IEC 61188-6-1:2021

(Main)Circuit boards and circuit board assemblies - Design and use - Part 6-1: Land pattern design - Generic requirements for land pattern on circuit boards

Circuit boards and circuit board assemblies - Design and use - Part 6-1: Land pattern design - Generic requirements for land pattern on circuit boards

IEC 61188-6-1:2021 specifies the requirements for soldering surfaces on circuit boards. This includes lands and land pattern for surface mounted components and also solderable hole configurations for through-hole mounted components. These requirements are based on the solder joint requirements of the IEC 61191-1, IEC 61191-2, IEC 61191-3 and IEC 61191-4.

Cartes imprimées et cartes imprimées équipées - Conception et utilisation - Partie 6-1: Conception de la zone de report - Exigences génériques pour la zone de report sur les cartes imprimées

L’IEC 61188-6-1:2021 spécifie les exigences relatives aux surfaces de brasage sur les cartes imprimées. Cela comprend les pastilles et la zone de report des composants montés en surface, ainsi que les configurations des trous de brasage des composants montés par trous traversants. Ces exigences se fondent sur les exigences relatives au joint de brasure de l’IEC 61191-1, l’IEC 61191-2, l’IEC 61191-3 et l’IEC 61191-4.

General Information

- Status

- Published

- Publication Date

- 22-Feb-2021

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 12 - TC 91/WG 12

- Current Stage

- PPUB - Publication issued

- Start Date

- 23-Feb-2021

- Completion Date

- 09-Mar-2021

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61188-6-1:2021 is an international standard published by the International Electrotechnical Commission (IEC) that specifies the generic requirements for land pattern design on circuit boards. Focused on the design and use of circuit boards and assemblies, this standard outlines the requirements for soldering surfaces-including lands and land patterns for surface-mounted components and solderable hole configurations for through-hole components. These requirements are aligned with solder joint quality standards as detailed in IEC 61191 series. This 2021 revision updates previous editions to reflect current industry trends and technology.

The purpose of IEC 61188-6-1 is to ensure reliable electrical connections, manufacturability, and optimized solder joint integrity through precise and standardized land pattern design on printed circuit boards (PCBs).

Key Topics

- Design Requirements for Lands and Land Patterns: The standard defines dimensional and geometric constraints for solderable surfaces to support different soldering processes, including reflow and wave soldering.

- Component Classification: Differentiation between surface mount and leaded components with corresponding terminal classifications, which influence land pattern design.

- Soldering Surface Specifications: Guidance on defining solder pads through metal-defined and solder mask-defined techniques, comparing both for robustness and manufacturability.

- Proportional Dimensioning System: Introduction of a dimensioning approach that accounts for component tolerances, fabrication allowances, and assembly precision to optimize land pattern accuracy.

- Terminal Types and Classes: Detailed definitions for flat-bottom, vertical-side terminals, and their impact on land geometry to support reliable solder joints.

- Solder Joint Requirements: Recommendations to achieve optimal solder fillet and joint strength based on land dimensions and terminal types.

Applications

IEC 61188-6-1:2021 serves a critical role across industries leveraging electronic assembly technologies, including:

- PCB Design and Manufacturing: Ensures designers create land patterns that conform to international soldering requirements, leading to improved assembly yields and reduced defects.

- Electronics Assembly Automation: Provides guidelines that optimize automated soldering processes such as reflow and wave soldering for both surface mount and through-hole components.

- Quality Assurance in Electronics Production: Enables manufacturers to meet rigorous solder joint reliability criteria essential for high-performance electronics in automotive, aerospace, industrial, and consumer electronics sectors.

- Component Libraries and CAD Tools: Acts as a reference for component package land pattern design within electronic design automation (EDA) tools for consistent and standardized PCB layout generation.

- Supply Chain and Compliance: Facilitates global trade and interoperability by ensuring land pattern designs adhere to internationally recognized standards, reducing rework and design errors.

Related Standards

- IEC 61191 Series: Detailed standards on soldering requirements for electronic assembly covering both the soldering process and inspection methods.

- IEC 61188 Series: Broader framework for PCB design and use, with parts addressing various aspects beyond land pattern design, including design rules and testing.

