IEC PAS 62611:2009

(Main)Vacuum cleaners for commercial use - Methods for measuring performance

Vacuum cleaners for commercial use - Methods for measuring performance

IEC/PAS 62611:2009(E) gives essential performance characteristics of vacuum cleaners being of interest to the users and to describe methods for measuring these characteristics.

General Information

- Status

- Replaced

- Publication Date

- 08-Jul-2009

- Technical Committee

- SC 59F - Surface cleaning appliances

- Drafting Committee

- WG 6 - TC 59/SC 59F/WG 6

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 22-Aug-2019

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Frequently Asked Questions

IEC PAS 62611:2009 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Vacuum cleaners for commercial use - Methods for measuring performance". This standard covers: IEC/PAS 62611:2009(E) gives essential performance characteristics of vacuum cleaners being of interest to the users and to describe methods for measuring these characteristics.

IEC/PAS 62611:2009(E) gives essential performance characteristics of vacuum cleaners being of interest to the users and to describe methods for measuring these characteristics.

IEC PAS 62611:2009 is classified under the following ICS (International Classification for Standards) categories: 97.080 - Cleaning appliances. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC PAS 62611:2009 has the following relationships with other standards: It is inter standard links to IEC 62885-8:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC PAS 62611:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC/PAS 62611 ®

Edition 1.0 2009-07

PUBLICLY AVAILABLE

SPECIFICATION

PRE-STANDARD

Vacuum cleaners for commercial use – Methods for measuring performance

IEC/PAS 62611:2009(E)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC/PAS 62611 ®

Edition 1.0 2009-07

PUBLICLY AVAILABLE

SPECIFICATION

PRE-STANDARD

Vacuum cleaners for commercial use – Methods for measuring performance

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

XB

ICS 97.080 ISBN 978-2-88910-815-2

– 2 – PAS 62611 © IEC:2009(E)

