IEC 60502-1:2021

(Main)Power cables with extruded insulation and their accessories for rated voltages from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV) - Part 1: Cables for rated voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV)

Power cables with extruded insulation and their accessories for rated voltages from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV) - Part 1: Cables for rated voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV)

IEC 60502-1:2021 specifies the construction, dimensions and test requirements of power cables with extruded solid insulation for rated AC voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV) for fixed installations such as distribution networks or industrial installations. Cables of rated AC voltage 1 kV (Um = 1,2 kV) designed and tested in accordance with this document can also be used, if declared by the manufacturer, in DC distribution systems having their nominal voltage ≤ 750 V DC (with a maximum of 900 V DC) between a live conductor and neutral/earth, or ≤ 1 500 V DC (with a maximum 1 800 V DC) between two live conductors. Applicable core identification for DC systems are considered in accordance with local installation regulations.

General Information

- Status

- Published

- Publication Date

- 08-Feb-2021

- Technical Committee

- TC 20 - Electric cables

- Drafting Committee

- WG 16 - TC 20/WG 16

- Current Stage

- PPUB - Publication issued

- Start Date

- 09-Feb-2021

- Completion Date

- 19-Feb-2021

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60502-1:2021 specifies the construction, dimensions and test requirements for power cables with extruded solid insulation for rated AC voltages of 1 kV (Um = 1.2 kV) and 3 kV (Um = 3.6 kV). It covers cables intended for fixed installations such as distribution networks and industrial installations, and includes provisions for materials (insulation and sheaths), conductor types, metallic layers and mechanical protections. The standard also allows, when declared by the manufacturer, the use of cables designed to this standard in certain DC distribution systems (limits defined in the standard).

Key Topics and Requirements

- Scope and applicability: Cables for 1 kV and 3 kV rated AC voltages; optional use in DC systems (e.g., ≤ 750 V DC nominal to earth, ≤ 1 500 V DC nominal live-to-live, subject to manufacturer declaration).

- Construction and dimensions: Requirements for conductors, extruded insulation (e.g., XLPE, EPR/HEPR options), inner coverings, metallic screens, concentric conductors, sheaths and armour.

- Material specifications: Insulating and sheathing compound types, conductor temperature ratings and permitted sheathing materials; includes provisions for halogen-free and low-smoke materials.

- Testing regime: Defined routine tests, sample tests, and type tests - both electrical (high-voltage, dielectric) and non-electrical (mechanical properties, ageing, flammability and halogen-free verification).

- Fire and safety characteristics: Requirements for reduced flame spread, low smoke emission and halogen-free emissions when exposed to fire.

- Installation and post-installation testing: Electrical tests after installation are addressed to ensure in-service safety and conformity.

Applications and Users

Practical uses:

- Medium-voltage distribution in urban/industrial power networks

- Fixed wiring for factories, substations and building distribution systems

- Cable specifications for projects requiring halogen-free or low-smoke behavior

Who uses it:

- Cable manufacturers and material suppliers (product design and type testing)

- Electrical engineers and specifiers (design, procurement and compliance)

- Test laboratories and certification bodies (routine, sample and type testing)

- Utilities, EPC contractors and maintenance teams (selection, installation and acceptance testing)

Related Standards

- IEC 60811 - Cable test methods (referenced for detailed mechanical and material tests)

- IEC 60445 - Core identification and colour recommendations (noted for DC systems)

- IEC 62930 - Cables for photovoltaic systems (covers PV-specific cables excluded from this part)

- IEC 60060-1 / IEC 60038 - High-voltage test techniques and standard voltages (normative references)

IEC 60502-1:2021 is the authoritative reference for specifying and verifying medium-voltage, extruded-insulation power cables (1 kV and 3 kV) used in fixed installations, emphasizing material performance, safety and comprehensive electrical and mechanical testing.

IEC 60502-1:2021 - Power cables with extruded insulation and their accessories for rated voltages from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV) - Part 1: Cables for rated voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV)

REDLINE IEC 60502-1:2021 - Power cables with extruded insulation and their accessories for rated voltages from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV) - Part 1: Cables for rated voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV) Released:2/9/2021 Isbn:9782832294277

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60502-1:2021 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Power cables with extruded insulation and their accessories for rated voltages from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV) - Part 1: Cables for rated voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV)". This standard covers: IEC 60502-1:2021 specifies the construction, dimensions and test requirements of power cables with extruded solid insulation for rated AC voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV) for fixed installations such as distribution networks or industrial installations. Cables of rated AC voltage 1 kV (Um = 1,2 kV) designed and tested in accordance with this document can also be used, if declared by the manufacturer, in DC distribution systems having their nominal voltage ≤ 750 V DC (with a maximum of 900 V DC) between a live conductor and neutral/earth, or ≤ 1 500 V DC (with a maximum 1 800 V DC) between two live conductors. Applicable core identification for DC systems are considered in accordance with local installation regulations.

IEC 60502-1:2021 specifies the construction, dimensions and test requirements of power cables with extruded solid insulation for rated AC voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV) for fixed installations such as distribution networks or industrial installations. Cables of rated AC voltage 1 kV (Um = 1,2 kV) designed and tested in accordance with this document can also be used, if declared by the manufacturer, in DC distribution systems having their nominal voltage ≤ 750 V DC (with a maximum of 900 V DC) between a live conductor and neutral/earth, or ≤ 1 500 V DC (with a maximum 1 800 V DC) between two live conductors. Applicable core identification for DC systems are considered in accordance with local installation regulations.

IEC 60502-1:2021 is classified under the following ICS (International Classification for Standards) categories: 29.060.20 - Cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60502-1:2021 has the following relationships with other standards: It is inter standard links to IEC 60502-1:2004/AMD1:2009, IEC 60502-1:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60502-1:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60502-1 ®

Edition 3.0 2021-02

INTERNATIONAL

STANDARD

Power cables with extruded insulation and their accessories for rated voltages

from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV) –

Part 1: Cables for rated voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60502-1 ®

Edition 3.0 2021-02

INTERNATIONAL

STANDARD

Power cables with extruded insulation and their accessories for rated voltages

from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV) –

Part 1: Cables for rated voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.060.20 ISBN 978-2-8322-9315-7

