IEC 61918:2018

(Main)Industrial communication networks - Installation of communication networks in industrial premises

Industrial communication networks - Installation of communication networks in industrial premises

IEC 61918:2018 specifies basic requirements for the installation of media for communication networks in industrial premises and within and between the automation islands, of industrial sites. This standard covers balanced and optical fibre cabling. It also covers the cabling infrastructure for wireless media, but not the wireless media itself. Additional media are covered in the IEC 61784-5 series.

This fourth edition cancels and replaces the third edition published in 2013. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

a) the reference to ISO/IEC 24702 has been replaced with reference to the new ISO/IEC 11801-3; this affects Table 2;

b) some terms and abbreviated terms have been modified in Clause 3;

c) Subclauses 4.1.2, 4.4.2.5, 4.4.3.4.1 and 5.7 have been updated;

d) Figure 2 and Figure 3 have been updated; Figure 13, Figure 16, Figure 30 and Figure 49 have been added;

e) Table 7 has been updated;

f) Annex D and Annex M have been extended to cover additional communication profile families; Annex H has been extended to cover the M12-8 X-coding connector use;

g) Annex O has been modified by including references to the new edition of the

ISO/IEC 11801 series, ISO/IEC TR 11801-9902 and ISO/IEC 14763-4;

h) Annex P has been added.

This standard is to be used in conjunction with the IEC 61784-5 series with regard to the installation of communication profiles (CPs).

Réseaux de communication industriels - Installation de réseaux de communication dans des locaux industriels

IEC 61918:2018 spécifie les exigences de base pour l’installation d'un support de réseaux de communication à l'intérieur et entre des îlots d'automatisation de sites industriels. Le présent document couvre le câblage symétrique et à fibres optiques. Elle couvre également l’infrastructure de câblage des supports sans fil, mais pas le support sans fil lui-même. D’autres supports sont couverts par l'IEC 61784-5 (toutes les parties).

Cette quatrième édition annule et remplace la troisième édition publiée en 2013. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) la référence à l'ISO/IEC 24702 a été remplacée par la référence à la nouvelle ISO/IEC 11801-3, ce qui a un impact sur le Tableau 2;

b) certains termes et abréviations ont été modifiés à l'Article 3;

c) les Paragraphes 4.1.2, 4.4.2.5, 4.4.3.4.1 et 5.7 ont été mis à jour;

d) la Figure 2 et la Figure 3 ont été mises à jour. La Figure 13, la Figure 16, la Figure 30 et la Figure 49 ont été ajoutées;

e) le Tableau 7 a été mis à jour;

f) l'Annexe D et l'Annexe M ont été développées afin de couvrir des familles de profils de communication supplémentaires. L'Annexe H a été développée pour couvrir l'utilisation du connecteur M12-8 codage X;

g) l'Annexe O a été modifiée en intégrant des références à la nouvelle édition de la série ISO/IEC 11801, à l'ISO/IEC TR 11801-9902 et à l'ISO/IEC 14763-4;

h) l'Annexe P a été ajoutée.

La présente norme doit être utilisée conjointement avec la série IEC 61784-5 en ce qui concerne l’installation des profils de communication (CP).

General Information

- Status

- Published

- Publication Date

- 14-Mar-2024

- Technical Committee

- SC 65C - Industrial networks

- Drafting Committee

- JWG 10 - TC 65/SC 65C/JWG 10

- Current Stage

- PPUB - Publication issued

- Start Date

- 20-Sep-2018

- Completion Date

- 05-Oct-2018

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61918:2018 - Industrial communication networks - Installation of communication networks in industrial premises - is an international standard that specifies basic requirements for installing media for communication networks across industrial sites. It covers balanced cabling, optical fibre cabling, and the cabling infrastructure used to support wireless systems (but not the wireless radio media itself). The standard addresses cabling within and between automation islands and is intended to be used with the IEC 61784-5 series for installation of Communication Profiles (CPs). This is the fourth edition (technical revision) and includes updated references to ISO/IEC 11801-3 and expanded annex material.

Key topics and technical requirements

- Installation planning: project workflows, cabling planning documentation, topology selection and network capability assessment.

- Cable and component selection: guidance on choosing balanced, fibre and other media, plus connectors (shielded/unshielded), terminators and mechanical protection.

- Earthing and bonding: detailed requirements for equipment and shielded cabling earthing methods and verification.

- Routing and separation: routing, mechanical protection, and separation from power or hazardous circuits to reduce EMI and improve reliability.

- Verification and acceptance testing: procedures for installation verification, Ethernet-based and non-Ethernet-based acceptance tests, and reporting.

- Installation implementation: practical routing, connector and terminator installation, device connections, labelling and storage/transportation of cables.

- Administration, maintenance and troubleshooting: as‑implemented documentation, scheduled and condition-based maintenance, fault diagnosis and simplified troubleshooting procedures.

- Supplementary guidance: informative annexes including the MICE (Mechanical, Ingress, Climatic, Electromagnetic) methodology, network topologies, and additional communication profile families.

Practical applications

IEC 61918 is applied where robust, deterministic and EMC-aware communication cabling is required in industrial environments:

- Factory automation networks (Ethernet/IP, PROFINET, EtherCAT, etc.)

- Process plants, machine cells and automation islands

- Industrial control system retrofits and new installations

- Plant-wide fiber optic backbone and zone cabling design

Who should use this standard

- System integrators and industrial network installers

- Plant and electrical engineers specifying cabling systems

- Maintenance teams and network administrators performing verification and troubleshooting

- Consultants, specifiers and project managers responsible for industrial network infrastructure

Related standards

- IEC 61784‑5 (communication profiles - installation guidance)

- ISO/IEC 11801‑3 (generic cabling for industrial premises) - referenced in the latest edition

- Other IEC/ISO standards on cabling verification and site testing

Keywords: IEC 61918:2018, industrial communication networks, cabling installation, fibre optic cabling, balanced cabling, earthing and bonding, MICE, network acceptance testing.

Buy Documents

IEC 61918:2018+AMD1:2022+AMD2:2024 CSV - Industrial communication networks - Installation of communication networks in industrial premises Released:3/15/2024

IEC 61918:2018 - Industrial communication networks - Installation of communication networks in industrial premises Released:9/20/2018

IEC 61918:2018+AMD1:2022 CSV - Industrial communication networks - Installation of communication networks in industrial premises Released:3/9/2022

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

TL 9000 QuEST Forum

Telecommunications quality management system.

Sponsored listings

Frequently Asked Questions

IEC 61918:2018 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Industrial communication networks - Installation of communication networks in industrial premises". This standard covers: IEC 61918:2018 specifies basic requirements for the installation of media for communication networks in industrial premises and within and between the automation islands, of industrial sites. This standard covers balanced and optical fibre cabling. It also covers the cabling infrastructure for wireless media, but not the wireless media itself. Additional media are covered in the IEC 61784-5 series. This fourth edition cancels and replaces the third edition published in 2013. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) the reference to ISO/IEC 24702 has been replaced with reference to the new ISO/IEC 11801-3; this affects Table 2; b) some terms and abbreviated terms have been modified in Clause 3; c) Subclauses 4.1.2, 4.4.2.5, 4.4.3.4.1 and 5.7 have been updated; d) Figure 2 and Figure 3 have been updated; Figure 13, Figure 16, Figure 30 and Figure 49 have been added; e) Table 7 has been updated; f) Annex D and Annex M have been extended to cover additional communication profile families; Annex H has been extended to cover the M12-8 X-coding connector use; g) Annex O has been modified by including references to the new edition of the ISO/IEC 11801 series, ISO/IEC TR 11801-9902 and ISO/IEC 14763-4; h) Annex P has been added. This standard is to be used in conjunction with the IEC 61784-5 series with regard to the installation of communication profiles (CPs).

