IEC 61340-4-7:2025

(Main)Electrostatics - Part 4-7: Standard test methods for specific applications - Ionization

Electrostatics - Part 4-7: Standard test methods for specific applications - Ionization

IEC 61340-4-7:2025 provides test methods and procedures for evaluating and selecting air ionization equipment and systems (ionizers). This document establishes measurement techniques, under specified conditions, to determine offset voltage (ion balance) and decay (charge neutralization) time for ionizers. This document does not include measurements of electromagnetic interference (EMI), or the use of ionizers in connection with ordnance, flammables, explosive items or electrically initiated explosive devices. As contained in this document, the test methods and test conditions can be used by manufacturers of ionizers to provide performance data describing their products. Users of ionizers are urged to modify the test methods and test conditions for their specific application in order to qualify ionizers for use, or to make periodic verifications of ionizer performance. The user will decide the extent of the data required for each application.

This edition includes the following significant technical changes with respect to the previous edition:

a) in Figure 5, a NOTE 3 was added to clarify that for AC bars and grids, a single emitter alternating between +/− polarity is used;

b) in Annex B, the relative error for measurement equipment was updated to include the consideration for the resolution of the voltmeter.

Electrostatique - Partie 4-7 : Méthodes d'essai normalisées pour des applications spécifiques - Ionisation

L'IEC 61340-4-7:2025 fournit des méthodes et des procédures d'essai pour évaluer et choisir le matériel et les systèmes d'ionisation de l'air (ioniseurs). Le présent document établit des techniques de mesure, dans des conditions spécifiées, destinées à déterminer la tension de décalage (équilibre ionique) et le temps de décroissance (neutralisation des charges) pour les ioniseurs. Le présent document ne traite pas des mesurages des brouillages électromagnétiques (EMI, Electromagnetic Interference) ni de l'emploi d'ioniseurs en relation avec des éléments pyrotechniques, inflammables, explosifs ou des appareils explosifs amorcés électriquement. Les méthodes d'essai et les conditions d'essai spécifiées dans le présent document peuvent être utilisées telles quelles par les fabricants d'ioniseurs afin de fournir des données de performance pour la description de leurs produits. Les utilisateurs d'ioniseurs sont encouragés à modifier les méthodes d'essai et les conditions d'essai de leur application spécifique afin de qualifier les ioniseurs pour l'utilisation ou d'effectuer des vérifications périodiques de la performance des ioniseurs. Il revient à l'utilisateur de déterminer la quantité de données exigées pour chaque application.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) une NOTE 3 a été ajoutée à la Figure 5 afin d'expliciter qu'un seul émetteur à alternance de polarité +/- est utilisé pour les barres et les grilles en courant alternatif;

b) à l'Annexe B, l'erreur relative aux appareils de mesure à été mise à jour pour prendre en compte la résolution du voltmètre.

General Information

- Status

- Published

- Publication Date

- 18-Aug-2025

- Technical Committee

- TC 101 - Electrostatics

- Drafting Committee

- WG 5 - TC 101/WG 5

- Current Stage

- PPUB - Publication issued

- Start Date

- 19-Aug-2025

- Completion Date

- 12-Sep-2025

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61340-4-7:2025 - "Electrostatics - Part 4-7: Standard test methods for specific applications - Ionization" defines standardized test methods for evaluating and selecting air ionization equipment (ionizers). The standard sets out measurement techniques, test fixtures and procedures to determine offset voltage (ion balance) and decay (charge neutralization) time for ionizers under specified conditions. It is intended to produce reproducible performance data that manufacturers, test labs and end users can rely on - while noting that users should adapt test conditions for their specific applications.

Key topics and requirements

- Primary measurements: offset voltage (ion balance) and charged-plate decay time (neutralization rate).

- Test methods and instrumentation: charged plate monitor arrangements (contacting and non-contacting), fixture and voltmeter considerations, and procedures for measuring capacitance of an isolated plate (Annex B).

- Equipment categories and test locations: room ionization, laminar flow hoods (vertical and horizontal), worksurface/benchtop ionizers, overhead ionizers, and compressed-gas ionizers (guns/nozzles).

- Test conditions and reproducibility: defined test points and set-ups to generate meaningful, repeatable data; guidance on preparing the test area and sources of measurement error (Annex A).

- Safety and exclusions: safety considerations (Annex C); the standard explicitly excludes EMI measurements and use of ionizers with ordnance, flammables, explosive items or electrically initiated explosive devices.

- Recent updates (2025 edition):

- Clarification that for AC bars/grids a single emitter alternating between +/− polarity is used (Figure 5 NOTE 3).

- Annex B updated to include voltmeter resolution in the relative error for measurement equipment.

Applications and who uses it

- Manufacturers: to provide standardized performance data for ionizers and to design product test protocols.

- Test laboratories and QA teams: to verify ionizer performance, characterize neutralization rates and ion balance, and perform periodic verifications.

- ESD control engineers and facility managers: in electronics assembly, cleanrooms, semiconductor fabs, medical device manufacturing, and other ESD-sensitive environments to qualify ionizers for specific processes.

- Procurement and compliance: to compare products objectively and ensure compatibility with an organization’s electrostatic discharge (ESD) control program.

Related standards

- Part of the IEC 61340 series on electrostatics. Developed by IEC Technical Committee 101 (Electrostatics). Users should consult other IEC 61340 parts for grounding, triboelectric charging, and ESD control program requirements.

Keywords: IEC 61340-4-7, ionization test methods, electrostatics standard, ionizers, offset voltage, decay time, charged plate monitor, ESD control.

Buy Documents

IEC 61340-4-7:2025 - Electrostatics - Part 4-7: Standard test methods for specific applications - Ionization Released:8/19/2025 Isbn:9782832706435

REDLINE IEC 61340-4-7:2025 CMV - Electrostatics - Part 4-7: Standard test methods for specific applications - Ionization Released:8/19/2025 Isbn:9782832706695

IEC 61340-4-7:2025 - Electrostatique - Partie 4-7 : Méthodes d'essai normalisées pour des applications spécifiques - Ionisation Released:8/19/2025 Isbn:9782832706435

IEC 61340-4-7:2025 - Electrostatics - Part 4-7: Standard test methods for specific applications - Ionization Released:8/19/2025 Isbn:9782832706435

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 61340-4-7:2025 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electrostatics - Part 4-7: Standard test methods for specific applications - Ionization". This standard covers: IEC 61340-4-7:2025 provides test methods and procedures for evaluating and selecting air ionization equipment and systems (ionizers). This document establishes measurement techniques, under specified conditions, to determine offset voltage (ion balance) and decay (charge neutralization) time for ionizers. This document does not include measurements of electromagnetic interference (EMI), or the use of ionizers in connection with ordnance, flammables, explosive items or electrically initiated explosive devices. As contained in this document, the test methods and test conditions can be used by manufacturers of ionizers to provide performance data describing their products. Users of ionizers are urged to modify the test methods and test conditions for their specific application in order to qualify ionizers for use, or to make periodic verifications of ionizer performance. The user will decide the extent of the data required for each application. This edition includes the following significant technical changes with respect to the previous edition: a) in Figure 5, a NOTE 3 was added to clarify that for AC bars and grids, a single emitter alternating between +/− polarity is used; b) in Annex B, the relative error for measurement equipment was updated to include the consideration for the resolution of the voltmeter.

