IEC 62790:2014

(Main)Junction boxes for photovoltaic modules - Safety requirements and tests

Junction boxes for photovoltaic modules - Safety requirements and tests

IEC 62790:2014 describes safety requirements, constructional requirements and tests for junction boxes up to 1 500 V dc for use on photovoltaic modules according to class II of IEC 61140:2001. This standard applies also to enclosures mounted on PV-modules containing electronic circuits for converting, controlling, monitoring or similar operations.

Boîtes de jonction pour modules photovoltaïques - Exigences de sécurité et essais

L'IEC 62790:2014 décrit les exigences de sécurité, les exigences de construction et les essais relatifs aux boîtes de jonction jusqu'à 1 500 V en courant continu utilisées sur des modules photovoltaïques conformes à la classe II de l'IEC 61140:2001. La présente Norme s'applique également aux enveloppes montées sur des modules photovoltaïques comportant des circuits électroniques pour la conversion, le contrôle, la surveillance ou opérations similaires.

General Information

- Status

- Published

- Publication Date

- 05-Nov-2014

- Technical Committee

- TC 82 - Solar photovoltaic energy systems

- Drafting Committee

- WG 2 - TC 82/WG 2

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 15-Jul-2020

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62790:2014 is an international standard published by the International Electrotechnical Commission (IEC) that defines the safety requirements, constructional criteria, and testing protocols for junction boxes used in photovoltaic (PV) modules. This standard applies to junction boxes operating up to 1500 V DC and is aligned with Class II requirements of IEC 61140:2001. It also covers PV module enclosures integrating electronic circuits for functions such as converting, controlling, or monitoring photovoltaic power.

By adhering to IEC 62790, manufacturers and installers ensure reliable and safe connectivity within solar modules, minimizing the risk of electrical hazards and improving the operational longevity of solar power systems.

Key Topics

Scope and Application

IEC 62790 covers junction boxes installed on photovoltaic modules, including those with embedded electronic circuits. It is relevant for systems with voltages up to 1500 V DC, addressing both mechanical and electrical safety aspects.Constructional Requirements

The standard specifies construction criteria including:- Marking and identification

- Protection against electric shock

- Design of terminations, connectors, and cables

- Resistance to aging, corrosion, and environmental conditions

- Degree of ingress protection (IP rating)

- Mechanical strength and thermal stability

- Specification of insulation types (basic, supplementary, double, and reinforced insulation)

- Clearances and creepage distances critical for preventing electrical discharge

Safety Tests

IEC 62790 outlines comprehensive test procedures to validate junction box compliance. Key tests include:- Dielectric strength and insulation resistance

- Mechanical strength at varying temperatures

- Thermal cycling and damp heat exposure

- Resistance to weathering and UV degradation

- Flammability and glow wire tests

- Bypass diode thermal performance

- Reverse current and cord anchorage testing

Documentation and Marking

The standard requires clear identification marks on junction boxes and thorough technical documentation that supports safety claims and aids verification.

Applications

IEC 62790 is essential for manufacturers designing and producing junction boxes for PV modules used in residential, commercial, and utility-scale solar installations. Its requirements enhance:

Electrical Safety

Ensures safe handling, installation, and operation by preventing electric shock and short circuits.Durability and Reliability

Through stringent testing, junction boxes maintain performance in harsh outdoor environments, including exposure to moisture, temperature fluctuations, and UV radiation.Quality Assurance

Helps manufacturers meet international certification requirements, facilitating global market access and ensuring customer confidence.Integration with PV Systems

Allows seamless integration of electronic components within junction boxes, such as MPPT converters or monitoring electronics, without compromising safety.

Related Standards

Adoption of IEC 62790 is often coordinated with other standards for PV systems and components, including:

- IEC 61140:2001 – Protection against electric shock classifications which IEC 62790 references for PV junction boxes.

- IEC 60068 – Environmental testing procedures such as thermal cycling and damp heat tests referenced in IEC 62790.

- IEC 60364 – Electrical installations of buildings that includes safety practices relevant to PV systems.

- IEC 61730 – Photovoltaic module safety qualification standards covering module construction and testing.

- IEC 61215 – Design qualification testing for crystalline silicon PV modules, complementing junction box safety.