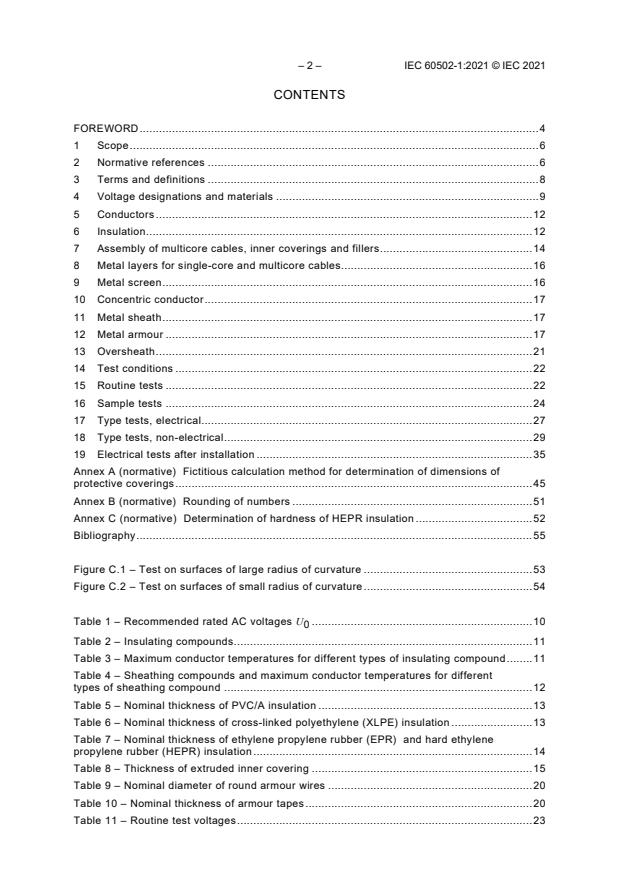

– 2 – IEC 60502-1:2021 © IEC 2021

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 8

4 Voltage designations and materials . 9

5 Conductors . 12

6 Insulation . 12

7 Assembly of multicore cables, inner coverings and fillers . 14

8 Metal layers for single-core and multicore cables. 16

9 Metal screen . 16

10 Concentric conductor . 17

11 Metal sheath . 17

12 Metal armour . 17

13 Oversheath . 21

14 Test conditions . 22

15 Routine tests . 22

16 Sample tests . 24

17 Type tests, electrical. 27

18 Type tests, non-electrical . 29

19 Electrical tests after installation . 35

Annex A (normative) Fictitious calculation method for determination of dimensions of

protective coverings . 45

Annex B (normative) Rounding of numbers . 51

Annex C (normative) Determination of hardness of HEPR insulation . 52

Bibliography . 55

Figure C.1 – Test on surfaces of large radius of curvature . 53

Figure C.2 – Test on surfaces of small radius of curvature . 54

Table 1 – Recommended rated AC voltages U . 10

Table 2 – Insulating compounds . 11

Table 3 – Maximum conductor temperatures for different types of insulating compound . 11

Table 4 – Sheathing compounds and maximum conductor temperatures for different

types of sheathing compound . 12

Table 5 – Nominal thickness of PVC/A insulation . 13

Table 6 – Nominal thickness of cross-linked polyethylene (XLPE) insulation . 13

Table 7 – Nominal thickness of ethylene propylene rubber (EPR) and hard ethylene

propylene rubber (HEPR) insulation . 14

Table 8 – Thickness of extruded inner covering . 15

Table 9 – Nominal diameter of round armour wires . 20

Table 10 – Nominal thickness of armour tapes . 20

Table 11 – Routine test voltages . 23

Table 12 – Number of samples for sample tests . 24

Table 13 – Electrical type test requirements for insulating compounds . 36

Table 14 – Non-electrical type tests (see Tables 15 to 23) . 37

Table 15 – Test requirements for mechanical characteristics of insulating compounds

(before and after ageing) . 38

Table 16 – Test requirements for particular characteristics of PVC insulating

compounds . 39

Table 17 – Test requirements for particular characteristics of various cross-linked

insulating compounds . 40

Table 18 – Test requirements for mechanical characteristics of sheathing compounds

(before and after ageing) . 41

Table 19 – Test requirements for particular characteristics of PVC sheathing

compounds . 42

Table 20 – Test requirements for particular characteristics of thermoplastic PE

sheathing compounds . 43

Table 21 – Test requirements for particular characteristics of halogen free sheathing

compounds . 43

Table 22 – Test requirements for particular characteristics of elastomeric sheathing

compounds . 44

Table 23 – Test methods and requirements for halogen free compounds . 44

Table A.1 – Fictitious diameter of conductor . 46

Table A.2 – Assembly coefficient k for laid-up cores . 47

Table A.3 – Increase of diameter for concentric conductors and metal screens . 48

Table A.4 – Increase of diameter for additional bedding . 50

– 4 – IEC 60502-1:2021 © IEC 2021

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

POWER CABLES WITH EXTRUDED INSULATION

AND THEIR ACCESSORIES FOR RATED VOLTAGES

FROM 1 kV (U = 1,2 kV) UP TO 30 kV (U = 36 kV) –

m m

Part 1: Cables for rated voltages of 1 kV

(U = 1,2 kV) and 3 kV (U = 3,6 kV)

m m

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 60502-1 has been prepared by IEC technical committee 20: Electric cables. It is an

International Standard.

This third edition cancels and replaces the second edition published in 2004 and

Amendment 1:2009. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) references to IEC 60811 (all parts) have been updated and mechanical testing requirements

specific to halogen free low-smoke oversheath of material type ST have been considered;

b) the use of the types of sheathing material to be used is now clearly defined;

c) the applicability of cables for use in DC systems is now included in the scope;

d) items which were earlier marked as "under consideration" were studied either for an

appropriate solution if found available, or for removal for the time being.

The text of this International Standard is based on the following documents:

Draft Report on voting

20/1938/FDIS 20/1949/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 60502 series, published under the general title Power cables with

extruded insulation and their accessories for rated voltages from 1 kV (U = 1,2 kV) up to 30 kV

m

(U = 36 kV) can be found on the IEC website.

m

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 60502-1:2021 © IEC 2021

POWER CABLES WITH EXTRUDED INSULATION

AND THEIR ACCESSORIES FOR RATED VOLTAGES

FROM 1 kV (U = 1,2 kV) UP TO 30 kV (U = 36 kV) –

m m

Part 1: Cables for rated voltages of 1 kV

(U = 1,2 kV) and 3 kV (U = 3,6 kV)

m m

1 Scope

This part of IEC 60502 specifies the construction, dimensions and test requirements of power

cables with extruded solid insulation for rated AC voltages of 1 kV (U = 1,2 kV) and 3 kV

m

(U = 3,6 kV) for fixed installations such as distribution networks or industrial installations.

m

Cables of rated AC voltage 1 kV (U = 1,2 kV) designed and tested in accordance with this

m

document can also be used, if declared by the manufacturer, in DC distribution systems having

their nominal voltage ≤ 750 V DC (with a maximum of 900 V DC) between a live conductor and

neutral/earth, or ≤ 1 500 V DC (with a maximum 1 800 V DC) between two live conductors.

Applicable core identification for DC systems are considered in accordance with local

installation regulations.

NOTE 1 Recommendations for preferred core colours for line conductors in DC systems are given in IEC 60445.

However, local installation regulations for DC systems can already contain specific identification requirements.

This document includes cables which exhibit properties of reduced flame spread, low levels of

smoke emission and halogen-free gas emission when exposed to fire.

