IEC 62061:2005

(Main)Safety of machinery - Functional safety of safety-related electrical, electronic and programmable electronic control systems

Safety of machinery - Functional safety of safety-related electrical, electronic and programmable electronic control systems

specifies requirements and makes recommendations for the design, integration and validation of safety-related electrical, electronic and programmable electronic control systems (SRECS) for machines (see Notes 1 and 2). It is applicable to control systems used, either singly or in combination, to carry out safety-related control functions on machines that are not portable by hand while working, including a group of machines working together in a co-ordinated manner. The contents of the corrigenda of July 2005 and April 2008 have been included in this copy.

Sécurité des machines - Sécurité fonctionnelle des systèmes de commande électriques, électroniques et électroniques programmables relatifs à la sécurité

spécifie les exigences et donne des recommandations pour la conception, l'intégration et la validation des systèmes de commande électriques, électroniques et électroniques programmables relatifs à la sécurité (SRECS) pour les machines (voir Notes 1 et 2). Elle s'applique aux systèmes de commande utilisés, séparément ou en combinaison, pour assurer des fonctions de commande relatives à la sécurité de machines qui ne sont pas portables à la main en fonctionnement, y compris un groupe de machines fonctionnant ensemble d'une manière coordonnée. Le contenu des corrigenda de juillet 2005 et d'avril 2008 a été pris en considération dans cet exemplaire.

General Information

- Status

- Published

- Publication Date

- 19-Jan-2005

- Technical Committee

- TC 44 - Safety of machinery - Electrotechnical aspects

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 22-Mar-2021

- Completion Date

- 02-Feb-2017

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 62061:2005, published by the International Electrotechnical Commission (IEC), is a pivotal international standard focusing on the functional safety of safety-related electrical, electronic, and programmable electronic control systems (SRECS) used in machinery. It provides comprehensive requirements and recommendations for the design, integration, validation, and maintenance of these safety-related systems. The standard is applicable to fixed machinery, including groups of machines working in coordinated functions, ensuring robust safety controls beyond portable hand-held equipment.

The standard's scope centers on ensuring that safety-related control functions (SRCFs) are specified, implemented, and maintained to minimize risks associated with machine operation, meeting international expectations for functional safety. Consolidated with amendments from 2012 and 2015, IEC 62061 reflects current best practices and technical rigor for engineers, safety specialists, and manufacturers working with machine control systems.

Key Topics

IEC 62061 covers several critical aspects to achieve effective functional safety:

- Management of Functional Safety: Defines organizational and procedural requirements to manage lifecycle activities ensuring consistent safety performance.

- Specification of Safety-Related Control Functions (SRCFs): Guides the precise specification of control functions linked to safety, defining performance requirements and failure tolerances.

- Design and Integration of SRECS: Covers hardware and software development, subsystem design, diagnostics, fault detection, and integration processes.

- Safety Integrity Levels (SIL): Establishes SIL classifications based on risk parameters and target failure probabilities, supporting tailored safety system designs.

- Validation and Verification: Provides requirements for system testing, validation of systematic integrity, and ongoing verification after installation.

- Modification and Configuration Management: Details procedures to manage changes to the safety system while preserving or improving safety integrity.

- Documentation and Information Handling: Specifies mandatory documentation covering design, installation, operation, and maintenance of safety-related systems.

The standard also includes numerous informative annexes addressing SIL assignment, software design guidance, failure modes, immunity to electromagnetic interference, and mitigation of common cause failures (CCF).

Applications

IEC 62061 is critical in industries where machinery safety is paramount. Its practical applications include:

- Manufacturing Equipment: Safeguarding automated machinery on production lines by ensuring that control systems respond reliably to faults and operator commands.

- Industrial Automation: Managing coordinated control across multiple machines to maintain safe operations in environments like automotive assembly or packaging plants.

- Process Industries: Implementing safety functions within control systems for heavy equipment that handle hazardous materials or complex processes.

- Safety System Design: Creating safety architectures combining electrical, electronic, and programmable components that meet defined SIL requirements.

