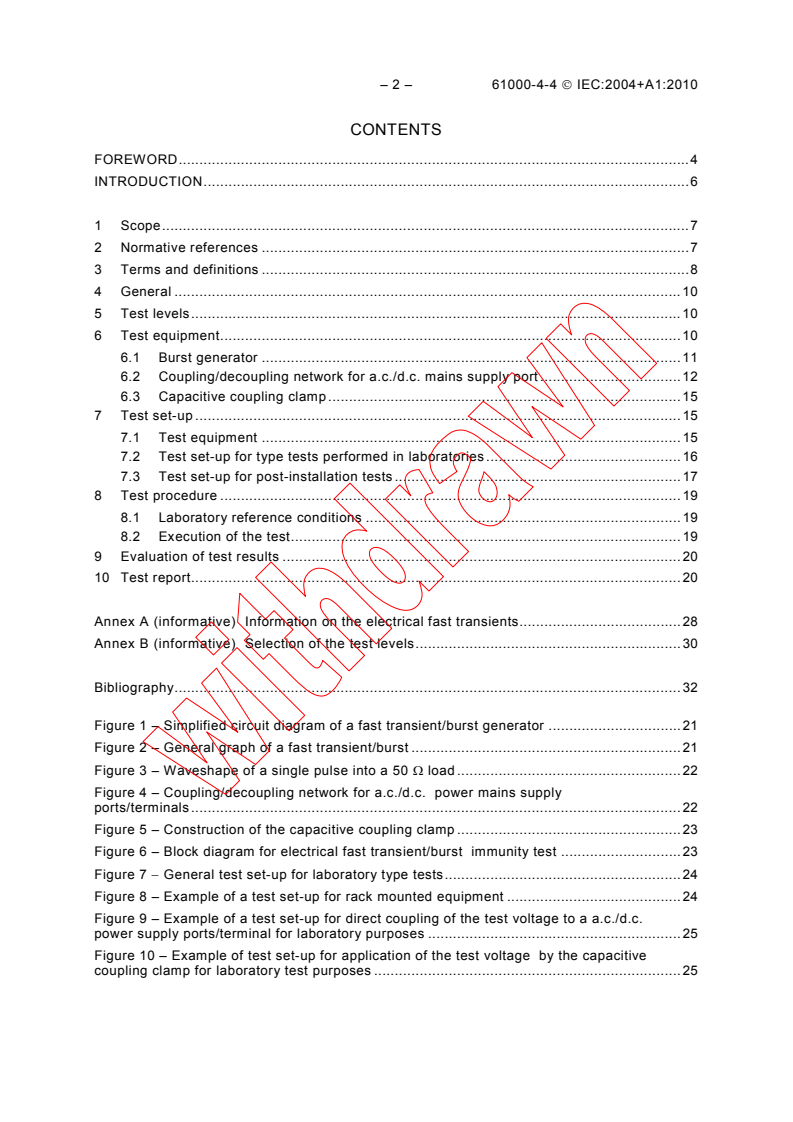

CONTENTS

FOREWORD.7

INTRODUCTION.11

1 Scope.13

2 Normative references.13

3 Terms and definitions .15

4 General.19

5 Test levels.19

6 Test equipment.19

6.1 Burst generator.21

6.2 Coupling/decoupling network for a.c./d.c. mains supply port.23

6.3 Capacitive coupling clamp.27

7 Test set-up.27

7.1 Test equipment.29

7.2 Test set-up for type tests performed in laboratories.29

7.3 Test set-up for post-installation tests .33

8 Test procedure.35

8.1 Laboratory reference conditions .35

8.2 Execution of the test.37

9 Evaluation of test results .37

10 Test report.39

Annex A (informative) Information on the electrical fast transients.55

Annex B (informative) Selection of the test levels.59

Bibliography.63

Figure 1 – Simplified circuit diagram of a fast transient/burst generator .41

Figure 2 – General graph of a fast transient/burst .41

Figure 3 – Waveshape of a single pulse into a 50 Ω load .43

Figure 4 – Coupling/decoupling network for a.c./d.c. power mains supply

ports/terminals.43

Figure 5 – Construction of the capacitive coupling clamp .45

Figure 6 – Block diagram for electrical fast transient/burst immunity test .45

Figure 7 − General test set-up for laboratory type tests.47

Figure 8 – Example of a test set-up for rack mounted equipment .47

Figure 9 – Example of a test set-up for direct coupling of the test voltage to a a.c./d.c.

power supply ports/terminal for laboratory purposes .49

Figure 10 – Example of test set-up for application of the test voltage by the capacitive

coupling clamp for laboratory test purposes .49

61000-4-4 © IEC:2004 – 5 –

Figure 11 – Example for post-installation test on a.c./d.c. power supply ports and

protective earth terminals for stationary, floor-mounted EUT .51

Figure 12 – Example for post-installation test on a.c. mains supply port and protective

earth terminals for non-stationary mounted EUT .53

Figure 13 – Example of post-installation test on communications and I/O ports without

the capacitive coupling clamp .53

Figure 14 – Verification of the waveform at the common mode output of the

coupling/decoupling network .25

Table 1 – Test levels.19

Table 2 – Output voltage peak values and repetition rates .23

61000-4-4 © IEC:2004 – 7 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

ELECTROMAGNETIC COMPATIBILITY (EMC) –

Part 4-4: Testing and measurement techniques –

Electrical fast transient/burst immunity test

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61000-4-4 has been prepared by sub-committee 77B: High

frequency phenomena, of IEC technical committee 77: Electromagnetic compatibility.

It forms Part 4-4 of IEC 61000. It has the status of a basic EMC publication in accordance

with IEC Guide 107, Electromagnetic compatibility – Guide to the drafting of electromagnetic

compatibility publications.

This second edition cancels and replaces the first edition published in 1995 and its amend-

ments 1 (2000) and 2 (2001) and constitutes a technical revision.

This second edition improves and clarifies simulator specifications, test criteria and test set-

ups. Only common mode injection is required.

61000-4-4 © IEC:2004 – 9 –

The text of this standard is based on the following documents:

FDIS Report on voting

77B/419/FDIS 77B/424/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of August 2006 and June 2007 have been included in this

copy.

61000-4-4 © IEC:2004 – 11 –

INTRODUCTION

IEC 61000 is published in separate parts, according to the following structure:

Part 1: General

General considerations (introduction, fundamental principles)

Definitions, terminology

Part 2: Environment

Description of the environment

Classification of the environment

Compatibility levels

Part 3: Limits

Emission limits

Immunity limits (in so far as they do not fall under the responsibility of the product

committees)

Part 4: Testing and measurement techniques

Measurement techniques

Testing techniques

Part 5: Installation and mitigation guidelines

Installation guidelines

Mitigation methods and devices

Part 6: Generic standards

Part 9: Miscellaneous

Each part is further subdivided into several parts, published either as international standards

or as technical specifications or technical reports, some of which have already been published

as sections. Others will be published with the part number followed by a dash and a second

number identifying the subdivision (example: 61000-6-1).