- IPC-7351: Complementary industry standard for land pattern design, often used alongside IEC standards for surface mount assembly.

- ISO/IEC Directives Part 1 & Part 2: Guidelines on standard development which underpin the structure and harmonization of IEC documents.

- IPC-6012: Qualification and performance specification for rigid PCBs, supporting overall reliability including land pattern adherence.

By adhering to the generic land pattern requirements set out in IEC 61188-6-1:2021, designers and manufacturers can ensure robust and manufacturable circuit board assemblies with consistent solder joint quality, enabling reliable operation of electronic devices across diverse sectors.

Buy Documents

IEC 61188-6-1:2021 - Circuit boards and circuit board assemblies - Design and use - Part 6-1: Land pattern design - Generic requirements for land pattern on circuit boards Released:2/23/2021

Frequently Asked Questions

IEC 61188-6-1:2021 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Circuit boards and circuit board assemblies - Design and use - Part 6-1: Land pattern design - Generic requirements for land pattern on circuit boards". This standard covers: IEC 61188-6-1:2021 specifies the requirements for soldering surfaces on circuit boards. This includes lands and land pattern for surface mounted components and also solderable hole configurations for through-hole mounted components. These requirements are based on the solder joint requirements of the IEC 61191-1, IEC 61191-2, IEC 61191-3 and IEC 61191-4.

IEC 61188-6-1:2021 specifies the requirements for soldering surfaces on circuit boards. This includes lands and land pattern for surface mounted components and also solderable hole configurations for through-hole mounted components. These requirements are based on the solder joint requirements of the IEC 61191-1, IEC 61191-2, IEC 61191-3 and IEC 61191-4.

IEC 61188-6-1:2021 is classified under the following ICS (International Classification for Standards) categories: 31.180 - Printed circuits and boards; 31.190 - Electronic component assemblies. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61188-6-1:2021 has the following relationships with other standards: It is inter standard links to IEC 61188-5-1:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61188-6-1:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61188-6-1 ®

Edition 1.0 2021-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Circuit boards and circuit board assemblies – Design and use –

Part 6-1: Land pattern design – Generic requirements for land pattern on

circuit boards

Cartes imprimées et cartes imprimées équipées – Conception et utilisation –

Partie 6-1: Conception de la zone de report – Exigences génériques pour la zone

de report sur les cartes imprimées

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC online collection - oc.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur adapté à vos besoins.

les projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au

Restez informé sur les nouvelles publications IEC. Just

monde, avec plus de 22 000 articles terminologiques en

Published détaille les nouvelles publications parues.

anglais et en français, ainsi que les termes équivalents dans

Disponible en ligne et une fois par mois par email.

16 langues additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61188-6-1 ®

Edition 1.0 2021-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Circuit boards and circuit board assemblies – Design and use –

Part 6-1: Land pattern design – Generic requirements for land pattern on

circuit boards

Cartes imprimées et cartes imprimées équipées – Conception et utilisation –

Partie 6-1: Conception de la zone de report – Exigences génériques pour la zone

de report sur les cartes imprimées

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.180; 31.190 ISBN 978-2-8322-9443-7