- Compliance and Risk Management: Assisting organizations in meeting regulatory requirements and industry best practices for machine safety standards.

This standard complements safety engineering efforts to prevent accidents and protect personnel by ensuring functional reliability of safety-related control systems at all stages from design to operation.

Related Standards

IEC 62061 aligns with and relates to other internationally recognized safety standards, including:

- ISO 13849-1: Safety of machinery - Safety-related parts of control systems - provides complementary guidance primarily focused on risk assessment and performance levels.

- IEC 61508: Functional safety of electrical/electronic/programmable electronic safety-related systems - a generic standard establishing fundamental principles for functional safety applied by IEC 62061 in a machinery context.

- IEC 61000-6-2: Electromagnetic compatibility (EMC) - industrial environments - supports IEC 62061 by addressing immunity requirements for SRECS in harsh electromagnetic environments.

- IEC 61511: Functional safety - Safety instrumented systems for the process industry sector - shares methodologies useful for safety system lifecycle and validation.

Understanding the interplay between these standards supports comprehensive safety management and technology integration strategies for control systems in machinery.

By adhering to the detailed lifecycle requirements and best practice recommendations of IEC 62061, manufacturers and engineers ensure high reliability and safety performance of machine control systems, minimizing operational risks and enhancing worker safety in diverse industrial settings.

IEC 62061:2005+AMD1:2012+AMD2:2015 CSV/COR1:2015 - Corrigendum 1 - Safety of machinery - Functional safety of safety-related electrical, electronic and programmable electronic control systems Released:8/5/2015

IEC 62061:2005 - Safety of machinery - Functional safety of safety-related electrical, electronic and programmable electronic control systems

IEC 62061:2005+AMD1:2012 CSV - Safety of machinery - Functional safety of safety-related electrical, electronic and programmable electronic control systems Released:11/13/2012 Isbn:9782832204870

IEC 62061:2005+AMD1:2012+AMD2:2015 CSV - Safety of machinery - Functional safety of safety-related electrical, electronic and programmable electronic control systems Released:6/26/2015 Isbn:9782832227749

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

NSF International

Global independent organization facilitating standards development and certification.

Sponsored listings

Frequently Asked Questions

IEC 62061:2005 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Safety of machinery - Functional safety of safety-related electrical, electronic and programmable electronic control systems". This standard covers: specifies requirements and makes recommendations for the design, integration and validation of safety-related electrical, electronic and programmable electronic control systems (SRECS) for machines (see Notes 1 and 2). It is applicable to control systems used, either singly or in combination, to carry out safety-related control functions on machines that are not portable by hand while working, including a group of machines working together in a co-ordinated manner. The contents of the corrigenda of July 2005 and April 2008 have been included in this copy.

specifies requirements and makes recommendations for the design, integration and validation of safety-related electrical, electronic and programmable electronic control systems (SRECS) for machines (see Notes 1 and 2). It is applicable to control systems used, either singly or in combination, to carry out safety-related control functions on machines that are not portable by hand while working, including a group of machines working together in a co-ordinated manner. The contents of the corrigenda of July 2005 and April 2008 have been included in this copy.

IEC 62061:2005 is classified under the following ICS (International Classification for Standards) categories: 13.110 - Safety of machinery; 25.040.99 - Other industrial automation systems; 29.020 - Electrical engineering in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62061:2005 has the following relationships with other standards: It is inter standard links to IEC 62061:2005/AMD2:2015, IEC 62061:2005/AMD1:2012, IEC 62061:2005/COR1:2005, IEC 62061:2005/COR2:2008, IEC 62061:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62061:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

AMD2:2015 CSV/COR1:2015 IEC 2015

INTERNATIONAL ELECTROTECHNICAL COMMISSION

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

IEC 62061 IEC 62061

Edition 1.2 2015-06 Édition 1.2 2015-06

Safety of machinery – Sécurité des machines –

Functional safety of safety-related electrical, Sécurité fonctionnelle des systèmes de

electronic and programmable electronic control commande électriques, él

...