IEC 61340-4-7:2025 provides test methods and procedures for evaluating and selecting air ionization equipment and systems (ionizers). This document establishes measurement techniques, under specified conditions, to determine offset voltage (ion balance) and decay (charge neutralization) time for ionizers. This document does not include measurements of electromagnetic interference (EMI), or the use of ionizers in connection with ordnance, flammables, explosive items or electrically initiated explosive devices. As contained in this document, the test methods and test conditions can be used by manufacturers of ionizers to provide performance data describing their products. Users of ionizers are urged to modify the test methods and test conditions for their specific application in order to qualify ionizers for use, or to make periodic verifications of ionizer performance. The user will decide the extent of the data required for each application. This edition includes the following significant technical changes with respect to the previous edition: a) in Figure 5, a NOTE 3 was added to clarify that for AC bars and grids, a single emitter alternating between +/− polarity is used; b) in Annex B, the relative error for measurement equipment was updated to include the consideration for the resolution of the voltmeter.

IEC 61340-4-7:2025 is classified under the following ICS (International Classification for Standards) categories: 17.200.99 - Other standards related to thermodynamics; 29.020 - Electrical engineering in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61340-4-7:2025 has the following relationships with other standards: It is inter standard links to IEC 61340-4-7:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61340-4-7:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61340-4-7 ®

Edition 3.0 2025-08

INTERNATIONAL

STANDARD

Electrostatics -

Part 4-7: Standard test methods for specific applications - Ionization

ICS 17.200.99; 29.020 ISBN 978-2-8327-0643-5

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or

by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either

IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC copyright

or have an enquiry about obtaining additional rights to this publication, please contact the address below or your local

IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Discover our powerful search engine and read freely all the

The advanced search enables to find IEC publications by a publications previews, graphical symbols and the glossary.

variety of criteria (reference number, text, technical With a subscription you will always have access to up to date

committee, …). It also gives information on projects, content tailored to your needs.

replaced and withdrawn publications.

Electropedia - www.electropedia.org

The world's leading online dictionary on electrotechnology,

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published containing more than 22 500 terminological entries in English

details all new publications released. Available online and and French, with equivalent terms in 25 additional languages.

once a month by email. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer

Service Centre: sales@iec.ch.

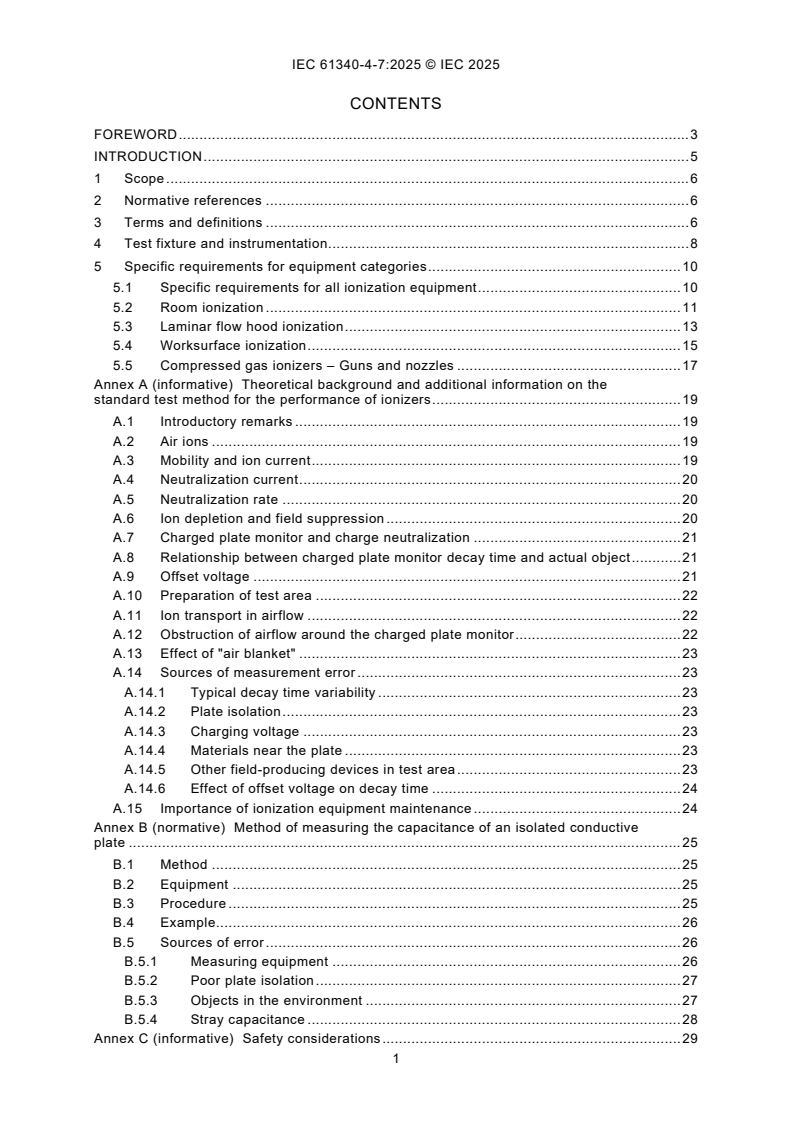

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Test fixture and instrumentation . 8

5 Specific requirements for equipment categories . 10

5.1 Specific requirements for all ionization equipment . 10

5.2 Room ionization . 11

5.3 Laminar flow hood ionization . 13

5.4 Worksurface ionization . 15

5.5 Compressed gas ionizers – Guns and nozzles . 17

Annex A (informative) Theoretical background and additional information on the

standard test method for the performance of ionizers . 19

A.1 Introductory remarks . 19

A.2 Air ions . 19

A.3 Mobility and ion current . 19

A.4 Neutralization current . 20

A.5 Neutralization rate . 20

A.6 Ion depletion and field suppression . 20

A.7 Charged plate monitor and charge neutralization . 21

A.8 Relationship between charged plate monitor decay time and actual object . 21

A.9 Offset voltage . 21

A.10 Preparation of test area . 22

A.11 Ion transport in airflow . 22

A.12 Obstruction of airflow around the charged plate monitor . 22

A.13 Effect of "air blanket" . 23

A.14 Sources of measurement error . 23

A.14.1 Typical decay time variability . 23

A.14.2 Plate isolation . 23

A.14.3 Charging voltage . 23

A.14.4 Materials near the plate . 23

A.14.5 Other field-producing devices in test area . 23

A.14.6 Effect of offset voltage on decay time . 24

A.15 Importance of ionization equipment maintenance . 24

Annex B (normative) Method of measuring the capacitance of an isolated conductive

plate . 25

B.1 Method . 25

B.2 Equipment . 25

B.3 Procedure . 25

B.4 Example. 26

B.5 Sources of error . 26

B.5.1 Measuring equipment . 26

B.5.2 Poor plate isolation . 27

B.5.3 Objects in the environment . 27

B.5.4 Stray capacitance . 28

Annex C (informative) Safety considerations . 29

C.1 General . 29

C.2 Electrical . 29

C.3 Ozone . 29

C.4 Radioactive . 29

C.5 X-ray . 29

C.6 Installation . 29

Bibliography . 30

Figure 1 – Charged plate monitor components for non-contacting plate measurement . 9

