IEC 60086-3:2021

(Main)Primary batteries - Part 3: Watch batteries

Primary batteries - Part 3: Watch batteries

IEC 60086-3-5:2021 specifies dimensions, designation, methods of tests and requirements for primary batteries for watches. In several cases, a menu of test methods is given. When presenting battery electrical characteristics and/or performance data, the manufacturer specifies which test method was used.

The contents of the corrigendum of June 2023 have been included in this copy.

Piles électriques - Partie 3: Piles pour montres

Le contenu du corrigendum de juin 2023 a été pris en considération dans cet exemplaire.

General Information

- Status

- Published

- Publication Date

- 26-Apr-2021

- Technical Committee

- TC 35 - Primary cells and batteries

- Drafting Committee

- MT 13 - TC 35/MT 13

- Current Stage

- PPUB - Publication issued

- Start Date

- 27-Apr-2021

- Completion Date

- 14-May-2021

Relations

- Corrected By

IEC 60086-3:2021/COR1:2023 - Corrigendum 1 - Primary batteries - Part 3: Watch batteries - Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60086-3:2021 - Primary batteries, Part 3: Watch batteries - is the IEC international standard that specifies dimensions, designation, test methods and performance requirements for primary (non‑rechargeable) watch batteries. Edition 5.0 (2021‑04) with the June 2023 corrigendum included, this standard ensures mechanical and electrical compatibility between watch movements and button/coin cells from different manufacturers.

Key topics and requirements

The standard focuses on practical, testable requirements for watch batteries, including:

Physical requirements

- Standardized dimensions, symbols and size codes for zinc and lithium systems (see dimensional drawings and tables).

- Terminal design, shape, and projection tolerances to ensure mechanical fit and contact.

- Mechanical resistance to pressure and allowable deformation.

- Mandatory marking and disposal information.

Electrical requirements

- Defined electrochemical systems, nominal and end‑point voltages, and open‑circuit voltage (OCV) minima.

- Measurement of closed‑circuit voltage (CCV), internal resistance / impedance, and capacity.

- Capacity retention criteria and reporting practices.

Test methods and quality

- Menu of standardized test methods for shape, electrical characteristics and leakage resistance.

- Environmental conditions for testing (temperature, humidity, storage).

- Tests for leakage resistance (high temperature/humidity, temperature cycles).

- Sampling, visual examination and acceptance criteria for production control.

Important: when presenting electrical or performance data, the manufacturer must specify which test method was used, allowing apples‑to‑apples comparison.

Practical applications and users

IEC 60086-3:2021 is essential for stakeholders who design, manufacture, test or certify watch batteries and watch movements:

- Battery manufacturers - to design cells that meet global dimension, electrical and safety expectations and to document test methods and results.

- Watch designers and OEMs - to ensure battery compatibility, contact design and expected runtime/performance for watch models.

- Test laboratories and QA teams - to perform standardized tests for capacity, internal resistance, leakage and mechanical robustness.

- Distributors, importers and compliance officers - to verify markings, declarations and conformity for market access.

- Standards developers and regulators - to align national rules with international practice.

Related standards

- IEC 60086-1 - Primary batteries: General

- IEC 60086-2 - Primary batteries: Physical and electrical specifications

- IEC 60086-4 / -5 - Safety of lithium and aqueous electrolyte batteries

- ISO/TC 114 - Horology (collaboration on watch‑related requirements)

By following IEC 60086-3:2021, manufacturers and designers can achieve consistent watch battery interchangeability, reliable performance data and improved consumer safety.

IEC 60086-3:2021 - Primary batteries - Part 3: Watch batteries

REDLINE IEC 60086-3:2021 - Primary batteries - Part 3: Watch batteries Released:4/27/2021 Isbn:9782832297605

IEC 60086-3:2021 - Primary batteries - Part 3: Watch batteries

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60086-3:2021 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Primary batteries - Part 3: Watch batteries". This standard covers: IEC 60086-3-5:2021 specifies dimensions, designation, methods of tests and requirements for primary batteries for watches. In several cases, a menu of test methods is given. When presenting battery electrical characteristics and/or performance data, the manufacturer specifies which test method was used. The contents of the corrigendum of June 2023 have been included in this copy.

IEC 60086-3-5:2021 specifies dimensions, designation, methods of tests and requirements for primary batteries for watches. In several cases, a menu of test methods is given. When presenting battery electrical characteristics and/or performance data, the manufacturer specifies which test method was used. The contents of the corrigendum of June 2023 have been included in this copy.

IEC 60086-3:2021 is classified under the following ICS (International Classification for Standards) categories: 29.220.10 - Primary cells and batteries; 39.040.10 - Watches. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60086-3:2021 has the following relationships with other standards: It is inter standard links to IEC 60086-3:2021/COR1:2023, IEC 60086-3:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60086-3:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60086-3 ®

Edition 5.0 2021-04

INTERNATIONAL

STANDARD

Primary batteries –

Part 3: Watch batteries

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60086-3 ®

Edition 5.0 2021-04

INTERNATIONAL

STANDARD

Primary batteries –

Part 3: Watch batteries

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.220.10; 39.040.10 ISBN 978-2-8322-9686-8

