IEC 61340-4-9:2024

(Main)Electrostatics - Part 4-9: Standard test methods for specific applications - Garments - Resistive characterization

Electrostatics - Part 4-9: Standard test methods for specific applications - Garments - Resistive characterization

IEC 61340-4-9:2024 provides test methods for measuring the electrical resistance of garments used for static control applications. These test methods can be used for evaluating outer garments that are homogenously conductive or homogeneously dissipative, or that utilize surface conductive or surface dissipative components or elements.

NOTE It is possible that the test methods defined in this document will not be able to measure materials with buried conductive layers.

This third edition includes the following significant technical changes with respect to the previous edition:

a) IEC 61010-1 and IEC 61010-2-030 added as requirements for measurement equipment;

b) testing voltage range for personnel ground path changed from "7 V DC to 30 V DC" to "7 V DC to 100 V DC";

c) cleaning requirements changed from a minimum of five cycles of cleaning to a minimum of three cycles of cleaning;

d) moderate humidity requirements deleted;

e) figures replaced with generic drawings.

Électrostatique - Partie 4-9: Méthodes d'essai normalisées pour des applications spécifiques - Vêtements - Caractéristiques résistives

L'IEC 61340-4-9:2024 fournit des méthodes d'essai pour mesurer la résistance électrique des vêtements utilisés pour des applications de contrôle des DES. Ces méthodes d'essai peuvent être utilisées pour évaluer des vêtements extérieurs conducteurs de façon homogène ou dissipatifs de façon homogène, ou qui comportent des composants ou des éléments à surface conductrice ou dissipative.

NOTE Il est possible que les méthodes d'essai spécifiées dans le présent document ne permettent pas le mesurage des matériaux à couches conductrices enfouies.

Cette troisième édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) l'IEC 61010-1 et l'IEC 61010-2-030 ont été ajoutées comme exigences pour les appareils de mesure;

b) la plage de tensions d'essai pour le chemin de mise à la terre du personnel est passée de "7 V à 30 V en courant continu" à "7 V à 100 V en courant continu";

c) les exigences de nettoyage sont passées de cinq cycles de nettoyage au minimum à trois cycles de nettoyage au minimum;

d) les exigences concernant l'humidité modérée ont été supprimées;

e) les figures ont été remplacées par des dessins génériques.

General Information

- Status

- Published

- Publication Date

- 22-Oct-2024

- Technical Committee

- TC 101 - Electrostatics

- Drafting Committee

- WG 5 - TC 101/WG 5

- Current Stage

- PPUB - Publication issued

- Start Date

- 23-Oct-2024

- Completion Date

- 01-Nov-2024

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61340-4-9:2024 - Electrostatics, Part 4-9 - defines standard test methods for resistive characterization of garments used in static control and electrostatic discharge (ESD) protection. The third edition updates measurement equipment requirements, personnel ground path testing range, cleaning and conditioning procedures, and replaces detailed figures with generic drawings. It is intended for evaluating outer garments that are homogeneously conductive or dissipative, or that include surface conductive/dissipative components. Note: these methods may not detect materials with buried conductive layers.

Key topics and technical requirements

- Scope of tests: Measurement of garment electrical resistance including:

- Resistance point-to-point (e.g., sleeve-to-sleeve, panel-to-panel)

- Resistance point-to-groundable point

- Cuff measurements

- Groundable garment system resistance (person + garment)

- Equipment and safety:

- Measurement equipment required to meet electrical safety standards IEC 61010-1 and IEC 61010-2-030.

- Specifics for resistance measurement apparatus, electrodes, clamps, cuff fixtures and hand-held electrodes are defined.

- Personnel ground path testing:

- Testing voltage range updated to 7 V DC to 100 V DC for personnel ground path measurements.

- Sample preparation and conditioning:

- Cleaning requirement revised to a minimum of three cleaning cycles before testing.

- Humidity conditioning focuses on low-humidity environments; previous “moderate humidity” requirement removed.

- Limitations:

- Methods may be unable to measure materials containing buried conductive layers.

- Reporting and product qualification:

- Defined procedures for product qualification, acceptance testing and standardized reporting formats (including example data collection sheets).

Applications and who uses this standard

- Who: Test laboratories, garment manufacturers, ESD program managers, QA engineers, procurement and compliance officers in electronics, semiconductor, aerospace, medical device, and cleanroom industries.

- Why:

- To verify and qualify ESD garments and groundable garment systems for use in static-sensitive work areas.

- To support product acceptance testing, supplier evaluations and internal quality control.

- To ensure garments provide appropriate resistance and ground paths for ESD control programs.

Related standards

- IEC 61340 series (other electrostatics standards) - for broader ESD control frameworks.

