IEC 60749-37:2022

(Main)Semiconductor devices - Mechanical and climatic test methods - Part 37: Board level drop test method using an accelerometer

Semiconductor devices - Mechanical and climatic test methods - Part 37: Board level drop test method using an accelerometer

IEC 60749-37:2022 provides a test method that is intended to evaluate and compare drop performance of surface mount electronic components for handheld electronic product applications in an accelerated test environment, where excessive flexure of a circuit board causes product failure. The purpose is to standardize the test board and test methodology to provide a reproducible assessment of the drop test performance of surface-mounted components while producing the same failure modes normally observed during product level test. This edition includes the following significant technical changes with respect to the previous edition:

- correction of a previous technical error concerning test conditions;

- updates to reflect improvements in technology.

Dispositifs à semiconducteurs - Méthodes d'essais mécaniques et climatiques - Partie 37: Méthode d'essai de chute au niveau de la carte avec utilisation d'un accéléromètre

L’IEC 60749-37:2022 fournit une méthode d’essai destinée à évaluer et comparer la performance de chute des composants électroniques à montage en surface dans des applications de produits électroniques portatifs dans un environnement d’essai accéléré, où une flexion excessive d’une carte de circuit imprimé provoque une défaillance de produit. Le but est de normaliser la carte d'essai et la méthodologie d'essai pour fournir une évaluation reproductible de la performance d'essai de chute des composants à montage en surface, en reproduisant les mêmes modes de défaillances que ceux observés normalement au cours d'un essai au niveau du produit. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- correction d’une erreur technique précédente concernant les conditions d’essai;

- mises à jour afin de refléter les progrès technologiques.

General Information

- Status

- Published

- Publication Date

- 11-Oct-2022

- Technical Committee

- TC 47 - Semiconductor devices

- Drafting Committee

- WG 2 - TC 47/WG 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 12-Oct-2022

- Completion Date

- 10-Nov-2022

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60749-37:2022 - "Semiconductor devices - Mechanical and climatic test methods - Part 37: Board level drop test method using an accelerometer" - specifies a standardized board-level drop test to evaluate and compare the drop performance of surface-mount electronic components used in handheld electronic products. This second edition (2022) updates the 2008 edition, corrects a prior technical error in test conditions and reflects technology improvements. The method uses an accelerometer to measure shock magnitude and duration applied to a standardized test board so that component failure modes observed at product level (caused by PCB flexure) are reproducibly produced in an accelerated laboratory test.

Key topics and requirements

- Test objective: Provide a reproducible, comparable assessment of component drop performance where excessive PCB flexure leads to product failure.

- Test scope: Applies to perimeter-leaded and area-array surface-mounted packages; not intended as a full component qualification or to replace system-level product drop tests.

- Measurement method: Uses an accelerometer to record shock magnitude and duration (proportional to local stress on mounted components). IEC 60749-40 (strain-gauge method) is an alternative referenced method.

- Test elements covered:

- Test apparatus and mounting scheme

- Standardized test board construction, material and layout (Annex A)

- Test board assembly, sample sizes and component placement

- Pre-test characterization, drop testing procedure, and data acquisition

- Failure criteria and failure analysis to identify board, interconnect or component cracks

- Reporting and comparability: Emphasizes standardized reporting and notes that cross-lab comparability requires matching studies before direct component performance comparisons.

Applications and who uses it

IEC 60749-37:2022 is relevant to:

- Reliability engineers and test labs performing board-level shock/drop assessments

- Component manufacturers evaluating robustness of surface-mount packages for handheld devices

- OEMs and product designers of portable electronics (e.g., phones, cameras, PDAs) wanting to screen components for drop-induced failures

- Test equipment vendors and PCB fabricators implementing standardized test vehicles and data acquisition

Practical uses include establishing baseline performance, comparing candidate packages, investigating failure modes related to board flexure, and augmenting system-level drop testing programs.

Related standards

- IEC 60749-10 - Mechanical shock (device and subassembly)

- IEC 60749-40 - Board level drop test method using strain gauge (alternative measurement)

- IEC 60749-20 / 20-1 - Moisture and soldering heat resistance for SMDs

- JEDEC JESD22-B111A - Basis document (permission used for this edition)

Keywords: IEC 60749-37:2022, board level drop test, accelerometer, surface-mount components, PCB flexure, handheld electronic products, drop performance, test board.

REDLINE IEC 60749-37:2022 - Semiconductor devices - Mechanical and climatic test methods - Part 37: Board level drop test method using an accelerometer Released:10/12/2022 Isbn:9782832258828

IEC 60749-37:2022 - Semiconductor devices - Mechanical and climatic test methods - Part 37: Board level drop test method using an accelerometer Released:10/12/2022

Frequently Asked Questions

IEC 60749-37:2022 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Semiconductor devices - Mechanical and climatic test methods - Part 37: Board level drop test method using an accelerometer". This standard covers: IEC 60749-37:2022 provides a test method that is intended to evaluate and compare drop performance of surface mount electronic components for handheld electronic product applications in an accelerated test environment, where excessive flexure of a circuit board causes product failure. The purpose is to standardize the test board and test methodology to provide a reproducible assessment of the drop test performance of surface-mounted components while producing the same failure modes normally observed during product level test. This edition includes the following significant technical changes with respect to the previous edition: - correction of a previous technical error concerning test conditions; - updates to reflect improvements in technology.

IEC 60749-37:2022 provides a test method that is intended to evaluate and compare drop performance of surface mount electronic components for handheld electronic product applications in an accelerated test environment, where excessive flexure of a circuit board causes product failure. The purpose is to standardize the test board and test methodology to provide a reproducible assessment of the drop test performance of surface-mounted components while producing the same failure modes normally observed during product level test. This edition includes the following significant technical changes with respect to the previous edition: - correction of a previous technical error concerning test conditions; - updates to reflect improvements in technology.

