IEC 61298-4:2008

(Main)Process measurement and control devices - General methods and procedures for evaluating performance - Part 4: Evaluation report content

Process measurement and control devices - General methods and procedures for evaluating performance - Part 4: Evaluation report content

IEC 61298-4:2008 specifies general methods and procedures for conducting tests, and reporting on the functional and performance characteristics of process measurement and control devices. The tests are applicable to any such devices characterized by their own specific input and output variables, and by the specific relationship (transfer function) between the inputs and outputs, and include analogue and digital devices. For devices that require special tests, this standard should be used, together with any product specific standard specifying special tests. It specifies the content of the written report on the evaluation or tests on a process measurement or control device, and the results obtained. It specifies the major items which should be included in the evaluation report.

Dispositifs de mesure et de commande de processus - Méthodes et procédures générales d'évaluation des performances - Partie 4: Contenu du rapport d'évaluation

La CEI 61298-4:2008 spécifie les méthodes et procédures générales pour l'exécution des essais portant sur les caractéristiques fonctionnelles et les caractéristiques de performances des dispositifs de mesure et de commande de processus. Ces essais sont applicables à tout dispositif à condition que ce dispositif soit caractérisé par ses propres grandeurs d'entrée et de sortie et par la relation spécifique (fonction de transfert) entre les entrées et les sorties. Ils concernent les dispositifs analogiques et numériques. Pour les dispositifs nécessitant des essais spéciaux, il convient que la présente norme soit utilisée en conjonction avec la norme particulière de produit spécifiant ces essais spéciaux. Elle précise le contenu du rapport écrit qui décrit l'évaluation ou une série d'essais sur un dispositif de mesure ou de commande de processus, et les résultats obtenus. Elle spécifie les principaux articles qu'il convient d'inclure dans le rapport d'évaluation.

General Information

- Status

- Published

- Publication Date

- 07-Oct-2008

- Technical Committee

- SC 65B - Measurement and control devices

- Drafting Committee

- WG 6 - TC 65/SC 65B/WG 6

- Current Stage

- PPUB - Publication issued

- Start Date

- 08-Oct-2008

- Completion Date

- 31-Oct-2008

Overview

IEC 61298-4:2008 is an International Electrotechnical Commission (IEC) standard focused on the evaluation reporting for process measurement and control devices. It outlines general methods and procedures for conducting performance tests and, most importantly, specifies the content requirements for the evaluation reports generated from such tests. This standard applies to a wide range of devices, including analog and digital, characterized by their unique input-output variables and transfer functions. It complements product-specific standards that may prescribe special tests, providing a consistent framework for documenting functional and performance characteristics.

Key Topics

Report Content and Structure

IEC 61298-4:2008 defines the critical sections and elements to be included in an evaluation report but leaves the exact formatting choices to the discretion of the testing laboratory. Essential components highlighted by the standard include:

- Report Title: Must contain the report number, date of issue, manufacturer’s name and country, instrument type, and model identification.

- Preliminary Pages: Such as title page, contents, and photographs of the device under test.

- Introduction: Contextualizing the evaluation scope and objectives.

- Major Findings and Comments: Summarizing key test results and interpretations.

- Manufacturer’s Comments: Allowing for manufacturer feedback on the test outcomes.

- Test Results: Presented both numerically and graphically, providing comprehensive insights into device performance.

- Operating Principles and Construction: Detailing the technical basis and mechanical setup of the device.

- Test Methods: Referencing applied procedures used during evaluation.

- Definitions and References: Clarifying terms and citing relevant documents.

- Annexes: Supplementary materials supporting the report.

Report Management Practices

The standard specifies good practices to ensure report reliability and clarity:

- Report Coverage: One report per device evaluation to maintain clarity and traceability.

- Binding and Pagination: Pages should be securely bound and sequentially numbered, employing formats like “Page x of y” to enhance usability.

- Draft and Final Versions: Drafts can be issued for review with clear labeling, followed by finalized versions for formal records.

- Abridged Reports: Optional summaries may be issued but must retain key elements consistent with the full report.

- Use of Units: Emphasizes the use of SI units, with other units allowed if accompanied by their SI equivalents.

