IEC 60502-1:2004

(Main)Power cables with extruded insulation and their accessories for rated voltages from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV) - Part 1: Cables for rated voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV)

Power cables with extruded insulation and their accessories for rated voltages from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV) - Part 1: Cables for rated voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV)

Specifies the construction, dimensions and test requirements of power cables with extruded solid insulation for rated voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV) for fixed installations such as distribution networks or industrial installations. This standard includes cables which exhibit properties of reduced flame spread, low levels of smoke emission and halogen-free gas emission when exposed to fire. Cables for special installation and service conditions are not included, for example cables for overhead networks, the mining industry, nuclear power plants (in and around the containment area), submarine use or shipboard application. The main changes with respect to the first edition relate to insulation and oversheath thickness requirements, and inclusion of constructions and requirements for halogen free cables with reduced flame propagation and low levels of smoke emission.

Câbles d'énergie à isolant extrudé et leurs accessoires pour des tensions assignées de 1 kV (Um = 1,2 kV) à 30 kV (Um = 36 kV) - Partie 1: Câbles de tensions assignées de 1 kV (Um = 1,2 kV) et 3 kV (Um = 3,6 kV)

Spécifie la constitution, les dimensions et les exigences d'essais des câbles d'énergie à isolation extrudée par diélectriques massifs, de tensions assignées de 1 kV (Um = 1,2 kV) et 3 kV (Um= 3,6 kV), pour installations fixes telles que les réseaux de distribution ou les installations industrielles. La présente norme introduit des câbles qui présentent des propriétés de propagation de la flamme réduite, de faibles niveaux d'émission de fumée et des émissions de gaz sans halogène lorsqu'ils sont exposés au feu. Les câbles destinés à des conditions particulières d'installations et de service ne sont pas inclus, par exemple les câbles pour réseaux aériens, pour l'industrie minière, les centrales nucléaires (à l'intérieur et à l'extérieur de l'enceinte de confinement), les câbles sous-marins ou les câbles de bord des navires. Les modifications majeures par rapport à la première édition concernent les exigences pour les épaisseurs des enveloppes isolantes et des gaines de protection extérieures ainsi que les exigences pour les câbles sans halogène avec des propriétés de propagation de la flamme réduites et de faibles niveaux d'émission de fumée.

General Information

- Status

- Published

- Publication Date

- 13-Apr-2004

- Technical Committee

- TC 20 - Electric cables

- Drafting Committee

- WG 16 - TC 20/WG 16

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 09-Feb-2021

- Completion Date

- 12-Apr-2019

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60502-1:2004 is the international standard that specifies the construction, dimensions and test requirements for power cables with extruded solid insulation for rated voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV). Intended for fixed installations such as distribution networks and industrial installations, the standard covers conductor construction, insulation types, metallic screens and armour, oversheaths and routine, sample and type tests. The 2004 second edition updates insulation and oversheath thickness requirements and adds provisions for halogen‑free, reduced flame‑propagation, low‑smoke cable constructions.

Key topics and requirements

- Scope and exclusions: Applies to extruded-insulation cables for fixed installations; excludes special-purpose cables (overhead lines, mining, nuclear containment, submarine or shipboard use).

- Insulation materials: Defines acceptable insulating compounds (e.g., XLPE, EPR/HEPR, PVC) and references tables for selection and nominal thicknesses.

- Conductor and assembly: Requirements for conductors, multicore assembly, inner coverings and fillers; includes guidance for concentric conductors and metallic screens.

- Armour and oversheath: Types and materials for metallic armour, armour dimensions, and oversheath materials plus minimum thickness rules (including halogen‑free options).

- Testing framework: Mandatory routine tests, sample tests and electrical and non‑electrical type tests. Test conditions cover ambient temperature, power‑frequency and impulse voltages, mechanical ageing, fire tests, and measurements (insulation thickness, external diameter, shrinkage, etc.).

- Documentation and annexes: Normative annexes include a fictitious calculation method for protective coverings, rounding rules and specific test procedures (e.g., hardness of HEPR).

Practical applications

- Where used: Medium‑voltage distribution networks, industrial power installations, factory feed and fixed cabling where 1 kV and 3 kV rated cables are required.

- Who uses it: Cable manufacturers, design engineers, utilities, procurement/specification teams, testing laboratories and certification bodies rely on IEC 60502-1 for product design, conformity assessment and procurement specifications.

- Why it matters: Ensures mechanical, thermal, electrical and fire performance consistency; supports selection of low‑smoke, halogen‑free options for enhanced safety in buildings and industrial sites.

Related standards

- IEC 60502 series (covers cables up to 30 kV) and other IEC cable standards provide complementary guidance for higher voltages, special environments and accessories. For full details and normative references, consult the IEC catalogue or the IEC web site.

Keywords: IEC 60502-1, power cables, extruded insulation, XLPE, EPR, halogen-free, low smoke, rated voltage 1 kV, 3 kV, cable testing, oversheath thickness.

Buy Documents

IEC 60502-1:2004 - Power cables with extruded insulation and their accessories for rated voltages from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV) - Part 1: Cables for rated voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV) Released:4/14/2004

IEC 60502-1:2004 - Câbles d'énergie à isolant extrudé et leurs accessoires pour des tensions assignées de 1 kV (Um = 1,2 kV) à 30 kV (Um = 36 kV) - Partie 1: Câbles de tensions assignées de 1 kV (Um = 1,2 kV) et 3 kV (Um = 3,6 kV) Released:4/14/2004

IEC 60502-1:2004+AMD1:2009 CSV - Power cables with extruded insulation and their accessories for rated voltages from 1 kV (<em>U</em><sub>m</sub> = 1,2 kV) up to 30 kV(<em>U</em><sub>m</sub> = 36 kV) - Part 1: Cables for rated voltages of 1 kV (<em>U</em><sub>m</sub> = 1,2 kV) and 3 kV (<em>U</em><sub>m</sub> = 3,6 kV) Released:11/25/2009 Isbn:9782889102006

IEC 60502-1:2004 - Power cables with extruded insulation and their accessories for rated voltages from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV) - Part 1: Cables for rated voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV)

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60502-1:2004 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Power cables with extruded insulation and their accessories for rated voltages from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV) - Part 1: Cables for rated voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV)". This standard covers: Specifies the construction, dimensions and test requirements of power cables with extruded solid insulation for rated voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV) for fixed installations such as distribution networks or industrial installations. This standard includes cables which exhibit properties of reduced flame spread, low levels of smoke emission and halogen-free gas emission when exposed to fire. Cables for special installation and service conditions are not included, for example cables for overhead networks, the mining industry, nuclear power plants (in and around the containment area), submarine use or shipboard application. The main changes with respect to the first edition relate to insulation and oversheath thickness requirements, and inclusion of constructions and requirements for halogen free cables with reduced flame propagation and low levels of smoke emission.

Specifies the construction, dimensions and test requirements of power cables with extruded solid insulation for rated voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV) for fixed installations such as distribution networks or industrial installations. This standard includes cables which exhibit properties of reduced flame spread, low levels of smoke emission and halogen-free gas emission when exposed to fire. Cables for special installation and service conditions are not included, for example cables for overhead networks, the mining industry, nuclear power plants (in and around the containment area), submarine use or shipboard application. The main changes with respect to the first edition relate to insulation and oversheath thickness requirements, and inclusion of constructions and requirements for halogen free cables with reduced flame propagation and low levels of smoke emission.

IEC 60502-1:2004 is classified under the following ICS (International Classification for Standards) categories: 29.060.20 - Cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60502-1:2004 has the following relationships with other standards: It is inter standard links to IEC 60502-1:2004/AMD1:2009, IEC 60502-1:2021, IEC 60502-1:1997/AMD1:1998, IEC 60502-1:1997. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60502-1:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 60502-1

Second edition

2004-04

Power cables with extruded insulation

and their accessories for rated voltages

from 1 kV (U = 1,2 kV) up to 30 kV (U = 36 kV) –

m m

Part 1:

Cables for rated voltages of 1 kV ((U = 1,2 kV)

m

and 3 kV (U = 3,6 kV)

m

This English-language version is derived from the original

bilingual publication by leaving out all French-language

pages. Missing page numbers correspond to the French-

language pages.