This part is an international standard which gives immunity requirements and test procedures

related to electrical fast transients/bursts.

61000-4-4 © IEC:2004 – 13 –

ELECTROMAGNETIC COMPATIBILITY (EMC) –

Part 4-4: Testing and measurement techniques –

Electrical fast transient/burst immunity test

1 Scope

This part of IEC 61000-4 relates to the immunity of electrical and electronic equipment to

repetitive electrical fast transients. It gives immunity requirements and test procedures related

to electrical fast transients/bursts. It additionally defines ranges of test levels and establishes

test procedures.

The object of this standard is to establish a common and reproducible reference for evaluating

the immunity of electrical and electronic equipment when subjected to electrical fast

transient/bursts on supply, signal, control and earth ports. The test method documented in

this part of IEC 61000-4 describes a consistent method to assess the immunity of an

equipment or system against a defined phenomenon.

NOTE As described in IEC Guide 107, this is a basic EMC publication for use by product committees of the IEC.

As also stated in Guide 107, the IEC product committees are responsible for determining whether this immunity

test standard should be applied or not, and if applied, they are responsible for determining the appropriate test

levels and performance criteria. TC 77 and its sub-committees are prepared to co-operate with product committees

in the evaluation of the value of particular immunity tests for their products.

The standard defines:

– test voltage waveform;

– range of test levels;

– test equipment;

– verification procedures of test equipment;

– test set-up;

– test procedure.

The standard gives specifications for laboratory and post-installation tests.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050-161:1990, International Electrotechnical Vocabulary (IEV) – Chapter 161: Electro-

magnetic compatibility

61000-4-4 © IEC:2004 – 15 –

3 Terms and definitions

For the purposes of this document, the following terms and definitions, together with those in

IEC 60050-161 apply.

NOTE Several of the most relevant terms and definitions from IEC 60050-161 are presented among the definitions

below.

3.1

burst

sequence of a limited number of distinct pulses or an oscillation of limited duration

[IEV 161-02-07]

3.2

calibration

set of operations which establishes, by reference to standards, the relationship which exists,

under specified conditions, between an indication and a result of a measurement

NOTE 1 This term is based on the "uncertainty" approach.

NOTE 2 The relationship between the indications and the results of measurement can be expressed, in principle,

by a calibration diagram.

[IEV 311-01-09]

3.3

coupling

interaction between circuits, transferring energy from one circuit to another

3.4

common mode (coupling)

simultaneous coupling to all lines versus the ground reference plane

3.5

coupling clamp

device of defined dimensions and characteristics for common mode coupling of the

disturbance signal to the circuit under test without any galvanic connection to it

3.6

coupling network

electrical circuit for the purpose of transferring energy from one circuit to another

3.7

decoupling network

electrical circuit for the purpose of preventing EFT voltage applied to the EUT from affecting

other devices, equipment or systems which are not under test

3.8

degradation (of performance)

undesired departure in the operational performance of any device, equipment or system from

its intended performance

NOTE The term "degradation" can apply to temporary or permanent failure.

[IEV 161-01-19]

61000-4-4 © IEC:2004 – 17 –

3.9

EFT/B

electrical fast transient/burst

3.10

electromagnetic compatibility (EMC)

ability of an equipment or system to function satisfactorily in its electromagnetic environment

without introducing intolerable electromagnetic disturbances to anything in that environment

[IEV 161-01-07]

3.11

EUT

equipment under test

3.12

ground reference plane

flat conductive surface whose potential is used as a common reference

[IEV 161-04-36]

3.13

immunity (to a disturbance)

ability of a device, equipment or system to perform without degradation in the presence of an

electromagnetic disturbance

[IEV 161-01-20]

3.14

port

particular interface of the EUT with the external electromagnetic environment

3.15

rise time

interval of time between the instants at which the instantaneous value of a pulse first reaches

10 % value and then the 90 % value

[IEV 161-02-05, modified]

3.16

transient

pertaining to or designating a phenomenon or a quantity which varies between two

consecutive steady states during a time interval which is short compared with the time-scale

of interest

[IEV 161-02-01]

3.17

verification

set of operations which is used to check the test equipment system (e.g. the test generator

and the interconnecting cables) and to demonstrate that the test system is functioning within

the specifications given in Clause 6

NOTE 1 The methods used for verification may be different from those used for calibration.

NOTE 2 The procedure of 6.1.2 and 6.2.2 is meant as a guide to insure the correct operation of the test

generator, and other items making up the test set-up so that the intended waveform is delivered to the EUT.

NOTE 3 For the purpose of this basic EMC standard this definition is different from the definition given in

IEV 311-01-13.

61000-4-4 © IEC:2004 – 19 –

4 General

The repetitive fast transient test is a test with bursts consisting of a number of fast transients,

coupled into power supply, control, signal and earth ports of electrical and electronic

equipment. Significant for the test are the high amplitude, the short rise time, the high

repetition rate, and the low energy of the transients.

The test is intended to demonstrate the immunity of electrical and electronic equipment when

subjected to types of transient disturbances such as those originating from switching

transients (interruption of inductive loads, relay contact bounce, etc.).

5 Test levels

The preferred test levels for the electrical fast transient test, applicable to power, ground,

signal and control ports of the equipment are given in Table 1.

Table 1 – Test levels

Open circuit output test voltage and repetition rate of the impulses

On I/O (input/output) signal, data

On power port, PE

and control ports

Level

Voltage peak Repetition rate Voltage peak Repetition rate

kV kHz kV kHz

1 0,5 5 or 100 0,25 5 or 100

2 1 5 or 100 0,5 5 or 100

3 2 5 or 100 1 5 or 100

4 4 5 or 100 2 5 or 100

a

X Special Special Special Special

NOTE 1 Use of 5 kHz repetition rates is traditional; however, 100 kHz is closer to reality. Product committees

should determine which frequencies are relevant for specific products or product types.

NOTE 2 With some products, there may be no clear distinction between power ports and I/O ports, in which case

it is up to product committees to make this determination for test purposes.

a

"X" is an open level. The level has to be specified in the dedicated equipment specification.

These open-circuit output voltages will be displayed on the EFT/B generator. For selection of

levels, see Annex B.

6 Test equipment

The verification procedures of 6.1.2 and 6.2.2 are meant as a guide to insure the correct

operation of the test generator, coupling/decoupling networks, and other items making up the

test set-up so that the intended waveform is delivered to the EUT.

61000-4-4 © IEC:2004 – 21 –

6.1 Burst generator

The simplified circuit diagram of the generator is given in Figure 1. The circuit elements C ,

c

R , R , and C are selected so that the generator delivers a fast transient under open circuit

s m d

conditions and with a 50 Ω resistive load. The effective output impedance of the generator

shall be 50 Ω.

