IEC 60287-3-2:2012

(Main)Electric cables - Calculation of the current rating - Part 3-2: Sections on operating conditions - Economic optimization of power cable size

Electric cables - Calculation of the current rating - Part 3-2: Sections on operating conditions - Economic optimization of power cable size

IEC 60287-3-2:2012 sets out a method for the selection of a cable size taking into account the initial investments and the future costs of energy losses during the anticipated operational life of the cable. Matters such as maintenance, energy losses in forced cooling systems and time of day energy costs have not been included in this standard. Two examples of the application of the method to hypothetical supply systems are given in Annex A.

Câbles électriques - Calcul du courant admissible - Partie 3-2: Sections concernant les conditions de fonctionnement - Optimisation économique des sections d'âme de cables électriques de puissance

La CEI 60287-3-2:2012 traite du choix économique de la section d'un câble prenant en compte les coûts des investissements initiaux et les coûts futurs des pertes d'énergie pendant la durée de service attendue du câble. Les questions telles que la maintenance, les pertes d'énergie dans les systèmes à refroidissement forcé et les coûts horaires de l'énergie ne sont pas traitées dans cette norme. Deux exemples d'application de la méthode à des systèmes d'alimentation théoriques sont donnés à l'Annexe A.

General Information

- Status

- Published

- Publication Date

- 03-Jul-2012

- Technical Committee

- TC 20 - Electric cables

- Drafting Committee

- WG 19 - TC 20/WG 19

- Current Stage

- PPUB - Publication issued

- Start Date

- 04-Jul-2012

- Completion Date

- 15-Jul-2012

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60287-3-2:2012 is an international standard published by the International Electrotechnical Commission (IEC) that addresses the economic optimization of power cable size. This part of the IEC 60287 series focuses specifically on selecting electric cable sizes by balancing the initial investment costs with the future costs of energy losses over the cable’s anticipated operational life. Unlike traditional cable sizing approaches that prioritize minimal initial cost, this standard promotes a comprehensive cost evaluation that considers the total cost of ownership, thereby enabling more sustainable and economically efficient decisions in cable design and selection.

This standard does not include factors such as maintenance costs, energy losses in forced cooling systems, or variable time-of-day energy pricing. It provides calculation methods and examples to support electrical engineers and designers in optimizing cable conductor sizes for power systems based on a long-term cost perspective.

Key Topics

Economic Cable Sizing

The standard introduces a method for calculating the economic size of electric cables by integrating both capital expenditure (purchase and installation costs) and operational expenditure (energy loss costs during usage). This balanced approach ensures cost-effective investment in cable infrastructure.Cost of Energy Losses

Energy losses, especially joule losses caused by conductor resistance at operating temperatures, constitute a significant portion of operational expenses. IEC 60287-3-2 guides practitioners in estimating these losses and their financial impact over time.Discounting Future Costs

To compare initial costs and future loss-related costs, the standard applies discounting techniques to convert future costs into present values. This ensures an accurate economic comparison by accounting for the cost of borrowing money and inflation neutrality.Calculation Procedures

It provides mathematical models and formulae to estimate total costs, economic current ranges, and the optimum conductor cross-sectional area. Both AC and DC system applications are supported, with adjustments detailed for DC resistance and loss factors.Practical Examples

Annex A of the document includes detailed examples illustrating applications to hypothetical supply systems, demonstrating calculation steps and decision criteria.

Applications

Power Distribution Systems

Utilities and power engineers can utilize the standard to optimize cable sizes in distribution networks, minimizing lifecycle costs while ensuring operational reliability.Industrial Electrical Installations

Designers of large industrial power systems can apply economic optimization to balance upfront cable costs with energy efficiency over operational life, reducing total costs.Infrastructure Projects

Infrastructure planners for commercial, residential, or transport projects can use this standard to make cost-effective decisions about cable sizing that consider future energy costs.Energy Efficiency Initiatives

Organizations aiming to improve energy efficiency and reduce operating expenses will benefit from applying IEC 60287-3-2 to guide investments in cable infrastructure.

Related Standards

IEC 60287 Series

The economic optimization standard is part of the IEC 60287 series on calculation of current ratings in electric cables. Other parts cover thermal, electrical, and environmental operating conditions affecting cable performance.IEC 60502

For technical specifications on power cables including construction and testing relevant for cable installation and operation.ISO/IEC Directives, Part 2

Governs the drafting of IEC standards and ensures methodological consistency including economic factors such as discounting.