IEC 61918:2018 specifies basic requirements for the installation of media for communication networks in industrial premises and within and between the automation islands, of industrial sites. This standard covers balanced and optical fibre cabling. It also covers the cabling infrastructure for wireless media, but not the wireless media itself. Additional media are covered in the IEC 61784-5 series. This fourth edition cancels and replaces the third edition published in 2013. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) the reference to ISO/IEC 24702 has been replaced with reference to the new ISO/IEC 11801-3; this affects Table 2; b) some terms and abbreviated terms have been modified in Clause 3; c) Subclauses 4.1.2, 4.4.2.5, 4.4.3.4.1 and 5.7 have been updated; d) Figure 2 and Figure 3 have been updated; Figure 13, Figure 16, Figure 30 and Figure 49 have been added; e) Table 7 has been updated; f) Annex D and Annex M have been extended to cover additional communication profile families; Annex H has been extended to cover the M12-8 X-coding connector use; g) Annex O has been modified by including references to the new edition of the ISO/IEC 11801 series, ISO/IEC TR 11801-9902 and ISO/IEC 14763-4; h) Annex P has been added. This standard is to be used in conjunction with the IEC 61784-5 series with regard to the installation of communication profiles (CPs).

IEC 61918:2018 is classified under the following ICS (International Classification for Standards) categories: 25.040.40 - Industrial process measurement and control; 33.020 - Telecommunications in general; 35.240.50 - IT applications in industry. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61918:2018 has the following relationships with other standards: It is inter standard links to IEC 61918:2018/AMD1:2022, IEC 61918:2018/AMD2:2024, IEC 61918:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61918:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61918 ®

Edition 4.2 2024-03

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

colour

inside

Industrial communication networks – Installation of communication networks in

industrial premises

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and once

containing more than 22 500 terminological entries in English

a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61918 ®

Edition 4.2 2024-03

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

colour

inside

Industrial communication networks – Installation of communication networks in

industrial premises

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 25.040.40; 33.020; 35.240.50 ISBN 978-2-8322-8571-8

