IEC 61511-2:2003

(Main)Functional safety - Safety instrumented systems for the process industry sector - Part 2: Guidelines for the application of IEC 61511-1

Functional safety - Safety instrumented systems for the process industry sector - Part 2: Guidelines for the application of IEC 61511-1

provides guidance on the specification, design, installation, operation and maintenance of Safety Instrumented Functions and related safety instrumented system as defined in IEC 61511-1. This standard has been organized so that each clause and subclause number herein addresses the same clause number in IEC 61511-1 (with the exception of the annexes). It has the status of a horizontal standard in accordance with IEC Guide 108.

Sécurité fonctionnelle - Systèmes instrumentés de sécurité pour le secteur des industries de transformation - Partie 2: Lignes directrices pour l'application de la CEI 61511-1

donne des conseils sur la spécification, la conception, l'installation, l'exploitation et la maintenance des fonctions instrumentées de sécurité et du système instrumenté de sécurité concerné, comme cela est défini par la CEI 61511-1. La présente Partie 2 de la CEI 61511 a été organisée de sorte que chaque numéro d'article mentionné corresponde au même numéro d'article que celui de la CEI 61511-1 (à l'exception des annexes). Elle a le statut d'une norme horizontale conformément au Guide 108 de la CEI.

General Information

- Status

- Published

- Publication Date

- 03-Jul-2003

- Technical Committee

- SC 65A - System aspects

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 28-Jul-2016

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview - IEC 61511-2:2003 (Functional safety, SIS guidelines)

IEC 61511-2:2003 is the IEC guidance document for applying IEC 61511-1 in the process industry sector. It provides practical guidance on the specification, design, installation, operation and maintenance of Safety Instrumented Functions (SIFs) and related Safety Instrumented Systems (SIS) (sensors, logic solvers and final elements). The standard is organized to mirror the clause structure of IEC 61511-1 to simplify application and has the status of a horizontal standard under IEC Guide 108.

Key topics and technical requirements

- Safety lifecycle: Guidance on lifecycle activities from hazard assessment through decommissioning, consistent with the safety lifecycle concept in IEC 61511-1.

- Management of functional safety: Organizational and procedural requirements to ensure functional safety objectives are met.

- Process hazard and risk assessment: Methods for determining required protective measures and allocating SIFs.

- Allocation of safety functions and SIL: Principles for assigning functions to protection layers and considerations for Safety Integrity Levels (SIL), including independence from Basic Process Control Systems (BPCS).

- SIS safety requirements specification (SRS): Content and structure guidance for clear, testable SRS documents.

- Design, engineering and hardware requirements: Guidance on system behaviour on fault detection, hardware fault tolerance, component selection, field devices and interfaces.

- Software and application lifecycle: Recommendations for application software development, verification, V-model lifecycle usage and selection criteria for utility software.

- Verification, validation, FAT and commissioning: Factory Acceptance Testing (FAT), commissioning, and validation practices to demonstrate that SIFs meet their requirements.

- Operation, maintenance and proof testing: Procedures for ongoing maintenance, proof testing, modification control and decommissioning.

- Dependence and common-cause failures: Measures to mitigate common-cause, common-mode and dependent failures.

Practical applications - who uses IEC 61511-2

- Process safety engineers and functional safety practitioners implementing SIS design and operation in chemical, petrochemical, oil & gas, and pharmaceutical plants.

- Asset owners, system integrators and OEMs producing or installing safety PLCs, logic solvers and field devices.

- Maintenance teams and commissioning engineers responsible for proof testing, FAT, validation and SIS modifications.

- Regulators and auditors assessing compliance with process industry functional safety best practices.

Related standards

- IEC 61511-1 - Normative framework, requirements for SIS (reference for Part 2).

- IEC 61511-3 - Guidance on determining required SILs.

- IEC 61508 - Base standard for functional safety (IEC 61511 is a sector implementation for process industries).

Keywords: IEC 61511-2, functional safety, safety instrumented systems, SIS, SIF, safety lifecycle, SIL, process industry, IEC 61511-1, IEC 61508.

IEC 61511-2:2003 - Functional safety - Safety instrumented systems for the process industry sector - Part 2: Guidelines for the application of IEC 61511-1 Released:7/4/2003 Isbn:2831871131

IEC 61511-2:2003 - Functional safety - Safety instrumented systems for the process industry sector - Part 2: Guidelines for the application of IEC 61511-1 Released:7/4/2003 Isbn:2831875560

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

NSF International

Global independent organization facilitating standards development and certification.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

Sponsored listings

Frequently Asked Questions

IEC 61511-2:2003 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Functional safety - Safety instrumented systems for the process industry sector - Part 2: Guidelines for the application of IEC 61511-1". This standard covers: provides guidance on the specification, design, installation, operation and maintenance of Safety Instrumented Functions and related safety instrumented system as defined in IEC 61511-1. This standard has been organized so that each clause and subclause number herein addresses the same clause number in IEC 61511-1 (with the exception of the annexes). It has the status of a horizontal standard in accordance with IEC Guide 108.

provides guidance on the specification, design, installation, operation and maintenance of Safety Instrumented Functions and related safety instrumented system as defined in IEC 61511-1. This standard has been organized so that each clause and subclause number herein addresses the same clause number in IEC 61511-1 (with the exception of the annexes). It has the status of a horizontal standard in accordance with IEC Guide 108.

IEC 61511-2:2003 is classified under the following ICS (International Classification for Standards) categories: 13.110 - Safety of machinery; 25.040.01 - Industrial automation systems in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61511-2:2003 has the following relationships with other standards: It is inter standard links to IEC 61511-2:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61511-2:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD

61511-2

First edition

2003-07

Functional safety –

Safety instrumented systems

for the process industry sector –

Part 2:

Guidelines for the application of IEC 61511-1

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD

61511-2

First edition

2003-07

Functional safety –

Safety instrumented systems

for the process industry sector –

Part 2:

Guidelines for the application of IEC 61511-1

IEC 2003 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale

XB

International Electrotechnical Commission

Международная Электротехническая Комиссия

For price, see current catalogue

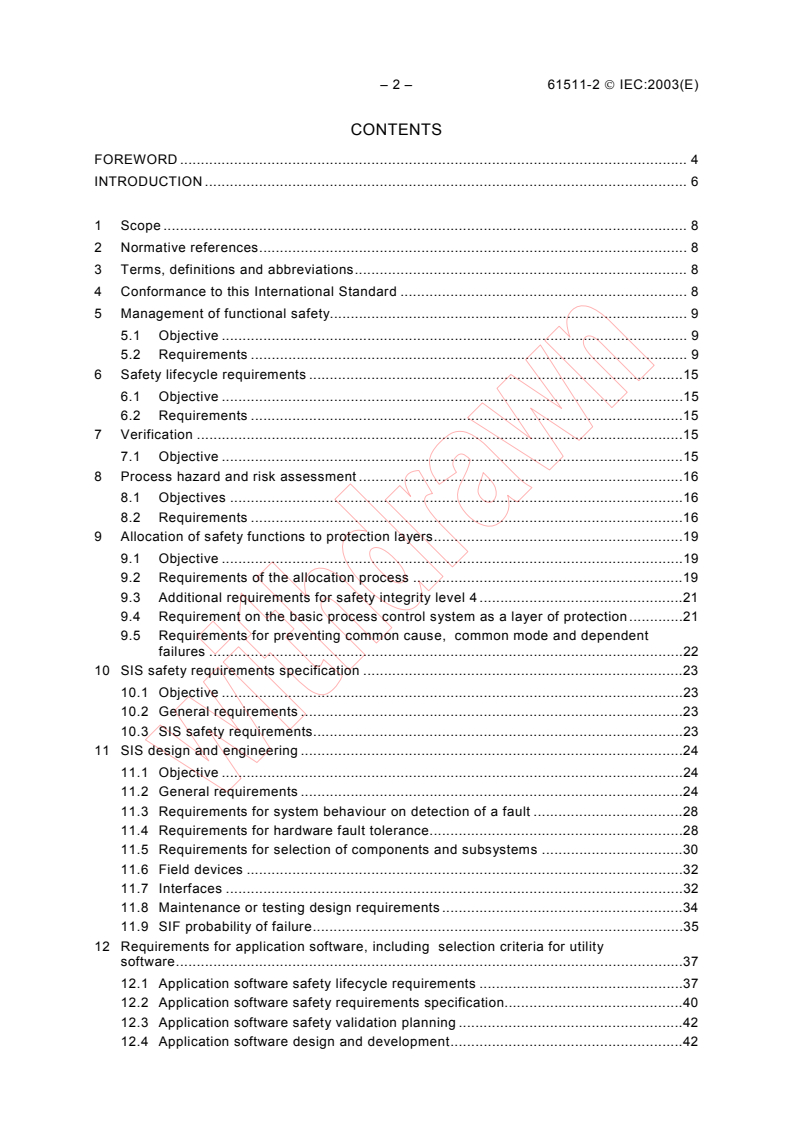

– 2 – 61511-2 IEC:2003(E)

CONTENTS

FOREWORD . 4

INTRODUCTION .6

1 Scope . 8

2 Normative references. 8

3 Terms, definitions and abbreviations. 8

4 Conformance to this International Standard . 8

5 Management of functional safety. 9

5.1 Objective . 9

5.2 Requirements . 9

6 Safety lifecycle requirements .15

6.1 Objective .15

6.2 Requirements .15

7 Verification .15

7.1 Objective .15

8 Process hazard and risk assessment .16

8.1 Objectives .16

8.2 Requirements .16

9 Allocation of safety functions to protection layers.19

9.1 Objective .19

9.2 Requirements of the allocation process .19

9.3 Additional requirements for safety integrity level 4 .21

9.4 Requirement on the basic process control system as a layer of protection .21

9.5 Requirements for preventing common cause, common mode and dependent

failures .22

10 SIS safety requirements specification .23

10.1 Objective .23

10.2 General requirements .23

10.3 SIS safety requirements.23

11 SIS design and engineering .24

11.1 Objective .24

11.2 General requirements .24

11.3 Requirements for system behaviour on detection of a fault .28

11.4 Requirements for hardware fault tolerance.28

11.5 Requirements for selection of components and subsystems .30

11.6 Field devices .32

11.7 Interfaces .32

11.8 Maintenance or testing design requirements .34

11.9 SIF probability of failure.35

12 Requirements for application software, including selection criteria for utility

software.37

12.1 Application software safety lifecycle requirements .37

12.2 Application software safety requirements specification.40

12.3 Application software safety validation planning .42

12.4 Application software design and development.42

61511-2 IEC:2003(E) – 3 –

12.5 Integration of the application software with the SIS subsystem .49

12.6 FPL and LVL software modification procedures .49

12.7 Application software verification.50

13 Factory acceptance testing (FAT) .51

13.1 Objectives .51

13.2 Recommendations .51

14 SIS installation and commissioning.52

14.1 Objectives .52

14.2 Requirements .52

15 SIS safety validation .52

15.1 Objective .52

15.2 Requirements .52

16 SIS operation and maintenance .53

16.1 Objectives .53

16.2 Requirements .53

16.3 Proof testing and inspection.53

17 SIS modification.55

17.1 Objective .55

17.2 Requirements .55

18 SIS decommissioning.55

18.1 Objectives .55

18.2 Requirements .55

19 Information and documentation requirements.55

19.1 Objectives .55

19.2 Requirements .55

Annex A (informative) Example of techniques for calculating the probability of failure

on demand for a safety instrumented function .57

Annex B (informative) Typical SIS architecture development.58

Annex C (informative) Application features of a safety PLC.63

Annex D (informative) Example of SIS logic solver application software development

methodology .65

Annex E (informative) Example of development of externally configured diagnostics

for a safety-configured PE logic solver .69

Figure 1 – Overall framework of this standard . 7

Figure 2 – BPCS function and initiating cause independence illustration .21

Figure 3 – Software development lifecycle (the V-model) .38

Figure C.1 – Logic solver .64

Figure E.1 – EWDT timing diagram .71

Table 1 – Typical Safety Manual organisation and contents .47

– 4 – 61511-2 IEC:2003(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FUNCTIONAL SAFETY –

SAFETY INSTRUMENTED SYSTEMS

FOR THE PROCESS INDUSTRY SECTOR –

Part 2: Guidelines for the application of IEC 61511-1

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, and Guides (hereafter referred to as “IEC Publication(s)”). Their preparation is entrusted to

technical committees; any IEC National Committee interested in the subject dealt with may participate in this

preparatory work. International, governmental and non-governmental organizations liaising with the IEC also

participate in this preparation. IEC collaborates closely with the International Organization for Standardization

(ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61511-2 has been prepared by subcommittee 65A: System

aspects, of IEC technical committee 65: Industrial-process measurement and control.

The text of this standard is based on the following documents:

FDIS Report on voting

65A/387A/FDIS 65A/390/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

IEC 61511 series has been developed as a process sector implementation of IEC 61508

series.

61511-2 IEC:2003(E) – 5 –

IEC 61511 consists of the following parts, under the general title Functional safety – Safety

Instrumented Systems for the process industry sector (see Figure 1):

Part 1: Framework, definitions, system, hardware and software requirements

Part 2: Guidelines for the application of IEC 61511-1

Part 3: Guidance for the determination of the required safety integrity levels

The committee has decided that the contents of this publication will remain unchanged until

2007. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version of this standard may be issued at a later date.