- IEC 61010-1 and IEC 61010-2-030 - referenced for measurement equipment safety requirements.

Keywords: IEC 61340-4-9, electrostatics, resistive characterization, ESD garments, static control garments, resistance measurement, personnel ground path, IEC 61010.

Frequently Asked Questions

IEC 61340-4-9:2024 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electrostatics - Part 4-9: Standard test methods for specific applications - Garments - Resistive characterization". This standard covers: IEC 61340-4-9:2024 provides test methods for measuring the electrical resistance of garments used for static control applications. These test methods can be used for evaluating outer garments that are homogenously conductive or homogeneously dissipative, or that utilize surface conductive or surface dissipative components or elements. NOTE It is possible that the test methods defined in this document will not be able to measure materials with buried conductive layers. This third edition includes the following significant technical changes with respect to the previous edition: a) IEC 61010-1 and IEC 61010-2-030 added as requirements for measurement equipment; b) testing voltage range for personnel ground path changed from "7 V DC to 30 V DC" to "7 V DC to 100 V DC"; c) cleaning requirements changed from a minimum of five cycles of cleaning to a minimum of three cycles of cleaning; d) moderate humidity requirements deleted; e) figures replaced with generic drawings.

IEC 61340-4-9:2024 provides test methods for measuring the electrical resistance of garments used for static control applications. These test methods can be used for evaluating outer garments that are homogenously conductive or homogeneously dissipative, or that utilize surface conductive or surface dissipative components or elements. NOTE It is possible that the test methods defined in this document will not be able to measure materials with buried conductive layers. This third edition includes the following significant technical changes with respect to the previous edition: a) IEC 61010-1 and IEC 61010-2-030 added as requirements for measurement equipment; b) testing voltage range for personnel ground path changed from "7 V DC to 30 V DC" to "7 V DC to 100 V DC"; c) cleaning requirements changed from a minimum of five cycles of cleaning to a minimum of three cycles of cleaning; d) moderate humidity requirements deleted; e) figures replaced with generic drawings.

IEC 61340-4-9:2024 is classified under the following ICS (International Classification for Standards) categories: 17.200.99 - Other standards related to thermodynamics; 29.020 - Electrical engineering in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61340-4-9:2024 has the following relationships with other standards: It is inter standard links to IEC 61340-4-9:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61340-4-9:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61340-4-9 ®

Edition 3.0 2024-10

COMMENTED VERSION

INTERNATIONAL

STANDARD

colour

inside

Electrostatics –

Part 4-9: Standard test methods for specific applications – Garments – Resistive

characterization

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a

Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and

containing more than 22 500 terminological entries in English

once a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61340-4-9 ®

Edition 3.0 2024-10

COMMENTED VERSION

INTERNATIONAL

STANDARD

colour

inside

Electrostatics –

Part 4-9: Standard test methods for specific applications – Garments – Resistive

characterization

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 17.200.99, 29.020 ISBN 978-2-8322-9965-4