– 2 – IEC 61188-6-1:2021 © IEC 2021

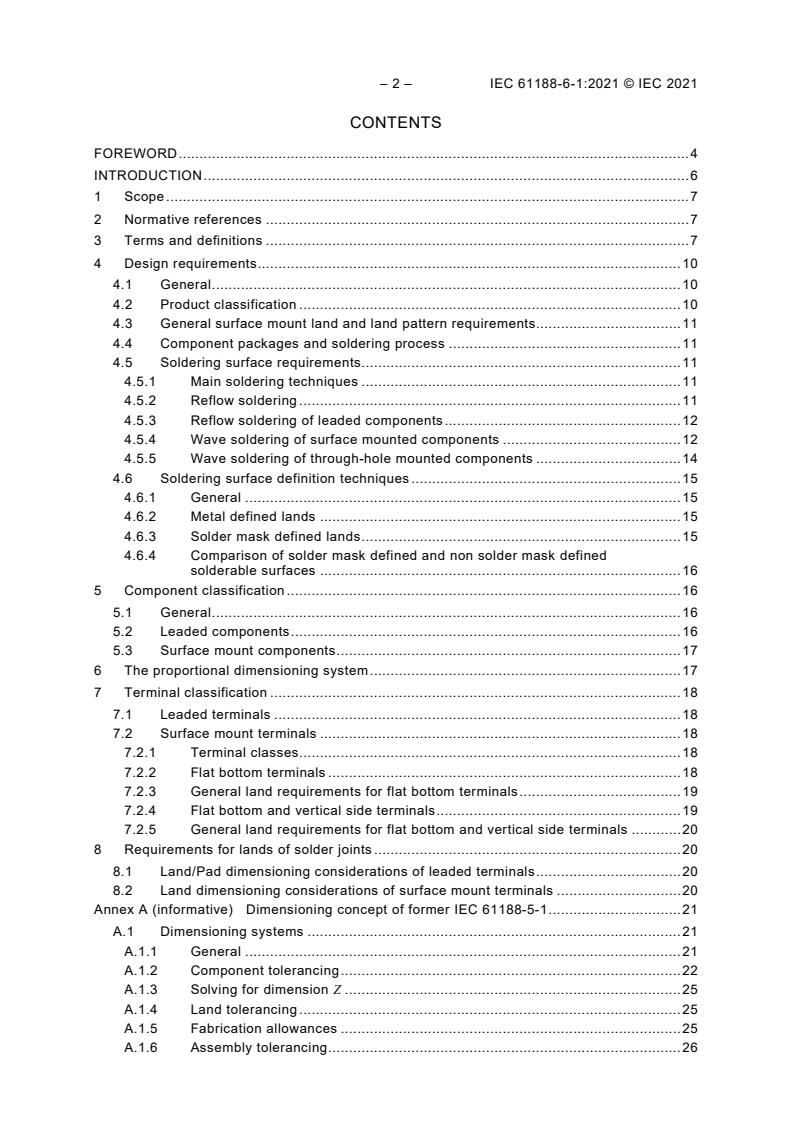

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Design requirements . 10

4.1 General . 10

4.2 Product classification . 10

4.3 General surface mount land and land pattern requirements. 11

4.4 Component packages and soldering process . 11

4.5 Soldering surface requirements. 11

4.5.1 Main soldering techniques . 11

4.5.2 Reflow soldering . 11

4.5.3 Reflow soldering of leaded components . 12

4.5.4 Wave soldering of surface mounted components . 12

4.5.5 Wave soldering of through-hole mounted components . 14

4.6 Soldering surface definition techniques . 15

4.6.1 General . 15

4.6.2 Metal defined lands . 15

4.6.3 Solder mask defined lands . 15

4.6.4 Comparison of solder mask defined and non solder mask defined

solderable surfaces . 16

5 Component classification . 16

5.1 General . 16

5.2 Leaded components . 16

5.3 Surface mount components . 17

6 The proportional dimensioning system . 17

7 Terminal classification . 18

7.1 Leaded terminals . 18

7.2 Surface mount terminals . 18

7.2.1 Terminal classes. 18

7.2.2 Flat bottom terminals . 18

7.2.3 General land requirements for flat bottom terminals . 19

7.2.4 Flat bottom and vertical side terminals . 19

7.2.5 General land requirements for flat bottom and vertical side terminals . 20

8 Requirements for lands of solder joints . 20

8.1 Land/Pad dimensioning considerations of leaded terminals . 20

8.2 Land dimensioning considerations of surface mount terminals . 20

Annex A (informative) Dimensioning concept of former IEC 61188-5-1 . 21

A.1 Dimensioning systems . 21

A.1.1 General . 21

A.1.2 Component tolerancing . 22

A.1.3 Solving for dimension Z . 25

A.1.4 Land tolerancing . 25

A.1.5 Fabrication allowances . 25

A.1.6 Assembly tolerancing . 26

A.1.7 Dimension and tolerance analysis . 27

Annex B (informative) History of land dimensioning standards . 29

B.1 IPC-782 . 29

B.2 IEC 61188-5 series . 29

B.3 IPC-7351 . 29

Bibliography . 30

Figure 1 – Component placed on solder paste . 12

Figure 2 – Component glued for wave soldering. 13

Figure 3 – Wave soldered component with solder thieves . 14

Figure 4 – Solder joint of a leaded component . 15

Figure 5 – Leaded component – Capacitor . 17

Figure 6 – Surface mount component – Chip capacitor . 17

Figure 7 – Flat bottom terminals with wettable flanks . 18

Figure A.1 – Profile tolerancing method . 21

Figure A.2 – Example of 3216M capacitor dimensioning for optimum solder fillet

condition . 22

Figure A.3 – Profile dimensioning of gull-wing leaded SOIC . 23

Figure A.4 – Pitch for multiple leaded component . 28

Table 1 – Flat bottom terminals . 19

Table 2 – Flat bottom/vertical side terminals . 19

Table A.1 – Conductor width tolerances . 26

Table A.2 – Feature location accuracy . 26

– 4 – IEC 61188-6-1:2021 © IEC 2021

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

CIRCUIT BOARDS AND CIRCUIT BOARD ASSEMBLIES –

DESIGN AND USE –

Part 6-1: Land pattern design –

Generic requirements for land pattern on circuit boards

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 61188-6-1 has been prepared by IEC technical committee 91: Electronics assembly

technology. It is an International Standard.