Cables for special installation and service conditions are not included, for example cables for

overhead networks, the mining industry, nuclear power plants (in and around the containment

area), submarine use or shipboard application, or cables directly connected to photovoltaic

systems.

NOTE 2 Cables for photovoltaic systems are covered by IEC 62930.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60060-1, High-voltage test techniques – Part 1: General definitions and test requirements

IEC 60183, Guidance for the selection of high-voltage A.C. cable systems

IEC 60228, Conductors of insulated cables

IEC 60230, Impulse tests on cables and their accessories

IEC 60332-1-2, Tests on electric and optical fibre cables under fire conditions – Part 1-2: Test

for vertical flame propagation for a single insulated wire or cable – Procedure for 1 kW

pre‑mixed flame

IEC 60332-3-24, Tests on electric and optical cables under fire conditions – Part 3-24: Test for

vertical flame spread of vertically-mounted bunched wires or cables – Category C

IEC 60684-2, Flexible insulating sleeving – Part 2: Methods of test

IEC 60724, Short-circuit temperature limits of electric cables with rated voltages of 1 kV

(U = 1,2 kV) and 3 kV (U = 3,6 kV)

m m

IEC 60754-1, Test on gases evolved during combustion of materials from cables – Part 1:

Determination of the halogen acid gas content

IEC 60754-2, Test on gases evolved during combustion of materials from cables – Part 2:

Determination of acidity (by pH measurement) and conductivity

IEC 60811-201, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 201: General tests – Measurement of insulation thickness

IEC 60811-202, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 202: General tests – Measurement of thickness of non-metallic sheath

IEC 60811-203, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 203: General tests – Measurement of overall dimensions

IEC 60811-401, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 401: Miscellaneous tests – Thermal ageing methods – Ageing in an air oven

IEC 60811-402, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 402: Miscellaneous tests – Water absorption tests

IEC 60811-403, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 403: Miscellaneous tests – Ozone resistance test on cross-linked compounds

IEC 60811-404, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 404: Miscellaneous tests – Mineral oil immersion tests for sheaths

IEC 60811-409, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 409: Miscellaneous tests – Loss of mass test for thermoplastic insulations and sheaths

IEC 60811-501, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 501: Mechanical tests – Tests for determining the mechanical properties of insulating and

sheathing compounds

IEC 60811-502, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 502: Mechanical tests – Shrinkage test for insulations

IEC 60811-503, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 503: Mechanical tests – Shrinkage test for sheaths

IEC 60811-504, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 504: Mechanical tests – Bending tests at low temperature for insulations and sheaths

IEC 60811-505, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 505: Mechanical tests – Elongation at low temperature for insulations and sheaths

– 8 – IEC 60502-1:2021 © IEC 2021

IEC 60811-506, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 506: Mechanical tests – Impact test at low temperature for insulations and sheaths

IEC 60811-507, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 507: Mechanical tests – Hot set test for cross-linked materials

IEC 60811-508, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 508: Mechanical tests – Pressure test at high temperature for insulation and sheaths

IEC 60811-509, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 509: Mechanical tests – Test for resistance of insulations and sheaths to cracking (heat

shock test)

IEC 60811-605, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 605: Physical tests – Measurement of carbon black and/or mineral filler in polyethylene

compounds

IEC 60811-606, Electric and optical fibre cables –Test methods for non-metallic materials –

Part 606: Physical tests – Methods for determining the density

IEC 61034-2, Measurement of smoke density of cables burning under defined conditions –

Part 2: Test procedure and requirements

IEC 62230, Electric cables – Spark-test method

ISO 48-2:2018, Rubber, vulcanized or thermoplastic – Determination of hardness – Part 2:

Hardness between 10 IRHD and 100 IRHD

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1 Definitions of dimensional values (thicknesses, cross-sections, etc.)

3.1.1

nominal value

value by which a quantity is designated and which is often used in tables

Note 1 to entry: Usually, in this document, nominal values give rise to values to be checked by measurements

taking into account specified tolerances.

3.1.2

approximate value

value which is neither guaranteed nor checked but is used, for example, for the calculation of

other dimensional values

3.1.3

median value

when several test results have been obtained and ordered in an increasing (or decreasing)

succession, middle value if the number of available values is odd, and mean of the two middle

values if the number is even

3.1.4

fictitious value

value calculated in accordance with the "fictitious method'' described in Annex A

3.2 Definitions relating to tests

3.2.1

routine test

test made by the manufacturer on each manufactured length of cable to check that each length

meets the specified requirements

3.2.2

sample test

test made by the manufacturer on samples of completed cable or components taken from a

completed cable, at a specified frequency, so as to verify that the finished product meets the

specified requirements

3.2.3

type test

test made before supplying, on a general commercial basis, a type of cable covered by this

document, in order to demonstrate satisfactory performance characteristics to meet the

intended application

Note 1 to entry: Type tests are of such a nature that, after they have been made, they need not be repeated, unless

changes are made in the cable materials or design or manufacturing process which might change the performance

characteristics.

3.2.4

electrical test after installation

test made to demonstrate the integrity of the cable and its accessories as installed

4 Voltage designations and materials

4.1 Rated voltages

4.1.1 Rated AC voltages

The rated AC voltages U /U (U ) of the cables considered in this document are 0,6/1 (1,2) kV

0 m

and 1,8/3 (3,6) kV.

NOTE 1 The voltages given above are the correct designations although in some countries other designations are

used, e.g. 1,7/3 kV or 1,9/3,3 kV instead of 1,8/3 kV.

For the voltage designation of cables U /U (U ), the definitions in IEC 60183 apply i.e.:

0 m

U is the rated RMS power frequency voltage between conductor and earth or metal screen

for which the cable is designed;

U is the rated RMS power frequency voltage between conductors for which the cable is

designed;

U is the maximum RMS power frequency voltage between conductors for which the cable is

m

designed.

– 10 – IEC 60502-1:2021 © IEC 2021

NOTE 2 U is the highest voltage that can be sustained under normal operating conditions at any time and at any

m

point in a system and excludes temporary voltage variations due to fault conditions and sudden disconnection of

large loads.

The rated voltage of the cable for a given application shall be suitable for the operating

conditions in the system in which the cable is used. To facilitate the selection of the cable,

systems are divided into three categories according to the duration of time the system can be

operated under earth fault conditions (see IEC 60183):

– Category A: this category comprises those systems in which any phase conductor that

comes in contact with earth or an earth conductor is disconnected from the

system within 1 min.

– Category B: this category comprises those systems which, under fault conditions, are

operated for a short time with one phase earthed. This period, in

accordance with IEC 60183, should, in general, not exceed 1 h. For cables

covered by this document, a longer period, not exceeding 8 h on any

occasion, can be tolerated. The total duration of earth faults in any year

should not exceed 125 h.

– Category C: this category comprises all systems which do not fall into category A or B.