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 60502-1

Second edition

2004-04

Power cables with extruded insulation

and their accessories for rated voltages

from 1 kV (U = 1,2 kV) up to 30 kV (U = 36 kV) –

m m

Part 1:

Cables for rated voltages of 1 kV ((U = 1,2 kV)

m

and 3 kV (U = 3,6 kV)

m

IEC 2004 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical,

including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale XA

International Electrotechnical Commission

Международная Электротехническая Комиссия

For price, see current catalogue

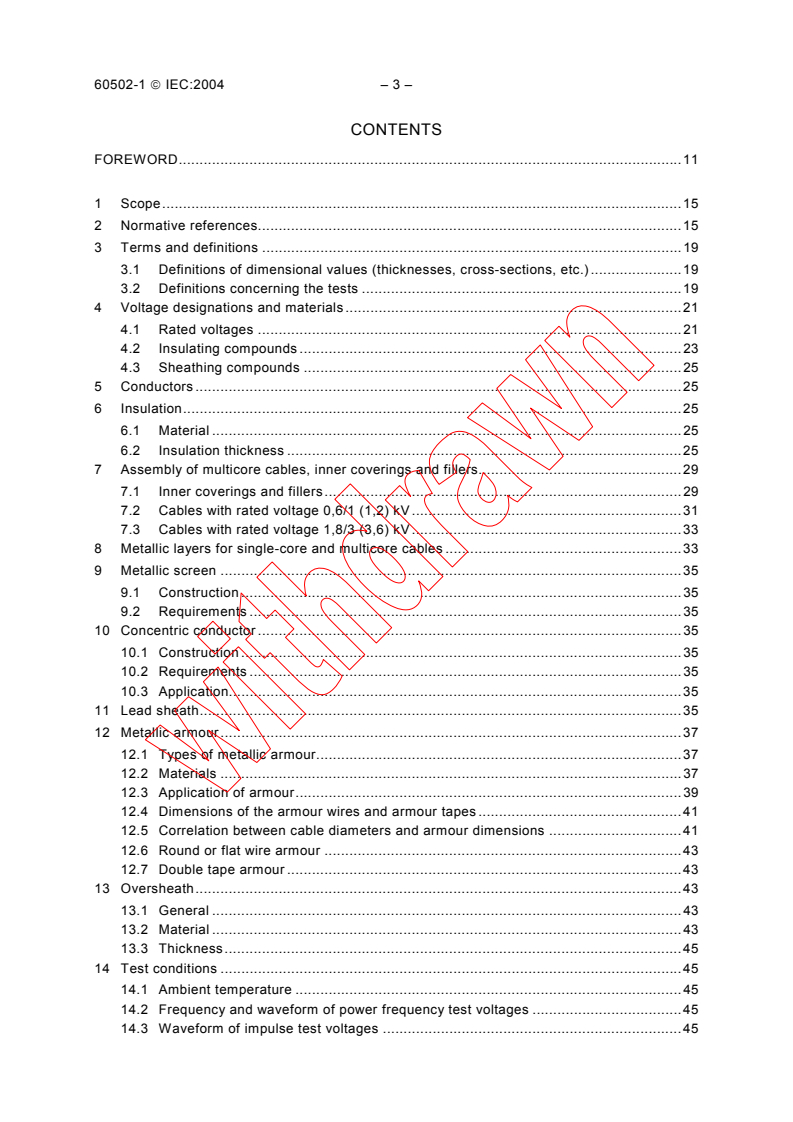

60502-1 IEC:2004 – 3 –

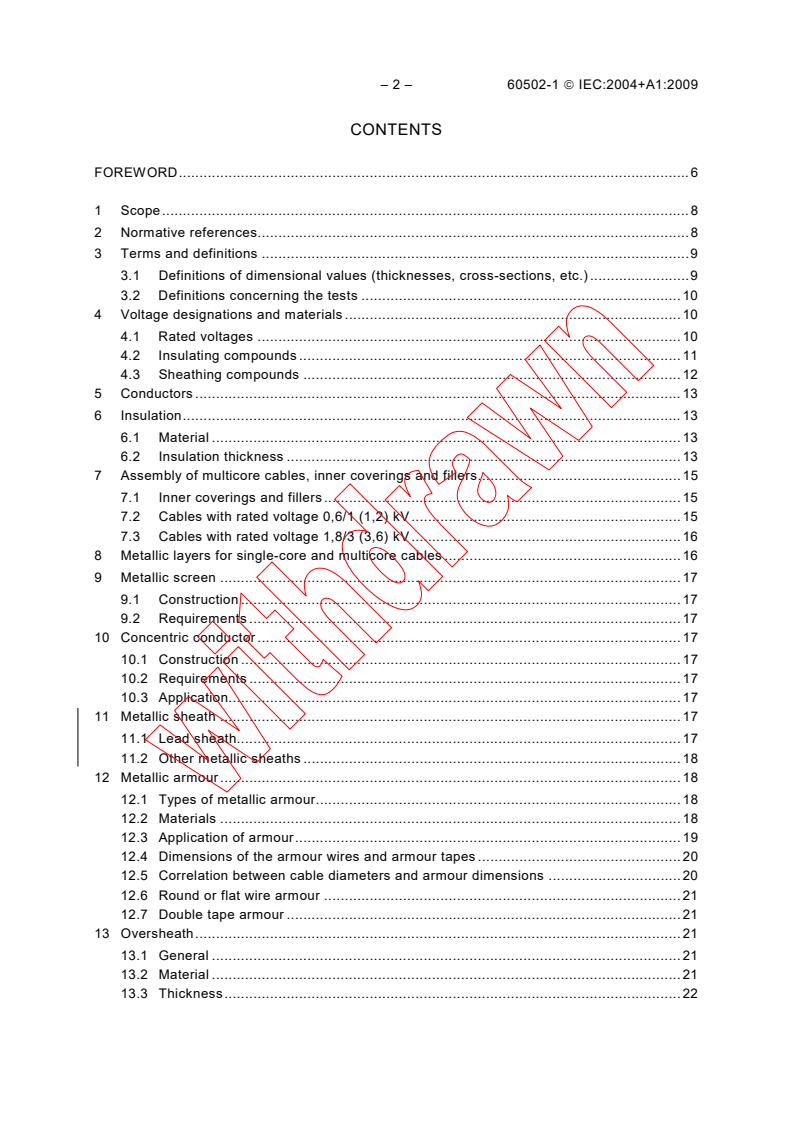

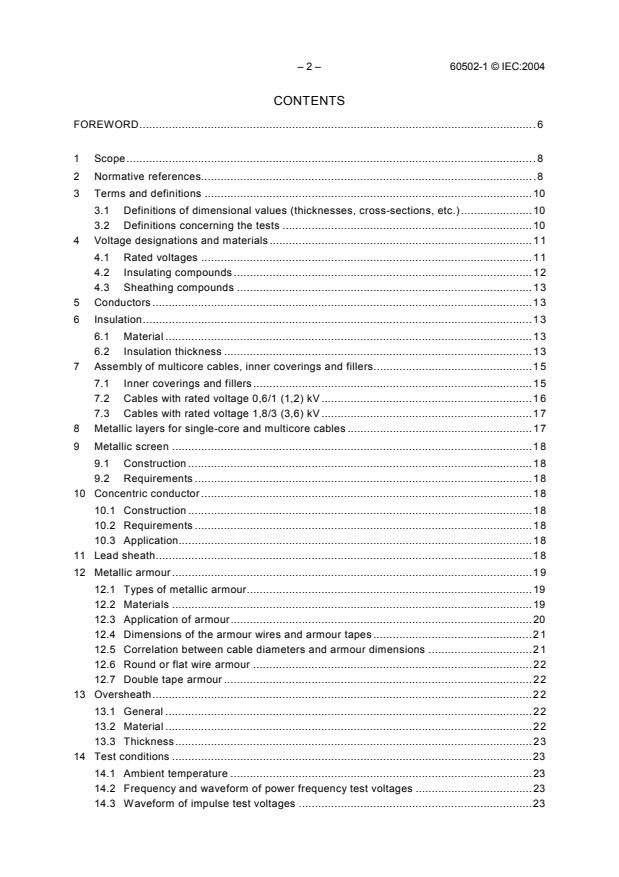

CONTENTS

FOREWORD.11

1 Scope.15

2 Normative references.15

3 Terms and definitions .19

3.1 Definitions of dimensional values (thicknesses, cross-sections, etc.) .19

3.2 Definitions concerning the tests .19

4 Voltage designations and materials .21

4.1 Rated voltages.21

4.2 Insulating compounds.23

4.3 Sheathing compounds.25

5 Conductors.25

6 Insulation.25

6.1 Material.25

6.2 Insulation thickness.25

7 Assembly of multicore cables, inner coverings and fillers.29

7.1 Inner coverings and fillers.29

7.2 Cables with rated voltage 0,6/1 (1,2) kV .31

7.3 Cables with rated voltage 1,8/3 (3,6) kV .33

8 Metallic layers for single-core and multicore cables .33

9 Metallic screen.35

9.1 Construction.35

9.2 Requirements.35

10 Concentric conductor.35

10.1 Construction.35

10.2 Requirements.35

10.3 Application.35

11 Lead sheath.35

12 Metallic armour.37

12.1 Types of metallic armour.37

12.2 Materials.37

12.3 Application of armour.39

12.4 Dimensions of the armour wires and armour tapes .41

12.5 Correlation between cable diameters and armour dimensions .41

12.6 Round or flat wire armour .43

12.7 Double tape armour .43

13 Oversheath.43

13.1 General.43

13.2 Material.43

13.3 Thickness.45

14 Test conditions.45

14.1 Ambient temperature.45

14.2 Frequency and waveform of power frequency test voltages .45

14.3 Waveform of impulse test voltages .45

60502-1 IEC:2004 – 5 –

15 Routine tests.45

15.1 General.45

15.2 Electrical resistance of conductors.47

15.3 Voltage test.47

16 Sample tests.49

16.1 General.49

16.2 Frequency of sample tests .49

16.3 Repetition of tests.51

16.4 Conductor examination.51

16.5 Measurement of thickness of insulation and of non-metallic sheaths (including

extruded separation sheaths, but excluding inner extruded coverings).51

16.6 Measurement of thickness of lead sheath .53

16.7 Measurement of armour wires and tapes.53

16.8 Measurement of external diameter .55

16.9 Hot set test for EPR, HEPR and XLPE insulations and elastomeric sheaths.55

17 Type tests, electrical.55

17.1 Insulation resistance measurement at ambient temperature .57

17.2 Insulation resistance measurement at maximum conductor temperature.57

17.3 Voltage test for 4 h .59

17.4 Impulse test for cables of rated voltage 1,8/3 (3,6) kV .59

18 Type tests, non-electrical .59

18.1 Measurement of thickness of insulation.61

18.2 Measurement of thickness of non-metallic sheaths (including extruded

separation sheaths, but excluding inner coverings) .61

18.3 Tests for determining the mechanical properties of insulation before and after

ageing .61

18.4 Tests for determining the mechanical properties of non-metallic sheaths

before and after ageing.63

18.5 Additional ageing test on pieces of completed cables .63

18.6 Loss of mass test on PVC sheaths of type ST .65

18.7 Pressure test at high temperature on insulations and non-metallic sheaths.65

18.8 Test on PVC insulation and sheaths and halogen free sheaths at low

temperatures .65

18.9 Test for resistance of PVC insulation and sheaths to cracking (heat shock test) .65

18.10 Ozone resistance test for EPR and HEPR insulations.67

18.11 Hot set test for EPR, HEPR and XLPE insulations and elastomeric sheaths.67

18.12 Oil immersion test for elastomeric sheaths.67

18.13 Water absorption test on insulation .67

18.14 Fire tests .67

18.15 Measurement of carbon black content of black PE oversheaths.69

18.16 Shrinkage test for XLPE insulation .71

18.17 Special bending test .71

18.18 Determination of hardness of HEPR insulation .71

18.19 Determination of the elastic modulus of HEPR insulation.71

60502-1 IEC:2004 – 7 –

18.20 Shrinkage test for PE oversheaths .73

18.21 Additional mechanical tests on halogen free oversheaths .73

18.22 Water absorption test for halogen free oversheaths.73

19 Electrical tests after installation.73

Annex A (normative) Fictitious calculation method for determination of dimensions of

protective coverings .95

A.1 General.95

A.2 Method .95

Annex B (normative) Rounding of numbers. 107

B.1 Rounding of numbers for the purpose of the fictitious calculation method. 107

B.2 Rounding of numbers for other purposes. 107

Annex C (normative) Determination of hardness of HEPR insulations . 111

C.1 Test piece. 111

C.2 Test procedure . 111

Figure C.1 – Test on surfaces of large radius of curvature . 113

Figure C.2 – Test on surfaces of small radius of curvature. 115

Table 1 – Recommended rated voltages U .21

Table 2 – Insulating compounds .23

Table 3 – Maximum conductor temperatures for different types of insulating compound .23

Table 4 – Maximum conductor temperatures for different types of sheathing compound.25

Table 5 – Nominal thickness of PVC/A insulation.27

Table 6 – Nominal thickness of cross-linked polyethylene (XLPE) insulation .27

Table 7 – Nominal thickness of ethylene propylene rubber (EPR) and hard ethylene

propylene rubber (HEPR) insulation.29

Table 8 – Thickness of extruded inner covering .31

Table 9 – Nominal diameter of round armour wires .41

Table 10 – Nominal thickness of armour tapes .41

Table 11 – Routine test voltages .49

Table 12 – Number of samples for sample tests .51

Table 13 – Electrical type test requirements for insulating compounds .75

Table 14 – Non-electrical type tests (see Tables 15 to 23) .77

Table 15 – Test requirements for mechanical characteristics of insulating compounds

(before and after ageing).79

Table 16 – Test requirements for particular characteristics for PVC insulating compound.81

Table 17 – Test requirements for particular characteristics of various thermosetting

insulating compounds.83

Table 18 – Test requirements for mechanical characteristics of sheathing compounds

(before and after ageing).85

60502-1 IEC:2004 – 9 –

Table 19 – Test requirements for particular characteristics for PVC sheathing

compounds .87