REDLINE VERSION – 2 – IEC 61918:2018+AMD1:2022

+AMD2:2024 CSV © IEC 2024

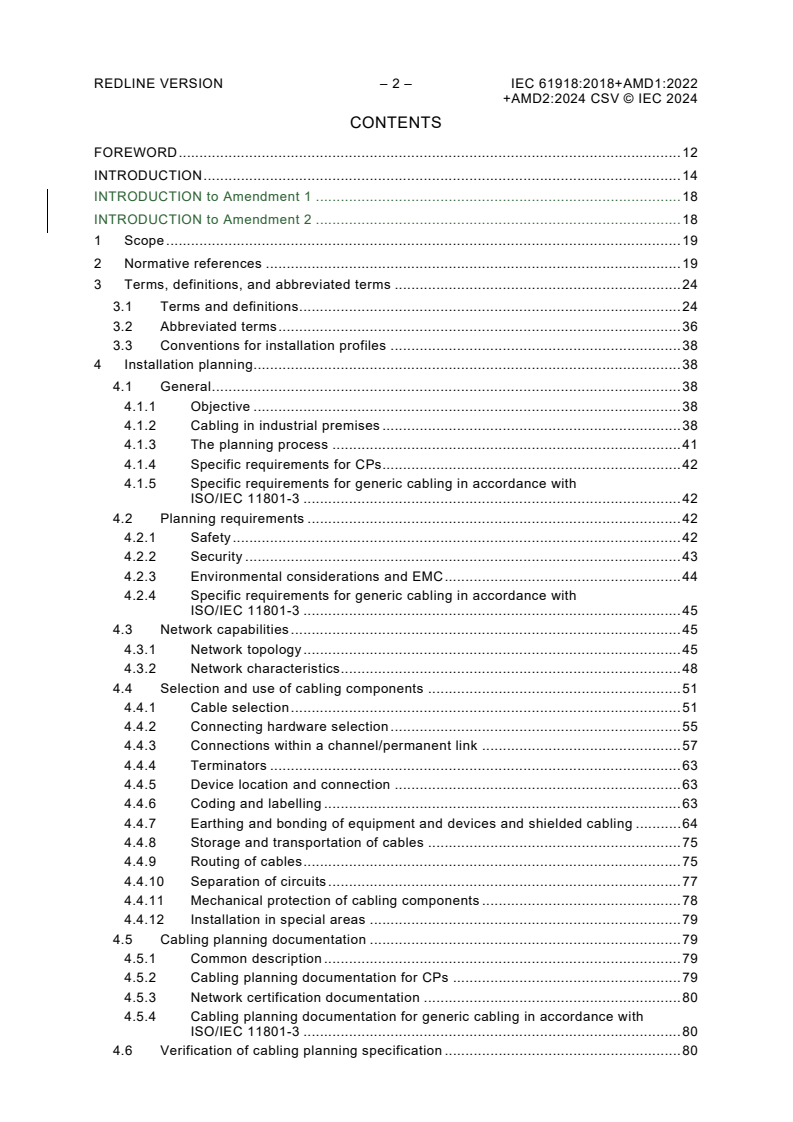

CONTENTS

FOREWORD . 12

INTRODUCTION . 14

INTRODUCTION to Amendment 1 . 18

INTRODUCTION to Amendment 2 . 18

1 Scope . 19

2 Normative references . 19

3 Terms, definitions, and abbreviated terms . 24

3.1 Terms and definitions . 24

3.2 Abbreviated terms . 36

3.3 Conventions for installation profiles . 38

4 Installation planning. 38

4.1 General . 38

4.1.1 Objective . 38

4.1.2 Cabling in industrial premises . 38

4.1.3 The planning process . 41

4.1.4 Specific requirements for CPs. 42

4.1.5 Specific requirements for generic cabling in accordance with

ISO/IEC 11801-3 . 42

4.2 Planning requirements . 42

4.2.1 Safety . 42

4.2.2 Security . 43

4.2.3 Environmental considerations and EMC . 44

4.2.4 Specific requirements for generic cabling in accordance with

ISO/IEC 11801-3 . 45

4.3 Network capabilities . 45

4.3.1 Network topology . 45

4.3.2 Network characteristics . 48

4.4 Selection and use of cabling components . 51

4.4.1 Cable selection . 51

4.4.2 Connecting hardware selection . 55

4.4.3 Connections within a channel/permanent link . 57

4.4.4 Terminators . 63

4.4.5 Device location and connection . 63

4.4.6 Coding and labelling . 63

4.4.7 Earthing and bonding of equipment and devices and shielded cabling . 64

4.4.8 Storage and transportation of cables . 75

4.4.9 Routing of cables . 75

4.4.10 Separation of circuits . 77

4.4.11 Mechanical protection of cabling components . 78

4.4.12 Installation in special areas . 79

4.5 Cabling planning documentation . 79

4.5.1 Common description . 79

4.5.2 Cabling planning documentation for CPs . 79

4.5.3 Network certification documentation . 80

4.5.4 Cabling planning documentation for generic cabling in accordance with

ISO/IEC 11801-3 . 80

4.6 Verification of cabling planning specification . 80

+AMD2:2024 CSV © IEC 2024

5 Installation implementation . 80

5.1 General requirements . 80

5.1.1 Common description . 80

5.1.2 Installation of CPs . 80

5.1.3 Installation of generic cabling in industrial premises . 80

5.2 Cable installation . 80

5.2.1 General requirements for all cabling types . 80

5.2.2 Installation and routing . 86

5.2.3 Specific requirements for CPs. 88

5.2.4 Specific requirements for wireless installation . 88

5.2.5 Specific requirements for generic cabling in accordance with

ISO/IEC 11801-3 . 88

5.3 Connector installation . 88

5.3.1 Common description . 88

5.3.2 Shielded connectors . 89

5.3.3 Unshielded connectors . 89

5.3.4 Specific requirements for CPs. 89

5.3.5 Specific requirements for wireless installation . 89

5.3.6 Specific requirements for generic cabling in accordance with

ISO/IEC 11801-3 . 89

5.4 Terminator installation . 90

5.4.1 Common description . 90

5.4.2 Specific requirements for CPs. 90

5.5 Device installation . 90

5.5.1 Common description . 90

5.5.2 Specific requirements for CPs. 90

5.6 Coding and labelling . 90

5.6.1 Common description . 90

5.6.2 Specific requirements for CPs. 90

5.7 Earthing and bonding of equipment and devices and shield cabling . 90

5.7.1 Common description . 90

5.7.2 Bonding and earthing of enclosures and pathways. 91

5.7.3 Earthing methods . 93

5.7.4 Shield earthing methods . 95

5.7.5 Specific requirements for CPs. 97

5.7.6 Specific requirements for generic cabling in accordance with

ISO/IEC 11801-3 . 97

5.8 As-implemented cabling documentation . 98

6 Installation verification and installation acceptance test . 98

6.1 General . 98

6.2 Installation verification . 98

6.2.1 General . 98

6.2.2 Verification according to cabling planning documentation . 99

6.2.3 Verification of earthing and bonding . 100

6.2.4 Verification of shield earthing . 101

6.2.5 Verification of cabling system . 102

6.2.6 Cable selection verification . 102

6.2.7 Connector verification . 102

6.2.8 Connection verification . 103

REDLINE VERSION – 4 – IEC 61918:2018+AMD1:2022

+AMD2:2024 CSV © IEC 2024

6.2.9 Terminator verification . 105

6.2.10 Coding and labelling verification . 105

6.2.11 Verification report . 105

6.3 Installation acceptance test . 105

6.3.1 General . 105

6.3.2 Acceptance test of Ethernet-based cabling . 107

6.3.3 Acceptance test of non-Ethernet-based cabling . 110

6.3.4 Specific requirements for wireless installation . 110

6.3.5 Acceptance test report . 111

7 Installation administration . 111

7.1 General . 111

7.2 Fields covered by the administration . 111

7.3 Basic principles for the administration system . 111

7.4 Working procedures . 112

7.5 Device location labelling . 112

7.6 Component cabling labelling . 112

7.7 Documentation . 113

7.8 Specific requirements for administration . 114

8 Installation maintenance and installation troubleshooting . 114

8.1 General . 114

8.2 Maintenance . 114

8.2.1 Scheduled maintenance . 114

8.2.2 Condition-based maintenance . 116

8.2.3 Corrective maintenance . 117

8.3 Troubleshooting . 117

8.3.1 General description . 117

8.3.2 Evaluation of the problem . 117

8.3.3 Typical problems . 118

8.3.4 Troubleshooting procedure . 120

8.3.5 Simplified troubleshooting procedure . 121

8.4 Specific requirements for maintenance and troubleshooting . 122

Annex A (informative) Overview of generic cabling for industrial premises . 123

Annex B (informative) MICE description methodology . 124

B.1 General . 124

B.2 Overview of MICE . 124

B.3 Examples of use of the MICE concept . 125

B.3.1 Common description . 125

B.3.2 Examples of mitigation . 125

B.4 Determining E classification . 127

B.5 The MICE table . 130

B.6 Communication devices and cabling considerations . 131

B.6.1 General . 131

B.6.2 Device types . 132

B.6.3 EMI resistance needed for E3 industrial applications . 133

Annex C (informative) Network topologies . 134

C.1 Common description . 134

C.2 Total cable demand . 134

C.3 Maximum cable segment length . 134

+AMD2:2024 CSV © IEC 2024

C.4 Maximum network length . 134

C.5 Fault tolerance . 134

C.5.1 General . 134

C.5.2 Use of redundancy . 134

C.5.3 Failure analysis for networks with redundancy . 134

C.6 Network access for diagnosis convenience . 135

C.7 Maintainability and on-line additions . 135

Annex D (informative) Connector tables . 136

Annex E (informative) Power networks with respect to electromagnetic interference –

TN-C and TN-S approaches . 157

Annex F (informative) Conductor sizes in electrical cables . 159

Annex G (informative) Installed cabling verification checklists . 160

G.1 General . 160

G.2 Copper cabling verification checklist . 160

G.3 Optical fibre cabling verification checklist . 163

Annex H (normative) Cord sets . 165

H.1 General . 165

H.2 Constructing cord sets . 165

H.2.1 Straight through cord sets with M12-4 D-coding connectors . 165

H.2.2 Crossover cord sets with M12-4 D-coding connectors . 166

H.2.3 Straight through cord sets with 8-way modular connectors . 166

H.2.4 Crossover cord sets with 8-way modular connectors . 167

H.2.5 Straight conversion from one connector family to another . 168

H.2.6 Crossover conversion from one connector family to another . 168

H.2.7 Assignment of PMA signal to MDI and MDI-X in outs . 169

H.2.8 Signal and pin assignment for MDI and TIA568A . 170

H.2.9 Signal and pin assignment for MDIX and TIA568B . 170

H.2.10 Signal and pin assignment for MDIX and TIA568A . 171

H.2.11 Straight through cord set with IEC 63171-6 connectors . 171

Annex I (informative) Guidance for terminating cable ends. 172

I.1 General . 172

I.2 Guidance for terminating shielded twisted pair cable ends for 8-way modular

plugs . 172

I.3 Guidance for terminating unshielded twisted pair cable ends for 8-way

modular plugs . 174

I.4 Guidance for M12-4 D-coding connector installation . 175

I.5 Guidance for terminating optical fibre cable ends . 178

Annex J (informative) Recommendations for bulkhead connection performance and

channel performance with more than 4 connections in the a 4-pair channel . 179

J.1 General . 179

J.2 Recommendations . 179

Annex K (informative) Fieldbus data transfer testing . 180

K.1 Background. 180

K.2 Allowable error rates for control systems . 180

K.2.1 Bit errors . 180

K.2.2 Burst errors . 180

K.3 Testing channel performance . 181

K.4 Testing cable parameters . 181

K.4.1 General . 181

REDLINE VERSION – 6 – IEC 61918:2018+AMD1:2022

+AMD2:2024 CSV © IEC 2024

K.4.2 Generic cable cabling testing . 181

K.4.3 Fieldbus cable cabling testing . 181

K.5 Testing fieldbus data rate performance . 182

K.5.1 General . 182

K.5.2 Fieldbus test . 182

K.5.3 Planning for fieldbus data rate testing . 182

K.5.4 Fieldbus data rate test reporting template . 183

K.5.5 Values for acceptable fieldbus performance . 183

Annex L (informative) Communication network installation work responsibility . 184

L.1 General . 184

L.2 Installation work responsibility . 184

L.3 Installation work responsibility table . 184

Annex M (informative) Trade names of communication profiles . 185

Annex N (informative) Validation measurements . 188

N.1 General . 188

N.2 DCR measurements . 188

N.2.1 Purpose of test . 188

N.2.2 Assumptions . 188

N.2.3 Measurements . 188

N.2.4 Calculations . 190

N.2.5 Measurement results . 190

Annex O (informative) End-to-end link . 194

O.1 General . 194

O.2 End-to-end link . 194

O.3 E2E link normative description . 195

O.4 E2E link measurement . 197

Annex P (normative) Temperature rise of cabling with remote powering . 198

P.1 General . 198

P.2 Scope . 198

P.3 Temperature de-rating calculation . 198

Annex Q (normative) Additional requirements for the installation of Ethernet-based

balanced 1-pair networks in industrial premises . 200

Q.1 Overview. 200

Q.2 Installation planning . 200

Q.2.1 General . 200

Q.2.2 Basic balanced 1-pair network characteristics . 200

Q.2.3 Balanced 1-pair cables . 201

Q.2.4 Balanced 1-pair connecting hardware . 201

Q.2.5 Balanced 1-pair cabling channels . 203

Q.2.6 Remote powering . 204

Q.2.7 Reuse of legacy cabling . 205

Q.3 Installation implementation. 205

Q.3.1 General . 205

Q.3.2 Additional installation implementation . 205

Q.4 Installation verification and installation acceptance test . 205

Q.4.1 General . 205

Q.4.2 Additional installation verification and acceptance test. 205

Bibliography . 206

+AMD2:2024 CSV © IEC 2024

Figure 1 – Industrial network installation life cycle . 15

Figure 2 – Standards relationships . 17

Figure 3 – Automation island cabling attached to elements of generic cabling . 39

