IEC 60164:1964

(Main)Recommendations in the field of quantities and units used in electricity

Recommendations in the field of quantities and units used in electricity

IEC 61298-3:2008 specifies general methods and procedures for conducting tests and reporting on the functional and performance characteristics of process measurement and control devices. The tests are applicable to any such devices characterized by their own specific input and output variables, and by the specific relationship (transfer function) between the inputs and outputs, and include analogue and digital devices. For devices that require special tests, this standard should be used, together with any product-specific standard specifying special tests. It covers tests for the effects of influence quantities.

Recommandations dans le domaine des grandeurs et unités utilisées en électricité

La CEI 61298-3:2008 spécifie les méthodes et procédures générales pour l'exécution des essais portant sur les caractéristiques fonctionnelles et les caractéristiques de performance des dispositifs de mesure et de commande de processus. Ces essais sont applicables à tout dispositif à condition que ce dispositif soit caractérisé par ses propres grandeurs d'entrée et de sortie et par la relation spécifique (fonction de transfert) entre les entrées et les sorties. Ils concernent les dispositifs analogiques et numériques. Pour les dispositifs nécessitant des essais spéciaux, il convient que la présente norme soit utilisée en conjonction avec la norme particulière de produit spécifiant ces essais spéciaux. Elle couvre les essais réalisés pour la détermination des effets des grandeurs d'influence.

General Information

- Status

- Published

- Publication Date

- 31-Dec-1963

- Technical Committee

- SC 65B - Measurement and control devices

- Drafting Committee

- WG 6 - TC 65/SC 65B/WG 6

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 01-Oct-1993

- Completion Date

- 26-Oct-2025

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61298-3:2008 is an international standard published by the International Electrotechnical Commission (IEC) that provides general methods and procedures for testing and evaluating the effects of influence quantities on process measurement and control devices. These devices, both analog and digital, are assessed based on their unique input-output relationships, defined by their transfer functions. The standard outlines comprehensive test criteria covering environmental, electrical, mechanical, and operational factors, ensuring robust performance evaluation in real-world industrial settings.

This standard serves as a foundational reference for manufacturers, testers, and regulatory bodies involved in the design, verification, and certification of process instrumentation, ensuring that devices maintain functional integrity under various influence conditions.

Key Topics

Scope and General Procedures

IEC 61298-3 applies to process measurement and control devices characterized by specific input and output variables. It includes guidelines on test criteria, general testing procedures, and electromagnetic compatibility (EMC) requirements.Environmental Influence Tests

- Ambient temperature and relative humidity effects

- Vibration testing including resonance search and endurance conditioning

- Shock, drop, and topple tests to assess mechanical robustness

- Effects of mounting position on device performance

- Atmospheric and static line pressure impact

- Influence of process medium conditions such as temperature and flow rate

Electrical Influence Tests

- Variations in power supply voltage, frequency, and transient conditions

- Fast transient/burst and surge immunity requirements

- Effects of harmonic distortion and magnetic fields

- Electrostatic discharge and electromagnetic field immunity

- Supply interruptions and voltage depressions

- Reverse polarity and supply pressure variability

Operational and Long-Term Performance

- Accelerated operational life testing

- Optional long-term drift measurement tests to evaluate device aging effects

Applications

IEC 61298-3:2008 is crucial for industries and sectors where precise and reliable process control instrumentation is essential. Applications include:

Industrial Automation

Ensuring process controllers, sensors, and actuators operate reliably despite changes in environmental and electrical conditions.Energy and Utilities

Verifying measurement devices used in power generation and distribution maintain accuracy in fluctuating supply conditions.Chemical and Pharmaceutical Manufacturing

Providing consistent process variable control under influence quantities such as temperature and pressure variations.Oil and Gas

Assessing the robustness of devices exposed to harsh environmental stressors like vibration, shock, and extreme temperatures.Equipment Certification and Regulatory Compliance

Serving as a reference standard for manufacturers and certifying bodies to demonstrate conformity with international testing requirements.

Related Standards

IEC 61298 Series

Part of the broader IEC 61298 set covering general methods and procedures for evaluating performance of process measurement and control devices.IEC 60654-2

Pertains to power supply classifications referenced for testing supply voltage variations in IEC 61298-3.IEC 61326-1

Governs EMC requirements and parameters such as burst and surge characteristics vital for immunity testing.ISO/IEC Directives

Guidelines followed in drafting this standard, providing structure and consistency in international standard development.