Applications

IEC 61298-4:2008 is highly relevant for laboratories, manufacturers, and certification bodies involved in:

- Performance Evaluation of Process Instruments: Standardizing how test results and functional specifications for measurement and control devices are documented.

- Quality Assurance: Ensuring consistency and transparency in reporting enhances trustworthiness across supply chains.

- Product Development and Validation: Offering structured feedback mechanisms through formalized report sections such as manufacturer comments and detailed test results.

- Regulatory Compliance and Certification: Supporting detailed, internationally recognized documentation for compliance with industry regulations.

This standard acts as a foundational document when developing product-specific standards within IEC or other organizations, streamlining efforts to maintain consistency and quality in performance reporting.

Related Standards

IEC 61298-4:2008 integrates with other IEC standards and references that support measurement and control technologies, such as:

- IEC 60050 Series: The International Electrotechnical Vocabulary (IEV) parts relevant to electrical and electronic measurements (Parts 300, 351, etc.), which provide standard terminology essential for clear report writing.

- Other Parts of IEC 61298 Series: Covering broader procedures for evaluating performance characteristics, with part 4 focusing specifically on report content.

- Industry-Specific Standards: Where special test procedures apply, IEC 61298-4 serves as a complementary referencing document for comprehensive evaluation documentation.

Keywords: IEC 61298-4:2008, process measurement devices, control device evaluation, performance testing, evaluation report content, process automation standards, IEC standards, IEC evaluation reports, measurement device testing, process control instrumentation, test report guidelines, international electrotechnical commission.

Frequently Asked Questions

IEC 61298-4:2008 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Process measurement and control devices - General methods and procedures for evaluating performance - Part 4: Evaluation report content". This standard covers: IEC 61298-4:2008 specifies general methods and procedures for conducting tests, and reporting on the functional and performance characteristics of process measurement and control devices. The tests are applicable to any such devices characterized by their own specific input and output variables, and by the specific relationship (transfer function) between the inputs and outputs, and include analogue and digital devices. For devices that require special tests, this standard should be used, together with any product specific standard specifying special tests. It specifies the content of the written report on the evaluation or tests on a process measurement or control device, and the results obtained. It specifies the major items which should be included in the evaluation report.

IEC 61298-4:2008 specifies general methods and procedures for conducting tests, and reporting on the functional and performance characteristics of process measurement and control devices. The tests are applicable to any such devices characterized by their own specific input and output variables, and by the specific relationship (transfer function) between the inputs and outputs, and include analogue and digital devices. For devices that require special tests, this standard should be used, together with any product specific standard specifying special tests. It specifies the content of the written report on the evaluation or tests on a process measurement or control device, and the results obtained. It specifies the major items which should be included in the evaluation report.

IEC 61298-4:2008 is classified under the following ICS (International Classification for Standards) categories: 25.040.40 - Industrial process measurement and control. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61298-4:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61298-4

Edition 2.0 2008-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Process measurement and control devices – General methods and procedures

for evaluating performance –

Part 4: Evaluation report content

Dispositifs de mesure et de commande de processus – Méthodes et procédures

générales d'évaluation des performances –

Partie 4: Contenu du rapport d'évaluation

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61298-4

Edition 2.0 2008-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Process measurement and control devices – General methods and procedures