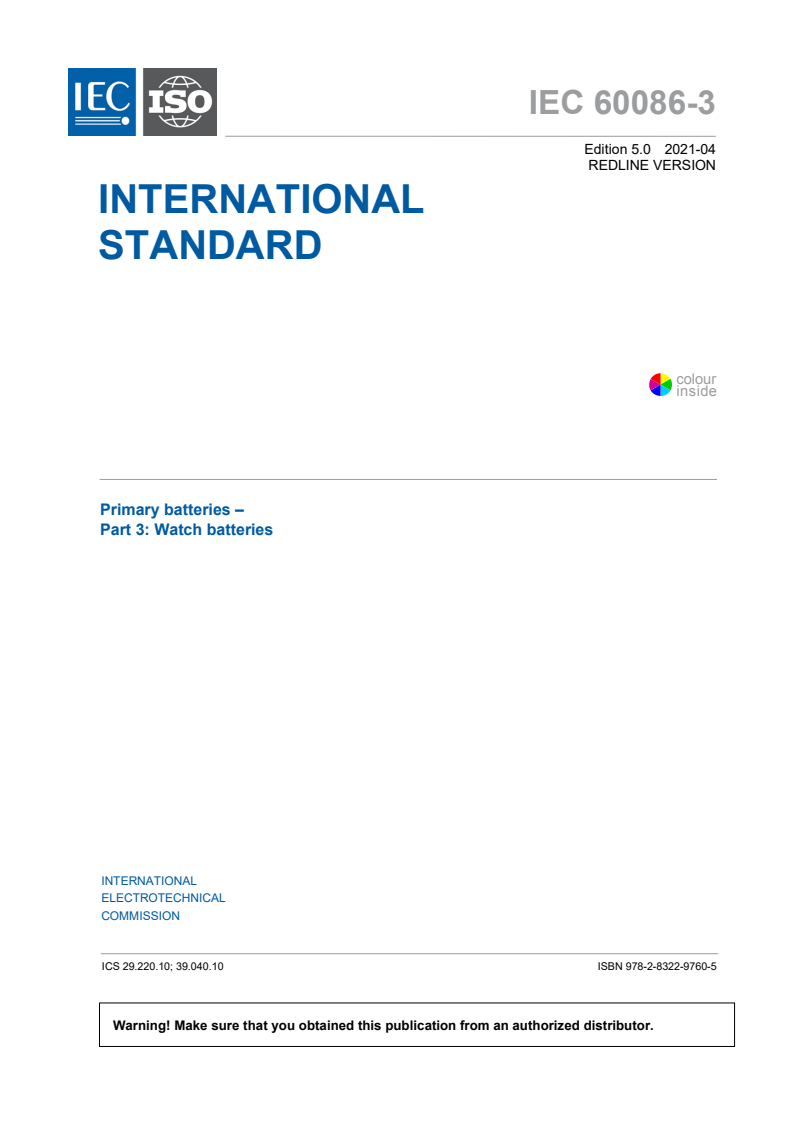

– 2 – IEC 60086-3:2021 © IEC 2021

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Physical requirements . 8

4.1 Battery dimensions, symbols and size codes . 8

4.2 Terminals . 11

4.3 Projection of the negative terminal (h ) . 11

4.4 Shape of battery . 11

4.5 Mechanical resistance to pressure . 12

4.6 Deformation . 12

4.7 Leakage . 12

4.8 Marking . 12

4.8.1 General . 12

4.8.2 Disposal . 13

5 Electrical requirements . 13

5.1 Electrochemical system, nominal voltage, end-point voltage and open-circuit

voltage . 13

5.2 Closed circuit voltage U (CCV), internal resistance and impedance . 13

cc

5.3 Capacity . 13

5.4 Capacity retention . 13

6 Sampling and quality assurance . 14

7 Test methods . 14

7.1 Shape and dimensions . 14

7.1.1 Shape requirement . 14

7.2 Electrical characteristics . 14

7.2.1 Environmental conditions . 14

7.2.2 Equivalent circuit – Effective internal resistance – DC method . 14

7.2.3 Equipment . 15

7.2.4 Measurement of open-circuit voltage U (OCV) and closed circuit

oc

voltage U (CCV) . 16

cc

7.2.5 Calculation of the internal resistance R . 17

i

7.2.6 Measurement of the capacity . 17

7.2.7 Calculation of the internal resistance R during discharge in case of

i

method A (optional) . 19

7.3 Test methods for determining the resistance to leakage . 19

7.3.1 Preconditioning and initial visual examination . 19

7.3.2 High temperature and humidity test . 20

7.3.3 Test by temperature cycles . 20

8 Visual examination and acceptance conditions . 20

8.1 Preconditioning . 20

8.2 Magnification . 21

8.3 Leakage levels and classification . 21

8.4 Acceptance conditions . 22

Annex A (normative) Designation . 23

Bibliography . 24

Figure 1 – Dimensional drawing . 8

Figure 2 – Shape of battery. 11

Figure 3 – Shape requirement . 14

Figure 4 – Schematic voltage transient . 15

Figure 5 – Curve: U = f(t) . 16

Figure 6 – Circuitry principle . 16

Figure 7 – Circuitry principle for method A . 18

Figure 8 – Circuitry principle for method B . 19

Figure 9 – Test by temperature cycles . 20

Table 1 – Zinc systems L and S dimensions and size codes . 9

Table 2 – Lithium systems B and C dimensions and size codes . 10

Table 3 – Values of l . 11

Table 4 – Applied force F by battery dimensions . 12

Table 5 – Standardised electrochemical systems . 13

Table 6 – Test method for U (CCV) measurement . 17

cc

Table 7 – Test method A for U (CCV) measurement . 18

cc

Table 8 – Storage conditions for the recommended test . 20

Table 9 – Storage conditions for optional test . 20

Table 10 – Leakage levels and classification . 21

– 4 – IEC 60086-3:2021 © IEC 2021

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PRIMARY BATTERIES –

Part 3: Watch batteries

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60086-3 has been prepared by IEC technical committee 35: Primary

cells and batteries, and ISO technical committee 114: Horology.

This fifth edition cancels and replaces the fourth edition published in 2016. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) reformatted Table 1 and Table 2. The reformatted tables are now divided by system.

Dimensional tolerances were changed when appropriate. Cell sizes were removed or added

based on the size prevalence in the market place;

b) in Table 3 the minimum values of l were reformatted;

c) the minimum OCV for the S system in Table 5 was changed to 1,55 V.

The text of this International Standard is based on the following documents:

FDIS Report on voting

35/1467/FDIS 35/1470/RVD

Full information on the voting for the approval of this International Standard can be found in the

report on voting indicated in the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 60086 series, published under the general title Primary batteries,

can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 60086-3:2021 © IEC 2021

INTRODUCTION

This part of IEC 60086 provides specific requirements and information for primary watch

batteries. This part of IEC 60086 was prepared through joint work between the IEC and ISO to

benefit primary battery users, watch designers and battery manufacturers by ensuring the best

compatibility between batteries and watches.

This part of IEC 60086 will remain under continual scrutiny to ensure that the publication is kept

up to date with the advances in both battery and watch technologies.

NOTE Safety information is available in IEC 60086-4 and IEC 60086-5.

PRIMARY BATTERIES –

Part 3: Watch batteries

1 Scope

This part of IEC 60086 specifies dimensions, designation, methods of tests and requirements

for primary batteries for watches. In several cases, a menu of test methods is given. When

presenting battery electrical characteristics and/or performance data, the manufacturer

specifies which test method was used.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60086-1, Primary batteries – Part 1: General

IEC 60086-2, Primary batteries – Part 2: Physical and electrical specifications

IEC 60086-4, Primary batteries – Part 4: Safety of lithium batteries

IEC 60086-5, Primary batteries – Part 5: Safety of batteries with aqueous electrolyte

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60086-1 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

capacitive reactance

part of the internal resistance that leads to a voltage drop during the first seconds under load

3.2

capacity

electric charge (quantity of electricity) which a cell or battery can deliver under specified

discharge conditions

Note 1 to entry: The SI unit for electric charge is the coulomb (1 C = 1 As) but, in practice, capacity is usually

expressed in ampere hours (Ah).