– 6 – 61511-2 IEC:2003(E)

INTRODUCTION

Safety instrumented systems have been used for many years to perform safety instrumented

functions in the process industries. If instrumentation is to be effectively used for safety

instrumented functions, it is essential that this instrumentation achieves certain minimum

standards.

This International Standard addresses the application of safety instrumented systems for the

Process Industries. It also deals with the interface between safety instrumented systems and

other safety systems in requiring that a process hazard and risk assessment be carried out.

The safety instrumented system includes sensors, logic solvers and final elements.

This International Standard has two concepts, which are fundamental to its application; safety

lifecycle and safety integrity levels. The safety lifecycle forms the central framework which

links together most of the concepts in this International Standard.

The safety instrumented system logic solvers addressed include Electrical (E)/Electronic (E)/

and Programmable Electronic (PE) technology. Where other technologies are used for logic

solvers, the basic principles of this standard may also be applied. This standard also

addresses the safety instrumented system sensors and final elements regardless of the

technology used. This International Standard is process industry specific within the framework

of the IEC 61508 series.

This International Standard sets out an approach for safety lifecycle activities to achieve

these minimum standards. This approach has been adopted in order that a rational and

consistent technical policy is used. The objective of this standard is to provide guidance on

how to comply with IEC 61511-1.

To facilitate use of this standard, the clause and subclause numbers provided are identical to

the corresponding normative text in 61511-1 (excluding the annexes).

In most situations, safety is best achieved by an inherently safe process design whenever

practicable, combined, if necessary, with a number of protective systems which rely on

different technologies (for example, chemical, mechanical, hydraulic, pneumatic, electrical,

electronic, thermodynamic (for example, flame arrestors), programmable electronic) which

manage any residual identified risk. Any safety strategy considers each individual safety

instrumented system in the context of the other protective systems. To facilitate this

approach, this standard

− requires that a hazard and risk assessment is carried out to identify the overall safety

requirements;

− requires that an allocation of the safety requirements to the safety functions and related

safety systems, such as the safety instrumented system(s), is carried out;

− works within a framework which is applicable to all instrumented methods of achieving

functional safety;

− details the use of certain activities, such as safety management, which may be applicable

to all methods of achieving functional safety.

This International Standard on safety instrumented systems for the process industry:

− addresses relevant safety lifecycle stages from initial concept, through design,

implementation, operation and maintenance and decommissioning;

− enables existing or new country specific process industry standards to be harmonized with

this standard.

This standard is intended to lead to a high level of consistency (for example, of underlying

principles, terminology, information) within the process industries. This should have both

safety and economic benefits.

61511-2 IEC:2003(E) – 7 –

Support

Technical

Parts

requirements

PART 1 References

Clause 2

Development of the overall safety

PART 1

requirements (concept, scope definition,

hazard and risk assessment)

Definitions and

abbreviations

Clause 8

Clause 3

PART 1

PART 1

Conformance

Allocation of the safety requirements to

Clause 4

the safety instrumented functions and

development of safety requirements

PART 1

Specification

Management of

Clauses 9 and 10

functional safety

Clause 5

PART 1

PART 1

Safety lifecycle

Design phase for Design phase for

requirements

safety

safety

Clause 6

Instrumented instrumented

PART 1

system software

systems

Clause 11 Clause 12

Verification

Clause 7

PART 1

PART 1

Information

Factory acceptance testing,

requirements

installation and commissioning and

Clause 19

safety validation of safety

instrumented systems PART 1

Clauses 13, 14, and 15

Differences

Annex A

PART 1

PART 1

Operation and maintenance,

modification and retrofit, Guidelines for the

decommissioning or disposal of application of part 1

safety instrumented systems

PART 2

Clauses 16, 17, and 18

Guidance for the

determination of the

required safety

integrity levels

PART 3

IEC 1827/03

Figure 1 – Overall framework of this standard

– 8 – 61511-2 IEC:2003(E)

FUNCTIONAL SAFETY –

SAFETY INSTRUMENTED SYSTEMS

FOR THE PROCESS INDUSTRY SECTOR –

Part 2: Guidelines for the application of IEC 61511-1

1 Scope

IEC 61511-2 provides guidance on the specification, design, installation, operation and

maintenance of Safety Instrumented Functions and related safety instrumented system as

defined in IEC 61511-1. This standard has been organized so that each clause and subclause

number herein addresses the same clause number in IEC 61511-1 (with the exception of the

annexes).

2 Normative references

No further guidance provided.

3 Terms, definitions and abbreviations

No further guidance provided except for 3.2.68 and 3.2.71 of IEC 61511-1.

3.2.68 A safety function should prevent a specified hazardous event. For example, “prevent

the pressure in vessel #ABC456 exceeding 100 bar.” A safety function may be achieved by

a) a single safety instrumented system (SIS), or

b) one or more safety instrumented systems and/or other layers of protection.

In case b), each safety instrumented system or other layer of protection has to be capable of

achieving the safety function and the overall combination has to achieve the required risk

reduction (process safety target).

3.2.71 Safety instrumented functions are derived from the safety function, have an

associated safety integrity level (SIL) and are carried out by a specific safety instrumented

system (SIS). For example, “close valve #XY123 within 5 s when pressure in vessel #ABC456

reaches 100 bar”. Note that components of a safety instrumented system may be used by

more than one safety instrumented function.

4 Conformance to this International Standard

No further guidance provided.

61511-2 IEC:2003(E) – 9 –

5 Management of functional safety

5.1 Objective

The objective of Clause 5 of IEC 61511-1 is to provide requirements for implementing the

management activities that are necessary to ensure that the functional safety objectives

are met.

5.2 Requirements

5.2.1 General

5.2.1.1 No further guidance provided.

5.2.1.2 When an organization has responsibility for one or more activities necessary for

functional safety and that organization works according to quality assurance procedures, then

many of these activities described in this clause will already be carried out for the purposes of

quality. Where this is the case, it may be unnecessary to repeat these activities for the

purposes of functional safety. In such cases, the quality assurance procedures should be

reviewed to establish that they are suitable so that the objectives of functional safety will

be achieved.

5.2.2 Organization and resources

5.2.2.1 The organizational structure associated with safety instrumented systems within a

Company/Site/Plant/Project should be defined and the roles and responsibilities of each

element clearly understood and communicated. Within the structure, individual roles, including

their description and purpose should be identified. For each role, unambiguous

accountabilities should be identified; and specific responsibilities should be recognised. In

addition, whom the individual reports to and who makes the appointment should be identified.

