IEC TS 60695-6-31:2013

(Main)Fire hazard testing - Part 6-31: Smoke obscuration - Small-scale static test - Materials

Fire hazard testing - Part 6-31: Smoke obscuration - Small-scale static test - Materials

IEC/TS 60695-6-31:2013 describes the test methods for the determination of the specific optical density of smoke produced by materials used in electrotechnical products using the apparatus described in technical specification IEC/TS 60695-6-30. Test specimens are exposed vertically to a radiant heat source with or without the application of a pilot flame in a closed chamber (i.e. without air-change). The test methods are only applicable to flat, solid, non-metallic test specimens of materials used in electrotechnical products. This technical specification does not provide a classification system for the behaviour of materials. The test methods are not applicable to materials which melt and flow away from the direct impingement of heat flux. The test methods are not recommended for further development for electrotechnical products, nor are they recommended as the basis for regulation or other controls on smoke release due to the limitations of the physical fire model and the test specimen geometry - see Clause 4. This second edition cancels and replaces the first edition published in 1999. It constitutes a technical revision. The main changes with respect to the previous edition are:

- the Foreword has been revised and updated,

- the Introduction has been updated,

- the Scope has been updated

- the Normative references have been updated,

- minor technical changes have been made throughout the document, and

- detailed editorial updates have been added throughout the document. It has the status of a basic safety publication in accordance with IEC Guide 104 and ISO/IEC Guide 51. Keywords: Fire Hazard testing, Smoke obscuration.

This publication is to be read in conjunction with IEC 60695-6-30:1996.

Essais relatifs aux risques du feu - Partie 6-31: Opacité des fumées - Méthode statique à petite échelle - Matériaux

La CEI/TS 60695-6-31:2013 décrit les méthodes d'essai permettant de déterminer la densité optique spécifique des fumées produites par les matériaux utilisés dans la fabrication de produits électrotechniques, à l'aide de l'appareillage décrit dans la spécification technique CEI 60695-6-30. Les éprouvettes sont exposées verticalement à un rayonnement thermique avec ou sans application de flammes pilotes dans une enceinte fermée (c'est-à-dire en atmosphère non renouvelée). Ces méthodes d'essai sont applicables uniquement aux éprouvettes de matériaux solides, non métalliques, plans, utilisés dans les produits électrotechniques. La présente spécification technique ne fournit pas de système de classification du comportement des matériaux. Ces méthodes d'essai ne sont pas applicables aux matériaux qui fondent ou qui fluent en dehors de la zone du flux thermique. Il n'est pas recommandé d'utiliser ces méthodes d'essai pour le développement de produits électrotechniques, ni pour servir de base à une réglementation ou à d'autres types de contrôle relatifs au dégagement de fumée, en raison des limites du modèle feu physique et de la géométrie des éprouvettes - voir Article 4. Cette deuxième édition annule et remplace la première édition parue en 1999. Elle constitue une révision technique. Les principales modifications par rapport à l'édition précédente sont:

- L'avant-propos a été révisé et mis à jour,

- l'Introduction a été mise à jour,

- le Domaine d'application et les Références normatives ont été mises à jour,

- des modifications techniques mineures ont été effectuées dans tout le document et

- des mises à jour éditoriales détaillées ont été ajoutées dans tout le document. Elle a le statut d'une publication fondamentale de sécurité conformément au Guide CEI 104 et au Guide ISO/CEI 51. Mots-clés: Essais relatifs aux risques du feu, Opacité des fumées

This publication is to be read in conjunction with IEC 60695-6-30:1996.

General Information

- Status

- Withdrawn

- Publication Date

- 21-Feb-2013

- Withdrawal Date

- 27-Jan-2016

- Technical Committee

- TC 89 - Fire hazard testing

- Drafting Committee

- WG 11 - TC 89/WG 11

- Current Stage

- WPUB - Publication withdrawn

- Start Date

- 10-Jul-2015

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

NSF International

Global independent organization facilitating standards development and certification.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC TS 60695-6-31:2013 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Fire hazard testing - Part 6-31: Smoke obscuration - Small-scale static test - Materials". This standard covers: IEC/TS 60695-6-31:2013 describes the test methods for the determination of the specific optical density of smoke produced by materials used in electrotechnical products using the apparatus described in technical specification IEC/TS 60695-6-30. Test specimens are exposed vertically to a radiant heat source with or without the application of a pilot flame in a closed chamber (i.e. without air-change). The test methods are only applicable to flat, solid, non-metallic test specimens of materials used in electrotechnical products. This technical specification does not provide a classification system for the behaviour of materials. The test methods are not applicable to materials which melt and flow away from the direct impingement of heat flux. The test methods are not recommended for further development for electrotechnical products, nor are they recommended as the basis for regulation or other controls on smoke release due to the limitations of the physical fire model and the test specimen geometry - see Clause 4. This second edition cancels and replaces the first edition published in 1999. It constitutes a technical revision. The main changes with respect to the previous edition are: - the Foreword has been revised and updated, - the Introduction has been updated, - the Scope has been updated - the Normative references have been updated, - minor technical changes have been made throughout the document, and - detailed editorial updates have been added throughout the document. It has the status of a basic safety publication in accordance with IEC Guide 104 and ISO/IEC Guide 51. Keywords: Fire Hazard testing, Smoke obscuration. This publication is to be read in conjunction with IEC 60695-6-30:1996.

