IEC 60454-2:2007

(Main)Pressure-sensitive adhesive tapes for electrical purposes - Part 2: Methods of test

Pressure-sensitive adhesive tapes for electrical purposes - Part 2: Methods of test

IEC 60454-2:2007 specifies methods of test for pressure-sensitive adhesive tapes for electrical purposes. This revision includes improved text regarding the flame test (Clause 20), the improved text on adhesion (Clause 11) and a new Figures 9a and 9b.

Rubans adhésifs sensibles à la pression à usages électriques - Partie 2: Méthodes d'essai

La CEI 60454-2:2007 spécifie les méthodes d'essai pour les rubans adhésifs sensibles à la pression, pour des usages électriques. La présente révision incorpore un texte enrichi concernant l'essai à la flamme (Article 20), un texte enrichi concernant l'adhérence (Article 11) et de nouvelles Figures 9a et 9b.

General Information

- Status

- Published

- Publication Date

- 20-Jun-2007

- Technical Committee

- TC 15 - Solid electrical insulating materials

- Drafting Committee

- MT 16 - TC 15/MT 16

- Current Stage

- PPUB - Publication issued

- Start Date

- 21-Jun-2007

- Completion Date

- 31-Aug-2007

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60454-2:2007 - third edition - is the International Electrotechnical Commission standard that defines methods of test for pressure-sensitive adhesive tapes for electrical purposes. It specifies standardized test methods, specimen preparation and conditioning, and how to record and report results for electrical tapes used as insulation, bundling or protective wrap. This edition includes improved wording for the flame test (Clause 20), revised text on adhesion (Clause 11), and adds new illustrations (Figures 9a and 9b) related to flame-test enclosures.

Key topics and technical requirements

The standard focuses on practical, repeatable test procedures relevant to electrical tape performance. Major test topics include:

- Specimen conditioning and preparation - ensuring consistent pre-test conditions.

- Dimensional measurements - thickness, width and roll length determination.

- Mechanical properties - tensile strength and elongation at break.

- Adhesion - peel/adherence tests including updated Clause 11 procedures and expression of results.

- Low-temperature behavior - flexibility and electrical strength after cold conditioning.

- Thermal endurance - referencing IEC 60216 series for thermal ageing and life assessment.

- Electrical properties - dielectric strength and electrical strength after humid conditioning.

- Corrosion-related properties - pH, conductivity, detection of corrosive sulfur and other effects on metals.

- Flame and fire behavior - Clause 20 flame test and resistance to flame propagation procedures (updated wording and new Figures 9a/9b for draught protection and burner use).

- Other tests - water-vapour permeability, flagging, shear adhesion after liquid immersion, cure behavior for thermosetting adhesives.

The document provides apparatus descriptions, specimen geometries and clear result reporting formats to support reproducible testing.

Applications and who uses this standard

IEC 60454-2:2007 is intended for stakeholders involved in the manufacture, testing and specification of electrical pressure-sensitive adhesive tapes, including:

- Tape manufacturers and R&D teams validating product performance.

- Independent test laboratories and quality assurance groups performing type and batch testing.

- Product compliance and certification bodies assessing safety and electrical performance.

- Specifiers and procurement professionals writing technical requirements for electrical tapes used in wiring harnesses, electrical insulation, repair, and OEM assemblies.

Using this standard helps ensure consistent, internationally recognized test methods for product comparison, regulatory compliance and safety risk mitigation.

Related standards and notes

- Linked to IEC 60454-1 (specifications) and IEC 60216 (thermal endurance).

- Users should verify they have the latest edition and any corrigenda or amendments from IEC for up-to-date requirements.

Keywords: IEC 60454-2, pressure-sensitive adhesive tapes, methods of test, electrical tapes, adhesion test, flame test, dielectric strength, thermal endurance.

Buy Documents

IEC 60454-2:2007 - Pressure-sensitive adhesive tapes for electrical purposes - Part 2: Methods of test Released:6/21/2007

IEC 60454-2:2007 - Pressure-sensitive adhesive tapes for electrical purposes - Part 2: Methods of test Released:6/21/2007

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60454-2:2007 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Pressure-sensitive adhesive tapes for electrical purposes - Part 2: Methods of test". This standard covers: IEC 60454-2:2007 specifies methods of test for pressure-sensitive adhesive tapes for electrical purposes. This revision includes improved text regarding the flame test (Clause 20), the improved text on adhesion (Clause 11) and a new Figures 9a and 9b.

IEC 60454-2:2007 specifies methods of test for pressure-sensitive adhesive tapes for electrical purposes. This revision includes improved text regarding the flame test (Clause 20), the improved text on adhesion (Clause 11) and a new Figures 9a and 9b.

IEC 60454-2:2007 is classified under the following ICS (International Classification for Standards) categories: 17.220.99 - Other standards related to electricity and magnetism; 29.035.20 - Plastics and rubber insulating materials. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60454-2:2007 has the following relationships with other standards: It is inter standard links to IEC 60454-2:2007/COR1:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60454-2:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 60454-2

Third edition

2007-06

Pressure-sensitive adhesive tapes

for electrical purposes –

Part 2:

Methods of test

Reference number

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 60454-2

Third edition

2007-06

Pressure-sensitive adhesive tapes

for electrical purposes –

Part 2:

Methods of test

PRICE CODE

Commission Electrotechnique Internationale X

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

– 2 – 60454-2 © IEC:2007(E)