Practical Value

By following IEC 61298-3:2008, manufacturers and users of process measurement devices can:

- Identify and quantify potential performance deviations caused by physical and electrical influence factors.

- Develop product designs incorporating enhanced resilience against environmental and operational stress.

- Ensure compliance with international testing protocols, facilitating global market acceptance.

- Improve safety and reliability in critical process control applications through standardized test methodologies.

- Optimize maintenance and calibration routines by understanding device behavior under various influence conditions.

This standard establishes a uniform framework for robust testing, enhancing the overall quality and dependability of industrial measurement and control systems globally.

Frequently Asked Questions

IEC 60164:1964 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Recommendations in the field of quantities and units used in electricity". This standard covers: IEC 61298-3:2008 specifies general methods and procedures for conducting tests and reporting on the functional and performance characteristics of process measurement and control devices. The tests are applicable to any such devices characterized by their own specific input and output variables, and by the specific relationship (transfer function) between the inputs and outputs, and include analogue and digital devices. For devices that require special tests, this standard should be used, together with any product-specific standard specifying special tests. It covers tests for the effects of influence quantities.

IEC 61298-3:2008 specifies general methods and procedures for conducting tests and reporting on the functional and performance characteristics of process measurement and control devices. The tests are applicable to any such devices characterized by their own specific input and output variables, and by the specific relationship (transfer function) between the inputs and outputs, and include analogue and digital devices. For devices that require special tests, this standard should be used, together with any product-specific standard specifying special tests. It covers tests for the effects of influence quantities.

IEC 60164:1964 is classified under the following ICS (International Classification for Standards) categories: 25.040.40 - Industrial process measurement and control. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60164:1964 has the following relationships with other standards: It is inter standard links to IEC 61298-3:1998. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60164:1964 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61298-3

Edition 2.0 2008-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Process measurement and control devices – General methods and procedures

for evaluating performance –

Part 3: Tests for the effects of influence quantities

Dispositifs de mesure et de commande de processus – Méthodes et procédures

générales d'évaluation des performances –

Partie 3: Essais pour la détermination des effets des grandeurs d'influence

IEC 61298-3:2008

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61298-3

Edition 2.0 2008-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Process measurement and control devices – General methods and procedures