IEC 62061

Edition 1.0 2005-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Safety of machinery – Functional safety of safety-related electrical, electronic

and programmable electronic control systems

Sécurité des machines – Sécurité fonctionnelle des systèmes de commande

électriques, électroniques et électroniques programmables relatifs à la sécurité

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 62061

Edition 1.0 2005-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Safety of machinery – Functional safety of safety-related electrical, electronic

and programmable electronic control systems

Sécurité des machines – Sécurité fonctionnelle des systèmes de commande

électriques, électroniques et électroniques programmables relatifs à la sécurité

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

XD

CODE PRIX

ICS 13.110; 25.040.99; 29.020 ISBN 2-8318-7818-7

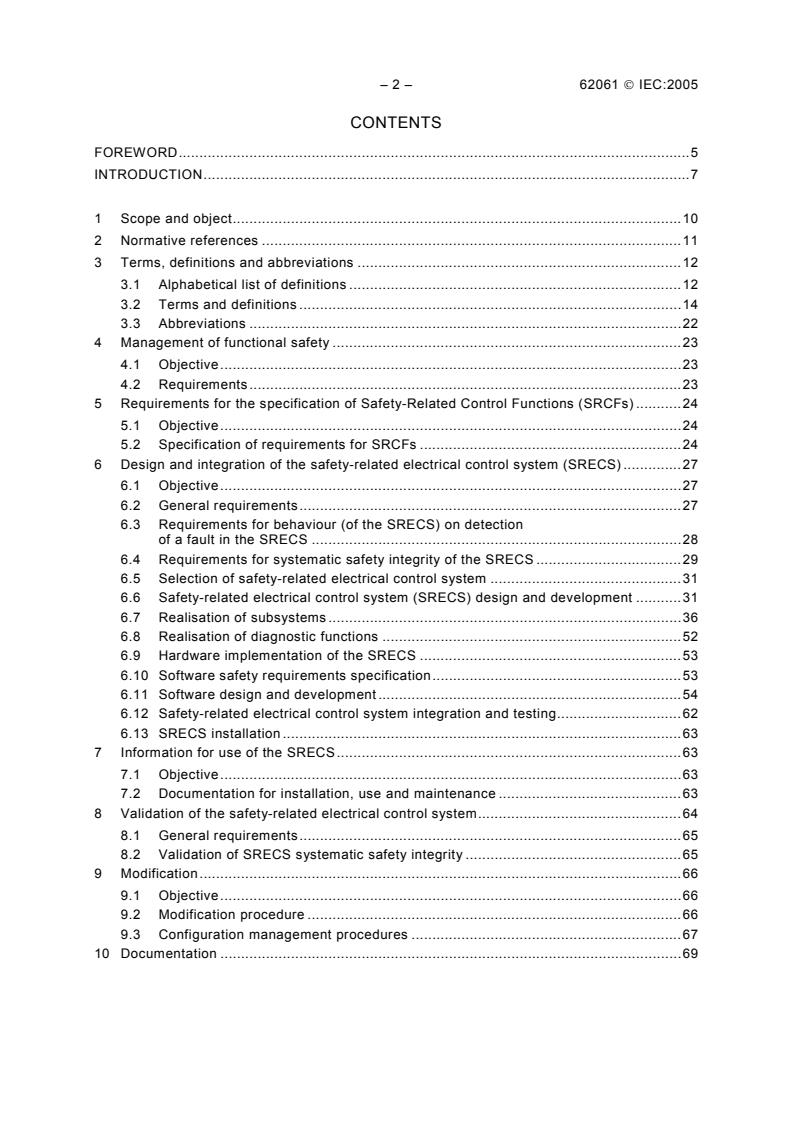

– 2 – 62061 © IEC:2005

CONTENTS

FOREWORD.5

INTRODUCTION.7

1 Scope and object.10

2 Normative references .11

3 Terms, definitions and abbreviations .12

3.1 Alphabetical list of definitions .12

3.2 Terms and definitions .14

3.3 Abbreviations .22

4 Management of functional safety .23

4.1 Objective.23

4.2 Requirements.23

5 Requirements for the specification of Safety-Related Control Functions (SRCFs) .24

5.1 Objective.24

5.2 Specification of requirements for SRCFs .24

6 Design and integration of the safety-related electrical control system (SRECS) .27

6.1 Objective.27

6.2 General requirements.27

6.3 Requirements for behaviour (of the SRECS) on detection

of a fault in the SRECS .28

6.4 Requirements for systematic safety integrity of the SRECS .29

6.5 Selection of safety-related electrical control system .31

6.6 Safety-related electrical control system (SRECS) design and development .31

6.7 Realisation of subsystems .36

6.8 Realisation of diagnostic functions .52

6.9 Hardware implementation of the SRECS .53

6.10 Software safety requirements specification.53

6.11 Software design and development.54

6.12 Safety-related electrical control system integration and testing.62

6.13 SRECS installation .63

7 Information for use of the SRECS.63

7.1 Objective.63

7.2 Documentation for installation, use and maintenance .63

8 Validation of the safety-related electrical control system.64

8.1 General requirements.65

8.2 Validation of SRECS systematic safety integrity .65

9 Modification.66

9.1 Objective.66

9.2 Modification procedure .66

9.3 Configuration management procedures .67

10 Documentation .69

62061 © IEC:2005 – 3 –

Annex A (informative) SIL assignment .71

Annex B (informative) Example of safety-related electrical control system (SRECS)

design using concepts and requirements of Clauses 5 and 6 .79