NOTE 3 In a system where an earth fault is not automatically and promptly isolated, the extra stresses on the

insulation of cables during the earth fault reduce the life of the cables to a certain degree. If the system is expected

to be operated fairly often with a permanent earth fault, it can be advisable to classify the system in Category C.

The values of U recommended for cables to be used in three-phase systems are listed in

Table 1.

Table 1 – Recommended rated AC voltages U

Highest system voltage

Rated voltage (U )

(U )

m

kV kV

Categories A and B Category C

1,2 0,6 0,6

a

3,6 1,8

3,6

a

This category is covered by 3,6/6 (7,2) kV cables in accordance with

IEC 60502‑2.

4.1.2 Rated DC voltages

Under consideration.

4.2 Insulating compounds

The types of insulating compound covered by this document are listed in Table 2, together with

their abbreviated designations.

Table 2 – Insulating compounds

Abbreviated

Insulating compound

designation

a) Thermoplastic

a

Polyvinyl chloride intended for cables with rated voltages U /U ≤ 1,8/3 kV

PVC/A

b) Cross-linked:

Ethylene propylene rubber or similar (EPM or EPDM) EPR

High modulus or hard grade ethylene propylene rubber HEPR

Cross-linked polyethylene XLPE

a

Insulating compound based on polyvinyl chloride intended for cables with rated AC voltages U /U = 3,6/6 kV

is designated PVC/B in IEC 60502-2.

The maximum conductor temperatures for different types of insulating compound covered by

this document are given in Table 3.

Table 3 – Maximum conductor temperatures for different types of insulating compound

Maximum conductor temperature

°C

Insulating compound

Short-circuit

Normal operation (5 s maximum

duration)

Polyvinyl chloride (PVC/A)

70 160

Conductor cross-section ≤ 300 mm

70 140

Conductor cross-section > 300 mm

Cross-linked polyethylene (XLPE) 90 250

Ethylene propylene rubber (EPR and HEPR) 90 250

The temperatures in Table 3 are based on the intrinsic properties of the insulating materials. It

is important to take into account other factors when using these values for the calculation of

current ratings.

For example, in normal operation, if a cable directly buried in the ground is operated under

continuous load (100 % load factor) at the maximum conductor temperature shown in Table 3,

the thermal resistivity of the soil surrounding the cable may, in the course of time, increase from

its original value as a result of drying-out processes. As a consequence, the conductor

temperature may greatly exceed the maximum value. If such operating conditions are foreseen,

adequate provisions shall be made.

For guidance on the short-circuit temperatures, reference shall be made to IEC 60724.

4.3 Sheathing compounds

The types of sheathing compound covered by this document are listed in Table 4, together with

their abbreviated designations.

The maximum conductor temperatures for the different types of sheathing compound covered

by this document are given in Table 4.

– 12 – IEC 60502-1:2021 © IEC 2021

Table 4 – Sheathing compounds and maximum conductor temperatures

for different types of sheathing compound

Maximum conductor

Abbreviated

temperature

designation

Sheathing compound

in normal operation

°C

a) Thermoplastic:

Polyvinyl chloride (PVC) ST 80

ST 90

Polyethylene ST 80

ST 90

Halogen free ST 90

b) Elastomeric:

Polychloroprene, chlorosulfonated polyethylene or SE 85

similar polymers

5 Conductors

The conductors shall be either of Class 1 or Class 2 of plain or metal-coated annealed copper

or of plain aluminium or aluminium alloy, or of Class 5 of plain or metal-coated copper in

accordance with IEC 60228.

6 Insulation

6.1 Material

The insulation shall be extruded dielectric of one of the types listed in Table 2.

For halogen free cables, the insulation shall also meet the requirements given in Table 23.

6.2 Insulation thickness

The nominal insulation thicknesses are specified in Table 5 to Table 7.

The thickness of any separator shall not be included in the thickness of the insulation.

Table 5 – Nominal thickness of PVC/A insulation

Nominal cross-sectional area of Nominal thickness of insulation at rated voltage

conductor

U / U (U )

0 m

0,6/1 (1,2) kV 1,8/3 (3,6) kV

mm mm

mm

1,5 and 2,5 0,8 –

4 and 6 1,0 –

10 and 16 1,0 2,2

25 and 35 1,2 2,2

50 and 70 1,4 2,2

95 and 120 1,6 2,2

150 1,8 2,2

185 2,0 2,2

240 2,2 2,2

300 2,4 2,4

400 2,6 2,6

500 to 800 2,8 2,8

1 000 3,0 3,0

Table 6 – Nominal thickness of cross-linked polyethylene (XLPE) insulation

Nominal cross-sectional area of Nominal thickness of insulation at rated voltage

conductor

U / U (U )

0 m

0,6/1 (1,2) kV 1,8/3 (3,6) kV

mm mm

mm

1,5 and 2,5 0,7 –

4 and 6 0,7 –

10 and 16 0,7 2,0

25 and 35 0,9 2,0

50 1,0 2,0

70 and 95 1,1 2,0

120 1,2 2,0

150 1,4 2,0

185 1,6 2,0

240 1,7 2,0

300 1,8 2,0

400 2,0 2,0

500 2,2 2,2

630 2,4 2,4

800 2,6 2,6

1 000 2,8 2,8

– 14 – IEC 60502-1:2021 © IEC 2021

Table 7 – Nominal thickness of ethylene propylene rubber (EPR)

and hard ethylene propylene rubber (HEPR) insulation

Nominal cross-sectional Nominal thickness of insulation at rated voltage

area of conductor

U / U (U )

0 m

0,6/1 (1,2) kV 1,8/3 (3,6) kV

EPR HEPR EPR HEPR

mm mm mm mm

mm

1,5 and 2,5 1,0 0,7 – –

4 and 6 1,0 0,7 – –

10 and 16 1,0 0,7 2,2 2,0

25 and 35 1,2 0,9 2,2 2,0

50 1,4 1,0 2,2 2,0

70 1,4 1,1 2,2 2,0

95 1,6 1,1 2,4 2,0

120 1,6 1,2 2,4 2,0

150 1,8 1,4 2,4 2,0

185 2,0 1,6 2,4 2,0

240 2,2 1,7 2,4 2,0

300 2,4 1,8 2,4 2,0

400 2,6 2,0 2,6 2,0

500 2,8 2,2 2,8 2,2

630 2,8 2,4 2,8 2,4

800 2,8 2,6 2,8 2,6

1 000 3,0 2,8 3,0 2,8

7 Assembly of multicore cables, inner coverings and fillers

7.1 General

The assembly of multicore cables depends on the rated voltage and whether a metallic layer is

applied to each core.

The following Subclauses 7.2 to 7.4 do not apply to assemblies of sheathed single-core cables.

7.2 Inner coverings and fillers

7.2.1 Construction

The inner coverings may be extruded or lapped.