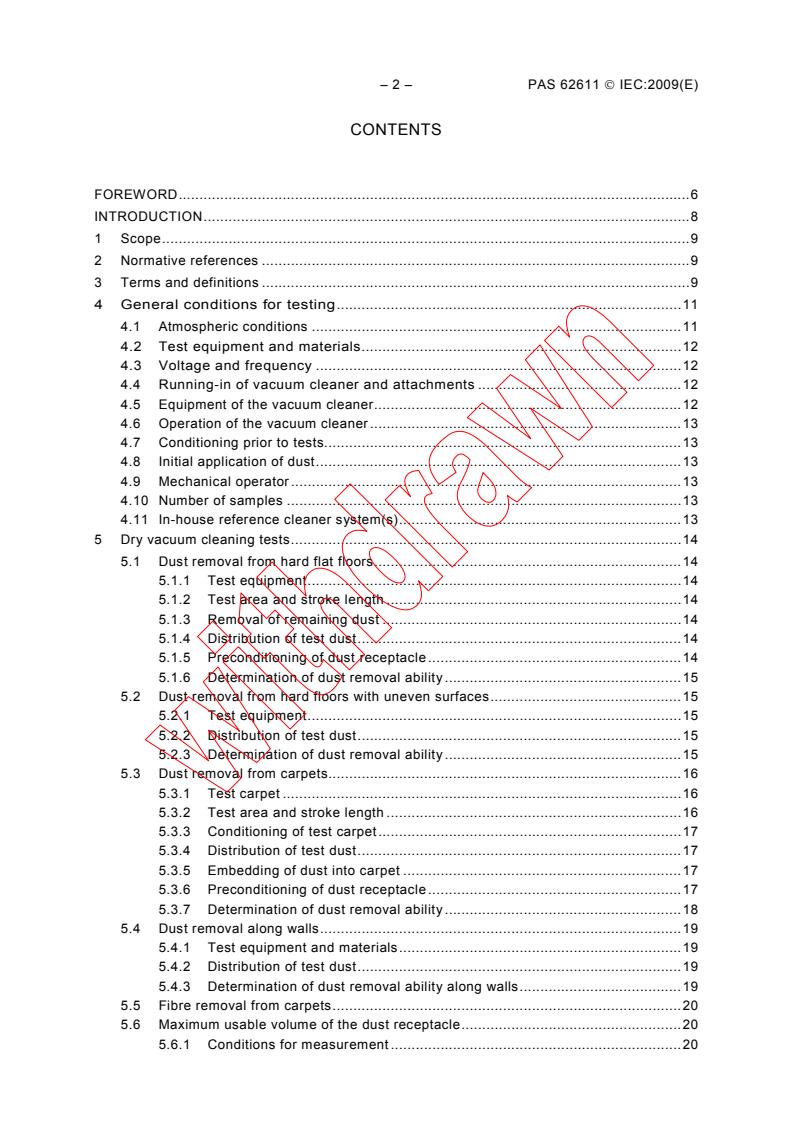

CONTENTS

FOREWORD.6

INTRODUCTION.8

1 Scope.9

2 Normative references .9

3 Terms and definitions .9

4 General conditions for testing.11

4.1 Atmospheric conditions .11

4.2 Test equipment and materials.12

4.3 Voltage and frequency .12

4.4 Running-in of vacuum cleaner and attachments .12

4.5 Equipment of the vacuum cleaner.12

4.6 Operation of the vacuum cleaner.13

4.7 Conditioning prior to tests.13

4.8 Initial application of dust.13

4.9 Mechanical operator.13

4.10 Number of samples .13

4.11 In-house reference cleaner system(s).13

5 Dry vacuum cleaning tests.14

5.1 Dust removal from hard flat floors.14

5.1.1 Test equipment.14

5.1.2 Test area and stroke length .14

5.1.3 Removal of remaining dust .14

5.1.4 Distribution of test dust.14

5.1.5 Preconditioning of dust receptacle.14

5.1.6 Determination of dust removal ability .15

5.2 Dust removal from hard floors with uneven surfaces.15

5.2.1 Test equipment.15

5.2.2 Distribution of test dust.15

5.2.3 Determination of dust removal ability .15

5.3 Dust removal from carpets.16

5.3.1 Test carpet .16

5.3.2 Test area and stroke length .16

5.3.3 Conditioning of test carpet.17

5.3.4 Distribution of test dust.17

5.3.5 Embedding of dust into carpet .17

5.3.6 Preconditioning of dust receptacle.17

5.3.7 Determination of dust removal ability .18

5.4 Dust removal along walls.19

5.4.1 Test equipment and materials.19

5.4.2 Distribution of test dust.19

5.4.3 Determination of dust removal ability along walls.19

5.5 Fibre removal from carpets.20

5.6 Maximum usable volume of the dust receptacle.20

5.6.1 Conditions for measurement .20

PAS 62611 © IEC:2009(E) – 3 –

5.6.2 Introduction of moulding granules .20

5.6.3 Determination of maximum usable volume of dust receptacle .20

5.7 Air data .20

5.7.1 Conditions for measurement .21

5.7.2 Test equipment.21

5.7.3 Determination of air data .21

5.8 Performance with loaded dust receptacle .22

5.8.1 Determination of suction pressure change with loaded dust

receptacle .22

5.8.2 Throttling to simulate loaded dust receptacle.25

5.8.3 Determination of performance with loaded dust receptacle .26

5.9 Filtration efficiency of the vacuum cleaner.26

5.9.1 Test conditions .26

5.9.2 Determining the test dust quantity .26

5.9.3 Test procedure .26

5.9.4 Evaluation .27

5.9.5 Particle concentration and dilution .29

5.9.6 Record keeping .29

5.10 HEPA filtration equivalence of the vacuum cleaner.30

5.10.1 Object of the test .30

5.10.2 Test procedure .30

5.10.3 Determination of HEPA equivalence .30

5.11 Total emissions of the vacuum cleaner .30

5.11.1 Test method .30

6 Miscellaneous tests .30

6.1 Motion resistance .31

6.1.1 Test carpet and test equipment .31

6.1.2 Determination of motion resistance.31

6.2 Cleaning under office furniture .31

6.2.1 Distribution of test dust.32

6.2.2 Determination of free office furniture height .32

6.3 Maximum radius of operation.32

6.3.1 Conditions for measurement .32

6.3.2 Determination of radius of operation .32

6.4 Impact resistance .32

6.4.1 Test equipment.33

6.4.2 Determination of impact resistance.33

6.5 Deformation of hose and connecting tubes .33

6.5.1 Test equipment.33

6.5.2 Determination of permanent deformation .33

6.6 Bump test.34

6.6.1 Test equipment.34

6.6.2 Test cycle.35