Annex C (informative) Guide to embedded software design and development.86

Annex D (informative) Failure modes of electrical/electronic components .95

Annex E (informative) Electromagnetic (EM) phenomenon and increased immunity

levels for SRECS intended for use in an industrial environment according to

IEC 61000-6-2 .100

Annex F (informative) Methodology for the estimation of susceptibility to common

cause failures (CCF).102

Figure 1 – Relationship of IEC 62061 to other relevant standards .8

Figure 2 – Workflow of the SRECS design and development process .33

Figure 3 – Allocation of safety requirements of the function blocks to subsystems

(see 6.6.2.1.1) .34

Figure 4 – Workflow for subsystem design and development (see box 6B of Figure 2) .39

Figure 5 – Decomposition of a function block into redundant function block elements

and their associated subsystem elements .40

Figure 6 – Subsystem A logical representation .46

Figure 7 – Subsystem B logical representation .47

Figure 8 – Subsystem C logical representation .47

Figure 9 – Subsystem D logical representation .49

Figure A.1 – Workflow of SIL assignment process.72

Figure A.2 – Parameters used in risk estimation .73

Figure A.3 – Example proforma for SIL assignment process .78

Figure B.1 – Terminology used in functional decomposition .79

Figure B.2 – Example machine .80

Figure B.3 – Specification of requirements for an SRCF .80

Figure B.4 – Decomposition to a structure of function blocks .81

Figure B.5 – Initial concept of an architecture for a SRECS .82

Figure B.6 – SRECS architecture with diagnostic functions embedded within each

subsystem (SS1 to SS4) .83

Figure B.7 – SRECS architecture with diagnostic functions embedded within

subsystem SS3.84

Figure B.8 – Estimation of PFH for a SRECS.85

D

Table 1 – Recommended application of IEC 62061 and ISO 13849-1(under revision) .9

Table 2 – Overview and objectives of IEC 62061 .11

Table 3 – Safety integrity levels: target failure values for SRCFs .26

Table 4 – Characteristics of subsystems 1 and 2 used in this example.36

Table 5 – Architectural constraints on subsystems: maximum SIL that can be claimed

for a SRCF using this subsystem .42

Table 6 – Architectural constraints: SILCL relating to categories.43

Table 7 – Probability of dangerous failure .45

Table 8 – Information and documentation of a SRECS.69

– 4 – 62061 © IEC:2005

Table A.1 – Severity (Se) classification.74

Table A.2– Frequency and duration of exposure (Fr) classification .74

Table A.3– Probability (Pr) classification.75

Table A.4– Probability of avoiding or limiting harm (Av) classification .76

Table A.5– Parameters used to determine class of probability of harm (Cl) .76

Table A.6 – SIL assignment matrix.76

Table D.1 – Examples of the failure mode ratios for electrical/electronic components .95