IEC 60749-37:2022 is classified under the following ICS (International Classification for Standards) categories: 31.080.01 - Semiconductor devices in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60749-37:2022 has the following relationships with other standards: It is inter standard links to IEC 60749-37:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60749-37:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60749-37 ®

Edition 2.0 2022-10

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Semiconductor devices – Mechanical and climatic test methods –

Part 37: Board level drop test method using an accelerometer

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 19 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60749-37 ®

Edition 2.0 2022-10

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Semiconductor devices – Mechanical and climatic test methods –

Part 37: Board level drop test method using an accelerometer

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.080.01 ISBN 978-2-8322-5882-8

– 2 – IEC 60749-37:2022 RLV © IEC 2022

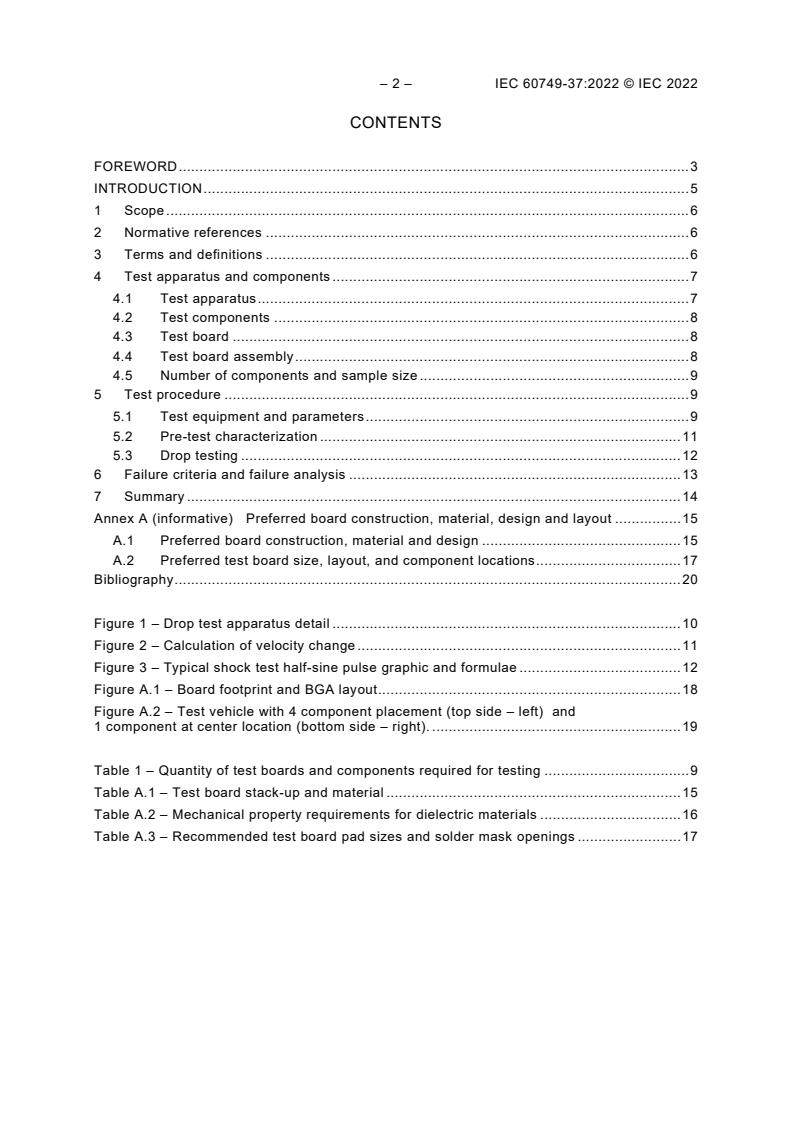

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope and object . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Test apparatus and components . 8

4.1 Test apparatus . 8

4.2 Test components . 8

4.3 Test board . 8

4.4 Test board assembly . 9

4.5 Number of components and sample size . 9

5 Test procedure . 10

5.1 Test equipment and parameters . 10

5.2 Pre-test characterization . 12

5.3 Drop testing . 14

6 Failure criteria and failure analysis . 15

7 Summary . 16

Annex A (informative) Preferred board construction, material, design and layout . 18

A.1 Preferred board construction, material and design . 18

A.2 Preferred test board size, layout, and component locations . 20

Bibliography . 24

Figure 1 – Typical drop test apparatus and mounting scheme for PCB assembly .

Figure 1 – Drop test apparatus detail . 11

Figure 2 – Calculation of velocity change . 12

Figure 3 – Fundamental mode of vibration of PCB supported with four screws .

Figure 3 – Typical shock test half-sine pulse graphic and formulae . 14

Figure A.1 – Recommended test board size and layout .

Figure A.1 – Board footprint and BGA layout . 22

Figure A.2 – Test vehicle with 4 component placement (top side – left)

and 1 component at center location (bottom side – right). . 23

Table 1 – Quantity of test boards and components required for testing . 10

Table 2 – Component locations for test boards .

Table A.1 – Test board stack-up and material . 18

Table A.2 – Mechanical property requirements for dielectric materials . 19

Table A.3 – Recommended test board pad sizes and solder mask openings . 20

Table A.4 – X, Y locations for components’ centre .

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SEMICONDUCTOR DEVICES –

MECHANICAL AND CLIMATIC TEST METHODS –

Part 37: Board level drop test method using an accelerometer

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes made to

the previous edition IEC 60749-37:2008. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

– 4 – IEC 60749-37:2022 RLV © IEC 2022

IEC 60749-37 has been prepared by IEC technical committee 47: Semiconductor devices. It is

an International Standard.

This second edition, based on JEDEC document JESD22-B111A, cancels and replaces the first

edition published in 2008. lt is used with permission of the copyright holder, JEDEC Solid State

Technology Association. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) correction of a previous technical error concerning test conditions;

b) updates to reflect improvements in technology.

The text of this International Standard is based on the following documents:

Draft Report on voting

47/2651/CDV 47/2719/RVC

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts of the IEC 60749 series, under the general title Semiconductor devices –

Mechanical and climatic test methods, can be found in the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

INTRODUCTION

Handheld electronic products fit into the consumer and portable market segments. Included in

handheld electronic products are cameras, calculators, cell phones, cordless phones, pagers,

palm size PCs, personal computer memory card international association (PCMCIA) cards,

smart cards, personal digital assistants (PDAs) and other electronic products that can be

conveniently stored in a pocket and used while held in user’s hand.