By ensuring compliance with IEC 62790, stakeholders in the solar industry reinforce safety, reliability, and performance in photovoltaic module connectivity, accelerating the deployment of secure and efficient solar energy systems worldwide.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC 62790:2014 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Junction boxes for photovoltaic modules - Safety requirements and tests". This standard covers: IEC 62790:2014 describes safety requirements, constructional requirements and tests for junction boxes up to 1 500 V dc for use on photovoltaic modules according to class II of IEC 61140:2001. This standard applies also to enclosures mounted on PV-modules containing electronic circuits for converting, controlling, monitoring or similar operations.

IEC 62790:2014 describes safety requirements, constructional requirements and tests for junction boxes up to 1 500 V dc for use on photovoltaic modules according to class II of IEC 61140:2001. This standard applies also to enclosures mounted on PV-modules containing electronic circuits for converting, controlling, monitoring or similar operations.

IEC 62790:2014 is classified under the following ICS (International Classification for Standards) categories: 01 - GENERALITIES. TERMINOLOGY. STANDARDIZATION. DOCUMENTATION; 27.160 - Solar energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62790:2014 has the following relationships with other standards: It is inter standard links to IEC 62790:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62790:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62790 ®

Edition 1.0 2014-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Junction boxes for photovoltaic modules – Safety requirements and tests

Boîtes de jonction pour modules photovoltaïques – Exigences de sécurité et

essais

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 55 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 62790 ®

Edition 1.0 2014-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Junction boxes for photovoltaic modules – Safety requirements and tests

