IEC 60335-2-104:2021

(Main)Household and similar electrical appliances - Safety - Part 2-104: Particular requirements for appliances to recover and/or recycle refrigerant from air conditioning and refrigeration equipment

Household and similar electrical appliances - Safety - Part 2-104: Particular requirements for appliances to recover and/or recycle refrigerant from air conditioning and refrigeration equipment

IEC 60335-2-104:2021 deals with the safety of electrical recovery and/or recycle equipment to recover and/or recycle refrigerant from air conditioning and refrigeration equipment. This applies to air-conditioning, heat-pumps and refrigeration equipment incorporating open drive or motor-compressors, their maximum rated voltages being not more than 300 V for single phase appliances and 600 V for all other equipment.

Appliances not intended for normal household use but which nevertheless may be a source of danger to the public, such as appliances intended to be used by service personnel in shops, in light industry and on farms, are within the scope of this standard.

The appliances referenced above may consist of one or more factory made assemblies. If provided in more than one assembly, the separate assemblies are to be used together, and the requirements are based on the use of matched assemblies.

This second edition cancels and replaces the first edition published in 2003. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

a) Clause 1 - The scope has been edited to reflect that "appliance" in this document means recovery and/or recycle equipment to recover and/or recycle refrigerant from air-conditioning and refrigeration equipment.

b) Clause 2 - Normative references were added.

c) Clause 3 - Some definitions were deleted, some were added.

d) Subclause 7.1 - Some markings were deleted, some were added.

e) Subclause 7.6 - Symbols were added for “read operator’s manual”, “operator’s manual; operating instructions” including coloring are placed in visible location; maximum allowable pressure markings following X MPa.

f) Subclause 19.11.4 was modified.

g) Subclause 21.1 was modified.

h) Subclause 21.2 was modified.

i) Subclause 22.102 was modified.

j) Subclause 22.104.1.1 was modified.

k) Subclause 22.104.5 was modified.

l) Subclause 22.104.10 was modified.

m) Subclause 22.104.11 was modified.

n) Subclause 22.105.1 was modified.

o) Subclause 22.107 was modified.

p) Subclause 30.2 was moved to Clause 29.

q) Annex AA was deleted and replaced with Annex AA.

r) Annex BB was deleted and replaced with former IEC 60335-2-104 Annex CC (normative) Compatibility requirements following addition to Annex BB.

s) Annex DD was deleted and replaced with Annex CC.

t) New Annex DD was added.

u) New Annex EE was added.

This part 2 is to be used in conjunction with the fifth edition of IEC 60335-1:2010 and its amendments.

Appareils électrodomestiques et analogues - Sécurité - Partie 2-104: Exigences particulières pour les appareils de récupération et/ou de recyclage des fluides frigorigènes des climatiseurs et des appareils de réfrigération

L'IEC 60335-2-104:2021 traite de la sécurité des appareils électriques de récupération et/ou de recyclage des fluides frigorigènes des climatiseurs et des appareils de réfrigération. Elle s'applique aux climatiseurs, pompes à chaleur et appareils de réfrigération qui comportent des compresseurs à circuit ouvert ou des motocompresseurs, dont la tension maximale assignée n'est pas supérieure à 300 V pour les appareils monophasés et à 600 V pour les autres appareils.

Les appareils non destinés à un usage domestique normal, mais qui peuvent néanmoins constituer une source de danger pour le public, tels que les appareils destinés à être utilisés par le personnel de service dans des magasins, chez des artisans et dans des fermes, relèvent du domaine d'application de la présente norme.

Les appareils indiqués ci-dessus peuvent consister en une ou plusieurs parties assemblées en usine. S'ils sont livrés en plus d'une partie, les différentes parties doivent être utilisées ensemble et les exigences sont fondées sur l'utilisation de ces parties assemblées.

Cette deuxième édition annule et remplace la première édition parue en 2003. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) Article 1 – le domaine d'application a été modifié pour indiquer que le terme "appareil" dans le présent document désigne les appareils de récupération et/ou de recyclage des fluides frigorigènes des climatiseurs et des appareils de réfrigération;

b) Article 2 – des références normatives ont été ajoutées;

c) Article 3 – certaines définitions ont été supprimées, d'autres ont été ajoutées;

d) 7.1 – certains marquages ont été supprimés, d'autres ont été ajoutés;

e) 7.6 – les symboles "lire le manuel de l'opérateur", "manuel de l'opérateur; instructions de fonctionnement", en couleur et placés à un endroit visible, ont été ajoutés; les marquages de la pression maximale admissible sont sous la forme X MPa;

f) le 19.11.4 a été modifié;

g) le 21.1 a été modifié;

h) le 21.2 a été modifié;

i) le 22.102 a été modifié;

j) le 22.104.1.1 a été modifié;

k) le 22.104.5 a été modifié;

l) le 22.104.10 a été modifié;

m) le 22.104.11 a été modifié;

n) le 22.105.1 a été modifié;

o) le 22.107 a été modifié;

p) le 30.2 a été déplacé à l'Article 29;

q) l'Annexe AA a été supprimée et remplacée par l'Annexe AA;

r) l'Annexe BB a été supprimée et remplacée par l'ancienne Annexe CC (normative) Exigences relatives à la compatibilité de l'IEC 60335-2-104, à la suite de l'ajout à l'Annexe BB;

s) l'Annexe DD a été supprimée et remplacée par l'Annexe CC;

t) une nouvelle Annexe DD a été ajoutée;

u) une nouvelle Annexe EE a été ajoutée.

La présente partie 2 doit être utilisée conjointement avec la cinquième édition de l'IEC 60335 1:2010 et ses amendements.

General Information

- Status

- Published

- Publication Date

- 06-May-2021

- Technical Committee

- SC 61D - Appliances for air-conditioning for household and similar purposes

- Drafting Committee

- MT 19 - TC 61/SC 61D/MT 19

- Current Stage

- PPUB - Publication issued

- Start Date

- 07-May-2021

- Completion Date

- 04-Jun-2021

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 05-Sep-2023

Overview

IEC 60335-2-104:2021 - Edition 2.0 (2021) is the international safety standard for electrical appliances that recover and/or recycle refrigerant from air‑conditioning and refrigeration equipment. It applies to service and shop equipment (including units used in light industry and on farms) with maximum rated voltages up to 300 V for single‑phase appliances and 600 V for other equipment. This part 2 standard is intended to be used together with IEC 60335-1:2010 (Part 1) and constitutes a technical revision of the 2003 edition.

Key topics and technical requirements

The standard sets particular safety requirements tailored to refrigerant recovery/recycle appliances and covers a broad set of technical topics, including:

- Scope and definitions specific to recovery/recycle appliances (Clause 1–3)

- Marking and instructions: mandatory markings, symbols (e.g., “read operator’s manual”) and maximum allowable pressure markings (Clause 7)

- Electrical safety: protection against access to live parts, leakage current, electric strength, transient overvoltages, and motor starting (Clauses 8–15)

- Temperature and heating limits: winding and abnormal temperature limits and related test methods (Tables and Annex AA)

- Mechanical construction and strength: stability, mechanical hazards, internal wiring, components, terminals and earthing (Clauses 20–28)

- Pressure and leak integrity: pressure strength tests, pressure values and leak simulation tests (Annexes CC, DD and relevant clauses)

- Compatibility and refrigerant considerations: compatibility testing for refrigerants and refrigerant-containing parts (Annex BB)

- Fire, corrosion and toxic hazards: resistance to heat, fire, rusting and radiation/toxicity checks (Clauses 30–32)

- Documentation: mandatory installation, operating and safety instructions (Annex EE)

Significant technical changes from the 2003 edition include updated normative references, revised definitions, added symbols and markings, multiple subclause modifications, and several new or revised annexes (AA, BB, CC, DD, EE).