These handheld electronic products are more prone to being dropped during their useful service

life because of their size and weight. This dropping event can not only cause mechanical failures

in the housing of the device but also create electrical failures in the printed circuit board (PCB)

assemblies mounted inside the housing due to transfer of energy through PCB supports. The

electrical failures may sometimes result from various failure modes such as cracking of the

circuit board, track cracking on the board, cracking of solder interconnections between the

components and the board, and component cracks. The primary driver of these failures is

excessive flexing of the circuit board due to input acceleration to the board created from

dropping the handheld electronic product. This flexing of the board causes relative motion

between the board and the components mounted on it, resulting in component, interconnect or

board failures. The failure is a function of the combination of the board design, construction,

material, thickness and surface finish; interconnect material and standoff height and component

size.

Correlation between test and field conditions is not yet fully established. Consequently, the test

procedure is presently more appropriate for relative component performance than for use as a

pass/fail criterion. Rather, results should can be used to augment existing data or establish a

baseline for potential investigative efforts in package/board technologies.

The comparability between different test sites, data acquisition methods, and board

manufacturers has not been fully demonstrated by existing data. As a result, if the data are to

be used for direct comparison of component performance, matching studies must will first be

performed to prove that the data are in fact comparable across different test sites and test

conditions.

This method is not intended to substitute for full characterization testing, which might could

incorporate substantially larger sample sizes and increased number of drops. Due to limited

sample size and number of drops specified here, it is possible that enough failure data may are

not be generated in every case to perform full statistical analysis.

– 6 – IEC 60749-37:2022 RLV © IEC 2022

SEMICONDUCTOR DEVICES –

MECHANICAL AND CLIMATIC TEST METHODS –

Part 37: Board level drop test method using an accelerometer

1 Scope and object

This part of IEC 60749 provides a test method that is intended to evaluate and compare drop

performance of surface mount electronic components for handheld electronic product

applications in an accelerated test environment, where excessive flexure of a circuit board

causes product failure. The purpose is to standardize the test board and test methodology to

provide a reproducible assessment of the drop test performance of surface-mounted

components while producing the same failure modes normally observed during product level

test.

This document aims at prescribing a standardized test method and reporting procedure. This is

not a component qualification test and is not meant to replace any system level drop test that

may be needed is sometimes used to qualify a specific handheld electronic product. The

standard is not meant to cover the drop test required to simulate shipping and handling-related

shock of electronic components or PCB assemblies. These requirements are already addressed

in test methods such as IEC 60749-10. The method is applicable to both area array and

perimeter-leaded surface mounted packages.

This test method uses an accelerometer to measure the mechanical shock duration and

magnitude applied which is proportional to the stress on a given component mounted on a

standard board. The test method described in IEC 60749-40 uses strain gauge to measure the

strain and strain rate of a board in the vicinity of a component. The detailed customer

specification states which test method is to be used.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60749-10:20022022, Semiconductor devices – Mechanical and climatic test methods – Part

10: Mechanical shock – Device and subassembly

IEC 60749-20, Semiconductor devices – Mechanical and climatic test methods – Part 20:

Resistance of plastic-encapsulated SMDs to the combined effect of moisture and soldering heat

IEC 60749-20-1, Semiconductor devices – Mechanical and climatic test methods – Part 20-1:

Handling, packing, labelling and shipping of surface-mount devices sensitive to the combined

effect of moisture and soldering heat

———————

Under consideration.

In preparation.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

IEC Electropedia: available at https://www.electropedia.org/

ISO Online browsing platform: available at https://www.iso.org/obp

3.1

component

packaged semiconductor device

3.2

single-sided PCB assembly

printed circuit board assembly with components mounted on only one side of the board

3.3

double-sided PCB assembly

printed circuit board assembly with components mounted on top and bottom sides of the board

3.4

handheld electronic product

product that can conveniently be stored in a pocket (of sufficient size) and used when held in

user’s hand

Note 1 to entry: Handheld electronic products include cameras, calculators, cell phones, pagers, palm-size PCs

(formerly called ‘pocket organizers’), personal computer memory card international association (PCMCIA) cards,

smart cards, mobile phones, personal digital assistants (PDAs) and other communication devices.

3.5

peak acceleration

maximum acceleration during the dynamic motion of the test apparatus

3.6

pulse duration

acceleration interval

time interval between the instant when the acceleration first reaches 10 % of its specified peak

level and the instant when the acceleration first returns to 10 % of the specified peak level after

having reached that peak level

3.7

table drop height

free-fall drop height of the drop table needed to attain the prescribed peak acceleration and

pulse duration

3.8

event

electrical discontinuity of resistance greater than 1 000 Ω lasting for 1 μs or longer

3.9

event detector

continuity test instrument capable of detecting electrical discontinuity of resistance greater than

1 000 Ω lasting for 1 μs or longer

– 8 – IEC 60749-37:2022 RLV © IEC 2022

4 Test apparatus and components

4.1 Test apparatus

The shock-testing apparatus shall be capable of providing shock pulses up to a peak

−2

acceleration of 2 900 m·s with a pulse duration between 0,3 ms and 8,0 ms to the body of the

–1 −1 −1

device and a velocity change of 710 mm·s 1 250 mm·s to 5 430 mm·s . For free-state

−1 −1

testing, a velocity change of 1 250 mm·s to 5 430 mm·s and a pulse duration between

0,3 ms and 2,0 ms is sufficient. Conversely, for mounted-state testing, apparatus capable of a

−1 −1

velocity change of 1 000 mm·s to 5 430 mm·s and a pulse duration between 5,0 ms and

8,0 ms to the body of the component is sufficient.