3.3

fresh battery

undischarged battery 60 days maximum after date of manufacture

– 8 – IEC 60086-3:2021 © IEC 2021

3.4

ohmic drop

part of the internal resistance that leads to a voltage drop immediately after switching the load

on

4 Physical requirements

4.1 Battery dimensions, symbols and size codes

Dimensions and tolerances of batteries for watches shall be in accordance with Figure 1,

Table 1 and Table 2. The dimensions of the batteries shall be tested in accordance with 7.1.

The symbols used to denote the various dimensions in Figure 1 are in accordance with

IEC 60086-2:2021, Clause 4.

Dimensions in millimetres

Key

h maximum overall height of the battery

h minimum distance between the flats of the positive and negative contacts

h minimum projection of the flat negative contact

maximum and minimum diameter of the battery

d

d minimum diameter of the flat positive contact

d minimum diameter of the flat negative contact

NOTE This numbering follows the harmonization in the IEC 60086 series.

Figure 1 – Dimensional drawing

Table 1 – Zinc systems L and S dimensions and size codes

Dimensions in millimetres

Height h /h

Diameter

1 2

a

Code

10 12 14 16 20 21 26 27 30 31 36 42 54

d

a

d

Tolerance

Code

Tolerances

0 0 0 0 0 0 0 0 0 0 0 0 0

−0,10 −0,15 −0,15 −0,18 −0,20 −0,20 −0,20 −0,20 −0,20 −0,25 −0,25 −0,25 −0,25

4 4,8 1,05 1,65 2,15

−0,15

5 5,8 2,6 1,05 1,25 1,65 2,15 2,70

−0,15

6 6,8 3,0 1,45 1,65 2,15 2,60

−0,15

7 7,9 3,5 1,25 1,45 1,65 2,10 2,60 3,10 3,60 5,40

−0,15

9 9,5 4,5 1,05 1,25 1,45 1,65 2,05 2,

...

IEC 60086-3

Edition 5.0 2021-04

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Primary batteries –

Part 3: Watch batteries

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60086-3

Edition 5.0 2021-04

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Primary batteries –

Part 3: Watch batteries

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.220.10; 39.040.10 ISBN 978-2-8322-9760-5