IEC/TS 60695-6-31:2013 describes the test methods for the determination of the specific optical density of smoke produced by materials used in electrotechnical products using the apparatus described in technical specification IEC/TS 60695-6-30. Test specimens are exposed vertically to a radiant heat source with or without the application of a pilot flame in a closed chamber (i.e. without air-change). The test methods are only applicable to flat, solid, non-metallic test specimens of materials used in electrotechnical products. This technical specification does not provide a classification system for the behaviour of materials. The test methods are not applicable to materials which melt and flow away from the direct impingement of heat flux. The test methods are not recommended for further development for electrotechnical products, nor are they recommended as the basis for regulation or other controls on smoke release due to the limitations of the physical fire model and the test specimen geometry - see Clause 4. This second edition cancels and replaces the first edition published in 1999. It constitutes a technical revision. The main changes with respect to the previous edition are: - the Foreword has been revised and updated, - the Introduction has been updated, - the Scope has been updated - the Normative references have been updated, - minor technical changes have been made throughout the document, and - detailed editorial updates have been added throughout the document. It has the status of a basic safety publication in accordance with IEC Guide 104 and ISO/IEC Guide 51. Keywords: Fire Hazard testing, Smoke obscuration. This publication is to be read in conjunction with IEC 60695-6-30:1996.

IEC TS 60695-6-31:2013 is classified under the following ICS (International Classification for Standards) categories: 13.220.99 - Other standards related to protection against fire; 29.020 - Electrical engineering in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 60695-6-31:2013 has the following relationships with other standards: It is inter standard links to IEC TS 60695-6-31:1999. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TS 60695-6-31:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC/TS 60695-6-31 ®