Table 20 – Test requirements for particular characteristics of thermoplastic PE

sheathing compounds .89

Table 21 – Test requirements for particular characteristics of halogen free sheathing

compound.91

Table 22 – Test requirements for particular characteristics of elastomeric sheathing

compound.93

Table 23 – Test methods and requirements for halogen free compounds .93

Table A.1 – Fictitious diameter of conductor .48

Table A.2 – Assembly coefficient k for laid-up cores .99

Table A.3 – Increase of diameter for concentric conductors and metallic screens. 101

Table A.4 – Increase of diameter for additional bedding. 105

60502-1 IEC:2004 – 11 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

POWER CABLES WITH EXTRUDED INSULATION

AND THEIR ACCESSORIES FOR RATED VOLTAGES

FROM 1 kV (U = 1,2 kV) UP TO 30 kV (U = 36 kV) –

m m

Part 1: Cables for rated voltages of 1 kV

(U = 1,2 kV) and 3 kV (U = 3,6 kV)

m m

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60502-1 has been prepared by IEC technical committee 20: Electric

cables.

This second edition cancels and replaces the first edition, published in 1997, its amendment 1

(1998) and constitutes a technical revision.

The main changes with respect to the first edition relate to insulation and oversheath thickness

requirements, and inclusion of constructions and requirements for halogen free cables with

reduced flame propagation and low levels of smoke emission.

60502-1 IEC:2004 – 13 –

The text of this standard is based on the following documents:

FDIS Report on voting

20/683/FDIS 20/691/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

IEC 60502 consists of the following parts, under the general title Power cables with extruded

insulation and their accessories for rated voltages from 1 kV (U = 1,2 kV) up to 30 kV

m

(U = 36 kV):

m

Part 1: Cables for rated voltages of 1 kV (U = 1,2 kV) and 3 kV (U = 3,6 kV);

m m

Part 2: Cables for rated voltages from 6 kV (U = 7,2 kV) up to 30 kV (U = 36 kV);

m m

Part 3: Reserved;

Part 4: Test requirements on accessories for cables with rated voltages from 6 kV

(U = 7,2 kV) up to 30 kV (U = 36 kV).

m m

The committee has decided that the contents of this publication will remain unchanged until

2009. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

60502-1 IEC:2004 – 15 –

POWER CABLES WITH EXTRUDED INSULATION

AND THEIR ACCESSORIES FOR RATED VOLTAGES

FROM 1 kV (U = 1,2 kV) UP TO 30 kV (U = 36 kV) –

m m

Part 1: Cables for rated voltages of 1 kV

(U = 1,2 kV) and 3 kV (U = 3,6 kV)

m m

1 Scope

This part of IEC 60502 specifies the construction, dimensions and test requirements of power

cables with extruded solid insulation for rated voltages of 1 kV (U = 1,2 kV) and 3 kV (U =

m m

3,6 kV) for fixed installations such as distribution networks or industrial installations.

This standard includes cables which exhibit properties of reduced flame spread, low levels of

smoke emission and halogen-free gas emission when exposed to fire.

Cables for special installation and service conditions are not included, for example cables for

overhead networks, the mining industry, nuclear power plants (in and around the containment

area), submarine use or shipboard application.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60038:1983, IEC standard voltages

IEC 60060-1:1989, High-voltage test techniques – Part 1: General definitions and test

requirements

IEC 60183:1984, Guide to the selection of high-voltage cables

IEC 60228:1978, Conductors of insulated cables

IEC 60230:1966, Impulse tests on cables and their accessories

IEC 60332-1:1993, Tests on electric cables under fire conditions – Part 1: Test on a single

vertical insulated wire or cable

IEC 60332-3-24:2000, Tests on electric cables under fire conditions – Part 3-24: Test for

vertical flame spread of vertically-mounted bunched wires or cables – Category C

IEC 60502-2:1997, Power cables with extruded insulation and their accessories for rated

voltages from 1 kV (U = 1,2 kV) up to 30 kV (U = 36 kV) – Part 2: Cables for rated voltages

m m

from 6 kV (U = 7,2 kV) up to 30 kV (U = 36 kV)

m m

60502-1 IEC:2004 – 17 –

IEC 60684-2:1987, Flexible insulating sleeving – Part 2: Methods of test

IEC 60724:2000, Short-circuit temperature limits of electric cables with rated voltages of 1 kV

(U = 1,2 kV) and 3 kV (U = 3,6 kV)

m m

IEC 60754-1:1994, Test on gases evolved during combustion of materials from cables – Part 1:

Determination of the amount of halogen gas

IEC 60754-2:1991, Test on gases evolved during combustion of electric cables – Part 2:

Determination of degree of acidity of gases evolved during the combustion of materials taken

from electric cables by measuring pH and conductivity

IEC 60811-1-1:1993, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section 1: Measurement of thickness and

overall dimensions – Tests for determining the mechanical properties

IEC 60811-1-2:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section 2: Thermal ageing methods

IEC 60811-1-3:1993, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section 3: Methods for determining the

density – Water absorption tests – Shrinkage test

IEC 60811-1-4:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section 4: Tests at low temperature

IEC 60811-2-1:1998, Insulating and sheathing materials of electric and optical cables –

Common test methods – Part 2-1: Methods specific to elastomeric compounds – Ozone

resistance, hot set and mineral oil immersion tests

IEC 60811-3-1:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 3: Methods specific to PVC compounds – Section 1: Pressure test at high

temperature – Tests for resistance to cracking

IEC 60811-3-2:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 3: Methods specific to PVC compounds – Section 2: Loss of mass test – Thermal

stability test

IEC 60811-4-1:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 4: Methods specific to polyethylene and polypropylene compounds – Section 1:

Resistance to environmental stress cracking – Wrapping test after thermal ageing in air –

Measurement of the melt flow index – Carbon black and/or mineral content measurement in PE

IEC 61034-2: 1997, Measurement of smoke density of cables burning under defined conditions

– Part 2: Test procedure and requirements

ISO 48:1994, Rubber, vulcanized or thermoplastic – Determination of hardness (hardness

between 10 IRHD and 100 IRHD)

60502-1 IEC:2004 – 19 –

3 Terms and definitions

For the purposes of this document, the following definitions apply.