for evaluating performance –

Part 4: Evaluation report content

Dispositifs de mesure et de commande de processus – Méthodes et procédures

générales d'évaluation des performances –

Partie 4: Contenu du rapport d'évaluation

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

M

CODE PRIX

ICS 25.040.40 ISBN 978-2-88910-486-4

– 2 – 61298-4 © IEC:2008

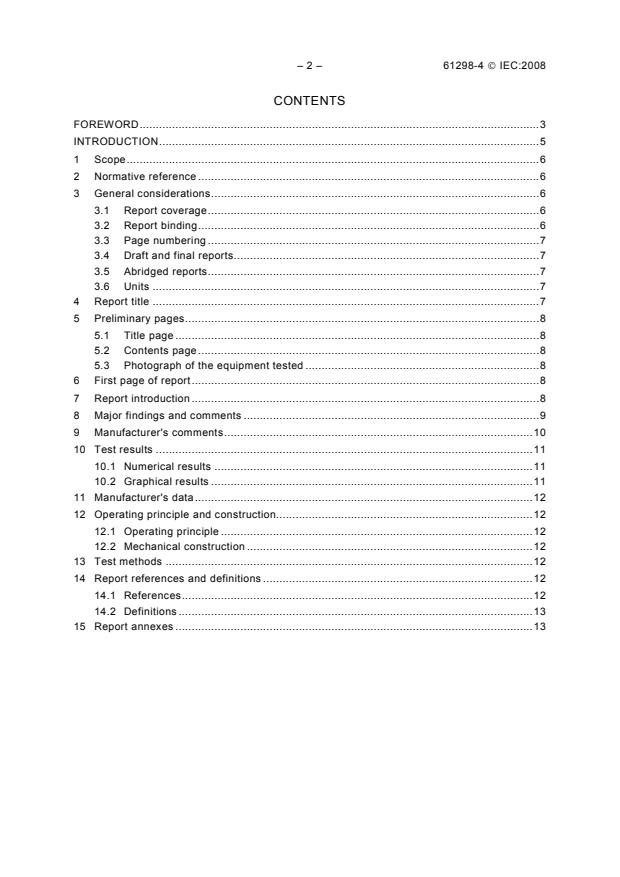

CONTENTS

FOREWORD.3

INTRODUCTION.5

1 Scope.6

2 Normative reference .6

3 General considerations.6

3.1 Report coverage.6

3.2 Report binding.6

3.3 Page numbering .7

3.4 Draft and final reports.7

3.5 Abridged reports.7

3.6 Units .7

4 Report title .7

5 Preliminary pages.8

5.1 Title page .8

5.2 Contents page.8

5.3 Photograph of the equipment tested .8

6 First page of report.8

7 Report introduction .8

8 Major findings and comments .9

9 Manufacturer's comments.10

10 Test results .11

10.1 Numerical results .11

10.2 Graphical results .11

11 Manufacturer's data.12

12 Operating principle and construction.12

12.1 Operating principle .12

12.2 Mechanical construction .12

13 Test methods .12

14 Report references and definitions .12

14.1 References.12

14.2 Definitions .13

15 Report annexes .13

61298-4 © IEC:2008 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PROCESS MEASUREMENT AND CONTROL DEVICES –

GENERAL METHODS AND PROCEDURES

FOR EVALUATING PERFORMANCE –

Part 4: Evaluation report content

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61298-4 has been prepared by subcommittee 65B: Devices and

process analysis, of IEC technical committee 65: Industrial-process measurement, control and

automation.

This second edition cancels and replaces the first edition published in 1995 and constitutes a

technical revision.

This edition is a general revision with respect to the previous edition and does not include any

significant changes (see Introduction).

– 4 – 61298-4 © IEC:2008

The text of this standard is based on the following documents:

FDIS Report on voting

65B/688/FDIS 65B/696/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 61298 series, under the general title Process measurement and

control devices – General methods and procedures for evaluating performance, can be found

on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

61298-4 © IEC:2008 – 5 –

INTRODUCTION

This standard is not intended as a substitute for existing standards, but is rather intended as a

reference document for any future standards developed within the IEC or other standards

organizations, concerning the evaluation of process instrumentation. Any revision of existing

standards should take this standard into account.

This common standardized basis should be utilized for the preparation of future relevant

standards, as follows:

– any test method or procedure, already treated in this standard, should be specified and

described in the new standard by referring to the corresponding clause of this standard.

Consequently new editions of this standard are revised without any change in numbering

and scope of each clause;

– any particular method or procedure, not covered by this standard, should be developed

and specified in the new standard in accordance with the criteria, as far as they are

applicable, stated in this standard;

– any conceptual or significant deviation from the content of this standard, should be clearly

identified and justified if introduced in a new standard.

– 6 – 61298-4 © IEC:2008

PROCESS MEASUREMENT AND CONTROL DEVICES –

GENERAL METHODS AND PROCEDURES

FOR EVALUATING PERFORMANCE –

Part 4: Evaluation report content

1 Scope

This part of IEC 61298 specifies general methods and procedures for conducting tests, and

reporting on the functional and performance characteristics of process measurement and

control devices. The tests are applicable to any such devices characterized by their own

specific input and output variables, and by the specific relationship (transfer function) between

the inputs and outputs, and include analogue and digital devices. For devices that require

special tests, this standard should be used, together with any product specific standard

specifying special tests.