Table E.1 – EM phenomenon and increased immunity levels for SRECS .100

Table E.2 – Selected frequencies for RF field tests.101

Table E.3 – Selected frequencies for conducted RF tests .101

Table F.1 – Criteria for estimation of CCF.102

Table F.2 – Estimation of CCF factor (β).103

62061 © IEC:2005 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SAFETY OF MACHINERY –

FUNCTIONAL SAFETY OF SAFETY-RELATED ELECTRICAL,

ELECTRONIC AND PROGRAMMABLE ELECTRONIC

CONTROL SYSTEMS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62061 has been prepared by IEC technical committee 44: Safety

of machinery – Electrotechnical aspects.

The text of this standard is based on the following documents:

FDIS Report on voting

44/460/FDIS 44/470/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 6 – 62061 © IEC:2005

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

The contents of the corrigenda of July 2005 and April 2008 have been included in this copy.

62061 © IEC:2005 – 7 –

INTRODUCTION

As a result of automation, demand for increased production and reduced operator physical

effort, Safety-Related Electrical Control Systems (referred to as SRECS) of machines play an

increasing role in the achievement of overall machine safety. Furthermore, the SRECS

themselves increasingly employ complex electronic technology.

Previously, in the absence of standards, there has been a reluctance to accept SRECS in

safety-related functions for significant machine hazards because of uncertainty regarding the

performance of such technology.

This International Standard is intended for use by machinery designers, control system

manufacturers and integrators, and others involved in the specification, design and validation

of a SRECS. It sets out an approach and provides requirements to achieve the necessary

performance.

This standard is machine sector specific within the framework of IEC 61508. It is intended to

facilitate the specification of the performance of safety-related electrical control systems in

relation to the significant hazards (see 3.8 of ISO 12100-1) of machines.

This standard provides a machine sector specific framework for functional safety of a SRECS

of machines. It only covers those aspects of the safety lifecycle that are related to safety

requirements allocation through to safety validation. Requirements are provided for

information for safe use of SRECS of machines that can also be relevant to later phases of

the life of a SRECS.

There are many situations on machines where SRECS are employed as part of safety

measures that have been provided to achieve risk reduction. A typical case is the use of an

interlocking guard that, when it is opened to allow access to the danger zone, signals the

electrical control system to stop hazardous machine operation. Also in automation, the

electrical control system that is used to achieve correct operation of the machine process

often contributes to safety by mitigating risks associated with hazards arising directly from

control system failures. This standard gives a methodology and requirements to

• assign the required safety integrity level for each safety-related control function to be

implemented by SRECS;

• enable the design of the SRECS appropriate to the assigned safety-related control

function(s);

• integrate safety-related subsystems designed in accordance with ISO 13849 ;

• validate the SRECS.

This standard is intended to be used within the framework of systematic risk reduction

described in ISO 12100-1 and in conjunction with risk assessment according to the principles

described in ISO 14121 (EN 1050). A suggested methodology for safety integrity level (SIL)

assignment is given in informative Annex A.

Measures are given to co-ordinate the performance of the SRECS with the intended risk

reduction taking into account the probabilities and consequences of random or systematic

faults within the electrical control system.

Figure 1 shows the relationship of this standard to other relevant standards.

Table 1 gives recommendations on the recommended application of this standard and the

revision of ISO 13849-1.

– 8 – 62061 © IEC:2005

Design and risk asseessment of the machine

ISO 12100, Safety of machinery – Basic concept, general principles

for design

ISO 14121, Safety of machinery – Principles for risk assessement

Design of safety-related electrical, electronic and programmable elecronic control systems

(SRECS) for machinery

Methodology using:

Safety-related control functions

System-based approach

- Quantitative index of safety:

- Index of safety:

Safety integrity level (SIL)