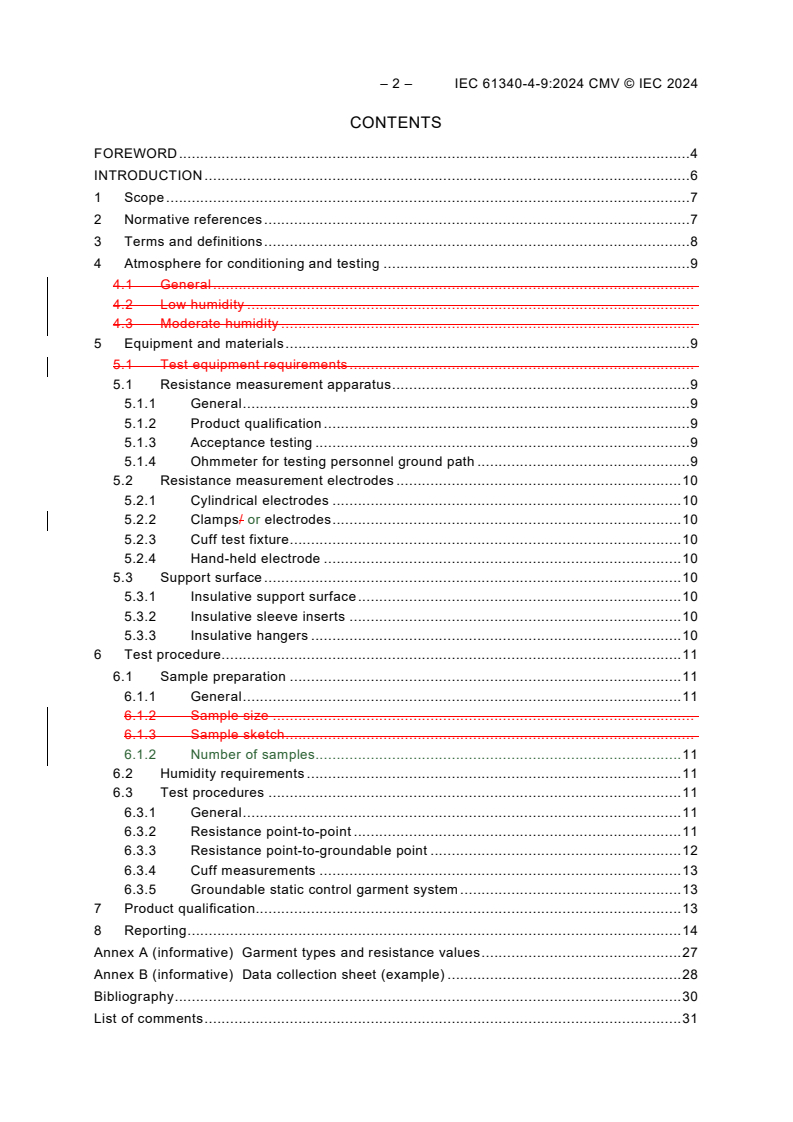

– 2 – IEC 61340-4-9:2024 CMV © IEC 2024

CONTENTS

FOREWORD .4

INTRODUCTION .6

1 Scope .7

2 Normative references .7

3 Terms and definitions .8

4 Atmosphere for conditioning and testing .9

4.1 General .

4.2 Low humidity .

4.3 Moderate humidity .

5 Equipment and materials .9

5.1 Test equipment requirements .

5.1 Resistance measurement apparatus .9

5.1.1 General .9

5.1.2 Product qualification .9

5.1.3 Acceptance testing .9

5.1.4 Ohmmeter for testing personnel ground path .9

5.2 Resistance measurement electrodes . 10

5.2.1 Cylindrical electrodes . 10

5.2.2 Clamps/ or electrodes . 10

5.2.3 Cuff test fixture . 10

5.2.4 Hand-held electrode . 10

5.3 Support surface . 10

5.3.1 Insulative support surface . 10

5.3.2 Insulative sleeve inserts . 10

5.3.3 Insulative hangers . 10

6 Test procedure . 11

6.1 Sample preparation . 11

6.1.1 General . 11

6.1.2 Sample size .

6.1.3 Sample sketch .

6.1.2 Number of samples . 11

6.2 Humidity requirements . 11

6.3 Test procedures . 11

6.3.1 General . 11

6.3.2 Resistance point-to-point . 11

6.3.3 Resistance point-to-groundable point . 12

6.3.4 Cuff measurements . 13

6.3.5 Groundable static control garment system . 13

7 Product qualification . 13

8 Reporting . 14

Annex A (informative) Garment types and resistance values . 27

Annex B (informative) Data collection sheet (example) . 28

Bibliography . 30

List of comments . 31

Figure 1 – Test set-up – Resistance point-to-point (sleeve-to-sleeve procedure with

insulative sleeve inserts) . 15

Figure 2 – Test set-up – Resistance point-to-point (insulative sleeve insert inserted

into sleeve detail) . 16

Figure 3 – Test set-up – Resistance point-to-point (panel-to-panel procedure with

insulative support surface). 17

Figure 4 – Test set-up – Resistance point-to-point (cuff-to-cuff procedure with

insulative sleeve inserts) . 18

Figure 5 – Test set-up – Resistance point-to-point (electrode inserted into cuff detail) . 19

Figure 6 – Test set-up – Resistance point-to-point (hanging clamp sleeve-to-sleeve

procedure) . 20

Figure 7 – Clamps/ or electrodes for hanging garment test . 21

Figure 8 – Test set-up – Resistance point-to-groundable point (cuff-to-groundable-

point procedure with insulative sleeve inserts) . 22

Figure 9 – Test set-up – Resistance point-to-groundable point (sleeve-to-groundable-

point procedure with insulative sleeve inserts) . 23

Figure 10 – Groundable garment cuff test . 24

Figure 11 – Test set-up – Groundable static control garment system resistance

(groundable garment in combination with a person using a meter and hand-held

electrode) . 25

Figure 12 – Test set-up – Groundable static control garment system resistance

(groundable garment in combination with a person using an integrated tester) . 26

Table 1 – Product qualification . 14

Table A.1 – Garment types and resistance values . 27

– 4 – IEC 61340-4-9:2024 CMV © IEC 2024

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTROSTATICS –

Part 4-9: Standard test methods for specific applications –

Garments – Resistive characterization

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

This commented version (CMV) of the official standard IEC 61340-4-9:2024 edition 3.0

allows the user to identify the changes made to the previous IEC 61340-4-9:2016

edition 2.0. Furthermore, comments from IEC TC 101 experts are provided to explain the

reasons of the most relevant changes, or to clarify any part of the content.