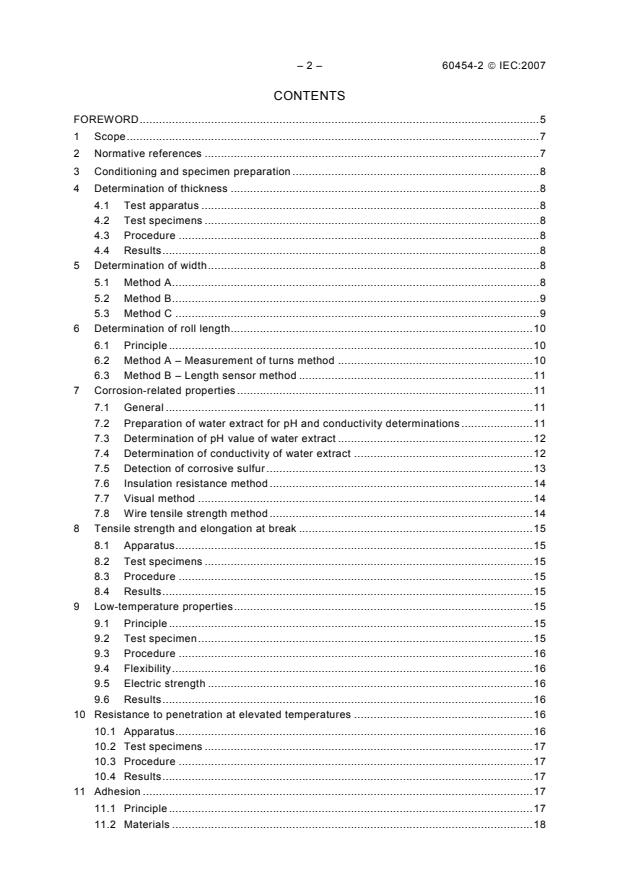

CONTENTS

FOREWORD.5

1 Scope.7

2 Normative references .7

3 Conditioning and specimen preparation .8

4 Determination of thickness .8

4.1 Test apparatus .8

4.2 Test specimens .8

4.3 Procedure .8

4.4 Results.8

5 Determination of width.8

5.1 Method A.8

5.2 Method B.9

5.3 Method C .9

6 Determination of roll length.10

6.1 Principle.10

6.2 Method A – Measurement of turns method .10

6.3 Method B – Length sensor method .11

7 Corrosion-related properties .11

7.1 General .11

7.2 Preparation of water extract for pH and conductivity determinations .11

7.3 Determination of pH value of water extract .12

7.4 Determination of conductivity of water extract .12

7.5 Detection of corrosive sulfur .13

7.6 Insulation resistance method .14

7.7 Visual method .14

7.8 Wire tensile strength method .14

8 Tensile strength and elongation at break .15

8.1 Apparatus.15

8.2 Test specimens .15

8.3 Procedure .15

8.4 Results.15

9 Low-temperature properties.15

9.1 Principle.15

9.2 Test specimen.16

9.3 Procedure .16

9.4 Flexibility.16

9.5 Electric strength .16

9.6 Results.16

10 Resistance to penetration at elevated temperatures .17

10.1 Apparatus.17

10.2 Test specimens .17

10.3 Procedure .17

10.4 Results.17

11 Adhesion .17

60454-2 © IEC:2007(E) – 3 –

11.1 Principle.17

11.2 Materials .18

11.3 Apparatus.18

11.4 Test samples and test pieces .19

11.5 Procedure .20

11.6 Expression of results.20

12 Adhesion to backing at low temperatures.21

12.1 Test specimens .21

12.2 Procedure .21

12.3 Results.21

13 Shear adhesion to backing after liquid immersion .21

13.1 Apparatus.21

13.2 Test specimens .21

13.3 Procedure .22

13.4 Results.22

14 Curing properties of thermosetting adhesive tapes .22

14.1 Bond separation during thermal treatment (adhesive to backing) .22

14.2 Bond separation after thermal treatment (adhesion to backing) .22

15 Flagging tests.23

15.1 Principle.23

15.2 Apparatus.23

15.3 Test specimens .23

15.4 Preparation of specimens for test .24

15.5 Test conditions.24

15.6 Results.24

16 Water vapor permeability.24

16.1 Apparatus.24

16.2 Test specimens .24

16.3 Procedure .25

16.4 Results.25

17 Electric strength .25

17.1 General .25

17.2 Test specimens .25

17.3 Procedure .25

17.4 Results.25

18 Electric strength after humid conditioning .26

19 Resistance to flame propagation .26

19.1 Principle.26

19.2 Apparatus.26

19.3 Test specimen.26

19.4 Procedure .27

19.5 Results.27

20 Flame test .27

20.1 Principle.27

20.2 Apparatus.28

20.3 Preparation of test specimen .28

20.4 Procedure .29

20.5 Results.29

– 4 – 60454-2 © IEC:2007(E)

21 Thermal endurance .29

21.1 Determination of thermal endurance (based on IEC 60216-1 and IEC 60216-2).29

21.2 Voltage breakdown.30

21.3 Loss of mass.31

Annex A (normative) Rollers to be used in various tests.40

Bibliography.41

Figure 1 – Measuring device for determination of roll length of tape (measurement of

turns method) .32

Figure 2 – Measuring device for determination of roll length of tape (length sensor

method) .32

Figure 3 – Sequence of bends .33

Figure 4 – Dielectric strength test in water .33

Figure 5 – Sketch of penetration tester .34

Figure 6 – Steel test plate.35

Figure 7 – Arrangement for stripping the tape from the plate.35

Figure 8 – Flagging test – Preparation of test specimen.36

Figure 9a – Draught protection device .37

Figure 9b – Use of Bunsen burner and sliding plate with draught protection device.37

Figure 9 – Flame test enclosures .37

Figure 10 – Essential dimensions for flame test (proportions exaggerated for clarity of

details) .38

Figure 11 – Dimensions of wedge .39

Table 1 – Conditioning for low temperature properties .16

60454-2 © IEC:2007(E) – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PRESSURE-SENSITIVE ADHESIVE TAPES

FOR ELECTRICAL PURPOSES –

Part 2: Methods of test

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60454-2 has been prepared by IEC technical committee 15: Solid

electrical insulating materials.

This third edition cancels and replaces the second edition published in 1994, and constitutes

a technical revision. This revision includes improved text regarding the flame test (Clause 20),

the improved text on adhesion (Clause 11) and a new Figures 9a and 9b.

The text of this standard is based on the following documents:

FDIS Report on voting

15/377/FDIS 15/387/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

– 6 – 60454-2 © IEC:2007(E)

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 60454 series, under the general title Pressure-sensitive

adhesive tapes for electrical purposes, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

The contents of the corrigendum of December 2009 have been included in this copy.

– 6 – 60454-2 © IEC:2007(E)

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 60454 series, under the general title Pressure-sensitive

adhesive tapes for electrical purposes, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

The contents of the corrigendum of December 2009 have been included in this copy.

60454-2 © IEC:2007(E) – 7 –

PRESSURE-SENSITIVE ADHESIVE TAPES

FOR ELECTRICAL PURPOSES –

Part 2: Methods of test

1 Scope

This part of IEC 60454 specifies methods of test for pressure-sensitive adhesive tapes for

electrical purposes.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60216-1:2001, Electrical insulating materials – Properties of thermal endurance – Part 1:

Ageing procedures and evaluation of test results

IEC 60216-2:2005, Electrical insulating materials – Thermal endurance properties – Part 2:

Determination of thermal endurance properties of electrical insulating materials – Choice of

test criteria

IEC 60216-3:2006, Electrical insulating materials – Thermal endurance properties – Part 3:

Instructions for calculating thermal endurance characteristics

IEC 60243-1:1998, Electrical strength of insulating materials – Test methods – Part 1: Tests

at power frequencies

IEC 60426:1973, Test methods for determining electrolytic corrosion with insulating materials

IEC 60454-3 (all parts), Pressure-sensitive adhesive tapes for electrical purposes – Part 3:

Specifications for individual materials

IEC 60589:1977, Methods of test for the determination of ionic impurities in electrical

insulating materials by extraction with liquids

ISO 383: 1976, Laboratory glassware – Interchangeable conical ground joints

ISO 527-3:1995, Plastics – Determination of tensile properties – Part 3: Test conditions for

films and sheets

ISO 2194:1991, Industrial screens – Woven wire cloth, perforated place and electroformed

sheet – Designation and nominal sizes of openings

ISO 3071:2005, Textiles – Determination of pH of the aqueous extract

ISO 3599:1976, Vernier callipers reading to 0,1 and 0,05 mm

ISO 10093:1998, Plastics – Fire tests – Standard ignition sources

EN 1939:2003, Self-adhesive tapes − Determination of peel adhesion properties (The peel

adhesion test method of Clause 11 is based on test method A of EN 1939:2003. This standard

is the result of the harmonisation of AFERA 5001 and PSTC-1,2,3 and 4, ASTM 3330/D,

ASTM 3330/M and agreed by JATMA.)