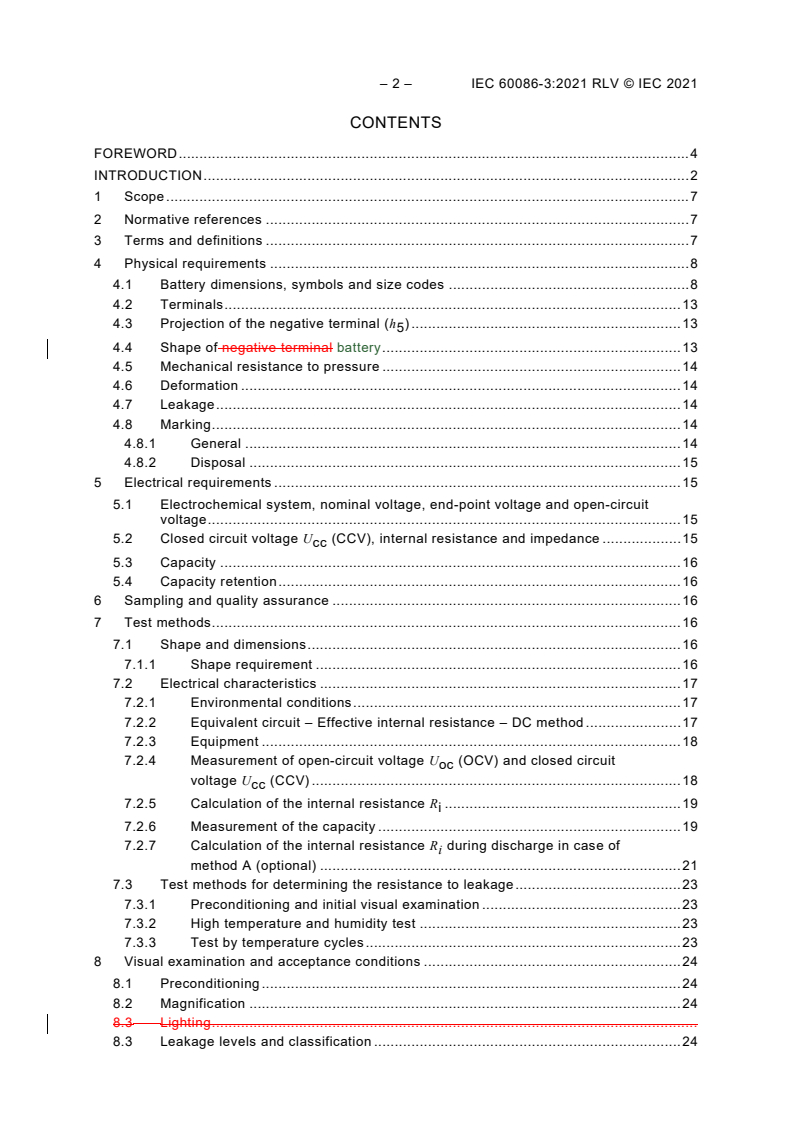

– 2 – IEC 60086-3:2021 RLV © IEC 2021

CONTENTS

FOREWORD . 4

INTRODUCTION . 2

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Physical requirements . 8

4.1 Battery dimensions, symbols and size codes . 8

4.2 Terminals . 13

4.3 Projection of the negative terminal (h ) . 13

4.4 Shape of negative terminal battery . 13

4.5 Mechanical resistance to pressure . 14

4.6 Deformation . 14

4.7 Leakage . 14

4.8 Marking . 14

4.8.1 General . 14

4.8.2 Disposal . 15

5 Electrical requirements . 15

5.1 Electrochemical system, nominal voltage, end-point voltage and open-circuit

voltage . 15

5.2 Closed circuit voltage U (CCV), internal resistance and impedance . 15

cc

5.3 Capacity . 16

5.4 Capacity retention . 16

6 Sampling and quality assurance . 16

7 Test methods . 16

7.1 Shape and dimensions . 16

7.1.1 Shape requirement . 16

7.2 Electrical characteristics . 17

7.2.1 Environmental conditions . 17

7.2.2 Equivalent circuit – Effective internal resistance – DC method . 17

7.2.3 Equipment . 18

7.2.4 Measurement of open-circuit voltage U (OCV) and closed circuit

oc

voltage U (CCV) . 18

cc

7.2.5 Calculation of the internal resistance R . 19

i

7.2.6 Measurement of the capacity . 19

7.2.7 Calculation of the internal resistance R during discharge in case of

i

method A (optional) . 21

7.3 Test methods for determining the resistance to leakage . 23

7.3.1 Preconditioning and initial visual examination . 23

7.3.2 High temperature and humidity test . 23

7.3.3 Test by temperature cycles . 23

8 Visual examination and acceptance conditions . 24

8.1 Preconditioning . 24

8.2 Magnification . 24

8.3 Lighting .

8.3 Leakage levels and classification . 24

8.4 Acceptance conditions . 25

Annex A (normative) Designation . 27

Bibliography . 28

Figure 1 – Dimensional drawing . 8

Figure 2 – Shape of negative terminal battery . 13

Figure 3 – Shape requirement . 16

Figure 4 – Schematic voltage transient . 17

Figure 5 – Curve: U = f(t) . 18

Figure 6 – Circuitry principle . 19

Figure 7 – Circuitry principle for method A . 20

Figure 8 – Circuitry principle for method B . 21

Figure 9 – Test by temperature cycles . 23

Table 1 – Zinc systems L and S dimensions and size codes . 9

Table 2 – Lithium systems B and C dimensions and size codes . 11

Table 3 – Minimum Values of l . 14

Table 4 – Applied force F by battery dimensions . 14

Table 5 – Standardised electrochemical systems . 15

Table 6 – Test method for U (CCV) measurement . 19

cc

Table 7 – Test method A for U (CCV) measurement . 20

cc

Table 8 – Discharge resistance (values) .

Table 8 – Storage conditions for the recommended test . 23

Table 9 – Storage conditions for optional test . 23

Table 10 – Leakage levels and classification . 24

– 4 – IEC 60086-3:2021 RLV © IEC 2021

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PRIMARY BATTERIES –

Part 3: Watch batteries

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes made to

the previous edition IEC 60086-3:2016. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 60086-3 has been prepared by IEC technical committee 35: Primary

cells and batteries, and ISO technical committee 114: Horology.

This fifth edition cancels and replaces the fourth edition published in 2016. This edition

constitutes a technical revision.

This publication is published as a double logo standard.

This edition includes the following significant technical changes with respect to the previous

edition:

a) reformatted Table 1 and Table 2. The reformatted tables are now divided by system.

Dimensional tolerances were changed when appropriate. Cell sizes were removed or added

based on the size prevalence in the market place;

b) in Table 3 the minimum values of l were reformatted;

c) the minimum OCV for the S system in Table 5 was changed to 1,55 V.

The text of this International Standard is based on the following documents:

FDIS Report on voting

35/1467/FDIS 35/1470/RVD

Full information on the voting for the approval of this International Standard can be found in the

report on voting indicated in the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 60086 series, published under the general title Primary batteries,

can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

The contents of the corrigendum 1 (2023-06) have been included in this copy.

– 6 – IEC 60086-3:2021 RLV © IEC 2021

INTRODUCTION

This part of IEC 60086 provides specific requirements and information for primary watch

batteries. This part of IEC 60086 was prepared through joint work between the IEC and ISO to

benefit primary battery users, watch designers and battery manufacturers by ensuring the best

compatibility between batteries and watches.

This part of IEC 60086 will remain under continual scrutiny to ensure that the publication is kept

up to date with the advances in both battery and watch technologies.

NOTE Safety information is available in IEC 60086-4 and IEC 60086-5.

PRIMARY BATTERIES –

Part 3: Watch batteries

1 Scope

This part of IEC 60086 specifies dimensions, designation, methods of tests and requirements

for primary batteries for watches. In several cases, a menu of test methods is given. When

presenting battery electrical characteristics and/or performance data, the manufacturer

specifies which test method was used.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60086-1:2015, Primary batteries – Part 1: General

IEC 60086-2:2015, Primary batteries – Part 2: Physical and electrical specifications

IEC 60086-4:2014, Primary batteries – Part 4: Safety of lithium batteries

IEC 60086-5:- , Primary batteries – Part 5: Safety of batteries with aqueous electrolyte

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60086-1 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

capacitive reactance

part of the internal resistance that leads to a voltage drop during the first seconds under load

3.2

capacity

electric charge (quantity of electricity) which a cell or battery can deliver under specified

discharge conditions

Note 1 to entry: The SI unit for electric charge is the coulomb (1 C = 1 As) but, in practice, capacity is usually

expressed in ampere hours (Ah).

___________

To be published.

– 8 – IEC 60086-3:2021 RLV © IEC 2021

3.3

fresh battery

undischarged battery 60 days maximum after date of manufacture

3.4

ohmic drop

part of the internal resistance that leads to a voltage drop immediately after switching the load

on

4 Physical requirements

4.1 Battery dimensions, symbols and size codes

Dimensions and tolerances of batteries for watches shall be in accordance with Figure 1,

Table 1 and Table 2. The dimensions of the batteries shall be tested in accordance with 7.1.

The symbols used to denote the various dimensions in Figure 1 are in accordance with

IEC 60086-2:20152021, Clause 4.

Dimensions in millimetres

Key

h maximum overall height of the battery

h minimum distance between the flats of the positive and negative contacts

h minimum projection of the flat negative contact

d maximum and minimum diameter of the battery

d minimum diameter of the flat positive contact

d minimum diameter of the flat negative contact

NOTE This numbering follows the harmonization in the IEC 60086 series.

Figure 1 – Dimensional drawing

Table 1 – Zinc systems L and S dimensions and size codes

Dimensions in millimetres

Height h /h

Diameter

1 2

a

Code

10 12 14 16 20 21 25 26 27 30 31 32 36 42 54

d

Tole-

a

d

Code

Tolerance

rance

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

–0,10 –0,15 –0,15 –0,18 –0,20 –0,20 –0,20 –0,20 –0,20 –0,25 –0,25 –0,25 –0,25 –0,25 –0,25

4 4,8 1,65 2,15

–0,15

5 5,8 2,6 1,05 1,25 1,45 1,65 2,15 2,70

–0,15

6 6,8 3,0 1,05 1,25 1,45 1,65 2,15 2,60

–0,15

7 7,9 3,5 1,05 1,25 1,45 1,65 2,10 2,60 3,10 3,60 5,40

–0,15

9 9,5 4,5 1,05 1,25 1,45 1,65 2,05 2,10 2,70 3,60

–0,15

10 10,0 3,0 2,50

–0,30

11 11,6 6,0 1,05 1,25 1,45 1,65 2,05 2,10 2,60 3,05 3,60 4,20 5,40

–0,20

12 12,5 4,0 1,20 1,60 2,00 2,50

–0,25

NOTE Open boxes in the above matrix are not necessarily available for standardisation due to the concept of overlapping tolerances.

a

See Annex A.