for evaluating performance –

Part 3: Tests for the effects of influence quantities

Dispositifs de mesure et de commande de processus – Méthodes et procédures

générales d'évaluation des performances –

Partie 3: Essais pour la détermination des effets des grandeurs d'influence

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

U

CODE PRIX

ICS 25.040.40 ISBN 978-2-88910-485-7

– 2 – 61298-3 © IEC:2008

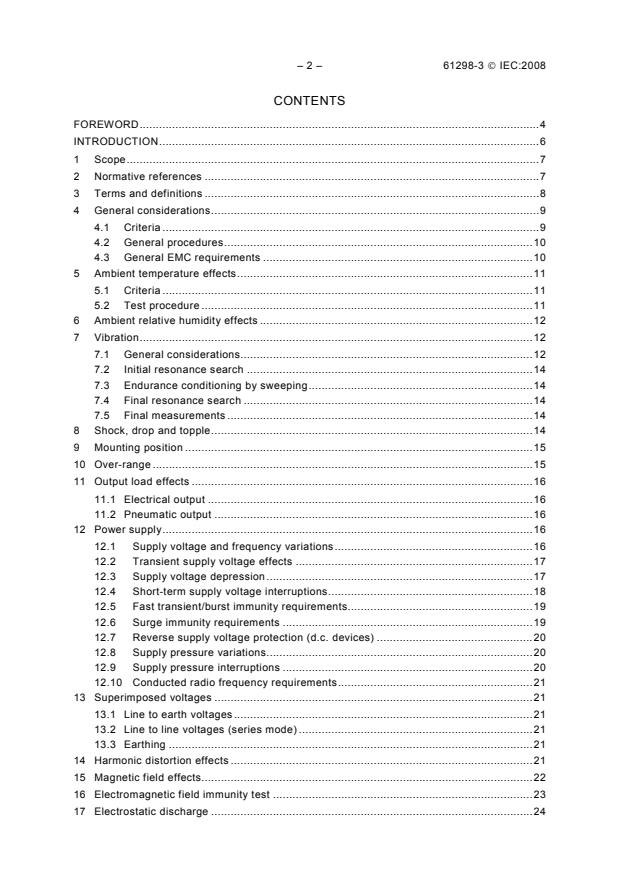

CONTENTS

FOREWORD.4

INTRODUCTION.6

1 Scope.7

2 Normative references .7

3 Terms and definitions .8

4 General considerations.9

4.1 Criteria .9

4.2 General procedures.10

4.3 General EMC requirements .10

5 Ambient temperature effects.11

5.1 Criteria .11

5.2 Test procedure .11

6 Ambient relative humidity effects .12

7 Vibration.12

7.1 General considerations.12

7.2 Initial resonance search .14

7.3 Endurance conditioning by sweeping.14

7.4 Final resonance search .14

7.5 Final measurements .14

8 Shock, drop and topple.14

9 Mounting position .15

10 Over-range .15

11 Output load effects .16

11.1 Electrical output .16

11.2 Pneumatic output .16

12 Power supply.16

12.1 Supply voltage and frequency variations.16

12.2 Transient supply voltage effects .17

12.3 Supply voltage depression.17

12.4 Short-term supply voltage interruptions.18

12.5 Fast transient/burst immunity requirements.19

12.6 Surge immunity requirements .19

12.7 Reverse supply voltage protection (d.c. devices) .20

12.8 Supply pressure variations.20

12.9 Supply pressure interruptions .20

12.10 Conducted radio frequency requirements.21

13 Superimposed voltages .21

13.1 Line to earth voltages.21

13.2 Line to line voltages (series mode) .21

13.3 Earthing .21

14 Harmonic distortion effects .21

15 Magnetic field effects.22

16 Electromagnetic field immunity test .23

17 Electrostatic discharge .24

61298-3 © IEC:2008 – 3 –

18 Effect of open-circuited and short-circuited input .25

19 Effect of open-circuited and short-circuited output .25

20 Effects of process medium conditions.25

20.1 Temperature of process fluid .25

20.2 Flow of process fluid through the device.26

20.3 Static line pressure effect.26

21 Atmospheric pressure effects .27

22 Flow of purge gas through the device .27

23 Accelerated operational life test.27

24 Operational long-term drift test (optional) .27

Bibliography.29

Figure 1 – Arrangement for supply voltage depression or interruption tests.18

Figure 2 – Arrangement for harmonic distortion effects test .22

Figure 3 – Examples of application of the test field .23

Figure 4 – Test set-up of the effects of static pressure.26

Figure 5 – Time schedule of input changes and changes of ambient temperature .28

Table 1 – Ambient temperature test ranges.11

Table 2 – Vibration test levels.13

Table 3 – Power supply classes (IEC 60654-2) .17

Table 4 – Power supply commutations-interruptions (IEC 60654-2).18

Table 5 – Burst characteristics (IEC 61326-1) .19

Table 6 – Surge characteristics (IEC 61326-1).20

Table 7 – Conducted RF characteristics (IEC 61326-1).21

– 4 – 61298-3 © IEC:2008

INTERNATIONAL ELECTROTECHNICAL COMMISSION

–––––––––––

PROCESS MEASUREMENT AND CONTROL DEVICES –

GENERAL METHODS AND PROCEDURES

FOR EVALUATING PERFORMANCE –

Part 3: Tests for the effects of influence quantities

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61298-3 has been prepared by sub-committee 65B: Devices and

process analysis, of IEC technical committee 65: Industrial-process measurement, control and

automation.

This second edition cancels and replaces the first edition published in 1998. This second

edition constitutes a technical revision.

This edition is a general revision with respect to the previous edition and does not include any

significant changes (see Introduction).

61298-3 © IEC:2008 – 5 –

The text of this standard is based on the following documents:

FDIS Report on voting

65B/687/FDIS 65B/695/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 61298 series, under the general title Process measurement and

control devices – General methods and procedures for evaluating performance, can be found

on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 61298-3 © IEC:2008

INTRODUCTION

This standard is not intended as a substitute for existing standards, but is rather intended as a

reference document for any future standard developed within the IEC, or other standards

organizations, concerning the evaluation of process instrumentation. Any revision of existing

standards should take this standard into account.