A vertical bar appears in the margin wherever a change has been made. Additions are in

green text, deletions are in strikethrough red text. Experts' comments are identified by a

blue-background number. Mouse over a number to display a pop-up note with the

comment.

This publication contains the CMV and the official standard. The full list of comments is

available at the end of the CMV.

IEC 61340-4-9 has been prepared by IEC technical committee 101: Electrostatics. It is an

International Standard.

This third edition cancels and replaces the second edition published in 2016. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) IEC 61010-1 and IEC 61010-2-030 added as requirements for measurement equipment;

b) testing voltage range for personnel ground path changed from "7 V DC to 30 V DC" to

"7 V DC to 100 V DC";

c) cleaning requirements changed from a minimum of five cycles of cleaning to a minimum of

three cycles of cleaning;

d) moderate humidity requirements deleted;

e) figures replaced with generic drawings.

The text of this International Standard is based on the following documents:

Draft Report on voting

101/718/FDIS 101/721/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 61340 series, published under the general title Electrostatics, can

be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

– 6 – IEC 61340-4-9:2024 CMV © IEC 2024

INTRODUCTION

This part of IEC 61340 provides test methods for evaluating the electrical resistance of

garments that contain surface conductive or dissipative components or materials used in the

electronics industry for the control of electrostatic discharge. This document defines procedures

for measuring electrical resistance, including a system resistance test for garments that provide

a ground path for personnel.

Clothing made from synthetic fibres is a common source of electrostatic charge. Wearing an

appropriate static control garment over personnel clothing can minimize the effect of this

charge. To effectively control electrostatic charges of the static control garments and effectively

shield the electrostatic field of personnel clothing, the static control garment should be

grounded.

Three categories of garments are considered in this document.

a) A static control garment may can suppress or otherwise affect an electric field from clothing

worn underneath the garment without being attached to ground. However, without

grounding, a charge may can accumulate on conductive or dissipative elements of a

garment, if present, resulting in a charged source.

b) A groundable static control garment may can provide a higher level of suppression when

the lower resistance fabric is connected to ground.

c) A groundable static control garment system provides a ground path for a person that

suppresses the electrical field from clothing worn underneath the garment and also bonds

the skin of the wearer to an identified ground path. Groundable static control garment

systems may can also be used in conjunction with a continuous or constant monitoring

system in a manner similar to those used in continuous monitoring of wrist straps in an ESD

protected area (EPA).

Resistive characterization is only one aspect to consider in evaluating garments for any specific

application. To fully characterize a garment, it can be necessary to take into consideration

electrical field attenuation, static decay, peak voltage, residual voltage and triboelectric

charging may need to be considered. Other attributes related to applications and environments,

such as cleanroom compatibility, chemical and fire resistance, should be evaluated in the

garment selection process but are beyond the scope of this document.

Garments constructed from fabrics made with fibres that are not surface conductive but may

can have other related properties that impart some level of electrostatic charge dissipation or

suppression when connected to ground, are not specifically measured by the methods provided

in this document. This being the case, some garment fabrics and construction may can allow

for surface voltage accumulation and charge transfer to occur which may can be detrimental to

electronic items.

Alternate methods for evaluating the electrostatic properties of garments are described in

IEC TS 61340-4-2 [1] .

___________

Numbers in square brackets refer to the Bibliography.

ELECTROSTATICS –

Part 4-9: Standard test methods for specific applications –

Garments – Resistive characterization

1 Scope

This part of IEC 61340 provides test methods for measuring the electrical resistance of

garments used for static control applications. These test methods can be used for evaluating

outer garments that are homogenously conductive or homogeneously dissipative, or that utilize

surface conductive or surface dissipative components or elements.

NOTE It is possible that the test methods defined in this document may will not be able to measure materials with

buried conductive layers.

The resistance point-to-point test method tests the electrical resistance between the two

sleeves, any two panels or any two or more electrically interconnected components of the static

control garment, including the electrical resistance across the seams and cuffs of the garment

as applicable.

An alternate sleeve-to-sleeve test method is allowed described, using clamps to hang a

garment.

Static control garments that electrically bond to the wearer and provide a path to ground from

the wearer are evaluated using the resistance point-to-point test method, the resistance point-

to-groundable point test method, as well as a system test to determine the resistance from the

person through the garment to the groundable point of the garment system.

A band resistance measurement test is provided in IEC 61340-4-6 which can be used for

garments so equipped with cuffs that are intended to perform the same function as a wrist strap

band.