Practical applications - who uses this standard

IEC 60335-2-104:2021 is essential for:

- Manufacturers and designers of refrigerant recovery/recycle units - to design safe products compliant with international safety rules.

- Test laboratories and certification bodies - to perform required electrical, mechanical and pressure tests for product approval.

- HVAC-R service equipment suppliers - to ensure equipment used by technicians meets safety and labeling obligations.

- Regulatory authorities and compliance engineers - for adoption into national regulations and market surveillance.

Related standards

- IEC 60335-1:2010 (Part 1) - general requirements for household and similar electrical appliances (this part 2 is to be used in conjunction with Part 1).

- The IEC 60335 series - for other appliance‑specific safety requirements.

Keywords: IEC 60335-2-104:2021, refrigerant recovery, refrigerant recycle, appliance safety, HVAC service equipment, pressure tests, leak simulation, IEC 60335-1.

Buy Documents

IEC 60335-2-104:2021 - Household and similar electrical appliances - Safety - Part 2-104: Particular requirements for appliances to recover and/or recycle refrigerant from air conditioning and refrigeration equipment Released:5/7/2021

IEC 60335-2-104:2021 RLV - Household and similar electrical appliances - Safety - Part 2-104: Particular requirements for appliances to recover and/or recycle refrigerant from air conditioning and refrigeration equipment Released:5/7/2021

IEC 60335-2-104:2021 - Appareils électrodomestiques et analogues - Sécurité - Partie 2-104: Exigences particulières pour les appareils de récupération et/ou de recyclage des fluides frigorigènes des climatiseurs et des appareils de réfrigération/7/2021

IEC 60335-2-104:2021 - Household and similar electrical appliances - Safety - Part 2-104: Particular requirements for appliances to recover and/or recycle refrigerant from air conditioning and refrigeration equipment/7/2021

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC 60335-2-104:2021 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Household and similar electrical appliances - Safety - Part 2-104: Particular requirements for appliances to recover and/or recycle refrigerant from air conditioning and refrigeration equipment". This standard covers: IEC 60335-2-104:2021 deals with the safety of electrical recovery and/or recycle equipment to recover and/or recycle refrigerant from air conditioning and refrigeration equipment. This applies to air-conditioning, heat-pumps and refrigeration equipment incorporating open drive or motor-compressors, their maximum rated voltages being not more than 300 V for single phase appliances and 600 V for all other equipment. Appliances not intended for normal household use but which nevertheless may be a source of danger to the public, such as appliances intended to be used by service personnel in shops, in light industry and on farms, are within the scope of this standard. The appliances referenced above may consist of one or more factory made assemblies. If provided in more than one assembly, the separate assemblies are to be used together, and the requirements are based on the use of matched assemblies. This second edition cancels and replaces the first edition published in 2003. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) Clause 1 - The scope has been edited to reflect that "appliance" in this document means recovery and/or recycle equipment to recover and/or recycle refrigerant from air-conditioning and refrigeration equipment. b) Clause 2 - Normative references were added. c) Clause 3 - Some definitions were deleted, some were added. d) Subclause 7.1 - Some markings were deleted, some were added. e) Subclause 7.6 - Symbols were added for “read operator’s manual”, “operator’s manual; operating instructions” including coloring are placed in visible location; maximum allowable pressure markings following X MPa. f) Subclause 19.11.4 was modified. g) Subclause 21.1 was modified. h) Subclause 21.2 was modified. i) Subclause 22.102 was modified. j) Subclause 22.104.1.1 was modified. k) Subclause 22.104.5 was modified. l) Subclause 22.104.10 was modified. m) Subclause 22.104.11 was modified. n) Subclause 22.105.1 was modified. o) Subclause 22.107 was modified. p) Subclause 30.2 was moved to Clause 29. q) Annex AA was deleted and replaced with Annex AA. r) Annex BB was deleted and replaced with former IEC 60335-2-104 Annex CC (normative) Compatibility requirements following addition to Annex BB. s) Annex DD was deleted and replaced with Annex CC. t) New Annex DD was added. u) New Annex EE was added. This part 2 is to be used in conjunction with the fifth edition of IEC 60335-1:2010 and its amendments.

IEC 60335-2-104:2021 deals with the safety of electrical recovery and/or recycle equipment to recover and/or recycle refrigerant from air conditioning and refrigeration equipment. This applies to air-conditioning, heat-pumps and refrigeration equipment incorporating open drive or motor-compressors, their maximum rated voltages being not more than 300 V for single phase appliances and 600 V for all other equipment. Appliances not intended for normal household use but which nevertheless may be a source of danger to the public, such as appliances intended to be used by service personnel in shops, in light industry and on farms, are within the scope of this standard. The appliances referenced above may consist of one or more factory made assemblies. If provided in more than one assembly, the separate assemblies are to be used together, and the requirements are based on the use of matched assemblies. This second edition cancels and replaces the first edition published in 2003. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) Clause 1 - The scope has been edited to reflect that "appliance" in this document means recovery and/or recycle equipment to recover and/or recycle refrigerant from air-conditioning and refrigeration equipment. b) Clause 2 - Normative references were added. c) Clause 3 - Some definitions were deleted, some were added. d) Subclause 7.1 - Some markings were deleted, some were added. e) Subclause 7.6 - Symbols were added for “read operator’s manual”, “operator’s manual; operating instructions” including coloring are placed in visible location; maximum allowable pressure markings following X MPa. f) Subclause 19.11.4 was modified. g) Subclause 21.1 was modified. h) Subclause 21.2 was modified. i) Subclause 22.102 was modified. j) Subclause 22.104.1.1 was modified. k) Subclause 22.104.5 was modified. l) Subclause 22.104.10 was modified. m) Subclause 22.104.11 was modified. n) Subclause 22.105.1 was modified. o) Subclause 22.107 was modified. p) Subclause 30.2 was moved to Clause 29. q) Annex AA was deleted and replaced with Annex AA. r) Annex BB was deleted and replaced with former IEC 60335-2-104 Annex CC (normative) Compatibility requirements following addition to Annex BB. s) Annex DD was deleted and replaced with Annex CC. t) New Annex DD was added. u) New Annex EE was added. This part 2 is to be used in conjunction with the fifth edition of IEC 60335-1:2010 and its amendments.

IEC 60335-2-104:2021 is classified under the following ICS (International Classification for Standards) categories: 27.200 - Refrigerating technology; 71.100.45 - Refrigerants and antifreezes. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60335-2-104:2021 has the following relationships with other standards: It is inter standard links to EN ISO 5149-4:2025, IEC 60335-2-104:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60335-2-104:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60335-2-104 ®

Edition 2.0 2021-05

INTERNATIONAL

STANDARD

colour

inside

Household and similar electrical appliances – Safety –

Part 2-104: Particular requirements for appliances to recover and/or recycle

refrigerant from air conditioning and refrigeration equipment

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60335-2-104 ®

Edition 2.0 2021-05

INTERNATIONAL

STANDARD

colour

inside

Household and similar electrical appliances – Safety –

Part 2-104: Particular requirements for appliances to recover and/or recycle

refrigerant from air conditioning and refrigeration equipment

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 27.200; 71.100.45 ISBN 978-2-8322-9784-1