Figure 2 – Charged plate monitor components for contacting plate measurement . 9

Figure 3 – Conductive plate detail of the non-contacting CPM . 9

Figure 4 – Conductive plate detail of the voltage follower CPM . 10

Figure 5 – Test locations for room ionization – AC bars, grids and DC bar systems . 12

Figure 6 – Test locations for room ionization – Single polarity emitter systems . 12

Figure 7 – Test locations for room ionization – Two DC-line systems . 13

Figure 8 – Test locations for room ionization – Pulsed DC emitter systems . 13

Figure 9 – Test locations for vertical laminar flow hood – Top view . 14

Figure 10 – Test locations for vertical laminar flow hood – Side view . 14

Figure 11 – Test locations for horizontal laminar flow hood – Top view . 15

Figure 12 – Test locations for horizontal laminar flow hood – Side view . 15

Figure 13 – Test locations for benchtop ionizer – Top view . 16

Figure 14 – Test locations for benchtop ionizer – Side view . 16

Figure 15 – Test locations for overhead ionizer – Top view . 17

Figure 16 – Test locations for overhead ionizer – Side view . 17

Figure 17 – Test locations for compressed gas ionizer (gun or nozzle) – Side view . 18

Table 1 – Test set-ups and test locations and points (TP) . 11

Table B.1 – Example measurement data . 26

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

Electrostatics -

Part 4-7: Standard test methods for specific applications - Ionization

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC 61340-4-7 has been prepared by IEC technical committee 101: Electrostatics. It is an

International Standard.

This third edition cancels and replaces the second edition published in 2017. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) in Figure 5, a NOTE 3 was added to clarify that for AC bars and grids, a single emitter

alternating between +/− polarity is used;

b) in Annex B, the relative error for measurement equipment was updated to include the

consideration for the resolution of the voltmeter.

The text of this International Standard is based on the following documents:

Draft Report on voting

101/739/FDIS 101/744/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 61340 series, published under the general title Electrostatics, can

be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

– reconfirmed,

– withdrawn, or

– revised.

INTRODUCTION

Grounding is the primary method used to limit static charge when protecting electrostatic

discharge sensitive items in the work environment. However, grounding methods are not

effective in removing static charges from the surfaces of non-conductive (insulative) or isolated

(ungrounded) conductive materials. Air ionization techniques, by means of ionizer systems, can

be utilized to reduce this charge.

The preferred way of evaluating the ability of an ionizer to neutralize a static charge is to directly

measure the rate of charge decay. Charges to be neutralized can be located on insulators as

well as on isolated conductors. It is difficult to charge an insulator reliably and repeatably.

Charge neutralization is more easily evaluated by measuring the rate of decay of the voltage of

an isolated conductive plate. The measurement of this decay should not interfere with or change

the nature of the actual decay. Four practical methods of air ionization are addressed in this

document:

a) radioactive emission;

b) high-voltage corona from AC electric fields;

c) high-voltage corona from DC electric fields;

d) soft X-ray emission.

This part of IEC 61340 provides test methods and procedures that can be used when evaluating

ionization equipment. The objective of the test methods is to generate meaningful, reproducible

data. The test methods are not meant to be a recommendation for any particular ionizer

configuration. The wide variety of ionizers, and the environments within which they are used,

will often require test methods different from those described in this document. Users of this

document should be prepared to adapt the test methods as required to produce meaningful data

in their own application of ionizers.

Similarly, the test conditions chosen in this document do not represent a recommendation for

acceptable ionizer performance. There is a wide range of item sensitivities to static charge.

There is also a wide range of environmental conditions affecting the operation of ionizers.

Performance specifications should be agreed upon between the user and manufacturer of the

ionizer in each application. Users of this document should be prepared to establish reasonable

performance requirements for their own application of ionizers.

Annex B provides a method for measuring capacitance of the isolated conductive plate.

1 Scope

This part of IEC 61340 provides test methods and procedures for evaluating and selecting air

ionization equipment and systems (ionizers).

This document establishes measurement techniques, under specified conditions, to determine

offset voltage (ion balance) and decay (charge neutralization) time for ionizers.

This document does not include measurements of electromagnetic interference (EMI), or the

use of ionizers in connection with ordnance, flammables, explosive items or electrically initiated

explosive devices.

As contained in this document, the test methods and test conditions can be used by

manufacturers of ionizers to provide performance data describing their products. Users of

ionizers are urged to modify the test methods and test conditions for their specific application

in order to qualify ionizers for use, or to make periodic verifications of ionizer performance. The

user will decide the extent of the data required for each application.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 61010-1, Safety requirements for electrical equipment for measurement, control, and

laboratory use - Part 1: General requirements

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

– IEC Electropedia: available at https://www.electropedia.org/

– ISO Online browsing platform: available at https://www.iso.org/obp

3.1

air conductivity

ability of air to conduct (pass) an electric current under the influence of an electric field

3.2

air ions

molecular clusters of about ten molecules (water, impurities, etc.) bound by polarization forces

to a singly charged oxygen or nitrogen molecule

3.3

charge decay

decrease or neutralization or both of a net electrostatic charge

3.4

charged plate monitor

CPM

instrument using a charged metal plate of a defined capacitance and geometry which is

discharged in order to measure charge dissipation and neutralization properties of products or

materials

3.5

compressed gas ionizer

ionization device that can be used to neutralize charged surfaces or remove surface particles

or both with pressurized gas

Note 1 to entry: This type of ionizer can be used to ionize the gas within production equipment.

3.6

corona

production of positive or negative ions by a very localized high electric field

Note 1 to entry: The field is normally established by applying a high voltage to a conductor in the shape of a sharp

point or wire.

3.7

decay time

time necessary for a voltage (due to an electrostatic charge) to decay from an initial value to

some chosen final value

3.8

emitter

conducting sharp object, usually a needle or wire, which will cause a corona discharge when

kept at a high potential

3.9

horizontal laminar flow

non-turbulent airflow in a horizontal direction

3.10

ionizer

device designed to generate positive or negative or both air ions

3.11

isolated conductor

conductor that has sufficiently high resistance to ground that significant charge dissipation is

prevented within the timescale of interest

3.12

laminar flow hood ionization

device or system that provides local area ionization coverage in vertical or horizontal laminar

flow hoods or benches

3.13

offset voltage

ion balance

observed voltage on the isolated conductive plate of a charged plate monitor (CPM) that has

been placed in an ionized environment

3.14

peak offset voltage

for pulsed ionizers, maximum value of the offset voltage for each polarity, as the ionizer cycles

between positive and negative ion outputs

3.15

room ionization

ionization system that provides large area coverage with air ions

3.16

worksurface ionization

ionization device or system used to control static charges on a worksurface

Note 1 to entry: Worksurface ionizers include benchtop ionizers, overhead worksurface ionizers and laminar flow

hood ionizers.

3.17

vertical laminar flow

non-turbulent airflow in a vertical direction

4 Test fixture and instrumentation

WARNING – Procedures and equipment described in this document can expose personnel to

hazardous electrical and non-electrical conditions. Users of this document are responsible for

selecting equipment that complies with applicable laws, regulatory codes and both external and

internal policy. Users are cautioned that this document cannot replace or supersede any

requirements for personnel safety. See Annex C for safety considerations.