The major elements of the test generator are:

– high-voltage source;

– charging resistor;

– energy storage capacitor;

– high voltage switch;

– impulse duration shaping resistor;

– impedance matching resistor;

– d.c. blocking capacitor.

6.1.1 Characteristics of the fast transient/burst generator

The characteristics of the fast transient/burst generator are the following:

– Output voltage range with 1 000 Ω load shall be at least 0,25 kV to 4 kV

– Output voltage range with 50 Ω load shall be at least 0,125 kV to 2 kV

The generator shall be capable of operating under short-circuit conditions.

Characteristics:

– polarity: positive/negative

– output type: coaxial, 50 Ω

– d.c. blocking capacitor 10 nF ± 20 %

– repetition frequency: (see Table 2) ± 20 %

– relation to power supply: asynchronous

– burst duration: 15 ms ± 20 % at 5 kHz

(see Figure 2) 0,75 ms ± 20 % at 100 kHz

– burst period: 300 ms ± 20 %

(see Figure 2)

– wave shape of the pulse

• into 50 Ω load rise time t = 5 ns ± 30 %

r

duration t (to 50 %) = 50 ns ± 30 %

d

peak voltage = according to Table 2, ±10 %

(see Figure 3 for the 50 Ω waveshape)

• into 1 000 Ω load rise time t = 5 ns ± 30 %

r

duration t (to 50 %) = 50 ns with a tolerance of

d

–15 ns to +100 ns

peak voltage = according to Table 2, ±20%

(see Note 2 below Table 2)

61000-4-4 © IEC:2004 – 23 –

– test load impedance 50 Ω ± 2 %

1 000 Ω ± 2 % in parallel with ≤ 6 pF. The resistance

measurement is made at d.c. and the capacitance

measurement is made using a commercially

available capacitance meter that operates at low

frequencies.

6.1.2 Verification of the characteristics of the fast transient/burst generator

The test generator characteristics shall be verified in order to establish a common reference

for all generators. For this purpose, the following procedure shall be undertaken.

The test generator output shall be connected to a 50 Ω and 1 000 Ω coaxial termination

respectively and the voltage monitored with an oscilloscope. The –3 dB bandwidth of the

measuring equipment and the test load impedance shall be at least 400 MHz. The test load

impedance at 1 000 Ω is likely to become a complex network. The rise time, impulse duration

and repetition rate of the impulses within one burst shall be monitored as well as the burst

duration and burst period.

For each of the set voltages of Table 2, measure the output voltage at a 50 Ω load

[V (50 Ω)]. This measured voltage shall be [0,5 × V (open circuit)] ± 10%.

p p

With the same generator setting (set voltage), measure the voltage at a 1 000 Ω load –

[V (1 000 Ω)]. This measured voltage shall be V (open circuit) ± 20%.

p p

NOTE 1 Measures should be taken to ensure that stray capacitance is kept to a minimum.

Table 2 – Output voltage peak values and repetition rates

Set voltage V (open circuit) Repetition

V (1 000 Ω) V (50 Ω)

p

p p

frequency

kV kV kV kV

kHz

0,25 0,25 0,24 0,125 5 or 100

0,5 0,5 0,48 0,25 5 or 100

1 1 0,95 0,5 5 or 100

2 2 1,9 1 5 or 100

4 4 3,8 2 5 or 100

NOTE 2 Use of a 1 000 Ω load resistor will automatically result in a voltage reading that is 5 % lower than the set

voltage as shown in column V (1 000 Ω). The reading V at 1000 Ω = V (open circuit) multiplied times

p p p

1000/1050 (the ratio of the test load to the total circuit impedance of 1000 Ω plus 50 Ω).

NOTE 3 With the 50 Ω load, the measured output voltage is 0,5 times the value of the unloaded voltage as

reflected in the table above.

6.2 Coupling/decoupling network for a.c./d.c. mains supply port

The coupling/decoupling network is required for acceptance tests of a.c./d.c. power supply

ports.

61000-4-4 © IEC:2004 – 25 –

The circuit diagram (example for a three-phase power mains supply) is given in Figure 4.

The waveform of the EFT/B generator shall be verified at the output of the coupling network

according to 6.2.2.

6.2.1 Characteristics of the coupling/decoupling network

The characteristics of the coupling/decoupling network are the following:

– coupling capacitors: 33 nF;

– coupling mode: common mode.

6.2.2 Verification of the characteristics of the coupling/decoupling network

The requirements given in 6.1.2 also apply to the measurement equipment that is used for the

verification of the characteristics of the coupling/decoupling network.

The waveform shall be verified at the common mode output of the coupling/decoupling

network with all outputs tied together and a single 50 Ω termination as shown in Figure 14. In

addition to verification of the waveform at the common mode output of the

coupling/decoupling network, it is recommended that each individual output be checked to

ensure that all outputs are functional."

Signal from test generator

Decoupling

L

L

Termination

L

resistor

N

50 Ω

U

meas

PE

IEC 1033/07

Figure 14 – Verification of the waveform at the common mode output

of the coupling/decoupling network

The verification is performed with the generator output voltage set to a nominal voltage of

4 kV. The generator is connected to input of the coupling/decoupling network. The output of

the CDN (normally connected to the EUT) is terminated with a 50 Ω load. The peak voltage

and waveform are recorded.

Rise time of the pulses (10 % to 90 % value) shall be 5 ns ± 30 %.

Impulse duration (50 % value) shall be 50 ns ± 30 % with the 50 Ω load.

61000-4-4 © IEC:2004 – 27 –

Peak voltage ±10 % according to Table 2.

The residual test pulse voltage on the inputs of the coupling/decoupling network when the

EUT and the power network are disconnected shall not exceed 10 % of applied test voltage.

NOTE Coupling/decoupling networks designed in accordance with Edition 1 of IEC 61000-4-4 (1995) may need

minor modifications to meet the common mode requirements of this document.

6.3 Capacitive coupling clamp

The clamp provides the ability of coupling the fast transients/bursts to the circuit under test

without any galvanic connection to the terminals of the EUT's ports, shielding of the cables or

any other part of the EUT.

The coupling capacitance of the clamp depends on the cable diameter, material of the cables,

and cable shielding (if any).

The device is composed of a clamp unit (made, for example, of galvanized steel, brass,

copper or aluminium) for housing the cables (flat or round) of the circuits under test and shall

be placed on a ground reference plane of minimum area of 1 m . The ground (reference)

plane shall extend beyond the clamp by a least 0,1 m on all sides.

The clamp shall be provided at both ends with a high-voltage coaxial connector for the

connection of the test generator at either end. The generator shall be connected to that end of

the clamp which is nearest to the EUT.

The clamp itself shall be closed as much as possible to provide maximum coupling

capacitance between the cable and the clamp.

The mechanical arrangement of the coupling clamp is given in Figure 5 and determines its

characteristics, such as frequency response, impedance, etc.

Characteristics:

− typical coupling capacitance between cable and clamp: 100 pF to 1 000 pF;

− usable diameter range of round cables: 4 mm to 40 mm;

− insulation withstand capability: 5 kV (test pulse: 1,2/50 µs).