This first edition cancels and replaces the first edition of IEC 61188-5-1 published in 2002, and

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) The content is completely updated to reflect current industry requirements. See Introduction.

The text of this International Standard is based on the following documents:

Draft Report on voting

91/1636/CDV 91/1671/RVC

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 61188 series, published under the general title Circuit boards and

circuit board assemblies – Design and use, can be found on the IEC website.

Future documents in this series will carry the new general title as cited above. Titles of existing

documents in this series will be updated at the time of the next edition.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

reconfirmed,

withdrawn,

replaced by a revised edition, or

amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

– 6 – IEC 61188-6-1:2021 © IEC 2021

INTRODUCTION

Explanation why the following standards will be replaced by the new IEC 6188-6 series:

IEC 61188-5-1:2002, Printed boards and printed board assemblies – Design and use – Part 5‑1:

Attachment (land/joint) considerations – Generic requirements

‑2:

IEC 61188-5-2:2003, Printed boards and printed board assemblies – Design and use – Part 5

Attachment (land/joint) considerations – Discrete components

IEC 61188-5-3:2007, Printed boards and printed board assemblies – Design and use – Part 5‑3:

Attachment (land/joint) considerations – Components with gull-wing leads on two sides

IEC 61188-5-4:2007, Printed boards and printed board assemblies – Design and use – Part 5‑4:

Attachment (land/joint) considerations – Components with J leads on two sides

IEC 61188-5-5:2007, Printed boards and printed board assemblies – Design and use – Part 5‑5:

Attachment (land/joint) considerations – Components with gull-wing leads on four sides

‑6:

IEC 61188-5-6:2003, Printed boards and printed board assemblies – Design and use – Part 5

Attachment (land/joint) considerations – Chip carriers with J-leads on four sides

IEC 61188-5-8:2007, Printed board and printed board assemblies – Design and use – Part 5‑8:

Attachment (land/joint) considerations – Area array components (BGA, FBGA, CGA, LGA)

Content is mostly equivalent to IPC-782A with Amendments 1 and 2, which was replaced in

2002 by IPC-7351. The component spectrum and pitch levels have dramatically increased since

publication of the IEC 61188-5 (all parts) and the dimensioning concept does no longer fulfil the

mounting and soldering requirements.

CIRCUIT BOARDS AND CIRCUIT BOARD ASSEMBLIES –

DESIGN AND USE –

Part 6-1: Land pattern design –

Generic requirements for land pattern on circuit boards

1 Scope

This part of IEC 61188 specifies the requirements for soldering surfaces on circuit boards. This

includes lands and land pattern for surface mounted components and also solderable hole

configurations for through-hole mounted components. These requirements are based on the

solder joint requirements of the IEC 61191-1, IEC 61191-2, IEC 61191-3 and IEC 61191-4.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60194, Printed board design, manufacture and assembly – Terms and definitions