By integrating initial and operational cost assessments, IEC 60287-3-2:2012 supports optimized cable sizing decisions that lead to significant cost savings-potentially up to 50% over the cable lifecycle. This enhances both economic and environmental sustainability in electrical power systems.

Frequently Asked Questions

IEC 60287-3-2:2012 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electric cables - Calculation of the current rating - Part 3-2: Sections on operating conditions - Economic optimization of power cable size". This standard covers: IEC 60287-3-2:2012 sets out a method for the selection of a cable size taking into account the initial investments and the future costs of energy losses during the anticipated operational life of the cable. Matters such as maintenance, energy losses in forced cooling systems and time of day energy costs have not been included in this standard. Two examples of the application of the method to hypothetical supply systems are given in Annex A.

IEC 60287-3-2:2012 sets out a method for the selection of a cable size taking into account the initial investments and the future costs of energy losses during the anticipated operational life of the cable. Matters such as maintenance, energy losses in forced cooling systems and time of day energy costs have not been included in this standard. Two examples of the application of the method to hypothetical supply systems are given in Annex A.

IEC 60287-3-2:2012 is classified under the following ICS (International Classification for Standards) categories: 29.060.20 - Cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60287-3-2:2012 has the following relationships with other standards: It is inter standard links to IEC 60287-3-2:1995/AMD1:1996. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60287-3-2:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60287-3-2 ®

Edition 2.0 2012-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric cables – Calculation of the current rating –

Part 3-2: Sections on operating conditions – Economic optimization of power

cable size

Câbles électriques – Calcul du courant admissible –

Partie 3-2: Sections concernant les conditions de fonctionnement – Optimisation

économique des sections d'âme de câbles électriques de puissance

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 60287-3-2 ®

Edition 2.0 2012-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric cables – Calculation of the current rating –