Edition 2.0 2013-02

TECHNICAL

SPECIFICATION

SPÉCIFICATION

TECHNIQUE

BASIC SAFETY PUBLICATION

PUBLICATION FONDAMENTALE DE SÉCURITÉ

Fire hazard testing –

Part 6-31: Smoke obscuration – Small-scale static test – Materials

Essais relatifs aux risques du feu –

Partie 6-31: Opacité des fumées – Méthode statique à petite échelle – Matériaux

IEC/TS 60695-6-31:2013

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC/TS 60695-6-31 ®

Edition 2.0 2013-02

TECHNICAL

SPECIFICATION

SPÉCIFICATION

TECHNIQUE

BASIC SAFETY PUBLICATION

PUBLICATION FONDAMENTALE DE SÉCURITÉ

Fire hazard testing –

Part 6-31: Smoke obscuration – Small-scale static test – Materials

Essais relatifs aux risques du feu –

Partie 6-31: Opacité des fumées – Méthode statique à petite échelle – Matériaux

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX R

ICS 13.220.99; 29.020 ISBN 978-2-83220-671-3

– 2 – TS 60695-6-31 © IEC:2013

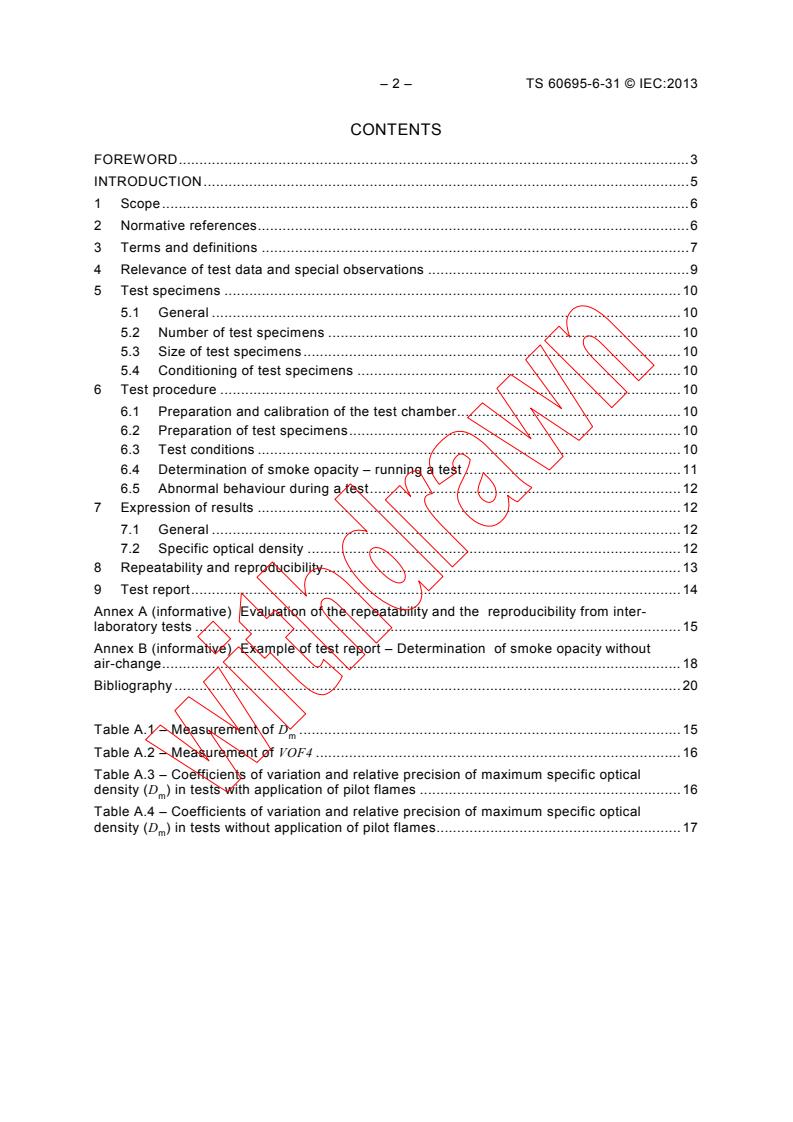

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Relevance of test data and special observations . 9

5 Test specimens . 10

5.1 General . 10

5.2 Number of test specimens . 10

5.3 Size of test specimens . 10

5.4 Conditioning of test specimens . 10

6 Test procedure . 10

6.1 Preparation and calibration of the test chamber . 10

6.2 Preparation of test specimens . 10

6.3 Test conditions . 10

6.4 Determination of smoke opacity – running a test . 11

6.5 Abnormal behaviour during a test . 12

7 Expression of results . 12

7.1 General . 12

7.2 Specific optical density . 12

8 Repeatability and reproducibility . 13

9 Test report . 14

Annex A (informative) Evaluation of the repeatability and the reproducibility from inter-

laboratory tests . 15

Annex B (informative) Example of test report – Determination of smoke opacity without

air-change . 18

Bibliography . 20

............................................................................................ 15

Table A.1 – Measurement of D

m

Table A.2 – Measurement of VOF4 . 16

Table A.3 – Coefficients of variation and relative precision of maximum specific optical

) in tests with application of pilot flames . 16

density (D

m

Table A.4 – Coefficients of variation and relative precision of maximum specific optical

density (D ) in tests without application of pilot flames. 17

m

TS 60695-6-31 © IEC:2013 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FIRE HAZARD TESTING –

Part 6-31: Smoke obscuration –

Small-scale static test – Materials

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a technical

specification when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC 60695-6-31, which is a technical specification, has been prepared by IEC technical

committee 89: Fire hazard testing.

– 4 – TS 60695-6-31 © IEC:2013

The text of this technical specification is based on the following documents:

Enquiry draft Report on voting

89/1055/DTS 89/1093/RVC

Full information on the voting for the approval of this technical specification can be found in the

report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

This second edition of IEC/TS 60695-6-31 cancels and replaces the first edition published in

1999. It constitutes a technical revision.

It has the status of a basic safety publication in accordance with IEC Guide 104 and ISO/IEC

Guide 51.

This technical specification is to be used in conjunction with IEC/TS 60695-6-30.

The main changes with respect to the previous edition are listed below:

– The Foreword has been revised and updated.

– The Introduction has been updated.

– The Scope has been updated.

– The Normative references have been updated.

– Minor technical changes have been made throughout the document.

– Detailed editorial updates have been added throughout the document.

A list of all parts of the IEC 60695 series, under the general title Fire hazard testing, can be

found on the IEC website.

Part 6 consists of the following parts:

Part 6-1: Smoke obscuration – General guidance

Part 6-2: Smoke obscuration – Summary and relevance of test methods

Part 6-30: Smoke obscuration – Small scale static method – Apparatus

Part 6-31: Smoke obscuration – Small-scale static test – Materials

The committee has decided that the contents of this publication will remain unchanged until the

stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data related to

the specific publication. At this date, the publication will be

• transformed into an International Standard,

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

TS 60695-6-31 © IEC:2013 – 5 –

INTRODUCTION

The risk of fire needs to be considered in any electrical circuit, and the objective of component,

circuit and equipment design, and the choice of materials, is to reduce the likelihood of fire,

even in the event of foreseeable abnormal use, malfunction or failure.

Electrotechnical products, primarily as victims of fire, may nevertheless contribute to the fire.

One of the contributing hazards is the release of smoke, which may cause a reduction of

visibility and/or orientation which could impede escape from the building, or could impede fire

fighting.