– 10 – IEC 60086-3:2021 RLV © IEC 2021

Dimensions in millimetres

Height h /h

Diameter

1 2

a

Code

10 12 14 16 20 21 26 27 30 31 36 42 54

d

a

d

Code Tolerance

Tolerances

0 0 0 0 0 0 0 0 0 0 0 0 0

−0,10 −0,15 −0,15 −0,18 −0,20 −0,20 −0,20 −0,20 −0,20 −0,25 −0,25 −0,25 −0,25

4 4,8 1,05 1,65 2,15

−0,15

5 5,8 2,6 1,05 1,25 1,65 2,15 2,70

−0,15

6 6,8 3,0 1,45 1,65 2,15 2,60

−0,15

7 7,9 3,5 1,25 1,45 1,65 2,10 2,60 3,10 3,60 5,40

−0,15

9 9,5 4,5 1,05 1,25 1,45 1,65 2,05 2,70 3,60

−0,15

11 11,6 6,0 1,65 2,05 3,05 3,60 4,20 5,40

−0,20

NOTE Open boxes in the above matrix are not necessarily available for standardization due to the concept of overlapping tolerances.

a

See Annex A.

Table 2 – Lithium systems B and C dimensions and size codes

Dimensions in millimetres

Height h /h

Diameter

1 2

a

Code

12 16 20 25 30 32

d

a

d

Tolerance

Code

Tolerances

0 0 0 0 0 0

–0,20 –0,20 –0,25 –0,30 –0,30 –0,30

16 16 5,00 1,20 1,60 2,00 2,50 3,20

–0,25

20 20 8,00 1,20 1,60 2,00 2,50 3,20

–0,25

23 23 8,00 1,20 1,60 2,00 2,50 3,00

–0,30

24 24,5 8,00 1,20 1,60 3,00

–0,30

NOTE Open boxes in the above matrix are not necessarily available for standardisation due to the concept of

overlapping tolerances.

a

See Annex A.

– 12 – IEC 60086-3:2021 RLV © IEC 2021

Dimensions in millimetres

Height h /h

Diameter

1 2

a

Code

12 16 20 25 30 32 50

d

a

d

Code Tolerance

Tolerances

0 0 0 0 0 0 0

−0,15 −0,18 −0,20 −0,20 −0,20 −0,25 −0,30

10 10,0 3,0 2,50

−0,15

12 12,5 4,0 1,60 2,00 2,50

−0,25

16 16 5,0 1,20 1,60 2,00 3,20

−0,25

20 20 8,0 1,20 1,60 2,50 3,20

−0,25

23 23 8,0 2,00 2,50

−0,25

24 24,5 8,0 3,00 5,00

−0,25

NOTE Open boxes in the above matrix are not necessarily available for standardization due to the concept of overlapping tolerances.

a

See Annex A.

4.2 Terminals

Negative contact (–): The negative contact (dimension d ) shall be in accordance with

Table 1 and Table 2. This is not applied to those batteries with

a two-step negative contact.

The cylindrical surface is connected to the positive terminal.

Positive contact (+):

Positive contact should be made to the side of the battery but

may be made to the base.

4.3 Projection of the negative terminal (h )

The dimension h shall be as follows:

h ≥ 0,02 for h /h ≤ 1,65

5 1 2

h ≥ 0,06 for 1,65 < h /h < 2,5

5 1 2

≥ 0,08 for h /h ≥ 2,5

h

5 1 2

The negative contact should be the highest point of the battery.

4.4 Shape of negative terminal battery

The space requirements shall be contained within secure the area enclosed by an angle of 45°

(see Figure 2).

The minimum values of l , for different heights of h /h , are given in Table 3.

1 1 2

l

45°

d

IEC

a) Figure 2a b) Figure 2b

Figure 2 – Shape of negative terminal battery

h /h

1 2

– 14 – IEC 60086-3:2021 RLV © IEC 2021

Table 3 – Minimum Values of l

Dimensions in millimetres

h /h l

1 2 1 min

1 < h /h ≤ 1,90

0,20

1 2

1,90 < h /h ≤ 3,10

0,35

1 2

3,10 < h /h ≤ 3,60

0,50

1 2

3,60 < h /h ≤ 4,20

0,70

1 2

4,20 < h /h ≤ 5.40

0,80

1 2

5,40 ≤< h /h

0,90

1 2

4.5 Mechanical resistance to pressure

A force F (N), as specified in Table 4, applied for 10 s through a steel ball of 1 mm diameter, at

the centre of each contact area, shall not cause any deformation prejudicial to the proper

functioning of the battery, i.e. after this test, the battery shall pass the tests specified in Clause 7.

Table 4 – Applied force F by battery dimensions

Battery dimensions Force

d h /h F

1 1 2

mm mm N

<3,0 5

< 7,9

≥3,0 10

<3,0 10

≥ 7,9

≥3,0 10

4.6 Deformation

The dimensions of batteries shall conform with the relevant specified dimensions at all times

including discharge to the defined end-point voltage.

NOTE 1 A battery height increase up to 0,25 mm can occur, if discharged below this voltage.

NOTE 2 A battery height decrease can occur in B and C systems as discharge continues.

Refer to IEC 60086-1 for dimensional stability.

4.7 Leakage

Undischarged batteries and, if required, batteries tested according to 7.2.6 shall be examined

as stated in 7.3. The acceptable number of defects shall be agreed between the manufacturer

and the purchaser.

4.8 Marking

4.8.1 General

The designation and the polarity shall be marked on the battery. Battery marking should not

impede electrical contact. All other markings may be given on the packing instead of on the

battery:

The battery and/or its packaging must be marked with the following:

a) designation according to normative Annex A, or common;

b) expiration of a recommended usage period or year and month or week of manufacture.

The year and month or week of manufacture may be in code. The code is composed of the

last digit of the year and of a number indicating the month. October, November and

December should be represented by the letters O, Y and Z respectively;

EXAMPLE

4191: January 20142019;

4Y9Y: November 20142019.

c) polarity of the positive (+) terminal;

d) nominal voltage;

e) name or trade mark of the supplier;

f) cautionary advice;

g) caution for ingestion of batteries shall be given. Refer to IEC 60086-4:20142019, 7.2 a) and

9.2, and IEC 60086-5:- 2016, 7.1 l) and 9.2, for details.

NOTE Examples of the common designations can be found in Annex D of IEC 60086-2:2015.

Battery marking should not impede electrical contact. The designation and the polarity shall be

marked on the battery. All other markings may be given on the packing instead of the battery.

4.8.2 Disposal

Marking of batteries with respect to the method of disposal shall be in accordance with local

legal requirements.

5 Electrical requirements

5.1 Electrochemical system, nominal voltage, end-point voltage and open-circuit

voltage

The requirements concerning the electrochemical system, the nominal voltage, the end-point

voltage and the open-circuit voltage are given in Table 5.