Part 3-2: Sections on operating conditions – Economic optimization of power

cable size

Câbles électriques – Calcul du courant admissible –

Partie 3-2: Sections concernant les conditions de fonctionnement – Optimisation

économique des sections d'âme de câbles électriques de puissance

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX W

ICS 29.060.20 ISBN 978-2-83220-151-0

– 2 – 60287-3-2 © IEC:2012

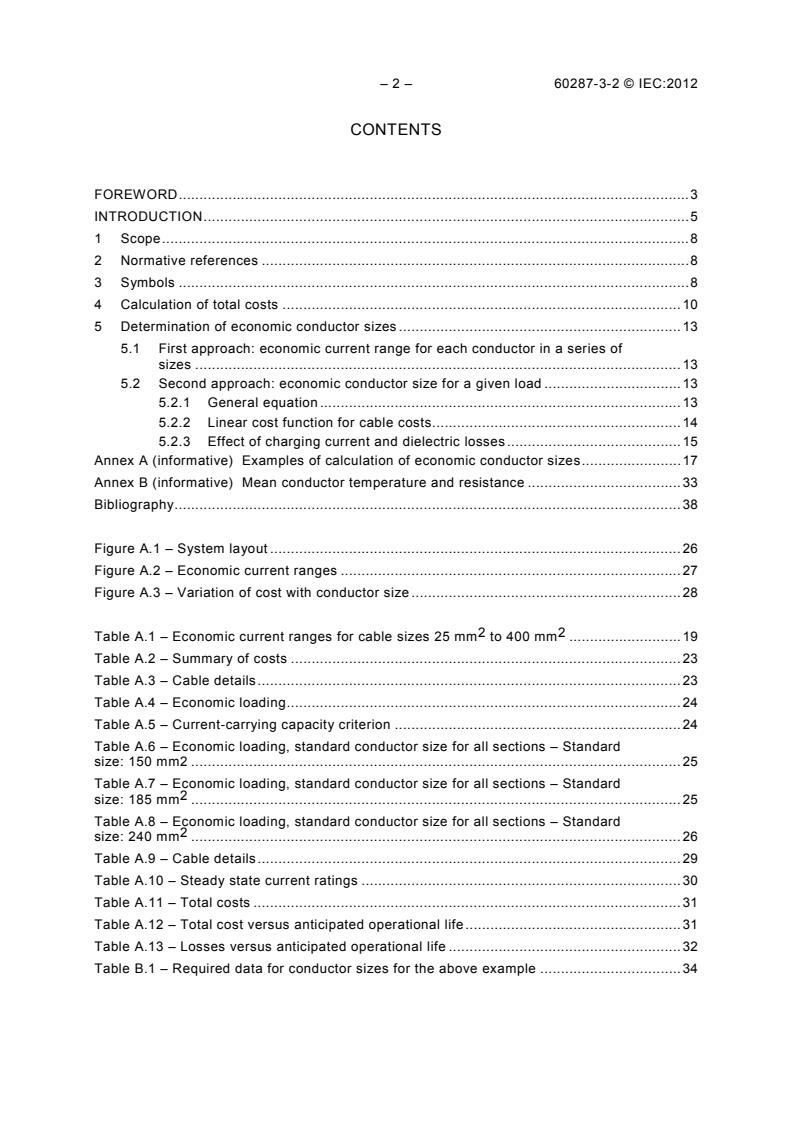

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 8

2 Normative references . 8

3 Symbols . 8

4 Calculation of total costs . 10

5 Determination of economic conductor sizes . 13

5.1 First approach: economic current range for each conductor in a series of

sizes . 13

5.2 Second approach: economic conductor size for a given load . 13

5.2.1 General equation . 13

5.2.2 Linear cost function for cable costs. 14

5.2.3 Effect of charging current and dielectric losses . 15

Annex A (informative) Examples of calculation of economic conductor sizes . 17

Annex B (informative) Mean conductor temperature and resistance . 33

Bibliography . 38

Figure A.1 – System layout . 26

Figure A.2 – Economic current ranges . 27

Figure A.3 – Variation of cost with conductor size . 28

2 2

Table A.1 – Economic current ranges for cable sizes 25 mm to 400 mm . 19

Table A.2 – Summary of costs . 23

Table A.3 – Cable details . 23

Table A.4 – Economic loading . 24

Table A.5 – Current-carrying capacity criterion . 24

Table A.6 – Economic loading, standard conductor size for all sections – Standard

size: 150 mm2 . 25

Table A.7 – Economic loading, standard conductor size for all sections – Standard

size: 185 mm . 25

Table A.8 – Economic loading, standard conductor size for all sections – Standard

size: 240 mm . 26

Table A.9 – Cable details . 29

Table A.10 – Steady state current ratings . 30

Table A.11 – Total costs . 31

Table A.12 – Total cost versus anticipated operational life . 31

Table A.13 – Losses versus anticipated operational life . 32

Table B.1 – Required data for conductor sizes for the above example . 34

60287-3-2 © IEC:2012 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC CABLES –

CALCULATION OF THE CURRENT RATING –

Part 3-2: Sections on operating conditions –

Economic optimization of power cable size

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60287-3-2 has been prepared by IEC technical committee 20:

Electric cables.

This second edition cancels and replaces the first edition, published in 1995 and its

Amendment 1:1996. This edition consitutes a technical revision. This edition incorporates

Amendment 2 which was not published separately due to the number of changes and pages.

The main changes with respect to the previous edition are as follows:

– update of the normative references;

– clarification of some symbols;

– correction of some formulae;

– introduction of a second example in Annex A for the calculation of the economic conductor

size.

– 4 – 60287-3-2 © IEC:2012

The text of this standard is based on the first edition, its amendment 1 and the following

documents:

FDIS Report on voting

20/1367/FDIS 20/1373/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60287 series can be found on the IEC website under the general

title: Calculation of the current rating.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

60287-3-2 © IEC:2012 – 5 –

INTRODUCTION

0.1 General part

The procedure generally used for the selection of a cable size leads to the minimum

admissible cross-sectional area, which also minimizes the initial investment cost of the cable.

It does not take into account the cost of the losses that will occur during the life of the cable.

The increasing financial and environmental cost of energy, together with the energy losses

which follow from conductors operating at high temperatures, requires that cable size

selection be considered on wider grounds. Rather than minimizing the initial cost only, the

sum of the initial cost and the cost of the losses over the anticipated operational life of the

system should be minimized. For this latter condition, a larger size of conductor than would be

chosen based on minimum initial cost will lead to a lower power loss for the same current.

This, when considered over its anticipated operational life, will reduce the energy losses and

the total cost of the system. Where thermal consideration dictates the use of the largest

practical conductor size, the installation of a second parallel cable circuit can result in a

reduction in the total cost over the life of the installation.

The formulae and examples given in this standard are arranged to facilitate the calculation of

the economic conductor size after factors such as system voltage, cable route, cable

configuration and sheath bonding arrangements have been decided. Although these factors

are not considered in detail, they have an impact on both the installation and operating costs

of a cable system. The effect of changing any of the above factors on the total cost over the

anticipated operational life of the system can be determined using the principles set out in this

standard.

Future costs of energy losses during the anticipated operational life of the cable can be

calculated by making suitable estimates of load growth and cost of energy. The most

economical size of conductor is achieved when the sum of the future costs of energy losses

and the initial cost of purchase and installation are minimized.