– 2 – IEC 60335-2-104:2021 © IEC 2021

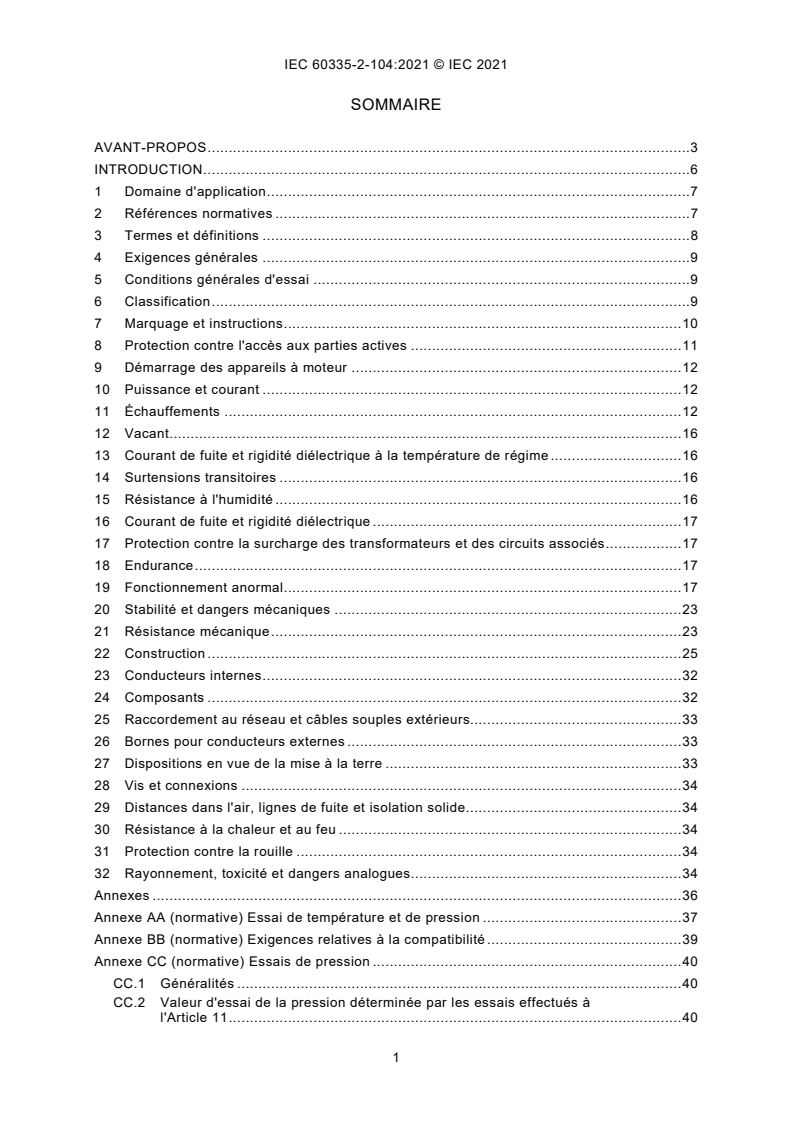

CONTENTS

FOREWORD . 4

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 9

4 General requirement . 10

5 General conditions for the tests . 10

6 Classification . 10

7 Marking and instructions . 11

8 Protection against access to live parts . 12

9 Starting of motor-operated appliances . 13

10 Power input and current . 13

11 Heating . 13

12 Void . 17

13 Leakage current and electric strength at operating temperature . 17

14 Transient overvoltages . 17

15 Moisture resistance . 17

16 Leakage current and electric strength . 18

17 Overload protection of transformers and associated circuits . 18

18 Endurance . 18

19 Abnormal operation . 18

20 Stability and mechanical hazards . 23

21 Mechanical strength . 23

22 Construction . 26

23 Internal wiring . 32

24 Components . 33

25 Supply connection and external flexible cords . 33

26 Terminals for external conductors . 33

27 Provision for earthing . 33

28 Screws and connections . 34

29 Clearances, creepage distances and solid insulation . 34

30 Resistance to heat and fire . 34

31 Resistance to rusting . 34

32 Radiation, toxicity and similar hazards . 34

Annexes . 36

Annex AA (normative) Temperature and pressure test . 37

Annex BB (normative) Compatibility requirements . 39

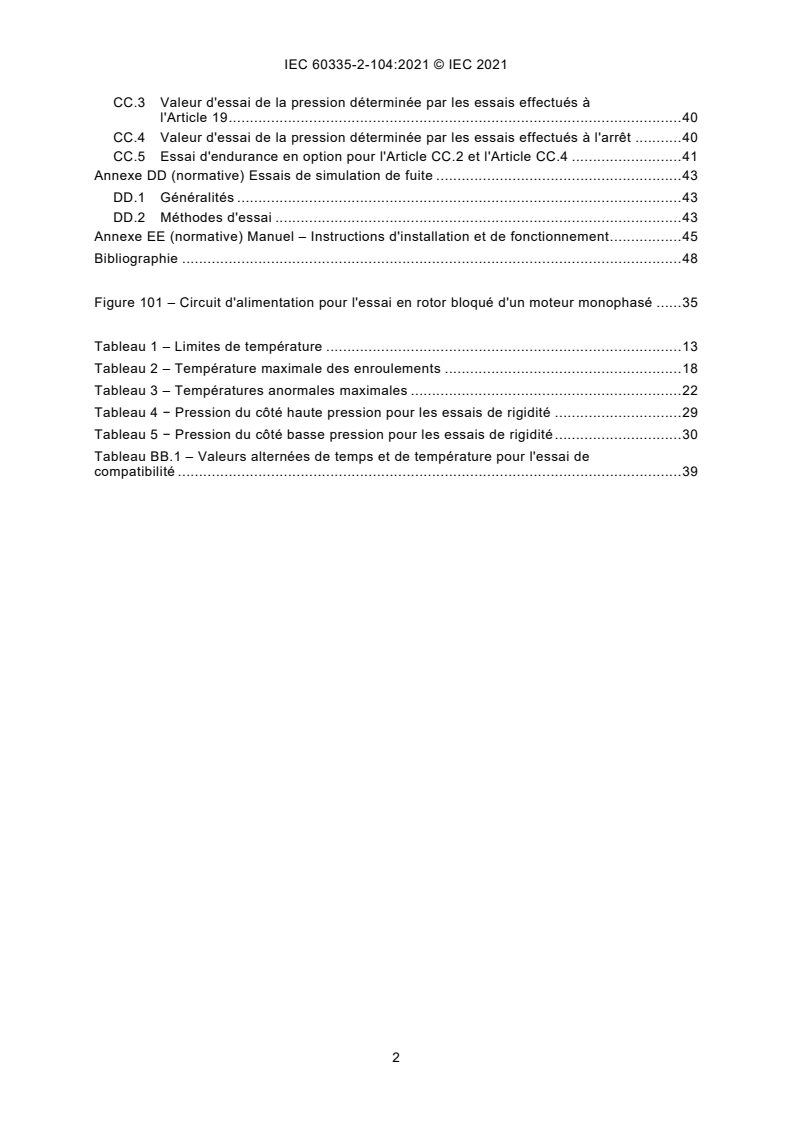

Annex CC (normative) Pressure tests . 40

CC.1 General . 40

CC.2 Pressure test value determined under testing carried out in Clause 11. 40

CC.3 Pressure test value determined under testing carried out in Clause 19. 40

CC.4 Pressure test value determined under testing carried out under standstill

conditions . 40

CC.5 Fatigue test option for Clause CC.2 and CC.4 . 41

Annex DD (normative) Leak simulation tests . 43

DD.1 General . 43

DD.2 Test methods . 43

Annex EE (normative) Manual – Installation and operating instructions . 45

Bibliography . 47

Figure 101 – Supply circuit for locked-rotor test of a motor of the single-phase type . 35

Table 1 – Temperature limits . 14

Table 2 – Maximum winding temperature . 19

Table 3 – Maximum abnormal temperature . 22

Table 4 − High side pressure for strength tests . 30

Table 5 – Low side pressure for strength tests . 30

Table BB.1 – Alternate values of time and temperature for the compatibility test . 39

– 4 – IEC 60335-2-104:2021 © IEC 2021

INTERNATIONAL ELECTROTECHNICAL COMMISSION

_____________

HOUSEHOLD AND SIMILAR ELECTRICAL APPLIANCES –

SAFETY –

Part 2-104: Particular requirements for appliances to recover and/or

recycle refrigerant from air conditioning and refrigeration equipment

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any equipment

declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 60335-2-104 has been prepared by subcommittee 61D: Appliances for air-conditioning for

household and similar purposes, of IEC technical committee 61: Safety of household and similar

electrical appliances. It is an International Standard.