The intent is to ensure that everyone in an organization understands their role and

responsibilities for safety instrumented systems.

5.2.2.2 The skills and knowledge required to implement any of the activities of the safety life

cycle relating to the safety instrumented systems should be identified; and for each skill, the

required competency levels should be defined. Resources should be assessed against each

skill for competency and also the number of people per skill required. When differences are

identified, development plans should be established to enable the required competency levels

to be achieved in a timely manner. When shortages of skills arise, suitably qualified and

experienced personnel may be recruited or contracted.

5.2.3 Risk evaluation and risk management

The requirement stated in 5.2.3 of IEC 61511 is that hazards are identified, risks evaluated

and the necessary risk reduction is determined. It is recognized that there are numerous

different methodologies available for conducting these evaluations. IEC 61511-1 does not

endorse any particular methodology. Instead, the reader is encouraged to review a number of

methodologies on this issue in IEC 61511-3. See 8.2.1 for further guidance.

5.2.4 Planning

The intent of this subclause is to ensure that, within the overall project, adequate safety

planning is conducted so that all of the required activities during each phase of the lifecycle

(for example, engineering design, plant operation) are addressed. The standard does not

require any particular structure for these planning activities, but it does require periodic

update or review of them.

– 10 – 61511-2 IEC:2003(E)

5.2.5 Implementing and monitoring

5.2.5.1 The intent of this subclause is to ensure that effective management procedures are in

place to

− ensure that all recommendations resulting from hazard analysis, risk assessment, other

assessment and auditing activities, verification and validation activities are satisfactorily

resolved.

− determine that the SIS is performing in accordance with its safety requirements

specification throughout its operational lifetime.

5.2.5.2 Note that, in this context, suppliers could include design contractors and maintenance

contractors as well as suppliers of components.

5.2.5.3 A review of the SIS performance should be periodically undertaken to ensure the

original assumptions made during the development of the safety requirements specification

(SRS) are still adhered to. For example, a periodic review of the assumed failure rate of

different components in a SIS should be carried out to ensure that it remains as originally

defined. If the failure rates are worse than originally anticipated, a design modification may be

necessary. Likewise, the demand rate on the SIS should be reviewed. If the rate is more than

that which was originally assumed, then an adjustment in the SIL may be needed.

5.2.6 Assessment, auditing and revision

Assessments and audits are tools targeted at the detection and elimination of errors. The

paragraphs below make clear the distinction between these activities

Functional safety assessment aims to evaluate whether provisions made during the assessed

lifecycle phases are adequate for the achievement of safety. Judgements are made by

assessors on the decisions taken by those responsible for the realisation of functional safety.

An assessment would for example be made prior to commissioning as to whether procedures

for maintenance are adequate.

Functional safety auditors will determine from project or plant records whether the necessary

procedures have been applied at the specified frequency by persons with the necessary

competence. Auditors are not required to make judgements on the adequacy of the work they

are considering. However, if they became aware that there would be benefits in making

changes, then an observation should be included in the report.

It should be noted that in many cases there can be an overlap between the work of the

assessor and the auditor. For example an auditor may need to determine not only whether an

operator has been given the necessary training but in addition make judgements as to

whether the training has resulted in the required competency.

5.2.6.1 Functional safety assessment

5.2.6.1.1 The use of Functional Safety Assessment (FSA) is fundamental in demonstrating

that a Safety Instrumented System (SIS) fulfils its requirements regarding safety instrumented

function(s) and Safety Integrity Level (SIL). The basic objective of this assessment is to

demonstrate compliance with agreed standards and practices through independent assess-

ment of the system's development process. An assessment of a SIS may be needed at

different lifecycle stages. In order to conduct an effective assessment, a procedure should be

developed that defines the scope of this assessment along with some guidance on the

makeup of the assessment team.

The following attributes are considered good practice for Functional Safety Assessment:

− A plan should be generated for each FSA identifying such arrangements as the scope of

the assessment, the assessors, the competencies of the assessors and the information to

be generated by the assessment.

61511-2 IEC:2003(E) – 11 –

− The FSA should take into account other standards and practices, which may be contained

within external or internal corporate standards, guides, procedures or codes of practice.

The FSA plan should define what is to be assessed for the particular assessment/

system/application area.

− The frequency of FSAs may vary across different system developments but as a minimum

should always take place before the potential hazards being presented to the system.

Some companies also like to conduct an assessment prior to the construction/installation

phase to prevent costly rework later in the lifecycle.

− FSA frequency and rigour should be defined taking into account system attributes such as:

• complexity;

• safety significance;

• previous experience of similar systems;

• standardization of design features.

− Sufficient evidence of design, installation, verification and validation activities should be

available prior to the assessment. The availability of sufficient evidence could itself be an

assessment criterion. The evidence should represent the current/approved state of system

design or installation.

− The independence of the assessor(s) must be appropriate.

− The assessor(s) should have experience and knowledge appropriate to the technology

and application area of the system being assessed.

− A systematic and consistent approach to FSA should be maintained throughout the

lifecycle and across systems. FSA is a subjective activity therefore detailed guidance,

possibly through the use of checklists, as to what is acceptable for an organisation should

be defined to remove as much subjectivity as possible.

Records generated from the FSA should be complete and the conclusions agreed with those

responsible for the management of functional safety for the SIS prior to commencement of the

next lifecycle phase.

5.2.6.1.2 The need for someone independent to the project team is to increase objectivity in

the assessment. The need for someone of senior stature (for example, experience, grade

level, position) is to ensure their concerns are duly noted and addressed. As the note also

suggests, on some large projects or assessment teams, it may be necessary to have more

than one senior person on this team that is independent to the original project team.

Depending upon the company organisation and expertise within the company, the requirement

for an independent assessor may have to be met by using an external organisation.

Conversely, companies that have internal organisations skilled in risk assessment and the

application of safety instrumented systems, which are independent to and separate (by ways

of management and other resources) from those responsible for the project, may be able to

use their own resources to meet the requirements for an independent organisation.

5.2.6.1.3 The amount of assessment depends on the size and complexity of a project. It may

be possible to assess the results of different phases at the same time. This is particularly true

in the case of small changes in a running plant.

5.2.6.1.4 In some countries, a functional safety assessment undertaken at stage 3 is often

referred to as the Pre-Startup-Safety-Review (PSSR).

5.2.6.1.5 No further guidance provided.

5.2.6.1.6 No further guidance provided.

5.2.6.1.7 The assessment team should have access to any information they deem necessary

for them to conduct the assessment. This should include information from the hazard and risk

assessment, design phase through installation, commissioning and validation.