The saving in overall cost, when a conductor size larger than that determined by thermal

constraints is chosen, is due to the considerable reduction in the cost of the joule losses

compared with the increase in cost of purchase. For the values of the financial and electrical

parameters used in this standard, which are not exceptional, the saving in the combined cost

of purchase and operation is of the order of 50 % (see A.2.5). Calculations for much shorter

financial periods can show a similar pattern.

A further important feature, which is demonstrated by examples, is that the savings possible

are not critically dependent on the conductor size when it is in the region of the economic

value, see Figure A.3. This has two implications:

a) the impact of errors on financial data, particularly those which determine future costs, is

small. While it is advantageous to seek data having the best practicable accuracy,

considerable savings can be achieved using data based on reasonable estimates;

b) other considerations with regard to the choice of conductor size which feature in the

overall economics of an installation, such as fault currents, voltage drop and size

rationalization, can all be given appropriate emphasis, without losing too many of the

benefits arising from the choice of an economic size.

The formulae given in this standard are written for a.c. systems but they are equally

applicable to d.c. systems. Clearly, for d.c. systems, the d.c. resistance is used in place of the

a.c. resistance and the sheath and armour loss factors are set to zero.

– 6 – 60287-3-2 © IEC:2012

0.2 Economic aspects

In order to combine the purchase and installation costs with costs of energy losses arising

during the anticipated operational life of a cable, it is necessary to express them in

comparable economic values, that is values which relate to the same point in time. It is

convenient to use the date of purchase of the installation as this point and to refer to it as the

"present". The "future" costs of the energy losses are then converted to their equivalent

"present values". This is done by the process of discounting, the discounting rate being linked

to the cost of borrowing money.

In the procedure given here, inflation has been omitted on the grounds that it will affect both

the cost of borrowing money and the cost of energy. If these items are considered over the

same period of time and the effect of inflation is approximately the same for both, the choice

of an economic conductor size can be made satisfactorily without introducing the added

complication of inflation.

To calculate the present value of the costs of the losses it is necessary to choose appropriate

values for the future development of the load, annual increases in kWh price and annual

discounting rates over the anticipated operational life of the cable, which could be 25 years or

more. It is not possible to give guidance on these aspects in this standard because they are

dependent on the conditions and financial constraints of individual installations. Only the

appropriate formulae are given: it is the responsibility of the designer and the user to agree on

the economic factors to be used.

The formulae proposed in this standard are straightforward, but in their application due regard

should be taken of the assumption that the financial parameters are assumed to remain

unchanged during the anticipated operational life of the cable. Nevertheless, the above

comments on the effect of the accuracy of these parameters is also relevant here.

There are two approaches to the calculation of the economic size, based on the same

financial concepts. The first, where a series of conductor sizes is being considered, is to

calculate a range of economic currents for each of the conductor sizes envisaged for

particular installation conditions and then to select that size whose economic range contains

the required value of the load. This approach is appropriate where several similar installations

are under consideration. The second method, which may be more suitable where only one

installation is involved, is to calculate the optimum cross-sectional area for the required load

and then to select the closest standard conductor size.

0.3 Other criteria

Other criteria, for example short-circuit current and its duration, voltage drop and cable size

rationalization, should also be considered. However, a cable chosen to have an economical

size of conductor may well be satisfactory also from these other points of view, so that when

sizing a cable, the following sequence may be advantageous:

a) calculate the economic cross-sectional area;

b) check by the methods given in IEC 60287-1-1, in IEC 60287-2-1 and in the IEC 60853

series that the size indicated by a) is adequate to carry the maximum load expected to

occur at the end of the economic period without its conductor temperature exceeding the

maximum permitted value;

c) check that the size of cable selected can safely withstand the prospective short-circuit and

earth fault currents for the corresponding durations;

d) check that the voltage drop at the end of the cable remains within acceptable limits;

e) check against other criteria appropriate to the installation.

To complete the field of economic selection, proper weight should be given to the

consequences of interruption of supply. It may be necessary to use a larger cross-section of

60287-3-2 © IEC:2012 – 7 –

conductor than the normal load conditions require and/or the economic choice would suggest,

or to adapt the network accordingly.

A further cost component may be recognized in the financial consequence of making a faulty

decision weighted by its probability. However, in doing so one enters the field of decision

theory which is outside the scope of this standard.

Thus, economic cable sizing is only a part of the total economic consideration of a system and

may give way to other important economic factors.

0.4 Environmental impact

When determining optimum size for a given circuit, consideration should also be given to

environmental impact. Based on the projected life of a circuit, the environmental impact of

operational losses may well outweigh all other impacts in the life cycle and may justify a

larger conductor size than that determined by economic factors alone. Further guidance can

be found in IEC/TR 62125.