Consequently, a reduction in the amount and the rate of generation of smoke produced by

materials/products during a fire reduces damage to equipment, facilitates evacuation of people

and facilitates the intervention of emergency services.

– 6 – TS 60695-6-31 © IEC:2013

FIRE HAZARD TESTING –

Part 6-31: Smoke obscuration –

Small-scale static test – Materials

1 Scope

This part of IEC 60695 describes the test methods for the determination of the specific optical

density of smoke produced by materials used in electrotechnical products using the apparatus

described in technical specification IEC/TS 60695-6-30. Test specimens are exposed vertically

to a radiant heat source with or without the application of a pilot flame in a closed chamber (i.e.

without air-change).

The test methods are only applicable to flat, solid, non-metallic test specimens of materials

used in electrotechnical products.

This technical specification does not provide a classification system for the behaviour of

materials.

The test methods are not applicable to materials which melt and flow away from the direct

impingement of heat flux.

The test methods are not recommended for further development for electrotechnical products,

nor are they recommended as the basis for regulation or other controls on smoke release due

to the limitations of the physical fire model and the test specimen geometry – see Clause 4.

WARNING: Appropriate safety measures are to be taken as toxic and harmful fire

effluents may be produced by pyrolysis or combustion of test specimens.

This basic safety publication is intended for use by technical committees in the preparation of

standards in accordance with the principles laid down in IEC Guide 104 and ISO/IEC Guide 51.

One of the responsibilities of a technical committee is, wherever applicable, to make use of

basic safety publications in the preparation of its publications. The requirements, test methods

or test conditions of this basic safety publication will not apply unless specifically referred to or

included in the relevant publications.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments)

applies.

IEC 60695-6-1, Fire hazard testing – Part 6-1: Smoke obscuration – General guidance

IEC/TS 60695-6-30:2012, Fire hazard testing – Part 6: Guidance and test methods on the

assessment of obscuration hazards of vision caused by smoke opacity from electrotechnical

products involved in fires – Section 30: Small scale static method. Determination of smoke

opacity. Description of the apparatus

IEC Guide 104:2010, The preparation of safety publications and the use of basic safety

publications and group safety publications

TS 60695-6-31 © IEC:2013 – 7 –

ISO 5659-2:2012, Plastics – Smoke generation – Part 2: Determination of optical density by a

single-chamber test

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply:

3.1

fire effluent

totality of gases and aerosols, including suspended particles, created by combustion or

pyrolysis in a fire

[SOURCE: ISO/IEC 13943, definition 4.105]

3.2

fire hazard assessment

evaluation of the possible causes of fire, the possibility and nature of subsequent fire growth,

and the possible consequences of fire

3.3

fire-safety engineering

application of engineering methods based on scientific principles to the development or

assessment of designs in the built environment through the analysis of specific fire scenarios

or through the quantification of risk for a group of fire scenarios

[SOURCE: ISO/IEC 13943:2008, definition 4.126]

3.4

fire scenario

qualitative description of the course of a fire with respect to time, identifying key events that

characterise the studied fire and differentiate it from other possible fires

Note 1 to entry: It typically defines the ignition and fire growth processes, the fully developed fire stage, the fire

decay stage, and the environment and systems that impact on the course of the fire.

[SOURCE: ISO/IEC 13943:2008, definition 4.129]

3.5

heat flux

amount of thermal energy emitted, transmitted or received per unit area and per unit time

–2

Note 1 to entry: The typical units are watts per square metre (W × m ).

[SOURCE: ISO/IEC 13943:2008, definition 4.173]

3.6

obscuration of smoke

reduction in the intensity of light due to its passage through smoke

Note 1 to entry: In practice, obscuration of smoke is usually measured as the transmittance, which is normally

expressed as a percentage.

Note 2 to entry: Obscuration of smoke causes a reduction in visibility.

[SOURCE: ISO/IEC 13943:2008, definition 4.242]

– 8 – TS 60695-6-31 © IEC:2013

3.7

opacity of smoke

ratio of incident light intensity to transmitted light intensity through smoke, under specified

conditions

Note 1 to entry: Opacity of smoke is the reciprocal of transmittance.

Note 2 to entry: The opacity of smoke is dimensionless.

[SOURCE: ISO/IEC 13943:2008, definition 4.243]

3.8

optical density of smoke

measure of the attenuation of a light beam passing through smoke expressed as the logarithm

to the base 10 of the opacity of smoke

cf. specific optical density, D (3.13)

s

Note 1 to entry: The optical density of smoke is dimensionless.

[SOURCE: ISO/IEC 13943:2008, definition 4.244]

3.9

physical fire model

laboratory process, including the apparatus, the environment and the fire test procedure

intended to represent a certain phase of a fire

[SOURCE: ISO/IEC 13943:2008, definition 4.251]

3.10

real-scale fire test

fire test that simulates a given application, taking into account the real scale, the real way the

item is installed and used, and the environment

Note 1 to entry: Such a fire test normally assumes that the products are used in accordance with the conditions

laid down by the specifier and/or in accordance with normal practice.