– 12 – 61511-2 IEC:2003(E)

5.2.6.2 Auditing and revision

5.2.6.2.1 This subclause is intended to give guidance about auditing, using an example

illustrating relevant activities.

a) Audit categories

Safety instrumented system audits provide beneficial information to plant management,

instrument maintenance engineers and instrument design engineers. This enables

management to be proactive and aware of the degree of implementation and effectiveness

of their safety instrumented systems. Many types of audits, which can be carried out exist.

The actual type, scope, and frequency of the audit of any specific activity should reflect

the potential impact of the activity on the safety integrity.

Types of audit include:

1) audits, both independent and self-audit;

2) inspections;

3) safety visits (for example, plant walk about and incident review);

4) safety instrumented systems surveys (via questionnaires).

A distinction needs to be made between “surveillance and checking” and audit activities.

Surveillance and checking focuses on evaluating the performance of specific lifecycle

activities (for example, supervisor checking completion of maintenance activity prior to the

component being returned to service.) In contrast, audit activities are more comprehensive

and focus on overall implementation of safety instrumented systems concerning the safety

lifecycle. An audit would include determination as to whether the surveillance and

checking program is carried out.

Audits and inspections may be carried out by a company’s/site’s/plant’s/project’s own staff

(for example, self-audit) or by independent persons (for example, corporate auditors,

quality assurance department, regulators, customers or third parties).

Management at the various levels may want to apply the relevant type of audit to gain

information on the effectiveness of the implementation of their safety instrumented

systems. Information from audits could be used to identify the procedures that have not

been properly applied, leading to improved implementation.

b) Audit strategy

Site/plant/project implementing audit programmes might consider rolling, independent or

self-audit and inspection programmes.

Rolling programmes are updated regularly to reflect previous safety instrumented systems

performance and audit results, and current concerns and priorities. These cover all

site/plant/project related activities and aspects of the safety instrumented systems in an

appropriate time period and to an appropriate depth.

The primary reason for, and the added value from audits comes from acting on

the information they provide in a timely manner. The actions aim to strengthen the

effectiveness of safety instrumented systems, for example, to help minimize the risk of

employees or members of the public being injured or killed, contribute to improving safety

culture, contribute to prevent any avoidable release of substance into the environment.

In summary, the audit strategy may have a mix of audits types, driven by management

(the customer), and in order to feed back the relevant information up the management

chain for timely action.

c) Audit process and protocols

The overall aim is to achieve maximum value from the performance of the audit, which can

only be achieved when all parties (including auditors, contact nominee, plant managers

and head of departments, etc.) understand the need for and can influence each audit.

The following audit process and protocols might help to ensure some consistency in the

approach to achieving these aims. They bear on the following five key stages of the audit

process:

61511-2 IEC:2003(E) – 13 –

1) Audit strategy and programme

The purpose of each audit should be clearly defined and the audit groups identified,

together with the roles and responsibilities of each audit group.

There should be an auditing strategy.

There should be a programme of audits.

There should be regular reviews of the audit process, programme and strategy

implementation.

2) Audit preparation and pre-planning

Prior to commencement of an audit, the senior manager of the site/plant/project and/or

the appropriate audit coordinator should identify a contact nominee.

The auditors and contact nominee should at an early stage discuss, understand and

agree on:

– the scope of the audit;

– the timing of the audit;

– the people who need to be available;

– the basis for the audit or audit standard;

– putting the extra effort into the preparation stage and involving the plant personnel,

thereby increasing the chances of a successful audit.

The following should be used as a guide for time to be spent at each stage:

– audit preparation: 30 %

– conducting the audit: 40 %

– reporting of findings: 20 %

– audit follow-up: 10 %

The auditor should prepare for the audit by gathering information, procedures/

instructions etc., and data and preparing checklists when appropriate.

The auditor should highlight and explain how the possibility of a change to the scope of

the audit may occur during the audit, if serious observations/failings are discovered.

3) Conducting the audit

The auditor is to conduct the audit within groups of consecutive days during the

set audit period, taking due cognisance of possible disruption to site/plant/project

personnel.

The contact nominee should be periodically briefed during the audit of the findings

identified, thereby avoiding surprises at the end of the audit.

The auditor should try to involve plant personnel in the audit process in order to impart

learning and understanding (of the process and findings) to achieve ownership.

The style of the auditor is crucial to the success of the audit – he should try to be

helpful, constructive, courteous, focused and objective.

As a minimum the auditor should try to achieve the agreed scope and timetable -

variations will need to be negotiated.

4) Reporting the findings

The auditor should hold a closing meeting either at the end of the audit or later, but

before the final report is issued.

The appropriate management should be given the opportunity to comment on the draft

report and findings and discuss these at a formal close out meeting if desired.

It is normal practice to request a plan of action from the site/plant/project to address

the findings of the report.

– 14 – 61511-2 IEC:2003(E)

5) Audit follow-up

Audit reports normally require a response in the form of an action plan. The auditor

might verify satisfactory completion of the action at the due date or at the next audit,

whichever is appropriate.

Site/plant/project tracking systems may be used to check the implementation of action

plans.

A periodic review/summary of audit findings of each audit group should be considered

and its results widely communicated.

The findings/outcome from audits may be used to review the frequency of audits and

are input to the management review of safety instrumented systems.

5.2.6.2.2 This subclause reinforces the role that management of change plays in the auditing

process.

5.2.7 SIS configuration management

5.2.7.1 Requirements

5.2.7.1.1 To manage and maintain traceability of devices through the lifecycle, a mechanism

to identify, control and track the model/versions of each device may be established.

At the earliest possible stage of the safety lifecycle, a unique plant identification should be

given to each device. In some cases, earlier models/versions still in use may also be

maintained and controlled. This is the first step in the configuration management program

which should incorporate the following considerations.

The configuration management system may include:

a) the provision of a procedure for identification of all devices during all phases of the

lifecycle;

b) the unique identification, of the model/version and build status of each device including

software, including the supplier, date and where applicable, change from the model/

version originally specified;

c) the identification and tracking of all actions and changes resulting from fault observations

and audits;

d) control of the issue of a release into service, identifying the status and model/version of

the associated devices;

e) safeguards that have been established to assure that unauthorised alterations/

modifications are not made to the SIS while in operation;

f) the identification of the versions of each software item which together constitute a specific

version of a complete device;

g) the provision of co-ordination for the updating of multiple SIS in one or more plants;

h) documented authorisation of release into service;

i) an authorised list of signatures for device release into service;

j) the stage/phase devices are brought under configuration control;

k) control of the associated deliverable documentation;

l) identification of the each model/version of a device;

− functional specification;

− technical specification;

m) all departments/organizations involved in the management and maintenance of SIS are

identified and responsibilities assigned and understood.