– 8 – 60287-3-2 © IEC:2012

ELECTRIC CABLES –

CALCULATION OF THE CURRENT RATING –

Part 3-2: Sections on operating conditions –

Economic optimization of power cable size

1 Scope

This part of IEC 60287 sets out a method for the selection of a cable size taking into account

the initial investments and the future costs of energy losses during the anticipated operational

life of the cable.

Matters such as maintenance, energy losses in forced cooling systems and time of day

energy costs have not been included in this standard.

Two examples of the application of the method to hypothetical supply systems are given in

Annex A.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60228, Conductors of insulated cables

IEC 60287-1-1, Electric cables – Calculation of the current rating – Part 1-1: Current rating

equations (100 % load factor) and calculation of losses – General

IEC 60287-2-1, Electric cables – Calculation of the current rating – Part 2-1: Thermal

resistance – Calculation of thermal resistance

IEC 60853 (all parts), Calculation of the cyclic and emergency current rating of cables

3 Symbols

The symbols used in this standard and the quantities which they represent are given in the

following list:

a annual increase in I %

max

A constant component of cost per unit length related to cu/m

L

laying conditions, etc.

A variable component of cost per unit length related to cu/(m·mm )

S

conductor size

b annual increase in P, not covered by inflation %

B auxiliary quantity defined by Formula (16) –

c annual increase in loss load factor %

C capacitance per core F/m

CI installed cost of the length of cable being considered cu

60287-3-2 © IEC:2012 – 9 –

CI(S) installed cost of a cable as a function of its cross-sectional cu

area

CI installed cost of the next smaller standard size of cu

conductor

CI installed cost of the next larger standard size of conductor cu

CJ present value of the cost of joule losses during N years cu

CT total cost of a system cu

D demand charge each year cu/(W·year)

d diameter of conductor, including screen, if any mm

c

D diameter over insulation mm

i

f system frequency Hz

F auxiliary quantity defined by Formula (10) cu/W

F auxiliary quantity defined by Formula (27) –

g factor used in calculation of charging current losses –

i discounting rate used to compute present values %

I(t) load as a function of time A

I charging current per unit length A/m

c

I maximum load in first year i.e. the highest hourly mean A

max

value

L cable length m

N period covered by financial calculations, also referred to as year

"anticipated operational life"

N number of circuits carrying the same type and value of –

c

load

N number of phase conductors per circuit –

p

N number of earthed sections in a single-core cable system –

s

P cost of one watt-hour at relevant voltage level cu/(W·h)

Q auxiliary quantity defined by Formula (8) –

Q auxiliary quantity defined by Formula (28) –

v

r auxiliary quantity defined by Formula (9) –

r auxiliary quantity defined by Formula (29) –

v

R a.c. resistance of conductor per unit length (considered to

Ω/m

be a constant value at an average operating temperature,

see Clause 4)

R cable a.c. resistance per unit length, including the effect of

Ω/m

L

λ and λ , R = R(1+ λ and λ )

1 2 L 1 2

(S)

R a.c. resistance per unit length of a conductor as a function Ω/m

L

of its area, including the effect of λ and λ

1 2

R a.c. resistance per unit length of next smaller standard

Ω/m

L1

conductor size, including the effect of λ and λ

1 2

R a.c. resistance per unit length of next larger standard

Ω/m

L2

conductor size, including the effect of λ and λ

1 2

R a.c. resistance of sheath, or screen, per unit length

Ω/m

s

(considered to be a constant value at an average

operating temperature)

– 10 – 60287-3-2 © IEC:2012

S cross-sectional area of a cable conductor mm

S economic conductor size mm

ec

t time h

T operating time at maximum joule loss h/year

T equivalent operating time at maximum loss, including h/year

t

dielectric loss

U voltage between conductor and screen or sheath V

W losses due to charging current in conductors W

chc

W losses due to charging current flowing in screen/armour W

chs

W dielectric losses per unit length per phase W/m

d

y proximity effect factor, see IEC 60287-1-1 –

p

y skin effect factor, see IEC 60287-1-1 –

s

temperature coefficient of conductor resistance at 20 °C 1/K

α

reciprocal of the temperature coefficient of resistivity of the K

β

conductor material at 0 °C. For aluminium β = 228, for

copper β = 234,5

loss factor of insulation –

tan δ

is the relative permittivity of insulation –

ε

sheath and armour loss factors, see IEC 60287-1-1 –

λ , λ

1 2

loss load factor, see the IEC 60853 series –

µ

conductor resistivity at 20 °C, see 5.2

ρ Ω·m

θ maximum rated conductor operating temperature °C

ambient average temperature °C

θ

α

mean operating conductor temperature °C

θ

µ

The unit cu is an arbitrary currency unit.