This second edition cancels and replaces the first edition published in 2003. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Clause 1 – The scope has been edited to reflect that "appliance" in this document means

recovery and/or recycle equipment to recover and/or recycle refrigerant from air-

conditioning and refrigeration equipment.

b) Clause 2 – Normative references were added.

c) Clause 3 – Some definitions were deleted, some were added.

d) Subclause 7.1 – Some markings were deleted, some were added.

e) Subclause 7.6 – Symbols were added for “read operator’s manual”, “operator’s manual;

operating instructions” including coloring are placed in visible location; maximum allowable

pressure markings following X MPa.

f) Subclause 19.11.4 was modified.

g) Subclause 21.1 was modified.

h) Subclause 21.2 was modified.

i) Subclause 22.102 was modified.

j) Subclause 22.104.1.1 was modified.

k) Subclause 22.104.5 was modified.

l) Subclause 22.104.10 was modified.

m) Subclause 22.104.11 was modified.

n) Subclause 22.105.1 was modified.

o) Subclause 22.107 was modified.

p) Subclause 30.2 was moved to Clause 29.

q) Annex AA was deleted and replaced with Annex AA.

r) Annex BB was deleted and replaced with former IEC 60335-2-104 Annex CC (normative)

Compatibility requirements following addition to Annex BB.

s) Annex DD was deleted and replaced with Annex CC.

t) New Annex DD was added.

u) New Annex EE was added.

The text of this International Standard is based on the following documents:

Draft Report on voting

61D/472/FDIS 61D/474/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts of the IEC 60335 series, under the general title Household and similar electrical

appliances – Safety, can be found on the IEC website.

This part 2 is to be used in conjunction with the fifth edition of IEC 60335-1:2010 and its

amendments.

NOTE 1 When "Part 1" is mentioned in this standard, it refers to IEC 60335-1.

This part 2 supplements or modifies the corresponding clauses in IEC 60335-1 so as to convert

that publication into the IEC Standard: Safety requirements for electrical appliances to recover

and/or recycle refrigerant from air conditioning and refrigeration equipment.

When a particular subclause of Part 1 is not mentioned in this part 2, that subclause applies as

far as is reasonable. When this standard states "addition", "modification" or "replacement", the

relevant text in Part 1 is to be adapted accordingly.

– 6 – IEC 60335-2-104:2021 © IEC 2021

NOTE 2 The following numbering system is used:

– subclauses, tables and figures that are numbered starting from 101 are additional to those

in Part 1;

– unless notes are in a new subclause or involve notes in Part 1, they are numbered starting

from 101, including those in a replaced clause or subclause;

– additional annexes are lettered AA, BB, etc.

NOTE 3 The following print types are used:

– requirements: in roman type;

– test specifications: in italic type;

– notes: in smaller roman type.

Words in bold in the text are defined in Clause 3. When a definition concerns an adjective, the adjective and the

associated noun are also in bold.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

NOTE 4 The attention of National Committees is drawn to the fact that equipment manufacturers and testing

organizations may need a transitional period following publication of a new, amended or revised IEC publication in

which to make products in accordance with the new requirements and to equip themselves for conducting new or

revised tests.

It is the recommendation of the committee that the content of this publication be adopted for implementation nationally

not earlier than 12 months or later than 36 months from the date of publication.

The following differences exist in the countries indicated below:

• 6.1: Class 01 appliances are allowed (Japan).

• 11.8: The temperature of the wooden walls in the test casing is limited to 85 °C (Sweden).

IMPORTANT – The "colour inside" logo on the cover page of this document indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

INTRODUCTION

It has been assumed in the drafting of this International Standard that the execution of its

provisions is entrusted to appropriately qualified and experienced persons.

This standard recognizes the internationally accepted level of protection against hazards such

as electrical, mechanical, thermal, fire and radiation of appliances when operated as in normal

use taking into account the manufacturer's instructions. It also covers abnormal situations that

can be expected in practice and takes into account the way in which electromagnetic

phenomena can affect the safe operation of appliances.

This standard takes into account the requirements of IEC 60364 as far as possible so that there

is compatibility with the wiring rules when the appliance is connected to the supply mains.

However, national wiring rules may differ.

If an appliance within the scope of this standard also incorporates functions that are covered

by another part 2 of IEC 60335, the relevant part 2 is applied to each function separately, as

far as is reasonable. If applicable, the influence of one function on the other is taken into

account.

When a part 2 standard does not include additional requirements to cover hazards dealt with in

Part 1, Part 1 applies.

NOTE 1 This means that the technical committees responsible for the part 2 standards have determined that it is

not necessary to specify particular requirements for the appliance in question over and above the general

requirements.

This standard is a product family standard dealing with the safety of appliances and takes

precedence over horizontal and generic standards covering the same subject.

NOTE 2 Horizontal and generic standards covering a hazard are not applicable since they have been taken into

consideration when developing the general and particular requirements for the IEC 60335 series of standards. For

example, in the case of temperature requirements for surfaces on many appliances, generic standards, such as

ISO 13732-1 for hot surfaces, are not applicable in addition to Part 1 or part 2 standards.

An appliance that complies with the text of this standard will not necessarily be considered to

comply with the safety principles of the standard if, when examined and tested, it is found to

have other features that impair the level of safety covered by these requirements.

An appliance employing materials or having forms of construction differing from those detailed

in the requirements of this standard may be examined and tested according to the intent of the

requirements and, if found to be substantially equivalent, may be considered to comply with the

standard.

– 8 – IEC 60335-2-104:2021 © IEC 2021

HOUSEHOLD AND SIMILAR ELECTRICAL APPLIANCES –

SAFETY –

Part 2-104: Particular requirements for appliances to recover and/or

recycle refrigerant from air conditioning and refrigeration equipment

1 Scope

This clause of Part 1 is replaced by the following:

This part of IEC 60335 deals with the safety of electrical recovery and/or recycle equipment

to recover and/or recycle refrigerant from air conditioning and refrigeration equipment. This

applies to air-conditioning, heat-pumps and refrigeration equipment incorporating open drive or

motor-compressors, their maximum rated voltages being not more than 300 V for single phase

appliances and 600 V for all other equipment.

Appliances not intended for normal household use but which nevertheless may be a source of

danger to the public, such as appliances intended to be used by service personnel in shops, in

light industry and on farms, are within the scope of this standard.

The appliances referenced above may consist of one or more factory made assemblies. If

provided in more than one assembly, the separate assemblies are to be used together, and the

requirements are based on the use of matched assemblies.

NOTE 101 In this document, the term appliance is to denote recovery equipment.

2 Normative references

This clause of Part 1 is applicable except as follows.

Replacement:

IEC 60065:2014, Audio, video and similar electronic apparatus − Safety requirements

Addition:

IEC 60079-14, Explosive atmospheres – Part 14: Electrical installations design, selection and

erection

IEC 60079-15:2010 , Explosive atmospheres – Part 15: Equipment protection by type of

protection "n"

IEC 600320 (all parts), Appliance couplers for household and similar general purposes

IEC 60335-2-34:2012, Household and similar electrical appliances – Safety – Part 2-34:

Particular requirements for motor-compressors

____________

Withdrawn.