For cables with circular cores, except cables with more than five cores, a lapped inner covering

shall be permitted only if the interstices between the cores are substantially filled.

A suitable binder is permitted before application of an extruded inner covering.

7.2.2 Material

The materials used for inner coverings and fillers shall be suitable for the operating temperature

of the cable and compatible with the insulating material.

For halogen free cables, the inner covering and fillers shall meet the requirements given in

Table 23.

7.2.3 Thickness of extruded inner covering

The approximate thickness of extruded inner coverings shall be derived from Table 8.

Table 8 – Thickness of extruded inner covering

Thickness of extruded inner covering

Fictitious diameter over laid-up cores

(approximate values)

Above Up to and including

mm mm mm

– 25 1,0

25 35 1,2

35 45 1,4

45 60 1,6

60 80 1,8

80 – 2,0

7.2.4 Thickness of lapped inner coverings

The approximate thickness of lapped inner coverings shall be 0,4 mm for fictitious diameters

over laid-up cores up to and including 40 mm and 0,6 mm for larger diameters.

7.3 Cables with rated voltage 0,6/1 (1,2) kV

7.3.1 General

Cables with a rated voltage of 0,6/1 (1,2) kV may have a metallic layer collectively surrounding

the cores.

NOTE The choice between cables having and cables not having a metallic layer depends upon national regulations

and installation requirements for the prevention of possible dangers from mechanical damage or direct electrical

contact.

7.3.2 Cables having a collective metal layer (see Clause 8)

Cables shall have an inner covering over the laid-up cores. The inner covering and fillers shall

comply with 7.2.

Metal tapes may, however, be applied directly over the assembled cores, omitting the inner

covering, provided that the nominal thickness of each tape does not exceed 0,3 mm and that

the completed cable complies with the special bending test specified in 18.18.

7.3.3 Cables having no collective metal layer (see Clause 8)

The inner covering may be omitted, provided the outer shape of the cable remains practically

circular and no adhesion occurs between cores and sheath.

The oversheath may penetrate into the interstices of the cores, except in the case of

thermoplastic oversheaths over circular cores exceeding 10 mm .

If, however, an inner covering is applied, its thickness need not comply with 7.2.3 or 7.2.4.

– 16 – IEC 60502-1:2021 © IEC 2021

7.4 Cables with rated voltage 1,8/3 (3,6) kV

7.4.1 General

Cables with a rated voltage of 1,8/3 (3,6) kV shall have a metal layer surrounding the cores

either individually or collectively.

7.4.2 Cables having only a collective metal layer (see Clause 8)

Cables shall have an inner covering over the laid-up cores. The inner covering and fillers shall

comply with 7.2 and shall be non-hygroscopic.

7.4.3 Cables having a metal layer over each individual core (see Clause 9)

The metal layers of the individual cores shall be in contact with each other.

Cables with an additional collective metal layer (see Clause 8) of the same material as the

underlying individual metal layers shall have an inner covering over the laid-up cores. The inner

covering and fillers shall comply with 7.2 and shall be non-hygroscopic.

When the underlying individual metal layers and the collective metal layer are of different

materials, they shall be separated by an extruded sheath of one of the materials specified

in 13.2. For lead-sheathed cables, the separation from the underlying individual metal layers

may be obtained by an inner covering in accordance with 7.2.

For cables having neither armour, nor concentric conductor, nor other collective metal layer

(see Clause 8), the inner covering may be omitted, provided the outer shape of the cable

remains practically circular. The oversheath may penetrate into the interstices of the cores,

except in the case of thermoplastic oversheaths over circular cores exceeding 10 mm . If,

however, an inner covering is applied, its thickness need not comply with 7.2.3 nor 7.2.4.

8 Metal layers for single-core and multicore cables

The following types of metal layers are included in this document:

a) metal screen (see Clause 9);

b) concentric conductor (see Clause 10);

c) lead sheath (see Clause 11);

d) metal armour (see Clause 12).

The metal layer(s) shall comprise one or more of the types listed above and shall be non-

magnetic when applied to either single-core cables or individual cores of multicore cables.

9 Metal screen

9.1 Construction

The metal screen shall consist of one or more tapes, or a braid, or a concentric layer of wires

or a combination of wires and tape(s).

It may also be a sheath or, in the case of a collective screen, an armour which complies with 9.2.

When choosing the material of the screen, special consideration shall be given to the possibility

of corrosion, not only for mechanical safety but also for electrical safety.

Gaps in the screen shall comply with national regulations and/or standards.

9.2 Requirements

The dimensional, physical and electrical requirements of the metal screen shall be determined

by national regulations and/or standards.

10 Concentric conductor

10.1 Construction

Gaps in the concentric conductor shall comply with national regulations and/or standards.

When choosing the material of the concentric conductor, special consideration shall be given

to the possibility of corrosion, not only for mechanical safety but also for electrical safety.

10.2 Requirements

The dimensional and physical requirements of the concentric conductor and its electrical

resistance shall be determined by national regulations and/or standards.

10.3 Application

When a concentric conductor is required, it shall be applied over the inner covering in the case

of multicore cables. In the case of single-core cables, it shall be applied either directly over the

insulation or over a suitable inner covering.

11 Metal sheath

The sheath shall consist of lead or lead alloy and shall be applied as a reasonably tight-fitting

seamless tube.

The nominal thickness shall be calculated using the following formula:

t = 0,03 D + 0,7

pb g

where

t is the nominal thickness of lead sheath, in millimetres;

pb

D is the fictitious diameter under the lead sheath, in millimetres (rounded to the first decimal

g

place in accordance with Annex B).

In all cases, the smallest nominal thickness shall be 1,2 mm. Calculated values shall be rounded

to the first decimal place (see Annex B).

12 Metal armour

12.1 Types of metal armour

The armour types covered by this document are as follows:

a) flat wire armour;

b) round wire armour;

c) double tape armour.

– 18 – IEC 60502-1:2021 © IEC 2021

NOTE For cables with a rated voltage of 0,6/1 (1,2) kV with conductor cross-sectional areas not exceeding 6 mm ,

galvanized steelwire braid armour can be provided by agreement between the manufacturer and the purchaser.

12.2 Materials

Round or flat wires shall be of galvanized steel, copper or tinned copper, aluminium or

aluminium alloy.

Tapes shall be of steel, galvanized steel, aluminium or aluminium alloy. Steel tapes shall be

hot- or cold-rolled of commercial quality.

In those cases where the steel armour wire layer is required to comply with a minimum

conductance, it is permissible to include sufficient copper or tinned copper wires in the armour

layer to ensure compliance.

When choosing the material of the armour, the possibility of corrosion shall be taken into

consideration, not only for mechanical safety, but also for electrical safety, especially when the

armour is used as a screen.

The armour of single-core cables for use on AC systems shall consist of non-magnetic material,

unless a special construction is chosen.

12.3 Application of armour

12.3.1 Single-core cables

In the case of single-core cables, an inner covering, extruded or lapped, of the thickness

specified in 7.2.3 or 7.2.4, shall be applied under the armour.

