IEC 61511-1:2003

(Main)Functional safety - Safety instrumented systems for the process industry sector - Part 1: Framework, definitions, system, hardware and software requirements

Functional safety - Safety instrumented systems for the process industry sector - Part 1: Framework, definitions, system, hardware and software requirements

gives requirements for the specification, design, installation, operation and maintenance of a safety instrumented system, so that it can be confidently entrusted to place and/or maintain the process in a safe state. This standard has been developed as a process sector implementation of IEC 61508. The contents of the corrigendum of November 2004 have been included in this copy. It has the status of a horizontal standard in accordance with IEC Guide 108.

Sécurité fonctionnelle - Systèmes instrumentés de sécurité pour le domaine de la production par processus - Partie 1: Cadre, définitions, exigences pour le système, le matériel et le logiciel

permet de définir des prescriptions relatives aux spécifications, à la conception, à l'installation, à l'exploitation et à l'entretien d'un système instrumenté de sécurité, de telle manière qu'il puisse être mis en oeuvre en toute confiance, et ainsi établir et/ou maintenir les processus dans un état de sécurité convenable. La présente norme a été conçue pour être une mise en uvre de la norme internationale CEI 61508 "Sécurité fonctionnelle des systèmes électriques/électroniques/ électroniques programmables relatifs à la sécurité" dans le domaine de l'industrie des processus. Le contenu du corrigendum de novembre 2004 a été pris en considération dans cet exemplaire. Elle a le statut d'une norme horizontale conformément au Guide 108 de la CEI.

General Information

- Status

- Published

- Publication Date

- 29-Jan-2003

- Technical Committee

- SC 65A - System aspects

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 24-Feb-2016

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Referred By

EN 62282-5-1:2012 - Fuel cell technologies - Part 5-1: Portable fuel cell power systems - Safety - Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Referred By

EN 62282-3-1:2007 - Fuel cell technologies - Part 3-1: Stationary fuel cell power systems - Safety - Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

Overview

IEC 61511-1:2003 - "Functional safety - Safety instrumented systems for the process industry sector - Part 1" defines requirements for the specification, design, installation, operation and maintenance of Safety Instrumented Systems (SIS) so they can be confidently entrusted to place and/or maintain a process in a safe state. Developed as the process-industry application of IEC 61508, IEC 61511-1 provides a safety lifecycle framework, definitions, and system, hardware and software requirements specific to process plants. This edition includes the November 2004 corrigendum and has the status of a horizontal standard per IEC Guide 108.

Key Topics and Technical Requirements

The standard covers the full SIS safety lifecycle and prescribes activities, documentation and verification necessary to achieve functional safety:

- Safety lifecycle & management of functional safety - roles, responsibilities, and lifecycle phases from concept through decommissioning.

- Process hazard and risk analysis - deriving Safety Instrumented Functions (SIFs) and required risk reduction.

- Safety Integrity Levels (SILs) - allocation of SILs to SIFs and associated probability/frequency targets.

- SIS specification & design - SIS safety requirements specification (SRS), architecture, hardware fault tolerance and selection of sensors, logic solvers and final elements.

- Software requirements - application software lifecycle, development, verification, validation and modification control for programmable electronic systems.

- Verification, testing and validation - factory acceptance testing (FAT), commissioning, proof testing, periodic inspection and SIS safety validation.

- Operation, maintenance & modification control - procedures for safe operation, maintenance, proof testing intervals, and managing changes.

- Documentation & evidence - traceability, records and information required for audits and functional safety assessments.

Practical Applications and Users

IEC 61511-1 is applied in industries where process safety is critical, including oil & gas, petrochemical, chemical, power generation, pharmaceutical and water/wastewater treatment. Typical uses:

- Defining SIF performance requirements and SIL targets for new plants or modifications.

- Guiding procurement and acceptance testing of SIS equipment and software.

- Establishing maintenance, proof test and validation programs to sustain safety performance.

- Supporting compliance, third‑party audits and regulatory reviews.

Primary users include process safety engineers, instrument & control engineers, system integrators, maintenance managers, operations teams, safety auditors and regulatory bodies.

Related Standards

- IEC 61508 - Generic functional safety standard (parent standard).

- IEC 61511-2 - Application guidelines for IEC 61511-1.

- IEC 61511-3 - Guidance for determination of required SILs.

Keywords: IEC 61511-1, functional safety, safety instrumented system, SIS, process industry, SIL, safety lifecycle, IEC 61508, safety requirements.

Buy Documents

IEC 61511-1:2003 - Functional safety - Safety instrumented systems for the process industry sector - Part 1: Framework, definitions, system, hardware and software requirements Released:1/30/2003

IEC 61511-1:2003 - Functional safety - Safety instrumented systems for the process industry sector - Part 1: Framework, definitions, system, hardware and software requirements Released:1/30/2003

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

NSF International

Global independent organization facilitating standards development and certification.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

Sponsored listings

Frequently Asked Questions

IEC 61511-1:2003 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Functional safety - Safety instrumented systems for the process industry sector - Part 1: Framework, definitions, system, hardware and software requirements". This standard covers: gives requirements for the specification, design, installation, operation and maintenance of a safety instrumented system, so that it can be confidently entrusted to place and/or maintain the process in a safe state. This standard has been developed as a process sector implementation of IEC 61508. The contents of the corrigendum of November 2004 have been included in this copy. It has the status of a horizontal standard in accordance with IEC Guide 108.

gives requirements for the specification, design, installation, operation and maintenance of a safety instrumented system, so that it can be confidently entrusted to place and/or maintain the process in a safe state. This standard has been developed as a process sector implementation of IEC 61508. The contents of the corrigendum of November 2004 have been included in this copy. It has the status of a horizontal standard in accordance with IEC Guide 108.

IEC 61511-1:2003 is classified under the following ICS (International Classification for Standards) categories: 13.110 - Safety of machinery; 25.040.01 - Industrial automation systems in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61511-1:2003 has the following relationships with other standards: It is inter standard links to EN 61326-3-2:2008, EN 60079-28:2007, EN 61784-3-3:2008, EN 62282-5-1:2012, EN 61784-3-1:2010, EN 61784-3-8:2010, EN 62424:2009, EN 60947-4-1:2010, EN 61784-3-14:2010, EN 61784-3-3:2010, CLC/TR 60079-33:2015, EN 62282-3-1:2007, EN 61784-3-1:2008, EN 61784-3-6:2010, EN 61069-1:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61511-1:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD

61511-1

First edition

2003-01

Functional safety –

Safety instrumented systems

for the process industry sector –

Part 1:

Framework, definitions, system,

hardware and software requirements

Sécurité fonctionnelle –

Systèmes instrumentés de sécurité pour le secteur

des industries de transformation –

Partie 1:

Cadre, définitions et prescriptions concernant

le système,

le matériel et le logiciel

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (http://www.iec.ch/searchpub/cur_fut.htm)

enables you to search by a variety of criteria including text searches, technical

committees and date of publication. On-line information is also available on

recently issued publications, withdrawn and replaced publications, as well as

corrigenda.