This common standardized basis should be utilized for the preparation of future relevant

standards, as follows:

– any test method or procedure, already treated in this standard, should be specified and

described in the new standard by referring to the corresponding clause of this standard.

Consequently new editions of this standard are revised without any change in numbering

and scope of each clause;

– any particular method or procedure, not covered by this standard, should be developed

and specified in the new standard in accordance with the criteria, as far as they are

applicable, stated in this standard;

– any conceptual or significant deviation from the content of this standard should be clearly

identified and justified if introduced in a new standard.

61298-3 © IEC:2008 – 7 –

PROCESS MEASUREMENT AND CONTROL DEVICES –

GENERAL METHODS AND PROCEDURES

FOR EVALUATING PERFORMANCE –

Part 3: Tests for the effects of influence quantities

1 Scope

This part of IEC 61298 specifies general methods and procedures for conducting tests and

reporting on the functional and performance characteristics of process measurement and

control devices. The tests are applicable to any such devices characterized by their own

specific input and output variables, and by the specific relationship (transfer function) between

the inputs and outputs, and include analogue and digital devices. For devices that require

special tests, this standard should be used, together with any product-specific standard

specifying special tests.

This standard covers tests for the effects of influence quantities.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050-300, International Electrotechnical Vocabulary (IEV) – Electrical and electronic

measurements and measuring instruments (composed of Part 311, 312, 313 and 314)

IEC 60050-351, International Electrotechnical Vocabulary (IEV) – Part 351 : Control

technology

IEC 61298-1:2008, Process measurement and control devices – General methods and

procedures for evaluating performance – Part 1: General considerations

IEC 61298-2:2008, Process measurement and control devices – General methods and

procedures for evaluating performance – Part 2: Tests under reference conditions

IEC 61298-4:2008, Process measurement and control devices – General methods and

procedures for evaluating performance – Part 4: Evaluation report content

IEC 60068-2-1, Environmental testing – Part 2-1: Tests – Test A: Cold

IEC 60068-2-2, Environmental testing – Part 2-2: Tests – Test B: Dry heat

IEC 60068-2-6, Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal)

IEC 60068-2-30, Environmental testing – Part 2-30: Tests – Test Db: Damp heat, cyclic (12 +

12 h cycle)

IEC 60068-2-31, Environmental testing – Part 2-31: Tests – Test Ec: Drop and topple,

primarily for equipment-type specimens

– 8 – 61298-3 © IEC:2008

IEC 60654-1:1993, Operating conditions for industrial-process measurement and control

equipment – Part 1: Climatic conditions

IEC 60654-2:1992, Operating conditions for industrial-process measurement and control

equipment – Part 2: Power

IEC 60654-3:1983, Operating conditions for industrial-process measurement and control

equipment – Part 3: Mechanical influences

IEC 61326 (all parts), Electrical equipment for measurement, control and laboratory use –

EMC Requirements

IEC 61326-1:2005, Electrical equipment for measurement, control and laboratory use – EMC

Requirements – Part 1: General requirements

IEC 61000-4-2:2001, Electromagnetic compatibility (EMC) – Part 4-2: Testing and

measurement techniques – Electrostatic discharge immunity test. Basic EMC publication

IEC 61000-4-3:2002, Electromagnetic compatibility (EMC) – Part 4-3: Testing and

measurement techniques – Radiated, radio-frequency, electromagnetic field immunity test.

Basic EMC publication

IEC 61000-4-4:2004, Electromagnetic compatibility (EMC) – Part 4-4: Testing and

measurement techniques – Electrical fast transient/burst immunity test. Basic EMC publication

IEC 61000-4-5:1995, Electromagnetic compatibility (EMC) – Part 4-5: Testing and

measurement techniques – Surge immunity test. Basic EMC publication

IEC 61000-4-6:2006, Electromagnetic compatibility (EMC) – Part 4-6: Testing and

measurement techniques – Immunity to conducted disturbances, induced by radio-frequency

fields

IEC 61000-4-8:2001, Electromagnetic compatibility (EMC) – Part 4-8: Testing and

measurement techniques – Power frequency magnetic field immunity test. Basic EMC

publication

IEC 61000-4-11:2004, Electromagnetic compatibility (EMC) – Part 4-11: Testing and

measurement techniques – Voltage dips, short interruptions and voltage variations immunity

tests . Basic EMC publication

3 Terms and definitions

For the purpose of this document, the following relevant terms and definitions, some of them

based on IEC 60050(300) or IEC 60050(351), apply.