Figure 4 – Automation islands . 40

Figure 5 – Automation island network external connections . 41

Figure 6 – How to meet environmental conditions . 45

Figure 7 – How enhancement, isolation and separation work together . 45

Figure 8 – Basic physical topologies for passive networks . 46

Figure 9 – Basic physical topologies for active networks . 47

Figure 10 – Example of combination of basic topologies . 47

Figure 53 – Example of mesh topology . 47

Figure 11 – Basic reference implementation model . 58

Figure 12 – Enhanced reference implementation model . 59

Figure 13 – Equalisation and earthing conductor cross-sectional versus maximum

length . 66

Figure 14 – Selection of the earthing and bonding systems . 67

Figure 15 – Placement of equalisation conductors . 69

Figure 16 – Impedance of the earthing conductors and equalisation conductors versus

noise frequency . 70

Figure 17 – Wiring for bonding and earthing in an equipotential a mesh configuration . 71

Figure 18 – Wiring of the earths in a star earthing configuration . 72

Figure 19 – Schematic diagram of a field device with direct earthing . 73

Figure 20 – Schematic diagram of a field device with parallel RC circuit earthing . 73

Figure 21 – Insert edge protector . 82

Figure 22 – Use an uncoiling device and avoid forming loop . 83

Figure 23 – Avoid torsion . 83

Figure 24 – Maintain minimum bending radius . 84

Figure 25 – Do not pull by the individual wires . 84

Figure 26 – Use cable clamps with a large (wide) surface . 84

Figure 27 – Cable gland with bending protection . 85

Figure 28 – Spiral tube . 85

Figure 29 – Separate cable pathways . 88

Figure 30 – Impedance of the earthing circuit as a function of distance from the

metallic pathway . 91

Figure 31 – Use of flexible bonding straps at movable metallic pathways . 92

Figure 32 – Surface preparation for earthing and bonding electromechanical

connections . 93

Figure 33 – Example of isolated bus bar . 94

Figure 34 – Example of isolator for mounting DIN rails . 95

Figure 35 – Parallel RC shield earthing . 95

Figure 36 – Direct shield earthing . 96

Figure 37 – Examples for shielding application . 96

Figure 38 – Voltage offset mitigation . 97

Figure 39 – First example of derivatives of shield earthing . 97

REDLINE VERSION – 8 – IEC 61918:2018+AMD1:2022

+AMD2:2024 CSV © IEC 2024

Figure 40 – Second example of derivatives of shield earthing . 97

Figure 41 – Installation verification process . 100

Figure 42 – Test of earthing connections . 101

Figure 43 – Pin and pair grouping assignments for two eight position IEC 60603-7

subparts and four position IEC 60603-7 series to IEC 61076-2-101 connectors . 104

Figure 44 – Two pair 8-way modular connector . 104

Figure 45 – Transposed pairs, split pairs and reversed pair . 104

Figure 46 – Validation process . 106

Figure 47 – Schematic representation of the channel . 107

Figure 48 – Schematic representation of the permanent link . 107

Figure 49 – Schematic representation of an E2E link . 108

Figure 50 – Communication network maintenance . 116

Figure 51 – Troubleshooting procedure . 121

Figure 52 – Fault detection without special tools . 122

Figure B.1 – MICE classifications . 124

Figure B.2 – Example MICE classifications within a facility . 125

Figure B.3 – Enhancement, isolation and separation . 125

Figure B.4 – Example 1 of mitigation . 126

Figure B.5 – Example 2 of mitigation . 127

Figure B.6 – Frequency range of electromagnetic disturbance from common industrial

devices . 127

Figure B.7 – Example of a general guidance for separation versus EFT value. 129

Figure B.8 – Communication device interface with limited EMI immunity . 132

Figure B.9 – Communication device interfaces with medium EMI immunity . 132

Figure B.10 – Communication device interface with the highest EMI immunity (type 2) . 133

Figure E.1 – Four-wire power network (TN-C) . 157

Figure E.2 – Five wire power network (TN-S) . 158

Figure H.1 – Straight through cord sets with M12-4 D-coding connectors . 165

Figure H.2 – Straight through cord sets with 8-way modular connectors, 8 poles . 166

Figure H.3 – Straight through cord sets with 8-way modular connectors, 4 poles . 167

Figure H.4 –M12-8 X-coding connector . 169

Figure I.1 – Stripping the cable jacket . 172

Figure I.2 – Example of wire preparation for type A cables . 173

Figure I.3 – 8-way modular plug . 173

Figure I.4 – Inserting the cable into the connector body . 174

Figure I.5 – Crimping the connector . 174

Figure I.6 – Example of a cable preparation for type A wiring . 175

Figure I.7 – Connector components . 176

Figure I.8 – Cable preparation . 176

Figure I.9 – Connector wire gland, nut and shell on the cable . 176

Figure I.10 – Conductors preparation . 176

Figure I.11 – Jacket removal . 177

Figure I.12 – Shield preparation . 177

Figure I.13 – Conductors preparation . 177

+AMD2:2024 CSV © IEC 2024

Figure I.14 – Installing conductors in connector . 177

Figure I.15 – Assembling the body of the connector . 178

Figure I.16 – Final assembling . 178

Figure N.1 – Loop resistance measurement wire to wire . 189

Figure N.2 – Loop resistance measurement wire 1 to shield . 189

Figure N.3 – Loop resistance measurement wire 2 to shield . 189

Figure N.4 – Resistance measurement for detecting wire shorts . 189

Figure N.5 – Resistance measurement between wire 1 and wire 2 . 190

Figure N.6 – Validation of the cable DCR . 191

Figure N.7 – Conclusions for cable open or shorts . 192

Figure N.8 – Determination of proper cable terminator value . 193

Figure O.1 – Channel according to ISO/IEC 11801 . 194

Figure O.2 – End-to-end link . 195

Figure O.3 – One segment, two Connection E2E link . 195

Figure O.4 – Two Segment, three Connection E2E link . 196

Figure O.5 – Three Segment, one Connection bulkheads, four Connection E2E link . 196

Figure O.6 – Three Segment, two Connection, six Connection E2E link . 196

Figure O.7 – Three Segment, four Connection E2E link . 196

Figure O.8 – Four Segment, five Connection E2E link . 196

Figure O.9 – Five Segment, six Connection E2E link . 197

Figure Q.1 – Balanced 1-pair network . 200

Figure Q.2 – IP65/IP67 IEC 63171-6 connectors . 202

Figure Q.3 – Mating parts of the IEC 63171-6 connectors . 202

Figure Q.4 – Balanced 1-pair channel model with 40 m max length . 203

Figure Q.5 – Balanced 1-pair channel

...

IEC 61918 ®

Edition 4.0 2018-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Industrial communication networks –

Installation of communication networks in industrial premises

Réseaux de communication industriels –

Installation de réseaux de communication dans des locaux industriels

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 21 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC -

Glossaire IEC - std.iec.ch/glossary

webstore.iec.ch/advsearchform

67 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC et en français, extraites des articles Termes et Définitions des

en utilisant différents critères (numéro de référence, texte, publications IEC parues depuis 2002. Plus certaines entrées

comité d’études,…). Elle donne aussi des informations sur les antérieures extraites des publications des CE 37, 77, 86 et

projets et les publications remplacées ou retirées. CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just Si vous désirez nous donner des commentaires sur cette

Published détaille les nouvelles publications parues. publication ou si vous avez des questions contactez-nous:

Disponible en ligne et aussi une fois par mois par email. sales@iec.ch.