The system test with a person wearing a groundable static control garment system includes the

ground cord that connects to the groundable point of the garment.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 61010-1, Safety requirements for electrical equipment for measurement, control, and

laboratory use – Part 1: General requirements

IEC 61010-2-030, Safety requirements for electrical equipment for measurement, control, and

laboratory use – Part 2-030: Particular requirements for equipment having testing or measuring

circuits

IEC 61340-2-3, Electrostatics – Part 2-3: Methods of test for determining the resistance and

resistivity of solid planar materials used to avoid electrostatic charge accumulation

– 8 – IEC 61340-4-9:2024 CMV © IEC 2024

IEC 61340-4-6, Electrostatics – Part 4-6: Standard test methods for specific applications – Wrist

straps

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1

acceptance testing

testing used to confirm to users that products delivered are substantially the same as the

samples used to qualify products

3.2

garment system

any electrically interconnected components of a static control apparel

3.3

point-to-point resistance

resistance measured from one point to another on the surface of the same panel or two different

panels of a garment

Note 1 to entry: Point-to-point resistance is expressed in Ω.

3.4

static control garment

personnel garment that is designed for electrostatic charge control

3.5

product qualification

testing used to confirm that products comply with the requirements of an ESD control program

or other specification

3.6

groundable static control garment

garment that exhibits an electrical resistance from point-to-point and from any point or panel on

the garment to the groundable point on the garment

Note 1 to entry: The groundable point may can be a cuff contact to the wearer's skin or a separate dedicated

grounding point connector.

3.7

groundable static control garment system

system whereby a garment that is used to establish the primary ground path for a person to the

groundable point of the garment and the connection of the garment to ground, typically through

a grounding cord

Note 1 to entry: The garment shall also meet all the requirements included in the definition for groundable static

control garments. The garment is a groundable static control garment as defined in 3.6, with additional features to

enable grounding of the wearer.

4 Atmosphere for conditioning and testing

4.1 General

The following requirements supersede any other specification relating to the atmosphere for

conditioning and testing that may can be given in one or more of the documents referred to in

this document.

4.2 Low humidity

Unless otherwise agreed, the atmosphere for conditioning and testing for laboratory evaluations

at low humidity shall be at a temperature of 23 °C ± 2 °C and 12 % ± 3 % relative humidity. The

conditioning time prior to testing shall be at least 48 h. 1

4.3 Moderate humidity

The atmosphere for conditioning and testing for laboratory evaluations at moderate humidity

shall be at a temperature of 23 °C ± 2 °C and 50 % ± 2 % relative humidity. The conditioning

time prior to testing shall be at least 48 h.

5 Equipment and materials

5.1 Test equipment requirements

5.1 Resistance measurement apparatus

5.1.1 General

Electrical equipment for measurement shall comply with the safety requirements of IEC 61010‑1

and IEC 61010-2-030. The measurement apparatus, called the meter, whether it is a single

meter or collection of instruments, shall be capable of the following.

5.1.2 Product qualification

The meter shall have a circuit voltage while under load of 100 V (±5 %) (100 ± 5) V for

measurements of 1,0 × 10 Ω and above, and 10 V (±5 %) (10 ± 0,5) V for measurements less

6 4 6

than 1,0 × 10 Ω from 1,0 × 10 Ω to 1,0 × 10 Ω. The meter shall have an open circuit or under

3 4

load voltage of (10 ± 0,5) V) for measurement from 1,0 × 10 Ω to 1,0 × 10 Ω. 2

3 12

The meter shall be capable of making measurements from 1,0 × 10 Ω to 1,0 × 10 Ω.

5.1.3 Acceptance testing

The product qualification meter may can be used for acceptance testing or the following:

The meter shall have an open circuit voltage of 100 V (±5 %) (100 ± 5) V for measurements of

6 6

1,0 × 10 Ω and above, and 10 V (±5 %) (10 ± 0,5) V for measurements less than 1,0 × 10 Ω.

3 12

The meter shall be capable of making measurements from 1,0 × 10 Ω to 1,0 × 10 Ω.

In case of disagreement, the meter used for product qualification will shall be used to resolve

any disputes.

5.1.4 Ohmmeter for testing personnel ground path

Integrated tester or meter, whether it is a single meter (ohmmeter) or a collection of instruments

4 8

that are capable of measuring from 5,0 × 10 Ω to at least 1,0 × 10 Ω with a test voltage from

7 V DC to 30 100 V DC open circuit. If the test voltage exceeds 60 V DC, or 35 V DC in wet

– 10 – IEC 61340-4-9:2024 CMV © IEC 2024

locations, the additional safety limits for current and capacitive charge specified in IEC 61010-1

shall be applied.