3.1 Definitions of dimensional values (thicknesses, cross-sections, etc.)

3.1.1

nominal value

value by which a quantity is designated and which is often used in tables

NOTE Usually, in this standard, nominal values give rise to values to be checked by measurements taking into

account specified tolerances.

3.1.2

approximate value

value which is neither guaranteed nor checked; it is used, for example, for the calculation of

other dimensional values

3.1.3

median value

when several test results have been obtained and ordered in an increasing (or decreasing)

succession, the median value is the middle value if the number of available values is odd, and

the mean of the two middle values if the number is even

3.1.4

fictitious value

value calculated according to the "fictitious method'' described in Annex A

3.2 Definitions concerning the tests

3.2.1

routine tests

tests made by the manufacturer on each manufactured length of cable to check that each

length meets the specified requirements

3.2.2

sample tests

tests made by the manufacturer on samples of completed cable or components taken from a

completed cable, at a specified frequency, so as to verify that the finished product meets the

specified requirements

3.2.3

type tests

tests made before supplying, on a general commercial basis, a type of cable covered by this

standard, in order to demonstrate satisfactory performance characteristics to meet the

intended application

NOTE These tests are of such a nature that, after they have been made, they need not be repeated, unless

changes are made in the cable materials or design or manufacturing process which might change the performance

characteristics.

3.2.4

electrical tests after installation

tests made to demonstrate the integrity of the cable and its accessories as installed

60502-1 IEC:2004 – 21 –

4 Voltage designations and materials

4.1 Rated voltages

The rated voltages U /U (U ) of the cables considered in this standard are 0,6/1 (1,2) kV and

0 m

1,8/3 (3,6) kV.

NOTE 1 The voltages given above are the correct designations although in some countries other designations are

used, e.g. 1,7/3 kV or 1,9/3,3 kV instead of 1,8/3 kV.

In the voltage designation of cables U /U (U ):

0 m

U is the rated power frequency voltage between conductor and earth or metallic screen for

which the cable is designed;

U is the rated power frequency voltage between conductors for which the cable is designed;

U is the maximum value of the "highest system voltage'' for which the equipment may be

m

used (see IEC 60038).

The rated voltage of the cable for a given application shall be suitable for the operating

conditions in the system in which the cable is used. To facilitate the selection of the cable,

systems are divided into three categories:

– Category A: this category comprises those systems in which any phase conductor that

comes in contact with earth or an earth conductor is disconnected from the

system within 1 min;

– Category B: this category comprises those systems which, under fault conditions, are

operated for a short time with one phase earthed. This period, according to

IEC 60183, should not exceed 1 h. For cables covered by this standard, a

longer period, not exceeding 8 h on any occasion, can be tolerated. The total

duration of earth faults in any year should not exceed 125 h;

– Category C: this category comprises all systems which do not fall into category A or B.

NOTE 2 It should be realized that in a system where an earth fault is not automatically and promptly isolated, the

extra stresses on the insulation of cables during the earth fault reduce the life of the cables to a certain degree. If

the system is expected to be operated fairly often with a permanent earth fault, it may be advisable to classify the

system in Category C.

The values of U recommended for cables to be used in three-phase systems are listed in

Table 1.

Table 1 – Recommended rated voltages U

Highest system voltage Rated voltage (U )

(U ) kV

m

kV Categories A and B Category C

1,2 0,6 0,6

*

3,6 1,8 3,6

*

This category is covered by 3,6/6 (7,2) kV cables according to IEC 60502-2.

60502-1 IEC:2004 – 23 –

4.2 Insulating compounds

The types of insulating compound covered by this standard are listed in Table 2, together with

their abbreviated designations.

Table 2 – Insulating compounds

Insulating compound Abbreviated

designation

a) Thermoplastic

*

Polyvinyl chloride intended for cables with rated voltages U /U ≤ 1,8/3 kV PVC/A

b) Thermosetting:

Ethylene propylene rubber or similar (EPM or EPDM) EPR

High modulus or hard grade ethylene propylene rubber HEPR

Cross-linked polyethylene XLPE

* Insulating compound based on polyvinyl chloride intended for cables with rated voltages U /U = 3,6/6 kV is

designated PVC/B in IEC 60502-2.

The maximum conductor temperatures for different types of insulating compound covered by

this standard are given in Table 3.

Table 3 – Maximum conductor temperatures for different types of insulating compound

Maximum conductor temperature

°C

Insulating compound

Short-circuit

Normal operation (5 s maximum

duration)

Polyvinyl chloride (PVC/A)

Conductor cross-section ≤300 mm 70 160

70 140

Conductor cross-section >300 mm

Cross-linked polyethylene (XLPE) 90 250

Ethylene propylene rubber (EPR and HEPR) 90 250

The temperatures in Table 3 are based on the intrinsic properties of the insulating materials. It

is important to take into account other factors when using these values for the calculation of

current ratings.

For example, in normal operation, if a cable directly buried in the ground is operated under

continuous load (100 % load factor) at the maximum conductor temperature shown in the table,

the thermal resistivity of the soil surrounding the cable may, in the course of time, increase

from its original value as a result of drying-out processes. As a consequence, the conductor

temperature may greatly exceed the maximum value. If such operating conditions are foreseen,

adequate provisions shall be made.

For guidance on the short-circuit temperatures, reference should be made to IEC 60724.

60502-1 IEC:2004 – 25 –

4.3 Sheathing compounds

The maximum conductor temperatures for the different types of sheathing compound covered

by this standard are given in Table 4.

Table 4 – Maximum conductor temperatures for different types of sheathing compound

Maximum conductor

Abbreviated temperature

Sheathing compound

designation in normal operation

°C

a) Thermoplastic:

Polyvinyl chloride (PVC) ST 80

ST 90

Polyethylene ST 80

ST 90

Halogen free ST 90

b) Elastomeric:

Polychloroprene, chlorosulfonated polyethylene SE 85

or similar polymers

5 Conductors

The conductors shall be either of Class 1 or Class 2 of plain or metal-coated annealed copper

or of plain aluminium or aluminium alloy, or of Class 5 of plain or metal-coated copper in

accordance with IEC 60228.

6 Insulation

6.1 Material

The insulation shall be extruded dielectric of one of the types listed in Table 2.

For halogen free cables, the insulation shall meet the requirements given in Table 23.

6.2 Insulation thickness

The nominal insulation thicknesses are specified in Tables 5 to 7.

The thickness of any separator shall not be included in the thickness of the insulation.

60502-1 IEC:2004 – 27 –

Table 5 – Nominal thickness of PVC/A insulation

Nominal cross-sectional Nominal thickness of insulation at rated voltage

area of conductor U /U (U )

0 m

0,6/1 (1,2) kV 1,8/3 (3,6) kV

mm mm mm

1,5 and 2,5 0,8 –

4 and 6 1,0 –

2,2

10 and 16 1,0

25 and 35 1,2 2,2

50 and 70 1,4 2,2

95 and 120 1,6 2,2

1,8 2,2

185 2,0 2,2

240 2,2 2,2

300 2,4 2,4

400 2,6 2,6

500 to 800 2,8 2,8

1 000 3,0 3,0

NOTE Any conductor cross-section smaller than those given in this table is not recommended.

Table 6 – Nominal thickness of cross-linked polyethylene (XLPE) insulation

Nominal cross-sectional Nominal thickness of insulation at rated voltage

area of conductor U /U (U )

0 m

0,6/1 (1,2) kV 1,8/3 (3,6) kV

mm mm mm

1,5 and 2,5 0,7 –

4 and 6 0,7 –

10 and 16 0,7 2,0

25 and 35 0,9 2,0

50 1,0 2,0

70 and 95 1,1 2,0

120 1,2 2,0

150 1,4 2,0

185 1,6 2,0

240 1,7 2,0

300 1,8 2,0

400 2,0 2,0

500 2,2 2,2

630 2,4 2,4

800 2,6 2,6

1 000 2,8 2,8

NOTE Any conductor cross-section smaller than those given in this table is not recommended.

60502-1 IEC:2004 – 29 –

Table 7 – Nominal thickness of ethylene propylene rubber (EPR)

and hard ethylene propylene rubber (HEPR) insulation

Nominal cross-sectional Nominal thickness of insulation at rated voltage

area of conductor U /U (U )

0 m

0,6/1 (1,2) kV 1,8/3 (3,6) kV

EPR HEPR EPR HEPR

mm

mm mm mm mm

1,5 and 2,5 1,0 0,7 – –

4 and 6 1,0 0,7 – –

10 and 16 1,0 0,7 2,2 2,0

25 and 35 1,2 0,9 2,2 2,0

50 1,4 1,0 2,2 2,0

70 1,4 1,1 2,2 2,0

95 1,6 1,1 2,4 2,0

120 1,6 1,2 2,4 2,0

150 1,8 1,4 2,4 2,0

2,0 1,6 2,4 2,0

240 2,2 1,7 2,4 2,0

300 2,4 1,8 2,4 2,0

400 2,6

2,0 2,6 2,0

500 2,8 2,2 2,8 2,2

630 2,8 2,4 2,8 2,4

800 2,8 2,6

2,8 2,6

1 000 3,0 2,8 3,0 2,8

NOTE Any conductor cross-section smaller than those given in this table is not recommended.