NOTE EN: European Norm (Europe) − AFERA: Association des fabricants européens de rubans auto-adhésifs −

PSTC: Pressure sensitive tape council (USA) − ASTM: American society for testing and materials (USA) − JATMA:

Japanese adhesive tapes manufacturers association.

– 8 – 60454-2 © IEC:2007(E)

3 Conditioning and specimen preparation

Unless otherwise specified, rolls are to be conditioned for at least 24 h at (23 ± 2) °C and

(50 ± 5) % relative humidity and all test procedures are to be carried out in this atmosphere.

Remove and discard the three outer turns before taking any test specimens from the

conditioned roll. Specimen preparation shall be done with care in a clean environment.

Specific specimen preparation details will be included with the appropriate test method.

Further conditioning of test specimens may be required.

4 Determination of thickness

4.1 Test apparatus

A dead-weight thickness gauge having two ground and concentric circular surfaces, flat within

0,001 mm and parallel to within 0,003 mm. The upper surface shall be 6 mm to 8 mm in

diameter and the lower surface larger than the upper one. The upper surface shall move on

the axis perpendicular to the two faces.

The gauge shall be graduated to read directly to 0,002 mm. The frame of the thickness gauge

shall be of such rigidity that a load of 15 N applied to the gauge housing, out of contact with

either the weight or the pressure foot spindle, will produce a deflection of the frame not

greater than 0,002 mm (as indicated on the thickness gauge). The pressure exerted on the

specimen shall be (50 ± 5) kPa.

The accuracy of the thickness gauge shall be checked frequently by means of a set of steel

gauges; the measuring errors of the thickness gauge shall not exceed 0,005 mm.

4.2 Test specimens

Five specimens, at least 75 mm long, are cut from the roll at intervals not less than 300 mm.

The specimen shall be allowed to relax for at least 5 min.

4.3 Procedure

Place the test specimen between the jaws of the thickness gauge in contact with the fixed

foot. Take care to ensure that no air bubbles are trapped. Lower the moving pressure foot

gently on to the surface of the tape and take the reading on the gauge within 2 s. Read the

measurement to the nearest 0,002 mm on the thickness gauge scale.

4.4 Results

Report the central value as well as the maximum and minimum values of the five readings of

thickness in millimetres.

5 Determination of width

5.1 Method A

5.1.1 Use a steel rule graduated to 0,5 mm. The total measuring error of the rule shall not

exceed 0,1 mm.

5.1.2 A specimen of tape, at least 450 mm long, is removed from the roll and placed

adhesive side up on a smooth flat surface. The specimen shall be allowed to relax for at least

5 min.

60454-2 © IEC:2007(E) – 9 –

The width of the relaxed specimen is measured with the adhesive side down to the nearest

0,5 mm using the rule. Ten measurements shall be made, uniformly distributed along the

length of the specimen. The width shall be the mean value of the ten measurements.

5.2 Method B

5.2.1 Principle

The adhesive tape roll is placed between the jaws of a pair of calipers.

The width is the perpendicular distance, expressed in millimetres, between the opposite cut

edges of the test specimen of adhesive tape. This method may not be suitable for slit or

rewound rolls if the turns are not exactly coincident.

5.2.2 Apparatus

Vernier calipers with a scale length not less than the roll width according to ISO 3599.

5.2.3 Test specimen

One roll of tape.

5.2.4 Conditioning

Conditioning shall conform to Clause 3 with the exception that it is not necessary to remove

any layers unless damaged.

5.2.5 Procedure

Hold the roll so that the cut edges are in a vertical plane. If the outer turns of the tape on the

roll have crushed or damaged cut edges, these should be discarded prior to measurement.

Hold the calipers so that the scale shaft is in the horizontal plane.

Carefully close the caliper jaws so as to just touch the cut edges of the outer turns of the roll

of tape, taking the following precautions:

a) do not crush the roll edges;

b) ensure that calliper jaws are perpendicular to cut edges.

Measure the roll width in millimetres to the nearest 0,1 mm.

Carry out two further measurements at equally spaced intervals around the circumference.

5.2.6 Results

Report the mean value as the width of tape in millimetres.

5.3 Method C

This method will only be used where a very high degree of accuracy is required.

Use a travelling microscope with a vernier control on one axis which has an accuracy

of 0,001 mm. Using the specimen obtained and relaxed as in 5.1.2, measure the width to the

nearest 0,01 mm, taking ten measurements. The width of the tape is taken as the mean value

in milimetres.

– 10 – 60454-2 © IEC:2007(E)

6 Determination of roll length

6.1 Principle

The length can be calculated from a measurement of the number of turns of tape on the reel

and a measurement of the outer circumference of the tape and the outer circumference of the

core. Alternatively, length can be measured directly by using a length sensor that includes a

rotating wheel that revolves on the roll of tape as it is being unwound.

For non-extensible tapes the length measured by these methods will be the same as the

length after unrolling.

For extensible tapes the length after unrolling will be greater if the tape is stretched

irreversibly by unrolling.

6.2 Method A – Measurement of turns method

6.2.1 Apparatus (see Figure 1)

a) A measuring device capable of counting both whole revolutions and part revolutions,

continuously driven by a spindle. The spindle has a suitable locking device by means of

which a conical shaft can be quickly fitted to suit the internal diameters of cores for the

rolls of tape. (For example, for a nominal 25 mm internal diameter core the conical shaft

will give a 24,5 mm diameter to 26,5 mm diameter over a shaft length of 50 mm.

Alternative size conical shafts would be needed for tapes on a core with significantly

different nominal diameters, such as 76 mm.)

b) Measuring tape. A narrow, flexible, steel tape (6 mm or narrower) calibrated in milimetres.

6.2.2 Test specimen

One roll of tape.

6.2.3 Procedure

Measure the circumference of the roll C in milimetres by means of a steel tape. Apply the

r

tape to the roll like a belt.

Mount the roll on the conical shaft of the counter. Set the counter to zero and pull the tape

from the roll in a direction perpendicular to the spindle. Remove all the tape from the core and

record the number of revolutions (to the nearest tenth of a revolution) as read from the

counter when the last turn of tape has left the core: N turns.