Both test leads should be capable of being isolated from ground. AC line-powered resistance

measuring devices may can give erroneous results due to undefined ground paths. Battery

powered equipment is recommended.

5.2 Resistance measurement electrodes

5.2.1 Cylindrical electrodes

A cylindrical 2,5 kg ± 0,25 kg rubber electrode with a diameter of 65 mm ± 0,5 mm

63,5 mm ± 1 mm, having a contact of electrically conductive material with a Shore-A (IRHD)

durometer hardness between 50 and 70. The resistance between two electrodes should be less

than 1,0 × 10 Ω when measured at 10 V on a metallic surface.

5.2.2 Clamps/ or electrodes

The clamps/ or electrodes shall consist of two flat electrically conductive plates (e.g. stainless

steel) with a dimension of approximately 50 mm × 25 mm each. The clamp/clamps or electrodes

shall be electrically conductive with sufficient compression force to retain and suspend the

garment. See Figure 7.

5.2.3 Cuff test fixture

A test fixture comprising an insulative stand and two stainless steel cylinders approximately

(25,0 ± 0,5) mm in diameter, with one cylinder fixed to the stand directly above the second. The

second cylinder will weigh approximately 0,11 kg shall have a mass of (0,11 ± 0,01) kg and is

mounted in a slot in the stand that allows free vertical movement. See Figure 10.

5.2.4 Hand-held electrode

A hand-held electrode, for example stainless steel, brass, copper or other suitable metal round

or tubular stock, approximately 25 mm in diameter and 75 mm or greater in length, with

provision for connection to the meter (such as a banana plug receptacle or screw connector)

attached to one end of the cylinder. See Figure 11.

5.3 Support surface

5.3.1 Insulative support surface

An insulative surface when used for specimen support shall have a surface resistance of greater

than 1,0 × 10 Ω when measured in accordance with IEC 61340-2-3. The insulative surface

shall be large enough to accommodate the entire garment when it is laid out flat.

5.3.2 Insulative sleeve inserts

Two pieces of insulative material meeting the requirements of 5.3.1 cut into approximately

75 mm by 152 mm strips to slide into the sleeves (and cuffs if so equipped) of garments under

test to isolate one side of the sleeve from the other.

5.3.3 Insulative hangers

The points to which the clamps described in 5.2.2 holding a garment under test shall be isolated

from ground by a resistance greater than 1,0 × 10 Ω when measured with an instrument

meeting the requirements of 5.1.3. Insulating thread may can be used for this purpose.

6 Test procedure

6.1 Sample preparation

6.1.1 General

The test samples shall be processed through a minimum of five cycles of the garment

manufacturer’s prescribed or user defined cleaning process prior to performing laboratory tests.

6.1.2 Sample size

Test a minimum of three samples for each style and manufacturer for product qualification. For

acceptance testing, the sample size shall be determined by the user.

6.1.3 Sample sketch

Garments can have a temporary finish on them, either a residue from processing treatments or

deliberately applied by garment manufacturers, that can reduce electrical resistance. Such

finishes shall be removed before proper evaluation of the long-term properties of garments can

be made. This can be achieved by processing garments through a minimum of three cycles of

the garment manufacturer's specified or user defined cleaning process, prior to performing

laboratory tests. 3

The person performing the tests should examine the garment's construction and make a general

sketch showing separate front and back panels used to fabricate the garment. Number the

panels for measurement identification purposes from No. 1 to No. n. Identify the sleeves and

cuffs as left and right. The groundable points, if they exist, should be shown on the sketch. The

sketch should accompany the test results to become part of the test report.

6.1.2 Number of samples

Test a minimum of three samples for each style and manufacturer when using this test method

for qualification.

6.2 Humidity requirements

For product qualification, resistance point-to-point, resistance point-to-groundable point and

cuff measurements shall be conducted at two humidity conditions according to Clause 4.

Humidity conditioning for product qualification of the groundable static control garment system

is optional and may can require a walk-in environmental chamber.

NOTE Laboratory testing has shown that low and moderate humidity conditions do not have a consequential impact

on the electrical resistance measurement of a garment in combination with a person.

6.3 Test procedures

6.3.1 General

Subclause 6.3 defines the test methods for measuring the electrical resistance of garments. It

includes a resistance point-to-point test and a resistance point-to-groundable point test. The

described test procedures may can be used for product qualification and acceptance testing. A

system test for a garment that provides a path to ground from a person while being worn is also

described.