• IEC Just Published

This summary of recently issued publications (http://www.iec.ch/online_news/

justpub/jp_entry.htm) is also available by email. Please contact the Customer

Service Centre (see below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD

61511-1

First edition

2003-01

Functional safety –

Safety instrumented systems

for the process industry sector –

Part 1:

Framework, definitions, system,

hardware and software requirements

Sécurité fonctionnelle –

Systèmes instrumentés de sécurité pour le secteur

des industries de transformation –

Partie 1:

Cadre, définitions et prescriptions concernant

le système,

le matériel et le logiciel

IEC 2003 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale

XC

International Electrotechnical Commission

Международная Электротехническая Комиссия

For price, see current catalogue

– 2 – 61511-1 IEC:2003(E)

CONTENTS

FOREWORD . 5

INTRODUCTION .7

1 Scope . 9

2 Normative references.14

3 Abbreviations and definitions .15

3.1 Abbreviations.15

3.2 Definitions .16

4 Conformance to this International Standard .30

5 Management of functional safety.30

5.1 Objective .30

5.2 Requirements .30

6 Safety life-cycle requirements .35

6.1 Objective .35

6.2 Requirements .35

7 Verification .37

7.1 Objective .37

8 Process hazard and risk analysis.38

8.1 Objectives .38

8.2 Requirements .38

9 Allocation of safety functions to protection layers.39

9.1 Objective .39

9.2 Requirements of the allocation process .39

9.3 Additional requirements for safety integrity level 4 .40

9.4 Requirements on the basic process control system as a protection layer .41

9.5 Requirements for preventing common cause, common mode and dependent

failures .42

10 SIS safety requirements specification .43

10.1 Objective .43

10.2 General requirements .43

10.3 SIS safety requirements.43

11 SIS design and engineering .44

11.1 Objective .44

11.2 General requirements .44

11.3 Requirements for system behaviour on detection of a fault .46

11.4 Requirements for hardware fault tolerance.47

11.5 Requirements for selection of components and subsystems .48

11.6 Field devices .51

11.7 Interfaces .52

11.8 Maintenance or testing design requirements .54

11.9 SIF probability of failure.54

61511-1 IEC:2003(E) – 3 –

12 Requirements for application software, including selection criteria for utility software .55

12.1 Application software safety life-cycle requirements .56

12.2 Application software safety requirements specification.62

12.3 Application software safety validation planning .64

12.4 Application software design and development.64

12.5 Integration of the application software with the SIS subsystem .69

12.6 FPL and LVL software modification procedures .70

12.7 Application software verification.70

13 Factory acceptance testing (FAT) .71

13.1 Objectives .72

13.2 Recommendations .72

14 SIS installation and commissioning.73

14.1 Objectives .73

14.2 Requirements .73

15 SIS safety validation .74

15.1 Objective .74

15.2 Requirements .74

16 SIS operation and maintenance .76

16.1 Objectives .76

16.2 Requirements .77

16.3 Proof testing and inspection.78

17 SIS modification.79

17.1 Objective .79

17.2 Requirements .79

18 SIS decommissioning.80

18.1 Objectives .80

18.2 Requirements .80

19 Information and documentation requirements.81

19.1 Objectives .81

19.2 Requirements .81

Annex A (informative) Differences .83

Figure 1 – Overall framework of this standard . 8

Figure 2 – Relationship between IEC 61511 and IEC 61508.11

Figure 3 – Relationship between IEC 61511 and IEC 61508 (see 1.2) .12

Figure 4 – Relationship between safety instrumented functions and other functions .13

Figure 5 – Relationship between system, hardware, and software of IEC 61511-1.14

Figure 6 – Programmable electronic system (PES): structure and terminology .23

Figure 7 – Example SIS architecture .26

Figure 8 – SIS safety life-cycle phases and functional safety assessment stages.33

Figure 9 – Typical risk reduction methods found in process plants .42

Figure 10 – Application software safety life cycle and its relationship to the SIS safety

life cycle.56

– 4 – 61511-1 IEC:2003(E)

Figure 11 – Application software safety life cycle (in realization phase).58

Figure 12 − Software development life cycle (the V-model) .59

Figure 13 – Relationship between the hardware and software architectures of SIS.62

Table 1 – Abbreviations used in IEC 61511 .15

Table 2 – SIS safety life-cycle overview .36

Table 3 – Safety integrity levels: probability of failure on demand .40

Table 4 – Safety integrity levels: frequency of dangerous failures of the SIF .40

Table 5 – Minimum hardware fault tolerance of PE logic solvers .47

Table 6 – Minimum hardware fault tolerance of sensors and final elements and non-PE

logic solvers.48

Table 7 – Application software safety life cycle: overview.60

61511-1 IEC:2003(E) – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FUNCTIONAL SAFETY –

SAFETY INSTRUMENTED SYSTEMS

FOR THE PROCESS INDUSTRY SECTOR –

Part 1: Framework, definitions, system,

hardware and software requirements

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International

Organization for Standardization (ISO) in accordance with conditions determined by agreement between the

two organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61511-1 has been prepared by subcommittee 65A: System

aspects, of IEC technical committee 65: Industrial-process measurement and control. The text

of this standard is based on the following documents:

FDIS Report on voting

65A/368/FDIS 65A/372/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

IEC 61511 consists of the following parts, under the general title Functional safety: Safety

instrumented systems for the process industry sector (see Figure 1):

− Part 1: Framework, definitions, system, hardware and software requirements

− Part 2: Guidelines in the application of IEC 61511-1

− Part 3: Guidance for the determination of the required safety integrity levels

– 6 – 61511-1 IEC:2003(E)

The committee has decided that the contents of this publication will remain unchanged until

2007. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version of this standard may be issued at a later date.

61511-1 IEC:2003(E) – 7 –

INTRODUCTION

Safety instrumented systems have been used for many years to perform safety instrumented

functions in the process industries. If instrumentation is to be effectively used for safety

instrumented functions, it is essential that this instrumentation achieves certain minimum

standards and performance levels.

This international standard addresses the application of safety instrumented systems for the

Process Industries. It also requires a process hazard and risk assessment to be carried out to

enable the specification for safety instrumented systems to be derived. Other safety systems

are only considered so that their contribution can be taken into account when considering the

performance requirements for the safety instrumented systems. The safety instrumented

system includes all components and subsystems necessary to carry out the safety

instrumented function from sensor(s) to final element(s).