IEC 61191-1, Printed board assemblies – Part 1: Generic specification – Requirements for

soldered electrical and electronic assemblies using surface mount and related assembly

technologies

IEC 61191-2:2017, Printed board assemblies – Part 2: Sectional specification – Requirements

for surface mount soldered assemblies

IEC 61191-3, Printed board assemblies – Part 3: Sectional specification – Requirements for

through-hole mount soldered assemblies

IEC 61191-4, Printed board assemblies – Part 4: Sectional specification – Requirements for

terminal soldered assemblies

IEC 61760-3, Surface mounting technology – Part 3: Standard method for the specification of

components for through hole reflow (THR) soldering

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60194, and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

– 8 – IEC 61188-6-1:2021 © IEC 2021

3.1

assembly

number of parts, subassemblies or combinations thereof joined together

Note 1 to entry: This term can be used in conjunction with other terms listed herein, for example, "printed board

assembly".

[SOURCE: IEC 60194:2015, 80.1327, modified – The second term "assembled board" has been

removed.]

3.2

annular ring

portion of conductive material that completely surrounds a hole

3.3

basic dimension

numerical value used to describe the theoretical exact location of a feature or hole

Note 1 to entry: it is the basis from which permissible variations are established by tolerance on other dimensions

in notes or by feature-control symbols.

[SOURCE: IEC 60194-1:2021, 3.2.24, modified – In the definition "for example a hole" has been

replaced by "or hole".]

3.4

castellation

recessed metallised feature on the edge of a leadless chip carrier that is used to interconnect

conducting surfaces or planes within or on the chip carrier

[SOURCE: IEC 60194-1:2021, 3.3.17]

3.5

component

individual part or combination of parts that, when together, perform (a) design function(s)

Note 1 to entry: See also "discrete component" in 3.4.17 of IEC 60194-2:2017.

[SOURCE: IEC 60194-2:2017, 3.3.19]

3.6

land

portion of a conductive pattern usually, but not exclusively, used for the connection and/or

attachment of components

3.7

land pattern

footprint

combination of lands that is used for the mounting, interconnection and testing of a particular

component

Note 1 to entry: Land pattern is also known as "footprint".

[SOURCE: IEC 60194-1:2021, 3.12.9]

3.8

nominal dimension

dimension that is between the maximum and minimum size of a feature (the tolerance on a

nominal dimension gives the limits of variation of a feature size)

3.9

plated through-hole

PTH

hole with plating on its walls that makes an electrical connection between conductive patterns

on internal layers, external layers, or both, of a printed board

[SOURCE: IEC 60194-1, 3.16.72, modified – The figure has been removed.]

3.10

printed board

PB

completely processed printed circuit and printed wiring configurations

Note 1 to entry: This includes single-sided, double-sided and multilayer boards with rigid, flexible, and rigid-flex

base materials.

Note 2 to entry: "Printed board" is a general term.

[SOURCE: IEC 60194-2:2017, 3.16.23, modified – The second term "board" has been removed

as well as the admitted terms "card" and "circuit card.]

3.11

registration

degree of conformity of the position of a pattern (or portion thereof), a hole, or other feature to

its intended position on a product

[SOURCE: IEC 60194-1:2021, 3.18.28]

3.12

soldering surface

solderable metallized surfaces on circuit boards

Note 1 to entry: This includes lands, annular rings and solderable surfaces of plated through-holes.

3.13

SOIC

small outline integrated circuit

surface-mount technology

SMT

technology where electrical connection of components is made to the surface of a conductive

pattern of a printed board and does not utilize component lead holes

3.14

terminal

connection element of an electronic component

3.15

through-hole technology

THT

assembly process for mounting component packages where leads are passed through

supported (plated-through) or unsupported (bare) holes in an interconnection substrate

3.16

via

plated through-hole that is used as an interlayer connection, but in which there is no intention

to insert a component lead or other reinforcing material

Note 1 to entry: See also "blind via" and "buried via" in 3.2.57 and 3.2.118 of IEC 60194-1:2021.