Boîtes de jonction pour modules photovoltaïques – Exigences de sécurité et

essais

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX XA

ICS 27.160 ISBN 978-2-8322-1899-0

– 2 – IEC 62790:2014 © IEC 2014

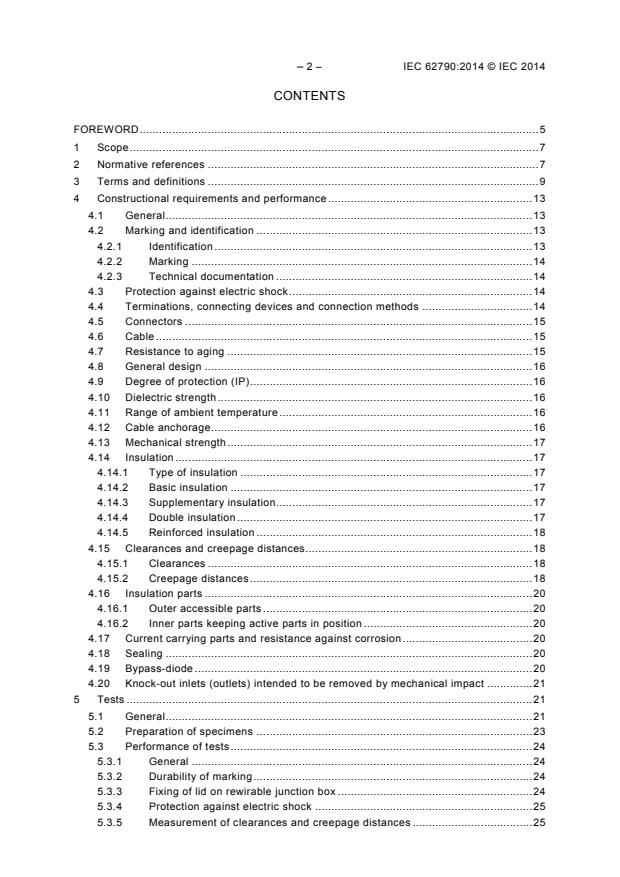

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 9

4 Constructional requirements and performance . 13

4.1 General . 13

4.2 Marking and identification . 13

4.2.1 Identification . 13

4.2.2 Marking . 14

4.2.3 Technical documentation . 14

4.3 Protection against electric shock . 14

4.4 Terminations, connecting devices and connection methods . 14

4.5 Connectors . 15

4.6 Cable . 15

4.7 Resistance to aging . 15

4.8 General design . 16

4.9 Degree of protection (IP) . 16

4.10 Dielectric strength . 16

4.11 Range of ambient temperature . 16

4.12 Cable anchorage . 16

4.13 Mechanical strength . 17

4.14 Insulation . 17

4.14.1 Type of insulation . 17

4.14.2 Basic insulation . 17

4.14.3 Supplementary insulation . 17

4.14.4 Double insulation . 17

4.14.5 Reinforced insulation . 18

4.15 Clearances and creepage distances . 18

4.15.1 Clearances . 18

4.15.2 Creepage distances . 18

4.16 Insulation parts . 20

4.16.1 Outer accessible parts . 20

4.16.2 Inner parts keeping active parts in position . 20

4.17 Current carrying parts and resistance against corrosion . 20

4.18 Sealing . 20

4.19 Bypass-diode . 20

4.20 Knock-out inlets (outlets) intended to be removed by mechanical impact . 21

5 Tests . 21

5.1 General . 21

5.2 Preparation of specimens . 23

5.3 Performance of tests . 24

5.3.1 General . 24

5.3.2 Durability of marking . 24

5.3.3 Fixing of lid on rewirable junction box . 24

5.3.4 Protection against electric shock . 25

5.3.5 Measurement of clearances and creepage distances . 25

5.3.6 Dielectric strength . 25

5.3.7 Resistance to corrosion . 25

5.3.8 Mechanical strength at lower temperatures . 25

5.3.9 Thermal cycle test (IEC 60068-2-14:2009, Test Nb) . 26

5.3.10 Damp heat test . 26

5.3.11 Weather resistance test . 26

5.3.12 Flammability class . 27

5.3.13 Ball pressure test . 27

5.3.14 Glow wire test . 27

5.3.15 Resistance against ageing . 27

5.3.16 Wet leakage current test . 27

5.3.17 Humidity-freeze-test . 28

5.3.18 Bypass diode thermal test . 29

5.3.19 Test of terminations and connection methods . 30

5.3.20 Knock-out inlets (outlets) intended to be removed by mechanical impact . 30

5.3.21 Test of cord anchorage . 31

5.3.22 Retention on the mounting surface . 32

5.3.23 Reverse current test at junction box . 33

5.4 Test schedule . 33

Annex A (informative) Symbol "Do not disconnect under load" . 42

Annex B (normative) Qualification of conformal coatings for protection against

pollution . 43

B.1 General . 43

B.2 Technical properties . 43

B.3 Qualification of coatings . 43

Annex C (normative) Measurement of clearances and creepage distances . 46

Bibliography . 50

Figure 1 – Thermal cycling test . 38

Figure 2 – Humidity-freeze cycle . 39

Figure 3 – Typical arrangement for the cable anchorage pull test . 39

Figure 4 – Typical arrangement for torsion test . 40

Figure 5 – Typical arrangement for flammability test according to 5.3.12.2 . 40

Figure 6 – Measurement of voltage drop . 41

Figure A.1 – Symbol "DO NOT DISCONNECT UNDER LOAD" . 42

Figure A.2 – Symbol "DO NOT DISCONNECT UNDER LOAD" (IEC 60417-6070) . 42

Figure B.1 – Test sequence and conformity check . 45

Figure C.1 – Examples of methods of measuring clearances and creepage distances . 49

Table 1 – Required type of insulation . 17

Table 2 – Rated impulse voltages and minimum clearances . 18

Table 3 – Creepage distances for basic insulation . 19

Table 4 – Number of specimens . 22

Table 5 – Values of torque for screw-type clamping units . 23

Table 6 – Pull forces for cord anchorage . 32

Table 7 – Values for torsion test . 32

– 4 – IEC 62790:2014 © IEC 2014

Table 8 – Marking, information, documentation, test group A . 33

Table 9 – Material test, test group B (single tests) . 34

Table 10 – Constructional requirements, test group C (single tests) . 35

Table 11 – Mechanical tests, test group D (single tests) . 35

Table 12 – Test sequence I, test group E (tests to be performed consecutively in this

order). 36

Table 13 – Test sequence II, test group F (tests to be performed consecutively in this

order). 36

Table 14 – Test sequence III, test group G (tests to be performed consecutively in this

order). 37

Table 15 – Test sequence IV, test group H (tests to be performed consecutively in this

order). 37

Table 16 – Reverse current test, test group I . 37

Table 17 – Test sequence V, test group J (tests to be performed consecutively in this

order). 38

Table B.1 – Test parameters, test conditions and test procedures. 44

Table C.1 – Dimensions of X . 46

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

JUNCTION BOXES FOR PHOTOVOLTAIC MODULES –

SAFETY REQUIREMENTS AND TESTS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62790 has been prepared by IEC technical committee 82: Solar

photovoltaic energy systems.

The European Standard EN 50548 (first edition, 2011), has served as a basis for the

elaboration of this standard.