Category/performance level

- SIL assignment methodology for

- Category assigned by

SRECS of machinery

qualitative risk graphing

- Architecture oriented

- Architecture oriented

- Requirements for

avoidance/control of systematic

failures

Design objective for the

SRECS

Relevant standards

Electrical safety aspects of machinery

Design of low complexity

IEC 60204-1, Safety of machinery -

subsystems to categories

Electrical equipment of machinery -

Part 1: General requirements

ISO 13849-1 and 2 Safety of

machinery – Safety related

parts of control systems (SRPCS)

- Part 1: General princples

for design and Part 2:

Design of complex subsystems Validation

to SILs

Non-electrical SRPCS

IEC 61508, Functional safety of

(mechanical,

electrical, electronic and

pneumatic, etc.)

programmable electronic safety -

related systems

Electrical SRPCS

IEC 62061

Safety of machinery -

Functional safety of

safety-related electrical,

electronic and programmable

Key:

electronic control systems

Electrical safety aspects

Functional safety aspects

Figure 1 – Relationship of IEC 62061 to other relevant standards

Information on the recommended application of IEC 62061 and ISO 13849-1

(under revision)

62061 © IEC:2005 – 9 –

IEC 62061 and ISO 13849-1 (under revision) specify requirements for the design and

implementation of safety-related control systems of machinery. The use of either of these

standards, in accordance with their scopes, can be presumed to fulfil the relevant essential

safety requirements. Table 1 summarises the scopes of IEC 62061 and ISO 13849-1(under

revision).

NOTE ISO 13849-1 is currently under preparation by ISO TC 199 and CEN TC 114.

Table 1 – Recommended application of IEC 62061 and ISO 13849-1(under revision)

Technology implementing the safety- ISO IEC 62061

related control function(s) 13849-1 (under revision)

A Non electrical, e.g. hydraulics X Not covered

B Electromechanical, e.g. relays, or non Restricted to designated All architectures and up to SIL 3

complex electronics architectures

(see Note 1) and up to PL=e

C Complex electronics, e.g. programmable Restricted to designated All architectures and up to SIL 3

architectures (see Note 1) and up

to PL=d

D A combined with B Restricted to designated X see Note 3

architectures (see Note 1) and up

to PL=e

E C combined with B Restricted to designated All architectures and up to SIL 3

architectures (see Note 1) and up

to PL=d

F C combined with A, or C combined with X see Note 2 X see Note 3

A and B

“X” indicates that this item is dealt with by the standard shown in the column heading.

NOTE 1 Designated architectures are defined in Annex B of EN ISO 13849-1(rev.) to give a simplified approach for

quantification of performance level.

NOTE 2 For complex electronics: Use of designated architectures according to EN ISO 13849-1(rev.) up to PL=d or

any architecture according to IEC 62061.

NOTE 3 For non-electrical technology use parts according to EN ISO 13849-1(rev.) as subsystems.

– 10 – 62061 © IEC:2005

SAFETY OF MACHINERY –

FUNCTIONAL SAFETY OF SAFETY-RELATED ELECTRICAL,

ELECTRONIC AND PROGRAMMABLE ELECTRONIC

CONTROL SYSTEMS

1 Scope

This International Standard specifies requirements and makes recommendations for the

design, integration and validation of safety-related electrical, electronic and programmable

electronic control systems (SRECS) for machines (see Notes 1 and 2). It is applicable to

control systems used, either singly or in combination, to carry out safety-related control

functions on machines that are not portable by hand while working, including a group of

machines working together in a co-ordinated manner.

NOTE 1 In this standard, the term “electrical control systems” is used to stand for ”Electrical, Electronic and

Programmable Electronic (E/E/PE) control systems” and “SRECS” is used to stand for “safety-related electrical,

electronic and programmable electronic control systems”.

NOTE 2 In this standard, it is presumed that the design of complex programmable electronic subsystems or

subsystem elements conforms to the relevant requirements of IEC 61508. This standard provides a methodology

for the use, rather than development, of such subsystems and subsystem elements as part of a SRECS.

This standard is an application standard and is not intended to limit or inhibit technological

advancement. It does not cover all the requirements (e.g. guarding, non-electrical interlocking

or non-electrical control) that are needed or required by other standards or regulations in

order to safeguard persons from hazards. Each type of machine has unique requirements to

be satisfied to provide adequate safety.