The instrument described in this document to make performance measurements on air

ionization equipment is the charged plate monitor (CPM); refer to Figure 1 and Figure 2. The

conductive plate shall be (15,0 ± 0,1) cm × (15,0 ± 0,1) cm and the total capacitance of the test

circuit, with plate, while the instrument is in its normal operating mode, shall be 20 pF ± 2 pF

as measured per Annex B. See Figure 3 and Figure 4. The instrument described in this

document can also be used for compliance verification of air ionizers.

For the isolated conductive plate design shown in Figure 3, there shall be no objects, grounded

or otherwise, closer than dimension "A" of the conductive plate, except the supporting insulators

or plate voltage contacts, as shown in Figure 3 (refer to Annex B). For the conductive plate

assembly shown in Figure 4, there shall be no objects, grounded or otherwise, within 2,5 cm of

the plate assembly in any direction, other than a support structure (e.g. a tripod) located below

the ground plate of the assembly.

The conductive plate, when charged to the desired test voltage, shall not decay by more than

10 % of the test voltage within 5 min, in the absence of ionization.

The voltage on the conductive plate shall be monitored with a response time sufficient to

accurately measure changing plate voltages. Changing plate voltages are a function of the

ionization technology type being monitored.

For safety reasons (see Clause C.1), the voltage source used to charge the conductive plate

should be current limited. The voltage source used to charge the conductive plate shall meet

the requirements of IEC 61010-1.

NOTE See Figure 3 for a detailed drawing of the non-contacting CPM.

Figure 1 – Charged plate monitor components for non-contacting plate measurement

NOTE See Figure 4 for a detailed drawing of the contacting CPM.

Figure 2 – Charged plate monitor components for contacting plate measurement

Figure 3 – Conductive plate detail of the non-contacting CPM

Figure 4 – Conductive plate detail of the voltage follower CPM

5 Specific requirements for equipment categories

5.1 Specific requirements for all ionization equipment

See Annex A for information regarding theoretical background and additional information on the

standard test method for the performance of ionizers.

For the types of ionization equipment listed in 5.2, 5.3, 5.4 and 5.5, the following specific

requirements apply:

a) Decay time test – The conductive plate of the test fixture shall be charged to an initial

charging voltage, which shall be higher than the initial test voltage. The time required for

the voltage to decay from the initial test voltage to 10 % of that value shall be recorded

(refer to Clause 4 and Figure 1). Measurements shall be made with both polarities of

charging voltage.

b) Offset voltage test – The conductive plate shall be momentarily grounded to remove any

residual charges and to verify the zero setting of the voltage monitoring device. The plate

is then monitored within the ionized environment, per the procedure described for each

equipment category. The resulting observed voltage is referred to as the offset voltage.

c) Locations – The decay time and offset voltage shall be measured and recorded for each

test location and point (TP) described in the test location figures (see Table 1).

d) Same conditions – Decay time and offset voltage shall be measured under the same

conditions without any equipment adjustments.

e) Peak offset voltage – In the case of pulsed ionizers, offset voltage shall be measured and

recorded in peak values using the test equipment described in Clause 4.

f) Other parameters – Application specific parameters such as humidity, temperature, air

speed, for example shall be recorded.

Table 1 – Test set-ups and test locations and points (TP)

Charged plate

Offset voltage

initial voltage

Figure Number of test

Equipment category measurement time

(both polarities)

references locations

interval

V

Room ionization

Bars, grids, AC Figure 5 2 (1 to 5) min 1 000

Bars, pulsed and DC Figure 5 2 (1 to 5) min 1 000

Single polarity emitter Figure 6 3 (1 to 5) min 1 000

Two DC line Figure 7 3 (1 to 5) min 1 000

Pulsed DC emitter Figure 8 2 (1 to 5) min 1 000

Laminar flow hood

Figure 9 and

Vertical 8 (1 to 5) min 1 000

Figure 10

Figure 11 and

Horizontal 6 (1 to 5) min 1 000

Figure 12

Worksurface ionization

Benchtop Figure 13 and

12 (1 to 5) min 1 000

Figure 14

Overhead Figure 15 and

12 (1 to 5) min 1 000

Figure 16

Compressed gas ionization

Guns and nozzles Figure 17 1 10 s to 1 min 1 000

5.2 Room ionization

The area around the charged plate monitor should be cleared for a horizontal distance of 1,5 m

in all directions. The ionization system should be operated for a minimum of 30 min to stabilize

conditions in the test area.

To avoid affecting the test, the test technician should be grounded and stand outside the 1,5 m

cleared area.

Decay time from a 1 000 V initial test voltage to a 100 V final test voltage shall be measured

for both positive (+) and negative (−) polarities.

The air speed at the test location shall be recorded.

Measurements should be taken with the charged plate monitor at a distance of 1,5 m from the

ionizer under test. Since installed ionizer heights can vary, a consistent measurement height

should be selected for the evaluation of different systems. This height and the ionizer mounting

height shall be recorded in the test results.

The minimum number of test locations is determined by the type of system (see Table 1 and

refer to Figure 5 through Figure 8).

Decay time as described in 5.1 a), shall be measured at each test location.

Offset voltage as described in 5.1 b) and e) shall be determined at each test location. Offset

voltage shall be measured after a period of at least 1 min to allow the reading to stabilize (5 min

maximum).

NOTE 1 For AC bars or grids, the shaded areas represent areas where the coverage is less than 100 %.

NOTE 2 TP1 is directly under grid or bar while TP2 is centred between grids or bars.

NOTE 3 For AC bars and grids, a single emitter alternating between +/− polarity is used.

Figure 5 – Test locations for room ionization – AC bars, grids and DC bar systems

Three measurement locations required.

Figure 6 – Test locations for room ionization – Single polarity emitter systems

Three measurement locations required.

Figure 7 – Test locations for room ionization – Two DC-line systems

Two measurement locations required.

Figure 8 – Test locations for room ionization – Pulsed DC emitter systems

5.3 Laminar flow hood ionization

The test should be performed on a surface that does not contain obstructions to airflow. Unless

otherwise specified, the test surface should be static dissipative or conductive and grounded.

To avoid affecting the test, the test technician should be grounded.

Decay time from a 1 000 V initial test voltage to a 100 V final test voltage shall be measured

for both positive (+) and negative (−) polarities.

The air speed at test location TP4, as shown in Figure 9 and Figure 11, shall be recorded.

For a vertical laminar flow hood, the test set-up is shown in Figure 9 and Figure 10. Data shall

be taken at test positions TP1 through TP8 as shown in Figure 9.

For a horizontal laminar flow hood, the test set-up is shown in Figure 11 and Figure 12. Data

shall be taken at test positions TP1 through TP6 as shown in Figure 11.

Decay time as described in 5.1 a), shall be measured at each test location.

Offset voltage as described in 5.1 b) and e) shall be determined at each test locatio

...