This international standard has two concepts which are fundamental to its application; safety

lifecycle and safety integrity levels.

This standard addresses safety instrumented systems which are based on the use of

electrical/electronic/programmable electronic technology. Where other technologies are used

for logic solvers, the basic principles of this standard should be applied. This standard also

addresses the safety instrumented system sensors and final elements regardless of the

technology used. This International Standard is process industry specific within the framework

of IEC 61508 (see Annex A).

This International Standard sets out an approach for safety life-cycle activities to achieve

these minimum standards. This approach has been adopted in order that a rational and

consistent technical policy is used.

In most situations, safety is best achieved by an inherently safe process design If necessary,

this may be combined with a protective system or systems to address any residual identified

risk. Protective systems can rely on different technologies (chemical, mechanical, hydraulic,

pneumatic, electrical, electronic, programmable electronic) To facilitate this approach, this

standard

• requires that a hazard and risk assessment is carried out to identify the overall safety

requirements;

• requires that an allocation of the safety requirements to the safety instrumented system(s)

is carried out;

• works within a framework which is applicable to all instrumented methods of achieving

functional safety;

• details the use of certain activities, such as safety management, which may be applicable

to all methods of achieving functional safety.

This International Standard on safety instrumented systems for the process industry

• addresses all safety life-cycle phases from initial concept, design, implementation,

operation and maintenance through to decommissioning;

• enables existing or new country specific process industry standards to be harmonized with

this standard.

This International Standard is intended to lead to a high level of consistency (for example, of

underlying principles, terminology, information) within the process industries. This should

have both safety and economic benefits.

In jurisdictions where the governing authorities (for example, national, federal, state, province,

county, city) have established process safety design, process safety management, or other

requirements, these take precedence over the requirements defined in this standard.

– 8 – 61511-1 IEC:2003(E)

Support

Technical

parts

requirements

PART 1 References

Clause 2

Development of the overall safety

PART 1

requirements (concept, scope definition,

hazard and risk assessment)

Definitions and

abbreviations

Clause 8

Clause 3

PART 1

PART 1

Conformance

Allocation of the safety requirements to

Clause 4

the safety instrumented functions and

development of safety requirements

PART 1

specification

Management of

Clauses 9 and 10

functional safety

Clause 5

PART 1

PART 1

Safety life-cycle

Design phase for Design phase for

requirements

safety

safety

Clause 6

instrumented instrumented

PART 1

system software

systems

Clause 12

Clause 11

Verification

Clause 7

PART 1

PART 1

Information

Factory acceptance testing,

requirements

installation and commissioning and

Clause 19

safety validation of safety

PART 1

instrumented systems

Clauses 13, 14, and 15

Differences

Annex “A”

PART 1

PART 1

Operation and maintenance,

modification and retrofit, Guideline for the

decommissioning or disposal of application of part 1

safety instrumented systems

PART 2

Clauses 16, 17, and 18

Guidance for the

determination of the

required safety

integrity levels

PART 3

IEC 3240/02

Figure 1 – Overall framework of this standard

61511-1 IEC:2003(E) – 9 –

FUNCTIONAL SAFETY –

SAFETY INSTRUMENTED SYSTEMS

FOR THE PROCESS INDUSTRY SECTOR –

Part 1: Framework, definitions, system,

hardware and software requirements

1 Scope

This International Standard gives requirements for the specification, design, installation,

operation and maintenance of a safety instrumented system, so that it can be confidently

entrusted to place and/or maintain the process in a safe state. This standard has been

developed as a process sector implementation of IEC 61508.

In particular, this standard

a) specifies the requirements for achieving functional safety but does not specify who is

responsible for implementing the requirements (for example, designers, suppliers,

owner/operating company, contractor); this responsibility will be assigned to different

parties according to safety planning and national regulations;

b) applies when equipment that meets the requirements of IEC 61508, or of 11.5 of

IEC 61511-1, is integrated into an overall system that is to be used for a process sector

application but does not apply to manufacturers wishing to claim that devices are suitable

for use in safety instrumented systems for the process sector (see IEC 61508-2 and

IEC 61508-3);

c) defines the relationship between IEC 61511 and IEC 61508 (Figures 2 and 3);

d) applies when application software is developed for systems having limited variability or

fixed programmes but does not apply to manufacturers, safety instrumented systems

designers, integrators and users that develop embedded software (system software) or

use full variability languages (see IEC 61508-3);

e) applies to a wide variety of industries within the process sector including chemicals, oil

refining, oil and gas production, pulp and paper, non-nuclear power generation;

NOTE Within the process sector some applications, (for example, off-shore), may have additional

requirements that have to be satisfied.

f) outlines the relationship between safety instrumented functions and other functions

(Figure 4);

g) results in the identification of the functional requirements and safety integrity requirements

for the safety instrumented function(s) taking into account the risk reduction achieved by

other means;

h) specifies requirements for system architecture and hardware configuration, application

software, and system integration;

i) specifies requirements for application software for users and integrators of safety

instrumented systems (clause 12). In particular, requirements for the following are

specified:

– safety life-cycle phases and activities that are to be applied during the design and

development of the application software (the software safety life-cycle model). These

requirements include the application of measures and techniques, which are intended

to avoid faults in the software and to control failures which may occur;

– information relating to the software safety validation to be passed to the organization

carrying out the SIS integration;

– 10 – 61511-1 IEC:2003(E)

– preparation of information and procedures concerning software needed by the user for

the operation and maintenance of the SIS;

– procedures and specifications to be met by the organization carrying out modifications

to safety software;

j) applies when functional safety is achieved using one or more safety instrumented

functions for the protection of personnel, protection of the general public or protection of

the environment;

k) may be applied in non-safety applications such as asset protection;

l) defines requirements for implementing safety instrumented functions as a part of the

overall arrangements for achieving functional safety;

m) uses a safety life cycle (Figure 8) and defines a list of activities which are necessary to

determine the functional requirements and the safety integrity requirements for the safety

instrumented systems;

n) requires that a hazard and risk assessment is to be carried out to define the safety

functional requirements and safety integrity levels of each safety instrumented function;

NOTE See Figure 9 for an overview of risk reduction methods.

o) establishes numerical targets for average probability of failure on demand and frequency

of dangerous failures per hour for the safety integrity levels;

p) specifies minimum requirements for hardware fault tolerance;

q) specifies techniques/measures required for achieving the specified integrity levels;

r) defines a maximum level of performance (SIL 4) which can be achieved for a safety

instrumented function implemented according to this standard;

s) defines a minimum level of performance (SIL 1) below which this standard does not apply;

t) provides a framework for establishing safety integrity levels but does not specify the safety

integrity levels required for specific applications (which should be established based on

knowledge of the particular application);

u) specifies requirements for all parts of the safety instrumented system from sensor to final

element(s);

v) defines the information that is needed during the safety life cycle;

w) requires that the design of a safety instrumented function takes into account human

factors;

x) does not place any direct requirements on the individual operator or maintenance person.