The text of this standard is based on the following documents:

FDIS Report on voting

82/876/FDIS 82/902/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

– 6 – IEC 62790:2014 © IEC 2014

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

JUNCTION BOXES FOR PHOTOVOLTAIC MODULES –

SAFETY REQUIREMENTS AND TESTS

1 Scope

This International Standard describes safety requirements, constructional requirements and

tests for junction boxes up to 1 500 V dc for use on photovoltaic modules according to class II

of IEC 61140:2001.

This standard applies also to enclosures mounted on PV-modules containing electronic

circuits for converting, controlling, monitoring or similar operations. Additional requirements

concerning the relevant operations are applied under consideration of the environmental

conditions of the PV-modules. This standard does not apply to the electronic circuits of these

devices, for which other IEC-standards apply.

NOTE For junction boxes according to classes 0 and III of IEC 61140:2001, in photovoltaic-systems, this standard

can be used as a guideline.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60060-1, High-voltage test techniques – Part 1: General definitions and test requirements

IEC 60068-1, Environmental testing – Part 1: General and guidance

IEC 60068-2-14:2009, Environmental testing – Part 2-14: Tests – Test N: Change of

temperature

IEC 60068-2-70, Environmental testing – Part 2: Tests – Test Xb: Abrasion of markings and

letterings caused by rubbing of fingers and hands

IEC 60068-2-75, Environmental testing – Part 2-75: Tests – Test Eh: Hammer tests

IEC 60068-2-78, Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady

state

IEC 60228, Conductors of insulated cables

IEC 60352-2, Solderless connections – Part 2: Crimped connections – General requirements,

test methods and practical guidance

IEC 60512-12-1, Connectors for electronic equipment – Tests and measurements –

Part 12-1: Soldering tests – Test 12a: Solderability, wetting, solder bath method

IEC 60512-12-2, Connectors for electronic equipment – Tests and measurements –

Part 12-2: Soldering tests – Test 12b: Solderability, wetting, soldering iron method

IEC 60529, Degrees of protection provided by enclosures (IP Code)

– 8 – IEC 62790:2014 © IEC 2014

IEC 60664-1:2007, Insulation coordination for equipment within low-voltage systems –

Part 1: Principles, requirements and tests

IEC/TR 60664-2-1, Insulation coordination for equipment within low-voltage systems – Part 2-

1: Application guide – Explanation of the application of the IEC 60664 series, dimensioning

examples and dielectric testing

IEC 60664-3, Insulation coordination for equipment within low-voltage systems – Part 3: Use

of coating, potting or moulding for protection against pollution

IEC 60695-2-11, Fire hazard testing – Part 2-11: Glowing/hot-wire based test methods –

Glow-wire flammability test method for end-products

IEC 60695-11-10, Fire hazard testing – Part 11-10: Test flames – 50 W horizontal and vertical

flame test methods

IEC 60695-11-20:1999, Fire hazard testing – Part 11-20: Test flames – 500 W flame test

methods

IEC/TR 60943, Guidance concerning the permissible temperature rise for parts of electrical

equipment, in particular for terminals

IEC 60947-7-1, Low-voltage switchgear and controlgear – Part 7-1: Ancillary equipment –

Terminal blocks for copper conductors

IEC 60998-2-1, Connecting devices for low-voltage circuits for household and similar

purposes – Part 2-1: Particular requirements for connecting devices as separate entities with

screw-type clamping units

IEC 60998-2-2, Connecting devices for low-voltage circuits for household and similar

purposes – Part 2-2: Particular requirements for connecting devices as separate entities with

screwless-type clamping units

IEC 60999-1:2000, Connecting devices – Electrical copper conductors – Safety requirements

for screw-type and screwless-type clamping units – Part 1: General requirements and

2 2

particular requirements for clamping units for conductors from 0,2 mm up to 35 mm

(included)

IEC 60999-2, Connecting devices – Electrical copper conductors – Safety requirements for

screw-type and screwless-type clamping units – Part 2: Particular requirements for clamping

2 2

units for conductors above 35 mm up to 300 mm (included)

IEC 61032, Protection of persons and equipment by enclosures – Probes for verification

IEC 61140:2001, Protection against electric shock – Common aspects for installation and

equipment

IEC 61730-1, Photovoltaic (PV) module safety qualification – Part 1: Requirements for

construction

IEC 61730-2:2004, Photovoltaic (PV) module safety qualification – Part 2: Requirements for

testing

IEC 62852, Connectors for photovoltaic systems – Safety requirements and tests

ISO 868:2003, Plastics and ebonite – Determination of indentation hardness by means of a

durometer (Shore hardness)