7 Assembly of multicore cables, inner coverings and fillers

The assembly of multicore cables depends on the rated voltage and whether a metallic layer is

applied to each core.

The following subclauses 7.1 to 7.3 do not apply to assemblies of sheathed single-core cables.

7.1 Inner coverings and fillers

7.1.1 Construction

The inner coverings may be extruded or lapped.

For cables with circular cores, except cables with more than five cores, a lapped inner covering

shall be permitted only if the interstices between the cores are substantially filled.

A suitable binder is permitted before application of an extruded inner covering.

60502-1 IEC:2004 – 31 –

7.1.2 Material

The materials used for inner coverings and fillers shall be suitable for the operating

temperature of the cable and compatible with the insulating material.

For halogen free cables, the inner covering and fillers shall meet the requirements given in

Table 23.

7.1.3 Thickness of extruded inner covering

The approximate thickness of extruded inner coverings shall be derived from Table 8.

Table 8 – Thickness of extruded inner covering

Fictitious diameter over laid-up cores Thickness of extruded

inner covering

Above Up to and including

(approximate values)

mm mm

mm

– 25 1,0

1,2

25 35

35 45 1,4

45 60 1,6

60 80 1,8

80 – 2,0

7.1.4 Thickness of lapped inner coverings

The approximate thickness of lapped inner coverings shall be 0,4 mm for fictitious diameters

over laid-up cores up to and including 40 mm and 0,6 mm for larger diameters.

7.2 Cables with rated voltage 0,6/1 (1,2) kV

Cables with rated voltage 0,6/1(1,2) kV may have a metallic layer collectively surrounding the

cores.

NOTE The choice between cables having and cables not having a metallic layer depends upon national

regulations and installation requirements for the prevention of possible dangers from mechanical damage or direct

electrical contact.

7.2.1 Cables having a collective metallic layer (see Clause 8)

Cables shall have an inner covering over the laid-up cores. The inner covering and fillers shall

comply with 7.1.

Metallic tapes may, however, be applied directly over the assembled cores, omitting the inner

covering, provided that the nominal thickness of each tape does not exceed 0,3 mm and that

the completed cable complies with the special bending test specified in 18.17.

60502-1 IEC:2004 – 33 –

7.2.2 Cables having no collective metallic layer (see Clause 8)

The inner covering may be omitted, provided the outer shape of the cable remains practically

circular and no adhesion occurs between cores and sheath.

The oversheath may penetrate into the interstices of the cores, except in the case of

thermoplastic oversheaths over circular cores exceeding 10 mm .

If, however, an inner covering is applied, its thickness need not comply with 7.1.3 or 7.1.4.

7.3 Cables with rated voltage 1,8/3 (3,6) kV

Cables with rated voltage 1,8/3 (3,6) kV shall have a metallic layer surrounding the cores either

individually or collectively.

7.3.1 Cables having only a collective metallic layer (see Clause 8)

Cables shall have an inner covering over the laid-up cores. The inner covering and fillers shall

comply with 7.1 and shall be non-hygroscopic.

7.3.2 Cables having a metallic layer over each individual core (see Clause 9)

The metallic layers of the individual cores shall be in contact with each other.

Cables with an additional collective metallic layer (see Clause 8) of the same material as the

underlying individual metallic layers shall have an inner covering over the laid-up cores. The

inner covering and fillers shall comply with 7.1 and shall be non-hygroscopic.

When the underlying individual metallic layers and the collective metallic layer are of different

materials, they shall be separated by an extruded sheath of one of the materials specified

in 13.2. For lead-sheathed cables, the separation from the underlying individual metallic layers

may be obtained by an inner covering according to 7.1.

For cables having neither armour, nor concentric conductor, nor other collective metallic layer

(see Clause 8), the inner covering may be omitted, provided the outer shape of the cable

remains practically circular. The oversheath may penetrate into the interstices of the cores,

except in the case of thermoplastic oversheaths over circular cores exceeding 10 mm . If,

however, an inner covering is applied, its thickness need not comply with 7.1.3 or 7.1.4.

8 Metallic layers for single

...

NORME CEI

INTERNATIONALE 60502-1

Deuxième édition

2004-04

Câbles d'énergie à isolant extrudé

et leurs accessoires pour des tensions assignées

de 1 kV (U = 1,2 kV) à 30 kV (U = 36 kV) –

m m

Partie 1:

Câbles de tensions assignées de 1 kV (U =1,2 kV)

m

et 3 kV (U = 3,6 kV)

m

Cette version française découle de la publication d’origine

bilingue dont les pages anglaises ont été supprimées.

Les numéros de page manquants sont ceux des pages

supprimées.

Numéro de référence

CEI 60502-1:2004(F)

Numérotation des publications

Depuis le 1er janvier 1997, les publications de la CEI sont numérotées à partir de

60000. Ainsi, la CEI 34-1 devient la CEI 60034-1.

Editions consolidées

Les versions consolidées de certaines publications de la CEI incorporant les

amendements sont disponibles. Par exemple, les numéros d’édition 1.0, 1.1 et 1.2

indiquent respectivement la publication de base, la publication de base incorporant

l’amendement 1, et la publication de base incorporant les amendements 1 et 2

Informations supplémentaires sur les publications de la CEI

Le contenu technique des publications de la CEI est constamment revu par la CEI

afin qu'il reflète l'état actuel de la technique. Des renseignements relatifs à cette

publication, y compris sa validité, sont disponibles dans le Catalogue des

publications de la CEI (voir ci-dessous) en plus des nouvelles éditions, amende-

ments et corrigenda. Des informations sur les sujets à l’étude et l’avancement des

travaux entrepris par le comité d’études qui a élaboré cette publication, ainsi que la

liste des publications parues, sont également disponibles par l’intermédiaire de:

• Site web de la CEI (www.iec.ch)

• Catalogue des publications de la CEI

Le catalogue en ligne sur le site web de la CEI (www.iec.ch/searchpub) vous permet

de faire des recherches en utilisant de nombreux critères, comprenant des

recherches textuelles, par comité d’études ou date de publication. Des informations

en ligne sont également disponibles sur les nouvelles publications, les publications

remplacées ou retirées, ainsi que sur les corrigenda.

• IEC Just Published

Ce résumé des dernières publications parues (www.iec.ch/online_news/justpub)

est aussi disponible par courrier électronique. Veuillez prendre contact avec le

Service client (voir ci-dessous) pour plus d’informations.

• Service clients

Si vous avez des questions au sujet de cette publication ou avez besoin de

renseignements supplémentaires, prenez contact avec le Service clients:

Email: custserv@iec.ch

Tél: +41 22 919 02 11

Fax: +41 22 919 03 00

NORME CEI

INTERNATIONALE 60502-1

Deuxième édition

2004-04

Câbles d'énergie à isolant extrudé

et leurs accessoires pour des tensions assignées

de 1 kV (U = 1,2 kV) à 30 kV (U = 36 kV) –

m m

Partie 1:

Câbles de tensions assignées de 1 kV (U =1,2 kV)

m

et 3 kV (U = 3,6 kV)

m

IEC 2004 Droits de reproduction réservés

Aucune partie de cette publication ne peut être reproduite ni utilisée sous quelque forme que ce soit et par aucun

procédé, électronique ou mécanique, y compris la photocopie et les microfilms, sans l'accord écrit de l'éditeur.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