This standard specifies the content of the written report on the evaluation or tests on a

process measurement or control device, and the results obtained.

It specifies the major items which should be included in the evaluation report, but it does not

specify the exact format in which the contents should be presented. (This is left to the

discretion of the test laboratory which prepares and issues the report.)

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050 (all parts), International Electrotechnical Vocabulary (IEV)

IEC 60050-300, International Electrotechnical Vocabulary (IEV) – Electrical and electronic

measurements and measuring instruments (composed of Part 311, 312, 313 and 314)

IEC 60050-351, International Electrotechnical Vocabulary (IEV) – Part 351 : Control

technology

3 General considerations

3.1 Report coverage

One report shall refer to one evaluation on a subject device. If a second evaluation is made

on the same device, then a separately numbered report shall be issued.

3.2 Report binding

Each copy of the report shall be bound with covers, so that the pages cannot become

separated. No particular method of binding together the pages of the report is specified. This

is left to the discretion of the test laboratory issuing the report.

61298-4 © IEC:2008 – 7 –

3.3 Page numbering

Each page of the report shall be identified with a unique, sequential page number. It is a

convention to regard the first page of text in the report as page 1, with subsequent pages

numbered sequentially.

Page numbers shall be shown in the format "Page 'x' of 'y'" , where 'x' is the specific page

number and 'y' is the number of the last page of the report. The report number should be

given also.

If a separate title page is placed at the front of the report, this is not usually included in the

page numbering sequence.

3.4 Draft and final reports

It is sometimes desirable and advantageous to issue a preliminary, draft version of an

evaluation report for comment prior to the issue of a formal, final version of the report.

Each page of draft reports shall be clearly identified as such, but need not be presented or

bound exactly as the subsequent final report.

3.5 Abridged reports

At the discretion of the issuing authority, or the test laboratory, an abridged version of the

report may be issued, complementary to the full report. If an abridged report is issued, it shall

always include at least the introduction, major findings, and manufacturer's comments, exactly

as presented in the full report.

3.6 Units

SI units should be used throughout the report. When other units need to be used, the SI

equivalent should be given in brackets alongside.

4 Report title

Each report title shall give all the following information:

– report number;

– date of issue;

– manufacturer's name, and country of manufacture;

– instrument type;

– model name or number.

The report number shall be a unique number, one of a series, which refers only to one report

of one evaluation, or possibly a series of evaluations.

The manufacturer's name shall be the full name of the manufacturer company at the time

when the instrument was supplied for evaluation. Any changes in name during the period of

evaluation should be indicated in the introduction of the report.

The country of manufacture shall be where the device was finally assembled into a complete

'instrument'. This may not be the same as the country from which the instrument was supplied

for evaluation. The correct status may need to be confirmed by the author of the report.

The instrument type shall be a brief, general description of function, application details and

size or range.

– 8 – 61298-4 © IEC:2008

Any further details about the equipment itself, or the range of tests applied, should be

described in the introduction of the report.

5 Preliminary pages

5.1 Title page

This page shall include the full report title, as specified in Clause 4, plus the name of the test

laboratory and the names(s) of the author(s).

The report shall identify the sponsor of the evaluation and any information regarding the use

of any proprietary information contained.

Additional information about the laboratory compiling the report may be provided on this page

at the discretion of the laboratory.

This page is not usually numbered.

5.2 Contents page

This page is not included in the sequence of page numbers for the text of the report.

5.3 Photograph of the equipment tested

This shall always be shown in Figure 1. It should preferably appear facing page 1 of the

report.

It should be a photograph of the equipment actually tested with the covers on, three-quarter

front view, if this is possible. If a photograph of the same type of equipment, provided by the

manufacturer, is used, this should be stated.

A scale, or some other means to indicate the size of the equipment, shall be included in

Figure 1.