ISO 4892-2:2013, Plastics – Methods of exposure to laboratory light sources – Part 2: Xenon-

arc lamps

ISO 4892-3:2006, Plastics – Methods of exposure to laboratory light sources – Part 3:

Fluorescent UV lamps

EN 50618, Electric cables for photovoltaic systems

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

module junction box

combination of parts, such as boxes, covers, cover-plates, lids, box extensions, accessories,

etc., providing after assembly and installation at the photovoltaic-module in normal use, an

appropriate protection against external influences, and a defined protection against contact

with enclosed live parts from any accessible direction

3.1.1

junction box for re-opening

junction box that can be opened at any time

Note 1 to entry: It may contain rewirable and non-rewirable connections.

3.1.1.1

junction box for factory wiring

junction box which is attached and connected to the PV module under controlled conditions,

usually at manufacturer’s location

3.1.1.2

junction box for field wiring

junction box containing wiring connections that are intended to made in the field

3.1.2

junction box, not intended to be re-opened

junction box that cannot be opened after mounting in the end application

Note 1 to entry: It may contain rewirable and non-rewirable connections.

3.2

cable gland

device permitting the introduction of one or more electric cables into the junction box so as to

maintain the relevant type of protection

[SOURCE: IEC 60050-426:2008, 426-04-18, modified – "and/or fibre optics" has been deleted

and "an electrical apparatus" has been replaced by "the junction box".]

3.3

sealing

method for providing the ability of a component to resist the ingress of contaminants

[SOURCE: IEC 60050-581:2008, 581-23-16]

– 10 – IEC 62790:2014 © IEC 2014

3.4

spout hub

open entry of a box permitting the insertion and containment of a conduit

3.5

cable anchorage

ability to limit the displacement of a fitted flexible cable against pull and push forces and

torques

3.6

connector for photovoltaic-systems

component suitable for use in PV-systems that terminates conductors for the purpose of

providing connection to and disconnection from a suitable mating component

3.7

intended use

use of a junction box in accordance with the information for use provided by the manufacturer

[SOURCE: IEC 60050-903:2013, 903-01-13, modified – "product, process or service" has

been replaced by "junction box" and "supplier" has been replaced by "manufacturer".]

3.8

terminal

part(s) of the terminal necessary for the mechanical clamping and the electrical connection of

the conductor(s), including the parts that are necessary to ensure the correct contact pressure

3.9

clearance

shortest distance in air between two conductive parts

[SOURCE: IEC 60050-426:2008, 426-04-12]

3.10

creepage distance

shortest distance along the surface of the insulating material between two conductive parts

[SOURCE: IEC 60050-151:2001, 151-15-50, modified – "a solid" has been replaced by "the".]

3.11

overvoltage category

numeral defining a transient overvoltage condition

[SOURCE: IEC 60050-581:2008, 581-21-02]

3.12

pollution

any addition of foreign matter, solid, liquid, or gaseous that can result in a reduction of electric

strength or surface resistivity of the insulation

[SOURCE: IEC 60050-442:1998, 442-01-28]

3.13

pollution degree

numeral characterising the expected pollution of the micro-environment

[SOURCE: IEC 60050-581:2008, 581-21-07]

3.14

rated voltage

value of voltage assigned by the manufacturer to the junction box and to which operation and

performance characteristics are referred

Note 1 to entry: Rated voltage is equivalent to the rated system voltage according to IEC 61730-1.

[SOURCE: IEC 60664-1:2007, 3.9, modified – "a component, device or equipment" has been

replaced by "the junction box" and the note has been replaced by Note 1 to entry.]

3.15

rated insulation voltage

r.m.s. withstand voltage value assigned by the manufacturer to the junction box,

characterising the specified (long term) withstand capability of its insulation

Note 1 to entry: The rated insulation voltage is not necessarily equal to the rated voltage, which is primarily

related to functional performance.

[SOURCE: IEC 60664-1:2007, 3.9.1, modified – "equipment or to a part of it" has been

replaced by "junction box".]

3.16

rated impulse voltage

impulse withstand voltage value assigned by the manufacturer to the junction box,

characterising the specified withstand capability of its insulation against transient

overvoltages

[SOURCE: IEC 60664-1:2007, 3.9.2, modified – "equipment or to a part of it" has been

replaced by "junction box".]