The acceleration pulse shall be a half-sine waveform with an allowable deviation from specified

peak acceleration level not greater than ± 20 % 10 % of the specified peak acceleration. This

is determined by a transducer having a natural frequency 5 times the frequency of the shock

pulse being established and measured through a low pass filter having a band width preferably

at least 5 times the frequency of the shock pulse being established. It is very important that the

transducer resonance does not approach the measured value. Filtering should not be used in

lieu of good measurement set-up and procedure practices. The pulse duration shall be

measured between the points at 10 % of the peak acceleration during rise time and 10 % of the

peak acceleration during decay time. Absolute tolerances of the pulse duration shall be ±30 %

of the specified duration. It is recommended that the test velocity change should be ±10 % of

the specified level. The test velocity change shall be ±10 %of the specified level. The pulse

duration shall be measured between the points at 10 % of the peak acceleration during rise

time and 10 % of the peak acceleration during decay time. Absolute tolerances of the pulse

duration shall be ±15 % of the specified duration. The test equipment transducer shall have a

natural frequency greater than 5 times the frequency of the shock pulse being established, and

measured through a low-pass filter having a bandwidth greater than 5 times the frequency of

the shock pulse being established. Filtering shall not be used in lieu of good measurement

setup and procedure practices.

Appropriate equipment calibration shall be carried out prior to any testing.

4.2 Test components

This document covers all area arrays and perimeter-leaded surface-mountable packaged

semiconductor devices such as ball grid arrays (BGA), land grid arrays (LGA), chip scale

packages (CSP), thin small outline packages (TSOP) and quad flat no-lead packages (QFN)

typically used in handheld electronic product. The maximum size of the component body

covered in this document is 15 mm x 15 mm in general. A larger body size may be used for a

special board layout as described in detail in 4.3. All components used for this testing must

shall be daisy-chained. The daisy chain should either be is made at the die level or by providing

daisy chain links at the lead-frame or substrate level. In case of non-daisy chain die, a

mechanical dummy die shall be used inside the package to simulate the actual structure of the

package. The die size and thickness should shall be similar to the functional die size to be used

in application. The component materials, dimensions and assembly processes shall be

representative of typical production device.

4.3 Test board

Since the drop test performance is a function of the test board used for evaluation, this

document describes a preferred test board construction, dimensions, and material that is

representative of those used in handheld electronic products. If another board

construction/material better represents a specific application, the test board construction,

dimensions and material should shall be documented. The test data generated using such a

board shall be correlated at least once by generating the same data on the same component

using the preferred board defined in this document (see Annex A for recommendations).

4.4 Test board assembly

Prior to board assembly, all devices shall be inspected for missing balls or bent leads. Board

thickness, warpage and pad sizes shall also be measured using a sampling plan. A visual

inspection shall be performed on all boards for solder mask registration, contamination and

daisy chain connection. It is recommended that boards should be inspected and accepted in

accordance with a relevant national or international standard. One board shall also be used to

measure the mechanical properties (modulus and glass transition temperature, T ) of the board

g

at the component location using dynamic mechanical analysis (DMA) and thermomechanical

analysis (TMA) methods. It is highly recommended that the coefficient of thermal expansion

(CTE) of the board be also measured in X, Y and Z direction. The mechanical property

measurements are not required for every board lot, unless the fabrication process, material or

vendor is changed from lot to lot.

The components shall be baked according to IEC 60749-20 and the future IEC 60749-20-1 prior

to board assembly. The test boards shall be assembled using best known methods of printed

circuit assembly process, representative of production methods. At least one board shall be

used to adjust the board mounting process such as paste printing, placement and reflow profile.

All assemblies shall be single-sided only, unless the component is anticipated for use in mirror-

sided board assemblies. In that case, the components shall be mounted on each side of the

board.

A 100 % X-ray inspection is recommended on assembled units to check for voids, short-circuits

and other abnormalities. Electrical continuity test shall also be performed on all mounted units

to detect any open-circuits or short-circuits.

4.5 Number of components and sample size

The board design recommended in Annex A allows up to 15 locations for component mounting

and it is preferred that components be mounted on all 15 locations. Since the drop performance

is a function of component location on the board, testing with components mounted on all 15

locations will provide useful information to the users of this data in proper layout of their product

board. With the board supported at four corners, these locations cover the worst case board

curvature (U8 location), the effect of proximity to support locations (U1, U5, U11, and U15

locations) and various locations in between. Because of various designs for tests, and designs

for failure analysis practices used in the industry, it is recognized that populating boards with

all 15 locations may not leave enough room between components for a large number of test

points to properly identify the exact failure location. Therefore, options are provided for

mounting just 1 or 5 components on the board using the following locations:

– 1-component configurations: location U8

– 5-component configurations: locations U2, U4, U8, U12, and U14

The board design recommended in Annex A allows 4 locations for component mounting and is

recommended that all 4 components are mounted. Since the board is designed with full

symmetry, all 4 components are expected to be subjected to the same drop performance and

hereby the test results are treated as one single group. Statistical analysis on the data

equivalence is suggested to ensure that variability in the component performance is insignificant

before comprehensive data or full qualification is pursued. In order to get good statistically

meaningful results, a total of 6 boards or 24 components are recommended as a minimum

quantity per each design.

Since the number and size of the components mounted on the board may can influence the

dynamic response of the test board assembly during drop, it is required that additional data are

be provided whenever these 1-component or 5-component configurations are the 1-component

configuration is employed. The additional data shall directly compare the effect of optional

component mounting (1- or 5- component case) to the preferred 15 4-component mounting

configuration. This comparison shall be provided for a component similar in size (within 20 %

in both length and width) to the component, which has been tested using 1- or 5-component per

board configuration only.

– 10 – IEC 60749-37:2022 RLV © IEC 2022

Depending on the number of components mounted per board, Table 1 shall be used to

determine the minimum quantity of assembled boards required for testing and the total number

of components to be tested. Sample sizes greater than specified in Table 1 can be used to

generate statistically sufficient data. In case of rectangular components, the longer side of the

component should be parallel to the longer side of the board when mounted.

In the case of 1 component mount on the board, Table 1 shall be used to determine the minimum

quantity of assembled board required for testing and total number of components to be tested.

Sample sizes greater than specified below can also be used to generate statistically sufficient

data.