IEC 60335-2-40:2018, Household and similar electrical appliances – Safety – Part 2-40:

Particular requirements for electrical heat pumps, air-conditioners and dehumidifiers

IEC 62640:2011, Residual current devices with or without overcurrent protection for socket-

outlets for household and similar uses

IEC 62640:2011/AMD1:2015

ISO 5149-2, Refrigerating systems and heat pumps – Safety and environmental requirements

– Part 2: Design, construction, testing, marking and documentation

ISO 817:2014, Refrigerants – Designation and safety classification

ISO 817:2014/AMD1:2017

ASTM D4728-17, Standard Test Method for Random Vibration Testing of Shipping Containers

SAE J2210 HFC-134a (R-134a), Recovery/Recycling Equipment for Mobile Air-Conditioning

Systems

SAE J2843 R-1234yf [HFO-1234yf], Recovery/Recycling/Recharging Equipment for Flammable

Refrigerants for Mobile Air-Conditioning Systems

SAE J3030, Automotive Refrigerant Recovery/Recycling/Recharging Equipment Intended for

use with Both R-1234yf and R-134a

3 Terms and definitions

This clause of part 1 is applicable except as follows.

3.1.6

rated current

Note 101 to entry: If the appliance comprises electrical accessories, including fans, the rated current is based

upon the total maximum electrical power input with all accessories energized, when operating continuously under

the appropriate environmental conditions.

Replacement:

3.1.9

normal operation

conditions that apply when the appliance is mounted as in normal use and is operating under

the most severe operating conditions specified by the manufacturer

3.101

compressor

open drive compressor or motor-compressor (hermetically sealed) with the suction side (low

pressure side) which is intended to be temporarily connected to the appliance’s low pressure

side to remove refrigerant

3.102

pressure-limiting device

mechanism that automatically responds to a predetermined pressure by stopping the operation

of the pressure-imposing element

3.104

recovery

pumping out (removal) of refrigerant from air conditioning or refrigeration equipment

– 10 – IEC 60335-2-104:2021 © IEC 2021

3.105

recycle

pumping out (removal) and cleaning of refrigerant from air conditioning or refrigeration

equipment

3.106

refrigerant

substance that is classified by ISO 817 as A1, A2L, A2, A3 or B1

3.107

flammable refrigerant

substance that is classified by ISO 817 as A2L, A2, or A3

3.108

recovery cylinder

receptacle used for recovered refrigerant

3.109

scale

weighing device which is capable of measuring recovered refrigerant

4 General requirement

This clause of Part 1 is applicable.

5 General conditions for the tests

This clause of Part 1 is applicable except as follows.

Replacement:

5.7 The tests and test conditions of Clause 10 and Clause 11 are carried out under conditions

as in 11.4 or under the most severe operating conditions within the operating temperature range

specified by the manufacturer.

6 Classification

This clause of Part 1 is applicable except as follows.

Modification:

6.1 Appliances shall be of one of the following classes with respect to protection against

electric shock:

class I, class II or class III.

Compliance is checked by inspection and by the relevant tests.

6.2 Addition:

Appliances shall be classified according to degree of protection against harmful ingress of water

in accordance with IEC 60529:

– appliances or parts of appliances intended for outdoor use shall be at least IPX4;

– appliances intended only for indoor use may be IPX0.

7 Marking and instructions

This clause of Part 1 is applicable except as follows.

7.1 Modification:

Replace the second dash by:

– symbol for nature of supply including number of phases, unless for single phase operation;

Replace the third dash by:

– rated current in amperes;

Addition:

– rated frequency;

– IP rating;

– maximum high and low side pressure;

– each applicable refrigerant for which the appliance is rated;

– for each refrigerant, one of the following:

• the chemical name;

• the refrigerant number (R designation) per ISO 817;

– the recovery cylinder shall meet the pressure of the refrigerant being recovered. Maximum

allowable pressure for the refrigerant circuit; if the permissible excessive operating

pressure for the suction and discharge side differ, a separate indication is required;

– appliances (recovery equipment) intended for use in service garages or other

environments where flammable gases may be present shall be marked: "This appliance

should be used in locations with mechanical ventilation that provides at least four air

changes per hour;

– recovery equipment intended for use in service garages that are covered by SAE J

standards covering recovery equipment for flammable equipment shall be exempt from this

marking and fall under the appropriate SAE or VDA standard.

For flammable refrigerants, any tubing or other devices through which the refrigerant is

intended to be serviced shall be painted or colored red. This color shall be present at all places

where service puncturing, or otherwise creating an opening in the refrigerant circuit might be

expected. In the case of a process tube on a compressor, the color mark shall extend at least

25 mm from the compressor.

– 12 – IEC 60335-2-104:2021 © IEC 2021

7.6 Addition:

Markings shall include the symbols for "read operator’s manual", "operator’s manual; operating

instructions" (symbol ISO 7000-0790 (2004-01)) including colour, and be placed on the

recovery equipment in a location visible to the persons required to know the information. The

perpendicular height of the symbol shall be at least 10 mm.

The maximum allowable pressures shall be marked with symbol ISO 7000-1701 (2004-01)

followed by the text "(X) MPa".

If the recovery equipment is certified for use with flammable refrigerant, the flammable

refrigerant symbol shall be used per ISO 7010-W021 (2011-05) and the perpendicular height

of the triangle shall be at least 30 mm.

[symbol ISO 7000-1641 operator's manual; operating

(2004-01)] instructions

[symbol ISO 7000-1701

pressure

(2004-01)]

(X) MPa

[symbol ISO 7010-W021

warning; flammable material

(2011-05)]

7.15 Addition:

A marking may be located on a panel that can be removed for installation or service, providing

that the panel shall be in place for the normal operation of the appliance.

7.101 A marking shall be provided for a replaceable fuse or a replaceable overload protective

device provided as a part of a product. It shall be visible when the cover or door of the

compartment is open. This marking shall specify

– the rating of the fuse in amperes, the type and voltage rating, or

– the manufacturer and model designation of the replaceable overload protective device.

8 Protection against access to live parts

This clause of Part 1 is applicable.

9 Starting of motor-operated appliances

This clause of Part 1 is not applicable.

10 Power input and current

This clause of Part 1 is applicable.

11 Heating

This clause of Part 1 is replaced by the following.

11.1 Appliances and their surroundings shall not attain excessive temperatures in normal use.

Compliance is checked by determining the temperatures of the various parts under the

conditions specified in 11.2 to 11.7. Nevertheless, if the temperature of the motor winding

exceeds the value specified in Table 1 or if there is a doubt with regard to the classification of

the insulation system employed in a motor, compliance is checked by the tests of Annex C.

11.2 The appliance is installed in a test room in accordance with the manufacturer’s

installation instructions. In particular

– clearances to adjacent surfaces specified by the manufacturer shall be maintained;

– adjustable limit controls are set at the maximum cut-out setting and the minimum differential

permitted by the control adjusting means.

11.3 Temperatures are determined by means of fine-wire thermocouples so chosen and

positioned that they have the minimum effect on the temperature of the part under test.

NOTE 101 Thermocouples having wires with a diameter not exceeding 0,3 mm are considered to be fine-wire

thermocouples.

The temperature of motor windings or of coils may be measured by the change-in-resistance

method.

Thermocouples used for determining the temperatures of the surface of walls, ceiling and floor

are embedded in the surface or attached to the back of small blackened disks of copper or

brass, 15 mm in diameter and 1 mm thick, which are flush with the surface.

So far as is possible, the appliance is positioned so that parts likely to attain the highest

temperatures touch the disks.