12.3.2 Multicore cables

In the case of multicore cables, the armour shall be applied on an inner covering complying with

7.2 except for special applications using metallic tapes, see 7.3.2.

12.3.3 Separation sheath

When the underlying metallic layer and the armour are of different materials, they shall be

separated by an extruded sheathing compound of one of the types listed in Table 4.

The sheathing compound type shall be suitable for the operation temperature in accordance

with Table 4.

For halogen free cables, the separation sheath (ST ) shall meet the requirements given in

Table 23.

When an armour is required for a lead-sheathed cable, it may be applied over a lapped bedding

in accordance with 12.3.4.

If a separation sheath is used, it shall be applied under the armour instead of, or in addition to,

the inner covering.

The nominal thickness of the separation sheath T expressed in millimetres shall be calculated

s

by the following formula:

T = 0,02 D + 0,6

s u

where D is the fictitious diameter under this sheath, in millimetres, calculated as described in

u

Annex A.

The value resulting from the formula shall be rounded off to the nearest 0,1 mm (see Annex B).

For cables without a lead sheath, the nominal thickness shall be not less than 1,2 mm. For

cables where the separation sheath is applied directly over the lead sheath, the nominal

thickness shall be not less than 1,0 mm.

12.3.4 Lapped bedding under armour for lead-sheathed cables

The lapped bedding applied to the compou

...

IEC 60502-1 ®

Edition 3.0 2021-02

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Power cables with extruded insulation and their accessories for rated voltages

from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV) –

Part 1: Cables for rated voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60502-1 ®

Edition 3.0 2021-02

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Power cables with extruded insulation and their accessories for rated voltages

from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV) –

Part 1: Cables for rated voltages of 1 kV (Um = 1,2 kV) and 3 kV (Um = 3,6 kV)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.060.20 ISBN 978-2-8322-9427-7

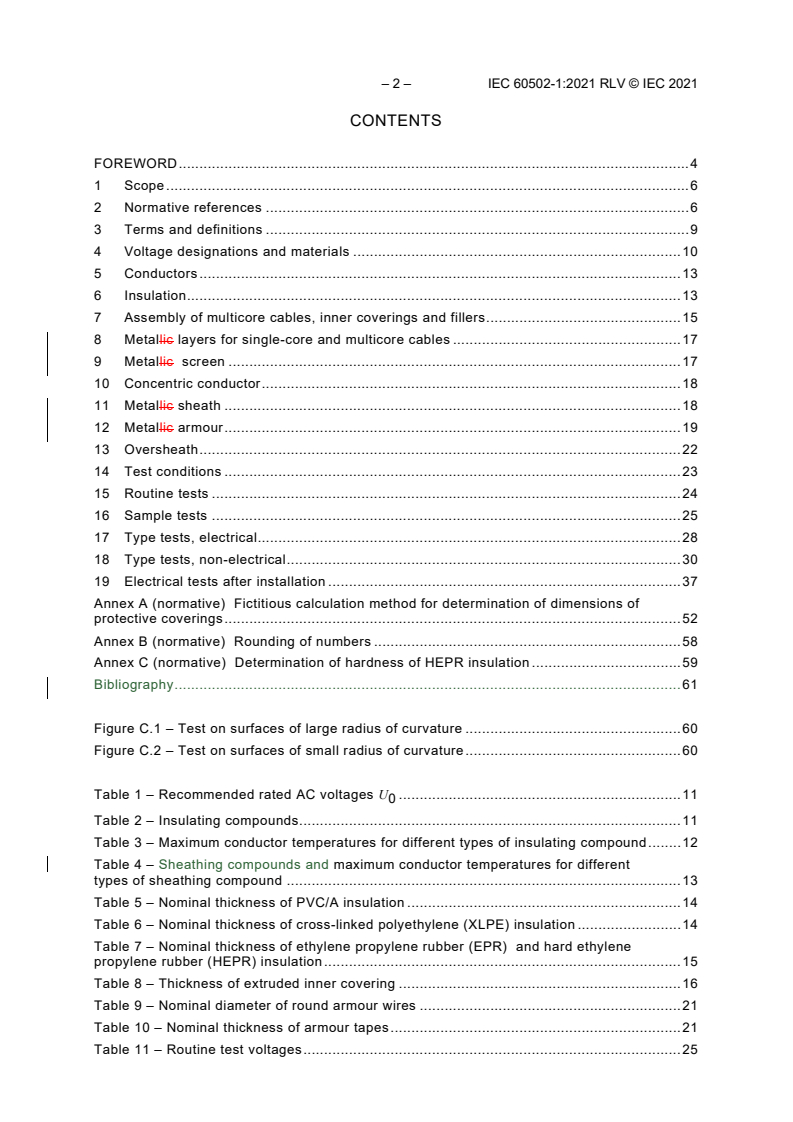

– 2 – IEC 60502-1:2021 RLV © IEC 2021

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 9

4 Voltage designations and materials . 10

5 Conductors . 13

6 Insulation . 13

7 Assembly of multicore cables, inner coverings and fillers . 15

8 Metallic layers for single-core and multicore cables . 17

9 Metallic screen . 17

10 Concentric conductor . 18

11 Metallic sheath . 18

12 Metallic armour . 19

13 Oversheath . 22

14 Test conditions . 23

15 Routine tests . 24

16 Sample tests . 25

17 Type tests, electrical. 28

18 Type tests, non-electrical . 30

19 Electrical tests after installation . 37

Annex A (normative) Fictitious calculation method for determination of dimensions of

protective coverings . 52

Annex B (normative) Rounding of numbers . 58

Annex C (normative) Determination of hardness of HEPR insulation . 59

Bibliography . 61

Figure C.1 – Test on surfaces of large radius of curvature . 60

Figure C.2 – Test on surfaces of small radius of curvature . 60

Table 1 – Recommended rated AC voltages U . 11

Table 2 – Insulating compounds . 11

Table 3 – Maximum conductor temperatures for different types of insulating compound . 12

Table 4 – Sheathing compounds and maximum conductor temperatures for different

types of sheathing compound . 13

Table 5 – Nominal thickness of PVC/A insulation . 14

Table 6 – Nominal thickness of cross-linked polyethylene (XLPE) insulation . 14

Table 7 – Nominal thickness of ethylene propylene rubber (EPR) and hard ethylene

propylene rubber (HEPR) insulation . 15

Table 8 – Thickness of extruded inner covering . 16

Table 9 – Nominal diameter of round armour wires . 21

Table 10 – Nominal thickness of armour tapes . 21

Table 11 – Routine test voltages . 25

Table 12 – Number of samples for sample tests . 26

Table 13 – Electrical type test requirements for insulating compounds . 38

Table 14 – Non-electrical type tests (see Tables 15 to 23) . 39

Table 15 – Test requirements for mechanical characteristics of insulating compounds