61511-1 IEC:2003(E) – 11 –

PROCESS SECTOR

SAFETY

INSTRUMENTED

SYSTEM

STANDARDS

Safety

Manufacturers and

instrumented

suppliers of systems designers,

devices integrators and

users

IEC 61508

IEC 61511

IEC 3241/02

Figure 2 – Relationship between IEC 61511 and IEC 61508

– 12 – 61511-1 IEC:2003(E)

PROCESS SECTOR

SAFETY

INSTRUMENTED

SYSTEM STANDARD

PROCESS

PROCESS

SECTOR SECTOR

HARDWARE

SOFTWARE

DEVELOPING

DEVELOPING USING USING DEVELOPING DEVELOPING APPLICATION

NEW HARDWARE EMBEDDED APPLICATION SOFTWARE

PROVEN-IN-

HARDWARE DEVELOPED (SYSTEM) SOFTWARE

USING

USE

DEVICES AND SOFTWARE USING FULL

LIMITED

HARDWARE

ACCESSED VARIABILITY

VARIABILITY

DEVICES

ACCORDING LANGUAGES

LANGUAGES

TO IEC 61508

OR FIXED

PROGRAMS

FOLLOW FOLLOW FOLLOW FOLLOW FOLLOW

FOLLOW

IEC 61508 IEC 61511 IEC 61511

IEC 61511 IEC 61508-3 IEC 61508-3

IEC 3242/02

Figure 3 – Relationship between IEC 61511 and IEC 61508 (see clause 1)

61511-1 IEC:2003(E) – 13 –

Start

Is it an

No Yes

instrumented

function?

Safety

Yes Yes

No No

instrumented

Safety

related function?

?

Not

relevant

Continuous Demand

Safety instrumented

Mode

protection function

Mitigation

Prevention

Type?

Other Safety Safety Safety

Basic process

instrumented

means of instrumented instrumented

control and/or asset

control

risk prevention mitigation

protection function

function function function

reduction

Standard specifies activities which are to be carried out but requirements are not detailed.

IEC 3243/02

Figure 4 – Relationship between safety instrumented functions and other functions

– 14 – 61511-1 IEC:2003(E)

Management of functional safety (clause 5)

Determination of function and integrity (clause 8)

Verification and validation (clause 7, 12.3, 12.7,

clauses 13 and 15)

Operation, maintenance and modification (clauses 16 and 17)

Safety instrumented functions

Continuous mode

Safety instrumented control function

Demand mode control

Safety instrumented protection function

- Safety instrumented prevention function

- Safety instrumented mitigation function

Safety instrumented systems

System and hardware requirements (clause 6)

Input Logic Output

(Function) (Function) (Function)

Software

Safety instrumented systems

Software requirements (clause 12)

IEC 3244/02

Figure 5 – Relationship between system, hardware, and software of IEC 61511-1

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60654-1:1993, Industrial-process measurement and control equipment – Operating

conditions – Part 1: Climatic conditions

IEC 60654-3:1998, Industrial-process measurement and control equipment – Operating

conditions – Part 3: Mechanical influences

IEC 61326-1:Electrical equipment for measurement, control and laboratory use – EMC

requirements

IEC 61508, Functional safety of electrical/electronic/programmable electronic safety-related

systems – Part 2: Requirements for electrical/electronic/programmable electronic safety-

related systems

IEC 61508-3, Functional safety of electrical/electronic/programmable electronic safety-related

systems – Part 3: Software requirements

61511-1 IEC:2003(E) – 15 –

IEC 61511-2: Functional safety – Safety instrumented systems for the process industry sector

– Part 2: Guidelines in the application of IEC 61511-1

3 Abbreviations and definitions

3.1 Abbreviations

Abbreviations used throughout IEC 61511 are given in Table 1.

Table 1 – Abbreviations used in IEC 61511

Abbreviation Full expression

AC/DC Alternating current/direct current

ALARP As low as reasonably practicable

ANSI American National Standards Institute

BPCS Basic process control system

DC Diagnostic coverage

E/E/PE Electrical/electronic/programmable electronic

E/E/PES Electrical/electronic/programmable electronic system

EMC Electro-magnetic compatibility

FAT Factory acceptance testing

FPL Fixed program language

FTA Fault tree analysis

FVL Full variability language

HFT Hardware fault tolerance

HMI Human machine interface

H&RA Hazard and risk assessment

HRA Human reliability analysis

H/W Hardware

IEC International Electrotechnical Commission

IEV International Electrotechnical Vocabulary

ISA Instrumentation, Systems and Automation Society

ISO International Organization for Standardization

LVL Limited variability language

MooN “M” out of “N” (see 3.2.45)

NP Non-programmable

PE Programmable electronics

PES Programmable electronic system

PFD Probability of failure on demand

PFD Average probability of failure on demand

avg

PLC Programmable logic controller

SAT Site acceptance test

SFF Safe failure fraction

SIF Safety instrumented function

SIL Safety integrity level

SIS Safety instrumented system

SRS Safety requirement specification

S/W Software

___________

To be published.

– 16 – 61511-1 IEC:2003(E)

3.2 Definitions

For the purposes of this document, the following definitions apply.

3.2.1

architecture

arrangement of hardware and/or software elements in a system, for example,

(1) arrangement of safety instrumented system (SIS) subsystems;

(2) internal structure of an SIS subsystem;

(3) arrangement of software programs

NOTE This term differs from the definition in IEC 61508-4 to reflect differences in the process sector terminology.

3.2.2

asset protection

function allocated to system design for the purpose of preventing loss to assets

3.2.3

basic process control system (BPCS)

system which responds to input signals from the process, its associated equipment, other

programmable systems and/or an operator and generates output signals causing the process

and its associated equipment to operate in the desired manner but which does not perform

any safety instrumented functions with a claimed SIL ≥ 1

NOTE See Clause A.2.

3.2.4

channel

element or group of elements that independently perform(s) a function

NOTE 1 The elements within a channel could include input/output (I/O) modules, logic systems (see 3.2.40),

sensors, final elements.

NOTE 2 A dual channel (i.e., a two-channel) configuration is one with two channels that independently perform

the same function.

NOTE 3 The term can be used to describe a complete system or a portion of a system (for example, sensors or

final elements).