IEC 61918 ®

Edition 4.0 2018-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Industrial communication networks –

Installation of communication networks in industrial premises

Réseaux de communication industriels –

Installation de réseaux de communication dans des locaux industriels

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 25.040.40; 33.020; 35.240.50 ISBN 978-2-8322-6027-2

– 2 – IEC 61918:2018 © IEC 2018

CONTENTS

FOREWORD . 11

INTRODUCTION . 13

1 Scope . 16

2 Normative references . 16

3 Terms, definitions, and abbreviated terms . 19

3.1 Terms and definitions . 19

3.2 Abbreviated terms . 31

3.3 Conventions for installation profiles . 32

4 Installation planning. 33

4.1 General . 33

4.1.1 Objective . 33

4.1.2 Cabling in industrial premises . 33

4.1.3 The planning process . 35

4.1.4 Specific requirements for CPs. 36

4.1.5 Specific requirements for generic cabling in accordance with

ISO/IEC 11801-3 . 36

4.2 Planning requirements . 36

4.2.1 Safety . 36

4.2.2 Security . 37

4.2.3 Environmental considerations and EMC . 37

4.2.4 Specific requirements for generic cabling in accordance with

ISO/IEC 11801-3 . 39

4.3 Network capabilities . 39

4.3.1 Network topology . 39

4.3.2 Network characteristics . 41

4.4 Selection and use of cabling components . 44

4.4.1 Cable selection . 44

4.4.2 Connecting hardware selection . 48

4.4.3 Connections within a channel/permanent link . 50

4.4.4 Terminators . 55

4.4.5 Device location and connection . 56

4.4.6 Coding and labelling . 56

4.4.7 Earthing and bonding of equipment and devices and shielded cabling . 57

4.4.8 Storage and transportation of cables . 67

4.4.9 Routing of cables . 67

4.4.10 Separation of circuits . 69

4.4.11 Mechanical protection of cabling components . 70

4.4.12 Installation in special areas . 71

4.5 Cabling planning documentation . 71

4.5.1 Common description . 71

4.5.2 Cabling planning documentation for CPs . 71

4.5.3 Network certification documentation . 72

4.5.4 Cabling planning documentation for generic cabling in accordance with

ISO/IEC 11801-3 . 72

4.6 Verification of cabling planning specification . 72

5 Installation implementation . 72

5.1 General requirements . 72

5.1.1 Common description . 72

5.1.2 Installation of CPs . 72

5.1.3 Installation of generic cabling in industrial premises . 72

5.2 Cable installation . 72

5.2.1 General requirements for all cabling types . 72

5.2.2 Installation and routing . 78

5.2.3 Specific requirements for CPs. 80

5.2.4 Specific requirements for wireless installation . 80

5.2.5 Specific requirements for generic cabling in accordance with

ISO/IEC 11801-3 . 80

5.3 Connector installation . 80

5.3.1 Common description . 80

5.3.2 Shielded connectors . 81

5.3.3 Unshielded connectors . 81

5.3.4 Specific requirements for CPs. 81

5.3.5 Specific requirements for wireless installation . 81

5.3.6 Specific requirements for generic cabling in accordance with

ISO/IEC 11801-3 . 81

5.4 Terminator installation . 82

5.4.1 Common description . 82

5.4.2 Specific requirements for CPs. 82

5.5 Device installation . 82

5.5.1 Common description . 82

5.5.2 Specific requirements for CPs. 82

5.6 Coding and labelling . 82

5.6.1 Common description . 82

5.6.2 Specific requirements for CPs. 82

5.7 Earthing and bonding of equipment and devices and shield cabling . 82

5.7.1 Common description . 82

5.7.2 Bonding and earthing of enclosures and pathways. 83

5.7.3 Earthing methods . 85

5.7.4 Shield earthing methods . 87

5.7.5 Specific requirements for CPs. 89

5.7.6 Specific requirements for generic cabling in accordance with

ISO/IEC 11801-3 . 89

5.8 As-implemented cabling documentation . 90

6 Installation verification and installation acceptance test . 90

6.1 General . 90

6.2 Installation verification . 90

6.2.1 General . 90

6.2.2 Verification according to cabling planning documentation . 91

6.2.3 Verification of earthing and bonding . 92

6.2.4 Verification of shield earthing . 93

6.2.5 Verification of cabling system . 93

6.2.6 Cable selection verification . 93

6.2.7 Connector verification . 94

6.2.8 Connection verification . 94

6.2.9 Terminator verification . 96

6.2.10 Coding and labelling verification . 96

– 4 – IEC 61918:2018 © IEC 2018

6.2.11 Verification report . 96

6.3 Installation acceptance test . 96

6.3.1 General . 96

6.3.2 Acceptance test of Ethernet-based cabling . 98

6.3.3 Acceptance test of non-Ethernet-based cabling . 100

6.3.4 Specific requirements for wireless installation . 101

6.3.5 Acceptance test report . 101

7 Installation administration . 102

7.1 General . 102

7.2 Fields covered by the administration . 102

7.3 Basic principles for the administration system . 102

7.4 Working procedures . 102

7.5 Device location labelling . 103

7.6 Component cabling labelling . 103

7.7 Documentation . 104

7.8 Specific requirements for administration . 105

8 Installation maintenance and installation troubleshooting . 105

8.1 General . 105

8.2 Maintenance . 105

8.2.1 Scheduled maintenance . 105

8.2.2 Condition-based maintenance . 107

8.2.3 Corrective maintenance . 108

8.3 Troubleshooting . 108

8.3.1 General description . 108

8.3.2 Evaluation of the problem . 108

8.3.3 Typical problems . 109

8.3.4 Troubleshooting procedure . 110

8.3.5 Simplified troubleshooting procedure . 111

8.4 Specific requirements for maintenance and troubleshooting . 112

Annex A (informative) Overview of generic cabling for industrial premises . 113

Annex B (informative) MICE description methodology . 114

B.1 General . 114

B.2 Overview of MICE . 114

B.3 Examples of use of the MICE concept . 115

B.3.1 Common description . 115

B.3.2 Examples of mitigation . 115

B.4 Determining E classification . 117

B.5 The MICE table . 120

Annex C (informative) Network topologies . 122

C.1 Common description . 122

C.2 Total cable demand . 122

C.3 Maximum cable segment length . 122

C.4 Maximum network length . 122

C.5 Fault tolerance . 122

C.5.1 General . 122

C.5.2 Use of redundancy . 122

C.5.3 Failure analysis for networks with redundancy . 122

C.6 Network access for diagnosis convenience . 123

C.7 Maintainability and on-line additions . 123

Annex D (informative) Connector tables . 124

Annex E (informative) Power networks with respect to electromagnetic interference –

TN-C and TN-S approaches . 137

Annex F (informative) Conductor sizes in electrical cables . 139

Annex G (informative) Installed cabling verification checklists . 141

G.1 General . 141

G.2 Copper cabling verification checklist . 141

G.3 Optical fibre cabling verification checklist . 144

Annex H (normative) Cord sets . 146

H.1 General . 146

H.2 Constructing cord sets . 146

H.2.1 Straight through cord sets with M12-4 D-coding connectors . 146

H.2.2 Crossover cord sets with M12-4 D-coding connectors . 147

H.2.3 Straight through cord sets with 8-way modular connectors . 147

H.2.4 Crossover cord sets with 8-way modular connectors . 148

H.2.5 Straight conversion from one connector family to another . 149

H.2.6 Crossover conversion from one connector family to another . 149

H.2.7 Assignment of PMA signal to MDI and MDI-X in outs . 150

H.2.8 Signal and pin assignment for MDI and TIA568A . 151

H.2.9 Signal and pin assignment for MDIX and TIA568B . 151

H.2.10 Signal and pin assignment for MDIX and TIA568A . 152

Annex I (informative) Guidance for terminating cable ends. 153

I.1 General . 153

I.2 Guidance for terminating shielded twisted pair cable ends for 8-way modular

plugs . 153

I.3 Guidance for terminating unshielded twisted pair cable ends for 8-way

modular plugs . 155

I.4 Guidance for M12-4 D-coding connector installation . 156

I.5 Guidance for terminating optical fibre cable ends . 159

Annex J (informative) Recommendations for bulkhead connection performance and

channel performance with more than 4 connections in the channel . 160

J.1 General . 160

J.2 Recommendations . 160

Annex K (informative) Fieldbus data transfer testing . 161

K.1 Background. 161

K.2 Allowable error rates for control systems . 161

K.2.1 Bit errors . 161

K.2.2 Burst errors . 161

K.3 Testing channel performance . 162

K.4 Testing cable parameters . 162

K.4.1 General . 162

K.4.2 Generic cable testing . 162

K.4.3 Fieldbus cable testing . 162

K.5 Testing fieldbus data rate performance . 163

K.5.1 General . 163

K.5.2 Fieldbus test . 163

K.5.3 Planning for fieldbus data rate testing . 163

K.5.4 Fieldbus data rate test reporting template . 164

– 6 – IEC 61918:2018 © IEC 2018

K.5.5 Values for acceptable fieldbus performance . 164

Annex L (informative) Communication network installation work responsibility . 165