6.6.3 Test procedure .36

6.7 Flexibility of the hose .36

6.7.1 Preparation of test object.36

6.7.2 Determination of the flexibility of the hose .37

6.8 Repeated bending of the hose.37

– 4 – PAS 62611 © IEC:2009(E)

6.8.1 Test equipment.37

6.8.2 Test method .38

6.9 Life test .38

6.10 Mass .39

6.11 Weight in hand .39

6.12 Dimensions .39

6.13 Noise level .39

6.14 Energy consumption.39

6.14.1 Energy consumption when vacuuming of carpets.39

6.14.2 Energy consumption with vacuuming of hard floors with uneven

surfaces .41

7 Test material and equipment .42

7.1 Material for measurements .42

7.1.1 Test carpets .42

7.1.2 Standard dust type .43

7.1.3 Fibre material .45

7.1.4 Moulding granules .45

7.2 Equipment for measurements .45

7.2.1 Floor test plate .45

7.2.2 Test plates with uneven surfaces.45

7.2.3 Carpet-beating machine .45

7.2.4 Carpet hold-downs and guides .46

7.2.5 Dust spreader.47

7.2.6 Rollers for embedding .47

7.2.7 Equipment for air data measurement .48

7.2.8 Test equipment for determining the fractional filtration efficiency of

the vacuum cleaner .52

7.2.9 Device for motion resistance test.54

7.2.10 Device for impact test.54

7.2.11 Device for determination of deformation of hoses and connecting

tubes .55

7.2.12 Mechanical operator .56

7.2.13 Weighing machine .57

8 Instructions for use.57

9 Information at the point of sale .58

Annex A (informative) Information on materials.59

Annex B (informative) Information at the point of sale .62

Annex C (informative) Information on materials.63

Bibliography.65

Figure 1 – Right-angled T .19

Figure 2 – Air data curves.22

Figure 3a – Connecting tube openings.23

Figure 4 – Test dust for loading dust receptacle.24

Figure 5 – Dust spread uniformly on surface .25

Figure 6 – Insertion depth .32

Figure 7 – Position of test object and cross-section for measurement of deformation.34

PAS 62611 © IEC:2009(E) – 5 –

Figure 8a – Profile of threshold.35

Figure 8b – Arrangements for bump test .35

Figure 9 – Preparation of hoses for testing flexibility.37

Figure 10 – Equipment for repeated bending of hoses .38

Figure 11 – Grain size diagram for test dust.44

Figure 12 – Carpet-beating machine .46

Figure 13 – Carpet hold-downs and guides .46

Figure 14 – Dust spreader and roller for embedding dust into carpets.47

Figure 15a – Alternative A equipment for air data measurements.48

Figure 15b – Measuring box for alternative A .49

Figure 15c – Alternative B equipment for air data measurements.50

Figure 15 – Alternative A and B .50

Figure 16 – Drum for impact test.55

Figure 17 – Device for testing deformation of hoses and connecting tubes.56

Figure 18 – Mechanical operator for the measurement of dust removal from carpets

and of motion resistance.57

Table 1 – Confidence limits of a Poisson distribution for 95 % – confidence range.29

– 6 – PAS 62611 © IEC:2009(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

VACUUM CLEANERS FOR COMMERCIAL USE –

METHODS FOR MEASURING PERFORMANCE

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

A PAS is a technical specification not fulfilling the requirements for a standard, but made

available to the public.

IEC-PAS 62611 has been processed by subcommittee 59F: Floor treatment appliances, of

IEC technical committee 59: Performance of household and similar electrical appliances.