The coupling method using the clamp is required for acceptance tests on lines connected to

I/O and communication ports. It may also be used on ac/dc power supply ports only if the

coupling/decoupling network defined in 6.2 cannot be used.

7 Test set-up

Different types of tests are defined based on test environments. These are:

– type (conformance) tests performed in laboratories;

– post-installation tests performed on equipment in its final installed conditions.

The preferred test method is that of type tests performed in laboratories.

The EUT shall be arranged in accordance with the manufacturer's instructions for installation

(if any).

61000-4-4 © IEC:2004 – 29 –

7.1 Test equipment

The test set-up includes the following equipment (see Figure 6):

– ground reference plane;

– coupling device (network or clamp);

– decoupling network;

– test generator.

7.2 Test set-up for type tests performed in laboratories

7.2.1 Test conditions

The following requirements apply to tests performed in laboratories with the environmental

reference conditions specified in 8.1.

EUTs, whether stationary floor-mounted or table top, and equipment designed to be mounted

in other configurations, shall be placed on a ground reference plane and shall be insulated

from it by an insulating support 0,1 m ± 0,01 m thick (see Figure 7).

In the case of table-top equipment, the EUT should be located 0,1 m ± 0,01 m above the

ground reference plane (see Figure 7). Equipment normally mounted on ceilings or walls shall

be tested as table-top equipment with the EUT located 0,1m ± 0,01 m above the ground

reference plane.

The test generator and the coupling/decoupling network shall be placed directly on, and

bonded to, the ground reference plane.

The ground reference plane shall be a metallic sheet (copper or aluminium) of 0,25 mm

minimum thickness; other metallic materials may be used but they shall have 0,65 mm

minimum thickness.

The minimum area of the ground reference plane is 1 m × 1 m. The actual size depends on

the dimensions of the EUT.

The ground reference plane shall project beyond the EUT by at least 0,1 m on all sides.

The ground reference plane shall be connected to the protective earth.

The EUT shall be arranged and connected to satisfy its functional requirements, according to

the equipment installation specifications.

The minimum distance between the EUT and all other conductive structures (e.g. the walls of

a shielded room), except the ground reference plane shall be more than 0,5 m.

All cables to the EUT shall be placed on the insulation support 0,1 m above the ground

reference plane. Cables not subject to electrical fast transients shall be routed as far as

possible from the cable under test to minimize the coupling between the cables.

The EUT shall be connected to the earthing system in accordance with the manufacturer's

installation specifications; no additional earthing connections are allowed.

The connection impedance of the coupling/decoupling network earth cables to the ground

reference plane and all bondings shall provide a low inductance.

61000-4-4 © IEC:2004 – 31 –

Either a direct coupling network or a capacitive clamp shall be used for the application of the

test voltages. The test voltages shall be coupled to all of the EUT ports including those

between two units of equipment involved in the test, unless the length of the interconnecting

cable makes it impossible to test.

Decoupling networks shall be used to protect auxiliary equipment and public networks.

When using the coupling clamp, the minimum distance between the coupling plates and all

other conductive surfaces, except the ground reference plane beneath the coupling clamp,

shall be 0,5 m.

Unless otherwise specified in the product standard or the product family standard, the length

of the signal and power lines between the coupling device and the EUT shall be

0,5 m ± 0,05 m.

If the manufacturer provides a non-detachable supply cable more than 0,5 m ± 0,05 m long

with the equipment, the excess length of this cable shall be folded to avoid a flat coil and

situated at a distance of 0,1 m above the ground reference plane.

Examples of the test set-up for laboratory tests are given in Figures 7 and 8.

In Figure 8, an additional ground plane, connected to the chassis of the EUT is used.

7.2.2 Methods of coupling the test voltage to the EUT

The method of coupling the test voltage to the EUT is dependent on the type of EUT port (as

indicated below).

7.2.2.1 Power supply ports

An example for the test set-up for direct coupling of the EFT/B disturbance voltage via a

coupling/decoupling network is given in Figure 9. This is the preferred method of coupling to

power supply ports.

If a suitable coupler/decoupler cannot be obtained, i.e. for a.c. mains currents >100 A,

alternative methods can be employed; however, use of the capacitive clamp is discouraged

since its efficiency in coupling the bursts is considerably less than direct injection using the

33 nF capacitors.

7.2.2.2 I/O and communication ports

The examples in Figures 7 and 10 show how to use the capacitive coupling clamp for

application of the disturbance test voltage to I/O and communication ports. When using the

capacitive coupling clamp, non-tested or auxiliary equipment connected should be

appropriately decoupled.

7.2.2.3 Cabinet earth port

The test point on the cabinet shall be the terminal for the protective earth conductor.

The test voltage shall be applied to the protective earth (PE) connection through a 33 nF

coupling capacitor according to Figure 11.

61000-4-4 © IEC:2004 – 33 –

7.3 Test set-up for post-installation tests

These tests are optional. They may be applied only when agreed between manufacturer and

customer. It has to be considered that the test itself may be destructive to the EUT and other

co-located equipment may be damaged or otherwise unacceptably affected.

The equipment or system shall be tested in the final installed conditions. Post-installation

tests shall be performed without coupling/decoupling networks in order to simulate the actual

electromagnetic environment as closely as possible.

If equipment or system other than the EUT are unduly affected during the test procedure,

decoupling networks shall be used by agreement between the user and the manufacturer.

7.3.1 Test on power supply ports and earth ports

7.3.1.1 Stationary, floor-mounted equipment

The test voltage shall be applied simultaneously between a ground reference plane and all of

the power supply terminals, a.c. or d.c., and the protective or functional earth port on the EUT

cabinet.

For the test set-up, see Figure 11.

A ground reference plane of minimum area of 1 m (as described in 7.2.1) shall be mounted

near the EUT and connected to the protective earth conductor at the power supply mains

outlet.

The EFT/B generator shall be located on the ground reference plane. The length of the "hot

wire" from the coaxial output of the EFT/B-coupling device to the ports on the EUT shall be

0,5 m ± 0,05 m. This connection shall be unshielded but well insulated. If a.c./d.c. blocking

capacitors are necessary, their capacitance shall be 33 nF. All other connections of the EUT

should be in accordance with its functional requirements.

7.3.1.2 Non-stationary mounted EUT, connected to the mains supply by flexible cord

and plugs

The test voltage shall be applied simultaneously between each of the power supply

conductors and the protective earth at the power supply (see Figure 12).

7.3.2 Test on I/O and communication ports

The capacitive coupling clamp is the preferred method for coupling the test voltage into I/O

and communication ports. However, if the clamp cannot be used due to mechanical problems

(size, cable routing) in the cabling, it shall be replaced by a tape or a conductive foil

enveloping the lines under test. The capacitance of this coupling arrangement with foil or tape

should be equivalent to that of the standard coupling clamp.