IEC 61340-4-7 ®

Edition 3.0 2025-08

INTERNATIONAL

STANDARD

COMMENTED VERSION

Electrostatics -

Part 4-7: Standard test methods for specific applications - Ionization

ICS 17.200.99; 29.020 ISBN 978-2-8327-0669-5

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or

by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either

IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC copyright

or have an enquiry about obtaining additional rights to this publication, please contact the address below or your local

IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Discover our powerful search engine and read freely all the

The advanced search enables to find IEC publications by a publications previews, graphical symbols and the glossary.

variety of criteria (reference number, text, technical With a subscription you will always have access to up to date

committee, …). It also gives information on projects, content tailored to your needs.

replaced and withdrawn publications.

Electropedia - www.electropedia.org

The world's leading online dictionary on electrotechnology,

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published containing more than 22 500 terminological entries in English

details all new publications released. Available online and and French, with equivalent terms in 25 additional languages.

once a month by email. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer

Service Centre: sales@iec.ch.

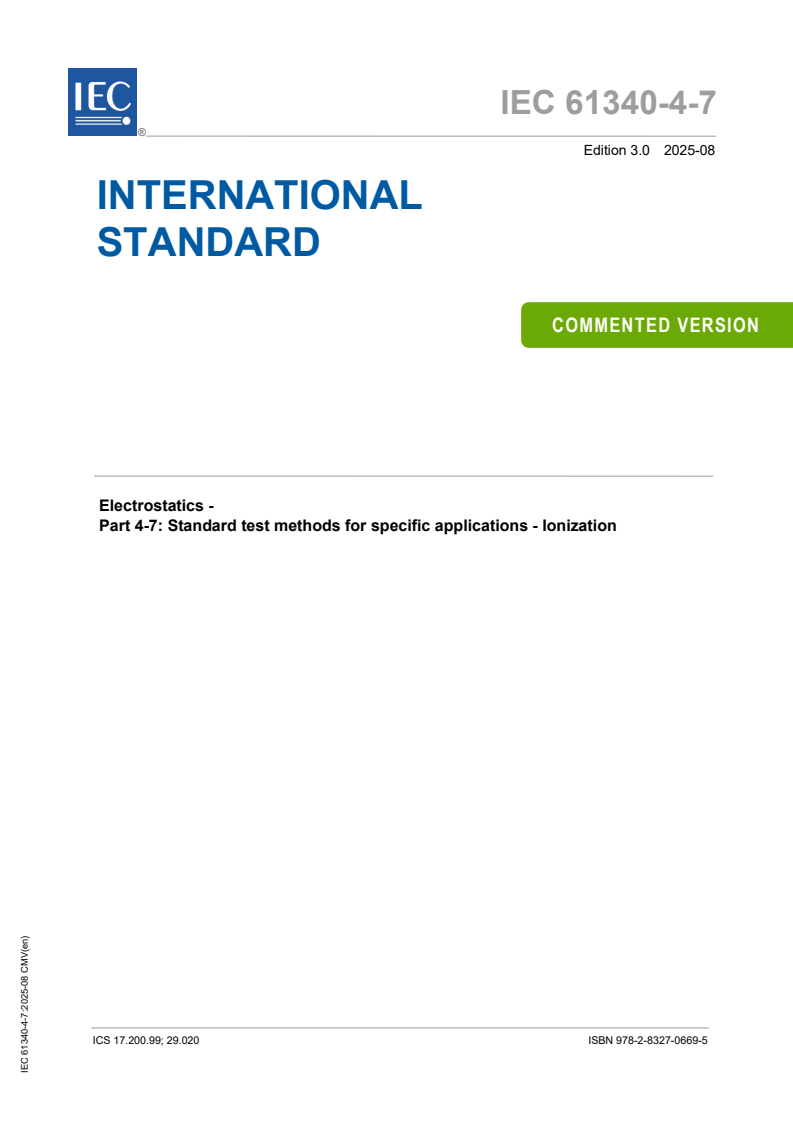

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Test fixture and instrumentation. 8

5 Specific requirements for equipment categories . 10

5.1 Specific requirements for all ionization equipment . 10

5.2 Room ionization . 11

5.3 Laminar flow hood ionization . 14

5.4 Worksurface ionization . 16

5.5 Compressed gas ionizers – Guns and nozzles . 18

Annex A (informative) Theoretical background and additional information on the

standard test method for the performance of ionizers . 20

A.1 Introductory remarks . 20

A.2 Air ions . 20

A.3 Mobility and ion current . 20

A.4 Neutralization current . 21

A.5 Neutralization rate . 21

A.6 Ion depletion and field suppression . 21

A.7 Charged plate monitor and charge neutralization . 22

A.8 Relationship between charged plate monitor decay time and actual object . 22

A.9 Offset voltage . 22

A.10 Preparation of test area . 23

A.11 Ion transport in airflow . 23

A.12 Obstruction of airflow around the charged plate monitor . 23

A.13 Effect of "air blanket" . 24

A.14 Sources of measurement error . 24

A.14.1 Typical decay time variability . 24

A.14.2 Plate isolation . 24

A.14.3 Charging voltage . 24

A.14.4 Materials near the plate . 24

A.14.5 Other field-producing devices in test area . 24

A.14.6 Effect of offset voltage on decay time . 25

A.15 Importance of ionization equipment maintenance . 25

Annex B (normative) Method of measuring the capacitance of an isolated conductive

plate . 26

B.1 Method . 26

B.2 Equipment . 26

B.3 Procedure . 26

B.4 Example . 27

B.5 Sources of error . 27

B.5.1 Measuring equipment . 27

B.5.2 Poor plate isolation . 28

B.5.3 Objects in the environment . 28

B.5.4 Stray capacitance . 29

Annex C (informative) Safety considerations . 30

C.1 General . 30

C.2 Electrical . 30

C.3 Ozone . 30

C.4 Radioactive . 30

C.5 X-ray . 30

C.6 Installation . 30

Bibliography . 31

List of comments. 32

Figure 1 – Charged plate monitor components for non-contacting plate measurement . 9

Figure 2 – Charged plate monitor components for contacting plate measurement . 9

Figure 3 – Conductive plate detail of the non-contacting CPM. 10

Figure 4 – Conductive plate detail of the voltage follower CPM . 10

Figure 5 – Test locations for room ionization – AC bars, grids and DC bar systems . 12

Figure 6 – Test locations for room ionization – Single polarity emitter systems . 13

Figure 7 – Test locations for room ionization – Two DC-line systems . 13

Figure 8 – Test locations for room ionization – Pulsed DC emitter systems . 13

Figure 9 – Test locations for vertical laminar flow hood – Top view . 14

Figure 10 – Test locations for vertical laminar flow hood – Side view . 15

Figure 11 – Test locations for horizontal laminar flow hood – Top view . 15

Figure 12 – Test locations for horizontal laminar flow hood – Side view . 16

Figure 13 – Test locations for benchtop ionizer – Top view . 17

Figure 14 – Test locations for benchtop ionizer – Side view . 17

Figure 15 – Test locations for overhead ionizer – Top view . 18

Figure 16 – Test locations for overhead ionizer – Side view . 18

Figure 17 – Test locations for compressed gas ionizer (gun or nozzle) – Side view . 19

Table 1 – Test set-ups and test locations/ and points (TP) . 11

Table B.1 – Example measurement data . 27

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

Electrostatics -

Part 4-7: Standard test methods for specific applications - Ionization

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

This commented version (CMV) of the official standard IEC 61340-4-7:2025 edition 3.0 allows

the user to identify the changes made to the previous IEC 61340-4-7:2017

edition 2.0. Furthermore, comments from IEC TC 101 experts are provided to explain the

reasons of the most relevant changes, or to clarify any part of the content.