Measure the circumference of the core: C mm.

o

6.2.4 Results

Calculate the length (L) of the tape as follows:

C + C

r o

L (metres) = N

2 000

If the length of tape in contact with the core is not to be included in the total length, then

C + C C

r o o

L (metres) = N −

2 000 1 000

60454-2 © IEC:2007(E) – 11 –

6.3 Method B – Length sensor method

6.3.1 Apparatus (see Figure 2)

A measuring device capable of measuring the length of a roll of tape in metres by using a

calibrated rotating wheel which rolls, with low torque and contact pressure, against the

circumference of the tape as it unwinds. The apparatus includes a spindle for mounting the

tape, a length sensor, a read-out system and a rotating wind-up roll that can be used to

unwind, either manually or automatically, the roll of tape.

6.3.2 Test specimen

One roll of tape.

6.3.3 Procedure

Mount the roll on the shaft adjacent to the sensor. Position the roll and length sensor so that

the sensor is in contact with the circumference of roll and the leading end of the roll is directly

under the sensor. Set the sensor to zero and manually pull the leading edge of the tape and

fix it to the wind-up roll. At the start of unwinding, ensure that the length sensor maintains

good contact with the roll and does not slip or bind. On completion of unwinding, take the

reading of the length sensor.

6.3.4 Results

Report the length in metres as recorded on the read-out.

7 Corrosion-related properties

7.1 General

The requirements for individual products are given in IEC 60454-3. The test methods will be

selected from those given in this part. When electrolytic corrosion is of significance, i.e. when

fine wire approximately 1 mm in diameter or finer is used, the determination is carried out

according to IEC 60426.

Where required by IEC 60454-3, the test methods for the determination of conductivity, pH

and corrosive sulphur shall be used.

7.2 Preparation of water extract for pH and conductivity determinations

7.2.1 Precautions

Avoid contamination of the material during storage, sampling, preparation of test pieces and

testing.

– 12 – 60454-2 © IEC:2007(E)

Ensure that the sample roll and the material taken therefrom are not contaminated by the

atmosphere, particularly the atmosphere of a chemical laboratory, or by contact with bare

hands, and that the implements used for cutting or handling the test piece are chemically

clean.

7.2.2 Test piece

Cut strips of tape, each approximately 25 mm × 6 mm, from the sample roll.

If a strip is folded, it shall be folded adhesive surface outwards.

7.2.3 Method

Use water having a conductivity not greater than 0,2 mS/m. Make a blank test of the

extraction vessel before each extraction, and if the resultant conductivity exceeds 0,2 mS/m

repeat the test with the same extraction vessel. Change the vessel if the second result also

exceeds this value.

Prepare the extract by putting a ratio of 1 g of tape to 100 ml of water into a borosilicate glass

(high chemical resistance glass) or quartz flask fitted with a reflux condenser of the same

quality glass or quartz. Use an apparatus with interchangeable conical ground-glass joints

complying with the requirements of ISO 383.

Boil the water gently for 60 min, except in the case of cellulose acetate film tape for which the

period should be 10 min, taking care that the material is not charred. Allow it to cool as rapidly

as possible, taking precautions against admission of carbon dioxide (e.g. CO trap).

7.2.4 Quantity

Sufficient quantity of extracts should be prepared so that pH and conductivity are measured

on separate portions of the extracts.

7.3 Determination of pH value of water extract

Determine the pH value at a temperature of (23 ± 2) °C according to 8.2 of ISO 3071.

7.4 Determination of conductivity of water extract

7.4.1 Apparatus

The following apparatus is required.

7.4.1.1 A suitable conductivity cell which may consist of two inert electrodes, e.g., platinized

platinum maintained at a fixed distance apart and adequately insulated from each other.

7.4.1.2 A measuring instrument capable of measuring conductance or admittance with an

accuracy of 5 % and a minimum reading of 1 μS in the frequency range 50 Hz to 3 000 Hz at

a voltage not exceeding 100 V; alternatively, resistance may be measured to the same

accuracy.

NOTE 1 It is important that any insulation immersed in the test liquid should not be water absorbent or subject to

contamination by aqueous electrolytes.

NOTE 2 The conductivity cell should be easy to clean and free from recesses where impurities can be retained.

NOTE 3 Care should be taken to ensure that the electrodes do not become polarized.

NOTE 4 Platinized platinum electrodes are platinum-coated with platinum black.

60454-2 © IEC:2007(E) – 13 –

7.4.2 Determination of electrical conductivity

7.4.2.1 General

Determination of the conductivity cell constant. If not known, determine the conductivity cell

–1

constant K (m ) using the method specified in IEC 60589.

NOTE For test apparatus, where the cell constant is calibrated into the apparatus electronics, this step is not

necessary.

7.4.2.2 Determination of the conductivity of the blank

After thoroughly cleaning the conductivity cell with water as specified in 7.2.3, fill it with water

obtained as a result of the blank extraction test, and measure its conductivity G in mS/m at

(23 ± 2) °C. The conductivity of the blank in mS/m is then KG .

7.4.2.3 Determination of the conductivity of the water extract

Thoroughly rinse the conductivity cell with the extract to be tested, and then fill with the

extract. Adjust the temperature to (23 ± 2) °C, maintain for 15 min and then measure the

conductivity G in mS/m at that temperature.

The conductivity of the water extract in mS/m is then calculated as K(G – G ).

2 1

NOTE For most purposes, where it is not convenient to test the water extract at (23 ± 2) °C, it is sufficiently

accurate to apply the following correction:

G

Conductivity at 23 °C =

1+ 0,02 (t − 23)

where G is the conductivity obtained when the measurement is made at t °C.

7.4.3 Results

Express the conductivity in mS/m at a temperature of 23 °C.

7.5 Detection of corrosive sulfur

7.5.1 Test specimens

Cut two test specimens, each 100 mm long, from the sample roll.

7.5.2 Apparatus

Three smooth copper rods are required, each approximately 6 mm in diameter and 75 mm

long, cleaned and polished with water and silicon carbide powder size 90 μm to 125 μm and

wiped clean and dried with cotton wool or filter paper. Finally the rods are washed with a

volatile sulfur-free solvent, such as diethyl ether, and allowed to dry.

7.5.3 Method

Handle the copper rods with clean, dry metal forceps. Wind two of the copper rods centrally

with approximately 100 mm of tape so that succeeding layers are superimposed one on

another. Leave at least 12 mm at each end of the copper rods clear of tape.

NOTE Tapes above 50 mm in width should be slit to allow the copper rods to be bare at each end for the required

12 mm.

Apply the tape to the first rod, adhesive side downwards in contact with the copper, and to the

second rod, adhesive side upwards with the tape backing in contact with the copper. Leave

the third rod bare to act as a control.

– 14 – 60454-2 © IEC:2007(E)

Place each rod in a separate glass-stoppered, chemically cleaned glass tube and maintain

them at a temperature of (100 ± 2) °C for 16 h. Take the rods out of the tubes after they have

cooled to room temperature.

Remove the tapes, together with any exudations that may have occurred, from the rods.