CODE PRIX

Commission Electrotechnique Internationale XA

International Electrotechnical Commission

Международная Электротехническая Комиссия

Pour prix, voir catalogue en vigueur

– 2 – 60502-1 CEI:2004

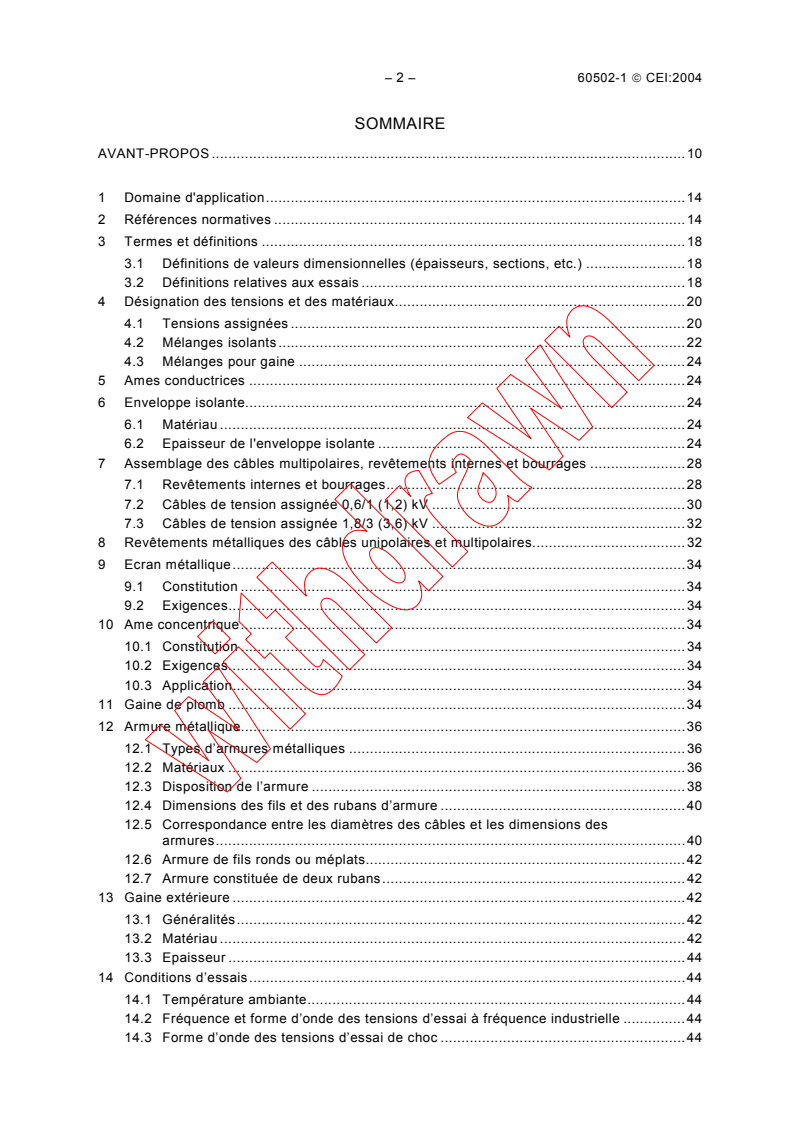

SOMMAIRE

AVANT-PROPOS .10

1 Domaine d'application.14

2 Références normatives.14

3 Termes et définitions .18

3.1 Définitions de valeurs dimensionnelles (épaisseurs, sections, etc.) .18

3.2 Définitions relatives aux essais .18

4 Désignation des tensions et des matériaux.20

4.1 Tensions assignées.20

4.2 Mélanges isolants.22

4.3 Mélanges pour gaine .24

5 Ames conductrices.24

6 Enveloppe isolante.24

6.1 Matériau.24

6.2 Epaisseur de l'enveloppe isolante .24

7 Assemblage des câbles multipolaires, revêtements internes et bourrages .28

7.1 Revêtements internes et bourrages.28

7.2 Câbles de tension assignée 0,6/1 (1,2) kV .30

7.3 Câbles de tension assignée 1,8/3 (3,6) kV .32

8 Revêtements métalliques des câbles unipolaires et multipolaires.32

9 Ecran métallique.34

9.1 Constitution.34

9.2 Exigences.34

10 Ame concentrique.34

10.1 Constitution.34

10.2 Exigences.34

10.3 Application.34

11 Gaine de plomb .34

12 Armure métallique.36

12.1 Types d’armures métalliques .36

12.2 Matériaux.36

12.3 Disposition de l’armure .38

12.4 Dimensions des fils et des rubans d’armure .40

12.5 Correspondance entre les diamètres des câbles et les dimensions des

armures.40

12.6 Armure de fils ronds ou méplats.42

12.7 Armure constituée de deux rubans.42

13 Gaine extérieure.42

13.1 Généralités.42

13.2 Matériau.42

13.3 Epaisseur.44

14 Conditions d’essais.44

14.1 Température ambiante.44

14.2 Fréquence et forme d’onde des tensions d’essai à fréquence industrielle .44

14.3 Forme d’onde des tensions d’essai de choc .44

– 4 – 60502-1 CEI:2004

15 Essais individuels.44

15.1 Généralités.44

15.2 Résistance électrique des âmes.46

15.3 Essai de tension .46

16 Essais sur prélèvements .48

16.1 Généralités.48

16.2 Fréquence des essais sur prélèvements .48

16.3 Répétition des essais.50

16.4 Examen de l’âme.50

16.5 Mesure de l’épaisseur des enveloppes isolantes et des gaines non métalliques

(y compris les gaines de séparation extrudées, mais à l’exclusion des

revêtements internes extrudés).50

16.6 Mesure de l’épaisseur de la gaine de plomb.52

16.7 Mesure sur les fils et rubans d’armure .52

16.8 Mesure du diamètre extérieur .54

16.9 Essai d’allongement à chaud des enveloppes isolantes en EPR, HEPR et PR

et des gaines en matériau élastomérique .54

17 Essais de type électriques .54

17.1 Mesure de la résistance d’isolement à la température ambiante .56

17.2 Mesure de la résistance d’isolement à la température maximale de l’âme.56

17.3 Essai de tension pendant 4 h .58

17.4 Essai aux ondes de choc pour les câbles de tension assignée 1,8/3 (3,6) kV.58

18 Essais de type non électriques.58

18.1 Mesure de l’épaisseur de l’enveloppe isolante.60

18.2 Mesure de l'épaisseur des gaines non métalliques (y compris les gaines de

séparation extrudées, mais à l'exclusion des revêtements internes) .60

18.3 Essai de détermination des propriétés mécaniques des enveloppes isolantes

avant et après vieillissement .60

18.4 Détermination des propriétés mécaniques des gaines non métalliques avant

et après vieillissement .62

18.5 Essai additionnel de vieillissement sur tronçons de câbles complets.62

18.6 Essai de perte de masse des gaines en PVC du type ST .64

18.7 Essai de pression à température élevée des enveloppes isolantes et des

gaines non métalliques .64

18.8 Essai à basse température de l’enveloppe isolante en PVC et des gaines en PVC.64

18.9 Essai de résistance à la fissuration de l’enveloppe isolante en PVC et des

gaines en PVC (essai de choc thermique) .64

18.10 Essai de résistance à l’ozone des enveloppes isolantes en EPR et en HEPR.66

18.11 Essai d'allongement à chaud des enveloppes isolantes en EPR, HEPR et PR

et des gaines en matériau élastomérique .66

18.12 Essai de résistance à l'huile minérale des gaines en matériau élastomérique .66

18.13 Essai d’absorption d’eau des enveloppes isolantes .66

18.14 Essais au feu.66

18.15 Mesure du taux de noir de carbone des gaines en PE de couleur noire.68

18.16 Essai de rétraction des enveloppes isolantes en PR.70

18.17 Essai spécial de pliage .70

18.18 Détermination de la dureté de l’enveloppe isolante en HEPR.70

18.19 Détermination du module d’élasticité de l’enveloppe isolante en HEPR.70

– 6 – 60502-1 CEI:2004

18.20 Essai de rétraction des gaines extérieures en PE.72

18.21 Essais mécaniques additionnels pour les gaines externes sans halogène.72

18.22 Essai d’absorption d’eau pour les gaines externes sans halogène .72

19 Essais électriques après pose.72

Annexe A (normative) Méthode du calcul fictif pour déterminer les dimensions des

revêtements de protection .94

A.1 Généralités.94

A.2 Méthode .94

Annexe B (normative) Arrondissement des nombres. 106

B.1 Arrondissement des nombres pour l'utilisation de la méthode du calcul fictif . 106

B.2 Arrondissement des nombres pour d'autres utilisations . 106

Annexe C (normative) Détermination de la dureté des enveloppes isolantes en HEPR . 110

C.1 Eprouvette. 110

C.2 Procédure d'essai . 110

Figure C.1 – Essai des surfaces de grand rayon de courbure. 112

Figure C.2 – Essai des surfaces de petit rayon de courbure. 114

Tableau 1 – Tensions assignées recommandées U .20

Tableau 2 – Mélanges isolants .22

Tableau 3 – Températures maximales de l’âme pour les différents types de mélanges

isolants .22

Tableau 4 – Températures maximales de l'âme pour les différents types de mélanges

pour gaine.24

Tableau 5 – Epaisseur nominale de l’enveloppe isolante en PVC/A.26

Tableau 6 – Epaisseur nominale de l’enveloppe isolante en polyéthylène réticulé (PR).26

Tableau 7 – Epaisseur nominale de l’enveloppe isolante en caoutchouc d’éthylène-

propylène (EPR) et caoutchouc d’éthylène-propylène dur (HEPR) .28

Tableau 8 – Epaisseur du revêtement interne extrudé.30

Tableau 9 – Diamètre nominal des fils d’armure ronds.40

Tableau 10 – Epaisseur nominale des rubans d’armure .40

Tableau 11 – Tensions des essais individuels.48

Tableau 12 – Nombre d’échantillons pour essais sur prélèvements.50

Tableau 13 – Exigences pour les essais de type électriques pour les mélanges isolants .74