4 Calculation of total costs

The total cost of installing and operating a cable during its anticipated operational life,

expressed in present values, is calculated as follows. Note that all financial quantities are

expressed in arbitrary currency units, (cu).

The total cost = CT = CI + CJ (cu) (1)

where

CI is the cost of the installed length of cable, in cu;

CJ is the equivalent cost at the date the installation was purchased, i.e. the present value,

of the joule losses during an anticipated operational life of N years, in cu.

Evaluation of CJ

The total cost due to the losses is composed of two parts: a) the energy charge, and b) the

charge for the additional supply capacity to provide the losses.

a) Cost due to energy charge

Energy loss during the first year = (I × R × L × N × N )T (W × h) (2)

max L p c

60287-3-2 © IEC:2012 – 11 –

where

I is the maximum load on the cable during the first year, in A;

max

L is the length of cable, in m;

R cable a.c. resistance per unit length, including the effect of λ and λ , R = R(1+ λ + λ ).

L 1 2 L 1 2

The selection of the method of bonding the sheaths, screens or armour of single-core cables

will have a significant effect on the losses due to circulating currents in these components.

Where the system design permits, the bonding method should be selected to balance the cost

of these losses over the life of the installation against the initial cost of installing the

equipment and additional earth conductors required for certain bonding arrangements.

As the economic conductor size is usually larger than the size based on thermal

considerations (i.e. the size determined by the use of IEC 60287-1-1, IEC 60287-2-1 and/or

the IEC 60853 series), its temperature will be lower than the maximum permissible value. It is

convenient to assume, in the absence of more precise information, that R is constant and

L

has a value corresponding to a temperature of (θ – θ )/3 + θ .

a a

Here θ is the maximum rated conductor temperature for the type of cable concerned and θ is

a

the ambient average temperature. Factor 3 is empirical, see Annex B.

NOTE 1 If greater precision is required (for example where the calculations do not indicate clearly which nominal

conductor size should be chosen or the growth in load is such that its value during the final years is significantly

higher than that of the first year) a better estimate of conductor temperature can be made using as a starting point

the conductor size obtained from the approximate temperature given above.

Methods for making a more refined estimate of conductor temperature and resistance are given in Annex B. The

economical size is then redetermined using the revised value of conductor resistance.

The effect of conductor resistance on the value of the economical size is small and it is seldom worthwhile to

perform the iteration more than once.

N is the number of phase conductors per circuit;

p

N is the number of circuits carrying the same value and type of load;

c

T is the equivalent operating time at maximum loss, in h/year;

is the number of hours per year that the maximum current I would need to flow in

max

order to produce the same total yearly energy losses as the actual, variable, load

current;

I(t ) ×dt

T =

∫ 2

I

max

If the loss load factor µ is known and can be assumed to be constant during the

anticipated operational life, then:

T is equal to µ × 8 760

See the IEC 60853 series for the derivation of the loss load factor, in µ.

NOTE 2 The loss-load factor used in the IEC 60853 series is a daily average factor. The use of this factor as an

annual average is a simplification which assumes that the circuit is in continuous operation and the load pattern for

the circuit being considered remains constant throughout the year.

t is the time, in h;

I(t) is the load current as a function of time, in A.

The cost of the first year's losses is:

– 12 – 60287-3-2 © IEC:2012

= (I × R × L × N × N ) × T × P (cu) (3)

max L p c

where

P is the cost of one watt-hour of energy at the relevant voltage level, in cu/(W·h).

b) Cost due to additional supply capacity

The cost of additional supply capacity to provide these losses is:

= (I × R × L × N × N ) × D (cu/year) (4)

max L p c

where

D is the demand charge per year, in cu/(W•year).

The overall cost of the first year's losses is therefore:

= (I × R × L × N × N ) × (T × P + D) (cu) (5)

max L p c

If costs are paid at the end of the year, then at the date of the purchase of the installation

their present value is:

(I ×R × L × N × N )× (T × P + D)

max L p c

= (cu) (6)

(1+ i /100)

where

i is the discount rate, not including the effect of inflation, in %.