The text of this PAS is based on the This PAS was approved for

following document: publication by the P-members of the

committee concerned as indicated in

the following document

Draft PAS Report on voting

59F/184/PAS 59F/185/RVD

Following publication of this PAS, which is a pre-standard publication, the technical committee

or subcommittee concerned may transform it into an International Standard.

th

This PAS is based on the 4 edition of IEC 60312 (Vacuum cleaners for household use –

Method of measuring the performance), and has been adapted to the operating environment

of commercial appliances.

PAS 62611 © IEC:2009(E) – 7 –

This PAS shall remain valid for an initial maximum period of 3 years starting from the

publication date. The validity may be extended for a single 3-year period, following which it

shall be revised to become another type of normative document, or shall be withdrawn.

– 8 – PAS 62611 © IEC:2009(E)

INTRODUCTION

This PAS specifies provisional methods of measuring the performance of commercial vacuum

cleaners for use in offices, shops and similar commercial establishments taking into account

the differences in operation compared to household vacuum cleaners.

It is the intention of subcommittee SC 59F to review this PAS based on experience achieved

and publish an International Standard on this subject.

PAS 62611 © IEC:2009(E) – 9 –

VACUUM CLEANERS FOR COMMERCIAL USE –

METHODS FOR MEASURING PERFORMANCE

1 Scope

These test methods are applicable to vacuum cleaners for commercial use.

The purpose of this PAS is to specify essential performance characteristics of vacuum

cleaners being of interest to the users and to describe methods for measuring these

characteristics.

NOTE Due to the influence of environmental conditions, variations in time, origin of test materials and proficiency

of the operator, most of the described test methods will give more reliable results when applied for comparative

testing of a number of appliances at the same time, in the same laboratory and by the same operator.

For safety requirements, refer to IEC 60335-1, IEC 60335-2-2 and IEC 60335-2-69.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60312, Vacuum cleaners for household use – Methods of measuring the performance

IEC 60704-1, Household and similar electrical appliances – Test code for the determination of

airborne acoustical noise – Part 1: General requirements

IEC 60704-2-1, Household and similar electrical appliances – Test code for the determination

of airborne acoustical noise – Part 2-1: Particular requirements for vacuum cleaners

ISO 554, Standard atmospheres for conditioning and/or testing – Specifications

ISO 679, Cement – Test methods – Determination of strength

ISO 5167-1, Measurement of fluid flow by means of pressure differential devices inserted in

circular cross-section conduits running full – Part 1: General principles and requirements

EN 1822, Classification of HEPA and ULPA filters

ASTM F2608, Total emissions of a vacuum cleaner

ASTM F1977, Fractional filtration efficiency of a vacuum cleaner

3 Terms and definitions

For the purpose of this document, the following terms and definitions apply:

3.1

cleaning head

plain nozzle or a brush attached to a connecting tube, or a power nozzle, separate or part of

the cleaner housing, and that part of a vacuum cleaner which is applied to a surface to be

cleaned

– 10 – PAS 62611 © IEC:2009(E)

3.2

power nozzle

cleaning head provided with an agitation device to assist dirt removal. The agitation device

may be driven by an incorporated electric motor (motorized nozzle), an incorporated turbine

powered by the air flow (air-turbine nozzle) or an incorporated friction or gear mechanism

actuated by moving the cleaning head over the surface to be cleaned (mechanical nozzle)

3.3

self-propelled cleaning head

cleaning head provided with a propulsion mechanism

3.4

upright cleaner

vacuum cleaner with the cleaning head forming an integral part of or permanently connected

to the cleaner housing, the cleaning head normally being provided with an agitation device to

assist dirt removal and the complete cleaner housing being moved over the surface to be

cleaned by means of an attached handle

3.5

double stroke

one forward and one backward movement of the cleaning head performed in a parallel pattern

3.6

forward stroke

forward movement of a stroke pattern

NOTE On test carpets, forward strokes are carried out in the direction of the carpet pile (direction of

manufacture).