L.1 General . 165

L.2 Installation work responsibility . 165

L.3 Installation work responsibility table . 165

Annex M (informative) Trade names of communication profiles . 166

Annex N (informative) Validation measurements . 169

N.1 General . 169

N.2 DCR measurements . 169

N.2.1 Purpose of test . 169

N.2.2 Assumptions . 169

N.2.3 Measurements . 169

N.2.4 Calculations . 171

N.2.5 Measurement results . 171

Annex O (informative) End-to-end link . 175

O.1 General . 175

O.2 End-to-end link . 175

O.3 E2E link normative description . 176

O.4 E2E link measurement . 178

Annex P (normative) Temperature rise of cabling with remote powering . 179

P.1 General . 179

P.2 Scope . 179

P.3 Temperature de-rating calculation . 179

Bibliography . 181

Figure 1 – Industrial network installation life cycle . 14

Figure 2 – Standards relationships . 15

Figure 3 – Automation island cabling attached to elements of generic cabling . 33

Figure 4 – Automation islands . 34

Figure 5 – Automation island network external connections . 35

Figure 6 – How to meet environmental conditions . 38

Figure 7 – How enhancement, isolation and separation work together . 39

Figure 8 – Basic physical topologies for passive networks . 40

Figure 9 – Basic physical topologies for active networks . 40

Figure 10 – Example of combination of basic topologies . 40

Figure 11 – Basic reference implementation model . 51

Figure 12 – Enhanced reference implementation model . 52

Figure 13 – Equalisation and earthing conductor cross-sectional versus maximum

length . 58

Figure 14 – Selection of the earthing and bonding systems . 59

Figure 15 – Placement of equalisation conductors . 61

Figure 16 – Impedance of the earthing conductors and equalisation conductors versus

noise frequency . 62

Figure 17 – Wiring for bonding and earthing in an equipotential configuration . 63

Figure 18 – Wiring of the earths in a star earthing configuration . 64

Figure 19 – Schematic diagram of a field device with direct earthing . 65

Figure 20 – Schematic diagram of a field device with parallel RC circuit earthing . 65

Figure 21 – Insert edge protector . 74

Figure 22 – Use an uncoiling device and avoid forming loop . 75

Figure 23 – Avoid torsion . 75

Figure 24 – Maintain minimum bending radius . 76

Figure 25 – Do not pull by the individual wires . 76

Figure 26 – Use cable clamps with a large (wide) surface . 76

Figure 27 – Cable gland with bending protection . 77

Figure 28 – Spiral tube . 77

Figure 29 – Separate cable pathways . 80

Figure 30 – Impedance of the earthing circuit as a function of distance from the

metallic pathway . 83

Figure 31 – Use of flexible bonding straps at movable metallic pathways . 84

Figure 32 – Surface preparation for earthing and bonding electromechanical

connections . 85

Figure 33 – Example of isolated bus bar . 86

Figure 34 – Example of isolator for mounting DIN rails . 87

Figure 35 – Parallel RC shield earthing . 87

Figure 36 – Direct shield earthing . 88

Figure 37 – Examples for shielding application . 88

Figure 38 – Voltage offset mitigation . 89

Figure 39 – First example of derivatives of shield earthing . 89

Figure 40 – Second example of derivatives of shield earthing . 89

Figure 41 – Installation verification process . 91

Figure 42 – Test of earthing connections . 92

Figure 43 – Pin and pair grouping assignments for two eight position IEC 60603-7

subparts and four position IEC 60603 series to IEC 61076-2-101 connectors . 95

Figure 44 – Two pair 8-way modular connector . 95

Figure 45 – Transposed pairs, split pairs and reversed pair . 95

Figure 46 – Validation process . 97

Figure 47 – Schematic representation of the channel . 98

Figure 48 – Schematic representation of the permanent link . 98

Figure 49 – Schematic representation of an E2E link . 99

Figure 50 – Communication network maintenance . 107

Figure 51 – Troubleshooting procedure . 111

Figure 52 – Fault detection without special tools . 112

Figure B.1 – MICE classifications . 114

Figure B.2 – Example MICE classifications within a facility . 115

Figure B.3 – Enhancement, isolation and separation . 115

Figure B.4 – Example 1 of mitigation . 116

Figure B.5 – Example 2 of mitigation . 117

Figure B.6 – Frequency range of electromagnetic disturbance from common industrial

devices . 117

Figure B.7 – Example of a general guidance for separation versus EFT value. 119

– 8 – IEC 61918:2018 © IEC 2018

Figure E.1 – Four-wire power network (TN-C) . 137

Figure E.2 – Five wire power network (TN-S) . 138

Figure H.1 – Straight through cord sets with M12-4 D-coding connectors . 146

Figure H.2 – Straight through cord sets with 8-way modular connectors, 8 poles . 147

Figure H.3 – Straight through cord sets with 8-way modular connectors, 4 poles . 148

Figure H.4 –M12-8 X-coding connector . 150

Figure I.1 – Stripping the cable jacket . 153

Figure I.2 – Example of wire preparation for type A cables . 154

Figure I.3 – 8-way modular plug . 154

Figure I.4 – Inserting the cable into the connector body . 155

Figure I.5 – Crimping the connector . 155

Figure I.6 – Example of a cable preparation for type A wiring . 156

Figure I.7 – Connector components . 157

Figure I.8 – Cable preparation . 157

Figure I.9 – Connector wire gland, nut and shell on the cable . 157

Figure I.10 – Conductors preparation . 157

Figure I.11 – Jacket removal . 157

Figure I.12 – Shield preparation . 158

Figure I.13 – Conductors preparation . 158

Figure I.14 – Installing conductors in connector . 158

Figure I.15 – Assembling the body of the connector . 158

Figure I.16 – Final assembling . 159

Figure N.1 – Loop resistance measurement wire to wire . 169

Figure N.2 – Loop resistance measurement wire 1 to shield . 170

Figure N.3 – Loop resistance measurement wire 2 to shield . 170

Figure N.4 – Resistance measurement for detecting wire shorts . 170

Figure N.5 – Resistance measurement between wire 1 and wire 2 . 170

Figure N.6 – Validation of the cable DCR . 172

Figure N.7 – Conclusions for cable open or shorts . 173

Figure N.8 – Determination of proper cable terminator value . 174

Figure O.1 – Channel according to ISO/IEC 11801 . 175

Figure O.2 – End-to-end link . 176

Figure O.3 – One segment, two Connection E2E link . 176

Figure O.4 – Two Segment, three Connection E2E link . 176

Figure O.5 – Three Segment, one Connection bulkheads, four Connection E2E link . 177

Figure O.6 – Three Segment, two Connection, six Connection E2E link . 177

Figure O.7 – Three Segment, four Connection E2E link . 177

Figure O.8 – Four Segment, five Connection E2E link . 177

Figure O.9 – Five Segment, six Connection E2E link . 177

Table 1 – Basic network characteristics for balanced cabling not based on Ethernet . 42

Table 2 – Network characteristics for balanced cabling based on Ethernet. 42

Table 3 – Network characteristics for optical fibre cabling . 43

Table 4 – Information relevant to copper cable: fixed cables . 45

Table 5 – Information relevant to copper cable: cords . 45

Table 6 – Information relevant to opt

...