[SOURCE: ISO/IEC 13943:2008, definition 4.273]

3.11

small-scale fire test

fire test performed on a test specimen of small dimensions

Note 1 to entry: A fire test performed on a test specimen of which the maximum dimension is less than 1 m is

usually called a small-scale fire test.

[SOURCE: ISO/IEC 13943:2008, definition 4.292]

3.12

smoke

visible part of fire effluent

[SOURCE: ISO/IEC 13943:2008, definition 4.293]

3.13

specific optical density, D

s

optical density of smoke multiplied by a geometric factor, plus a filter factor

Note 1 to entry: The geometric factor is V /(A × L), where V is the volume of the test chamber, A is the area of the

exposed surface of the test specimen, and L is the light path length.

TS 60695-6-31 © IEC:2013 – 9 –

Note 2 to entry: The use of the term “specific” does not denote “per unit mass” but rather denotes a quantity

associated with a particular test apparatus and area of the exposed surface of the test specimen.

Note 3 to entry: The filter factor is a number which is calculated from the optical density of a moveable neutral

density filter (see 7.2).

Note 4 to entry: The specific optical density of smoke is dimensionless.

3.14

transmittance

〈smoke〉 ratio of transmitted light intensity through smoke to incident light intensity, under

specified conditions

cf. obscuration of smoke (3.6)

Note 1 to entry: Transmittance through smoke is the reciprocal of opacity of smoke.

Note 2 to entry: It is dimensionless and is usually expressed as a percentage.

[SOURCE: ISO/IEC 13943:2008 definition 4.346]

4 Relevance of test data and special observations

This small-scale fire test apparatus has been in worldwide use since about 1970, primarily for

material evaluation purposes. In the early 1990s, ISO/TC61 developed a similar apparatus that

was designed, in part, to overcome a number of limitations of the IEC apparatus, and in 1994

the first edition of ISO 5659-2 was published. It is now recognised that ISO 5659-2 overcomes

the following significant limitations:

a) The heat flux is relatively low; consequently the method is only able to replicate conditions

found in ISO 19706 fire stage 1b and, possibly, fire stage 2.

b) The test specimen is vertically mounted, which excludes liquids and some thermoplastics.

Test specimens which swell towards the furnace also give problems, as the incident heat

flux experienced by the front of the test specimen increases significantly, and the pilot

flames can be extinguished, rendering the test invalid.

c) The limitations of the low heat flux and test specimen geometry mean that it is difficult to

establish a link between data from the apparatus and real fire scenarios.

d) There are no means of monitoring the test specimen mass during the test

Further limitations include the following:

e) There is little or no correlation between data from this apparatus, and the behaviour of

products in fires or real-scale fire tests.

f) The air supply is limited and the test specimen ceases to burn if the oxygen concentration

falls below approximately 14 %.

g) The deposition of smoke on the walls is significant.

The test methods do however offer the useful option to evaluate smoke production from both

flaming and non-flaming combustion, albeit at a low heat flux.

The data generated are not suitable for use as input to fire hazard assessment or for fire safety

engineering.

Overall, these test methods are not recommended for further development for electrotechnical

products. Neither are they recommended as the basis for regulation or other controls on smoke

release for electrotechnical products, due to the limitations of the physical fire model and the

test specimen geometry.

– 10 – TS 60695-6-31 © IEC:2013

5 Test specimens

5.1 General

These test methods are sensitive to small variations in geometry, surface orientation,

thickness, mass, composition and method of preparation; results obtained by these test

methods are therefore dependent on the above parameters.

5.2 Number of test specimens

For each test on a given material, at least three test specimens shall be tested under the same

conditions.

Under certain circumstances, it may be necessary to test three additional test specimens

(see 6.5).

5.3 Size of test specimens

This method is applicable only to essentially flat solid materials.

+0,2

The test specimens shall be square with sides 76 mm. The thickness shall be a maximum

−0,6

of 25,4 mm and, when practicable, shall be that of the end-use application of the material.

For comparative testing, materials shall be tested at the same thickness as there is no known

correlation between the specific optical density and thickness.

5.4 Conditioning of test specimens

Before the test, the test specimens shall be conditioned for at least 24 h at 23 °C ± 3 °C and at

a relative humidity of 50 % ± 10 %. The test specimen shall be tested within 30 min of being

conditioned.

6 Test procedure

6.1 Preparation and calibration of the test chamber

Preparation and calibration of the test chamber shall be carried out as described in Clause 7 of

IEC/TS 60695-6-30:2012.

6.2 Preparation of test specimens

Each test specimen shall be wrapped in a single layer of aluminium foil (about 0,04 mm thick),

with the bright face outside, taking care to avoid unnecessary wrinkles or perforations.