Removal of exudation may be assisted by the use of a solvent but no mechanical abrasive

aids shall be employed.

Visually examine the copper rods for signs of blue-black staining, characteristic of copper

sulfide. If blue-black staining of the test rods is more intense or extensive than that of the

control rod, such staining is an indication of the presence of corrosive sulfur.

7.5.4 Report

Report whether blue-black staining of the test rods is greater than that of the control rod.

7.6 Insulation resistance method

7.6.1 General

The test shall be performed in accordance with the requirements of Clause 14 of IEC 60426

with the following exceptions.

7.6.2 Test specimens

Samples shall be taken from the roll at intervals of not less than 300 mm.

7.6.3 Electrodes

The electrodes shall have corners rounded to 1 mm radius and shall be constructed from an

inert high conductivity metal, e.g. nickel-plated brass.

7.6.4 Equipment

A means for measuring resistance up to 10 MΩ (1 TΩ) to an accuracy of ±20 % shall be

used. Screened leads, with the screens connected to the guard circuit, should be used for all

connecting purposes.

7.6.5 Results

For tapes less than 25 mm in width, calculate the resistance in Ω/25 mm assuming that

resistance is inversely proportional to width.

7.7 Visual method

The test shall be performed in accordance with the requirements of Clause 3 of IEC 60426.

7.8 Wire tensile strength method

7.8.1 General

The test shall be performed in accordance with the requirements of Clause 9 of IEC 60426

with the following exception.

7.8.2 Test specimens

At least ten specimens shall be tested.

60454-2 © IEC:2007(E) – 15 –

7.8.3 Tensile strength of test wire

The mean value of the breaking load for unexposed wire must be in the range of 7 N to 9 N.

7.8.4 Cleaning of apparatus

Metal parts shall be cleaned with pure, clean methanol followed by distilled water.

7.8.5 Tensile test equipment

The rate of grip separation shall be the same for the test on exposed and unexposed wires.

8 Tensile strength and elongation at break

8.1 Apparatus

As described in Clause 5 of ISO 527-3.

8.2 Test specimens

Cut five strips of tape, each of sufficient length to give the required initial test length, from the

sample roll at intervals of not less than 300 mm. For tapes having an elongation at break of

50 % or less, the initial test length shall be 200 mm. For tapes having an elongation >50 %,

the test length shall be 100 mm.

The width of the test piece shall be equal to or less than 50 mm.

In the case of tapes wider than 50 mm, cut the test pieces out of the middle of the tape to a

width of 25 mm, using a sharp tool to produce clean-cut edges. For tapes less than 6 mm

wide, edge effects can have a significant effect on these determinations. For tapes below this

width the results should not be used for specification purposes.

8.3 Procedure

Insert the test specimens into the equipment so that the load is applied evenly across the

width of the tape. The test shall be carried out at (300 ± 30) mm/min, unless otherwise

specified in IEC 60454-3. Different speeds of separation shall be selected from Clause 9 of

ISO 527-3. Make five valid determinations, disregarding any test in which the break occurs

within 10 mm of either grip (or jaw). During the test ensure that the tape does not slip in the

grips of the testing equipment.

8.4 Results

Report the breaking strength measurements as the central value of the five determinations in

N/10 mm width and the elongation at break as the central value of increase in distance

between the grips at the moment of break as a percentage of the original distance between

the grips. Where a tape has been cut down from a large width, this shall be reported.

9 Low-temperature properties

9.1 Principle

A copper conductor is covered by the tape under test and then subjected to a flexing

procedure after conditioning at low temperature. The specimen is tested for the presence of

cracking or unwinding.

– 16 – 60454-2 © IEC:2007(E)

9.2 Test specimen

The copper conductor of a 300 mm length of thermoplastic insulated cable (of a type suitable

for exposed wiring in wet locations) with a solid conductor approximately 1,6 mm in diameter

(giving maximum allowable conductor temperature of 75 °C) shall be bared for 50 mm at the

middle. The bared portion shall then be wrapped with 3 layers of tape (using one piece of

tape), half-lapped, with the layers extending a minimum of a full lap beyond the bared portion

at each end so that the insulation is covered. The tape shall be applied smoothly with a

minimum tension in a manner so as to conform to the splice area.

9.3 Procedure

The prepared specimen shall be placed in a cold chamber and condition

...

IEC 60454-2 ®

Edition 3.0 2007-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Pressure-sensitive adhesive tapes for electrical purposes –

Part 2: Methods of test

Rubans adhésifs sensibles à la pression à usages électriques –

Partie 2: Méthodes d’essai

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60454-2 ®

Edition 3.0 2007-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Pressure-sensitive adhesive tapes for electrical purposes –