In determining the temperatures of handles, knobs, grips and the like, consideration is given to

all parts which are gripped in normal use and, if of insulating material, to parts in contact with

hot metal.

The temperature of electrical insulation, other than that of windings, is determined on the

surface of the insulation, at places where failure could cause a short circuit, contact between

live parts and accessible metal parts, bridging of insulation or reduction of creepage distances

or clearances below the values specified in 29.1.

11.4 Appliance is operated at normal operating voltage in a test room maintained at 43 °C or

at the maximum temperature specified by the manufacturer if higher, until temperatures reach

stabilisation.

– 14 – IEC 60335-2-104:2021 © IEC 2021

11.5 Appliances of the water-cooled type shall be operated with the water flow maintained at

the most severe condition as specified by the manufacturer.

11.6 All appliances are operated continuously until steady state conditions are obtained. All

appliances shall be operated according to the conditions in Annex AA.

11.7 During the test, the temperatures and pressures are monitored continuously and shall

not exceed the values shown in Table 1. Protective devices shall not operate and sealing

compound shall not flow out. Pressures are recorded and used in Clause 21.

Table 1 – Temperature limits

Part Temperature

°C

a

Windings of sealed motor-compressors

– with synthetic insulation

– with other insulation

External enclosures of sealed motor-compressors or of any other motor

b

Windings if the winding insulation is (other than motor-compressors):

c

– of class A material 100 (90)

c

– of class E material 115 (105)

c

– of class B material 120 (110)

c

– of class F material 140

c

– of class H material 165

– of class 200

– of class 220

– of class 250

Terminals, including earthing terminals, for external conductors of stationary appliances,

unless they are provided with a supply cord

d

Ambient of switches, and thermostats and temperature limiters

– without T marking

– with T marking

T

Rubber or polyvinyl chloride insulation of internal and external wiring, including supply

cords:

e

– without temperature rating 75

– with temperature rating (T)

T

Cord sheaths used as supplementary insulation

Rubber, other than synthetic, used for gaskets or other parts, the deterioration of which could

affect safety:

– when used as a supplementary insulation or reinforced insulation

– in other cases

Lampholders B22, E26 and E27:

– metal or ceramic type

– insulated type, other than ceramic

– with T-marking

T

Lampholders E14 and B15:

– metal or ceramic type 155

– insulated type, other than ceramic

– with T-marking

T

Part Temperature

°C

Material used as insulation other than that specified for wires and windings:

– impregnated or varnished textile, paper or press board

– laminated bonded with:

• melamine-formaldehyde, phenol-formaldehyde or phenol-furfural resins

• urea-formaldehyde resin

– printed circuit boards bonded with epoxy resin

– moulding of:

• phenol-formaldehyde with cellulose fillers

• phenol-formaldehyde with mineral fillers

• melamine-formaldehyde

• urea-formaldehyde

– polyester with glass-fibre reinforcement

– silicone rubber

– polytetrafluoroethylene

– pure mica and tightly sintered ceramic material, when such materials are used as

supplementary insulation or reinforced insulation

f

– thermoplastic material -

g

Wood, in general 90

Wooden walls of the test casing

h

Outer surface of capacitors

i

T

– with marking of maximum operating temperature (T)

– without marking of maximum operating temperature:

• small ceramic capacitors for radio and television interference suppression

• capacitors complying with IEC 60384-14 or 14.2 of IEC 60065:2014

• other capacitors

External enclosure of appliances without supplementary heater

Handles, knobs, grips and the like and all parts which are gripped in normal use:

– of metal

– of porcelain or vitreous material

– of moulded material, rubber or wood

Parts in contact with oil having a flash-point of t °C

t-25

Any point where the insulation of wires can come into contact with parts of a terminal block

or compartment for fixed wiring of a stationary appliance not provided with a supply cord:

– if the instructions require the use of supply wires with a temperature rating (T)

T

e

– in other cases 75

– 16 – IEC 60335-2-104:2021 © IEC 2021

a

Not required for motor-compressors that comply with IEC 60335-2-34.

b

The temperatures within parentheses apply when thermocouples are used. The figures without parentheses

apply when the resistance method is used.

c

The classification is in accordance with IEC 60085.

Examples of class A material are:

– impregnated cotton, silk, artificial silk and paper,

– enamels based on oleo or polyamide resins.

Examples of class B materials are:

– glass fibre, melamine-formaldehyde and phenol-formaldehyde resins.

Examples of class E materials are:

– mouldings with cellulose fillers, cotton fabric laminates and paper laminates, materials bonded with melamine-

formaldehyde, phenol-formaldehyde or phenol-furfural resins;

– cross-linked polyester resins, cellulose triacetate films, polyethylene terephthalate films;

– varnished polyethylene terephthalate textile bonded with oil-modified alkyd resin varnish;

– enamels based on polyvinyl formalin, polyurethane or epoxy resins.

For totally enclosed motors, the temperature limits for Class A, Class E and Class B materials may be

increased by 5 °C (5 K).

A totally enclosed motor is a motor so constructed that the circulation of the air between the inside and the

outside of the case is prevented, but which is not necessarily sufficiently enclosed to be called airtight.

d

T means the maximum operating temperature. The ambient temperature of switches and thermostats is the

temperature of the air at the hottest point at a distance of 5 mm from the surface of the switch and thermostat

concerned. For the purpose of this test, switches and thermostats marked with the individual ratings may be

considered as having no marking for the maximum operating temperature, if this is requested by the

manufacturer of the appliance.

e

This limit applies to cables, cords and wires complying with the relevant IEC standards; for others, it may be

different.

f

There is no specific limit for thermoplastic material, which shall withstand the tests of 30.1 or 30.2 of Part 1, for

which purpose the temperature shall be measured.

g

The limit specified concerns the deterioration of wood and it does not take into account the deterioration of

surface finishes.

h

There is no limit for the temperature rise of capacitors which are short-circuited in 19.7.

i

Temperature marking for capacitors mounted on printed circuit boards may be given in the technical sheet.

If these or other materials are used, they shall not be subjected to temperatures in excess of the thermal

capabilities as determined by aging tests made on the materials themselves.

NOTE 101 The value of the temperature of a winding is calculated from the formula:

R

T = (k+ T )− k

R

where

T is the temperature of the copper winding at the end of the test;

R is the resistance at the beginning of the test;

R is the resistance at the end of the test;

T is the ambient temperature at the beginning of the test;

k is equal to 234,5 for copper windings and 225 for aluminium windings.

At the beginning of the test, the windings are at ambient temperature.

the resistance of windings at the end of the test is determined by taking resistance measurements as soon as possible

after switching off, and then at short intervals so that a curve of resistance against time can be plotted for

ascerTaining the resistance at the instant of switching off.

12 Void

13 Leakage current and electric strength at operating temperature

This clause of Part 1 is applicable except as follows.

13.2 Modification:

For permanently connected stationary class I recovery equipment, the leakage current shall

not exceed 2 mA per kilowatt at rated power input with a maximum value of 10 mA for

appliances accessible to the general public, and a maximum value of 30 mA for appliances not

accessible to the general public.

14 Transient overvoltages

This clause of Part 1 is applicable.

15 Moisture resistance

This clause of Part 1 is replaced by the following.

15.1 Electrical components of appliances shall be protected against the ingress of water which

may be present in the appliance.

Compliance is checked by the tests of 15.2, followed immediately by the spillage test of 15.3,

and this is followed by the tests of 11.6 and the tests of Clause 16.

Following these tests, an inspection is made within the enclosures. The water which may have

entered the enclosure shall not have reduced the creepage distances and clearances below the

minimum values specified in Clause 29.

NOTE 101 Appliances designed to be installed completely inside a building and which have no outdoor parts are

not subjected to the test of 15.2.