6.3.2 Resistance point-to-point

6.3.2.1 Panel-to-panel

Precondition the test samples according to 6.2 as required. Place the garment on an insulative

support surface as described in 5.3.1. Place the garment with the front panels opened and laid

out as flat as possible (it is possible that larger garments such as overalls may will not allow

– 12 – IEC 61340-4-9:2024 CMV © IEC 2024

this completely). Place the insulative sleeve inserts from 5.3.2 into each sleeve (including the

cuff, if so equipped, or leg cuffs of an overall) of the garment under test. Attach test leads from

the resistance measuring apparatus (meter) to the electrodes defined in 5.2.1. Place one

electrode on a panel of the sample. Place the second electrode on another panel of the same

sample. Ensure the panels are on the insulative support surface and do not touch any other

part of the garment. Apply 10 V and observe the reading after 15 5 s. If the reading is less than

6 6

1,0 × 10 Ω, record the value. If the reading is greater than or equal to 1,0 × 10 Ω, apply 100 V

for a minimum of 15 s (or until reading stabilizes) and record the results. Switching the test

voltage to 100 V can result in a resistance reading of less than 1,0 × 10 Ω. When this occurs

the reading made with the 100 V test voltage shall be recorded. Repeat for all electrically

interconnected components and panels as well as exterior cuff-to-cuff and sleeve-to-sleeve,

making sure that the electrodes are directly above the insulative inserts (see Figure 1, Figure 2

and Figure 3). Resistance point-to-point measurements can give variable results depending on

the arrangement of the garment under test and location of electrodes on it. For qualification

testing, at least three measurements shall be made with the garment arrangement and electrode

location re-arranged between each measurement. The result is the highest of the three

measured values 4. Repeat for all test samples.

6.3.2.2 Interior cuff-to-cuff

Some garments may can have an insulative exterior and conductive interior of the cuff or

incorporate a wrist strap band or another wrist bonding mechanism or device. Precondition the

test samples according to 6.2 as required. Insert the measurement electrodes inside the cuffs

or wrist bonding devices (see Figure 4 and Figure 5). Apply 10 V and observe the reading after

15 5 s. If the reading is less than 1,0 × 10 Ω, record the value. If the reading is greater than or

equal to 1,0 × 10 Ω, apply 100 V for a minimum of 15 s (or until reading stabilizes) and record

the results. Switching the test voltage to 100 V can result in a resistance reading of less than

1,0 × 10 Ω. When this occurs, the reading made with the 100 V test voltage shall be recorded.

Repeat for all test samples.

6.3.2.3 Hanging clamp sleeve-to-sleeve

Precondition the test samples according to 6.2 as required. Hang the garment from each sleeve

with electrically isolated clamps (see Figure 6). Place the clamps so that they connect the

exterior and the interior of the cuff. The resistance measurement shall be made by applying

the voltage lead (positive) to one clamp and attaching the sensor lead (negative) attaching a

test lead to one clamp and attaching the other test lead to the other clamp. Apply 10 V and

observe the reading after 15 5 s. If the reading is less than 1,0 × 10 Ω, record the value. If the

reading is greater than or equal to 1,0 × 10 Ω, apply 100 V for a minimum of 15 s (or until

reading stabilizes) and record the results. Switching the test voltage to 100 V can result in a

resistance reading of less than 1,0 × 10 Ω. When this occurs, the reading made with the 100 V

test voltage shall be recorded. Repeat for all test samples.

6.3.3 Resistance point-to-groundable point

Precondition the test samples according to 6.2 as required. Place the garment with the front

panels opened and laid out as flat as possible (it is possible that larger garments such as

overalls may will not allow this completely) on an insulative support surface as described

in 5.3.1. Use one electrode as described in 5.2.1 connected to the positive one test lead of the

meter. Place the insulative sleeve insert from 5.3.2 into each sleeve of the garment under test.

Place the electrode on a cuff (or inside as described in 6.3.2.2 see 6.3.2.2 for interior cuff-to-

cuff measurements), sleeve (directly above the insulative insert) or panel. Connect the negative

other test lead of the meter to the garment groundable point. Apply 10 V and observe the

reading after 15 5 s. If the reading is less than 1,0 × 10 Ω, record the value. If the reading is

greater than or equal to 1,0 × 10 Ω, apply 100 V for a minimum of 15 s (or until reading

stabilizes) and record the results. Switching the test voltage to 100 V can result in a resistance

reading of less than 1,0 × 10 Ω. When this occurs, the reading made with the 100 V test voltage

shall be recorded. If cuffs are designated as groundable points, measurements shall be made

between sleeves and cuffs or between panels and cuffs; see 6.3.2.2 for cuff-to-cuff

measurements. Repeat for all panels, sleeves and cuffs and groundable points (see Figure 8

and Figure 9). Repeat for all test samples.