61511-2 IEC:2003(E) – 15 –

6 Safety lifecycle requirements

6.1 Objectives

The functional safety achieved in any process facility is dependent on a number of activities

being carried out in a satisfactory manner. The purpose of adopting a systematic safety

lifecycle approach towards a safety instrumented system is to ensure that all the activities

necessa

...

IEC 61511-2

Edition 1.0 2003-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Functional safety – Safety instrumented systems for the process industry sector –

Part 2: Guidelines for the application of IEC 61511-1

Sécurité fonctionnelle – Systèmes instrumentés de sécurité pour le secteur des

industries de transformation –

Partie 2: Lignes directrices pour l’application de la CEI 61511-1

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61511-2

Edition 1.0 2003-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Functional safety – Safety instrumented systems for the process industry sector –

Part 2: Guidelines for the application of IEC 61511-1

Sécurité fonctionnelle – Systèmes instrumentés de sécurité pour le secteur des

industries de transformation –

Partie 2: Lignes directrices pour l’application de la CEI 61511-1

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

XC

CODE PRIX

ICS 13.110; 25.040.01 ISBN 2-8318-7556-0

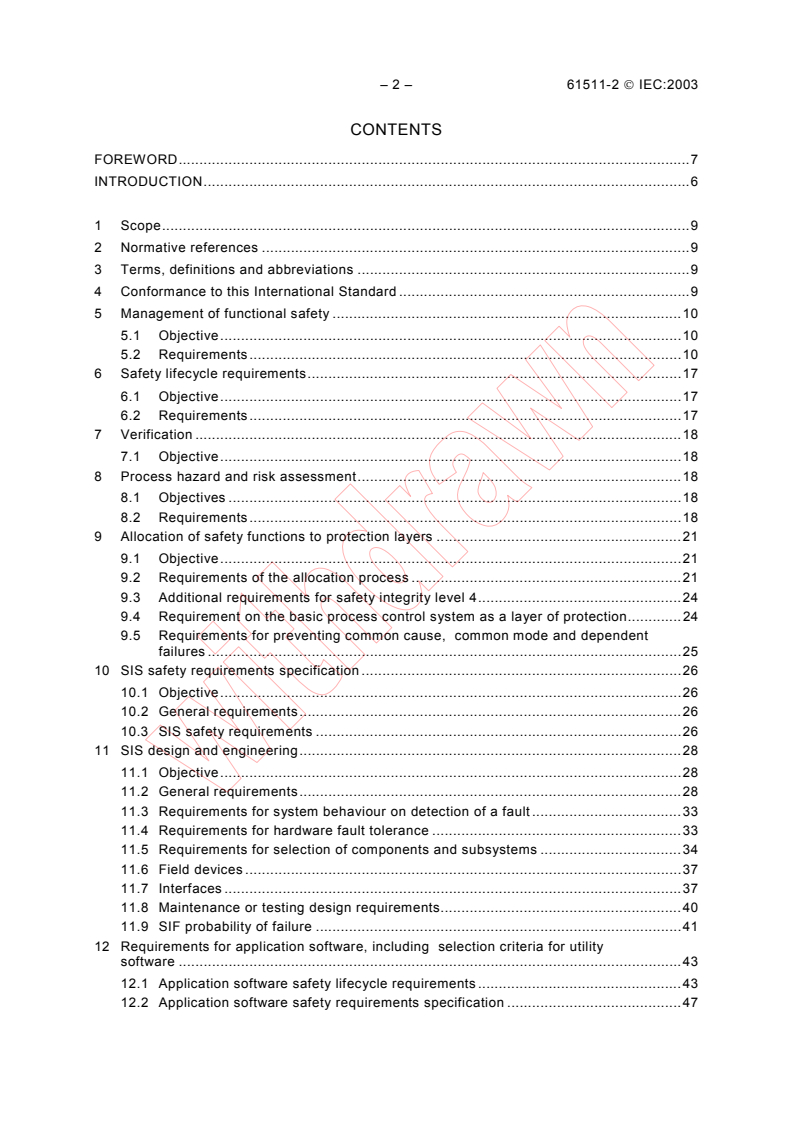

– 2 – 61511-2 © IEC:2003

CONTENTS

FOREWORD.7

INTRODUCTION.6

1 Scope.9

2 Normative references.9

3 Terms, definitions and abbreviations .9

4 Conformance to this International Standard .9

5 Management of functional safety .10

5.1 Objective.10

5.2 Requirements.10

6 Safety lifecycle requirements.17

6.1 Objective.17

6.2 Requirements.17

7 Verification.18

7.1 Objective.18

8 Process hazard and risk assessment.18

8.1 Objectives.18

8.2 Requirements.18

9 Allocation of safety functions to protection layers .21

9.1 Objective.21

9.2 Requirements of the allocation process .21

9.3 Additional requirements for safety integrity level 4.24

9.4 Requirement on the basic process control system as a layer of protection.24

9.5 Requirements for preventing common cause, common mode and dependent

failures .25

10 SIS safety requirements specification .26

10.1 Objective.26

10.2 General requirements.26

10.3 SIS safety requirements .26

11 SIS design and engineering.28

11.1 Objective.28

11.2 General requirements.28

11.3 Requirements for system behaviour on detection of a fault .33

11.4 Requirements for hardware fault tolerance .33

11.5 Requirements for selection of components and subsystems .34

11.6 Field devices.37

11.7 Interfaces.37

11.8 Maintenance or testing design requirements.40

11.9 SIF probability of failure .41

12 Requirements for application software, including selection criteria for utility

software .43

12.1 Application software safety lifecycle requirements .43

12.2 Application software safety requirements specification .47

61511-2 © IEC:2003 – 3 –

12.3 Application software safety validation planning.49

12.4 Application software design and development .49

12.5 Integration of the application software with the SIS subsystem .57

12.6 FPL and LVL software modification procedures .57

12.7 Application software verification.58

13 Factory acceptance testing (FAT) .59

13.1 Objectives.59

13.2 Recommendations.59

14 SIS installation and commissioning.60

14.1 Objectives.60

14.2 Requirements.60

15 SIS safety validation.60

15.1 Objective.60

15.2 Requirements.60

16 SIS operation and maintenance.61

16.1 Objectives.61

16.2 Requirements.61

16.3 Proof testing and inspection .61

17 SIS modification.63

17.1 Objective.63

17.2 Requirements.63

18 SIS decommissioning .63

18.1 Objectives.63

18.2 Requirements.63

19 Information and documentation requirements .64

19.1 Objectives.64

19.2 Requirements.64

Annex A (informative) Example of techniques for calculating the probability of failure

on demand for a safety instrumented function.65

Annex B (informative) Typical SIS architecture development.66

Annex C (informative) Application features of a safety PLC .71

Annex D (informative) Example of SIS logic solver application software development

methodology .73

Annex E (informative) Example of development of externally configured diagnostics

for a safety-configured PE logic solver.78

Figure 1 – Overall framework of this standard.8

Figure 2 – BPCS function and initiating cause independence illustration.25

Figure 3 – Software development lifecycle (the V-model) .44

Figure C.1 – Logic solver .72

Figure E.1 – EWDT timing diagram .80

Table 1 – Typical Safety Manual organisation and contents .55

– 4 – 61511-2 © IEC:2003

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FUNCTIONAL SAFETY –

SAFETY INSTRUMENTED SYSTEMS

FOR THE PROCESS INDUSTRY SECTOR –

Part 2: Guidelines for the application of IEC 61511-1

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61511-2 has been prepared by subcommittee 65A: System

aspects, of IEC technical committee 65: Industrial-process measurement and control.