6 First page of report

This page shall always contain the heading to the report and the introduction. It may also

contain the first part of the "Major findings and comments" clause.

The heading to the report shall always contain at least the following information:

– title of the report (including manufacturer's name, type of device and model);

– author(s) names(s) and professional qualifications;

– name of evaluation laboratory;

– project number;

– sponsor(s) of the project;

– report number;

– date (month and year) of issue of the final report.

7 Report introduction

The introduction should not cover more than one page. The paragraphs indicated below

should be included in this clause, using the standard wording shown in italic print, wherever

relevant.

61298-4 © IEC:2008 – 9 –

Paragraph 1 – "This report describes the evaluation of a. (instrument and model)

manufactured by. (manufacturer's name). The instrument was a.

(standard production/prototype/etc. model) manufactured in. (country of

manufacture)".

Paragraph 2 – "The instrument was evaluated to a test programme drawn up by.

(laboratory or sponsor) based on. (quote briefly the main relevant

standards – do not give full references here – these will be given in

subclause 14.1)".

Paragraph 3 – Functional purpose of instrument tested. Give also, as appropriate, input

span, output span, range, and whether adjustable or not.

Paragraph 4 – The manufacturer's quoted indication of general performance.

Paragraph 5 – A brief description of the principle of operation.

Paragraph 6 – Primary application, intended environment, ancillary equipment, options

available, special features, etc., power supply required, safety status

(whether approved or not for use in flammable atmospheres).

Paragraph 7 – "The equipment was delivered on. and was evaluated over a period

of. weeks/months from. (commencement date) until. (date of

completion of tests)." If this period is unduly protracted the reason(s) for

the delays should be briefly stated.

8 Major findings and comments

Two sentences similar to the following examples shall appear immediately under the title.

"These findings are summarized here for ready reference, and to give an overview of the

evaluation. For a complete assessment of the instrument, the report shall be read and

considered as a whole."

"All errors and changes are expressed as a percentage of output span unless otherwise

stated."

This clause should summarize and comment on the most significant findings from the

evaluation. The comments should be brief and concise, and, for example, may be grouped

under the following headings.

Manufacturer's performance specifications

Briefly comment if the manufacturer's specifications are not comprehensive.

Satisfactory performance features

State all the tests in which the results were satisfactory and within the manufacturer's relevant

specification. If required, a summary of the results may be given.

Performance outside specification

State all the tests in which the results were not satisfactory, or outside the manufacturer's

specification. A summary of the results should be given.

– 10 – 61298-4 © IEC:2008

Aspects of unspecified performance

Summarize the results of tests for which there was no manufacturer's specification.

Unexpected events

Unexpected events observed during the evaluation, such as a fault, and the action taken,

should be reported here. More detailed reference to this should be given in Clause 10. Give

brief details of any repairs carried out, by whom, and how quickly. If essential, a detailed

description can be included as an annex to the report.

Construction and maintenance

Give brief comments on the quality of materials, construction, workmanship, finishes, etc.

State any production faults found during initial visual inspection, and during testing. If

possible, state whether components were of assessed quality, and whether finishes stood up

to humidity testing, corrosion testing, drop or shock testing, and ordinary handling. If

appropriate, comment on any potential difficulties for maintenance.

Installation

State the method of installation and give any comments on the likely ease or difficulties and

state the time likely to be taken.

Commissioning

Report whether or not any commissioning was necessary and, if so, the time taken, who did it

and how easy it was, or whether any difficulties were experienced.

Safety

State the operator safety aspects (covers over live terminals, interlocks on doors, etc.). This

paragraph should only be included when there is an unsafe feature to report.

Packaging

Comment on the adequacy, or otherwise, of the packaging for shipment. This paragraph

should be included only when there is some deficiency to report.

Comments on documentation

Comment on the quality, adequacy and ease of use of the handbooks, manuals, spare parts

list and other printed data and literature supplied automatically by the manufacturer, or on the

request of the test laboratory. State the language in which the manuals are written and

whether they are available in any other language.

9 Manufacturer's comments

When an evaluation report is to be distributed to organizations other than the manufacturer,

the manufacturer should be invited to make comments on a draft copy of the relevant report.

The manufacturer's written comments should be included in the final version of the report.