A vertical bar appears in the margin wherever a change has been made. Additions are in green

text, deletions are in strikethrough red text. Experts' comments are identified by a blue-

background number. Mouse over a number to display a pop-up note with the comment.

This publication contains the CMV and the official standard. The full list of comments is available

at the end of the CMV.

IEC 61340-4-7 has been prepared by IEC technical committee 101: Electrostatics. It is an

International Standard.

This third edition cancels and replaces the second edition published in 2017. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) in Figure 5, a NOTE 3 was added to clarify that for AC bars and grids, a single emitter

alternating between +/− polarity is used;

b) in Annex B, the relative error for measurement equipment was updated to include the

consideration for the resolution of the voltmeter.

The text of this International Standard is based on the following documents:

Draft Report on voting

101/739/FDIS 101/744/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 61340 series, published under the general title Electrostatics, can

be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

– reconfirmed,

– withdrawn, or

– revised.

INTRODUCTION

Grounding is the primary method used to limit static charge when protecting electrostatic

discharge sensitive items in the work environment. However, grounding methods are not

effective in removing static charges from the surfaces of non-conductive (insulative) or isolated

(ungrounded) 1 conductive materials. Air ionization techniques, by means of ionizer systems,

can be utilized to reduce this charge.

The preferred way of evaluating the ability of an ionizer to neutralize a static charge is to directly

measure the rate of charge decay. Charges to be neutralized may can be located on insulators

as well as on isolated conductors. It is difficult to charge an insulator reliably and repeatably.

Charge neutralization is more easily evaluated by measuring the rate of decay of the voltage of

an isolated conductive plate. The measurement of this decay should not interfere with or change

the nature of the actual decay. Four practical methods of air ionization are addressed in this

document:

a) radioactive emission;

b) high-voltage corona from AC electric fields;

c) high-voltage corona from DC electric fields;

d) soft X-ray emission.

This part of IEC 61340 provides test methods and procedures that can be used when evaluating

ionization equipment. The objective of the test methods is to generate meaningful, reproducible

data. The test methods are not meant to be a recommendation for any particular ionizer

configuration. The wide variety of ionizers, and the environments within which they are used,

will often require test methods different from those described in this document. Users of this

document should be prepared to adapt the test methods as required to produce meaningful data

in their own application of ionizers.

Similarly, the test conditions chosen in this document do not represent a recommendation for

acceptable ionizer performance. There is a wide range of item sensitivities to static charge.

There is also a wide range of environmental conditions affecting the operation of ionizers.

Performance specifications should be agreed upon between the user and manufacturer of the

ionizer in each application. Users of this document should be prepared to establish reasonable

performance requirements for their own application of ionizers.

Annex B provides a method for measuring capacitance of the isolated conductive plate.

1 Scope

This part of IEC 61340 provides test methods and procedures for evaluating and selecting air

ionization equipment and systems (ionizers).

This document establishes measurement techniques, under specified conditions, to determine

offset voltage (ion balance) and decay (charge neutralization) time for ionizers.

This document does not include measurements of electromagnetic interference (EMI), or the

use of ionizers in connection with ordnance, flammables, explosive items or electrically initiated

explosive devices.

As contained in this document, the test methods and test conditions can be used by

manufacturers of ionizers to provide performance data describing their products. Users of

ionizers are urged to modify the test methods and test conditions for their specific application

in order to qualify ionizers for use, or to make periodic verifications of ionizer performance. The

user will decide the extent of the data required for each application.

CAUTION: Procedures and equipment described in this document can expose personnel to hazardous electrical and

non-electrical conditions. Users of this document are responsible for selecting equipment that complies with

applicable laws, regulatory codes and both external and internal policy. Users are cautioned that this document

cannot replace or supersede any requirements for personnel safety.

2 Normative references

There are no normative references in this document.

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 61010-1, Safety requirements for electrical equipment for measurement, control, and

laboratory use - Part 1: General requirements 2

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

– IEC Electropedia: available at https://www.electropedia.org/

– ISO Online browsing platform: available at https://www.iso.org/obp

3.1

air conductivity

ability of air to conduct (pass) an electric current under the influence of an electric field

3.2

air ions

molecular clusters of about ten molecules (water, impurities, etc.) bound by polarization forces

to a singly charged oxygen or nitrogen molecule

3.3

charge decay

decrease and/or neutralization or both of a net electrostatic charge

3.4

charged plate monitor

CPM

instrument using a charged metal plate of a defined capacitance and geometry which is

discharged in order to measure charge dissipation/ and neutralization properties of products or

materials

Note 1 to entry: This note applies to the French language only.

3.5

compressed gas ionizer

ionization device that can be used to neutralize charged surfaces and/or remove surface

particles or both with pressurized gas

Note 1 to entry: This type of ionizer may can be used to ionize the gas within production equipment.

3.6

corona

production of positive or negative ions by a very localized high electric field

Note 1 to entry: The field is normally established by applying a high voltage to a conductor in the shape of a sharp

point or wire.

3.7

decay rate 3

decrease of charge or voltage per unit time

3.7

decay time

time necessary for a voltage (due to an electrostatic charge) to decay from an initial value to

some chosen final value

3.8

emitter

conducting sharp object, usually a needle or wire, which will cause a corona discharge when

kept at a high potential

3.9

horizontal laminar flow

non-turbulent airflow in a horizontal direction

3.10

ionizer

device designed to generate positive and/or negative or both air ions

3.11

isolated conductor

non-grounded conductor

conductor that has sufficiently high resistance to ground that significant charge dissipation is

prevented within the timescale of interest 4

3.12

laminar flow hood ionization

device or system that provides local area ionization coverage in vertical or horizontal laminar

flow hoods or benches

3.14

non-contacting voltage measurement 5

measurement technique using an electrostatic fieldmeter or voltmeter to monitor the voltage

induced on an isolated conductive plate where there is no direct connection from the

measurement sensor to the isolated conductive plate

3.13

offset voltage

ion balance

observed voltage on the isolated conductive plate of a charged plate monitor (CPM) that has

been placed in an ionized environment

3.14

peak offset voltage

for pulsed ionizers, maximum value of the offset voltage for each polarity, as the ionizer cycles

between positive and negative ion outputs

3.15

room ionization

ionization system that provides large area coverage with air ions

3.16

worksurface ionization

ionization device or system used to control static charges at on a worksurface

Note 1 to entry: This type Worksurface ionizers include benchtop ionizers, overhead worksurface ionizers and

laminar flow hood ionizers.