The motor-compressor is not operated during the tests of 15.2 and 15.3.

15.2 Appliances other than IPXO are subjected to the tests of IEC 60529:1989 as follows:

– IPX1 appliances as described in 14.2.1;

– IPX2 appliances as described in 14.2.2;

– IPX3 appliances as described in 14.2.3;

– IPX4 appliances as described in 14.2.4;

– IPX5 appliances as described in 14.2.5;

– IPX6 appliances as described in 14.2.6;

– IPX7 appliances as described in 14.2.7.

For this test, the appliance is immersed in water containing 1 % NaCI by weight.

– 18 – IEC 60335-2-104:2021 © IEC 2021

15.3 The appliance is installed according to the manufacturer's installation instructions, but

not operated. Covers which provide access for manual operation of electrical controls are set

in the open position, unless such covers are of the self-closing type. A solution of 0,25 l of water

containing 2,5 g of ordinary table salt is poured onto the unit in a manner most likely to cause

entrance of the water into or on electrical controls or uninsulated live parts. After the spillage

is completed, the appliance shall withstand the tests of Clause 16. The spillage test is not

applicable to units if the minimum dimension of a horizontal or near horizontal top surface of

the cabinet is 75 mm or less.

16 Leakage current and electric strength

This clause of Part 1 is applicable except as follows.

16.2 Modification:

For permanently connected stationary class I appliances, the leakage current shall not exceed

2 mA per kilowatt of rated power input, with a maximum value of 10 mA for appliances

accessible to the general public and a maximum value of 30

...

IEC 60335-2-104 ®

Edition 2.0 2021-05

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Household and similar electrical appliances – Safety –

Part 2-104: Particular requirements for appliances to recover and/or recycle

refrigerant from air conditioning and refrigeration equipment

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 18 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60335-2-104 ®

Edition 2.0 2021-05

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Household and similar electrical appliances – Safety –

Part 2-104: Particular requirements for appliances to recover and/or recycle

refrigerant from air conditioning and refrigeration equipment

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 27.200; 71.100.45 ISBN 978-2-8322-9788-9

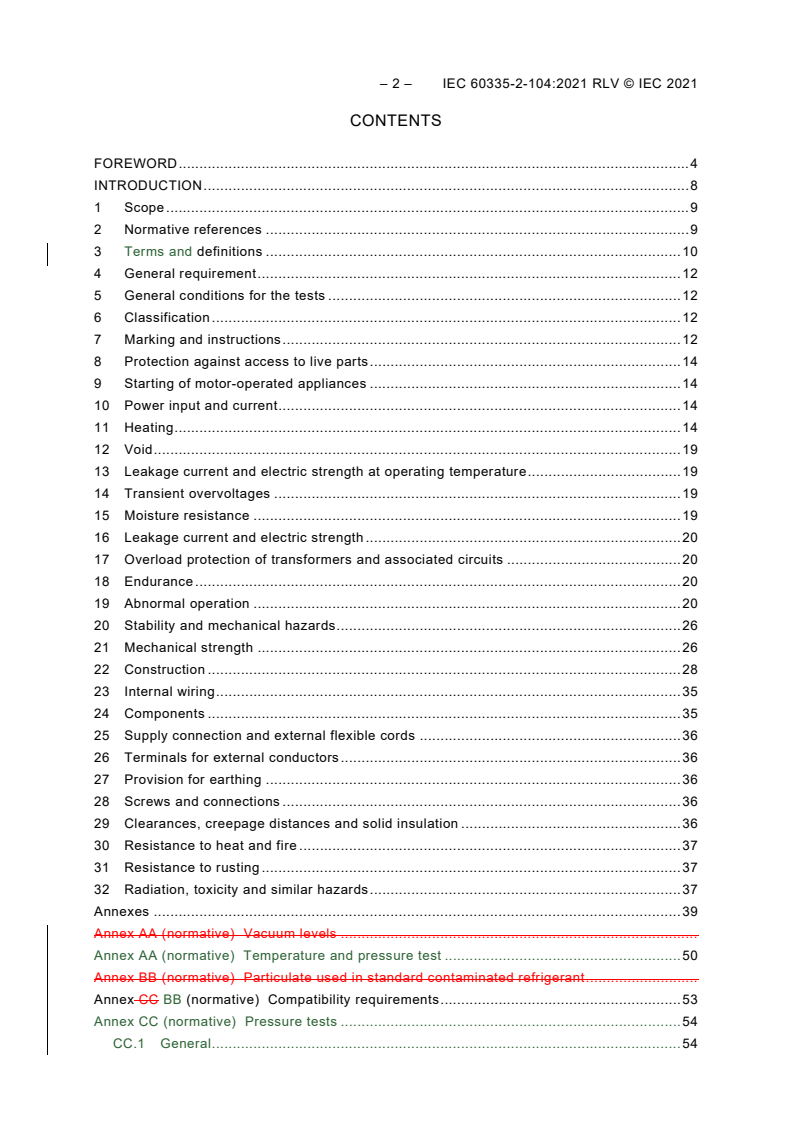

– 2 – IEC 60335-2-104:2021 RLV © IEC 2021

CONTENTS

FOREWORD . 4

INTRODUCTION . 8

1 Scope . 9

2 Normative references . 9

3 Terms and definitions . 10

4 General requirement . 12

5 General conditions for the tests . 12

6 Classification . 12

7 Marking and instructions . 12

8 Protection against access to live parts . 14

9 Starting of motor-operated appliances . 14

10 Power input and current . 14

11 Heating . 14

12 Void . 19

13 Leakage current and electric strength at operating temperature . 19

14 Transient overvoltages . 19

15 Moisture resistance . 19

16 Leakage current and electric strength . 20

17 Overload protection of transformers and associated circuits . 20

18 Endurance . 20

19 Abnormal operation . 20

20 Stability and mechanical hazards . 26

21 Mechanical strength . 26

22 Construction . 28

23 Internal wiring . 35

24 Components . 35

25 Supply connection and external flexible cords . 36

26 Terminals for external conductors . 36

27 Provision for earthing . 36

28 Screws and connections . 36

29 Clearances, creepage distances and solid insulation . 36

30 Resistance to heat and fire . 37

31 Resistance to rusting . 37

32 Radiation, toxicity and similar hazards . 37

Annexes . 39

Annex AA (normative) Vacuum levels .

Annex AA (normative) Temperature and pressure test . 50

Annex BB (normative) Particulate used in standard contaminated refrigerant .

Annex CC BB (normative) Compatibility requirements . 53

Annex CC (normative) Pressure tests . 54

CC.1 General . 54

CC.2 Pressure test value determined under testing carried out in Clause 11. 54

CC.3 Pressure test value determined under testing carried out in Clause 19. 54

CC.4 Pressure test value determined under testing carried out under standstill

conditions . 54

CC.5 Fatigue test option for Clause CC.2 and CC.4 . 55

Annex DD (normative) Requirements for swelling oil .

Annex DD (normative) Leak simulation tests . 58

DD.1 General . 58

DD.2 Test methods . 58

Annex EE (normative) Manual – Installation and operating instructions . 60

Bibliography . 62

Figure 101 – Supply circuit for locked-rotor test of a motor of the single-phase type . 38

Table 3 1 – Temperature limits. 16

Table 8 2 – Maximum winding temperature . 21

Table 9 3 – Maximum abnormal temperature . 25

Table 4 − High side pressure for strength tests . 32

Table 5 – Low side pressure for strength tests . 33

Table AA.1 – Standard contaminated refrigerant samples .

Table BB.1 – Weight % in various size ranges pm .