3.2.5

coding

see “programming”

3.2.6

3.2.6.1

common cause failure

failure, which is the result of one or more events, causing failures of two or more separate

channels in a multiple channel system, leading to system failure

3.2.6.2

common mode failure

failure of two or more channels in the same way, causing the same erroneous result

3.2.7

component

one of the parts of a system, subsystem, or device performing a specific function

3.2.8

configuration

see “architecture”

61511-1 IEC:2003(E) – 17 –

3.2.9

configuration management

discipline of identifying the components of an evolving (hardware and software) system for the

purposes of controlling changes to those components and maintaining continuity and

traceability throughout the life cycle

3.2.10

control system

system which responds to input signals from the process and/or from an operator and

generates output signals causing the process to operate in the desired manner

NOTE The control system includes input devices and final elements and may be either a BPCS or an SIS or

a combination of the two.

3.2.11

dangerous failure

failure which has the potential to put the safety instrumented system in a hazardous or fail-

to-function state

NOTE Whether or not the potential is realized may depend on the channel architecture of the system; in systems

with multiple channels to improve safety, a dangerous hardware failure is less likely to lead to the overall

hazardous or fail-to-function state.

3.2.12

dependent failure

failure whose probability cannot be expressed as the simple product of the unconditional

probabilities of the individual events which caused it

NOTE 1 Two events A and B are dependent, where P(z) is the probability of event z, only if P(A and B) > P(A) × P(B).

NOTE 2 See 9.5 as an example of dependent failure consideration between layers of protection.

NOTE 3 Dependent failure includes common cause (see 3.2.6).

3.2.13

detected

revealed

overt

in relation to hardware failures and software faults, detected by the diagnostic tests or through

normal operation

3.2.14

device

functional unit of hardware or software, or both, capable of accomplishing a specified purpose

(for example, field devices; equipment connected to the field side of the SIS I/O terminals;

such equipment includes field wiring, sensors, final elements, logic solvers, and those

operator interface devices hard-wired to SIS I/O terminals)

3.2.15

diagnostic coverage (DC)

ratio of the detected failure rate to the total failure rate of the component or subsystem as

detected by diagnostic tests. Diagnostic coverage does not include any faults detected by

proof tests.

NOTE 1 The diagnostic coverage is used to compute the detected (λ ) and undetected failure rates (λ )

detected undected

from the total failure rate (λ ) as follows: λ = DC × λ and λ = (1-DC) × λ .

detected undected

total failure rate total failure rate total failure rate

NOTE 2 Diagnostic coverage is applied to components or subsystems of a safety instrumented system. For

example, the diagnostic coverage is typically determined for a sensor, final element or a logic solver.

NOTE 3 For safety applications the diagnostic coverage is typically applied to the safe and dangerous failures of

a component or subsystem. For example, the diagnostic coverage for the dangerous failures of a component

or subsystem is DC = λ /λ , where λ is the dangerous detected failure rate and λ is the total dangerous

DD DT DD DT

failure rate.

– 18 – 61511-1 IEC:2003(E)

3.2.16

diversity

existence of different means performing a required function

NOTE Diversity may be achieved by different physical methods or different design approaches.

3.2.17

electrical/electronic/programmable (E/E/PE)

based on electrical (E) and/or electronic (E) and/or programmable electronic (PE) technology

NOTE The term is intended to cover any and all devices or systems operating on electrical principles and would

include

- electro-mechanical devices (electrical);

- solid-state non-programmable electronic devices (electronic);

- electronic devices based on computer technology (programmable electronic) (see 3.2.55).

3.2.18

error

discrepancy between a computed, observed or measured value or condition and the true,

specified or theoretically correct value or condition

NOTE Adapted from IEV 191-05-24 by excluding the notes.

3.2.19

external risk reduction facilities

measures to reduce or mitigate the risks, which are separate and distinct from the SIS

NOTE 1 Examples include a drain system, fire wall, bund (dike).

NOTE 2 This term deviates from the definition in IEC 61508-4 to reflect differences in the process sector

terminology.

3.2.20

failure

termination of the ability of a functional unit to perform a required function

NOTE 1 This definition (excluding these notes) matches ISO/IEC 2382-14-01-09:1997.

NOTE 2 For further information, see IEC 61508-4.

NOTE 3 Performance of required functions necessarily excludes certain behaviour, and some functions may be

specified in terms of behaviour to be avoided. The occurrence of such behaviour is a failure.

NOTE 4 Failures are either random or systematic (see 3.2.62 and 3.2.85).

3.2.21

fault

abnormal condition that may cause a reduction in, or loss of, the capability of a functional unit

to perform a required function

NOTE IEV 191-05-01 defines “fault” as a state characterized by the inability to perform a required function,

excluding the inability during preventive maintenance or other planned actions, or due to lack of external

resources. [ISO/IEC 2382-14-01-09]

3.2.22

fault avoidance

use of techniques and procedures which aim to avoid the introduction of faults during any

phase of the safety life cycle of the safety instrumented system

3.2.23

fault tolerance

ability of a functional unit to continue to perform a required function in the presence of faults

or errors

NOTE The definition in IEV 191-15-05 refers only to sub-item faults. See the note for the term fault in 3.2.21.

[ISO/IEC 2382-14-04-06]

61511-1 IEC:2003(E) – 19 –

3.2.24

final element

part of a safety instrumented system which implements the physical action necessary to

achieve a safe state

NOTE Examples are valves, switch gear, motors including their auxiliary elements, for example, a solenoid valve

and actuator if involved in the safety instrumented function.

3.2.25

functional safety

part of the overall safety relating to the process and the BPCS which depends on the correct

functioning of the SIS and other protection layers

NOTE This term deviates from the definition in IEC 61508-4 to reflect differences in process sector terminology.

3.2.26

functional safety assessment

investigation, based on evidence, to judge the functional safety achieved by one or more

protection layers

NOTE This term deviates from the definition in IEC 61508-4 to reflect differences in process sector terminology.

3.2.27

functional safety audit

systematic and independent examination to determine whether the procedures specific to the

functional safety requirements comply with the planned arrangements, are implemented

effectively and are suitable to achieve the specified objectives

NOTE A functional safety audit may be carried out as part of a functional safety assessment.

3.2.28

functional unit

entity of hardware or software, or both, capable of accomplishing a specified purpose

NOTE 1 In IEV 191-01-01 the more general term “item” is used in place of functional unit. An item may sometimes

include people.

NOTE 2 This is the definition given in ISO/IEC 2382-14-01-01.

3.2.29

hardware safety integrity

part of the safety integrity of the safety instrumented function relating to random hardware

failures in a dangerous mode of failure

NOTE 1 The term relates to failures in a dangerous mode. That is, those failures of a safety instrumented function

that would impair its safety integrity. The two parameters that are relevant in this context are the overall dangerous

failure rate and the probability of failure to operate on demand.

NOTE 2 See 3.2.86.

NOTE 3 This term deviates from the definition in IEC 61508-4 to reflect differences in process sector terminology.