3.17

vertical laminar flow

non-turbulent airflow in a vertical direction

3.20

contacting voltage measurement 6

measurement technique using high input impedance circuitry used to monitor the voltage induced on

an isolated conductive plate where there is a direct connection from the circuitry to the conductive

plate

4 Test fixture and instrumentation

WARNING – Procedures and equipment described in this document can expose personnel to

hazardous electrical and non-electrical conditions. Users of this document are responsible for

selecting equipment that complies with applicable laws, regulatory codes and both external and

internal policy. Users are cautioned that this document cannot replace or supersede any

requirements for personnel safety. See Annex C for safety considerations. 7

The instrument described in this document to make performance measurements on air

ionization equipment is the charged plate monitor (CPM); refer to Figure 1 and Figure 2. The

conductive plate shall be (15,0 ± 0,1) cm × (15,0 ± 0,1) cm and the total capacitance of the test

circuit, with plate, while the instrument is in its normal operating mode, shall be 20 pF ± 2 pF

as measured per Annex B. See Figure 3 and Figure 4. The instrument described in this

document may can also be used for compliance verification of air ionizers.

For the isolated conductive plate design shown in Figure 3, there shall be no objects, grounded

or otherwise, closer than dimension "A" of the conductive plate, except the supporting insulators

or plate voltage contacts, as shown in Figure 3 (refer to Annex B). For the conductive plate

assembly shown in Figure 4, there shall be no objects, grounded or otherwise, within 2,54

2,5 cm of the plate assembly in any direction, other than a support structure (e.g. a tripod)

located below the ground plate of the assembly.

The conductive plate, when charged to the desired test voltage, shall not decay by more than

10 % of the test voltage within 5 min, in the absence of ionization.

The voltage on the conductive plate shall be monitored in such a way that the system conforms

to 4.1, 4.2 and 4.3. The response time of the monitoring device shall be sufficient to accurately

measure changing plate voltages with a response time sufficient to accurately measure

changing plate voltages. Changing plate voltages are a function of the ionization technology

type being monitored. 8

For safety reasons (see Clause C.1), the voltage source used to charge the conductive plate

should be current limited. The voltage source used to charge the conductive plate shall meet

the requirements of IEC 61010-1. 9

NOTE See Figure 3 for a detailed drawing of the non-contacting CPM.

Figure 1 – Charged plate monitor components for non-contacting plate measurement

NOTE See Figure 4 for a detailed drawing of the contacting CPM.

Figure 2 – Charged plate monitor components for contacting plate measurement

(15,0 ± 0,1) cm × (15,0 ± 0,1) cm

Conductive plate

Dimension A

Insulator

Ground plate ≥ 15

Ground

cm

IEC

Figure 3 – Conductive plate detail of the non-contacting CPM

Figure 4 – Conductive plate detail of the voltage follower CPM

5 Specific requirements for equipment categories

5.1 Specific requirements for all ionization equipment

See Annex A for information regarding theoretical background and additional information on the

standard test method for the performance of ionizers. 10

For the types of ionization equipment listed in 5.2, 5.3, 5.4 and 5.5, the following specific

requirements apply:

a) Decay time test – The conductive plate of the test fixture shall be charged to an initial test

voltage and allowed to decay to 10 % of the initial test voltage. The time required shall be

monitored and recorded for both polarities of initial charge. This time is referred to as the

decay time (refer to 4.1 and Figure 1). The conductive plate of the test fixture shall be

charged to an initial charging voltage, which shall be higher than the initial test voltage. The

time required for the voltage to decay from the initial test voltage to 10 % of that value shall

be recorded (refer to Clause 4 and Figure 1). Measurements shall be made with both

polarities of charging voltage. 11

b) Offset voltage test – The conductive plate shall be momentarily grounded to remove any

residual charges and to verify the zero setting of the voltage monitoring device. The plate

is then monitored within the ionized environment, per the procedure described for each

equipment category. The resulting observed voltage is referred to as the offset voltage.

c) Locations – The decay time and offset voltage shall be measured and recorded 12 for each

test location/ and point (TP) described in the test location figures (see Table 1).

d) Same conditions – Decay time and offset voltage shall be measured under the same

conditions without any equipment adjustments. If ionizers from different categories are to

be compared, the same test voltages shall be used for all tests. 13

e) Peak offset voltage – In the case of pulsed ionizers, offset voltage shall be measured and

reported recorded in peak values using the test equipment described in Clause 4.

f) Other parameters – Application specific parameters such as humidity, temperature, air

speed, etc., for example shall be recorded.

Table 1 – Test set-ups and test locations/ and points (TP)

Charged plate

Offset voltage

initial voltage

Figure Number of test

Equipment category measurement time

(both polarities)

references locations

interval

V

Room ionization

Bars, grids, AC Figure 5 2 (1 to 5) min 1 000

Bars, pulsed and DC Figure 5 2 (1 to 5) min 1 000

Single polarity emitter Figure 6 3 (1 to 5) min 1 000

DualTwo DC line Figure 7 3 (1 to 5) min 1 000

Pulsed DC emitter Figure 8 2 (1 to 5) min 1 000

Laminar flow hood

Figure 9 and

Vertical 8 (1 to 5) min 1 000

Figure 10

Figure 11 and

Horizontal 6 (1 to 5) min 1 000

Figure 12

Worksurface ionization

Benchtop Figure 13 and

12 (1 to 5) min 1 000

Figure 14

Overhead Figure 15 and

12 (1 to 5) min 1 000

Figure 16

Compressed gas ionization

Guns and nozzles Figure 17 1 10 s to 1 min 1 000

5.2 Room ionization

The area around the charged plate monitor should be cleared for a horizontal distance of 1,5 m

in all directions. The ionization system should be operated for a minimum of 30 min to stabilize

conditions in the test area.

To avoid affecting the test, the test technician should be grounded and stand outside the 1,5 m

cleared area.

Decay time from a 1 000 V initial test voltage to a 100 V final test voltage shall be measured

for both positive (+) and negative (−) polarities.

The air speed at the test location shall be recorded.

Measurements should be taken with the charged plate monitor at a distance of 1,5 m from the

ionizer under test. Since installed ionizer heights can vary, a consistent measurement height

should be selected for the evaluation of different systems. This height and the ionizer mounting

height shall be recorded in the test results.

The minimum number of test locations is determined by the type of system (see Table 1 and

refer to Figure 5 through Figure 8).

Decay time as described in 5.1 a), shall be measured at each test location.

Offset voltage as described in 5.1 b) and e) shall be determined at each test location. Offset

voltage shall be measured after a period of at least 1 min to allow the reading to stabilize (5 min

maximum).

NOTE 1 Example For AC grids (shaded areas, less than 100 % coverage) and pulsed or steady-state DC bars. For

AC bars or grids, the shaded areas represent areas where the coverage is less than 100 %.

NOTE 2 TP1 is directly under grid or bar while TP2 is centred between grids or bars.

NOTE 3 For AC bars and grids, a single emitter alternating between +/− polarity is used.

Figure 5 – Test locations for room ionization – AC bars, grids and DC bar systems

Three measurement locations required.

Figure 6 – Test locations for room ionization – Single polarity emitter systems

Three measurement locations required.

Figure 7 – Test locations for room ionization – Dual Two DC-line systems

Two measurement locations required.

Figure 8 – Test locations for room ionization – Pulsed DC emitter systems

5.3 Laminar flow hood ionization

The test should be performed on a surface that does not contain obstructions to airflow. Unless

otherwise specified, the test surface should be static dissipative or conductive and properly

grounded.

To avoid affecting the test, the test technician should be properly grounded.