Part 2: Methods of test

Rubans adhésifs sensibles à la pression à usages électriques –

Partie 2: Méthodes d’essai

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

X

CODE PRIX

ICS 17.220.99; 29.035.20 ISBN 978-2-88910-195-5

– 2 – 60454-2 © IEC:2007

CONTENTS

FOREWORD.5

1 Scope.7

2 Normative references .7

3 Conditioning and specimen preparation .8

4 Determination of thickness .8

4.1 Test apparatus .8

4.2 Test specimens .8

4.3 Procedure .8

4.4 Results.8

5 Determination of width.8

5.1 Method A.8

5.2 Method B.9

5.3 Method C .9

6 Determination of roll length.10

6.1 Principle.10

6.2 Method A – Measurement of turns method .10

6.3 Method B – Length sensor method .11

7 Corrosion-related properties .11

7.1 General .11

7.2 Preparation of water extract for pH and conductivity determinations .11

7.3 Determination of pH value of water extract .12

7.4 Determination of conductivity of water extract .12

7.5 Detection of corrosive sulfur .13

7.6 Insulation resistance method .14

7.7 Visual method .14

7.8 Wire tensile strength method .14

8 Tensile strength and elongation at break .15

8.1 Apparatus.15

8.2 Test specimens .15

8.3 Procedure .15

8.4 Results.15

9 Low-temperature properties.15

9.1 Principle.15

9.2 Test specimen.15

9.3 Procedure .16

9.4 Flexibility.16

9.5 Electric strength .16

9.6 Results.16

10 Resistance to penetration at elevated temperatures .16

10.1 Apparatus.16

10.2 Test specimens .17

10.3 Procedure .17

10.4 Results.17

11 Adhesion .17

11.1 Principle.17

11.2 Materials .18

60454-2 © IEC:2007 – 3 –

11.3 Apparatus.18

11.4 Test samples and test pieces .19

11.5 Procedure .19

11.6 Expression of results.20

12 Adhesion to backing at low temperatures.20

12.1 Test specimens .20

12.2 Procedure .20

12.3 Results.21

13 Shear adhesion to backing after liquid immersion .21

13.1 Apparatus.21

13.2 Test specimens .21

13.3 Procedure .21

13.4 Results.21

14 Curing properties of thermosetting adhesive tapes .22

14.1 Bond separation during thermal treatment (adhesive to backing) .22

14.2 Bond separation after thermal treatment (adhesion to backing) .22

15 Flagging tests.23

15.1 Principle.23

15.2 Apparatus.23

15.3 Test specimens .23

15.4 Preparation of specimens for test .23

15.5 Test conditions.24

15.6 Results.24

16 Water vapor permeability.24

16.1 Apparatus.24

16.2 Test specimens .24

16.3 Procedure .24

16.4 Results.25

17 Electric strength .25

17.1 General .25

17.2 Test specimens .25

17.3 Procedure .25

17.4 Results.25

18 Electric strength after humid conditioning .25

19 Resistance to flame propagation .25

19.1 Principle.25

19.2 Apparatus.26

19.3 Test specimen.26

19.4 Procedure .27

19.5 Results.27

20 Flame test .27

20.1 Principle.27

20.2 Apparatus.27

20.3 Preparation of test specimen .28

20.4 Procedure .28

20.5 Results.29

21 Thermal endurance .29

21.1 Determination of thermal endurance (based on IEC 60216-1 and IEC 60216-2).29

– 4 – 60454-2 © IEC:2007

21.2 Voltage breakdown.29

21.3 Loss of mass.30

Annex A (normative) Rollers to be used in various tests.40

Bibliography.41

Figure 1 – Measuring device for determination of roll length of tape (measurement of

turns method) .31

Figure 2 – Measuring device for determination of roll length of tape (length sensor

method) .32

Figure 3 – Sequence of bends .32

Figure 4 – Dielectric strength test in water .33

Figure 5 – Sketch of penetration tester .34

Figure 6 – Steel test plate.35

Figure 7 – Arrangement for stripping the tape from the plate.35

Figure 8 – Flagging test – Preparation of test specimen.36

Figure 9a – Draught protection device .37

Figure 9b – Use of Bunsen burner and sliding plate with draught protection device.37

Figure 9 – Flame test enclosures .37

Figure 10 – Essential dimensions for flame test (proportions exaggerated for clarity of

details) .38

Figure 11 – Dimensions of wedge .39

Table 1 – Conditioning for low temperature properties .16

60454-2 © IEC:2007 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PRESSURE-SENSITIVE ADHESIVE TAPES

FOR ELECTRICAL PURPOSES –

Part 2: Methods of test

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60454-2 has been prepared by IEC technical committee 15: Solid

electrical insulating materials.

This third edition cancels and replaces the second edition published in 1994, and constitutes

a technical revision. This revision includes improved text regarding the flame test (Clause 20),

the improved text on adhesion (Clause 11) and a new Figures 9a and 9b.

This bilingual version, published in 2010-01, corresponds to the English version.

– 6 – 60454-2 © IEC:2007

The text of this standard is based on the following documents:

FDIS Report on voting

15/377/FDIS 15/387/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

The French version of this standard has not been voted upon.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 60454 series, under the general title Pressure-sensitive

adhesive tapes for electrical purposes, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

60454-2 © IEC:2007 – 7 –

PRESSURE-SENSITIVE ADHESIVE TAPES

FOR ELECTRICAL PURPOSES –

Part 2: Methods of test

1 Scope

This part of IEC 60454 specifies methods of test for pressure-sensitive adhesive tapes for

electrical purposes.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60216-1:2001, Electrical insulating materials – Properties of thermal endurance – Part 1:

Ageing procedures and evaluation of test results

IEC 60216-2:2005, Electrical insulating materials – Thermal endurance properties – Part 2:

Determination of thermal endurance properties of electrical insulating materials – Choice of

test criteria

IEC 60216-3:2006, Electrical insulating materials – Thermal endurance properties – Part 3:

Instructions for calculating thermal endurance characteristics

IEC 60243-1:1998, Electrical strength of insulating materials – Test methods – Part 1: Tests

at power frequencies

IEC 60426:1973, Test methods for determining electrolytic corrosion with insulating materials

IEC 60454-3 (all parts), Pressure-sensitive adhesive tapes for electrical purposes – Part 3:

Specifications for individual materials

IEC 60589:1977, Methods of test for the determination of ionic impurities in electrical

insulating materials by extraction with liquids

ISO 383: 1976, Laboratory glassware – Interchangeable conical ground joints

ISO 527-3:1995, Plastics – Determination of tensile properties – Part 3: Test conditions for

films and sheets

ISO 2194:1991, Industrial screens – Woven wire cloth, perforated place and electroformed

sheet – Designation and nominal sizes of openings

ISO 3071:2005, Textiles – Determination of pH of the aqueous extract

ISO 3599:1976, Vernier callipers reading to 0,1 and 0,05 mm

ISO 10093:1998, Plastics – Fire tests – Standard ignition sources

− Determination of peel adhesion properties (The peel

EN 1939:2003, Self-adhesive tapes

adhesion test method of Clause 11 is based on test method A of EN 1939:2003. This standard

is the result of the harmonisation of AFERA 5001 and PSTC-1,2,3 and 4, ASTM 3330/D,

ASTM 3330/M and agreed by JATMA.)

– 8 – 60454-2 © IEC:2007

NOTE EN: European Norm (Europe) − AFERA: Association des fabricants européens de rubans auto-adhésifs −

PSTC: Pressure sensitive tape council (USA) − ASTM: American society for testing and materials (USA) − JATMA:

Japanese adhesive tapes manufacturers association.

3 Conditioning and specimen preparation

Unless otherwise specified, rolls are to be conditioned for at least 24 h at (23 ± 2) °C and

(50 ± 5) % relative humidity and all test procedures are to be carried out in this atmosphere.

Remove and discard the three outer turns before taking any test specimens from the

conditioned roll. Specimen preparation shall be done with care in a clean environment.

Specific specimen preparation details will be included with the appropriate test method.

Further conditioning of test specimens may be required.

4 Determination of thickness

4.1 Test apparatus

A dead-weight thickness gauge having two ground and concentric circular surfaces, flat within

0,001 mm and parallel to within 0,003 mm. The upper surface shall be 6 mm to 8 mm in

diameter and the lower surface larger than the upper one. The upper surface shall move on

the axis perpendicular to the two faces.

The gauge shall be graduated to read directly to 0,002 mm. The frame of the thickness gauge

shall be of such rigidity that a load of 15 N applied to the gauge housing, out of contact with

either the weight or the pressure foot spindle, will produce a deflection of the frame not

greater than 0,002 mm (as indicated on the thickness gauge). The pressure exerted on the

specimen shall be (50 ± 5) kPa.

The accuracy of the thickness gauge shall be checked frequently by means of a set of steel

gauges; the measuring errors of the thickness gauge shall not exceed 0,005 mm.

4.2 Test specimens

Five specimens, at least 75 mm long, are cut from the roll at intervals not less than 300 mm.

The specimen shall be allowed to relax for at least 5 min.