An alternative method is to couple the EFT/B generator to the terminals of the lines via

discrete 100 pF capacitors instead of the distributed capacitance of the clamp or of the foil or

tape arrangement.

61000-4-4 © IEC:2004 – 35 –

If an EUT contains many similar ports, the manufacturer can elect to test a representative

number of cables as long as those are clearly identified.

Earthing of the coaxial cable from the test generator shall be made in the vicinity of the

coupling point. Application of the test voltage to the connectors (hot wires) of coaxial or

shielded communication lines is not permitted.

The test voltage should be applied in a way that the shielding protection of the equipment will

not be reduced. See Figure 13 for the test configuration.

The test results obtained with the discrete capacitor coupling arrangement are likely to be

different from those obtained with the coupling clamp or the foil coupling. Therefore, the test

levels specified in Clause 5 may be amended by a product committee in a product standard in

order to take significant installation characteristics into consideration.

In the post installation test it can be agreed between manufacturer and user that external

cables can be tested by routing all cables simultaneously in the coupling clamp.

8 Test procedure

The performance of the test equipment shall be checked prior to the test. This check can

usually be limited to the existence of the burst for the generator at the output of the coupling

device.

The test procedure includes:

– the verification of the laboratory reference conditions;

– the preliminary verification of the correct operation of the equipment;

– the execution of the test;

– the evaluation of the test results.

8.1 Laboratory reference conditions

In order to minimize the effect of environmental parameters on test results, the test shall be

carried out in climatic and electromagnetic reference conditions as specified in 8.1.1 and

8.1.2.

8.1.1 Climatic conditions

Unless otherwise specified by the committee responsible for the generic or product standard,

the climatic conditions in the laboratory shall be within any limits specified for the operation of

the EUT and the test equipment by their respective manufacturers.

Tests shall not be performed if the relative humidity is so high as to cause condensation on

the EUT or the test equipment.

NOTE Where it is considered that there is sufficient evidence to demonstrate that the effects of the phenomenon

covered by this standard are influenced by climatic conditions, this should be brought to the attention of the

committee responsible for this standard.

61000-4-4 © IEC:2004 – 37 –

8.1.2 Electromagnetic conditions

The electromagnetic conditions of the laboratory shall be such to guarantee the correct

operation of the EUT in order not to influence the test results.

8.2 Execution of the test

The test shall be carried out on the basis of a test plan that shall include the verification of the

performances of the EUT as defined in the technical specification.

The EUT shall be in the normal operating conditions.

The test plan shall specify:

– type of test that will be carried out;

– test level;

– polarity of the test voltage (both polarities are mandatory);

– internal or external generator;

– duration of the test not less than 1 min (1 min has been chosen in order to speed up the

test; however, to avoid synchronization, the test time may be broken down into six 10 s

bursts separated by a 10 s pause. In the real environment, bursts will occur randomly as

single events. It is not intended that the burst be synchronized with EUT signals. Product

committees may choose other test durations.)

– number of applications of the test voltage;

– EUT's ports to be tested;

– representative operating conditions of the EUT;

– sequence of application of the test voltage to the EUT's ports, each one after the other or

to cables belonging to more than one circuit, etc.;

– auxiliary equipment.

9 Evaluation of test results

The test results shall be classified in terms of the loss of function or degradation of

performance of the equipment under test, relative to a performance level defined by its

manufacturer or the requestor of the test, or agreed between the manufacturer and the

purchaser of the product. The recommended classification is as follows:

a) normal performance within limits specified by the manufacturer, requestor or purchaser;

b) temporary loss of function or degradation of performance which ceases after the

disturbance ceases, and from which the equipment under test recovers its normal

performance, without operator intervention;

c) temporary loss of function or degradation of performance, the correction of which requires

operator intervention;

d) loss of function or degradation of performance which is not recoverable, owing to damage

to hardware or software, or loss of data.

The manufacturer's specification may define effects on the EUT which may be considered

insignificant, and therefore acceptable.

61000-4-4 © IEC:2004 – 39 –

This cla

...

NORME CEI

INTERNATIONALE 61000-4-4

Deuxième édition

2004-07

PUBLICATION FONDAMENTALE EN CEM

Compatibilité électromagnétique (CEM) –

Partie 4-4:

Techniques d'essai et de mesure –

Essais d’immunité aux transitoires

électriques rapides en salves

Cette version française découle de la publication d’origine

bilingue dont les pages anglaises ont été supprimées.

Les numéros de page manquants sont ceux des pages

supprimées.

Numéro de référence

CEI 61000-4-4:2004(F)

Numérotation des publications

Depuis le 1er janvier 1997, les publications de la CEI sont numérotées à partir de

60000. Ainsi, la CEI 34-1 devient la CEI 60034-1.

Editions consolidées

Les versions consolidées de certaines publications de la CEI incorporant les

amendements sont disponibles. Par exemple, les numéros d’édition 1.0, 1.1 et 1.2

indiquent respectivement la publication de base, la publication de base incorporant

l’amendement 1, et la publication de base incorporant les amendements 1 et 2.

Informations supplémentaires

sur les publications de la CEI

Le contenu technique des publications de la CEI est constamment revu par la CEI afin

qu'il reflète l'état actuel de la technique. Des renseignements relatifs à cette

publication, y compris sa validité, sont disponibles dans le Catalogue des publications

de la CEI (voir ci-dessous) en plus des nouvelles éditions, amendements et corrigenda.

Des informations sur les sujets à l’étude et l’avancement des travaux entrepris par le

comité d’études qui a élaboré cette publication, ainsi que la liste des publications

parues, sont également disponibles par l’intermédiaire de:

• Site web de la CEI (www.iec.ch)

• Catalogue des publications de la CEI

Le catalogue en ligne sur le site web de la CEI (http://www.iec.ch/searchpub/cur_fut.htm)

vous permet de faire des recherches en utilisant de nombreux critères, comprenant des

recherches textuelles, par comité d’études ou date de publication. Des informations en

ligne sont également disponibles sur les nouvelles publications, les publications rem-

placées ou retirées, ainsi que sur les corrigenda.

• IEC Just Published

Ce résumé des dernières publications parues (http://www.iec.ch/online_news/

justpub/jp_entry.htm) est aussi disponible par courrier électronique. Veuillez

prendre contact avec le Service client (voir ci-dessous) pour plus d’informations.