It is then mounted in the test specimen holder ensuring that it is retained close against the front

window by a backing board, rod and a spring arrangement behind the test specimen.

Excess aluminium foil along the side and top edges should be trimmed off after mounting. The

excess foil on the bottom edge shall be folded in such a way as to minimize losses of any

melted material at the bottom of the holder.

6.3 Test conditions

The test specimen is exposed to the radiant heat flux emitted by the furnace. The average heat

2 2

flux at the surface of the test specimen shall be 25 kW/m ± 0,5 kW/m .

TS 60695-6-31 © IEC:2013 – 11 –

In the test with the pilot flame, in addition to the radiant heat flux, the test specimen is exposed

to a multi-flame burner fed with a mixture of air and propane (air: 0,5 l/min; propane:

0,05 l/min).

The test chamber shall be located in a room or enclosed space having an ambient temperature

of 23 °C ± 3 °C and relative humidity of approximately 50 % at the time of test. Precautions

shall be taken to provide a means for removing potentially hazardous gases from the area of

operation.

Caution shall be exercised during use of the apparatus to prevent explosion of pyrolyzates,

particularly under conditions without application of pilot flames, and exposure of the operator to

smoke, particularly during removal of the sample from the chamber or during clean-up.

The chamber walls shall be cleaned whenever periodic visual inspection indicates the need.

Before each test, the exposed surfaces of the glass windows separating the photo detector and

light source housing from the interior of the chamber shall be cleaned (ethyl alcohol is

generally effective). Charred residues on the test specimen holder should be removed between

tests to avoid contamination.

During the warm-up period all electric systems (furnace, light source, photometer, etc.) should

be on, the exhaust vent and chamber door closed, and the inlet vent open. When the

temperature on the centre surface of the back wall reaches a steady-state value in the range of

33 °C ± 4 °C, the chamber is ready for furnace calibrating or testing.

The blank test specimen holder should always be directly in front of the furnace, except when

displaced to the side by the test specimen holder during a test, or by the radiometer during

calibration. It should be returned immediately to this position when testing or calibration is

completed to prevent excessive heating of the adjacent wall surface.

The calibration is performed according to the procedure described in Clause 7 of

IEC/TS 60695-6-30:2012.

For exposures without application of pilot flames, remove the multi-flame burner; for exposures

with application of pilot flames, position the burner across the lower edge of the test specimen

as described in 6.4 of IEC/TS 60695-6-30:2012.

Before positioning the test specimen, flush the chamber with the door and exhaust and inlet

vents open for about 2 min, and verify the starting temperature of the chamber.

6.4 Determination of smoke opacity – running a test

Stop the exhaust extractor, close the exhaust vent and place the specimen holder containing

the test specimen on the retaining rods, adjacent to the blank test specimen holder.

Slide the test specimen holder along the retaining rods, displacing the blank test specimen

holder, such that the test specimen is positioned centrally in front of the furnace.

Close the door, and start the data recorder and stopwatch. When the data recorder shows a

reduction in transmittance from 100 %, close the inlet vent.

Throughout the test monitor, and, where appropriate, adjust the following:

– The furnace voltage, to maintain it at the level established during calibration (see 6.3).

– The reading on the potentiometer scale, and adjust the range setting so that readings are

always between 10 % and 100 %. If the transmittance falls below 0,01 %, the neutral

density filter shall be removed and the range setting adjusted to 10 times greater. To avoid

spurious results from ambient light, the chamber door shall be blacked out at range settings

below 0,01 %.

– 12 – TS 60695-6-31 © IEC:2013

– The internal pressure in the chamber, as indicated by the manometer. If the pressure

exceeds 150 mm of water (which may occur during or after rapid burning) briefly open the

exhaust vent, and, if the pressure falls below 0 mm of water, briefly open the inlet vent.

– The flow-rates of air and propane to the pilot burner (if used).

– The behaviour of the test specimen.

The end of the test is reached either 3 min after minimum transmittance has occurred, or after

20 min, whichever is sooner.

NOTE Tests may be continued for longer than 20 min if required, but if so, this shall be reported on the test report.

At the end of test, slide the sample holder away from the front of the furnace, extinguish the

pilot flames (if used), replace the blank holder in position, turn on the exhaust fan and open the

exhaust and inlet vents.

Continue evacuating the smoke until a maximum value of transmittance (T ) is recorded.

c

6.5 Abnormal behaviour during a test

Some test specimens can exhibit abnormal behaviour during testing, which may result in the

test results being invalid.

The following types of behaviour are regarded as abnormal:

– collapse of the test specimen from the sample holder, or other movement of the test

specimen out of the calibrated radiation zone;

– self-ignition of the test specimen during a test without application of pilot flames;

– flow of melted material from the sample holder;

– extinction of any of the pilot flames (even for a short time) during a test with application of

pilot flames.