4.3 Procedure

Place the test specimen between the jaws of the thickness gauge in contact with the fixed

foot. Take care to ensure that no air bubbles are trapped. Lower the moving pressure foot

gently on to the surface of the tape and take the reading on the gauge within 2 s. Read the

measurement to the nearest 0,002 mm on the thickness gauge scale.

4.4 Results

Report the central value as well as the maximum and minimum values of the five readings of

thickness in millimetres.

5 Determination of width

5.1 Method A

5.1.1 Use a steel rule graduated to 0,5 mm. The total measuring error of the rule shall not

exceed 0,1 mm.

60454-2 © IEC:2007 – 9 –

5.1.2 A specimen of tape, at least 450 mm long, is removed from the roll and placed

adhesive side up on a smooth flat surface. The specimen shall be allowed to relax for at least

5 min.

The width of the relaxed specimen is measured with the adhesive side down to the nearest

0,5 mm using the rule. Ten measurements shall be made, uniformly distributed along the

length of the specimen. The width shall be the mean value of the ten measurements.

5.2 Method B

5.2.1 Principle

The adhesive tape roll is placed between the jaws of a pair of calipers.

The width is the perpendicular distance, expressed in millimetres, between the opposite cut

edges of the test specimen of adhesive tape. This method may not be suitable for slit or

rewound rolls if the turns are not exactly coincident.

5.2.2 Apparatus

Vernier calipers with a scale length not less than the roll width according to ISO 3599.

5.2.3 Test specimen

One roll of tape.

5.2.4 Conditioning

Conditioning shall conform to Clause 3 with the exception that it is not necessary to remove

any layers unless damaged.

5.2.5 Procedure

Hold the roll so that the cut edges are in a vertical plane. If the outer turns of the tape on the

roll have crushed or damaged cut edges, these should be discarded prior to measurement.

Hold the calipers so that the scale shaft is in the horizontal plane.

Carefully close the caliper jaws so as to just touch the cut edges of the outer turns of the roll

of tape, taking the following precautions:

a) do not crush the roll edges;

b) ensure that calliper jaws are perpendicular to cut edges.

Measure the roll width in millimetres to the nearest 0,1 mm.

Carry out two further measurements at equally spaced intervals around the circumference.

5.2.6 Results

Report the mean value as the width of tape in millimetres.

5.3 Method C

This method will only be used where a very high degree of accuracy is required.

Use a travelling microscope with a vernier control on one axis which has an accuracy

of 0,001 mm. Using the specimen obtained and relaxed as in 5.1.2, measure the width to the

– 10 – 60454-2 © IEC:2007

nearest 0,01 mm, taking ten measurements. The width of the tape is taken as the mean value

in milimetres.

6 Determination of roll length

6.1 Principle

The length can be calculated from a measurement of the number of turns of tape on the reel

and a measurement of the outer circumference of the tape and the outer circumference of the

core. Alternatively, length can be measured directly by using a length sensor that includes a

rotating wheel that revolves on the roll of tape as it is being unwound.

For non-extensible tapes the length measured by these methods will be the same as the

length after unrolling.

For extensible tapes the length after unrolling will be greater if the tape is stretched

irreversibly by unrolling.

6.2 Method A – Measurement of turns method

6.2.1 Apparatus (see Figure 1)

a) A measuring device capable of counting both whole revolutions and part revolutions,

continuously driven by a spindle. The spindle has a suitable locking device by means of

which a conical shaft can be quickly fitted to suit the internal diameters of cores for the

rolls of tape. (For example, for a nominal 25 mm internal diameter core the conical shaft

will give a 24,5 mm diameter to 26,5 mm diameter over a shaft length of 50 mm.

Alternative size conical shafts would be needed for tapes on a core with significantly

different nominal diameters, such as 76 mm.)

b) Measuring tape. A narrow, flexible, steel tape (6 mm or narrower) calibrated in milimetres.

6.2.2 Test specimen

One roll of tape.

6.2.3 Procedure

Measure the circumference of the roll C in milimetres by means of a steel tape. Apply the

r

tape to the roll like a belt.

Mount the roll on the conical shaft of the counter. Set the counter to zero and pull the tape

from the roll in a direction perpendicular to the spindle. Remove all the tape from the core and

record the number of revolutions (to the nearest tenth of a revolution) as read from the

counter when the last turn of tape has left the core: N turns.

Measure the circumference of the core: C mm.

o

6.2.4 Results

Calculate the length (L) of the tape as follows:

C + C

r o

L (metres) = N

2 000

If the length of tape in contact with the core is not to be included in the total length, then

60454-2 © IEC:2007 – 11 –

C + C C

r o o

L = −

(metres) N

2 000 1 000

6.3 Method B – Length sensor method

6.3.1 Apparatus (see Figure 2)

A measuring device capable of measuring the length of a roll of tape in metres by using a

calibrated rotating wheel which rolls, with low torque and contact pressure, against the

circumference of the tape as it unwinds. The apparatus includes a spindle for mounting the

tape, a length sensor, a read-out system and a rotating wind-up roll that can be used to

unwind, either manually or automatically, the roll of tape.

6.3.2 Test specimen

One roll of tape.

6.3.3 Procedure

Mount the roll on the shaft adjacent to the sensor. Position the roll and length sensor so that

the sensor is in contact with the circumference of roll and the leading end of the roll is directly

under the sensor. Set the sensor to zero and manually pull the leading edge of the tape and

fix it to the wind-up roll. At the start of unwinding, ensure that the length sensor maintains

good contact with the roll and does not slip or bind. On completion of unwinding, take the

reading of the length sensor.

6.3.4 Results

Report the length in metres as recorded on the read-out.

7 Corrosion-related properties

7.1 General

The requirements for individual products are given in IEC 60454-3. The test methods will be

selected from those given in this part. When electrolytic corrosion is of significance, i.e. when

fine wire approximately 1 mm in diameter or finer is used, the determination is carried out

according to IEC 60426.

Where required by IEC 60454-3, the test methods for the determination of conductivity, pH

and corrosive sulphur shall be used.

7.2 Preparation of water extract for pH and conductivity determinations

7.2.1 Precautions

Avoid contamination of the material during storage, sampling, preparation of test pieces and

testing.

Ensure that the sample roll and the material taken therefrom are not contaminated by the

atmosphere, particularly the atmosphere of a chemical laboratory, or by contact with bare

hands, and that the implements used for cutting or handling the test piece are chemically

clean.

7.2.2 Test piece

Cut strips of tape, each approximately 25 mm × 6 mm, from the sample roll.

– 12 – 60454-2 © IEC:2007

If a strip is folded, it shall be folded adhesive surface outwards.

7.2.3 Method

Use water having a conductivity not greater than 0,2 mS/m. Make a blank test of the

extraction vessel before each extraction, and if the resultant conductivity exceeds 0,2 mS/m

repeat the test with the same extraction vessel. Change the vessel if the second result also

exceeds this value.