Similarly, the present value of energy costs during N years of operation, discounted to the

date of purchase is:

Q

CJ = (I × R × L ×N × N ) × (T × P + D) × (cu) (7)

max L p c

(1+ i /100)

where

Q is a coefficient, taking into account the increase in load and loss load factor, the increase

in cost of energy over N years and the discount rate:

N

N

1− r

n−1

( )

Q = r =

∑

1− r

n=1

(8)

(1+ a /100) × (1+ b /100)× (1+ c /100)

r =

(1+ i /100)

(9)

If r = 1, then Q = N and

a is the increase in load per year, in %;

b is the increase in cost of energy per year, not including the effect of inflation, in %;

c is the increase in loss load factor per year, in %; c shall be selected such that the loss-

load factor does not exceed 1 over the anticipated operational life of the installation.

60287-3-2 © IEC:2012 – 13 –

Where a number of calculations involving different sizes of conductor are required, it is

advantageous to express all the parameters excepting conductor current and resistance in

one coefficient, F, where

Q

F = N × N × (T × P + D) × (cu/W) (10)

p c

(1+ i /100)

The total cost is then given by:

CT = CI + I² × R × L × F (cu) (11)

max L

Formulae (7), (8) and (9) can be used to calculate the operational losses over the anticipated

life, rather than the cost of the losses by setting D = 0, P = 1, b = 0 and i = 0. This would

allow a direct comparison of the losses for a range of cable sizes.

5 Determination of economic conductor sizes

5.1 First approach: economic current range for each conductor in a series of sizes

All conductor sizes have an economic current range for given installation conditions.

The upper and lower limits of the economic range for a given conductor size are given by:

Cl − Cl

Lower limit of I = (A) (12)

max

F × L × (R − R )

L1 L

Cl − Cl

Upper limit of I = (A) (13)

max

F × L × (R − R )

L L2

where

CI is the installed cost of the length of cable whose conductor size is being considered, in cu;

R is the a.c. resistance per unit length of the conductor size being considered, in Ω/m;

L

CI is the installed cost of the next smaller standard conductor, in cu;

R is the a.c. resistance per unit length of next smaller standard conductor size, including

L1

the effect of λ and λ ;

1 2

CI is the installed cost of the next larger standard conductor, in cu;

R is the a.c. resistance per unit length of next larger standard conductor size, including

L2

the effect of λ and λ .

1 2

NOTE 1 The upper and lower economic current limits of each conductor size may be tabulated and used to select

the most economic size of conductor for a particular load.

NOTE 2 The upper economic current limit of one conductor size is the lower economic current limit for the next

larger conductor size.

5.2 Second approach: economic conductor size for a given load

5.2.1 General equation

The economic conductor size, S is the cross-section that minimizes the total cost function:

ec

CT(S) = CI(S) + I × R × (S) × L × F (cu) (14)

max L

where CI(S) and R (S) are expressed as functions of the conductor cross-section S,

L

see 5.2.2.

– 14 – 60287-3-2 © IEC:2012

The formula for the relationship between CI(S) and conductor size can be derived from known

costs of standard cable sizes. In general, if a reasonably linear relationship can be fitted to

the costs, possibly over a restricted range of conductor sizes, it should be used. This will

cause little error in the results, in view of the possible uncertainties in the assumed financial

parameters for the anticipated operational life period chosen.

According to IEC 60287-1-1, the apparent conductor resistance can be expressed as a

function of the cross-section by:

ρ × B [1+ α (θ − 20)]

20 20 m

R (S) = × 10 (Ω/m) (15)

L

S

B = (1 + y + y ) (1 + λ + λ ) (16)

p s 1 2

where

ρ is the d.c. resistivity of the conductor, in Ω×m.

NOTE The economic conductor size is unlikely to be identical to a standard size and so it is necessary to provide

a continuous relationship between resistance and size. This is done by assuming a value of resistivity for each

–9 –9

conductor material. The values recommended here for ρ are: 18,35 × 10 for copper and 30,3 × 10 for

aluminium. These values are not the actual values for the materials, but are compromise values chosen so that

conductor resistances can be calculated directly from nominal conductor sizes, rather than from the actual effective

cross-sectional areas.

y y are the skin and proximity effect factors, see IEC 60287-1-1;

p, s

λ , λ are the sheath and armour loss factors, see IEC 60287-1-1;

1 2

α is the temperature coefficient of resistivity for the particular conductor material at

–1

20 °C, K ;

θ is the conductor temperature, see explanation given in the definition of R for

m L

Formula (2), in °C;

B is the auxiliary value defined by Formula (16), which can be calculated from

IEC 60287-1-1 by assuming a probable value for the economic size of conductor;

S is the cross-sectional area of cable conductor, mm .