3.17

impulse withstand voltage

highest peak value of impulse voltage of prescribed form and polarity that does not cause

breakdown of the insulation under specified conditions

Note 1 to entry: The impulse withstand voltage is equal to or higher than the rated impulse voltage.

[SOURCE: IEC 60664-1:2007, 3.8.1 – Note 1 to entry has been added.]

3.18

r.m.s. withstand voltage

power-frequency withstand voltage

highest r.m.s. value of a voltage that does not cause breakdown of insulation under specified

conditions

[SOURCE: IEC 60664-1:2007, 3.8.2]

3.19

Current

3.19.1

rated current

current value assigned by the manufacturer, which the junction box can carry continuously

(without interruption) and simultaneously through all its contacts and bypass-diodes, if

applicable, wired with the largest specified conductor, at the highest specified ambient

temperature, without the upper limiting temperature being exceeded

– 12 – IEC 62790:2014 © IEC 2014

3.19.2

reverse current

I

REV

current value assigned by the manufacturer, which the junction box can carry at the highest

specified ambient temperature, without causing a hazardous situation

Note 1 to entry: The reverse current is comparable with the reverse test current of the photovoltaic module (see

IEC 61730-2).

3.20

functional insulation

insulation between conductive parts that is necessary only for the proper functioning of the

equipment

[SOURCE: IEC 60664-1:2007, 3.17.1]

3.21

basic insulation

insulation applied to live parts to provide basic protection against electric shock

Note 1 to entry: Basic insulation does not necessarily include insulation used exclusively for functional purposes

(see IEC 61140:2001, 3.10.1).

[SOURCE: IEC 60664-1:2007, 3.17.2, modified – " against electric shock " and Note 1 to entry

have been added.]

3.22

supplementary insulation

independent insulation applied in addition to basic insulation, in order to provide protection

against electric shock in the event of a failure of basic insulation

[SOURCE: IEC 60664-1:2007, 3.17.3, modified – “for fault protection” has been replaced by

“in order to provide protection against electric shock in the event of a failure of basic

insulation”.]

3.23

double insulation

insulation comprising both basic insulation and supplementary insulation

[SOURCE: IEC 60664-1:2007, 3.17.4]

3.24

reinforced insulation

single insulation system applied to live parts, which provides a degree of protection against

electric shock equivalent to double insulation under the conditions specified in the relevant

IEC standard (IEC 61140:2001, 3.10.4)

Note 1 to entry: A single insulation system does not imply that the insulation must be a homogeneous piece. It

may comprise several layers that cannot be tested singly as basic or supplementary insulation.

[SOURCE: IEC 60664-1:2007, 3.17.5, modified – "insulation of hazardous live parts" has been

replaced by "single insulation system applied to live parts" and "under the conditions specified

in the relevant IEC standard" and Note 1 to entry have been added.]

3.25

working voltage

highest r.m.s. value of the dc voltage across any particular insulation which can occur inside

the junction box when the it operates at rated voltage

[SOURCE: IEC 60664-1:2007, 3.5, modified – "a.c. or" has been removed and “when the

equipment is supplied at rated voltage" has been replaced by "which can occur inside the

junction box when it operates at rated voltage".]

3.26

comparitive tracking index

CTI

numerical value of the maximum voltage in volts which a material can withstand without

tracking and without a persistent flame occurring under specified test conditions

[SOURCE: IEC 60050-212:2010, 212-11-59]

3.27

accessible part

part which can be touched by means of standard test finger

[SOURCE: IEC 60050-442:1998, 442-01-15]

4 Constructional requirements and performance

4.1 General

For junction boxes according to this standard, no values have been specified for electric rated

voltage and current. These values shall be declared by the manufacturer.

Junction boxes shall be suitable for durable use outside in an ambient temperature area from

–40 °C to + 85 °C.

Junction boxes shall be so designed and dimensioned that they can withstand the electrical,

mechanical, thermal and corrosive stresses occurring in their intended use and present no

danger to the user or the environment.

Compliance with these requirements is verified by specified tests of this International

Standard.