Prepare the extract by putting a ratio of 1 g of tape to 100 ml of water into a borosilicate glass

(high chemical resistance glass) or quartz flask fitted with a reflux condenser of the same

quality glass or quartz. Use an apparatus with interchangeable conical ground-glass joints

complying with the requirements of ISO 383.

Boil the water gently for 60 min, except in the case of cellulose acetate film tape for which the

period should be 10 min, taking care that the material is not charred. Allow it to cool as rapidly

as possible, taking precautions against admission of carbon dioxide (e.g. CO trap).

7.2.4 Quantity

Sufficient quantity of extracts should be prepared so that pH and conductivity are measured

on separate portions of the extracts.

7.3 Determination of pH value of water extract

Determine the pH value at a temperature of (23 ± 2) °C according to 8.2 of ISO 3071.

7.4 Determination of conductivity of water extract

7.4.1 Apparatus

The following apparatus is required.

7.4.1.1 A suitable conductivity cell which may consist of two inert electrodes, e.g., platinized

platinum maintained at a fixed distance apart and adequately insulated from each other.

7.4.1.2 A measuring instrument capable of measuring conductance or admittance with an

accuracy of 5 % and a minimum reading of 1 μS in the frequency range 50 Hz to 3 000 Hz at

a voltage not exceeding 100 V; alternatively, resistance may be measured to the same

accuracy.

NOTE 1 It is important that any insulation immersed in the test liquid should not be water absorbent or subject to

contamination by aqueous electrolytes.

NOTE 2 The conductivity cell should be easy to clean and free from recesses where impurities can be retained.

NOTE 3 Care should be taken to ensure that the electrodes do not become polarized.

NOTE 4 Platinized platinum electrodes are platinum-coated with platinum black.

7.4.2 Determination of electrical conductivity

7.4.2.1 General

Determination of the conductivity cell constant. If not known, determine the conductivity cell

–1

constant K (m ) using the method specified in IEC 60589.

NOTE For test apparatus, where the cell constant is calibrated into the apparatus electronics, this step is not

necessary.

60454-2 © IEC:2007 – 13 –

7.4.2.2 Determination of the conductivity of the blank

After thoroughly cleaning the conductivity cell with water as specified in 7.2.3, fill it with water

obtained as a result of the blank extraction test, and measure its conductivity G in mS/m at

(23 ± 2) °C. The conductivity of the blank in mS/m is then KG .

7.4.2.3 Determination of the conductivity of the water extract

Thoroughly rinse the conductivity cell with the extract to be tested, and then fill with the

extract. Adjust the temperature to (23 ± 2) °C, maintain for 15 min and then measure the

conductivity G in mS/m at that temperature.

The conductivity of the water extract in mS/m is then calculated as K(G – G ).

2 1

NOTE For most purposes, where it is not convenient to test the water extract at (23 ± 2) °C, it is sufficiently

accurate to apply the following correction:

G

Conductivity at 23 °C =

1+ 0,02 (t − 23)

where G is the conductivity obtained when the measurement is made at t °C.

7.4.3 Results

Express the conductivity in mS/m at a temperature of 23 °C.

7.5 Detection of corrosive sulfur

7.5.1 Test specimens

Cut two test specimens, each 100 mm long, from the sample roll.

7.5.2 Apparatus

Three smooth copper rods are required, each approximately 6 mm in diameter and 75 mm

long, cleaned and polished with water and silicon carbide powder size 90 μm to 125 μm and

wiped clean and dried with cotton wool or filter paper. Finally the rods are washed with a

volatile sulfur-free solvent, such as diethyl ether, and allowed to dry.

7.5.3 Method

Handle the copper rods with clean, dry metal forceps. Wind two of the copper rods centrally

with approximately 100 mm of tape so that succeeding layers are superimposed one on

another. Leave at least 12 mm at each end of the copper rods clear of tape.

NOTE Tapes above 50 mm in width should be slit to allow the copper rods to be bare at each end for the required

12 mm.

Apply the tape to the first rod, adhesive side downwards in contact with the copper, and to the

second rod, adhesive side upwards with the tape backing in contact with the copper. Leave

the third rod bare to act as a control.

Place each rod in a separate glass-stoppered, chemically cleaned glass tube and maintain

them at a temperature of (100 ± 2) °C for 16 h. Take the rods out of the tubes after they have

cooled to room temperature.

Remove the tapes, together with any exudations that may have occurred, from the rods.

Removal of exudation may be assisted by the use of a solvent but no mechanical abrasive

aids shall be employed.

– 14 – 60454-2 © IEC:2007

Visually examine the copper rods for signs of blue-black staining, characteristic of copper

sulfide. If blue-black staining of the test rods is more intense or extensive than that of the

control rod, such staining is an indication of the presence of corrosive sulfur.

7.5.4 Report

Report whether blue-black staining of the test rods is greater than that of the control rod.

7.6 Insulation resistance method

7.6.1 General

The test shall be performed in accordance with the requirements of Clause 14 of IEC 60426

with the following exceptions.

7.6.2 Test specimens

Samples shall be taken from the roll at intervals of not less than 300 mm.

7.6.3 Electrodes

The electrodes shall have corners rounded to 1 mm radius and shall be constructed from an

inert high conductivity metal, e.g. nickel-plated brass.

7.6.4 Equipment

A means for measuring resistance up to 10 MΩ (1 TΩ) to an accuracy of ±20 % shall be

used. Screened leads, with the screens connected to the guard circuit, should be used for all

connecting purposes.

7.6.5 Results

For tapes less than 25 mm in width, calculate the resistance in Ω/25 mm assuming that

resistance is inversely proportional to width.

7.7 Visual method

The test shall be performed in accordance with the requirements of Clause 3 of IEC 60426.

7.8 Wire tensile strength method

7.8.1 General

The test shall be performed in accordance with the requirements of Clause 9 of IEC 60426

with the following exception.

7.8.2 Test specimens

At least ten specimens shall be tested.

7.8.3 Tensile strength of test wire

The mean value of the breaking load for unexposed wire must be in the range of 7 N to 9 N.

7.8.4 Cleaning of apparatus

Metal parts shall be cleaned with pure, clean methanol followed by distilled water.

60454-2 © IEC:2007 – 15 –

7.8.5 Tensile test equipment

The rate of grip separation shall be the same for the test on exposed and unexposed wires.

8 Tensile strength and elongation at break

8.1 Apparatus

As described in Clause 5 of ISO 527-3.

8.2 Test specimens

Cut five strips of tape, each of sufficient length to give the required initial test length, from the

sample roll at intervals of not less than 300 mm. For tapes having an elongation at break of

50 % or less, the initial test length shall be 200 mm. For tapes having an elongation >50 %,

the test length shall be 100 mm.

The width of the test piece shall be equal to or less than 50 mm.

In the case of tapes wider than 50 mm, cut the test pieces out of the middle of the tape to a

width of 25 mm, using a sharp tool to produce clean-cut edges. For tapes less than 6 mm

wide, edge effects can have a significant effect on these determinations. For tapes below this

width the results should not be used for spe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...