3.7

return stroke

backward movement of a stroke pattern

3.8

stroke length

distance between the two parallel lines defining the limits of a stroke patter

3.9

stroke pattern

arrangement of the forward and return strokes on the surface to be cleaned

3.10

parallel pattern

stroke pattern where the forward and the return strokes are congruent and are carried out in

the direction of the carpet pile (direction of manufacture) unless otherwise specified

3.11

commercial vacuum cleaner

mobile vacuum cleaner used in offices, shops and other similar commercial premises

3.12

multi-motor vacuum cleaners

vacuum cleaner with more than one vacuum motor in series

3.13

industrial vacuum cleaner

vacuum cleaner used in an environment where industrial processes take place and skilled

operation is required.

PAS 62611 © IEC:2009(E) – 11 –

3.14

test width

outside width of the cleaning head less 20 mm

3.15

active depth of the cleaning head

distance from the front edge of the cleaning head to its rear edge or a line 10 mm behind the

rear edge of the suction opening on the underside of the cleaning head, whichever is the

shortest

3.16

stroke speed

speed of the cleaning head, moved as uniformly as possible, during a forward or a return

stroke

3.17

cleaning cycle

for a given measurement, the sequence of forward and return strokes to be carried out at a

specified stroke speed over the test area according to the appropriate stroke pattern

3.18

vacuum cleaner

electronically operated appliance that removes dry material (dust, fibre, threads) from

the surface to be cleaned by an airflow created by a vacuum developed within the unit.

The material thus removed is separated in the appliance and the cleaned suction air is

returned to the ambient

3.19

wet cleaning appliance

electrically operated appliance that removes dry and/or wet material (soil) from the

surface to be cleaned by an airflow created by a vacuum developed within the unit. The

material thus removed is separated in the appliance and the cleaned suction air is

returned to the ambient

3.20

passive nozzle

cleaning head without any agitation devices

3.21

cleaning head width

the external maximum width of the cleaning head in mm

4 General conditions for testing

4.1 Atmospheric conditions

Unless otherwise specified, the test procedures and measurements shall be carried out

under the following conditions (in accordance with ISO 554):

Standard atmosphere 23/50

Temperature: (23 ± 2) ºC

Relative humidity (50 ± 5) %

Air pressure: 86 kPa to 106 kPa

– 12 – PAS 62611 © IEC:2009(E)

NOTE Temperature and humidity conditions within the specified ranges are required for good repeatability

and reproducibility. Care should be taken to avoid changes during a test.

For test procedures and measurements which may be carried out at other than standard

atmospheric conditions, the ambient temperature shall be maintained at (23 ± 5) °C.

4.2 Test equipment and materials

To minimize the influence of electrostatic phenomena, measurements on carpets shall

be carried out on a flat floor consisting of a smooth untreated pine plywood or equivalent

panel, at least 15 mm thick and of a size appropriate for the test.

Equipment and materials for measurements (devices, test carpets, test dust etc.) to be

used in a test shall, prior to the test, be kept for at least 16 h at standard atmospheric

conditions according to 4.1.

NOTE It is recommended that carpets that are already being used shall be stored unbeaten at standard

atmospheric conditions according to 4.1. When not in use they should be hanging free, not lying or rolled.

4.3 Voltage and frequency

Measurements shall be carried out at rated voltage with a tolerance of ±1 % and, if applicable,

at rated frequency.

Vacuum cleaners designed for d.c. only shall be operated at d.c. Vacuum cleaners

designed for both a.c. and d.c. shall be operated at a.c. Vacuum cleaners not marked

with rated frequency shall be operated at either 50 Hz or 60 Hz, as is common in the

country of use.

For vacuum cleaners with a rated voltage range, measurements shall be carried out at

the mean value of the voltage range if the difference between the limits of the range

does not exceed 10 % of the mean value. If the difference exceeds 10 % of the mean

value, measurements shall be carried out both at the upper and lower limits of the

voltage range.

If the rated voltage differs from the nominal system voltage of the country concerned,

measurements carried out at rated voltage may give test results misleading for the

consumer and additional measurements may be required. If the test voltage differs from

the rated voltage, this shall be reported.

4.4 Running-in of vacuum cleaner and attachments

Prior to the initial test, the vacuum cleaner, wet cleaning appliances and their attachments, if

any, shall be kept running with unrestricted air flow for at least 2 h to ensure adequate

running-in. For upright cleaners or power nozzles, the agitation device shall be running but

not in contact with the floor.