Table 1 – Quantity of test boards and components required for testing

Number of boards

Number of

Total number of

components

Side A assembly Side B assembly

components

per board

(via in pad) (not via in pad)

15 4 4 120

5 4 4 40

1 10 10 20

Number of boards

Number of

Total number of

components Location

Side A assembly Side B assembly

components

per board

(via in pad) (not via in pad)

4 U1, U2, U3 and U4 6 6 48

1 Centre of the board 16 16 32

5 Test procedure

5.1 Test equipment and parameters

The shock testing apparatus shall be mounted on a sturdy laboratory table or equivalent base

and levelled before use. Means shall be provided in the apparatus (such as an automatic

braking mechanism) to eliminate bounce and to prevent multiple shocks to the board. Figure 1

shows the typical drop test apparatus where the drop table travels down on guide rods and

strikes the rigid fixture. The rigid fixture typically is covered with some form of material to

achieve the desirable pulse and acceleration levels. The bottom of the drop table is usually

rounded slightly to ensure a very small area of contact with the strike surface.

PCB assembly

Guide rods

Stand-offs

Accelerometer

Base plate

Base plate

Drop table

Drop table

Strike surface

Rigid base

IEC 001/08

Figure 1 – Typical drop test apparatus and mounting scheme for PCB assembly

d) Sample stand-off design

a) Typical drop test apparatus b) Pre-characterization set up c) Assembly set up with board

without test board

Figure 1 – Drop test apparatus detail

A base plate with suitable standoffs (e.g. 6 mm hexagonal outside diameter / M3 × 0,5 inside

diameter, 10 mm long) shall be rigidly mounted on the drop table. The thickness and mounting

locations of the base plate shall be selected such that there is no relative movement between

the drop table and any part of base plate during drop testing. This plate will serve as the

mounting structure for the PCB assemblies. This is pictorially shown in Figure 1. The PCB

assembly shall be mounted to the base plate standoffs using four screws, one at each corner

of the board. The board shall be mounted using four suitable precision shoulder screws (e.g.

M3 × 0,5). Test data suggests that the variations in response acceleration and strain are

– 12 – IEC 60749-37:2022 RLV © IEC 2022

reduced significantly depending upon the choice of screw. Since the length of shoulder is

nominal, a number of washers should shall be placed between the screw head and the top

surface of the board (nominal 1,0 mm thick) to avoid any gap between the top of the standoffs

and the bottom surface of the board. Due to tolerance stack up, a small gap is still possible but

this gap shall not exceed 50 µm. The use of shoulder screw eliminates the need to re-tighten

screws between drops. The screws shall be tightened in a diagonal pattern in the order of SW,

NE, SE, and NW corners of the board. The screw shall be tightened until the shoulder of the

screw bottoms out against the standoff. The number of washers used shall be the same for all

four screws. A custom board jig may be used instead of mounting the board directly to the plate.

Experience with different board orientations has suggested that the horizontal board orientation

with components facing down results in maximum PCB flexure and, thus, the worst orientation

for failures. Therefore, this document requires that the board shall be horizontal in orientation

with components facing in downward direction during the test. Drop testing using other board

orientations is not required but may be performed if deemed necessary. However, this is an

additional test option and not a replacement for testing in the required orientation.

–2

This document requires test condition B (1 500 15 000 m·s , 0,5 ms duration, half-sine pulse),

as listed in Table 1 of IEC 60749-10:2022, as the input shock pulse to the printed circuit

assembly. This is the applied shock pulse to the base plate and shall be measured by

accelerometer mounted at the centre of base plate or close to the support posts for the board.

–2

Other shock conditions, such as 2 900 m·s , 0,3 ms duration, in addition to the required

condition can also be used. The velocity change of the drop pulse shall be also controlled and

maintained at 4,67 m/s. The calculation of the velocity change is defined by the effective pulse

–2

where the acceleration must be equal to or above 1 500 m·s as shown in Figure 2. No

rebounces are allowed in this calculation.

Figure 2 – Calculation of velocity change

5.2 Pre-test characterization

A set-up board with components mounted on it shall be used to adjust and characterize the

drop test parameters and board response. A lightweight accelerometer should be attached with

beeswax (or equivalent adhesive) on top of the component located at position U8 to

characterize the output acceleration response of the PCB assembly. It should be noted,

however, that any additional mass will add significant dynamic weight to the board and may

alter its dynamic response. Therefore, it is recommended that this characterization should only

be carried out on a set-up board. In addition, a 45 ° rectangular rosette strain gauge shall be

mounted on this set-up board underneath position U8 on the other side (non-component) side

of the board to characterize strains in the X and Y directions as well as the principal strain and

principal strain angle. A lightweight accelerometer is attached with (using suitable adhesive) in

the centre of the mounting plate. Since the board weight is negligible as compared to mounting

plate, setup characterization without a test board will not alter the results. Both the

accelerometer and the strain gauge shall be connected to a data acquisition system capable of

measuring at a scan frequency of 20 kHz and greater with a 16-bit signal width. Additional strain

gauges may can also be mounted at different locations on the board to fully characterize the

strain response of the assembly.

The board assembly shall then be mounted on the drop test fixture using four screws. The

screws shall be tightened in diagonal pattern in the order of SW, NE, SE, and NW corners of

the board. An additional accelerometer may also be mounted on the board assembly at or close

to one of the support locations to ensure that the input pulse to the base plate is transmitted to

the PCB without any distortion. The drop table shall then be raised to the height required to

meet test condition B of Table 1 of IEC 60749-10:2022 and dropped on to the strike surface

while measuring the G level, pulse duration, and pulse shape.