Decay time from a 1 000 V initial test voltage to a 100 V final test voltage shall be measured

for both positive (+) and negative (−) polarities.

The air speed at test location TP4, as shown in Figure 9 and Figure 11, should shall be

recorded.

For a vertical laminar flow hood, the test set-up is shown in Figure 9 and Figure 10. Data shall

be taken at test positions TP1 through TP8 as shown in Figure 9.

For a horizontal laminar flow hood, the test set-up is shown in Figures 9 Figure 11 and 10

Figure 12. Data shall be taken at test positions TP1 through TP6 as shown in Figure 11.

Decay time as described in 5.1 a), shall be measured at each test location.

Offset voltage as described in 5.1 b) and e) shall be determined at each test location. Offset

voltage shall be measured after a period of at least 1 min, or as necessary to allow the reading

to stabilize (5 min maximum).

Dimensions in centimetres

Eight measurement locations required, all dimensions nominal.

Figure 9 – Test locations for vertical laminar flow hood – Top view

Dimensions in centimetres

All dimensions nominal.

Figure 10 – Test locations for vertical laminar flow hood – Side view

Dimensions in centimetres

Six measurement locations required, all dimensions nominal.

Figure 11 – Test locations for horizontal laminar flow hood – Top view

Dimensions in centimetres

All dimensions nominal.

Figure 12 – Test locations for horizontal laminar flow hood – Side view

5.4 Worksurface ionization

The test should be performed on a surface that does not contain obstructions to airflow. Unless

otherwise specified, the test surface should be static dissipative or conductive and properly

grounded.

To avoid affecting the test, the test technician should be properly grounded.

Decay time from a 1 000 V initial test voltage to a 100 V final test voltage shall be measured

for both positive (+) and negative (−) polarities.

The unit shall be measured with the heater on and off, if so equipped. The unit shall be tested

with any filters in place if so equipped. Measurements shall be made at both minimum and

maximum airflows for units with variable airflow. The air speed shall be measured and included

in the test results. End users should test ionizers with the same configuration of operating

heaters and filters that they intend to use.

For benchtop units, the ionizer shall be placed as shown in Figure 13 and Figure 14. Airflow

shall be directed at test location TP2 and measured at test locations TP2 and TP5. The charged

plate monitor shall face the ionizer. Measurements with the charged plate monitor shall be made

at test locations TP1 through TP12 as shown in Figure 13.

For overhead units, the ionizer shall be placed as shown in Figure 15 and Figure 16. Airflow

shall be measured at test locations TP5 and TP8. Measurements with the charged plate monitor

shall be made at test locations TP1 through TP12 as shown in Figure 15.

Decay time as described in 5.1 a), shall be measured at each test location.

Offset voltage as described in 5.1 b) and e) shall be determined at each test location. Offset

voltage shall be measured after a period of at least 1 min, or as necessary to allow the reading

to stabilize (5 min maximum).

Dimensions in centimetres

Twelve measurement locations required, all dimensions nominal.

Figure 13 – Test locations for benchtop ionizer – Top view

Dimensions in centimetres

All dimensions nominal.

Figure 14 – Test locations for benchtop ionizer – Side view

Dimensions in centimetres

Twelve measurement locations required, all dimensions nominal.

Figure 15 – Test locations for overhead ionizer – Top view

Dimensions in centimetres

All dimensions nominal.

Figure 16 – Test locations for overhead ionizer – Side view

5.5 Compressed gas ionizers – Guns and nozzles

The test should be performed on a surface that does not contain obstructions to airflow. Unless

otherwise specified, the test surface should be static dissipative or conductive and properly

grounded.

To avoid affecting the test, the test technician should be properly grounded.

Decay time from a 1 000 V initial test voltage to a 100 V final test voltage shall be measured

for both positive (+) and negative (−) polarities.

Unless otherwise specified, the input pressure shall be 200 kPa. End users should test

compressed gas ionizers in the same configuration of input pressure and distance that they

intend to use.

The tests shall be performed using the test set-up shown in Figure 17.

Decay time as described in 5.1 a), shall be measured at the test location.

Offset voltage as described in 5.1 b) and e) shall be determined at the test location. Offset

voltage shall be measured after a period of at least 10 s or as necessary to allow the reading

to stabilize (1 min maximum).

Dimensions in centimetres

One measurement location required, all dimensions nominal.

Figure 17 – Test locations for compressed gas ionizer (gun or nozzle) – Side view

Annex A

(informative)

Theoretical background and additional information on the standard test

method for the performance of ionizers

A.1 Introductory remarks

The field from static charges, located on insulators or isolated conductors, can be neutralized

by oppositely charged air ions depositing on the charged bodies.

A.2 Air ions

Air ions are molecular clusters consisting of about ten molecules (often water) around a (singly)

charged oxygen or nitrogen molecule. Normally, relatively few ions are present in the air.

Typically, the number is less than 1 000 per cm . These "natural" ions are usually formed by

radiation from radioactive materials in the air, in the ground or in building materials.

For neutralization purposes, much higher ion concentrations are needed. Although radioactivity

can also be employed in such situations, the most common ion production method is by collision

between neutral molecules and electrons accelerated in an electric field with field strengths

exceeding 3 MV/m (at atmospheric pressure). This is generally referred to as high voltage

corona ionization.

A.3 Mobility and ion current

If an ion is exposed to an electric field E, it will move with an average drift speed (v) proportional

to E, i.e.

v= kE

(A.1)

where k is the mobility of the ion.

–4 2 –1 –1

Ordinary air ions have mobilities in the range of 1 to 2 × 10 m V s (square metre per volt-

second).

If the air has a concentration n of positive ions with the mobility k, and charge e, an electric field

E will cause an electric current to flow in the direction of E with the density j.

j enkE λE

(A.2)

The constant λ (enk) is called the positive conductivity of the air (or more precisely, the polar

conductivity due to the positive ions). Negative ions will move in the opposite direction of the

field, but Formula (A.2) can still be used to calculate the current density from negative ions,

when e is taken as the numerical value of the ion charge. The current density from negative

ions will thus also be in the direction of the field.

==

A.4 Neutralization current

If a body completely surrounded by ionized air is given a charge q, an electric field is established

around the body and charges will flow towards it and away from it. The field will vary from point

to point, but is always proportional to the charge q. The current towards the body is carried by

the ions of polarity opposite to that of q, and is known as the neutralization current. The

neutralization current is proportional to the charge q and to the relevant opposite conductivity

of the surrounding air.

A.5 Neutralization rate

If the conductivity does not change, the relative rate of charge neutralization is constant and

the charge will decay exponentially with a time constant τ equal to the permittivity of the air e

o

divided by the conductivity λ.

τλ= e /

o

(A.3)

It should be noted that it is the conductivity, not the ion concentration itself that determines the

neutralizing ability of the air. If the particle concentration of the air is increased, by smoke for

example, the average mobility of the ions, and thus the conductivity, can decrease by a factor

of ten or more. The number of charged particles per unit volume of air, i.e. the ion concentration,

can still be more or less constant.

A.6 Ion depletion and field suppression

The conditions for fulfilling Formula (A.3) are almost never met.

It was assumed that the conductivity was not affected by the neutralization process. In the case