Table 5 – Standardised electrochemical systems

Letter Negative Electrolyte Positive electrode Nominal End- Open-circuit

electrode voltage point voltage

voltage

(V U ) (EV) (U or OCV)

n n OC

V V V

Max. Min.

B Lithium (Li) Organic electrolyte Carbon monofluoride (CF) 3,0 2,0 3,70 3,00

x

C Lithium (Li) Organic electrolyte Manganese dioxide (MnO ) 3,0 2,0 3,70 3,00

L Zinc (Zn) Alkali metal hydroxide Manganese dioxide (MnO ) 1,5 1,0 1,68 1,50

S Zinc (Zn) Alkali metal hydroxide Silver oxide (Ag O) 1,55 1,2 1,63 1,57

1,55

5.2 Closed circuit voltage U (CCV), internal resistance and impedance

cc

Closed circuit voltage and internal resistance shall be measured according to 7.2.

– 16 – IEC 60086-3:2021 RLV © IEC 2021

AC impedance should be measured with an LCR meter.

Limit values shall be agreed between the manufacturer and the purchaser.

5.3 Capacity

The capacity shall be agreed between the manufacturer and the purchaser on the basis of a

continuous discharge test lasting approximately 30 days, according to 7.2.6.

5.4 Capacity retention

The capacity retention is the ratio between the capacities under the given discharge conditions

measured on fresh batteries and a sample of the same lot stored during 365 days at (20 ± 2) °C

and a relative humidity between (55 ± 20) %.

The ratio of capacity retention shall be agreed between the manufacturer and the purchaser.

The minimum value should be at least 90 % for a period of 12 months. The capacity

measurement is carried out according to 7.2.6.

For the purpose of verifying compliance with this document, conditional acceptance may be

given after completion of the initial capacity tests.

6 Sampling and quality assurance

The use of sampling plans or product quality indices should be agreed between manufacturer

and purchaser.

Where no agreement is specified, refer to ISO 2859 and ISO 21747 for sampling and quality

compliance assessment advice.

7 Test methods

7.1 Shape and dimensions

7.1.1 Shape requirement

The shape of the negative contact is checked preferably by optical projection or by an open

gauge according to Figure 3.

The measurement method shall be agreed between the manufacturer and the purchaser.

Figure 3 – Shape requirement

Procedure:

The procedure to inspect with the open gauge is shown. The battery is moved toward the side

A of the gauge while applying the outer periphery of the positive electrode to the side B and

maintaining the flat part of the negative electrode terminal at 90 ° with respect to the side B. A

battery having a gap without contact between the side A of the gauge and the flat part of the

negative electrode terminal does not satisfy the requirements.

NOTE The surface of the open gauge is made of non-conductive hard resin to prevent external short circuit.

7.2 Electrical characteristics

7.2.1 Environmental conditions

Unless otherwise specified, the sample batteries shall be tested at a temperature of (20 ± 2) °C

+20

and a relative humidity between (55 ) %.

−40

During use, batteries may can be exposed to low temperatures; it is therefore recommended to

carry out complementary tests at (0 ± 2) °C and at (−10 ± 2) °C.

7.2.2 Equivalent circuit – Effective internal resistance – DC method

Resistance of any electrical component is determined by calculating the ratio between the

voltage drop ΔU across this component and the range of current Δi passing through this

component and causing the voltage drop R = ΔU / Δi.

NOTE As an analogy, the internal DC resistance R of any electrochemical cell is defined by the following relation:

i

∆U V()

R ()Ω=

(1)

i

∆i A()

The internal DC resistance is illustrated by the schematic voltage transient as given below in

Figure 4.

Figure 4 – Schematic voltage transient

As can be seen from the diagram in Figure 4, the voltage drop ΔU of the two components differs

in nature, as shown in the following relation:

(2)

∆U = ∆U +∆Ut

( )

Ω

– 18 – IEC 60086-3:2021 RLV © IEC 2021

The first component ΔU for (t = t ) is independent of time (ohmic drop), and results from the

Ω 1

increase in current Δi according to the relation:

∆U =∆×iR (3)

ΩΩ

In this relation, R is a pure ohmic resistance. The second component ΔU (t) is time dependent

Ω

and is of electrochemical origin (capacitive reactance).

7.2.3 Equipment

The equipment used for the voltage measurements shall have the following specifications:

– accuracy: ≤ 0,25 %;

– precision: ≤ 50 % of last digit;

– internal resistance: ≥ 1 MΩ;

– measurement time: in the tests proposed in the following subclauses, it is important

to make sure that the measurement is taken during the flat period

of the voltage transient (see Figure 5). Otherwise, a measurement

error due to the capacitive reactance may occur (lower internal

resistance).

The time Δt' necessary for the measurement shall be brief in comparison to Δt, and the

measurement equipment compatible with these criteria.

Key

1 open-circuit voltage U (OCV)

oc

2 effect of capacitive reactance

3 closed circuit voltage U (CCV)

cc

4 Δt' (measurement U )

cc

Figure 5 – Curve: U = f(t)

7.2.4 Measurement of open-circuit voltage U (OCV) and closed circuit voltage

oc

U (CCV)

cc

Refer to Figure 6:

First measurement U : The switch is left open while this measurement is being carried

oc

out.

Next measurement U : The battery being tested shall be connected to the load R . The

cc m

switch shall be left closed during the duration Δt according to Table 6.

Key

1 reading U / U

cc oc

2 R resistance of measurement

m

Figure 6 – Circuitry principle

Table 6 – Test method for U (CCV) measurement

cc

a

Test method All other batteries

Battery with KOH electrolyte

R Δt R Δt

m m

Ω s Ω ms

b

150 ± 0,5 % 1 ± 5 % 1 500 ± 0,5 % 10 ± 5 %

A

c

150 ± 0,5 % 0,5 – 2 470 ± 0,5 % 500 – 2 000

B

d

200 ± 0,5 % 5 ± 5 % 2 000 ± 0,5 % 7,8 ± 5 %

C

R should take into consideration the resistance of the connection lines of the battery being tested and the contact

m

resistance of the switch.

a

Application with high peak current.

b

Method A (recommended test): requires specialised test equipment.

c

Method B: to be used in the absence of method A test equipment.

d

Method C: to be used only by agreement between the manufacturer and the purchaser.

7.2.5 Calculation of the internal resistance R

i

The internal resistance may be determined by the following calculation:

U − U

oc cc

R = (4)

i

UR/

cc m

NOTE The relation U / R corresponds to the current delivered through the discharge resistance R (see 7.2.4).

cc m m

7.2.6 Measurement of the capacity

7.2.6.1 General

There are two methods for measuring capacity:

– the recommended method is method A, which is more indicative of watch requirements;

– method B is a more general method and is already specified in IEC 60086-1 and

IEC 60086-2.