3.2.30

harm

physical injury or damage to the health of people, either directly or indirectly, as a result of

damage to property or to the environment

NOTE This definition matches ISO/IEC Guide 51.

3.2.31

hazard

potential source of harm

NOTE 1 This definition (without notes) matches 3.4 of ISO/IEC Guide 51.

NOTE 2 The term includes danger to persons arising within a short time scale (for example, fire and explosion)

and also those that have a long-term effect on a person's health (for example, release of a toxic substance).

– 20 – 61511-1 IEC:2003(E)

3.2.32

human error

mistake

human action or inaction that produces an unintended result

NOTE This is the definition found in ISO/IEC 2382-14-02-03 and differs from that given in IEV 191-05-25 by the

addition of “or inaction”.

3.2.33

impact analysis

activity of determining the effect that a change to a function or component will have to other

functions or components in that system as well as to other systems

3.2.34

independent department

department which is separate and distinct from the departments responsible for the activities

which take place during the specific phase of the safety life cycle that is subject to the

functional safety assessment or validation

3.2.35

independent organization

organization which is separate and distinct, by management and other

...

IEC 61511-1

Edition 1.0 2003-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Functional safety – Safety instrumented systems for the process industry sector –

Part 1: Framework, definitions, system, hardware and software requirements

Sécurité fonctionnelle – Systèmes instrumentés de sécurité pour le secteur des

industries de transformation –

Partie 1: Cadre, définitions, exigences pour le système, le matériel et le logiciel

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61511-1

Edition 1.0 2003-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Functional safety – Safety instrumented systems for the process industry sector –

Part 1: Framework, definitions, system, hardware and software requirements

Sécurité fonctionnelle – Systèmes instrumentés de sécurité pour le secteur des

industries de transformation –

Partie 1: Cadre, définitions, exigences pour le système, le matériel et le logiciel