[SOURCE: IEC 60194-1:2021, 3.22.15]

– 10 – IEC 61188-6-1:2021 © IEC 2021

4 Design requirements

4.1 General

Although soldering surfaces are dimensionally defined and since they are a part of the printed

board circuitry geometry, they are subject to the producibility requirements and are influenced

by tolerances associated with plating, etching, assembly or other conditions. The producibility

aspects also pertain to the use of solder mask and legend printing and the registration required

between the solder mask and the conductor patterns. The smaller the component dimensions,

the more is producibility influenced by solder mask and silkscreen thickness. For circuit boards

with component packages size 1005M (0402 imperial size) and smaller, legend printing should

be avoided because it can have detrimental effects on solder paste printing.

This document assumes that the land pattern follows the principle that under nominal conditions,

the overlap of the component termination and the corresponding soldering land will be complete.

The dimensions used for component descriptions shall be taken from standards developed by

industrial and/or standards bodies. Designers should refer to these standards for additional or

specific component package dimensions. When packages are not standardized, manufacturer

datasheets are the foundation for dimensioning.

NOTE 1 For a comprehensive description of the given circuit board and for achieving the best possible solder joints

to the devices assembled, the whole set of design elements includes, in addition to the land pattern definition:

– solder mask;

– copper foil thickness;

– plating thickness;

– solder paste stencil;

– clearance between adjacent components;

– clearance between bottom of component and PCB surface, if relevant;

– keep-out areas, if relevant;

– suitable rules for adhesive applications.

All of these design elements are commonly defined for the mounting conditions. This standard is limited to defining

requirements for land patterns and includes recommendations for clearances between adjacent components and for

other design elements.

NOTE 2 Heat dissipation aspects have not been taken into account in this document.

Heavier components (greater mass per land) require larger lands or annular rings. In some

cases, the lands shown in the standard may not be large enough; in these cases, consideration

of additional measures like gluing can be necessary.

The preferred land form should be rectangular with rounded corners. The area of the smallest

circumscribed rectangle shall be equal to that of one land with straight corners.

4.2 Product classification

The IEC standard on soldering requirements (see IEC 61191-1) recognizes that electrical and

electronic assemblies are subject to classifications by intended end-item use. Three general

end-product types have been established to reflect differences in producibility, functional

performance requirements, and verification (inspection/test) frequency. It should be recognized

that there may be overlaps of equipment between types.

The user of the assemblies is responsible for determining the performance type of the product.

The purchase contract shall specify the product type required and indicate any exceptions or

additional requirements to the parameters, where appropriate.

Products are divided into levels A, B and C according to IEC 61191-1.

– LEVEL A: General electronic products

Includes consumer products, some computers and computer peripherals, and hardware

suitable for applications where the major requirement is functionality of the completed

assembly.

– LEVEL B: Dedicated service electronic products

Includes communications equipment, sophisticated business machines, and instruments

where high performance and extended life is required, and for which uninterrupted service

is desired but not mandatory. Typically the end-use environment would not cause failures.

– LEVEL C: High-performance electronic products

Includes all equipment where continued performance or performance-on-demand is

mandatory. Equipment downtime cannot be tolerated, end-use environment may be

uncommonly harsh, and the equipment shall function when required, such as life support

systems and other critical systems.

4.3 General surface mount land and land pattern requirements

The land pattern for components on circuit boards have to be dimensioned in such a way that,

regardless of the type of termination, a sufficient wettable surface on the circuit board is

provided to form a reliable solder joint during the soldering process, whatever the soldering

technique. This applies to the same extent to surface mounted components as to through-hole

components.

4.4 Component packages and soldering process

The circuit designer selects electronic components that fulfill the electrical requirements of the

end product. With the components, the circuit designer also selects the component package

with the terminals that allow to connect the components to the circuit board. Depending on the

type of terminal, the possible soldering process is also determined. For good manufacturability,

it is very important that the circuit designer knows the relationship between component

packages and the possible soldering methods.

4.5 Soldering surface requirements

4.5.1 Main soldering techniques

Each soldering process has its own requirements for the soldering surfaces. The two main

soldering techniques are reflow soldering and several types of wave soldering. The main

differences between both methods is the available amount of solder and the possibility of

components to move during reflow soldering.

Due to the process characteristics of both soldering techniques, different land dimensions are

required to form reliable solder joints and accurate placement of components after soldering.