• Service clients

Si vous avez des questions au sujet de cette publication ou avez besoin de

renseignements supplémentaires, prenez contact avec le Service clients:

Email: custserv@iec.ch

Tél: +41 22 919 02 11

Fax: +41 22 919 03 00

NORME CEI

INTERNATIONALE 61000-4-4

Deuxième édition

2004-07

PUBLICATION FONDAMENTALE EN CEM

Compatibilité électromagnétique (CEM) –

Partie 4-4:

Techniques d'essai et de mesure –

Essais d’immunité aux transitoires

électriques rapides en salves

” IEC 2004 Droits de reproduction réservés

Aucune partie de cette publication ne peut être reproduite ni utilisée sous quelque forme que ce soit et par aucun

procédé, électronique ou mécanique, y compris la photocopie et les microfilms, sans l'accord écrit de l'éditeur.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

CODE PRIX

Commission Electrotechnique Internationale V

International Electrotechnical Commission

ɆɟɠɞɭɧɚɪɨɞɧɚɹɗɥɟɤɬɪɨɬɟɯɧɢɱɟɫɤɚɹɄɨɦɢɫɫɢɹ

Pour prix, voir catalogue en vigueur

– 2 – 61000-4-4 © CEI:2004

SOMMAIRE

AVANT-PROPOS.6

INTRODUCTION.10

1 Domaine d'application .12

2 Références normatives.12

3 Termes et définitions .14

4 Généralités.18

5 Niveaux d'essai .18

6 Matériel d'essai .18

6.1 Générateur de salves .20

6.2 Réseau de couplage/découplage pour accès d'alimentation en courant

alternatif et continu.22

6.3 Pince de couplage capacitive .26

7 Montage d'essai .26

7.1 Matériel d'essai .28

7.2 Montage d'essai pour les essais de type en laboratoire .28

7.3 Montage d'essai pour les essais sur site .32

8 Procédure d'essai.34

8.1 Conditions de référence en laboratoire .34

8.2 Exécution de l'essai.36

9 Evaluation des résultats d’essai .36

10 Rapport d’essai .38

Annexe A (informative) Information sur les transitoires électriques rapides .54

Annexe B (informative) Sélection des niveaux d’essai.58

Bibliographie.62

Figure 1 − Schéma simplifié d’un générateur de transitoires rapides en salves .40

Figure 2 − Allure générale d’un transitoire rapide en salve.40

Figure 3 − Forme d’onde d’une impulsion unique sur une charge de 50 Ω.42

Figure 4 – Réseau de couplage/découplage pour accès et bornes d'alimentation en

courant alternatif ou en courant continu .42

Figure 5 – Construction de la pince de couplage capacitive .44

Figure 6 – Diagramme synoptique de l'essai d'immunité de transitoires électriques

rapides en salves.44

Figure 7 – Montage général d'essai pour les essais de type en laboratoire .46

Figure 8 – Exemple de dispositif d’essai pour un équipement monté en rack .46

Figure 9 – Exemple de montage d'essai pour le couplage direct de la tension d'essai

aux accès ou aux bornes d'alimentation en courant alternatif ou en courant continu

pour les essais en laboratoire .48

Figure 10 – Exemple de montage d'essai pour l'application de la tension d'essai au

moyen de la pince de couplage capacitive pour les essais en laboratoire .48

– 4 – 61000-4-4 © CEI:2004

Figure 11 – Exemple d'essai sur site sur les accès d'alimentation en courant alternatif

ou en courant continu sur les bornes de terre de protection pour des EST fixes

montés sur le sol .50

Figure 12 – Exemple d'essai sur site sur l'accès d'alimentation en courant alternatif et

sur les bornes de terre de protection pour des EST mobiles .52

Figure 13 – Exemple d'essai sur site sur les accès de communication et d'entrée/sortie

sans la pince de couplage capacitive .52

Figure 14 – Vérification de la forme d’onde à la sortie de mode commun du réseau de

couplage/découplage.24

Tableau 1 – Niveaux d'essai .18

Tableau 2 – Fréquences de répétition des impulsions et valeurs de crête des tensions

de sortie .22

– 6 – 61000-4-4 © CEI:2004

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

COMPATIBILITÉ ÉLECTROMAGNÉTIQUE (CEM) –

Partie 4-4: Techniques d'essai et de mesure –

Essais d'immunité aux transitoires électriques

rapides en salves

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (CEI) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI – entre autres activités – publie des Normes

internationales, des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au

public (PAS) et des Guides (ci-après dénommés "Publication(s) de la CEI"). Leur élaboration est confiée à des

comités d'études, aux travaux desquels tout Comité national intéressé par le sujet traité peut participer. Les

organisations internationales, gouvernementales et non gouvernementales, en liaison avec la CEI, participent

également aux travaux. La CEI collabore étroitement avec l'Organisation Internationale de Normalisation (ISO),

selon des conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de la CEI

intéressés sont représentés dans chaque comité d’études.

3) Les Publications de la CEI se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de la CEI. Tous les efforts raisonnables sont entrepris afin que la CEI

s'assure de l'exactitude du contenu technique de ses publications; la CEI ne peut pas être tenue responsable

de l'éventuelle mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d'encourager l'uniformité internationale, les Comités nationaux de la CEI s'engagent, dans toute la

mesure possible, à appliquer de façon transparente les Publications de la CEI dans leurs publications

nationales et régionales. Toutes divergences entre toutes Publications de la CEI et toutes publications

nationales ou régionales correspondantes doivent être indiquées en termes clairs dans ces dernières.

5) La CEI n’a prévu aucune procédure de marquage valant indication d’approbation et n'engage pas sa

responsabilité pour les équipements déclarés conformes à une de ses Publications.

6) Tous les utilisateurs doivent s'assurer qu'ils sont en possession de la dernière édition de cette publication.

7) Aucune responsabilité ne doit être imputée à la CEI, à ses administrateurs, employés, auxiliaires ou

mandataires, y compris ses experts particuliers et les membres de ses comités d'études et des Comités

nationaux de la CEI, pour tout préjudice causé en cas de dommages corporels et matériels, ou de tout autre

dommage de quelque nature que ce soit, directe ou indirecte, ou pour supporter les coûts (y compris les frais

de justice) et les dépenses découlant de la publication ou de l'utilisation de cette Publication de la CEI ou de

toute autre Publication de la CEI, ou au crédit qui lui est accordé.

8) L'attention est attirée sur les références normatives citées dans cette publication. L'utilisation de publications

référencées est obligatoire pour une application correcte de la présente publication.

9) L’attention est attirée sur le fait que certains des éléments de la présente Publication de la CEI peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 61000-4-4 a été établie par le sous-comité 77B: Phénomènes

haute fréquence, du comité d'études 77 de la CEI: Compatibilité électromagnétique.

Elle constitue la Partie 4-4 de la CEI 61000. Elle a le statut de publication fondamentale en

CEM en accord avec le Guide 107 de la CEI, Compatibilité électromagnétique – Guide pour la

rédaction des publications sur la compatibilité électromagnétique.

Cette deuxième édition annule et remplace la première édition, parue en 1995, et ses

amendements 1 (2000) et 2 (2001). Cette deuxième édition constitue une révision technique.

Cette deuxième édition améliore et clarifie les spécifications du simulateur, les critères de test

et les montages d'essai. Seule l'injection en mode commun est demandée.

– 8 – 61000-4-4 © CEI:2004

Le texte de cette norme est issu des documents suivants:

FDIS Rapport de vote

77B/419/FDIS 77B/424/RVD

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote ayant

abouti à l'approbation de cette norme.