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

XC

CODE PRIX

ICS 25.040.01; 13.110 ISBN 2-8318-7316-9

61511-1 ¤ IEC:2003 –– 3 2 – – 61511-1 © IEC:2003

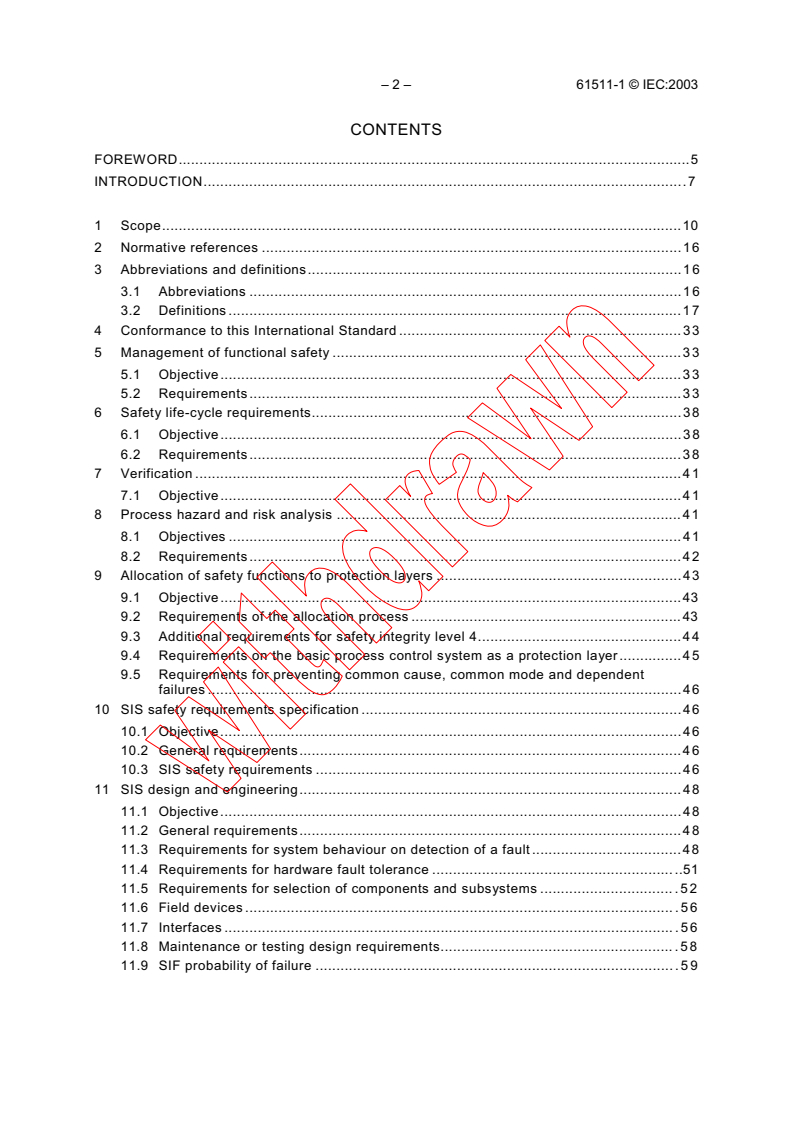

CONTENTS

FOREWORD.5

INTRODUCTION.7

1 Scope.10

2 Normative references.16

3 Abbreviations and definitions.16

3.1 Abbreviations .16

3.2 Definitions .17

4 Conformance to this International Standard .33

5 Management of functional safety .33

5.1 Objective.33

5.2 Requirements.33

6 Safety life-cycle requirements.38

6.1 Objective.38

6.2 Requirements.38

7 Verification.41

7.1 Objective.41

8 Process hazard and risk analysis .41

8.1 Objectives .41

8.2 Requirements.42

9 Allocation of safety functions to protection layers .43

9.1 Objective.43

9.2 Requirements of the allocation process .43

9.3 Additional requirements for safety integrity level 4.44

9.4 Requirements on the basic process control system as a protection layer.45

9.5 Requirements for preventing common cause, common mode and dependent

failures .46

10 SIS safety requirements specification .46

10.1 Objective.46

10.2 General requirements.46

10.3 SISsafetyrequirements .46

11 SIS design and engineering.48

11.1 Objective.48

11.2 General requirements.48

11.3 Requirements for system behaviour on detection of a fault .48

11.4 Requirements for hardware fault tolerance .51

11.5 Requirements for selection of components and subsystems .52

11.6 Field devices .56

11.7 Interfaces .56

11.8 Maintenance or testing design requirements.58

11.9 SIF probability of failure .59

61511-1 © IEC:200361511-1 ¤ IEC:2003 –– 5 3 – –

12 Requirements for application software, including selection criteria for utility software . .60

12.1 Application software safety life-cycle requirements.60

12.2 Application software safety requirements specification .66

12.3 Application software safety validation planning.68

12.4 Application software design and development .68

12.5 Integration of the application software with the SIS subsystem .74

12.6 FPL and LVL software modification procedures .75

12.7 Application software verification .75

13 Factory acceptance testing (FAT) .76

13.1 Objectives .76

13.2 Recommendations.77

14 SIS installation and commissioning.78

14.1 Objectives .78

14.2 Requirements.78

15 SISsafetyvalidation.79

15.1 Objective.79

15.2 Requirements.79

16 SIS operation and maintenance.82

16.1 Objectives .82

16.2 Requirements.82

16.3 Proof testing and inspection .84

17 SISmodification .8 5

17.1 Objective.85

17.2 Requirements.85

18 SISdecommissioning.86

18.1 Objectives .86

18.2 Requirements.86

19 Information and documentation requirements .86

19.1 Objectives .86

19.2 Requirements.87

Annex A (informative) Differences.88

Bibliography.89

Figure 1 – Overall framework of this standard.9

Figure 2 – Relationship between IEC 61511 and IEC 61508 .12

Figure 3 – Relationship between IEC 61511 and IEC 61508 (see 1.2).13

Figure 4 – Relationship between safety instrumented functions and other functions.14

Figure 5 – Relationship between system, hardware, and software of IEC 61511-1 .15

Figure 6 – Programmable electronic system (PES): structure and terminology .25

Figure 7 – Example SIS architecture.28

Figure 8 – SIS safety life-cycle phases and functional safety assessment stages .36

Figure 9 – Typical risk reduction methods found in process plants .45

61511-1 ¤ IEC:2003 –– 7 4 – – 61511-1 © IEC:2003

Figure 10 – Application software safety life cycle and its relationship to the SIS safety

life cycle .61

Figure 11 – Application software safety life cycle (in realization phase) .63

Figure 12 − Software development life cycle (the V-model) .63

Figure 13 – Relationship between the hardware and software architectures of SIS .66

Table 1 – Abbreviations used in IEC 61511.16

Table 2 – SIS safety life-cycle overview .39

Table 3 – Safety integrity levels: probability of failure on demand .43

Table 4 – Safety integrity levels: frequency of dangerous failures of the SIF .44

Table 5 – Minimum hardware fault tolerance of PE logic solvers .51

Table 6 – Minimum hardware fault tolerance of sensors and final elements and non-PE

logic solvers .52

Table 7 – Application software safety life cycle: overview .64

61511-1 © IEC:2003 – 9 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FUNCTIONAL SAFETY –

SAFETY INSTRUMENTED SYSTEMS

FOR THE PROCESS INDUSTRY SECTOR –

Part 1: Framework, definitions, system,

hardware and software requirements

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61511-1 has been prepared by subcommittee 65A: System

aspects, of IEC technical committee 65: Industrial-process measurement and control.

This bilingual version, published in 2003-12, corresponds to the English version.

61511-1 ¤ IEC:2003 –– 11 6 – – 61511-1 © IEC:2003

The text of this standard is based on the following documents:

FDIS Report on voting

65A/368/FDIS 65A/372/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

The French version of this standard has not been voted upon.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

IEC 61511 consists of the following parts, under the general title Functional safety: Safety

instrumented systems for the process industry sector (see Figure 1):

Part 1: Framework, definitions, system, hardware and software requirements

Part 2: Guidelines in the application of IEC 61511-1

Part 3: Guidance for the determination of the required safety integrity levels

The committee has decided that the contents of this publication will remain unchanged until

2007. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of November 2004 have been included in this copy.

61511-1 © IEC:200361511-1 ¤ IEC:2003 –– 13 7 – –

INTRODUCTION

Safety instrumented systems have been used for many years to perform safety instrumented

functions in the process industries. If instrumentation is to be effectively used for safety

instrumented functions, it is essential that this instrumentation achieves certain minimum

standards and performance levels.

This standard addresses the application of safety instrumented systems for the process

industries. It also requires a process hazard and risk assessment to be carried out to enable

the specification for safety instrumented systems to be derived. Other safety systems are only

considered so that their contribution can be taken into account when considering the

performance requirements for the safety instrumented systems. The safety instrumented

system includes all components and subsystems necessary to carry out the safety

instrumented function from sensor(s) to final element(s).

This standard has two concepts which are fundamental to its application; safety lifecycle and

safety integrity levels.

This standard addresses safety instrumented systems which are based on the use of

electrical/electronic/programmable electronic technology. Where other technologies are used

for logic solvers, the basic principles of this standard should be applied. This standard also

addresses the safety instrumented system sensors and final elements regardless of the

technology used. This standard is process industry specific within the framework of IEC 61508

(see Annex A).

This standard sets out an approach for safety life-cycle activities to achieve these minimum

standards. This approach has been adopted in order that a rational and consistent technical

policy is used.

In most situations, safety is best achieved by an inherently safe process design. If necessary,

this may be combined with a protective system or systems to address any residual identified

risk. Protective systems can rely on different technologies (chemical, mechanical, hydraulic,

pneumatic, electrical, electronic, programmable electronic). To facilitate this approach, this

standard

• requires that a hazard and risk assessment is carried out to identify the overall safety

requirements;

• requires that an allocation of the safety requirements to the safety instrumented system(s)

is carried out;

• works within a framework which is applicable to all instrumented methods of achieving

functional safety;

• details the use of certain activities, such as safety management, which may be applicable

to all methods of achieving functional safety.

This standard on safety instrumented systems for the process industry

• addresses all safety life-cycle phases from initial concept, design, implementation,

operation and maintenance through to decommissioning;

• enables existing or new country specific process industry standards to be harmonized with

this standard.

61511-1 ¤ IEC:2003 –– 15 8 – – 61511-1 © IEC:2003

This International Standard is intended to lead to a high level of consistency (for example, of

underlying principles, terminology, information) within the process industries. This should

have both safety and economic benefits.

In jurisdictions where the governing authorities (for example, national, federal, state, province,

county, city) have established process safety design, process safety management, or other

requirements, these take precedence over the requirements defined in this standard.