If one or more of the test specimens exhibit abnormal behaviour during the test, an additional

series of three new test specimens shall be tested, and results calculated based on all tests

completed without abnormal behaviour, providing that there were at least three such tests.

If more than three out of the six test specimens exhibited abnormal behaviour, then the results

obtained are not valid, and it shall be reported that this test method is not suitable for this test

specimen.

Any abnormal behaviour shall be reported – see Clause 9.

7 Expression of results

7.1 General

General guidance on smoke obscuration is given in IEC 60695-6-1. It contains information

concerning the optical measurement of smoke, and the meaning and use of smoke

parameters.

7.2 Specific optical density

For the purpose of this technical specification, D represents the specific optical density (a

s

dimensionless number), calculated as follows:

D = G [log (100/T) + F]

s

where

G is a constant derived from the geometry of the test equipment as follows:

TS 60695-6-31 © IEC:2013 – 13 –

G = V /(AL)

with

V = volume of the chamber (0,51 m )

A = exposed area of the test specimen (0,004225 m )

L = length of the light path through the smoke (0,914 m)

for this apparatus G = 132;

T is the light transmittance (%);

F is a factor based on the actual optical density of the moveable neutral density filter, as

follows:

a) if the neutral density filter is in the light path at the time T is measured, F = 0;

b) if the filter is moved out of the light path at the time T is measured, F is as calculated in

C.1.3.3 of IEC/TS 60695-6-30:2012;

c) if the optical system is not equipped with a moveable filter, F = 0.

A table of values of D as a function of T is given in Annex A of IEC/TS 60695-6-30:2012.

s

NOTE The use of the word "specific" in specific optical density does not mean optical density per mass (or mass

loss), but means optical density specific to the geometry of this apparatus.

Based on the above calculation of D , the following parameters can be determined:

s

D : the maximum value of specific optical density;

m

t : the time, in minutes, to reach D ;

m m

t : the time to reach D = 16 (T = 75 %);

16 s

Dc: the specific optical density corresponding to the maximum value of T recorded (T )

c

after smoke has been exhausted from the chamber – a measure of the deposits on

the windows of the optical system;

D : the maximum optical density, corrected for deposition of smoke on the windows of

(corr)

m

the optical system, calculates as follows:

D = D – D

(corr)

m m c

VOF4 is a smoke index obtained from specific optical density measurements at 1 min, 2 min,

3 min and 4 min. It is calculated as follows:

VOF4 = D + D + D + (D /2)

1 2 3 4

where

D , D , D and D are the specific optical densities, after 1 min, 2 min, 3 min and 4 min,

1 2 3 4

respectively.

NOTE VOF4 is a smoke index required by some national specifications.

For each series of tests, the results reported are expressed as the arithmetic mean of all valid

tests. For each parameter calculated, if the maximum value is more than 1,5 times greater than

the minimum value, the tests should be carried out with a further three test specimens, and the

means calculated based on all tests.

8 Repeatability and reproducibility

Repeatability and reproducibility data have been generated during the development of French

Standard NF C 20-902/1, and the British standard BS 6401.

A summary of the results is given in Annex A.

– 14 – TS 60695-6-31 © IEC:2013

9 Test report

For each series of tests, the test report shall include:

– a thorough description of the test specimen, including material type or reference, relevant

processing parameters, methods of preparation, thickness and mass of the test specimens;

– the number of valid tests completed;

– test conditions, including calibration values, test duration, exposure mode (with or without

pilot flames);

– the average values of D , t , D , D (corr), and the maximum variations between the

m m c m

minimum and maximum values;

– the correction factor of the neutral density filter (if removed);

– observations on the behaviour of the test specimen under test, and the validity of the test;

– observations of any abnormal behaviour.

Optionally, the following may also be recorded:

time curve;

– the D

s

– D at 1 min, 2 min, 3 min and 4 min;

s

– mass loss;

– VOF4.

One format of a test report is given in Annex B.

TS 60695-6-31 © IEC:2013 – 15 –

Annex A

(informative)

Evaluation of the repeatability and the

reproducibility from inter-laboratory tests

A.1 Inter-laboratory tests from the French standard NF C 20-902/1

Four materials used for electrotechnical products, including three used in electric cables, were

evaluated using 14 NBS smoke chambers, in accordance with the procedure described in the

French standard NF C 20-902/1.

The results of these tests related to the determination of D and VOF4 are summarized in

m

Tables A.1 and A.2.