Table CC.1 BB.1 – Alternate values of time and temperature for the compatibility test . 53

– 4 – IEC 60335-2-104:2021 RLV © IEC 2021

INTERNATIONAL ELECTROTECHNICAL COMMISSION

_____________

HOUSEHOLD AND SIMILAR ELECTRICAL APPLIANCES –

SAFETY –

Part 2-104: Particular requirements for appliances to recover and/or

recycle refrigerant from air conditioning and refrigeration equipment

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any equipment

declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes made to

the previous edition IEC 60335-2-104:2003. A vertical bar appears in the margin wherever a

change has been made. Additions are in green text, deletions are in strikethrough red text.

IEC 60335-2-104 has been prepared by subcommittee 61D: Appliances for air-conditioning for

household and similar purposes, of IEC technical committee 61: Safety of household and similar

electrical appliances. It is an International Standard.

This second edition cancels and replaces the first edition published in 2003. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Clause 1 – The scope has been edited to reflect that "appliance" in this document means

recovery and/or recycle equipment to recover and/or recycle refrigerant from air-

conditioning and refrigeration equipment.

b) Clause 2 – Normative references were added.

c) Clause 3 – Some definitions were deleted, some were added.

d) Subclause 7.1 – Some markings were deleted, some were added.

e) Subclause 7.6 – Symbols were added for “read operator’s manual”, “operator’s manual;

operating instructions” including coloring are placed in visible location; maximum allowable

pressure markings following X MPa.

f) Subclause 19.11.4 was modified.

g) Subclause 21.1 was modified.

h) Subclause 21.2 was modified.

i) Subclause 22.102 was modified.

j) Subclause 22.104.1.1 was modified.

k) Subclause 22.104.5 was modified.

l) Subclause 22.104.10 was modified.

m) Subclause 22.104.11 was modified.

n) Subclause 22.105.1 was modified.

o) Subclause 22.107 was modified.

p) Subclause 30.2 was moved to Clause 29.

q) Annex AA was deleted and replaced with Annex AA.

r) Annex BB was deleted and replaced with former IEC 60335-2-104 Annex CC (normative)

Compatibility requirements following addition to Annex BB.

s) Annex DD was deleted and replaced with Annex CC.

t) New Annex DD was added.

u) New Annex EE was added.

The text of this International Standard is based on the following documents:

Draft Report on voting

61D/472/FDIS 61D/474/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

– 6 – IEC 60335-2-104:2021 RLV © IEC 2021

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts of the IEC 60335 series, under the general title Household and similar electrical

appliances – Safety, can be found on the IEC website.

This part 2 is to be used in conjunction with the fifth edition of IEC 60335-1:2010 and its

amendments.

NOTE 1 When "Part 1" is mentioned in this standard, it refers to IEC 60335-1.

This part 2 supplements or modifies the corresponding clauses in IEC 60335-1 so as to convert

that publication into the IEC Standard: Safety requirements for electrical appliances to recover

and/or recycle refrigerant from air conditioning and refrigeration equipment.

When a particular subclause of Part 1 is not mentioned in this part 2, that subclause applies as

far as is reasonable. When this standard states "addition", "modification" or "replacement", the

relevant text in Part 1 is to be adapted accordingly.

NOTE 2 The following numbering system is used:

– subclauses, tables and figures that are numbered starting from 101 are additional to those

in Part 1;

– unless notes are in a new subclause or involve notes in Part 1, they are numbered starting

from 101, including those in a replaced clause or subclause;

– additional annexes are lettered AA, BB, etc.

NOTE 3 The following print types are used:

– requirements: in roman type;

– test specifications: in italic type;

– notes: in smaller roman type.

Words in bold in the text are defined in Clause 3. When a definition concerns an adjective, the adjective and the

associated noun are also in bold.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

NOTE 4 The attention of National Committees is drawn to the fact that equipment manufacturers and testing

organizations may need a transitional period following publication of a new, amended or revised IEC publication in

which to make products in accordance with the new requirements and to equip themselves for conducting new or

revised tests.

It is the recommendation of the committee that the content of this publication be adopted for implementation nationally

not earlier than 12 months or later than 36 months from the date of publication.

The following differences exist in the countries indicated below:

• 6.1: Class 01 appliances are allowed (Japan).

• 11.8: The temperature of the wooden walls in the test casing is limited to 85 °C (Sweden).

IMPORTANT – The "colour inside" logo on the cover page of this document indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

– 8 – IEC 60335-2-104:2021 RLV © IEC 2021

INTRODUCTION

It has been assumed in the drafting of this International Standard that the execution of its

provisions is entrusted to appropriately qualified and experienced persons.

This standard recognizes the internationally accepted level of protection against hazards such

as electrical, mechanical, thermal, fire and radiation of appliances when operated as in normal

use taking into account the manufacturer's instructions. It also covers abnormal situations that

can be expected in practice and takes into account the way in which electromagnetic

phenomena can affect the safe operation of appliances.

This standard takes into account the requirements of IEC 60364 as far as possible so that there

is compatibility with the wiring rules when the appliance is connected to the supply mains.

However, national wiring rules may differ.

If an appliance within the scope of this standard also incorporates functions that are covered

by another part 2 of IEC 60335, the relevant part 2 is applied to each function separately, as

far as is reasonable. If applicable, the influence of one function on the other is taken into

account.

When a part 2 standard does not include additional requirements to cover hazards dealt with in

Part 1, Part 1 applies.

NOTE 1 This means that the technical committees responsible for the part 2 standards have determined that it is

not necessary to specify particular requirements for the appliance in question over and above the general

requirements.

This standard is a product family standard dealing with the safety of appliances and takes

precedence over horizontal and generic standards covering the same subject.

NOTE 2 Horizontal and generic standards covering a hazard are not applicable since they have been taken into

consideration when developing the general and particular requirements for the IEC 60335 series of standards. For

example, in the case of temperature requirements for surfaces on many appliances, generic standards, such as

ISO 13732-1 for hot surfaces, are not applicable in addition to Part 1 or part 2 standards.

An appliance that complies with the text of this standard will not necessarily be considered to

comply with the safety principles of the standard if, when examined and tested, it is found to

have other features that impair the level of safety covered by these requirements.

An appliance employing materials or having forms of construction differing from those detailed

in the requirements of this standard may be examined and tested according to the intent of the

requirements and, if found to be substantially equivalent, may be considered to comply with the

standard.

HOUSEHOLD AND SIMILAR ELECTRICAL APPLIANCES –

SAFETY –

Part 2-104: Particular requirements for appliances to recover and/or

recycle refrigerant from air conditioning and refrigeration equipment

1 Scope

This clause of Part 1 is replaced by the following:

This part of IEC 60335 deals with the safety of electrical appliances recovery and/or recycle

equipment to recover and/or recycle refrigerant from air conditioning and refrigeration

equipment. This applies to air-conditioning, heat-pumps and refrigeration equipment

incorporating open drive or motor-compressors, their maximum rated voltages being not more

than 250 300 V for single phase appliances and 600 V for all other appliances equipment.

Appliances not intended for normal household use but which nevertheless may be a source of

danger to the public, such as appliances intended to be used by service personnel in shops, in

light industry and on farms, are within the scope of this standard.

The appliances referenced above may consist of one or more factory made assemblies. If

provided in more than one assembly, the separate assemblies are to be used together, and the

requirements are based on the use of matched assemblies.

NOTE 101 A definition of “sealed motor-compressor” is given in IEC 60335-2-34.

NOTE 102 Requirements for refrigeration safety are covered by ISO 5149.

NOTE 103 For appliances using flammable refrigerants, additional requirements are under consideration.

NOTE 104 Attention is drawn to the fact that

− for appliances intended to be used in vehicles or on board ships or aircraft, additional requirements may be

necessary;