IEC 61918 ®

Edition 4.1 2022-03

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Industrial communication networks – Installation of communication networks in

industrial premises

Réseaux de communication industriels – Installation de réseaux de

communication dans des locaux industriels

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 19 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur adapté à vos besoins.

les projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au

Restez informé sur les nouvelles publications IEC. Just

monde, avec plus de 22 300 articles terminologiques en

Published détaille les nouvelles publications parues.

anglais et en français, ainsi que les termes équivalents dans

Disponible en ligne et une fois par mois par email.

19 langues additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61918 ®

Edition 4.1 2022-03

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Industrial communication networks – Installation of communication networks in

industrial premises

Réseaux de communication industriels – Installation de réseaux de

communication dans des locaux industriels

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 25.040.40; 33.020, 35.240.50 ISBN 978-2-8322-4994-9

IEC 61918 ®

Edition 4.1 2022-03

CONSOLIDATED VERSION

REDLINE VERSION

VERSION REDLINE

colour

inside

Industrial communication networks – Installation of communication networks in

industrial premises

Réseaux de communication industriels – Installation de réseaux de

communication dans des locaux industriels

– 2 – IEC 61918:2018+AMD1:2022 CSV

© IEC 2022

CONTENTS

FOREWORD . 12

INTRODUCTION . 14

INTRODUCTION to Amendment 1 . 18

1 Scope . 19

2 Normative references . 19

3 Terms, definitions, and abbreviated terms . 23

3.1 Terms and definitions . 23

3.2 Abbreviated terms . 35

3.3 Conventions for installation profiles . 37

4 Installation planning. 37

4.1 General . 37

4.1.1 Objective . 37

4.1.2 Cabling in industrial premises . 37

4.1.3 The planning process . 40

4.1.4 Specific requirements for CPs. 41

4.1.5 Specific requirements for generic cabling in accordance with

ISO/IEC 11801-3 . 41

4.2 Planning requirements . 41

4.2.1 Safety . 41

4.2.2 Security . 42

4.2.3 Environmental considerations and EMC . 42

4.2.4 Specific requirements for generic cabling in accordance with

ISO/IEC 11801-3 . 44

4.3 Network capabilities . 44

4.3.1 Network topology . 44

4.3.2 Network characteristics . 46

4.4 Selection and use of cabling components . 49

4.4.1 Cable selection . 49

4.4.2 Connecting hardware selection . 53

4.4.3 Connections within a channel/permanent link . 55

4.4.4 Terminators . 61

4.4.5 Device location and connection . 61

4.4.6 Coding and labelling . 61

4.4.7 Earthing and bonding of equipment and devices and shielded cabling . 62

4.4.8 Storage and transportation of cables . 73

4.4.9 Routing of cables . 73

4.4.10 Separation of circuits . 75

4.4.11 Mechanical protection of cabling components . 76

4.4.12 Installation in special areas . 77

4.5 Cabling planning documentation . 77

4.5.1 Common description . 77

4.5.2 Cabling planning documentation for CPs . 77

4.5.3 Network certification documentation . 78

4.5.4 Cabling planning documentation for generic cabling in accordance with

ISO/IEC 11801-3 . 78

4.6 Verification of cabling planning specification . 78

© IEC 2022

5 Installation implementation . 78

5.1 General requirements . 78

5.1.1 Common description . 78

5.1.2 Installation of CPs . 78

5.1.3 Installation of generic cabling in industrial premises . 78

5.2 Cable installation . 78

5.2.1 General requirements for all cabling types . 78

5.2.2 Installation and routing . 84

5.2.3 Specific requirements for CPs. 86

5.2.4 Specific requirements for wireless installation . 86

5.2.5 Specific requirements for generic cabling in accordance with

ISO/IEC 11801-3 . 86

5.3 Connector installation . 86

5.3.1 Common description . 86

5.3.2 Shielded connectors . 87

5.3.3 Unshielded connectors . 87

5.3.4 Specific requirements for CPs. 87

5.3.5 Specific requirements for wireless installation . 87

5.3.6 Specific requirements for generic cabling in accordance with

ISO/IEC 11801-3 . 87

5.4 Terminator installation . 88

5.4.1 Common description . 88

5.4.2 Specific requirements for CPs. 88

5.5 Device installation . 88

5.5.1 Common description . 88

5.5.2 Specific requirements for CPs. 88

5.6 Coding and labelling . 88

5.6.1 Common description . 88

5.6.2 Specific requirements for CPs. 88

5.7 Earthing and bonding of equipment and devices and shield cabling . 88

5.7.1 Common description . 88

5.7.2 Bonding and earthing of enclosures and pathways. 89

5.7.3 Earthing methods . 91

5.7.4 Shield earthing methods . 93

5.7.5 Specific requirements for CPs. 95

5.7.6 Specific requirements for generic cabling in accordance with

ISO/IEC 11801-3 . 95

5.8 As-implemented cabling documentation . 96

6 Installation verification and installation acceptance test . 96

6.1 General . 96

6.2 Installation verification . 96

6.2.1 General . 96

6.2.2 Verification according to cabling planning documentation . 97

6.2.3 Verification of earthing and bonding . 98

6.2.4 Verification of shield earthing . 99

6.2.5 Verification of cabling system . 100

6.2.6 Cable selection verification . 100

6.2.7 Connector verification . 100

6.2.8 Connection verification . 101

– 4 – IEC 61918:2018+AMD1:2022 CSV

© IEC 2022

6.2.9 Terminator verification . 103

6.2.10 Coding and labelling verification . 103

6.2.11 Verification report . 103

6.3 Installation acceptance test . 103

6.3.1 General . 103

6.3.2 Acceptance test of Ethernet-based cabling . 105

6.3.3 Acceptance test of non-Ethernet-based cabling . 108

6.3.4 Specific requirements for wireless installation . 108

6.3.5 Acceptance test report . 109

7 Installation administration . 109

7.1 General . 109

7.2 Fields covered by the administration . 109

7.3 Basic principles for the administration system . 109

7.4 Working procedures . 110

7.5 Device location labelling . 110

7.6 Component cabling labelling . 110

7.7 Documentation . 111

7.8 Specific requirements for administration . 112

8 Installation maintenance and installation troubleshooting . 112

8.1 General . 112

8.2 Maintenance . 112

8.2.1 Scheduled maintenance . 112

8.2.2 Condition-based maintenance . 114

8.2.3 Corrective maintenance . 115

8.3 Troubleshooting . 115

8.3.1 General description . 115

8.3.2 Evaluation of the problem . 115

8.3.3 Typical problems . 116

8.3.4 Troubleshooting procedure . 118

8.3.5 Simplified troubleshooting procedure . 119

8.4 Specific requirements for maintenance and troubleshooting . 120

Annex A (informative) Overview of generic cabling for industrial premises . 121

Annex B (informative) MICE description methodology . 122

B.1 General . 122

B.2 Overview of MICE . 122

B.3 Examples of use of the MICE concept . 123

B.3.1 Common description . 123

B.3.2 Examples of mitigation . 123

B.4 Determining E classification . 125

B.5 The MICE table . 128

B.6 Communication devices and cabling considerations . 129

B.6.1 General . 129

B.6.2 Device types . 130

B.6.3 EMI resistance needed for E3 industrial applications . 131

Annex C (informative) Network topologies . 132

C.1 Common description . 132

C.2 Total cable demand . 132

C.3 Maximum cable segment length . 132

© IEC 2022

C.4 Maximum network length . 132

C.5 Fault tolerance . 132

C.5.1 General . 132

C.5.2 Use of redundancy . 132

C.5.3 Failure analysis for networks with redundancy . 132

C.6 Network access for diagnosis convenience . 133

C.7 Maintainability and on-line additions . 133

Annex D (informative) Connector tables . 134

Annex E (informative) Power networks with respect to electromagnetic interference –