(before and after ageing) . 40

Table 16 – Test requirements for particular characteristics of PVC insulating

compounds . 41

Table 17 – Test requirements for particular characteristics of various cross-linked

insulating compounds . 43

Table 18 – Test requirements for mechanical characteristics of sheathing compounds

(before and after ageing) . 45

Table 19 – Test requirements for particular characteristics of PVC sheathing

compounds . 46

Table 20 – Test requirements for particular characteristics of thermoplastic PE

sheathing compounds . 48

Table 21 – Test requirements for particular characteristics of halogen free sheathing

compounds . 48

Table 22 – Test requirements for particular characteristics of elastomeric sheathing

compounds . 50

Table 23 – Test methods and requirements for halogen free compounds . 51

Table A.1 – Fictitious diameter of conductor . 53

Table A.2 – Assembly coefficient k for laid-up cores . 54

Table A.3 – Increase of diameter for concentric conductors and metal screens . 55

Table A.4 – Increase of diameter for additional bedding . 57

– 4 – IEC 60502-1:2021 RLV © IEC 2021

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

POWER CABLES WITH EXTRUDED INSULATION

AND THEIR ACCESSORIES FOR RATED VOLTAGES

FROM 1 kV (U = 1,2 kV) UP TO 30 kV (U = 36 kV) –

m m

Part 1: Cables for rated voltages of 1 kV

(U = 1,2 kV) and 3 kV (U = 3,6 kV)

m m

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes made to

the previous edition IEC 60502-1:2004+AMD1:2009 CSV. A vertical bar appears in the margin

wherever a change has been made. Additions are in green text, deletions are in strikethrough

red text.

IEC 60502-1 has been prepared by IEC technical committee 20: Electric cables. It is an

International Standard.

This third edition cancels and replaces the second edition published in 2004 and

Amendment 1:2009. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) references to IEC 60811 (all parts) have been updated and mechanical testing requirements

specific to halogen free low-smoke oversheath of material type ST have been considered;

b) the use of the types of sheathing material to be used is now clearly defined;

c) the applicability of cables for use in DC systems is now included in the scope;

d) items which were earlier marked as "under consideration" were studied either for an

appropriate solution if found available, or for removal for the time being.

The text of this International Standard is based on the following documents:

Draft Report on voting

20/1938/FDIS 20/1949/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 60502 series, published under the general title Power cables with

extruded insulation and their accessories for rated voltages from 1 kV (U = 1,2 kV) up to 30 kV

m

(U = 36 kV) can be found on the IEC website.

m

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

– 6 – IEC 60502-1:2021 RLV © IEC 2021

POWER CABLES WITH EXTRUDED INSULATION

AND THEIR ACCESSORIES FOR RATED VOLTAGES

FROM 1 kV (U = 1,2 kV) UP TO 30 kV (U = 36 kV) –

m m

Part 1: Cables for rated voltages of 1 kV

(U = 1,2 kV) and 3 kV (U = 3,6 kV)

m m

1 Scope

This part of IEC 60502 specifies the construction, dimensions and test requirements of power

cables with extruded solid insulation for rated AC voltages of 1 kV (U = 1,2 kV) and 3 kV

m

(U = 3,6 kV) for fixed installations such as distribution networks or industrial installations.

m

Cables of rated AC voltage 1 kV (U = 1,2 kV) designed and tested in accordance with this

m

document can also be used, if declared by the manufacturer, in DC distribution systems having

their nominal voltage ≤ 750 V DC (with a maximum of 900 V DC) between a live conductor and

neutral/earth, or ≤ 1 500 V DC (with a maximum 1 800 V DC) between two live conductors.

Applicable core identification for DC systems are considered in accordance with local

installation regulations.

NOTE 1 Recommendations for preferred core colours for line conductors in DC systems are given in IEC 60445.

However, local installation regulations for DC systems can already contain specific identification requirements.

This document includes cables which exhibit properties of reduced flame spread, low levels of

smoke emission and halogen-free gas emission when exposed to fire.

Cables for special installation and service conditions are not included, for example cables for

overhead networks, the mining industry, nuclear power plants (in and around the containment

area), submarine use or shipboard application, or cables directly connected to photovoltaic

systems.

NOTE 2 Cables for photovoltaic systems are covered by IEC 62930.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60038:1983, IEC standard voltages

IEC 60060-1:1989, High-voltage test techniques – Part 1: General definitions and test

requirements

IEC 60183:1984, Guidance for the selection of high-voltage A.C. cable systems

IEC 60228:1978, Conductors of insulated cables

IEC 60230:1966, Impulse tests on cables and their accessories

IEC 60332-1:1993, Tests on electric cables under fire conditions – Part 1: Test on a single

vertical insulated wire or cable

IEC 60332-1-2, Tests on electric and optical fibre cables under fire conditions – Part 1-2: Test

for vertical flame propagation for a single insulated wire or cable – Procedure for 1 kW

pre‑mixed flame

IEC 60332-3-24:2000, Tests on electric and optical cables under fire conditions – Part 3-24:

Test for vertical flame spread of vertically-mounted bunched wires or cables – Category C

IEC 60502-2:1997, Power cables with extruded insulation and their accessories for rated

voltages from 1 kV (U = 1,2 kV) up to 30 kV (U = 36 kV) – Part 2: Cables for rated voltages

m m

from 6 kV (U = 7,2 kV) up to 30 kV (U = 36 kV)

m m

IEC 60684-2:1987, Flexible insulating sleeving – Part 2: Methods of test

IEC 60724:2000, Short-circuit temperature limits of electric cables with rated voltages of 1 kV

(U = 1,2 kV) and 3 kV (U = 3,6 kV)

m m

IEC 60754-1:1994, Test on gases evolved during combustion of materials from cables – Part 1:

Determination of the amount of halogen acid gas content

IEC 60754-2:1991, Test on gases evolved during combustion of electric materials from cables

– Part 2: Determination of degree of acidity of gases evolved during the combustion of materials

taken from electric cables by measuring pH (by pH measurement) and conductivity

IEC 60811-1-1:1993, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section 1: Measurement of thickness and

overall dimensions – Tests for determining the mechanical properties

IEC 60811-1-2:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section 2: Thermal ageing methods

IEC 60811-1-3:1993, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section 3: Methods for determining the

density – Water absorption tests – Shrinkage test

IEC 60811-1-4:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section 4: Tests at low temperature

IEC 60811-2-1:1998, Insulating and sheathing materials of electric and optical cables –

Common test methods – Part 2-1: Methods specific to elastomeric compounds – Ozone

resistance, hot set and mineral oil immersion tests

IEC 60811-3-1:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 3: Methods specific to PVC compounds – Section 1: Pressure test at high

temperature – Tests for resistance to cracking

IEC 60811-3-2:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 3: Methods specific to PVC compounds – Section 2: Loss of mass test – Thermal

stability test

IEC 60811-4-1:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 4: Methods specific to polyethylene and polypropylene compounds – Section 1:

Resistance to environmental stress cracking – Wrapping test after thermal ageing in air –

Measurement of the melt flow index – Carbon black and/or mineral content measurement in PE

– 8 – IEC 60502-1:2021 RLV © IEC 2021

IEC 61034-2: 1997, Measurement of smoke density of cables burning under defined conditions –

Part 2: Test procedure and requirements

ISO 48:1994, Rubber, vulcanized or thermoplastic – Determination of hardness (hardness

between 10 IRHD and 100 IRHD)

IEC 60811-201, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 201: General tests – Measurement of insulation thickness

IEC 60811-202, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 202: General tests – Measurement of thickness of non-metallic sheath

IEC 60811-203, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 203: General tests – Measurement of overall dimensions

IEC 60811-401, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 401: Miscellaneous tests – Thermal ageing methods – Ageing in an air oven

IEC 60811-402, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 402: Miscellaneous tests – Water absorption tests

IEC 60811-403, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 403: Miscellaneous tests – Ozone resistance test on cross-linked compounds

IEC 60811-404, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 404: Miscellaneous tests – Mineral oil immersion tests for sheaths

IEC 60811-409, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 409: Miscellaneous tests – Loss of mass test for thermoplastic insulations and sheaths

IEC 60811-501, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 501: Mechanical tests – Tests for determining the mechanical properties of insulating and

sheathing compounds

IEC 60811-502, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 502: Mechanical tests – Shrinkage test for insulations

IEC 60811-503, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 503: Mechanical tests – Shrinkage test for sheaths

IEC 60811-504, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 504: Mechanical tests – Bending tests at low temperature for insulations and sheaths

IEC 60811-505, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 505: Mechanical tests – Elongation at low temperature for insulations and sheaths

IEC 60811-506, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 506: Mechanical tests – Impact test at low temperature for insulations and sheaths

IEC 60811-507, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 507: Mechanical tests – Hot set test for cross-linked materials

IEC 60811-508, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 508: Mechanical tests – Pressure test at high temperature for insulation and sheaths

IEC 60811-509, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 509: Mechanical tests – Test for resistance of insulations and sheaths to cracking (heat

shock test)

IEC 60811-605, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 605: Physical tests – Measurement of carbon black and/or mineral filler in polyethylene

compounds

IEC 60811-606, Electric and optical fibre cables –Test methods for non-metallic materials –

Part 606: Physical tests – Methods for determining the density

IEC 61034-2, Measurement of smoke density of cables burning under defined conditions –

Part 2: Test procedure and requirements

IEC 62230, Electric cables – Spark-test method

ISO 48-2:2018, Rubber, vulcanized or thermoplastic – Determination of hardness – Part 2:

Hardness between 10 IRHD and 100 IRHD

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1 Definitions of dimensional values (thicknesses, cross-sections, etc.)

3.1.1

nominal value

value by which a quantity is designated and which is often used in tables

Note 1 to entry: Usually, in this document, nominal values give rise to values to be checked by measurements

taking into account specified tolerances.

3.1.2

approximate value

value which is neither guaranteed nor checked but is used, for example, for the calculation of

other dimensional values

3.1.3

median value

when several test results have been obtained and ordered in an increasing (or decreasing)

succession, middle value if the number of available values is odd, and mean of the two middle

values if the number is even

3.1.4

fictitious value

value calculated in accordance with the "fictitious method'' described in Annex A

– 10 – IEC 60502-1:2021 RLV © IEC 2021

3.2 Definitions relating to tests

3.2.1

routine test

test made by the manufacturer on each manufactured length of cable to check that each length

meets the specified requirements

3.2.2

sample test

test made by the manufacturer on samples of completed cable or components taken from a

completed cable, at a specified frequency, so as to verify that the finished product meets the

specified requirements

3.2.3

type test

test made before supplying, on a general commercial basis, a type of cable covered by this

document, in order to demonstrate satisfactory performance characteristics to meet the

intended application

Note 1 to entry: These Type tests are of such a nature that, after they have been made, they need not be repeated,

unless changes are made in the cable materials or design or manufacturing process which might change the

performance characteristics.

3.2.4

electrical test after installation

test made to demonstrate the integrity of the cable and its accessories as installed

4 Voltage designations and materials

4.1 Rated voltages

4.1.1 Rated AC voltages

The rated AC voltages U /U (U ) of the cables considered in this document are 0,6/1 (1,2) kV

0 m

and 1,8/3 (3,6) kV.

NOTE 1 The voltages given above are the correct designations although in some countries other designations are

used, e.g. 1,7/3 kV or 1,9/3,3 kV instead of 1,8/3 kV.

For the voltage designation of cables U /U (U ), the definitions in IEC 60183 apply i.e.:

0 m

U is the rated RMS power frequency voltage between conductor and earth or metallic screen

for which the cable is designed;

U is the rated RMS power frequency voltage between conductors for which the cable is

designed;

U is the maximum value of the "highest system voltage'' for which the equipment may be

m

used (see IEC 60038) RMS power frequency voltage between conductors for which the

cable is designed.

NOTE 2 U is the highest voltage that can be sustained under normal operating conditions at any time and at any

m

point in a system and excludes temporary voltage variations due to fault conditions and sudden disconnection of

large loads.

The rated voltage of the cable for a given application shall be suitable for the operating

conditions in the system in which the cable is used. To facilitate the selection of the cable,

systems are divided into three categories according to the duration of time the system can be

operated under earth fault conditions (see IEC 60183):

– Category A: this category comprises those systems in which any phase conductor that

comes in contact with earth or an earth conductor is disconnected from the

system within 1 min.

– Category B: this category comprises those systems which, under fault conditions, are

operated for a short time with one phase earthed. This period, in

accordance with IEC 60183, should, in general, not exceed 1 h. For cables

covered by this document, a longer period, not exceeding 8 h on any

occasion, can be tolerated. The total duration of earth faults in any year

should not exceed 125 h.

– Category C: this category comprises all systems which do not fall into category A or B.

NOTE 3 It should be realized that In a system where an earth fault is not automatically and promptly isolated, the

extra stresses on the insulation of cables during the earth fault reduce the life of the cables to a certain degree. If

the system is expected to be operated fairly often with a permanent earth fault, it may can be advisable to classify

the system in Category C.

The values of U recommended for cables to be used in three-phase systems are listed in

Table 1.

Table 1 – Recommended rated AC voltages U

Highest system voltage Rated voltage (U )

(U )

m

kV kV

Categories A and B Category C

1,2 0,6 0,6

a

3,6 1,8

3,6

a

This category is covered by 3,6/6 (7,2) kV cables in accordance with

IEC 60502‑2.

4.1.2 Rated DC voltages

Under consideration.

4.2 Insulating compounds

The types of insulating compound covered by this document are listed in Table 2, together with