4.5.2 Reflow soldering

Reflow soldering is the main soldering technique for soldering of surface mounted components.

First solder paste is deposited to solderable surfaces of the circuit board and after that the

components are placed on the solder paste. See Figure 1.

– 12 – IEC 61188-6-1:2021 © IEC 2021

Figure 1 – Component placed on solder paste

Typically, the components are only fixed by the stickiness of the flux. That is the reason why

the components are swimming on the liquid solder during soldering and can be moved by the

wetting forces of the solder.

The dimensions of the soldering surfaces for reflow soldering on the circuit board are critical:

• if the land is too small, the amount of solder may be insufficient to form a reliable solder

joint;

• if the land is too large, the wetting forces may move the component in one direction, which

can cause displacement to the extent of an open solder joint occurring;

• if the land is too large and the wetting forces on the vertical side of the terminal are greater

than on the bottom side, the component can be lifted by torque, leading to tombstoning and

an open solder joint.

• if the finished land sizes on the circuit board are different for both terminals of the

component, this imbalance also can cause tombstoning

4.5.3 Reflow soldering of leaded components

The process of reflow soldering of leaded components is called “through-hole reflow” or

sometimes also “pin in paste”. In this process, special requirements shall be met with regard to

the temperature resistance of components and the required volume of solder paste. The circuit

board designer has to select components carefully depending on the type of solder paste used

for reflow soldering. IEC 61760-3 shall be applied. Special care is required to apply enough

solder paste to fill the hole around the component pins and form a reliable solder joint.

4.5.4 Wave soldering of surface mounted components

During wave soldering, the surface mounted components shall be fixed by glue because they

are attached on the bottom surface of the circuit board. See Figure 2.

The board is then moved, face down, through the solder wave and the components are soldered.

There are only a limited number of surface mounted packages that can be wave soldered. The

circuit board designer shall check the manufacturer datasheets concerning soldering process

limitations.

For chip components smaller than 1608M (0603 imperial) and integrated circuits with pitches

less than 1,27 mm (50 mil imperial) wave soldering is not recommended.

In contrast to reflow soldering, the available solder volume compared to the required solder

volume to form a reliable solder joint is nearly unlimited. Additionally, as the components are

glued and cannot move, there is no risk that the lands are too large.

To avoid solder bridges, components shall be placed at a safe distance from each other.

Figure 2 – Component glued for wave soldering

Chip components should be placed parallel to the solder wave, integrated circuits like SO-

packages with gullwing terminals should be placed parallel to the board transport direction and

should be equipped with solder thieves. See Figure 3.

– 14 – IEC 61188-6-1:2021 © IEC 2021

Figure 3 – Wave soldered component with solder thieves

The dimensions of the soldering surfaces for wave soldering on the circuit board are only critical:

• if the lands are too small the solder wave may not get contact to the land, so that no sufficient

solder joint is formed;

• if the components are placed too close to each other solder bridging will occur.

4.5.5 Wave soldering of through-hole mounted components

Leaded components are inserted into holes of the circuit board from one side of the board and

then soldered from the other side. The solder wave contacts the leads and fills the holes in

direction of the opposite side with solder. See Figure 4.

Critical concerning solder fill of the hole is the gap between the lead and the plated hole wall:

– if the hole diameter is too small compared to the lead diameter, solder fill of the hole will be

insufficient to form a reliable solder joint;

– the same may be the case if the hole diameter is too big compared to the lead diameter.

Figure 4 – Solder joint of a leaded component

The second critical parameter for wave soldering is the size of the annular ring which influences

the heat input into the hole especially during selective soldering.

For lead-free selective wave soldering, dimensions of the annular ring should be especially

optimized for maximum heat transfer on the solder contact side and minimized for least heat

dissipation on the opposite side.

4.6 Soldering surface definition techniques

4.6.1 General

If the circuit board is covered with a solder mask, there are two different techniques to define

the extension of the solderable surfaces in design libraries. The more common concept are the

metal defined lands. The other concept are the solder mask defined lands. Both concepts have

advantages and disadvantages which are outlined in 4.6.2 to 4.6.4. The specific

recommendations made by the component manufacturers should also be taken into account.