4.5 Equipment of the vacuum cleaner

If the vacuum cleaner is designed to be used with disposable dust receptacles, it shall, prior

to each measurement, be equipped with a new dust receptacle of the type recommended or

supplied by the manufacturer of the vacuum cleaner.

If the vacuum cleaner is provided with a permanent dust receptacle (as the sole original dust

receptacle or as an enclosure for disposable dust receptacles), the dust receptacle shall, prior

to each measurement, be cleaned by shaking or beating until its weight is within 1 % or 2 g of

its original weight whichever is the lower. Brushing or washing of textile receptacles is not

allowed; however, plastic receptacles may be washed and dried thoroughly. (A question has

been raised as to whether this is still relevant in today's marketplace.)

PAS 62611 © IEC:2009(E) – 13 –

Some permanent receptacles consist of a rigid container and an integral filter. In this case the

container and the filter are considered to be the receptacle and should be treated as if they

were a single component.

4.6 Operation of the vacuum cleaner

The vacuum cleaner and its accessories shall be used and adjusted in accordance with the

manufacturer's instructions for normal operation for the test to be carried out. Height

adjustment controls for the cleaning head shall be set as appropriate for the surface to be

cleaned and the position noted. Any electrical controls shall be set for maximum continuous

air flow and, unless the manufacturer's instruction states otherwise, any air by-pass openings

for reduction of the suction power shall be closed.

NOTE This only applies to those air by-pass opening devices that may be operated by the user during normal

operation. Any safety device shall be allowed to operate.

The tube grip of cleaners with suction hose or the handle of other cleaners shall be held as

for normal operation at a height of (800 ± 50) mm above the test floor.

4.7 Conditioning prior to tests

The vacuum cleaner and attachments to be used shall then be kept running for at least 10 min

under the provisions given in 4.4 to allow them to stabilise.

4.8 Initial application of dust

Prior to tests where the quantity of the dust collected is to be weighed, dust shall initially be

applied to all parts of the vacuum cleaner through which the air passes before reaching the

dust receptacle by carrying out, on the appropriate test surface, two preliminary

measurements of dust removal, the results of which are not taken into account.

4.9 Mechanical operator

In order to achieve reliable results, certain measurements require the cleaning head to be

moved at uniform speed over the test area and without exerting an additional force pressing

the cleaning head against the test surface.

In such cases, it is recommended to simulate the handling of the vacuum cleaner by using a

mechanical operator such as described in 7.2.12. The tube grip of cleaners with suction hose

or the handle of other cleaners shall then be attached to the linear drive so that its centre

pivots at a height of (800 ± 50) mm above the test surface. The linear drive may be motorized

or operated by hand.

4.10 Number of samples

All measurements of performance shall be carried out on the same sample of the vacuum

cleaner with its accessories and attachments, if any.

Tests carried out to simulate stresses a vacuum cleaner may be exposed to during normal

use, possibly causing impairment of the cleaner's performance, may require additional

samples of replaceable parts. Such tests shall be carried out at the end of the test

programme.

4.11 In-house reference cleaner system(s)

Test carpets used in a laboratory for the determination of dust removal ability will, over time,

change from their original conditions, for instance due to wearing or gradual filling with dust. It

is therefore required that in-house reference cleaner system(s) be used to regularly check the

carpet conditions as a verification of the test results obtained and being recorded.

– 14 – PAS 62611 © IEC:2009(E)

Test carpets designated for testing of passive nozzles shall only be cleaned with a passive

nozzle on the face.

5 Dry vacuum cleaning tests

5.1 Dust removal from hard flat floors

5.1.1 Test equipment

A floor test plate in accordance with 7.2.1 shall be used.

5.1.2 Test area and stroke length

A length of at least 200 mm shall be added before the beginning of the test area and at least

300 mm after the end of the test area in order to allow acceleration and deceleration of the

cleaning head.