5.2.2 Linear cost function for cable costs

If a linear model can be fitted to the values of initial cost for the type of cable and installation

under consideration, then:

CI(S) = L × (A ×S + A ) (cu) (17)

s L

where

A is the variable component of cost, related to conductor size, cu/m × mm ;

s

A is the constant component of cost, unaffected by size of cable, in cu/m;

L

L is the length of cable, in m.

Then the optimum size S (mm ) can be obtained by equating to zero the derivative of

ec

Formula (14) with respect to S, giving:

0,5

I × F × × B [ + ( − )]

ρ 1 α θ 20

max 20 20 m

S = 1 000 mm (18)

ec

A

NOTE 1 As the economic size is unknown, it is necessary to make an assumption as to the probable cable size in

order that reasonable values of y , y , λ and λ , can be calculated. Recalculation may be necessary if the

p s 1 2

economic size is too different.

60287-3-2 © IEC:2012 – 15 –

NOTE 2 The constant component of the cost, A , in Formula (17), does not affect the evaluation of the economic

L

size S .

ec

S is unlikely to be exactly equal to a standard size (see IEC 60228) and so the cost for the

ec

adjacent larger and smaller standard sizes shall be calculated and the most economical one

chosen.

5.2.3 Effect of charging current and dielectric losses

Dielectric losses and the losses due to charging current are always present in an a.c. system

when the cable is energized and therefore operate at 100 % load factor. Both types of losses

are significant only at high-voltage levels and are dependent on cable capacitance. Evaluation

of transmission cable systems often assumes the placement of shunt reactors at the ends of

the cable system to supply the reactive VARs required by the cable. The reactors have losses

equal to about 0,8 % of power rating. Those losses should be considered in the evaluation of

cable system losses and the cost of the reactors added to the cable purchase cost.

For a given voltage level and insulation thickness, an increase in conductor diameter results

in an increase in cable capacitance and, as a result of this, an increase in voltage dependent

losses. Because of this, when dielectric losses are included in the analysis, these losses will

tend to decrease the conductor diameter as opposed to the effect of current dependent

losses.

The dielectric and charging current losses are sometimes referred to as voltage-dependent

losses, in contrast to the joule losses which are referred to as current-dependent losses. The

cost of these voltage-dependent losses is included in the calculation by the following

modification to Formula (11).

Cable capacitance C is given by

ε

−9

C = ×10

D

i

18 ln

(19)

d

c

where

ε is the relative permittivity of insulation;

d is the diameter of conductor, including screen, if any, in mm;

c

D is the diameter over insulation, in mm.

i

Charging current is calculated from

(20)

I = 2π f CU

c 0

where

f is the system frequency, in Hz;

U is the voltage between conductor and screen or sheath, in V.

Charging current is not uniform along the cable. In a cable, with all charging current flowing

from one end, the charging current losses are given by:

1 2 3

W = I × L × R

(21)

chc c L

– 16 – 60287-3-2 © IEC:2012

If the system has equal charging current flowing from each end, either due to natural system

conditions or to the addition of reactors to force the equal flow, the losses per phase are given

by:

1 L

W = 2 I × R (22)

chc c L

3 2

Thus, in general, the charging current losses per conductor can be expressed by:

2 3

W = g × I × L × R (23)

chc c L

where g = 1/ 3 or 1/12 , depending on whether Formula (21) or (22) applies.

For single-core cables installed as one section, the term R in Formulae (21) to (23) is

L

replaced by (R + R ).

L s

Where single-core cable systems are divided into a number of earthed sections the charging

current losses in the screen/armour can be expressed by:

L

W = N × g × I × × R (24)

chs s c s

N

s

where N is the number of earthed sections.

s

The dielectric losses, per unit length, are proportional to the square of the voltage:

(25)

W = 2π f × C ×U × tanδ

d o

where

tan δ is the loss factor of the insulation.

The total cost, including the effect of charging current and dielectric losses, can be

represented by extending Formula (11) to

2 2 3

(26)

CT = CI + I × R × L × F + (g × I × R × L + W × L)× F

L c L d 2

where

Q

v

F = N × N × [T × P + D]×

(27)

2 p c t

1+ i /100

where

N

N

1− r

n−1

v

Q = (r ) = (28)

v v

∑

1− r

v

n=1

(1+ b /100)

(29)

r =

v

( )

1+ i /100

If r = 1, then Q = N

v v

60287-3-2 © IEC:2012 – 17 –

Annex A

(informative)

Examples of calculation of economic conductor sizes

A.1 General

Two example calculations are provided in this annex. The first example relates to a 10 kV

cable circuit and the second example

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...