This bilingual version, published in 2004-07, corresponds to the English version.

The text of this standard is based on the following documents:

FDIS Report on voting

65A/387A/FDIS 65A/390/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

The French version of this standard has not been voted upon.

61511-2 © IEC:2003 – 5 –

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

IEC 61511 series has been developed as a process sector implementation of IEC 61508

series.

IEC 61511 consists of the following parts, under the general title Functional safety – Safety

Instrumented Systems for the process industry sector (see Figure 1):

Part 1: Framework, definitions, system, hardware and software requirements

Part 2: Guidelines for the application of IEC 61511-1

Part 3: Guidance for the determination of the required safety integrity levels

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 6 – 61511-2 © IEC:2003

INTRODUCTION

Safety instrumented systems have been used for many years to perform safety instrumented

functions in the process industries. If instrumentation is to be effectively used for safety

instrumented functions, it is essential that this instrumentation achieves certain minimum

standards.

This International Standard addresses the application of safety instrumented systems for the

Process Industries. It also deals with the interface between safety instrumented systems and

other safety systems in requiring that a process hazard and risk assessment be carried out.

The safety instrumented system includes sensors, logic solvers and final elements.

This International Standard has two concepts, which are fundamental to its application; safety

lifecycle and safety integrity levels. The safety lifecycle forms the central framework which

links together most of the concepts in this International Standard.

The safety instrumented system logic solvers addressed include Electrical (E)/Electronic (E)/

and Programmable Electronic (PE) technology. Where other technologies are used for logic

solvers, the basic principles of this standard may also be applied. This standard also

addresses the safety instrumented system sensors and final elements regardless of the

technology used. This International Standard is process industry specific within the framework

of the IEC 61508 series.

This International Standard sets out an approach for safety lifecycle activities to achieve

these minimum standards. This approach has been adopted in order that a rational and

consistent technical policy is used. The objective of this standard is to provide guidance on

how to comply with IEC 61511-1.

To facilitate use of this standard, the clause and subclause numbers provided are identical to

the corresponding normative text in 61511-1 (excluding the annexes).

In most situations, safety is best achieved by an inherently safe process design whenever

practicable, combined, if necessary, with a number of protective systems which rely on

different technologies (for example, chemical, mechanical, hydraulic, pneumatic, electrical,

electronic, thermodynamic (for example, flame arrestors), programmable electronic) which

manage any residual identified risk. Any safety strategy considers each individual safety

instrumented system in the context of the other protective systems. To facilitate this

approach, this standard

− requires that a hazard and risk assessment is carried out to identify the overall safety

requirements;

− requires that an allocation of the safety requirements to the safety functions and related

safety systems, such as the safety instrumented system(s), is carried out;

− works within a framework which is applicable to all instrumented methods of achieving

functional safety;

− details the use of certain activities, such as safety management, which may be applicable

to all methods of achieving functional safety.

61511-2 © IEC:2003 – 7 –

This International Standard on safety instrumented systems for the process industry:

− addresses relevant safety lifecycle stages from initial concept, through design,

implementation, operation and maintenance and decommissioning;

− enables existing or new country specific process industry standards to be harmonized with

this standard.

This standard is intended to lead to a high level of consistency (for example, of underlying

principles, terminology, information) within the process industries. This should have both

safety and economic benefits.

– 8 – 61511-2 © IEC:2003

Support

Technical

Parts

requirements

PART 1

References

Clause 2

Development of the overall safety

PART 1

requirements (concept, scope definition,

hazard and risk assessment)

Definitions and

abbreviations

Clause 8

Clause 3

PART 1

PART 1

Conformance

Allocation of the safety requirements to

Clause 4

the safety instrumented functions and

development of safety requirements

PART 1

Specification

Management of

Clauses 9 and 10

functional safety

Clause 5

PART 1

PART 1

Safety lifecycle

Design phase for

Design phase for

requirements

safety safety

Clause 6

instrumented

Instrumented

PART 1

systems system software

Clause 11 Clause 12

Verification

Clause 7

PART 1

PART 1

Information

Factory acceptance testing,

requirements

installation and commissioning and

Clause 19

safety validation of safety

instrumented systems PART 1

Clauses 13, 14, and 15

Differences

Annex A

PART 1

PART 1

Operation and maintenance,

modification and retrofit, Guidelines for the

decommissioning or disposal of application of part 1

safety instrumented systems

PART 2

Clauses 16, 17, and 18

Guidance for the

determination of the

required safety

integrity levels

PART 3

IEC 1827/03

Figure 1 – Overall framework of this standard

61511-2 © IEC:2003 – 9 –

FUNCTIONAL SAFETY –

SAFETY INSTRUMENTED SYSTEMS

FOR THE PROCESS INDUSTRY SECTOR –

Part 2: Guidelines for the application of IEC 61511-1

1 Scope

IEC 61511-2 provides guidance on the specification, design, installation, operation and

maintenance of Safety Instrumented Functions and related safety instrumented system as

defined in IEC 61511-1. This standard has been organized so that each clause and subclause

number herein addresses the same clause number in IEC 61511-1 (with the exception of the

annexes).

2 Normative references

No further guidance provided.

3 Terms, definitions and abbreviations

No further guidance provided except for 3.2.68 and 3.2.71 of IEC 61511-1.

3.2.68 A safety function should prevent a specified hazardous event. For example, “prevent

the pressure in vessel #ABC456 exceeding 100 bar.” A safety function may be achieved by

a) a single safety instrumented system (SIS), or

b) one or more safety instrumented systems and/or other layers of protection.

In case b), each safety instrumented system or other layer of protection has to be capable of

achieving the safety function and the overall combination has to achieve the required risk

reduction (process safety target).

3.2.71 Safety instrumented functions are derived from the safety function, have an

associated safety integrity level (SIL) and are carried out by a specific safety instrumented

system (SIS). For example, “close valve #XY123 within 5 s when pressure in vessel #ABC456

reaches 100 bar”. Note that components of a safety instrumented system may be used by

more than one safety instrumented function.