3.1

influence quantity

test parameter chosen to represent a condition representing one aspect of the environment

under which a device may operate

3.2

variable

quantity or condition whose value is subject to change and can usually be measured (e.g.

temperature, flow rate, speed, signal, etc.)

[IEV 351-21-01, modified]

61298-3 © IEC:2008 – 9 –

3.3

signal

physical variable, one or more parameters of which carry information about one or more

variables which the signal represents

[IEV 351-21-51, modified]

3.4

range

range of values defined by the two extreme values within which a variable can be measured

within the specified accuracy

[IEV 351-27-11, modified]

3.5

span

algebraic difference between the values of the upper and lower limits of the measuring range

[IEV 311-03-13]

3.6

unexpected event

device breakdown, failure to work, anomaly, or inadvertent damage occurring during an

evaluation which requires correction by the device manufacturer

3.7

test procedure

statement of the tests to be carried out, and the conditions for each test, agreed between the

manufacturer, the test laboratory, and the purchaser/user before the evaluation starts

3.8

type tests

a test of one or more devices made to a certain design to show that the design meets certain

specifications

NOTE The type tests are in principle applied only on a sample. Normally are not repeated on all the individual

units of equipment made in series.

4 General considerations

4.1 Criteria

Unless otherwise stated, any effects of the tests described in this standard shall be assessed

by determining the change in the functional and performance characteristics due to the single

influence quantity applied. A test is only to be performed if it is applicable to the Device Under

Test (DUT). If the specification of the DUT states limits for the influence considered, these

limits shall be noted and respected.

NOTE It is recommended to perform each influence test described in this standard, except if the DUT operates

under an environment that excludes the influence considered.

Rates of change of influence quantities shall be sufficiently slow to ensure that no overshoot

of the influence quantities occurs at any point in the DUT. Sufficient time shall be allowed for

stabilization at each value or state of the influence quantity before taking readings. It may be

useful to check, by means of specific measurements of the effects, whether the influence

quantities cause variations in the characteristics of the DUT other than those addressed in

this part of the standard.

In the case of discontinuous-output devices such as alarms, the tests shall be conducted to

establish the effects of the specified influence.

– 10 – 61298-3 © IEC:2008

Only that influence quantity for which a specific test is being conducted shall be applied

during a specified test. All other influences shall be maintained at the reference operating

conditions.

However, consideration should be given to any combination of two or more influence

quantities which may aggravate the operating conditions (e.g. for an electrical device,

temperature and supply voltage).

The limit values of influence quantities specified in this standard should be used if no other

limit values are specified by the manufacturer or by the user. Testing at these values shall be

agreed by the parties and the results of tests shall be added to the report.

4.2 General procedures

The procedures used for the determination of the effects of influence quantities depend on the

kind of test, on the type of device and on its most significant characteristics (e.g. zero, span,

etc.).

The procedures should be established in accordance with the criteria given in 5.1 and 5.2 of

IEC 61298-1 in order to avoid tests which are too severe.

To satisfy these criteria, the DUT should be tested by assessing the effects of all the

quantities which might influence the performance of the DUT; this general statement is strictly

valid for performance evaluation and for type tests.

For routine and sampling tests, only the influence quantity which is considered to have the

most effect or is agreed between the parties should be applied. Wherever possible, all the

tests shall be carried out by measurement of the change of the output of the DUT.

The deviations caused by the effect of the specific influence quantity should be expressed

generally as a percentage of the output span. On certain devices, it may be more convenient

to express it in terms of the input span (see 4.1.6 of IEC 61298-2). It is important that the

input should be set so that the output is not limited; so in all tests, inputs corresponding to, for

example, 5 % and 95 % may be used instead of 0 % and 100 %. For the same reason, tests

that can produce large deviations on output (for example, supply voltage interruptions,

electrical fast transients, and so on) may be executed at input levels held at a value which

produces 50 % output signal.