6.3.4 Cuff measurements

IEC 61340-4-6 provides test methods for the evaluation of wrist strap bands and cuffs. These

methods may can be adapted for use in testing garment cuffs or any wrist strap cuff type

grounding mechanism that may can be part of a garment and used to bond to the skin of the

wearer. The band resistance test procedure described in IEC 61340-4-6 may shall be used to

measure the interior resistance of the garment cuff or wrist strap grounding mechanism (see

Figure 10).

NOTE Some garments can be used in conjunction with resistance continuous monitoring systems. Garments of this

type can have one cuff that provides the skin contact for personnel grounding, and the other cuff is used for monitoring

the electrical continuity between the garment and the wearer. The two cuffs are isolated electrically from each other

in this type of garment. The manufacturer can be contacted for assistance in measuring this type of garment.

6.3.5 Groundable static control garment system

Users of this document should ensure that garments tested in this procedure meet the

grounding requirements at the lowest humidity levels experienced in their facility.

This procedure verifies the resistance path from a person wearing the garment, through the

body-garment cuff contacts or wrist strap cuff type grounding mechanism to the ground

termination point of the garment grounding wire. Testing in a controlled environment is not a

requirement of this subclause. Personnel shall wear the garment under test for a minimum of

10 min prior to testing.

This test is conducted with the meter described in 5.1.4. This test includes the ground cord and

wearer's resistance as part of the total system resistance (see Figure 11 and Figure 12). The

test can be performed using a proprietary integrated tester (Figure 12) or resistance meter of

similar specification (Figure 11). Connect the grounding point of the garment to the tester using

the ground cord. Contact is made to the tester via a push button, contact plate (on the integrated

tester, Figure 12) or a hand-held electrode (Figure 11). Apply the test voltage and record the

result.

7 Product qualification

Table 1 describes the test required, based on the garment that is being qualified. For more

information on garments, see Annex A.

– 14 – IEC 61340-4-9:2024 CMV © IEC 2024

Table 1 – Product qualification 5

Garment type Qualification testing required

Static control garment Point-to-point resistance (see 6.3.2)

Groundable static control garment Point-to-point resistance

Point-to-groundable point panel (if applicable) to

groundable point (see 6.3.2 and 6.3.3)

Groundable static control garment system Point to point resistance from panel to panel

Point to groundable point panel to groundable point

(see 6.3.2, 6.3.3 and integrated wrist strap in

accordance with IEC 61340-4-6)

Garment type Qualification testing Options to comply with testing requirements

required

Resistance point-to-point Interior cuff-to-cuff (see 6.3.2.2) – only required if exterior

(see 6.3.2) of cuff is insulative and interior is conductive

Static control

Panel-to-panel (see

Hanging clamp sleeve-to-sleeve (see 6.3.2.3) – can be used

garment

6.3.2.1) – all garments

as an alternative to panel-to-panel or interior cuff-to-cuff

testing

Resistance point-to-point Interior cuff-to-cuff (see 6.3.2.2) – only required if exterior

(see 6.3.2) of cuff is insulative and interior is conductive

Panel-to-panel (see

Hanging clamp sleeve-to-sleeve (see 6.3.2.3) – can be used

6.3.2.1) – all garments

Groundable static as an alternative to panel-to-panel or interior cuff-to-cuff

control garment testing

Resistance point-to- Cuff measurements (see 6.3.4) – can be used as an

groundable point (see alternative to the method described in 6.3.2.2 when

6.3.3) measuring resistance point-to-groundable point

Resistance point-to-point Interior cuff-to-cuff (see 6.3.2.2) – only required if exterior

(see 6.3.2) of cuff is insulative and interior is conductive

Panel-to-panel (see

Hanging clamp sleeve-to-sleeve (see 6.3.2.3) – can be used

6.3.2.1) – all garments as an alternative to panel-to-panel or interior cuff-to-cuff

Groundable static

testing

control garment

Resistance point-to- Cuff measurements (see 6.3.4) – can be used as an

system

groundable point (see alternative to the method described in 6.3.2.2 when

6.3.3) measuring resistance point-to-groundable point

Total system resistance

(see 6.3.5)

8 Reporting

Record all resistance values. Record the voltage levels, relative humidity and temperature for

each test sample. Record the type of test equipment used and test date. See Annex B for an

example of a data collection sheet with sketches.

Insulative sleeve inserts

IEC

Figure 1 – Test set-up – Resistance point-to-point

(sleeve-to-sleeve procedure with insulative sleeve inserts) 6

– 16 – IEC 61340-4-9:2024 CMV © IEC 2024

Insulative sleeve insert

IEC

Figure 2 – Test set-up – Resistance point-to-point

(insulative sleeve insert inserted into sleeve detail)

IEC

Figure 3 – Test set-up – Resistance poi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...