Cette publication a été rédigée selon les Directives ISO/CEI, Partie 2.

Le comité a décidé que le contenu de cette publication ne sera pas modifié avant la date de

maintenance indiquée sur le site web de la CEI sous «http://webstore.iec.ch» dans les

données relatives à la publication recherchée. A cette date, la publication sera

• reconduite;

• supprimée;

• remplacée par une édition révisée, ou

• amendée.

Le contenu des corrigenda d’août 2006 et juin 2007 a été pris en considération dans cet

exemplaire.

– 10 – 61000-4-4 © CEI:2004

INTRODUCTION

La CEI 61000 est publiée sous forme de plusieurs parties séparées, conformément à la

structure suivante:

Partie 1: Généralités

Considérations générales (introduction, principes fondamentaux)

Définitions, terminologie

Partie 2: Environnement

Description de l'environnement

Classification de l'environnement

Niveaux de compatibilité

Partie 3: Limites

Limites d'émission

Limites d'immunité (dans la mesure où elles ne relèvent pas des comités de produits)

Partie 4: Techniques d'essai et de mesure

Techniques de mesure

Techniques d'essai

Partie 5: Guide d'installation et d'atténuation

Guide d'installation

Méthodes et dispositifs d'atténuation

Partie 6: Normes génériques

Partie 9: Divers

Chaque partie est à son tour subdivisée en plusieurs parties, publiées soit comme normes

internationales soit comme spécifications techniques ou rapports techniques, dont certaines ont

déjà été publiées comme sections. D’autres seront publiées avec le numéro de partie, suivi d’un

tiret et complété d’un second numéro identifiant la subdivision (exemple: 61000-6-1).

La présente partie est une Norme internationale qui donne les exigences d'immunité et les

procédures d'essai relatives aux transitoires électriques rapides en salves.

– 12 – 61000-4-4 © CEI:2004

COMPATIBILITÉ ÉLECTROMAGNÉTIQUE (CEM) –

Partie 4-4: Techniques d'essai et de mesure –

Essais d'immunité aux transitoires électriques

rapides en salves

1 Domaine d'application

La présente partie de la CEI 61000-4 concerne l'immunité des matériels électriques et

électroniques aux transitoires rapides répétitifs. Elle donne les exigences d’immunité et les

procédures d’essai relatives aux transitoires électriques rapides en salves. Elle définit en

outre des gammes de niveaux d'essais et établit des procédures d'essai.

L’objet de cette norme est d’établir une référence commune et reproductible dans le but

d'évaluer l’immunité des matériels électriques et électroniques, quand ils sont soumis aux

transitoires électriques rapides en salves sur les accès d’alimentation, de signal, de

commande et de terre. La méthode d’essai documentée dans cette partie de la CEI 61000-4

décrit une méthode cohérente dans le but d’évaluer l’immunité d’un matériel ou système vis-

à-vis d’un phénomène défini.

NOTE Comme décrit dans le Guide 107 de la CEI, c’est une publication fondamentale en CEM pour utilisation par

les comités de produits de la CEI. Comme indiqué également dans le Guide 107, les comités de produits de la CEI

sont responsables de déterminer s’il convient d’appliquer ou non cette norme d’essai d’immunité et, si c’est le cas,

ils sont responsables de déterminer les niveaux d’essai et les critères de performance appropriés. Le comité

d’études 77 et ses sous-comités sont prêts à coopérer avec les comités de produits à l’évaluation de la valeur des

essais d’immunité particuliers pour leurs produits.

Cette norme définit:

– la forme d'onde de l'essai en tension;

– la gamme des niveaux d'essais;

– le matériel d'essai;

– les procédures de vérification du matériel d’essai;

– l'installation d'essai;

– la procédure d'essai.

Cette norme donne des spécifications pour les essais menés en laboratoire et les essais in

situ réalisés sur le matériel dans l'installation finale.

2 Références normatives

Les documents de référence suivants sont indispensables pour l'application du présent

document. Pour les références datées, seule l'édition citée s'applique. Pour les références

non datées, la dernière édition du document de référence s'applique (y compris les éventuels

amendements).

CEI 60050-161:1990, Vocabulaire Electrotechnique International (VEI) − Chapitre 161:

Compatibilité électromagnétique

– 14 – 61000-4-4 © CEI:2004

3 Termes et définitions

Pour les besoins du présent document, les termes et définitions suivantes s'appliquent, ainsi

que celles de la CEI 60050-161.

NOTE Plusieurs des termes et définitions les plus pertinents de la CEI 60050-161 sont présentés parmi les

définitions ci-dessous.

3.1

salve

suite d'un nombre fini d'impulsions distinctes ou oscillation de durée limitée

[VEI 161-02-07]

3.2

étalonnage

ensemble des opérations établissant, en référence à des étalons, la relation qui existe, dans

les conditions spécifiées, entre une indication et un résultat de mesure

NOTE 1 Cette définition est conçue dans l'approche « incertitude ».

NOTE 2 La relation entre les indications et les résultats de mesures peut être donnée, en principe, dans un

diagramme d'étalonnage.

[VEI 311-01-09]

3.3

couplage

interaction entre circuits avec transfert d'énergie d'un circuit dans un autre

3.4

mode commun (couplage)

couplage simultané de toutes les lignes par rapport au plan de sol

3.5

pince de couplage

dispositif de dimensions et de caractéristiques définies pour le couplage en mode commun du

signal perturbateur dans le circuit en essai sans aucune connexion galvanique avec ce

dernier

3.6

réseau de couplage

circuit électrique dont le but est de transférer de l'énergie d'un circuit dans un autre

3.7

réseau de découplage

circuit électrique dont le but est d'empêcher la tension de TER/S appliquée à l'EST

d'influencer d'autres appareils, équipements ou systèmes qui ne font pas partie de l'essai

3.8

dégradation (de fonctionnement)

écart non désiré des caractéristiques de fonctionnement d'un dispositif, d'un appareil ou d'un

système par rapport aux caractéristiques attendues

NOTE Une dégradation peut être un défaut de fonctionnement temporaire ou permanent.

[VEI 161-01-19]

– 16 – 61000-4-4 © CEI:2004

3.9

TER/S

transitoire électrique rapide en salve

3.10

compatibilité électromagnétique (CEM)

aptitude d'un matériel ou d'un système à fonctionner dans son environnement électro-

magnétique de façon satisfaisante et sans produire lui-même des perturbations électro-

magnétiques intolérables pour tout ce qui se trouve dans cet environnement

[VEI 161-01-07]

3.11

EST

matériel soumis à l'essai

3.12

plan de sol

surface conductrice plate dont le potentiel est pris comme référence

[VEI 161-04-36]

NOTE Le terme plan de référence peut être utilisé en lieu et place de plan de sol.