TN-C and TN-S approaches . 148

Annex F (informative) Conductor sizes in electrical cables . 150

Annex G (informative) Installed cabling verification checklists . 151

G.1 General . 151

G.2 Copper cabling verification checklist . 151

G.3 Optical fibre cabling verification checklist . 154

Annex H (normative) Cord sets . 156

H.1 General . 156

H.2 Constructing cord sets . 156

H.2.1 Straight through cord sets with M12-4 D-coding connectors . 156

H.2.2 Crossover cord sets with M12-4 D-coding connectors . 157

H.2.3 Straight through cord sets with 8-way modular connectors . 157

H.2.4 Crossover cord sets with 8-way modular connectors . 158

H.2.5 Straight conversion from one connector family to another . 159

H.2.6 Crossover conversion from one connector family to another . 159

H.2.7 Assignment of PMA signal to MDI and MDI-X in outs . 160

H.2.8 Signal and pin assignment for MDI and TIA568A . 161

H.2.9 Signal and pin assignment for MDIX and TIA568B . 161

H.2.10 Signal and pin assignment for MDIX and TIA568A . 162

H.2.11 Straight through cord set with IEC 63171-6 connectors . 162

Annex I (informative) Guidance for terminating cable ends. 163

I.1 General . 163

I.2 Guidance for terminating shielded twisted pair cable ends for 8-way modular

plugs . 163

I.3 Guidance for terminating unshielded twisted pair cable ends for 8-way

modular plugs . 165

I.4 Guidance for M12-4 D-coding connector installation . 166

I.5 Guidance for terminating optical fibre cable ends . 169

Annex J (informative) Recommendations for bulkhead connection performance and

channel performance with more than 4 connections in the a 4-pair channel . 170

J.1 General . 170

J.2 Recommendations . 170

Annex K (informative) Fieldbus data transfer testing . 171

K.1 Background. 171

K.2 Allowable error rates for control systems . 171

K.2.1 Bit errors . 171

K.2.2 Burst errors . 171

K.3 Testing channel performance . 172

K.4 Testing cable parameters . 172

K.4.1 General . 172

– 6 – IEC 61918:2018+AMD1:2022 CSV

© IEC 2022

K.4.2 Generic cable cabling testing . 172

K.4.3 Fieldbus cable cabling testing . 172

K.5 Testing fieldbus data rate performance . 173

K.5.1 General . 173

K.5.2 Fieldbus test . 173

K.5.3 Planning for fieldbus data rate testing . 173

K.5.4 Fieldbus data rate test reporting template . 174

K.5.5 Values for acceptable fieldbus performance . 174

Annex L (informative) Communication network installation work responsibility . 175

L.1 General . 175

L.2 Installation work responsibility . 175

L.3 Installation work responsibility table . 175

Annex M (informative) Trade names of communication profiles . 176

Annex N (informative) Validation measurements . 179

N.1 General . 179

N.2 DCR measurements . 179

N.2.1 Purpose of test . 179

N.2.2 Assumptions . 179

N.2.3 Measurements . 179

N.2.4 Calculations . 181

N.2.5 Measurement results . 181

Annex O (informative) End-to-end link . 185

O.1 General . 185

O.2 End-to-end link . 185

O.3 E2E link normative description . 186

O.4 E2E link measurement . 188

Annex P (normative) Temperature rise of cabling with remote powering . 189

P.1 General . 189

P.2 Scope . 189

P.3 Temperature de-rating calculation . 189

Annex Q (normative) Additional requirements for the installation of Ethernet-based

balanced 1-pair networks in industrial premises . 191

Q.1 Overview. 191

Q.2 Installation planning . 191

Q.2.1 General . 191

Q.2.2 Basic balanced 1-pair network characteristics . 191

Q.2.3 Balanced 1-pair cables . 192

Q.2.4 Balanced 1-pair connecting hardware . 192

Q.2.5 Balanced 1-pair cabling channels . 194

Q.2.6 Remote powering . 195

Q.2.7 Reuse of legacy cabling . 195

Q.3 Installation implementation. 196

Q.3.1 General . 196

Q.3.2 Additional installation implementation . 196

Q.4 Installation verification and installation acceptance test . 196

Q.4.1 General . 196

Q.4.2 Additional installation verification and acceptance test. 196

Bibliography . 197

© IEC 2022

Figure 1 – Industrial network installation life cycle . 15

Figure 2 – Standards relationships . 17

Figure 3 – Automation island cabling attached to elements of generic cabling . 38

Figure 4 – Automation islands . 39

Figure 5 – Automation island network external connections . 40

Figure 6 – How to meet environmental conditions . 43

Figure 7 – How enhancement, isolation and separation work together . 44

Figure 8 – Basic physical topologies for passive networks . 45

Figure 9 – Basic physical topologies for active networks . 45

Figure 10 – Example of combination of basic topologies . 45

Figure 11 – Basic reference implementation model . 56

Figure 12 – Enhanced reference implementation model . 57

Figure 13 – Equalisation and earthing conductor cross-sectional versus maximum

length . 64

Figure 14 – Selection of the earthing and bonding systems . 65

Figure 15 – Placement of equalisation conductors . 67

Figure 16 – Impedance of the earthing conductors and equalisation conductors versus

noise frequency . 68

Figure 17 – Wiring for bonding and earthing in an equipotential a mesh configuration . 69

Figure 18 – Wiring of the earths in a star earthing configuration . 70

Figure 19 – Schematic diagram of a field device with direct earthing . 71

Figure 20 – Schematic diagram of a field device with parallel RC circuit earthing . 71

Figure 21 – Insert edge protector . 80

Figure 22 – Use an uncoiling device and avoid forming loop . 81

Figure 23 – Avoid torsion . 81

Figure 24 – Maintain minimum bending radius . 82

Figure 25 – Do not pull by the individual wires . 82

Figure 26 – Use cable clamps with a large (wide) surface . 82

Figure 27 – Cable gland with bending protection . 83

Figure 28 – Spiral tube . 83

Figure 29 – Separate cable pathways . 86

Figure 30 – Impedance of the earthing circuit as a function of distance from the

metallic pathway . 89

Figure 31 – Use of flexible bonding straps at movable metallic pathways . 90

Figure 32 – Surface preparation for earthing and bonding electromechanical

connections . 91

Figure 33 – Example of isolated bus bar . 92

Figure 34 – Example of isolator for mounting DIN rails . 93

Figure 35 – Parallel RC shield earthing . 93

Figure 36 – Direct shield earthing . 94

Figure 37 – Examples for shielding application . 94

Figure 38 – Voltage offset mitigation . 95

Figure 39 – First example of derivatives of shield earthing . 95

Figure 40 – Second example of derivatives of shield earthing . 95

– 8 – IEC 61918:2018+AMD1:2022 CSV

© IEC 2022

Figure 41 – Installation verification process . 98

Figure 42 – Test of earthing connections . 99

Figure 43 – Pin and pair grouping assignments for two eight position IEC 60603-7

subparts and four position IEC 60603 series to IEC 61076-2-101 connectors . 102

Figure 44 – Two pair 8-way modular connector . 102

Figure 45 – Transposed pairs, split pairs and reversed pair . 102

Figure 46 – Validation process . 104

Figure 47 – Schematic representation of the channel . 105

Figure 48 – Schematic representation of the permanent link . 105

Figure 49 – Schematic representation of an E2E link . 106

Figure 50 – Communication network maintenance . 114

Figure 51 – Troubleshooting procedure . 119

Figure 52 – Fault detection without special tools . 120

Figure B.1 – MICE classifications . 122

Figure B.2 – Example MICE classifications within a facility . 123

Figure B.3 – Enhancement, isolation and separation . 123

Figure B.4 – Example 1 of mitigation . 124

Figure B.5 – Example 2 of mitigation . 125

Figure B.6 – Frequency range of electromagnetic disturbance from common industrial

devices . 125