Table A.1 – Measurement of D

m

Materials studied

Mode of test Parameter Silicone Chloro- Ethylene vinyl Polyamide

sulphonated acetate 6,6

polyethylene

m 278 234 314 70

r 43 113 42 11

Without pilot

S 15 40 17 4

r

flames

R 67 287 81 41

S 24 102 29 15

R

211 624 259 84

m

r 158 98 115 44

With pilot

S 56 85 41 16

r

flames

R 206 131 204 60

S 74 68 73 21

R

m = average specific optical density (D )

m

r = repeatability

S = standard deviation of repeatability

r

R = reproducibility

S = standard deviation of reproducibility

R

– 16 – TS 60695-6-31 © IEC:2013

Table A.2 – Measurement of VOF4

Materials studied

Mode of

Silicone Chloro- Ethylene vinyl Polyamide

Parameter

test

sulphonated acetate 6,6

polyethylene

m 99 12 255 20

r 33 12 84 7

Without pilot

S 12 4 30 2

r

flames

R 69 20 164 20

S 25 7 59 7

R

163 636 185 32

m

r 116 209 167 33

With pilot

41 75 60 12

S

flames r

R 234 577 109 62

84 206 71 22

S

R

m = average VOF4

r = repeatability

S = standard deviation of repeatability

r

R = reproducibility

S = standard deviation of reproducibility

R

A.2 Inter-laboratory tests from the British standard BS 6401

Eleven materials used for building applications were evaluated using seven NBS smoke

chambers, according to the procedure described in BS 6401.

The results of these tests, related to the determination of D with and without the application of

m

pilot flames, are summarized in Tables A.3 and A.4.

Table A.3 – Coefficients of variation and relative precision of maximum specific

optical density (D ) in tests with application of pilot flames

m

Coefficient of variation Relative precision

% %

Material

Within a Between Repeatability Reproducibility

laboratory laboratories

Carpet 29,8 0,0 41,4 41,4

Chipboard 15,2 8,7 21,1 32,0

Fibreboard 26,0 32,1 36,0 95,9

Glass reinforced polyester (GRP) 14,0 8,6 19,4 30,7

Hardboard 33,4 17,5 46,2 67,0

Plasterboard 12,8 22,3 17,7 64,2

Polyisocyanurate foam 10,6 10,1 14,7 31,5

Polystyrene foam 47,5 33,3 65,9 113,4

Polyurethane foam 8,1 0,2 11,2 11,3

Rigid polyvinyl chloride (PVC) 14,1 0,0 19,6 19,6

Acrylonitrile-butadiene-styrene 5,6 3,6 7,8 12,7

(ABS) plastic

TS 60695-6-31 © IEC:2013 – 17 –

Table A.4 – Coefficients of variation and relative precision of maximum specific

optical density (D ) in tests without application of pilot flames

m

Coefficient of variation Relative precision

% %

Material

Within a Between Repeatability Reproducibility

laboratory laboratories

Carpet 17,1 4,9 23,6 27,3

Chipboard 17,9 12,8 24,8 43,4

Fibreboard 24,3 11,7 33,6 46,8

Glass reinforced polyester (GRP) 12,8 9,3 17,4 31,0

Hardboard 9,4 5,9 13,0 20,8

Plasterboard 6,4 5,6 8,8 17,8

Polyisocyanurate foam 15,1 0,0 20,9 20,9

Polystyrene foam 31,3 29,0 43,4 91,4

Polyurethane foam 8,9 17,2 12,4 49,3

Rigid polyvinyl chloride (PVC) 7,7 10,7 10,7 31,6

Acrylonitrile-butadiene-styrene 4,6 0,0 6,4 6,4

(ABS) plastic

– 18 – TS 60695-6-31 © IEC:2013

Annex B

(informative)

Example of test report – Determination

of smoke opacity without air-change

– Reference of the material tested .

– Manufacturer of the apparatus .

– Test No. .

– Date .

– Laboratory .

B.1 Results

B.2 Readings and measurements before the test (optional)

B.2.1 Environment

– Room temperature . °C

– Relative humidity . %

B.2.2 Test equipment

– Surface condition of chamber .

– Leakage rate of the chamber:

to mm H O

.................

t min . mm H O

– Distance between furnace and test specimen . mm

– Voltage of furnace . V

– Check of non-distortion of heater .

– Radiometer reading . mV

– Heat flux . kW/m

– Chamber pressure (maximum during test) . mm H O

– Chamber temperature . °C

B.2.3 Thermal exposure with pilot flames

– Pilot flames . mm from lower edge of

test specimen holder

................. mm from test specimen

surface

– Dimension of pilot flames . mm

– Propane flow rate . cm /min

– Air flow rate . cm /min

TS 60695-6-31 © IEC:2013 – 19 –

B.2.4 Test specimen

Conditioning:

– temperature . °C

– duration . h

Test conditions:

– temperature . °C

– relative humidity . %

– duration . h

B.3 Readings and measurements after the test (optional)

– Room temperature . °C

– Temperature at rear side of test specimen . °C

(between the aluminium and the holding plate)

– 20 – TS 60695-6-31 © IEC:2013

Bibliography

ISO 13943:2008, Fire safety – Vocabulary

ISO 5725 (all parts), Accuracy (trueness

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...