3.13

immunité (à une perturbation)

aptitude d'un dispositif, d'un matériel ou d'un système à fonctionner sans dégradation en

présence d'une perturbation électromagnétique

[VEI 161-01-20]

3.14

accès

interface particulier entre l'EST et l'environnement électromagnétique extérieur

3.15

temps de montée

durée de l'intervalle de temps entre les instants auxquels la valeur instantanée d'une

impulsion atteint pour la première fois une valeur de 10 % puis une valeur de 90 %

[VEI 161-02-05, modifié]

3.16

transitoire

se dit d'un phénomène ou d'une grandeur qui varie entre deux régimes établis consécutifs

dans un intervalle de temps relativement court à l'échelle des temps considérée

[VEI 161-02-01]

3.17

vérification

ensemble des opérations utilisées pour vérifier le système de test (par exemple le générateur

d'essai et les câbles d'interconnexion) et pour démontrer que le système de test fonctionne à

l'intérieur des spécifications données à l'Article 6

NOTE 1 Les méthodes utilisées pour la vérification peuvent être différentes de celles utilisées pour l'étalonnage.

NOTE 2 La procédure de 6.1.2 et 6.2.2 est destinée à être un guide assurant le fonctionnement correct du

générateur d'essai et des autres dispositifs constituant l'installation d'essai, de telle sorte que la forme d'onde

prévue soit délivrée à l'EST.

NOTE 3 Pour les besoins de la présente norme fondamentale en CEM, cette définition est différente de celle

donnée dans le VEI 311-01-13.

– 18 – 61000-4-4 © CEI:2004

4 Généralités

L'essai avec des transitoires rapides répétitifs est un essai comportant des salves composées

d'un certain nombre de transitoires rapides, couplés sur les accès d'alimentation, de

commande, de signal et de terre de matériels électriques et électroniques. Les éléments

significatifs de cet essai sont l’amplitude élevée, la brièveté du temps de montée, la grande

fréquence de répétition et la faible énergie des transitoires.

L'essai est destiné à démontrer l'immunité des matériels électriques et électroniques lorsqu'ils

sont soumis à des perturbations transitoires du type de celles provenant de transitoires de

commutation (coupure de charges inductives, rebondissements de contacts de relais, etc.).

5 Niveaux d'essai

Les niveaux d'essai préférentiels pour l'essai aux transitoires rapides, applicables à

l'alimentation, la terre de protection, les accès de signal et de commande du matériel sont

donnés dans le Tableau 1.

Tableau 1 – Niveaux d'essai

Tension d'essai de sortie en circuit ouvert et taux de répétition des impulsions

Sur l'accès Sur les signaux E/S (entrée/sortie), les

de puissance, PE accès de données et de commande

Niveau Fréquence Fréquence

Tension de crête Tension de crête

de répétition de répétition

kV kV

kHz kHz

1 0,5 5 ou 100 0,25 5 ou 100

2 1 5 ou 100 0,5 5 ou 100

3 2 5 ou 100 1 5 ou 100

4 4 5 ou 100 2 5 ou 100

a

X Spécial Spécial Spécial Spécial

NOTE 1 Il est traditionnel d’utiliser des fréquences de répétition de 5 kHz; cependant, 100 kHz est plus près de

la réalité. Il convient que les comités de produits déterminent quelles fréquences sont adaptées à des produits

particuliers ou à des types de produits.

NOTE 2 Avec certains produits, il peut ne pas y avoir de distinction claire entre accès de puissance et

d'entrées/sorties, auquel cas c'est aux comités de produits de le déterminer pour les besoins de l'essai.

a

«X» est un niveau ouvert. Ce niveau doit être défini dans la spécification du matériel approprié.

Ces tensions de sortie en circuit ouvert seront indiquées sur le générateur TER/S. Pour le

choix des niveaux, voir l'Annexe B.

6 Matériel d'essai

Les procédures de vérification de 6.1.2 et 6.2.2 sont destinées à être un guide en vue

d’assurer le fonctionnement correct du générateur d’essai, des réseaux de couplage/

découplage, ainsi que des autres dispositifs constituant l’installation d’essai, de façon que la

forme d’onde prévue soit délivrée à l’EST.

– 20 – 61000-4-4 © CEI:2004

6.1 Générateur de salves

La Figure 1 montre le schéma simplifié du générateur. Les éléments du circuit C , R , R et

c s m

C , sont sélectionnés de telle sorte que le générateur fournisse un transitoire rapide dans des

d

conditions de circuit ouvert et avec une charge résistive de 50 Ω. L’impédance de sortie

efficace du générateur doit être de 50 Ω.

Les éléments principaux du générateur d'essai sont:

– la source haute tension;

– la résistance de charge;

– le condensateur de stockage d'énergie;

– l’interrupteur haute tension;

– la résistance déterminant la durée de l'impulsion;

– la résistance d'adaptation d'impédance;

– le condensateur de blocage du courant continu.

6.1.1 Caractéristiques du générateur de transitoires rapides en salves

Les caractéristiques du générateur de transitoires rapides en salves sont les suivantes.

− La plage de tensions de sortie avec une charge de 1 000 Ω doit être d’au moins 0,25 kV à

4 kV.

− La plage de tensions de sortie avec une charge de 50 Ω doit être d’au moins 0,125 kV à

2 kV.

Le générateur doit pouvoir fonctionner en court-circuit.

Caractéristiques:

– polarité: positive/négative

– type de sortie: coaxiale, 50 Ω

– condensateur de blocage du

courant continu: 10 nF ± 20 %

– fréquence de répétition: (voir Tableau 2) ±20 %

– relation avec l’alimentation: asynchrone

– durée de la salve: 15 ms ± 20 % à 5 kHz

(voir Figure 2) 0,75 ms ± 20 % à 100 kHz

– période de la salve: 300 ms ± 20 %

(voir Figure 2)

– forme d’onde de l’impulsion

• sur charge de 50 Ω: temps de montée t = 5 ns ± 30 %

r

durée t (à 50 %) = 50 ns ± 30 %

d

tension crête = selon le Tableau 2, ±10 %

(voir Figure 3 pour la forme d’onde sur 50 Ω)

• sur charge de 1 000 Ω: temps de montée t = 5 ns ± 30 %

r

durée t (à 50 %) = 50 ns avec une tolérance

d

de –15 ns à +100 ns

tension crête = selon le Tableau 2, ±20 %

(voir Note 2 sous le Tableau 2)

– 22 – 61000-4-4 © CEI:2004

– impédance de la charge d’essai: 50 Ω ± 2 %

1 000 Ω ± 2 % en parallèle avec ≤6 pF. La

mesure de la résistance est faite en courant

continu, et celle de la capacité l’est en utilisant

un capacimètre commercialement disponible

qui fonctionne aux basses fréquences.

6.1.2 Vérification des caractéristiques du générateur de transitoires rapides

en salves

Les caractéristiques du générateur d’essai doivent être vérifiées de manière à établir une

référence commune pour tous les générateurs. A cette fin, la procédure suivante doit être