Multiple drops might be required whilst adjusting the drop height and strike surface to achieve

–2

the specified acceleration levels and pulse duration (1 500 m·s , 0,5 ms half-sine pulse). It

should be noted that the peak acceleration and the pulse duration is a function of not only the

drop height but also the strike surface. The acceleration pulse shall follow a half-sine curve with

–2

a peak acceleration of 1 500 m·s during each drop as shown in Figure 2. Multiple drops can

be required while adjusting the drop height and impact surface to achieve the specified peak

–2

acceleration and change of velocity (1 500 m·s , 4,67 m/s respectively). The variations of the

peak acceleration and change of velocity needs to be controlled within 10 % on each individual

measurement and 5% tolerance on average when 20 repeating measurements. The change of

velocity is the total area enclosed by the acceleration pulse and the time axis. An effective

change of velocity shall be counted in which only an acceleration equal to or higher than

–2

1 500 m·s is considered and any rebounces after the acceleration dropping to below

–2

1 500 m·s from the peak shall be ignored in the calculation. The time duration for defining the

area of effective change of velocity is called effective pulse duration and shall also be

maintained at 0,5 ms within 15 % tolerance which is in accordance with IEC 60749-10. The test

equipment and transducer shall have a natural frequency greater than 5 times the frequency of

the shock pulse being established, and measured through a low-pass filter having a bandwidth

greater than 5 times the frequency of the shock pulse being established, see detail in

IEC 60749-10. However, both unfiltered and filtered acceleration profiles shall be reported for

the comparison purposes. It shall be noted that these pulse parameters are function of not only

the drop height but also the impact surface. Depending on the strike surface, the same drop

height could result in different acceleration levels and pulse durations. Theoretically, the drop

height needed to achieve the appropriate acceleration levels can be determined from Equations

(1) and (2) and the associated Figure 3, where H is the drop height and C is the rebound co-

efficient (1,0 for no rebound, 2,0 for full rebound). However, this equation does not include the

strike surface effect.

Experiments with different strike surfaces may can be needed necessary to achieve the desired

peak value and duration.

πt

A(t)= A sin (1)

t

w

2A t

0 w

2gH = A sin

(2)

0

Cπ

– 14 – IEC 60749-37:2022 RLV © IEC 2022

Figure 3 – Typical shock test half-sine pulse graphic and formulae

Once the specified drop parameters (acceleration level, duration and pulse shape) are

achieved, the PCB response acceleration and strain shall be measured. The strain rate shall

also be calculated by dividing the change in strain value by the time interval during which this

change occurred. The characterized board response (acceleration, strain and strain rate) and

its variation shall be documented and provided with the test data. Although it is recommended

that this characterization be performed for previously untested components, this may not be

required if such characterization data are available for a similar sized component.

5.3 Drop testing

With test parameters adjusted and PCB response characterized, the PCB assemblies shall be

prepared for drop testing. This involves soldering cables to the plated-through holes on one end

of the board, mounting the board on the drop fixture with components facing down, and

connecting cables to the event detector/data logger. Since the dynamic response of the board

can be affected by the mass and stiffening of the connector, it is recommended that no

connectors are used and wires are directly soldered to the board.

The event detector’s threshold resistance shall be set to no more than 1 000 Ω. The system

used for such event detections shall have a 55 MHz scan rate or 0,2 μs (or lower) event

detection window. Proper strain relief should shall also be provided to cables/wires to avoid a

failure at wires to board interconnects. All cables shall be cleared from the drop path. The initial

resistance of all nets for each assembly shall be measured and logged before conducting the

first drop. The drop test shall be conducted by releasing the drop table from the pre-established

height. The electrical resistance of each net shall be measured in situ during each drop and all

failures shall be logged. The board shall be dropped a required maximum number of times or

until a percentage of all devices has failed, whichever is earlier. The maximum number of drops

or percentage of devices failing shall be consistent with the application. The maximum number

of drops shall be irrespective of single or double-sided assembly. In the event that a shock

condition in addition to the required condition B is used to conduct the test, the maximum

number of drops shall be determined using the acceleration factor between the two conditions

for similar sized components. This acceleration factor shall be reported with the test data.

During the test, the shock pulse shall be measured for each drop to ensure that the input pulse

remains within the specified tolerance. Adjustments in drop height or replacement of strike

surface shall be made if the pulse deviates from that specified.

Depending on the number of components per board, Table 1 shall be used to determine the

number of boards to be tested per component type.

6 Failure criteria and failure analysis

In-situ electrical monitoring of daisy chain nets for failure is required during each drop. The

electrical continuity of all nets should shall either be detected by an event detector or by a high-

speed data acquisition system. The event detector should shall be able to detect any

intermittent discontinuity of resistance greater than 1 000 Ω lasting for 1 μs or longer. The high-

speed data acquisition system should shall be able to measure resistance with a sampling rate

of 50,000 samples per second or greater.

Depending on the monitoring system used, the failure is defined as follows:

– event detector: the first event of intermittent discontinuity as defined above followed by 3

additional such events during 5 subsequent drops.

– high speed data acquisition: the first indication of resistance value of 100 Ω or 20 %

increase in resistance from the initial resistance if initial resistance is greater than 85 Ω

followed by 3 additional such indications during 5 subsequent drops.

A visible partial separation of component from the test board, even without a significant increase

in resistance or intermittent discontinuity, shall also be considered as a failure. This can occur

if the PCB tracks come off the board with the component while maintaining electrical continuity.

As wires soldered to the board for electrical continuity test can also come off during the test, it

is highly recommended that all electrical connections be checked once a failure is indicated to

ensure that the failure is due to a component to board interconnection failure.

All failures after each drop shall be logged. A sufficient number of components from the test lot

shall be subjected to failure analysis to determine the root cause and to

...

IEC 60749-37 ®

Edition 2.0 2022-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Semiconductor devices – Mechanical and climatic test methods –

Part 37: Board level drop test method using an accelerometer

Dispositifs à semiconducteurs – Méthodes d’essais mécaniques et climatiques –

Partie 37: Méthode d'essai de chute au niveau de la carte avec utilisation d'un

accéléromètre

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 19 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur adapté à vos besoins.

les projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au

Restez informé sur les nouvelles publications IEC. Just

monde, avec plus de 22 300 articles terminologiques en

Published détaille les nouvelles publications parues.

anglais et en français, ainsi que les termes équivalents dans

Disponible en ligne et une fois par mois par email.