In the case of discontinuous output devices such as alarms, the tests shall be conducted in

the same way to establish the conditions at which the performance is affected, with the

alarm/switching level set to 10 % above or below the nominal output.

4.3 General EMC requirements

In the first edition of this standard, some EMC requirements were described with reference to

IEC 61326. In the meantime, IEC 61326 has been transferred into the IEC 61326 series with

more detailed requirements. If a reference to this standard series is given in the following

clauses, this standard series shall be applied, if applicable, and as far as the DUT is not

covered by a more dedicated IEC product standard. In the latter case, the more dedicated IEC

product standard shall be applied.

As far as no other performance criteria are specified, the following performance criteria

(conforming to the IEC 61326 series) shall be applied.

• Performance criteria A for continuously present disturbances (electromagnetic field,

magnetic field, HF currents induced by RF transmitters).

• Performance criteria B for short time transient disturbances (EDS, bursts, surges).

• Performance criteria C for long time transient disturbances (supply voltage interruption).

61298-3 © IEC:2008 – 11 –

As far as no other test severity levels are specified, the test severity levels shall be at least

according to Table 1 of IEC 61326-1:2005.

5 Ambient temperature effects

5.1 Criteria

Sufficient time shall be allowed at each test temperature to permit thermal stabilization of the

DUT before test measurements are taken (as specified in IEC 60068-2-1 and 60068-2-2).

The stabilization period is a function of the DUT mass and of energy dissipation. It is normally

checked by recording the output signal of the DUT. It may be as long as 3 h.

Whatever the temperature cycle prescribed, during the temperature cycles, it is important to

carry out the measurements at the same temperatures during repeat cycles so as to permit

comparison.

Pneumatic devices shall have sufficient air supply tubing inside the test chamber to ensure

that the supply and input air are at the same temperature as the DUT.

5.2 Test procedure

The effects of ambient temperature shall be measured in the temperature range specified by

the manufacturer or, if no value is specified, between the limits shown in Table 1 (according

to the standard range specified in IEC 60654-1).

The test limits for ambient temperature should be appropriate to the temperatures at the

intended operational location of the DUT.

The test shall be carried out by conducting the same performance test at each selected test

ambient temperature, beginning at the reference temperature (+20 °C).

Table 1 – Ambient temperature test ranges

Temperature Temperature Typical service

class (IEC 60654-1) application

°C

min. max.

+5 +40 B2 Heated or/and cooled enclosed

locations

–25 +55 C2 Sheltered locations

–33 +40 D1 Outdoor locations

–40 +85 DX Special outdoor locations

NOTE For others temperature classes, see IEC 60654-1.

The test ambient temperatures should be chosen generally at 20 °C intervals, up to the

specified limit temperatures for the DUT.

For example, for the temperature class C2, the test temperature cycle should be +20 °C

(reference), +40 °C, +55 °C, +20 °C, 0 °C, -25 °C, +20 °C.

If agreed by all parties in the test programme, a test at only four temperatures, 20 °C

(reference), maximum, minimum, and 20 °C, may be sufficient.

– 12 – 61298-3 © IEC:2008

The tolerance for each test temperature should be ±2 °C and the rate of change of ambient

temperature should be less than 1 °C per minute. No adjustments to the DUT shall be made

during the test cycle.

A second or third temperature cycle, without any adjustment of the DUT, may be specified in

the test programme. At each test temperature, data shall be recorded for increasing and

decreasing values of output at each 25 % of span.

The output changes at each test value shall be calculated from the average of the upscale

and downscale readings and reported in percent of ideal output span. Any significant changes

in hysteresis, linearity or repeatability shall also be calculated and reported. See IEC 61298-4.

Any effects on a digital display indicator shall also be reported, including loss of contrast,

brightness, distortion or missing bits.

6 Ambient relative humidity effects

The effects of ambient relative humidity shall be determined by placing the DUT in a humidity

test chamber in which the value of relative humidity should be controlled within +2 % to -3 %

of the specified relative humidity levels (as specified in IEC 60068-2-30).