4.2 Marking and identification

4.2.1 Identification

Junction boxes shall be identified and characterised by the following:

a) manufacturer’s name, trademark or mark of origin;

b) type identification;

c) rated current;

d) rated voltages or rated insulation voltages;

e) rated impulse voltage, if specified;

f) maximum working voltage;

g) pollution degree;

h) degree of protection by enclosure according to IEC 60529;

i) range of temperature; (lowest and upper ambient temperature), if different from this

standard;

j) type of terminals;

k) connectable conductors;

l) reference to this standard, if applicable;

– 14 – IEC 62790:2014 © IEC 2014

m) symbols ”Do not disconnect under load“, as given in Annex A, or an adequate warning

notice in the particular national language;

n) polarity of connector, if applicable;

o) type and number of bypass-diodes, if applicable;

p) reverse current (I ).

REV

4.2.2 Marking

The marking shall be indelible and easily legible.

The minimum marking on the junction boxes shall be that of items a), b) and n) in 4.2.1.

If connection of junction box is performed by connectors, the warning notice listed in m) of

4.2.1 shall be on a label or similar on or close to the connector.

If connection of the junction box is performed by a fixed cable that has implemented a

connector on its end, the warning notice listed in m) of 4.2.1 shall be on a label or similar on

or close to the connector. An instruction where to place the warning notice shall be included in

the technical documentation. Markings a) and b) of 4.2.1 shall be found on the smallest unit of

packaging.

4.2.3 Technical documentation

Identification items of 4.2.1 not marked on the junction box according to 4.2.2 and the

following information shall be given in the technical documentation of the manufacturer:

a) information on termination regarding the cable and cell connection, if applicable;

b) information regarding the connector (-system), if applicable;

c) information regarding mounting (e.g. backsheet material of the module) and mounting

material (e.g. sealing material, adhesive), if applicable.

4.3 Protection against electric shock

4.3.1 A junction box shall be so designed that, after mounting, the live parts are not

accessible. This requirement shall be fulfilled even if there is any deformation of the housing

and/or cover as a result of mechanical and thermal stress, which can occur during normal

use; furthermore, the degree of protection of the housing may not be impaired by this possible

deformation.

4.3.2 Parts intended to be removed shall only be detachable with the aid of tools. Lids that

are attached without screws shall have one or several detectable facilities, e.g. recesses,

which enable tools to be deployed in order to remove them. If the lid is removed correctly, the

tool shall not come into contact with the active parts.

4.3.3 Parts of junction boxes for field wiring according to 3.1.1.2 shall be prevented to be

lost or to become loose.

4.4 Terminations, connecting devices and connection methods

4.4.1 Terminations shall be suitable for the type and range of conductor cross-sectional

areas according to the specification of the manufacturer.

Terminations shall be held in such a position that a possible displacement does not result in a

reduction of clearances and creepage distances.

Measures needs to be taken to prevent contact stress resulting in contact degradation and

possible movement of contacts.

Terminations shall be so designed that the contact pressure is not transmitted through

insulating material other than ceramic, pure mica or other material with suitable

characteristics, unless there is sufficient resiliency in the metallic parts to compensate for any

shrinkage or yielding of the insulating material.

Measures shall be taken to prevent connections becoming loose, e.g. by using a washer.

4.4.2 Connecting devices shall meet the following requirements under the conditions

according to 5.1.3:

a) crimped connections according to IEC 60352-2

b) insulation displacement connections according to IEC 60352-3 (accessible IDC) or

IEC 60998-2-3

c) insulation displacement connections according to IEC 60352-4 (non-accessible

IDC) or IEC 60998-2-3

d) press-in connections according to IEC 60352-5

e) insulation piercing connections according to IEC 60352-6 or IEC 60998-2-3

f) screwless-type clamping units according to IEC 60999-1 or IEC 60999-2

or IEC 60352-7

g) screw-type clamping units according to IEC 60999-1 or IEC 60999-2

h) flat, quick-connect terminations according to and IEC 61210

i) terminal blocks IEC 60947-7-1

j) soldered connections IEC 61191-1

Connecting devices shall provide sufficient means to be held in position after connection.

Different terminals or connecting technologies may be used if they fulfil a comparable level of

safety as the above-mentioned standards.

Terminations by connectors inside the junction box shall meet the relevant requirements

according to IEC 62852.

Soldered connections of cables and cell connectors shall have additional means for retaining

the conductor in position.

Welded connections are also permitted.

4.4.3 Compliance is checked by tests according to 5.3.19.

4.5 Connectors

PV-connectors that are part of the junction box and PV-connectors connected via a cable with

the junction box shall comply with the requirements of IEC 62852. The values of the rated

current and voltage shall be minimum the rated values of the junction box.

4.6 Cable

Cables connected

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...