The manufacturer's comments should usually be restricted to one page, except under

exceptional circumstances. They should relate directly to the results of the evaluation/testing

as described in the report, and should not include any statements of a commercial or

promotional nature.

Wherever possible, comments made by the manufacturer should be reproduced verbatim. The

manufacturer's text should not be edited, except in the following circumstances:

61298-4 © IEC:2008 – 11 –

a) Comments made by the manufacturer on typographical errors, omissions or editorial

matters which have been amended in the final report are not to be reproduced.

b) Reference made to report page numbers or paragraphs shall be checked and amended if

necessary to make accurate references to the text of the final report.

c) Errors of fact (or statements of a promotional nature or of controversial opinion) made by

the manufacturer in his comments are to be amended only after his express agreement

has been obtained that this may be done.

d) If a manufacturer insists that his statements of a controversial nature shall stand, they

shall be reproduced verbatim. If this occurs, additional comments by the test laboratory

may be included to clarify the situation. Such comments shall be identified as "additional

laboratory comments".

In cases where the manufacturer does not provide any comments or states that he does not

have any comments to add, one of the two following statements should be included as

appropriate:

"The manufacturer, although requested to do so, did not provide any comments."

or

"The manufacturer stated that he had no comments to make on the report."

10 Test results

10.1 Numerical results

The full results of each test shall be presented, in tabular form, in the order in which the tests

were conducted.

A short statement of the measurement uncertainty, resolution, and method of expressing

errors shall be given at the head of the table.

Wherever possible, results should be presented in a standardized summary format, showing

the manufacturer's specification (where available) against the test results. Detailed tables of

test results shall be given separately at the end. Unexpected behaviour of the device shall be

reported.

Sufficient information shall be given to enable the reader to calculate differences in

performance from that under reference conditions.

10.2 Graphical results

Graphs of detailed results, chart recordings, etc., should be presented in addition to tabulated

results. Common axes should be used wherever possible.

The choice of information presented graphically shall be made in relation to its importance

and its visual impact.

The principal graphs included in a report are:

– inaccuracy under reference conditions;

– ambient temperature effects;

– frequency response;

– long-term drift.

– 12 – 61298-4 © IEC:2008

11 Manufacturer's data

Additional information about the instrument specification and other technical details from the

manufacturer's data sheet should be summarized. For example, the manufacturer's full name,

supplier's name and address, serial number, full model number, dimensions, mass, etc.

12 Operating principle and construction

12.1 Operating principle

The physical principle of measurement and/or operation (and, if appropriate, the chemical

principle) of the instrument shall be described, clearly and concisely. Usually it is not

sufficient merely to copy or paraphrase the manufacturer's sales brochures. Puzzling phrases,

technical jargon, and obscure abbreviations should be avoided. In general, two to three

paragraphs should be sufficient.

A simple block diagram or functional scheme is often appropriate and necessary as an aid to

understanding the description.

12.2 Mechanical construction

This subclause should be descriptive only and should be included if it is necessary to give

more information than that given in Clause 8. It may be useful to copy or refer to a diagram or

exploded view of the equipment taken from the manufacturer's literature.

13 Test methods

The clause shall begin with a statement of the basic test arrangement, the uncertainty of

measurement and the reference conditions. A simple diagram or scheme of test arrangements

shall accompany this statement, but over-elaborate drawings are not required for this purpose

and should be avoided.

Brief and concise descriptions of the actual method used for each test shall be given. It is

usually not sufficient to repeat or paraphrase the wording used in the test programme. Further

simple line diagrams may be useful to make clear the descriptions of some test arrangements.

If the test was carried out according to a specific test standard, reference shall be made to the

appropriate clause or figure.

The descriptions of the test methods shall be in the same sequence as the tests were carried

out.

Detailed descriptions of special or new test methods should not be included here. If such

detailed expositions are required, they should be included as an annex at the end of the

report.

14 Report references and definitions

14.1 References

The title of international standards, national standards, appropriate user test specifications,

and any other specifications, including the manufacturer's performance specification on which

the test programme was based, shall be given in full, including identification number and date

of issue. Reference to standard compilations of data, e.g. thermodynamic properties of ga

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...