4.6.2 Metal defined lands

If the circuit board is not equipped with a solder mask and even if there is a solder mask on the

circuit board, in most cases there is a solder mask clearance around the solderable surfaces.

Mostly this technique is called "Non Solder Mask Defined" (NSMD). Sometimes it is also called

“metal defined” because the metal part of the soldering surface determines its size.

4.6.3 Solder mask defined lands

In case of the solder mask defined lands there is a negative clearance of the solder mask

compared to the metal part, so that the solder mask opening is smaller than the metal surface

and the solder mask opening determines the solderable surface.

– 16 – IEC 61188-6-1:2021 © IEC 2021

4.6.4 Comparison of solder mask defined and non solder mask defined solderable

surfaces

Non solder mask defined lands are characterized by

• wettable surface bigger than solder mask defined of same diameter because the copper

thickness of the land increases the wettable surface;

• wettable surface is primarily dependent on the open metal surface connected to the pad or

land;

• variation of solder joints of same terminal type can be very big;

• copper adhesion less than solder mask defined because the solder mask improves land

adhesion;

• more frequently an uneven board topology depending on the surrounding circuitry with

solder mask over traces and copper planes.

Solder mask defined lands are defined by

• wettable surface smaller than metal defined, but all lands of same termination type have

same solderable surface. As a result the solder joint topology is very homogeneous for a

given terminal type;

• copper adhesion is better than metal defined of same diameter;

• flat board topology (if all solderable surfaces are solder mask defined).

5 Component classification

5.1 General

Based on construction of terminals and the related mounting and attachment technology

components are divided in two main classes. The first and historical class of components are

the components with leaded terminals which are soldered in plated through-holes (PTH) of the

circuit board. The mounting and attachment technology of the components is called Through-

Hole Technology or THT.

The second and newer component technology includes components with terminals that can be

soldered to the surface of the circuit board. The mounting and attachment technology of these

components is called Surface Mount Technology or SMT.

Due to the different shape and size of their terminals, the requirements for the lands and land

pattern are also different. For the circuit board designer, it is important to know the different

termination types, the solder joint requirements and the relation between solder joint formation

and land dimensions.

5.2 Leaded components

Leaded components consist of a body with one or multiple electrical functional elements and

leads which enable the connection to the surrounding circuitry of the circuit board by soldering.

See Figure 5.

Figure 5 – Leaded component – Capacitor

5.3 Surface mount components

Surface mounted components are equipped with terminals that allow attachment on the surface

of a circuit board without holes. See Figure 6. Since their emergence, several terminal types

were developed.

Figure 6 – Surface mount component – Chip capacitor

6 The proportional dimensioning system

The traditional dimensioning system of the former IEC 61188-5-1 and also the IPC 7351 is

based on an algorithm that assumes constant values for protrusions and process tolerances.

This causes increasing problems for circuit board assembly if the components become smaller.

In contrast, the proportional dimensioning concept is based on the type, properties, size and

height of the component terminals that are relevant for the formation of a reliable solder joint.

The size of the soldering surface on the circuit board for surface mounted devices is calculated

with the dimensions of the terminals.

If the solder joint requirements for a terminal type have a height requirement and thus a

protrusion of the soldering surface is required, the protrusion dimensions are calculated as a

percentage of the solder height requirement.

Therefore, the soldering surface is no longer classified by the component package but by the

terminal type of the component package.

– 18 – IEC 61188-6-1:2021 © IEC 2021

7 Terminal classification

7.1 Leaded terminals

Leaded terminals can have a round, square or rectangle profile and shall have a wettable end

metallisation.

7.2 Surface mount terminals

7.2.1 Terminal classes

Depending on the properties of the terminals, there are two classes of surface mounted

terminals.

The first class has flat bottom terminals. These terminals have flat soldering surfaces as

terminals on the bottom of the package. From the viewpoint of the soldering process, there are

two flat surfaces opposite to each other. The flat soldering surface on the bottom of the

component package and the flat soldering surface on the circuit board. Both soldering surfaces

are connected by the solder joint. In this case, no protrusion is required.

The second class are the flat bottom and vertical side terminals. See Figure 7. These ter

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...