When presenting capacity data, the manufacturer shall specify which test method was used.

– 20 – IEC 60086-3:2021 RLV © IEC 2021

7.2.6.2 Method A

a) Circuitry principle (see Figure 7).

Key

1 reading U / U’

cc oc

2 R resistance of measurement

m

3 R resistance of continuous discharge

d

Figure 7 – Circuitry principle for method A

b) Procedure

The duration of the discharge test at the resistor R approximates to 30 days.

d

Value of the resistance R : the value of the resistive load (specified in Tables 7 and 8) shall

d

include all parts of the external circuit and shall be accurate to within ±0,5 %.

c) Determination of the capacity

The measurements of the open-circuit voltage U' and that of the closed circuit voltage U

oc cc

are carried out at least once a day on the battery permanently connected to R , until the first

d

passage of the U under the end-point voltage defined in Table 5 is obtained.

cc

1) First measurement U' : the resistance R being much higher than R , U' approximates

oc d m oc

to U .

oc

The switch is left open while the measurement is being carried out.

: the battery being tested is connected to R . The switch is left

2) Next measurement U

cc m

closed during the duration Δt according to Table 7.

Table 7 – Test method A for U (CCV) measurement

cc

Batteries with KOH electrolyte All other batteries

R Δt R Δt

m m

Ω s Ω ms

150 ± 0,5 % 1 ± 5 % 1 500 ± 0,5 % 10 ± 5 %

3) Calculation of the capacity C: the capacity of the battery is obtained by adding the partial

capacity amounts C , calculated after each measurement by the following formula:

p

′

Ut×

oc i

C = (5)

p

R

d

where t is the time between two measurements

i

C = Σ C (6)

p

4) Near the end of discharge, it is recommended to carry out several measurements of U’

oc

a day in order to obtain sufficient accuracy.

7.2.6.3 Method B

a) Circuitry principle (see Figure 8).

Key

1 reading U

cc

2 R resistance of continuous discharge

d

Figure 8 – Circuitry principle for method B

b) See procedure in 7.2.6.2 b).

c) Determination of the capacity: when the on-load voltage of the battery under test drops for

the first time below the specified end point voltage as specified in Table 5, the time t is

calculated and defined as service life.

The capacity is calculated by the following formula:

U (average)

cc

C = t

R

d

(7)

where

C is the capacity;

U (average) is the average voltage value of U during discharge duration time

cc cc

(0 – t);

t is the service life.

7.2.7 Calculation of the internal resistance R during discharge in case of method A

i

(optional)

After each measurement of U' and U is carried out according to the procedure described in

oc cc

7.2.6, it is possible to calculate the internal resistance R of the battery by using the following

i

formula:

UU' −

oc cc

R = (8)

i

UR/

cc m

– 22 – IEC 60086-3:2021 RLV © IEC 2021

Table 8 – Discharge resistance (values)

Letter for electrochemical Letter for electrochemical

systems systems

Code number Code number

L S C B

according to the according to the

dimensions dimensions

Discharge resistance Discharge resistance

kΩ kΩ

416 1025 68

421 1212

510 1216 62

512 1220 62

514 1225 30

516 82 1612

521 68 1616 30

527 56 1620 47

610 1625

612 1632

614 120 2012 30

616 100 2016 30 30

621 68 2020 30

626 47 2025 15

710 2032 15

712 100 2312

714 68 2316

716 68 2320 15 15

721 47 2325 15

726 33 2412

731 27 2416

736 22 22 2330 15

754 15 2430 15

916 47

920 33

921 33

927 22

936 15

1116 39

1120 22

1121 22 22

1126 15

1130 15 15

1136 15

1142 10 10

1154 6,8 6,8

NOTE Blank values under consideration.

7.3 Test methods for determining the resistance to leakage

7.3.1 Preconditioning and initial visual examination

Before carrying out the tests specified in 7.3.2 and 7.3.3, the batteries shall be submitted to a

visual examination according to the requirements stated in Clause 8.

For tests in 7.3.2.1 and 7.3.2.2, batteries shall be pre-stored at the specified temperature (40 °C

and 45 °C respectively) for 2 h. Batteries shall be moved from the preconditioning (alternative

pre-stored) chamber (or oven) into the high temperature and humidity test chamber within

minutes in order to avoid cooling of the battery and the risk of condensation at elevated humidity.

7.3.2 High temperature and humidity test

7.3.2.1 Recommended test

The battery shall be stored under the conditions specified in Table 8.

Table 8 – Storage conditions for the recommended test

Temperature Relative humidity Test time

°C % days

40 ± 2 90 to 95 30 or 90

The test time of 30 days may be used for an accelerated routine quality control test,

whereas the test time of 90 days applies to qualification testing of new batteries.

7.3.2.2 Optional test

After agreement between the manufacturer and purchaser, the following testing conditions may

be chosen (see Table 9).

Table 9 – Storage conditions for optional test

Temperature Relative humidity Test time

°C % days

45 ± 2 90 to 95 20 or 60

The test time of 20 days may be used for an accelerated routine quality control test,

whereas the test time of 60 days applies to qualification testing of new batteries.

7.3.3 Test by temperature cycles

The battery shall be submitted to 150 temperature cycles according to the schedule in Figure 9:

Figure 9 – Test by temperature cycles

– 24 – IEC 60086-3:2021 RLV © IEC 2021

8 Visual examination and acceptance conditions

8.1 Preconditioning

Before carrying out the initial visual examination or after the tests specified in Clause 7, the

batteries shall be stored for at least 24 h at room temperature and at a relative humidity between

(55 ± 20) %.

The leakage should be observed after crystallisation of the electrolyte. The time of the storage

of 24 h can be prolonged if necessary. This examination may be applied to new or used batteries,

or to batteries which have been submitted to different tests.

8.2 Magnification

The visual examination shall be carried out at a magnification of x15.

8.3 Lighting

The visual examination shall be carried out under a diffuse white light of 900 lx to 1 100 lx at

the surface of the battery to be inspected.

8.3 Leakage levels and classification

The visual examination shall be carried out under a diffuse white light of 900 lx to 1 100 lx at

the surface of the battery to be inspected (see Table 10).

Table 10 – Leakage levels and classification

Leakage levels

Diagram Definition

Classification Grade

Little salting found near the gasket,

affecting less than 10 % of the

perimeter of the gasket, detected while

S1

observing at a magnification of x15.

The leak is not detectable with the

naked eye.