The DUT shall be stabilized at the reference relative humidity < 60 % at the temperature of

40 °C ± 2 °C.

Measurements shall be taken at each 25 % of output span in each direction.

+2

The relative humidity shall then be increased in not less than 3 h to ( 93 ) % avoiding the

−3

deposition of condensation on the DUT and maintained at this value for a period of at least

48 h. If agreed in the test programme, the DUT may be de-energized during this period.

The measurements shall again be taken at 25 % intervals of output span in each direction.

With the DUT remaining in operation, the relative humidity shall be reduced in not less than

3 h to the original reference value of < 60 %.

After stabilization for at least 12 h, the measurements shall be repeated.

Any changes in lower range value and span shall be calculated and reported in per cent of

output span.

In addition, any significant changes in hysteresis, linearity or repeatability should be

calculated and reported.

In addition, a visual examination shall be made after the test to check for indications of

component deterioration or moisture having entered sealed enclosures.

7 Vibration

7.1 General considerations

The general procedures of this test comply with the test procedure Fc of IEC 60068-2-6 and

the vibration ranges and values are in according with those reported in IEC 60654-3.

61298-3 © IEC:2008 – 13 –

The effect of vibration shall be determined by the following procedure using the peak

amplitudes, acceleration levels, and frequency ranges reported in Table 2 or specified by the

manufacturer.

Measurements shall be made before and after the vibration exposure.

The DUT shall be mounted, in accordance with the manufacturer's instructions for a normal

installation, on a vibration table where it shall be subjected to rectilinear sinusoidal vibrations

in each of three mutually perpendicular axes, one of which shall be the vertical.

The rigidity of the vibration table and of the mounting means for the DUT shall be such that

the vibration is transferred to the normal mounting point of the DUT with a minimum of loss or

gain.

The test vibration level shall be measured at the normal mounting point of the DUT.

Vibrations shall be applied with the DUT powered and operating with 50 % input signal.

The output signal shall be recorded in order to report any change in output.

Table 2 – Vibration test levels

Typical Test Displacement Acceleration

application frequency peak amplitude

Note1

range amplitude

mm m/s

Hz

Note 2

Control room or field with low 10 to 150 0,35 1

vibration level

Note 2

Control room or field with 10 to 150 0,75 2

medium vibration level

Note 3

Field with general application 10 to 1 000 0,15 20

or pipeline with low vibration

Note 3

Field with high vibration level or 10 to 1 000 0,35 50

pipe line with high vibration

NOTE 1 For a list of all test frequency ranges, see IEC 60654-3.

NOTE 2 Test frequency range derived from low-frequency classes (IEC 60654-3), but limited

to 10 Hz (instead of 0,1 Hz) and with crossover frequency at 8÷9 Hz.

NOTE 3 Test frequency range derived from high-frequency classes (IEC 60654-3), but

limited to 1 000 Hz (instead of 10 000 Hz) and with crossover frequency at 57÷62 Hz.

The crossover frequency is the region of change from constant amplitude and constant

acceleration.

The vibration tests shall include three stages:

– an initial resonance search;

– an endurance conditioning by sweeping the frequency over the appropriate frequency

range specified in Table 2 (or over another range reported in IEC 60654-3), or as specified

by the manufacturer or by the user;

– a final resonance search.

These three stages shall be performed in sequence. At each stage, the DUT shall be vibrated

in each of the three major axes before proceeding to the next stage.

– 14 – 61298-3 © IEC:2008

7.2 Initial resonance search

The initial resonance search shall be carried out to study behaviour of the DUT to determine

any component resonances and the corresponding resonance frequencies, and to obtain

information for comparison with the final resonance search.

The sweep rate shall be not greater than 0,5 octave per minute.

During the resonance search, frequencies shall be noted which cause

a) significant changes in the output signal;

b) mechanical resonances of components or sub-assemblies.

All the amplitudes and frequencies at which these effects occur shall be noted in order to be

compared with those found during the final resonance search specified below.

7.3 Endurance conditioning by sweeping

The test is carried out by sweeping the vibration frequency at a rate of one octave per minute

over the range selected.

The total number of sweep cycles should be 60, being 20 in each of the three mutually

perpendicular directions.