19 langues additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 60749-37 ®

Edition 2.0 2022-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Semiconductor devices – Mechanical and climatic test methods –

Part 37: Board level drop test method using an accelerometer

Dispositifs à semiconducteurs – Méthodes d’essais mécaniques et climatiques –

Partie 37: Méthode d'essai de chute au niveau de la carte avec utilisation d'un

accéléromètre

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.080.01 ISBN 978-2-8322-5837-8

– 2 – IEC 60749-37:2022 © IEC 2022

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Test apparatus and components . 7

4.1 Test apparatus . 7

4.2 Test components . 8

4.3 Test board . 8

4.4 Test board assembly . 8

4.5 Number of components and sample size . 9

5 Test procedure . 9

5.1 Test equipment and parameters . 9

5.2 Pre-test characterization . 11

5.3 Drop testing . 12

6 Failure criteria and failure analysis . 13

7 Summary . 14

Annex A (informative) Preferred board construction, material, design and layout . 15

A.1 Preferred board construction, material and design . 15

A.2 Preferred test board size, layout, and component locations . 17

Bibliography . 20

Figure 1 – Drop test apparatus detail . 10

Figure 2 – Calculation of velocity change . 11

Figure 3 – Typical shock test half-sine pulse graphic and formulae . 12

Figure A.1 – Board footprint and BGA layout . 18

Figure A.2 – Test vehicle with 4 component placement (top side – left) and

1 component at center location (bottom side – right). . 19

Table 1 – Quantity of test boards and components required for testing . 9

Table A.1 – Test board stack-up and material . 15

Table A.2 – Mechanical property requirements for dielectric materials . 16

Table A.3 – Recommended test board pad sizes and solder mask openings . 17

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SEMICONDUCTOR DEVICES –

MECHANICAL AND CLIMATIC TEST METHODS –

Part 37: Board level drop test method using an accelerometer

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 60749-37 has been prepared by IEC technical committee 47: Semiconductor devices. It is

an International Standard.

This second edition, based on JEDEC document JESD22-B111A, cancels and replaces the first

edition published in 2008. lt is used with permission of the copyright holder, JEDEC Solid State

Technology Association. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) correction of a previous technical error concerning test conditions;

b) updates to reflect improvements in technology.

– 4 – IEC 60749-37:2022 © IEC 2022

The text of this International Standard is based on the following documents:

Draft Report on voting

47/2651/CDV 47/2719/RVC

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts of the IEC 60749 series, under the general title Semiconductor devices –

Mechanical and climatic test methods, can be found in the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

INTRODUCTION

Handheld electronic products fit into the consumer and portable market segments. Included in

handheld electronic products are cameras, calculators, cell phones, cordless phones, pagers,

palm size PCs, personal computer memory card international association (PCMCIA) cards,

smart cards, personal digital assistants (PDAs) and other electronic products that can be

conveniently stored in a pocket and used while held in user’s hand.

These handheld electronic products are more prone to being dropped during their useful service

life because of their size and weight. This dropping event can not only cause mechanical failures

in the housing of the device but also create electrical failures in the printed circuit board (PCB)

assemblies mounted inside the housing due to transfer of energy through PCB supports. The

electrical failures sometimes result from various failure modes such as cracking of the circuit

board, track cracking on the board, cracking of solder interconnections between the

components and the board, and component cracks. The primary driver of these failures is

excessive flexing of the circuit board due to input acceleration to the board created from

dropping the handheld electronic product. This flexing of the board causes relative motion

between the board and the components mounted on it, resulting in component, interconnect or

board failures. The failure is a function of the combination of the board design, construction,

material, thickness and surface finish; interconnect material and standoff height and component

size.

Correlation between test and field conditions is not yet fully established. Consequently, the test

procedure is presently more appropriate for relative component performance than for use as a

pass/fail criterion. Rather, results can be used to augment existing data or establish a baseline

for potential investigative efforts in package/board technologies.

The comparability between different test sites, data acquisition methods, and board

manufacturers has not been fully demonstrated by existing data. As a result, if the data are to

be used for direct comparison of component performance, matching studies will first be

performed to prove that the data are in fact comparable across different test sites and test

conditions.

This method is not intended to substitute for full characterization testing, which could

incorporate substantially larger sample sizes and increased number of drops. Due to limited

sample size and number of drops specified here, it is possible that enough failure data are not

generated in every case to perform full statistical analysis.

– 6 – IEC 60749-37:2022 © IEC 2022

SEMICONDUCTOR DEVICES –

MECHANICAL AND CLIMATIC TEST METHODS –

Part 37: Board level drop test method using an accelerometer

1 Scope

This part of IEC 60749 provides a test method that is intended to evaluate and compare drop

performance of surface mount electronic components for handheld electronic product

applications in an accelerated test environment, where excessive flexure of a circuit board

causes product failure. The purpose is to standardize the test board and test methodology to

provide a reproducible assessment of the drop test performance of surface-mounted

components while producing the same failure modes normally observed during product level

test.

This document aims at prescribing a standardized test method and reporting procedure. This is

not a component qualification test and is not meant to replace any system level drop test that

is sometimes used to qualify a specific handheld electronic product. The standard is not meant

to cover the drop test required to simulate shipping and handling-related shock of electronic

components or PCB assemblies. These requirements are already addressed in test methods

such as IEC 60749-10. The method is applicable to both area array and perimeter-leaded

surface mounted packages.

This test method uses an accelerometer to measure the mechanical shock duration and

magnitude applied which is proportional to the stress on a given component mounted on a

standard board. The test method described in IEC 60749-40 uses strain gauge to measure the

strain and strain rate of a board in the vicinity of a component. The customer specification states

which test method is to be used.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60749-10:2022, Semiconductor devices – Mechanical and climatic test methods – Part 10:

Mechanical shock – Device and subassembly

IEC 60749-20, Semiconductor devices – Mechanical and climatic test methods – Part 20:

Resistance of plastic-encapsulated SMDs to the combined effect of moisture and soldering heat

IEC 60749-20-1, Semiconductor devices – Mechanical and climatic test methods – Part 20-1:

Handling, packing, labelling and shipping of surface-mount devices sensitive to the combined

effect of moisture and soldering heat

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

IEC Electropedia: available at https://www.electropedia.org/

ISO Online browsing platform: available at https://www.iso.org/obp

3.1

component

packaged semiconductor device

3.2

single-sided assembly

printed circuit board assembly with components mounted on only one side of the board

3.3

double-sided assembly

printed circuit board assembly with components mounted on top and bottom sides of the board

3.4

handheld electronic product

product that can conveniently be stored in a pocket (of sufficient size) and used when held in

user’s hand

Note 1 to entry: Handheld electronic products include cameras, calculators, cell phones, pagers, palm-size PCs

(formerly called ‘pocket organizers’), personal computer memory card international association (PCMCIA) cards,

smart cards, mobile phones, personal digital assistants (PDAs) and other communication devices.