Salting

Traces of salting near gasket can be

detected with the naked eye. At a

S2 magnification of x15, it may be noted

that these salts affect more than 10 %

of the perimeter of the gasket.

Leakage levels

Diagram Definition

Classification Grade

Salt spreads on both sides of the

gasket can be detected with the naked

S3

eye, but do not reach the flat of the

negative contact.

Leaks spread in clouds on both sides of

the gasket, do reach the flat of the

C1

negative contact but do not reach the

central part of the flat negative contact.

Clouds

Leaks spread in clouds, which reach

C2 the central part of the flat negative

contact.

The accumulation of crystallised liquid

coming from the electrolyte swells up

L1 on part of the cloud spread, which

covers the entire surface of the flat

negative contact.

Leaks

The accumulation of crystallised liquid

coming from the electrolyte swells up

L2 on the entire cloud spread, which

covers the entire surface of the flat

negative contact.

8.4 Acceptance conditions

The acceptable level, as well as the proportion of defective pieces, shall be agreed between

the manufacturer and the purchaser.

– 26 – IEC 60086-3:2021 RLV © IEC 2021

Fresh batteries, with a level of leakage exceeding S1, shall not be submitted for qualification.

The acceptance criteria may be less restrictive for batteries which have been tested according

to 7.3.2. If necessary, photographic references m

...

IEC 60086-3

Edition 5.0 2021-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Primary batteries –

Part 3: Watch batteries

Piles électriques –

Partie 3: Piles pour montres

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC online collection - oc.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur adapté à vos besoins.

les projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au

Restez informé sur les nouvelles publications IEC. Just

monde, avec plus de 22 000 articles terminologiques en

Published détaille les nouvelles publications parues.

anglais et en français, ainsi que les termes équivalents dans

Disponible en ligne et une fois par mois par email.

16 langues additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 60086-3

Edition 5.0 2021-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Primary batteries –

Part 3: Watch batteries

Piles électriques –

Partie 3: Piles pour montres

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.220.10; 39.040.10 ISBN 978-2-8322-1030-9

– 2 – IEC 60086-3:2021 © IEC 2021

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Physical requirements . 8

4.1 Battery dimensions, symbols and size codes . 8

4.2 Terminals . 11

4.3 Projection of the negative terminal (h ) . 11

4.4 Shape of battery . 11

4.5 Mechanical resistance to pressure . 12

4.6 Deformation . 12

4.7 Leakage . 12

4.8 Marking . 12

4.8.1 General . 12

4.8.2 Disposal . 13

5 Electrical requirements . 13

5.1 Electrochemical system, nominal voltage, end-point voltage and open-circuit

voltage . 13

5.2 Closed circuit voltage U (CCV), internal resistance and impedance . 13

cc

5.3 Capacity . 13

5.4 Capacity retention . 13

6 Sampling and quality assurance . 14

7 Test methods . 14

7.1 Shape and dimensions . 14

7.1.1 Shape requirement . 14

7.2 Electrical characteristics . 14

7.2.1 Environmental conditions . 14

7.2.2 Equivalent circuit – Effective internal resistance – DC method . 14

7.2.3 Equipment . 15

7.2.4 Measurement of open-circuit voltage U (OCV) and closed circuit

oc

voltage U (CCV) . 16

cc

7.2.5 Calculation of the internal resistance R . 17

i

7.2.6 Measurement of the capacity . 17

7.2.7 Calculation of the internal resistance R during discharge in case of

i

method A (optional) . 19

7.3 Test methods for determining the resistance to leakage . 19

7.3.1 Preconditioning and initial visual examination . 19

7.3.2 High temperature and humidity test . 20

7.3.3 Test by temperature cycles . 20

8 Visual examination and acceptance conditions . 20

8.1 Preconditioning . 20

8.2 Magnification . 21

8.3 Leakage levels and classification . 21

8.4 Acceptance conditions . 22

Annex A (normative) Designation . 23

Bibliography . 24

Figure 1 – Dimensional drawing . 8

Figure 2 – Shape of battery. 11

Figure 3 – Shape requirement . 14

Figure 4 – Schematic voltage transient . 15

Figure 5 – Curve: U = f(t) . 16

Figure 6 – Circuitry principle . 16

Figure 7 – Circuitry principle for method A . 18

Figure 8 – Circuitry principle for method B . 19

Figure 9 – Test by temperature cycles . 20

Table 1 – Zinc systems L and S dimensions and size codes . 9

Table 2 – Lithium systems B and C dimensions and size codes . 10

Table 3 – Values of l . 11

Table 4 – Applied force F by battery dimensions . 12

Table 5 – Standardised electrochemical systems . 13

Table 6 – Test method for U (CCV) measurement . 17

cc

Table 7 – Test method A for U (CCV) measurement . 18

cc

Table 8 – Storage conditions for the recommended test . 20

Table 9 – Storage conditions for optional test . 20

Table 10 – Leakage levels and classification . 21

– 4 – IEC 60086-3:2021 © IEC 2021

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PRIMARY BATTERIES –

Part 3: Watch batteries

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60086-3 has been prepared by IEC technical committee 35: Primary

cells and batteries, and ISO technical committee 114: Horology.

This fifth edition cancels and replaces the fourth edition published in 2016. This edition

constitutes a technical revision.

This publication is published as a double logo standard.

This edition includes the following significant technical changes with respect to the previous

edition:

a) reformatted Table 1 and Table 2. The reformatted tables are now divided by system.

Dimensional tolerances were changed when appropriate. Cell sizes were removed or added

based on the size prevalence in the market place;

were reformatted;

b) in Table 3 the minimum values of l

c) the minimum OCV for the S system in Table 5 was changed to 1,55 V.

The text of this International Standard is based on the following documents:

FDIS Report on voting

35/1467/FDIS 35/1470/RVD

Full information on the voting for the approval of this International Standard can be found in the

report on voting indicated in the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 60086 series, published under the general title Primary batteries,

can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 60086-3:2021 © IEC 2021

INTRODUCTION

This part of IEC 60086 provides specific requirements and information for primary watch

batteries. This part of IEC 60086 was prepared through joint work between the IEC and ISO to

benefit primary battery users, watch designers and battery manufacturers by ensuring the best

compatibility between batteries and watches.

This part of IEC 60086 will remain under continual scrutiny to ensure that the publication is kept

up to date with the advances in both battery and watch technologies.

NOTE Safety information is available in IEC 60086-4 and IEC 60086-5.

PRIMARY BATTERIES –

Part 3: Watch batteries

1 Scope

This part of IEC 60086 specifies dimensions, designation, methods of tests and requirements

for primary batteries for watches. In several cases, a menu of test methods is given. When

presenting battery electrical characteristics and/or performance data, the manufacturer

specifies which test method was used.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.