7.4 Final resonance search

The final resonance search shall be made in the same way as the initial resonance search

and with the same vibration characteristics.

The resonance frequencies, and the frequencies which cause significant changes in the

output signal, found in the initial resonance search and final resonance search shall be

compared.

7.5 Final measurements

The satisfactory mechanical condition of the DUT shall be verified at the end of the tests with

a visual examination for any deformation or cracks in the components or mountings.

The satisfactory performance of the DUT shall be verified with a measurement test; any

change in the lower range value and span shall be recorded in percent of output span.

8 Shock, drop and topple

The test shall be made according to the test procedure Ec of IEC 60068-2-31 and according

to the free fall method reported in IEC 60654-3

Before the test, reference measurements of lower range-value and span shall be recorded.

During the test, the power supply and inputs may be switched off.

The object of this test is

– to represent knocks and jolts likely to occur during repair work or rough handling in use;

– to verify the minimum degree of mechanical ruggedness.

The procedure of "dropping on to a face" shall be applied as follows:

61298-3 © IEC:2008 – 15 –

The DUT, standing in its normal position of use on a smooth, hard, rigid surface of concrete or

steel, is tilted about one bottom edge so that the distance between the opposite edge and the

test surface is 25 mm, 50 mm or 100 mm (value chosen by agreement between manufacturer

and use), or so that the angle made by the bottom and the test surface is 30°, whichever

condition is the less severe. It is then allowed to fall freely onto the test surface.

The DUT shall be subjected to one drop about each of the four bottom edges.

After this test, the DUT shall be examined for damage.

Any change in lower range-value and span shall be recorded.

If any changes are noted, it shall be verified that the DUT can be readjusted so that the initial

performance can be re-established.

NOTE In special cases, by agreement, one of the other shock tests in IEC 60068-2-31 may be used, or the free

fall method, reported in IEC 60654-3 (from height 25 mm to 1 000 mm or more), may be used.

9 Mounting position

Where the DUT might be position sensitive, the change in lower range-value and span caused

by 10° inclinations from the position(s) specified by the manufacturer shall be measured and

recorded in percent of output span.

Four measurements shall be made with tilt applied in two planes at right angles to each other.

Where a 10° inclination is excessive due to the design of the DUT, the maximum inclination

specified by the manufacturer shall be used.

10 Over-range

This test shall be carried out by measuring any residual changes in lower range-value and

span which result from over-ranging the input by 50 % at the minimum and maximum span

settings if not otherwise specified by the manufacturer.

The input shall be increased gradually from the lower range-value to the over-range selected

for the test.

After the over-range has been applied for 1 min, the input shall be reduced to the nominal

lower range-value.

After a further 5 min have elapsed, the lower range-value and the span shall be determined in

per cent of output span.

If the DUT is to be tested for over-range effect in both directions, as with differential

measuring devices and devices whose input may be both below the lower range-value and

above the upper range-value, it shall be tested as described above, first over-ranging above

the upper range-value, and then over-ranging below the lower range-value.

Any changes of lower range-value and span determined after over-ranging in each direction

shall be recorded.

NOTE If over-ranging produces significant thermal effects, the duration of application should be increased

accordingly.

– 16 – 61298-3 © IEC:2008

11 Output load effects

The purpose of this test is to determine any effects on the output signal when the output load

is varied.

11.1 Electrical output

To determine any effect on an electrical output signal, the load resistance shall be varied from

the minimum to the maximum value specified by the manufacturer. Any changes in lower

range-value and span caused by the variations shall be expressed as a percentage of the

output span. The output voltage drop at the DUT at the upper range value shall also be noted

when the DUT is a two-wire transmitter. Consideration should be given to the effect of

connecting capacitive or inductive loads.

11.2 Pneumatic output

This test shall be carried out as specified in 6.6 of IEC 61298-2.

12 Power supply

12.1 Supply voltage and frequency variations

For two-wire transmitters, reference should be made to 11.1 of this standard.

NOTE Power inputs for voltages up to 75 V d.c. or voltages up to 50 V a.c. with superimposed output signals (for

example 4 mA to 20 mA current loop with two-wire technology) are tested as input/output lines.

For electrical devices except two-wire transmitters, the test shall be carried out first setting

the values of the lower range and span at nominal supply vol

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...