3.5

peak acceleration

maximum acceleration during the dynamic motion of the test apparatus

3.6

pulse duration

acceleration interval

time interval between the instant when the acceleration first reaches 10 % of its specified peak

level and the instant when the acceleration first returns to 10 % of the specified peak level after

having reached that peak level

3.7

table drop height

free-fall drop height of the drop table needed to attain the prescribed peak acceleration and

pulse duration

3.8

event

electrical discontinuity of resistance greater than 1 000 Ω lasting for 1 μs or longer

3.9

event detector

continuity test instrument capable of detecting electrical discontinuity of resistance greater than

1 000 Ω lasting for 1 μs or longer

4 Test apparatus and components

4.1 Test apparatus

The shock-testing apparatus shall be capable of providing shock pulses up to a peak

−2

acceleration of 2 900 m·s with a pulse duration between 0,3 ms and 8,0 ms to the body of the

−1 −1

device and a velocity change of 1 250 mm·s to 5 430 mm·s . For free-state testing, a velocity

−1 −1

change of 1 250 mm·s to 5 430 mm·s and a pulse duration between 0,3 ms and 2,0 ms is

sufficient. Conversely, for mounted-state testing, apparatus capable of a velocity change of

– 8 – IEC 60749-37:2022 © IEC 2022

−1 −1

1 000 mm·s to 5 430 mm·s and a pulse duration between 5,0 ms and 8,0 ms to the body of

the component is sufficient.

The acceleration pulse shall be a half-sine waveform with an allowable deviation from specified

peak acceleration not greater than ±10 %. The test velocity change shall be ±10 %of the

specified level. The pulse duration shall be measured between the points at 10 % of the peak

acceleration during rise time and 10 % of the peak acceleration during decay time. Absolute

tolerances of the pulse duration shall be ±15 % of the specified duration. The test equipment

transducer shall have a natural frequency greater than 5 times the frequency of the shock pulse

being established, and measured through a low-pass filter having a bandwidth greater than 5

times the frequency of the shock pulse being established. Filtering shall not be used in lieu of

good measurement setup and procedure practices.

Appropriate equipment calibration shall be carried out prior to any testing.

4.2 Test components

This document covers all area arrays and perimeter-leaded surface-mountable packaged

semiconductor devices such as ball grid arrays (BGA), land grid arrays (LGA), chip scale

packages (CSP), thin small outline packages (TSOP) and quad flat no-lead packages (QFN)

typically used in handheld electronic product. The maximum size of the component body

covered in this document is 15 mm x 15 mm in general. A larger body size may be used for a

special board layout as described in detail in 4.3. All components used for this testing shall be

daisy-chained. The daisy chain is made at the die level or by providing daisy chain links at the

lead-frame or substrate level. In case of non-daisy chain die, a mechanical dummy die shall be

used inside the package to simulate the actual structure of the package. The die size and

thickness shall be similar to the functional die size to be used in application. The component

materials, dimensions and assembly processes shall be representative of typical production

device.

4.3 Test board

Since the drop test performance is a function of the test board used for evaluation, this

document describes a preferred test board construction, dimensions, and material that is

representative of those used in handheld electronic products. If another board

construction/material better represents a specific application, the test board construction,

dimensions and material shall be documented. The test data generated using such a board

shall be correlated at least once by generating the same data on the same component using

the preferred board defined in this document (see Annex A for recommendations).

4.4 Test board assembly

Prior to board assembly, all devices shall be inspected for missing balls or bent leads. Board

thickness, warpage and pad sizes shall also be measured using a sampling plan. A visual

inspection shall be performed on all boards for solder mask registration, contamination and

daisy chain connection. It is recommended that boards be inspected and accepted in

accordance with a relevant national or international standard. One board shall also be used to

measure the mechanical properties (modulus and glass transition temperature, T ) of the board

g

at the component location using dynamic mechanical analysis (DMA) and thermomechanical

analysis (TMA) methods. It is highly recommended that the coefficient of thermal expansion

(CTE) of the board be also measured in X, Y and Z direction. The mechanical property

measurements are not required for every board lot, unless the fabrication process, material or

vendor is changed from lot to lot.

The components shall be baked according to IEC 60749-20 and IEC 60749-20-1 prior to board

assembly. The test boards shall be assembled using best known methods of printed circuit

assembly process, representative of production methods. At least one board shall be used to

adjust the board mounting process such as paste printing, placement and reflow profile. All

assemblies shall be single-sided only, unless the component is anticipated for use in mirror-

sided board assemblies. In that case, the components shall be mounted on each side of the

board.

A 100 % X-ray inspection is recommended on assembled units to check for voids, short-circuits

and other abnormalities. Electrical continuity test shall also be performed on all mounted units

to detect any open-circuits or short-circuits.

4.5 Number of components and sample size

The board design recommended in Annex A allows 4 locations for component mounting and is

recommended that all 4 components are mounted. Since the board is designed with full

symmetry, all 4 components are expected to be subjected to the same drop performance and

hereby the test results are treated as one single group. Statistical analysis on the data

equivalence is suggested to ensure that variability in the component performance is insignificant

before comprehensive data or full qualification is pursued. In order to get good statistically

meaningful results, a total of 6 boards or 24 components are recommended as a minimum

quantity per each design.

Since the number and size of the components mounted on the board can influence the dynamic

response of the test board assembly during drop, it is required that additional data be provided

whenever the 1-component configuration is employed. The additional data shall directly

compare the effect of optional component mounting (1 component case) to the preferred 4-