Tableau 14 – Essais de type non électriques (voir tableaux 15 à 23).76

Tableau 15 – Exigences d'essai pour les propriétés mécaniques des mélanges pour

enveloppes isolantes (avant et après vieillissement) .78

Tableau 16 – Exigences d'essai pour les propriétés particulières des mélanges à base

de PVC pour enveloppes isolantes .78

Tableau 17 – Exigences d'essai pour les propriétés particulières des divers mélanges

réticulés pour enveloppes isolantes .82

Tableau 18 – Exigences d’essai pour les propriétés mécaniques des mélanges pour

gaines (avant et après vieillissement) .84

– 8 – 60502-1 CEI:2004

Tableau 19 – Exigences d'essai pour les propriétés particulières des mélanges à base

de PVC pour gaines .86

Tableau 20 – Exigences d’essai pour les propriétés particulières des mélanges

thermoplastiques à base de PE pour gaines .88

Tableau 21 – Exigences d’essai pour les caractéristiques particulières des mélanges de

gaine sans halogène .90

Tableau 22 – Exigences d'essai pour les propriétés particulières de mélanges

élastomères pour gaines .92

Tableau 23 – Méthodes d’essai et exigences pour les mélanges sans halogène.92

Tableau A.1 – Diamètre fictif des âmes .96

Tableau A.2 – Coefficient d'assemblage k pour les conducteurs assemblés .98

Tableau A.3 – Augmentation de diamètre pour les âmes concentriques et les écrans

métalliques . 100

Tableau A.4 – Augmentation de diamètre pour le matelas supplémentaire . 104

– 10 – 60502-1 CEI:2004

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

___________

CÂBLES D'ÉNERGIE À ISOLANT EXTRUDÉ

ET LEURS ACCESSOIRES POUR DES TENSIONS ASSIGNÉES

DE 1 kV (U = 1,2 kV) À 30 kV (U = 36 kV) –

m m

Partie 1: Câbles de tensions assignées de 1 kV

(U = 1,2 kV) et 3 kV (U = 3,6 kV)

m m

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (CEI) est une organisation mondiale de normalisation composée

de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a pour objet de

favoriser la coopération internationale pour toutes les questions de normalisation dans les domaines de

l'électricité et de l'électronique. A cet effet, la CEI – entre autres activités – publie des Normes internationales,

des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au public (PAS) et des

Guides (ci-après dénommés "Publication(s) de la CEI"). Leur élaboration est confiée à des comités d'études,

aux travaux desquels tout Comité national intéressé par le sujet traité peut participer. Les organisations

internationales, gouvernementales et non gouvernementales, en liaison avec la CEI, participent également aux

travaux. La CEI collabore étroitement avec l'Organisation Internationale de Normalisation (ISO), selon des

conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de la CEI

intéressés sont représentés dans chaque comité d’études.

3) Les Publications de la CEI se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de la CEI. Tous les efforts raisonnables sont entrepris afin que la CEI

s'assure de l'exactitude du contenu technique de ses publications; la CEI ne peut pas être tenue responsable de

l'éventuelle mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d'encourager l'uniformité internationale, les Comités nationaux de la CEI s'engagent, dans toute la

mesure possible, à appliquer de façon transparente les Publications de la CEI dans leurs publications

nationales et régionales. Toutes divergences entre toutes Publications de la CEI et toutes publications

nationales ou régionales correspondantes doivent être indiquées en termes clairs dans ces dernières.

5) La CEI n’a prévu aucune procédure de marquage valant indication d’approbation et n'engage pas sa

responsabilité pour les équipements déclarés conformes à une de ses Publications.

6) Tous les utilisateurs doivent s'assurer qu'ils sont en possession de la dernière édition de cette publication.

7) Aucune responsabilité ne doit être imputée à la CEI, à ses administrateurs, employés, auxiliaires ou

mandataires, y compris ses experts particuliers et les membres de ses comités d'études et des Comités

nationaux de la CEI, pour tout préjudice causé en cas de dommages corporels et matériels, ou de tout autre

dommage de quelque nature que ce soit, directe ou indirecte, ou pour supporter les coûts (y compris les frais

de justice) et les dépenses découlant de la publication ou de l'utilisation de cette Publication de la CEI ou de

toute autre Publication de la CEI, ou au crédit qui lui est accordé.

8) L'attention est attirée sur les références normatives citées dans cette publication. L'utilisation de publications

référencées est obligatoire pour une application correcte de la présente publication.

9) L’attention est attirée sur le fait que certains des éléments de la présente Publication de la CEI peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 60502-1 a été établie par le comité d’étude 20 de la CEI: Câbles

électriques.

Cette deuxième édition annule et remplace la première édition, parue en 1997, et son

amendement 1 (1998) et constitue une révision technique.

Les modifications majeures par rapport à la première édition concernent les exigences pour les

épaisseurs des enveloppes isolantes et des gaines de protection extérieures ainsi que les

exigences pour les câbles sans halogène avec des propriétés de propagation de la flamme

réduites et de faibles niveaux d’émission de fumée.

– 12 – 60502-1 CEI:2004

Le texte de cette norme est issu des documents suivants:

FDIS Rapport de vote

20/683/FDIS 20/691/RVD

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote ayant

abouti à l’approbation de cette norme.

Cette publication a été établie en accord avec les Directives ISO/CEI, Partie 2.

La CEI 60502 comprend les parties suivantes, présentées sous le titre général

Câbles d'énergie à isolant extrudé et leurs accessoires pour des tensions assignées de

1 kV (U = 1,2 kV) à 30 kV (U = 36 kV):

m m

Partie 1: Câbles de tensions assignées de 1 kV (U = 1,2 kV) et 3 kV (U = 3,6 kV);

m m

Partie 2: Câbles de tensions assignées de 6 kV (U = 7,2 kV) à 30 kV (U = 36 kV);

m m

Partie 3: Réservée;

Partie 4: Exigences d'essai pour les accessoires de câbles de tensions assignées de 6 kV

(U = 7,2 kV) à 30 kV (U = 36 kV).

m m

Le comité a décidé que le contenu de cette publication ne sera pas modifié avant 2009. A cette

date, la publication sera

• reconduite;

• supprimée;

• remplacée par une édition révisée, ou

• amendée.

– 14 – 60502-1 CEI:2004

CÂBLES D'ÉNERGIE À ISOLANT EXTRUDÉ

ET LEURS ACCESSOIRES POUR DES TENSIONS ASSIGNÉES

DE 1 kV (U = 1,2 kV) À 30 kV (U = 36 kV) –

m m

Partie 1: Câbles de tensions assignées de 1 kV

(U = 1,2 kV) et 3 kV (U = 3,6 kV)

m m

1 Domaine d'application

La présente partie de la CEI 60502 spécifie la constitution, les dimensions et les exigences

d'essais des câbles d’énergie à isolation extrudée par diélectriques massifs, de tensions

assignées de 1 kV (U = 1,2 kV) et 3 kV (U = 3,6 kV), pour installations fixes telles que les

m m

réseaux de distribution ou les installations industrielles.

La présente norme introduit des câbles qui présentent des propriétés de propagation de la

flamme réduite, de faibles niveaux d’émission de fumée et des émissions de gaz sans

halogène lorsqu’ils sont exposés au feu.

Les câbles destinés à des conditions particulières d'installations et de service ne sont pas

inclus, par exemple les câbles pour réseaux aériens, pour l’industrie minière, les centrales

nucléaires (à l’intérieur et à l’extérieur de l’enceinte de confinement), les câbles sous-marins

ou les câbles de bord des navires.

2 Références normatives

Les documents de référence suivants sont indispensables pour l'application du présent

document. Pour les références datées, seule l'édition citée s'applique. Pour les références non

datées, la dernière édition du document de référence s'applique (y compris les éventuels

amendements).

CEI 60038:1983, Tensions normales de la CEI

CEI 60060-1:1989, Techniques des essais à haute tension – Première partie: Définitions et

exigences générales relatives aux essais

CEI 60183:1984, Guide pour le choix des câbles à haute tension

CEI 60228:1978, Ames des câbles isolés

CEI 60230:1966, Essais de choc des câbles et de leurs accessoires

CEI 60332-1:1993, Essais des câbles électriques soumis au feu – Partie 1: Essai sur un

conducteur ou câble isolé vertical

CEI 60332-3-24:2000, Essais des câbles électriques soumis au feu – Partie 3-24: Essai de

propagation verticale de la flamme des fils ou câbles en nappes en position verticale –

Catégorie C

CEI 60502-2:1997, Câbles d'énergie à isolant extrudé et leurs accessoires pour des tensions

assignées de 1 kV (U = 1,2 kV) à 30 kV (U = 36 kV) – Partie 2: Câbles de tensions

m m

assignées de 6 kV (U = 7,2 kV) à 30 kV (U = 36 kV)

m m

– 16 – 60502-1 CEI:2004

CEI 60684-2:1987, Gaines isolantes souples – Partie 2: Méthodes d’essai

CEI 60724:2000, Limites de température de court-circuit des câbles électriques de tensions

assignées de 1 kV (U = 1,2 kV) et 3 kV (U = 3,6 kV)

m m

CEI 60754-1:1994, Essai sur les gaz émis lors de la combustion de matériaux prélevés sur

câbles – Partie 1: Détermination de la quantité de gaz acide halogéné

CEI 60754-2:1991, Essai sur les gaz émis lors de la combustion des câbles électriques –

Partie 2: Détermination de l'acidité des gaz émis lors de la combustion d’un matériau prélévé

sur un câble par mesurage du pH et de la conductivité

CEI 60811-1-1:1993, Méthodes d’essais communes pour les matériaux d’isolation et de

gainage des câbles électriques – Partie 1: Méthodes d'application générale – Section 1:

Mesure des épaisseurs et des dimensions extérieures – Détermination des propriétés

mécaniques

CEI 60811-1-2:1985, Méthodes d’essais communes pour les matériaux d’isolation et de

gainage des câbles électriques – Partie 1: Méthodes d'application générale – Section 2:

Méthodes de vieillissement thermique

CEI 60811-1-3:1993, Méthodes d’essais communes pour les matériaux d’isolation et de

gainage des câbles électriques – Partie 1: Méthodes d'application générale – Section 3:

Méthodes de détermination de la masse volumique – Essais d'absorption d'eau – Essai de

rétraction

CEI 60811-1-4:1985, Méthodes d’essais communes pour les matériaux d’isolation et de

gainage des câbles électriques – Partie 1: Méthodes d'application générale – Section 4: Essais

à basse température

CEI 60811-2-1:1998, Matériaux d’isolation et de gainage des câbles électriques et optiques –

Méthodes d’essai communes – Partie 2-1: Méthodes spécifiques pour les mélanges

élastomères – Essais relatifs à la résistance à l'ozone, à l'allongement à chaud et à la

résistance à l'huile

CEI 60811-3-1:1985, Méthodes d’essais communes pour les matériaux d’isolation et de

gainage des câbles électriques – Partie 3: Méthodes spécifiques pour les mélanges PVC –

Section 1: Essai de pression à température élevée – Essais de résistance à la fissuration

CEI 60811-3-2:1985, Méthodes d’essais communes pour les matériaux d’isolation et de

gainage des câbles électriques – Partie 3: Méthodes spécifiques pour les mélanges PVC –

Section 2: Essai de perte de masse – Essai de stabilité thermique

CEI 60811-4-1:1985, Méthodes d’essais communes pour les matériaux d’isolation et de

gainage des câbles électriques – Partie 4: Méthodes spécifiques pour les mélanges

polyéthylène et polypropylène – Section 1: Résistance aux craquelures sous contraintes dues

à l'environnement – Essai d'enroulement après vieillissement thermique dans l'air – Mesure de

l'indice de fluidité à chaud – Mesure dans le PE du taux de noir de carbone et/ou des charges

minérales

CEI 61034-2:1997, Mesure de la densité de fumées dégagées par des câbles brûlant dans des

conditions définies – Partie 2: Procédure d’essai et exigences

ISO 48:1994, Caoutchouc vulcanisé ou thermoplastique – Détermination de la dureté (dureté

comprise entre 10 IRHD et 100 IRHD)

– 18 – 60502-1 CEI:2004

3 Termes et définitions

Pour les besoins du présent document, les définitions suivantes s'appliquent.

3.1 Définitions de valeurs dimensionnelles (épaisseurs, sections, etc.)

3.1.1

valeur nominale

valeur par laquelle une grandeur est dénommée et qui est souvent utilisée dans les tableaux

NOTE Régulièrement, dans cette norme, les valeurs nominales correspondent à des valeurs qui sont vérifiées par

des mesures, compte tenu des tolérances spécifiées.

3.1.2

valeur approximative

valeur qui n'est ni garantie ni vérifiée; elle est utilisée, par exemple, pour le calcul d'autres

dimensions

3.1.3

valeur médiane

quand plusieurs résultats d'essais sont obtenus et classés par ordre de valeurs croissantes (ou

décroissantes), la valeur médiane est la valeur du milieu de la série si le nombre de valeurs

disponibles est impair, et la moyenne arithmétique des deux valeurs centrales de la série si le

nombre est pair

3.1.4

valeur fictive

valeur calculée suivant la «méthode du calcul fictif» définie à l’Annexe A

3.2 Définitions relatives aux essais

3.2.1

essais individuels

essais effectués par le fabricant sur chacune des longueurs de câble produit afin de vérifier

que chaque longueur répond aux caractéristiques spécifiées

3.2.2

essais sur prélèvements

essais effectués par le fabricant sur des échantillons de câble complet ou sur des constituants

prélevés sur câble complet, à une fréquence spécifiée, afin de vérifier que le produit fini répond

aux caractéristiques spécifiées

3.2.3

essais de type

essais effectués avant la livraison sur une base commerciale générale d'un type de câble

concerné par cette norme, afin de démontrer que ses caractéristiques répondent aux

applications prévues

NOTE Ces essais sont de telle nature qu'après avoir été effectués, il n'est pas nécessaire de les répéter, à moins

que des modifications n'aient été introduites dans les matériaux, dans la conception du câble ou dans le procédé de

fabrication, susceptibles d’en modifier les caractéristiques.

3.2.4

essais électriques après pose

essais effectués pour vérifier l’intégrité du câble et de ses accessoires après la pose

– 20 – 60502-1 CEI:2004

4 Désignation des tensions et des matériaux

4.1 Tensions assignées

Les tensions assignées U /U (U ) des câbles concernés par cette norme sont 0,6/1 (1,2) kV et

0 m

1,8/3 (3,6) kV.

NOTE 1 Les tensions indiquées ci-dessus constituent les désignations correctes, bien que d’autres désignations

soient employées dans certains pays, par exemple 1,7/3 kV ou 1,9/3,3 kV au lieu de 1,8/3 kV.

Dans la désignation des tensions des câbles U /U (U ):

0 m

U est la tension assignée à fréquence industrielle entre chacun des conducteurs et la terre,

ou l'écran métallique, pour laquelle le câble est conçu;

U est la tension assignée à fréquence industrielle entre conducteurs, pour laquelle le câble

est conçu;

U est la valeur maximale de la «tension la plus élevée du réseau» pour laquelle le matériel

m

peut être utilisé (voir CEI 60038).

Pour une application donnée, la tension assignée d'un câble doit être adaptée aux conditions

d'exploitation du réseau dans lequel il est utilisé. Pour faciliter le choix du câble, les réseaux

sont divisés en trois catégories:

– Catégorie A: cette catégorie comprend les réseaux dans lesquels tout conducteur de

phase qui entre en contact avec la terre ou avec un conducteur de terre est

déconnecté du réseau en moins de 1 min;

– Catégorie B: cette catégorie comprend les réseaux qui, en régime de défaut, continuent à

être exploités pendant un temps limité avec une phase à la terre. Selon la

CEI 60183, il convient que cette durée ne dépasse pas 1 h. Pour les câbles

concernés par cette norme, une durée plus longue peut être tolérée, ne

dépassant cependant 8 h en aucun cas. Il convient que la durée cumulée des

défauts à la terre sur une année quelconque ne dépasse pas 125 h;

– Catégorie C: cette catégorie comprend tous les réseaux qui n'entrent pas dans l'une des

catégories A ou B.

NOTE 2 Il convient d'avoir à l'esprit que, dans un réseau où un défaut à la terre n'est pas éliminé auto-

matiquement et rapidement, les contraintes supplémentaires supportées par l'isolation des câbles pendant la durée

du défaut réduisent la vie de ceux-ci dans une certaine proportion. S’il est prévu que le réseau fonctionne assez

souvent avec un défaut permanent à la terre, il peut être prudent de classer le réseau dans la Catégorie C.

Les valeurs recommandées de U pour les câbles utilisés dans les réseaux triphasés sont

indiquées au Tableau 1.

Tableau 1 – Tensions assignées recommandées U

Tension la plus élevée Tension assignée (U )

du réseau (U ) kV

m

kV Catégories A et B Catégorie C

1,2 0,6 0,6

*

3,6 1,8 3,6

*

Cette catégorie est couverte par les câbles 3,6/6 (7,2) kV selon la CEI 60502-2.

– 22 – 60502-1 CEI:2004

4.2 Mélanges isolants

Les types de mélanges isolants concernés par cette norme sont énumérés dans le Tableau 2,

ainsi que leurs désignations abrégées.

Tableau 2 – Mélanges isolants

Mélange isolant Désignation abrégée

a) Thermoplastique

*

PVC/A

Polychlorure de vinyle pour les câbles de tension assignée U /U ≤ 1,8/3 kV

b) Réticulé

Caoutchouc d’éthylène-propylène ou matériau similaire (EPM ou EPDM) EPR

Caoutchouc d’éthylène-propylène dur ou à module élevé HEPR

Polyéthylène réticulé PR

*

Le mélange isolant à base de polychlorure de vinyle destiné aux câbles de tension assignée U /U = 3,6/6 kV est

désigné PVC/B dans la CEI 60502-2.

Pour les différents types de mélanges isolants concernés par cette norme, les températures

maximales de l'âme sont données au Tableau 3.

Tableau 3 – Températures maximales de l’âme pour les différents types

de mélanges isolants

Température maximale de l'âme

°C

Mélange isolant

Court-circuit

Service normal

(durée maximale 5 s)

Polychlorure de vinyle (PVC/A)

70 160

Section d'âme ≤300 mm

Section d'âme >300 mm 70 140

Polyéthylène réticulé (PR) 90 250

Caoutchouc d’éthylène- (EPR et HEPR) 90 250

propylène

Les températures indiquées au Tableau 3 sont basées sur les propriétés intrinsèques des

matériaux isolants. Il est important de prendre en compte d'autres facteurs lorsque ces valeurs

sont utilisées pour le calcul d’intensités admissibles.

Par exemple, en service normal, si un câble enterré directement dans le sol est exploité en

régime permanent (facteur de charge de 100 %) à la température maximale de l'âme

conductrice indiquée dans le tableau, la résistivité thermique du sol environnant peut, à la

longue, dépasser sa valeur initiale par l'effet du dessèchement qui en résulte. La température

de l'âme risque alors de dépasser largement la valeur maximale. Si de telles conditions de

service sont envisagées, des précautions appropriées doivent être prises.

Pour des indications sur les températures de court-circuit, il convient de se référer à la

CEI 60724.

– 24 – 60502-1 CEI:2004

4.3 Mélanges pour gaine

Pour les différents types de mélanges pour gaine concernés par cette norme, les températures

maximales de l’âme sont données au Tableau 4.

Tableau 4 – Températures maximales de l'âme pour les différents types