Thus, the stroke length is at least 1200 mm for the given test length of 700 mm but shall not

be greater than 1600 mm.The centreline of the front edge of the cleaning head is aligned to

the centre line of the beginning of the acceleration area at the commencement of the stroke,

i.e. there shall be 10 mm overlap at each edge of the test area, allowing the distance of

200 mm to be used for acceleration The cleaning head shall reach the end of the stroke when

the rear edge of the active depth of the cleaning head is at least 200 mm past the end of the

test area, thus allowing a suitable distance for deceleration. The reverse stroke is carried out

in the same manner until the front edge of the cleaning head is once again lined up with the

beginning of the acceleration length in front of the test area.

The active depth of the cleaning head shall move at uniform stroke speed (0,50 m/s ± 0,02

m/s) and in a straight line over the test area.

For optimum control of the double stroke movement it is recommended that an

electromechanical operator (see 4.9) be used.

NOTE 1 The two hold-downs serve the purpose of acting as guides to keep the cleaning head in a straight line as

it is moved over the test area.

NOTE 2 Vacuum cleaners equipped with a self drive device should be operated at the prescribed stroke speed of

(0,5 m/s ± 0,02 m/s) if possible. Otherwise, the stroke speed will be determined by the vacuum cleaner.

5.1.3 Removal of remaining dust

Under consideration

5.1.4 Distribution of test dust

Test dust, Type 1 in accordance with 7.1.2.1, shall be distributed with a mean coverage of

125 g per square metre as uniformly as possible over the test area.

NOTE The amount of test dust to be used is calculated from the formula Tw × 0,7 × 125 g, where Tw is the test

width in metres. For uniform distribution of the test dust over the test area, it is recommended that a dust spreader

as described in 7.2.5 be used. The adjustment of the device is checked by visual examination of the test dust on

the carpet.

5.1.5 Preconditioning of dust receptacle

In order to minimize the effects of humidity, the dust receptacle shall be preconditioned as

follows.

The vacuum cleaner under test is equipped with a clean dust receptacle and allowed to run

with an unimpeded air flow for 8 min.

PAS 62611 © IEC:2009(E) – 15 –

After the preconditioning, the dust receptacle is removed from the cleaner to be weighed. The

weight is noted and the dust receptacle is replaced.

NOTE The cleaner air flow can have an effect on the weight of the dust receptacle during the 8 min

preconditioning; caution should be taken that the weight of the dust receptacle has stabilised before weighing.

5.1.6 Determination of dust removal ability

Three separate measurements, each comprising one double stroke, shall be carried out. After

the double stroke, the cleaning head shall be lifted at least 100 mm clear of the surface

before the vacuum cleaner is switched off. The dust receptacle shall not be removed before

the motor has completely stopped.

Once the cleaner has completely stopped, the receptacle is carefully removed and reweighed.

Due to effects of possible static charge build up during the time the vacuum cleaner is picking

up dust, it is necessary to ensure that the receptacle has completely stabilised prior to

recording the weight.

The dust removal ability is calculated as the ratio of the weight increase of the dust receptacle

during the double stroke to the weight of the test dust distributed on the test area. The mean

value for 3 measurements is calculated:

K (3) (K + K + K )/3

B = B1 Bc B3

K (i) = mean dust removal for i measurements in per cent

B

K = dust removal for measurement i in per cent

Bi

M = weight of the dust distributed on the test area in grams

D

m = weight of the preconditioned dust receptacle in grams

DRf

m = weight of the dust receptacle after cleaning in grams

DRf

NOTE When the mean value is lower than 90 %: should the range of measurements be greater than 3 percentage

units, two additional measurements are carried out and the mean value of all the measurements should be given as

the result.

When the mean value is equal or higher than 90 %: should the range of the measurements be greater than

(0,3 × 100 % – mean value), two additional measurements are carried out and the mean value of all the

measurements should be given as the result.

In both cases, consideration should be given to the control of repeatability within the laboratory and the design or

manufacture of the cleaner or cleaning head in order to ascertain whether any factors not previously observed may

affect the repeatability adversely.

5.2 Dust removal from hard floors with uneven surfaces

5.2.1 Test equipment

The equipment, in accordance with 7.2.2, consists of a test plate with an uneven surface.

NOTE The test area and stoke length is the same as for 5.1.

The type of test plate selected must be recorded.

5.2.2 Distribution of test dust

The surface is spread with the specified quantity of minera

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...