61511-1 © IEC:200361511-1 ¤ IEC:2003 –– 17 9 – –

Support

Technical

parts

requirements

PART 1 References

Clause 2

Development of the overall safety

PART 1

requirements (concept, scope definition,

hazard and risk assessment)

Definitions and

abbreviations

Clause 8

Clause 3

PART 1

PART 1

Conformance

Allocation of the safety requirements to

Clause 4

the safety instrumented functions and

development of safety requirements

PART 1

specification

Management of

Clauses 9 and 10

functional safety

Clause 5

PART 1

PART 1

Safety life-cycle

Design phase for Design phase for

requirements

safety

safety

Clause 6

instrumented instrumented

PART 1

systems system software

Clause 12

Clause 11

Verification

Clause 7

PART 1

PART 1

Information

Factory acceptance testing,

requirements

installation and commissioning and

Clause 19

safety validation of safety

instrumented systems PART 1

Clauses 13, 14, and 15

Differences

Annex “A”

PART 1

PART 1

Operation and maintenance,

modification and retrofit, Guideline for the

application of part 1

decommissioning or disposal of

safety instrumented systems

PART 2

Clauses 16, 17, and 18

Guidance for the

determination of the

required safety

integrity levels

PART 3

IEC 3240/02

Figure 1 – Overall framework of this standard

61511-1 ¤ IEC:2003 –– 19 10 – – 61511-1 © IEC:2003

FUNCTIONAL SAFETY –

SAFETY INSTRUMENTED SYSTEMS

FOR THE PROCESS INDUSTRY SECTOR –

Part 1: Framework, definitions, system,

hardware and software requirements

1 Scope

This International Standard gives requirements for the specification, design, installation,

operation and maintenance of a safety instrumented system, so that it can be confidently

entrusted to place and/or maintain the process in a safe state. This standard has been

developed as a process sector implementation of IEC 61508.

In particular, this standard

a) specifies the requirements for achieving functional safety but does not specify who is

responsible for implementing the requirements (for example, designers, suppliers,

owner/operating company, contractor); this responsibility will be assigned to different

parties according to safety planning and national regulations;

b) applies when equipment that meets the requirements of IEC 61508, or of 11.5 of

IEC 61511-1, is integrated into an overall system that is to be used for a process sector

application but does not apply to manufacturers wishing to claim that devices are suitable

for use in safety instrumented systems for the process sector (see IEC 61508-2 and

IEC 61508-3);

c) defines the relationship between IEC 61511 and IEC 61508 (Figures 2 and 3);

d) applies when application software is developed for systems having limited variability or

fixed programmes but does not apply to manufacturers, safety instrumented systems

designers, integrators and users that develop embedded software (system software) or

use full variability languages (see IEC 61508-3);

e) applies to a wide variety of industries within the process sector including chemicals, oil

refining, oil and gas production, pulp and paper, non-nuclear power generation;

NOTE Within the process sector some applications, (for example, off-shore), may have additional

requirements that have to be satisfied.

f) outlines the relationship between safety instrumented functions and other functions

(Figure 4);

g) results in the identification of the functional requirements and safety integrity requirements

for the safety instrumented function(s) taking into account the risk reduction achieved by

other means;

h) specifies requirements for system architecture and hardware configuration, application

software, and system integration;

i) specifies requirements for application software for users and integrators of safety

instrumented systems (clause 12). In particular, requirements for the following are

specified:

61511-1 © IEC:200361511-1 ¤ IEC:2003 –– 21 11 – –

– safety life-cycle phases and activities that are to be applied during the design and

development of the application software (the software safety life-cycle model). These

requirements include the application of measures and techniques, which are intended

to avoid faults in the software and to control failures which may occur;

– information relating to the software safety validation to be passed to the organization

carrying out the SIS integration;

– preparation of information and procedures concerning software needed by the user for

the operation and maintenance of the SIS;

– procedures and specifications to be met by the organization carrying out modifications

to safety software;

j) applies when functional safety is achieved using one or more safety instrumented

functions for the protection of personnel, protection of the general public or protection of

the environment;

k) may be applied in non-safety applications such as asset protection;

l) defines requirements for implementing safety instrumented functions as a part of the

overall arrangements for achieving functional safety;

m) uses a safety life cycle (Figure 8) and defines a list of activities which are necessary to

determine the functional requirements and the safety integrity requirements for the safety

instrumented systems;

n) requires that a hazard and risk assessment is to be carried out to define the safety

functional requirements and safety integrity levels of each safety instrumented function;

NOTE See Figure 9 for an overview of risk reduction methods.

o) establishes numerical targets for average probability of failure on demand and frequency

of dangerous failures per hour for the safety integrity levels;

p) specifies minimum requirements for hardware fault tolerance;

q) specifies techniques/measures required for achieving the specified integrity levels;

r) defines a maximum level of performance (SIL 4) which can be achieved for a safety

instrumented function implemented according to this standard;

s) defines a minimum level of performance (SIL 1) below which this standard does not apply;

t) provides a framework for establishing safety integrity levels but does not specify the safety

integrity levels required for specific applications (which should be established based on

knowledge of the particular application);

u) specifies requirements for all parts of the safety instrumented system from sensor to final

element(s);

v) defines the information that is needed during the safety life cycle;

w) requires that the design of a safety instrumented function takes into account human

factors;

x) does not place any direct requirements on the individual operator or maintenance person.

61511-1 ¤ IEC:2003 –– 23 12 – – 61511-1 © IEC:2003

PROCESS SECTOR

SAFETY

INSTRUMENTED

SYSTEM

STANDARDS

Safety

Manufacturers and

instrumented

suppliers of systems designers,

devices integrators and

users

IEC 61508

IEC 61511

IEC 3241/02

Figure 2 – Relationship between IEC 61511 and IEC 61508

61511-1 ¤ IEC:2003 – 25 –

61511-1 © IEC:2003 – 13 –

PROCESS SECTOR

SAFETY

INSTRUMENTED

SYSTEM STANDARD

PROCESS

PROCESS

SECTOR SECTOR

HARDWARE

SOFTWARE

DEVELOPING

DEVELOPING USING DEVELOPING DEVELOPING APPLICATION

USING

NEW HARDWARE EMBEDDED APPLICATION SOFTWARE

PROVEN-IN-

HARDWARE DEVELOPED (SYSTEM) SOFTWARE

USING

USE

DEVICES AND SOFTWARE USING FULL

LIMITED

HARDWARE

ACCESSED VARIABILITY

VARIABILITY

DEVICES

ACCORDING LANGUAGES

LANGUAGES

TO IEC 61508

OR FIXED

PROGRAMS

FOLLOW FOLLOW FOLLOW FOLLOW

FOLLOW FOLLOW

IEC 61508 IEC 61511

IEC 61511 IEC 61508-3 IEC 61508-3 IEC 61511

IEC 3242/02

Figure 3 – Relationship between IEC 61511 and IEC 61508 (see clause 1)

61511-1 ¤ IEC:2003 – 27 –

– 14 – 61511-1 © IEC:2003

Start

Is it an

No Yes

instrumented

function?

Safety

Yes Yes

No No

instrumented

Safety

related function?

?

Not

relevant

Continuous Demand

Safety instrumented

Mode

protection function

Mitigation

Prevention

Type?

Other Safety Safety Safety

Basic process

instrumented

means of instrumented instrumented

control and/or asset

control

risk prevention mitigation

protection function

function function function

reduction

Standard specifies activities which are to be carried out but requirements are not detailed.

IEC 3243/02

Figure 4 – Relationship between safety instrumented functions and other functions