4 Conformance to this International Standard

No further guidance provided.

– 10 – 61511-2 © IEC:2003

5 Management of functional safety

5.1 Objective

The objective of Clause 5 of IEC 61511-1 is to provide requirements for implementing the

management activities that are necessary to ensure that the functional safety objectives

are met.

5.2 Requirements

5.2.1 General

5.2.1.1 No further guidance provided.

5.2.1.2 When an organization has responsibility for one or more activities necessary for

functional safety and that organization works according to quality assurance procedures, then

many of these activities described in this clause will already be carried out for the purposes of

quality. Where this is the case, it may be unnecessary to repeat these activities for the

purposes of functional safety. In such cases, the quality assurance procedures should be

reviewed to establish that they are suitable so that the objectives of functional safety will

be achieved.

5.2.2 Organization and resources

5.2.2.1 The organizational structure associated with safety instrumented systems within a

Company/Site/Plant/Project should be defined and the roles and responsibilities of each

element clearly understood and communicated. Within the structure, individual roles, including

their description and purpose should be identified. For each role, unambiguous

accountabilities should be identified; and specific responsibilities should be recognised. In

addition, whom the individual reports to and who makes the appointment should be identified.

The intent is to ensure that everyone in an organization understands their role and

responsibilities for safety instrumented systems.

5.2.2.2 The skills and knowledge required to implement any of the activities of the safety life

cycle relating to the safety instrumented systems should be identified; and for each skill, the

required competency levels should be defined. Resources should be assessed against each

skill for competency and also the number of people per skill required. When differences are

identified, development plans should be established to enable the required competency levels

to be achieved in a timely manner. When shortages of skills arise, suitably qualified and

experienced personnel may be recruited or contracted.

5.2.3 Risk evaluation and risk management

The requirement stated in 5.2.3 of IEC 61511 is that hazards are identified, risks evaluated

and the necessary risk reduction is determined. It is recognized that there are numerous

different methodologies available for conducting these evaluations. IEC 61511-1 does not

endorse any particular methodology. Instead, the reader is encouraged to review a number of

methodologies on this issue in IEC 61511-3. See 8.2.1 for further guidance.

61511-2 © IEC:2003 – 11 –

5.2.4 Planning

The intent of this subclause is to ensure that, within the overall project, adequate safety

planning is conducted so that all of the required activities during each phase of the lifecycle

(for example, engineering design, plant operation) are addressed. The standard does not

require any particular structure for these planning activities, but it does require periodic

update or review of them.

5.2.5 Implementing and monitoring

5.2.5.1 The intent of this subclause is to ensure that effective management procedures are in

place to

− ensure that all recommendations resulting from hazard analysis, risk assessment, other

assessment and auditing activities, verification and validation activities are satisfactorily

resolved.

− determine that the SIS is performing in accordance with its safety requirements

specification throughout its operational lifetime.

5.2.5.2 Note that, in this context, suppliers could include design contractors and maintenance

contractors as well as suppliers of components.

5.2.5.3 A review of the SIS performance should be periodically undertaken to ensure the

original assumptions made during the development of the safety requirements specification

(SRS) are still adhered to. For example, a periodic review of the assumed failure rate of

different components in a SIS should be carried out to ensure that it remains as originally

defined. If the failure rates are worse than originally anticipated, a design modification may be

necessary. Likewise, the demand rate on the SIS should be reviewed. If the rate is more than

that which was originally assumed, then an adjustment in the SIL may be needed.

5.2.6 Assessment, auditing and revision

Assessments and audits are tools targeted at the detection and elimination of errors. The

paragraphs below make clear the distinction between these activities

Functional safety assessment aims to evaluate whether provisions made during the assessed

lifecycle phases are adequate for the achievement of safety. Judgements are made by

assessors on the decisions taken by those responsible for the realisation of functional safety.

An assessment would for example be made prior to commissioning as to whether procedures

for maintenance are adequate.

Functional safety auditors will determine from project or plant records whether the necessary

procedures have been applied at the specified frequency by persons with the necessary

competence. Auditors are not required to make judgements on the adequacy of the work they

are considering. However, if they became aware that there would be benefits in making

changes, then an observation should be included in the report.

It should be noted that in many cases there can be an overlap between the work of the

assessor and the auditor. For example an auditor may need to determine not only whether an

operator has been given the necessary training but in addition make judgements as to

whether the training has resulted in the required competency.

– 12 – 61511-2 © IEC:2003

5.2.6.1 Functional safety assessment

5.2.6.1.1 The use of Functional Safety Assessment (FSA) is fundamental in demonstrating

that a Safety Instrumented System (SIS) fulfils its requirements regarding safety instrumented

function(s) and Safety Integrity Level (SIL). The basic objective of this assessment is to

demonstrate compliance with agreed standards and practices through independent assess-

ment of the system's development process. An assessment of a SIS may be needed at

different lifecycle stages. In order to conduct an effective assessment, a procedure should be

developed that defines the scope of this assessment along with some guidance on the

makeup of the assessment team.

The following attributes are considered good practice for Functional Safety Assessment:

− A plan should be generated for each FSA identifying such arrangements as the scope of

the assessment, the assessors, the competencies of the assessors and the information to

be generated by the assessment.

− The FSA should take into account other standards and practices, which may be contained

within external or internal corporate standards, guides, procedures or codes of practice.

The FSA plan should define what is to be assessed for the particular assessment/

system/application area.

− The frequency of FSAs may vary across different system developments but as a minimum

should always take place before the potential hazards being presented to the system.

Some companies also like to conduct an assessment prior to the construction/installation

phase to prevent costly rework later in the lifecycle.

− FSA frequency and rigour should be defined taking into account system attributes such as:

• complexity;

• safety significance;

• previous experience of similar systems;

• standardization of design features.

− Sufficient evidence of design, installation, verification and validation activities should be

available prior to the assessment. The availability of sufficient evidence could itself be an

assessment criterion. The evidence should represent the current/approved state of system

design or installation.

− The independence of the assessor(s) must be appropriate.

− The assessor(s) should have experience and knowledge appropriate to the technology

and application area of the system being assessed.

− A systematic and consistent approach to FSA should be maintained throughout the

lifecycle and across systems. FSA is a subjective activity therefore detailed guidance,

possibly through the use of checklists, as to what is acceptable for an organisation should

be defined to remove as much subjectivity as possible.

Records generated from the FSA should be complete and the conclusions agreed with those

responsible for the management of functional safety for the SIS prior to commencement of the

next lifecycle phase.

61511-2 © IEC:2003 – 13 –

5.2.6.1.2 The need for someone independent to the project team is to increase objectivity in