This standard:

– is concerned only with functional safety requirements intended to reduce the risk of injury

or damage to the health of persons in the immediate vicinity of the machine and those

directly involved in the use of the machine;

– is restricted to risks arising directly from the hazards of the machine itself or from a group

of machines working together in a co-ordinated manner;

NOTE 3 Requirements to mitigate risks arising from other hazards are provided in relevant sector standards.

For example, where a machine(s) is part of a process activity, the machine electrical control system functional

safety requirements should, in addition, satisfy other requirements (e.g. IEC 61511) insofar as safety of the

process is concerned.

– does not specify requirements for the performance of non-electrical (e.g. hydraulic,

pneumatic) control elements for machines;

NOTE 4 Although the requirements of this standard are specific to electrical control systems, the framework

and methodology specified can be applicable to safety-related parts of control systems employing other

technologies.

– does not cover electrical hazards arising from the electrical control equipment itself (e.g.

electric shock – see IEC 60204–1).

62061 © IEC:2005 – 11 –

The objectives of specific Clauses in IEC 62061 are as given in Table 2.

Table 2 – Overview and objectives of IEC 62061

Clause Objective

4: To specify the management and technical activities which are necessary for the achievement of

Management the required functional safety of the SRECS.

of functional

safety

5: To set out the procedures to specify the requirements for safety-related control functions. These

Requirements requirements are expressed in terms of functional requirements specification, and safety integrity

for the requirements specification.

specification of

safety-related

control

functions

6: To specify the selection criteria and/or the design and implementation methods of the SRECS to

Design and meet the functional safety requirements. This includes:

integration of

the safety- selection of the system architecture,

related

electrical selection of the safety-related hardware and software,

control system

design of hardware and software,

verification that the designed hardware and software meets the functional safety requirements.

7: To specify requirements for the information for use of the SRECS, which has to be supplied with

Information for the machine. This includes:

use of the

machine provision of the user manual and procedures,

provision of the maintenance manual and procedures.

8: To specify the requirements for the validation process to be applied to the SRECS. This includes

Validation of inspection and testing of the SRECS to ensure that it achieves the requirements stated in the

the safety- safety requirements specification.

related

electrical

control system

9: To specify the requirements for the modification procedure that has to be applied when modifying

Modification of the SRECS. This includes:

the safety-

related modifications to any SRECS are properly planned and verified prior to making the change;

electrical

control system the safety requirements specification of the SRECS is satisfied after any modifications have taken

place.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60204–1, Safety of machinery – Electrical equipment of machines – Part 1: General

requirements

IEC 61000-6-2, Electromagnetic compatibility (EMC) – Part 6-2: Generic standards –

Immunity for industrial environments

– 12 – 62061 © IEC:2005

IEC 61310 (all parts), Safety of machinery – Indication, marking and actuation

IEC 61508-2, Functional safety of electrical/electronic/ programmable electronic safety-related

systems – Part 2: Requirements for electrical/electronic/programmable electronic safety-

related systems

IEC 61508-3, Functional safety of electrical/electronic/programmable electronic safety-related

systems – Part 3: Software requirements

ISO 12100-1:2003, Safety of machinery – Basic concepts, general principles for design –

Part 1: Basic terminology, methodology

ISO 12100-2:2003, Safety of machinery – Basic concepts, general principles for design –

Part 2: Technical principles

ISO 13849-1:1999, Safety of machinery – Safety related parts of control systems – Part 1:

General principles for design

ISO 13849-2:2003, Safety of machinery – Safety-related parts of control systems – Part 2:

Validation

ISO 14121, Safety of machinery – Principles of risk assessment

3 Terms, definitions and abbreviations

3.1 Alphabetical list of definitions

Term Definition

number

application software 3.2.46

architectural constraint 3.2.36

architecture 3.2.35

common cause failure 3.2.43

complex component 3.2.8

control function 3.2.14

dangerous failure 3.2.40

demand 3.2.25

diagnostic coverage 3.2.38

electrical control system 3.2.3

embedded software 3.2.47

failure 3.2.39

fault 3.2.30

fault tolerance 3.2.31

full variability language (FVL) 3.2.48

function block 3.2.32

function block element 3.2.33

62061 © IEC:2005 – 13 –

functional safety 3.2.9

hardware safety integrity 3.2.20

hazard (from machinery) 3.2.10

hazardous situation 3.2.11

high demand or continuous mode 3.2.27

limited variability language (LVL) 3.2.49

low complexity component 3.2.7

low demand mode 3.2.26

machine control system 3.2.2

machinery (machine) 3.2.1

mean time to failure (MTTF) 3.2.34

probability of dangerous failure per hour (PFH) 3.2.28

D

proof test 3.2.37

protective measure 3.2.12

random hardware failure 3.2.44

risk 3.2.13

safe failure 3.2.41

safe failure fraction 3.2.42

safety function 3.2.15

safety integrity 3.2.19

safety integrity level (SIL) 3.2.23

safety-related control function (SRCF) 3.2.16

safety-related electrical control system (SRECS) 3.2.4

safety-related software 3.2.50

SIL claim limit 3.2.24

software safety integrity 3.2.21

SRECS diagnostic function 3.2.17

SRECS fault reaction function 3.2.18

subsystem 3.2.5

subsystem element 3.2.6

systematic failure 3.2.45

systematic safety integrity 3.2.22

target failure value 3.2.29

validation 3.2.52

verification 3.2.51

– 14 – 62061 © IEC:2005

3.2 Terms and definitions

For the purposes of this standard, the following terms and definitions apply.

3.2.1

machinery

assembly of linked parts or components, at least one of which moves, with the appropriate

machine actuators, control and power circuits, joined together for a specific application, in

particular for the processing, treatment, moving or packaging of a material.

The terms “machinery” and “machine” also cover an assembly of machines which, in order to

achieve the same end, are arranged and controlled so that they function as an integral whole.

[ISO 12100-1:2003, 3.1]

3.2.2

machine control system

system which responds to an input from, for example, the process, other machine elements,

an operator, external control equipment, and generates an output(s) causing the machine to

behave in the intended manner

3.2.3

electrical control system

all the electrical, electronic and programmable electronic parts of the machine control system

used to provide, for example, operational control, monitoring, interlocking, communications,

protection and safety-related control functions

NOTE Safety-related control functions can be performed by an electrical control system that is either integral to or

independent of those parts of a machine’s control system that perform non-safety-related functions.

3.2.4

Safety-Related Electrical Control System

SRECS

electrical control system of a machine whose failure can result in an immediate increase of

the risk(s)

NOTE A SRECS includes all parts of an electrical control system whose failure may result in a reduction or loss of

functional safety and this can comprise both electrical power circuits and control circuits.

3.2.5

subsystem

entity of the top-level architectural design of the SRECS where a failure of any subsystem will

result in a failure of a safety-related control function

NOTE 1 A complete subsystem can be made up from a number of identifiable and separate subsystem elements,

which when put together implement the function blocks allocated to the subsystem.

NOTE 2 This definition is a limitation of the general definition of IEC 61508-4: `set of elements which interact

according to a design, where an element of a system can be another system, called a subsystem, which may

include hardware, software and human interaction.

NOTE 3 This differs from common language where “subsystem” may mean any sub-divided part of an entity, the

term “subsystem” is used in this standard within a strongly defined hierarchy of terminology: “subsystem” is the first

level subdivision of a system. The parts resulting from further subdivision of a subsystem are called “subsystem

elements”.

3.2.6

subsystem element

part of a subsystem, comprising a single component or any group of components

62061 © IEC:2005 – 15 –

3.2.7

low complexity component

component in which

– the failure modes are well-defined; and

– the behaviour under fault conditions can be completely defined

[IEC 61508-4, 3.4.4 modified]

NOTE 1 Behaviour of the low complexity component under fault conditions may be determined by analytical

and/or test methods.

NOTE 2 A subsystem or subsystem element comprising one or more limit switches, operating, possibly via

interposing electro-mechanical relays, one or more contactors to de-energise an electric motor is an example of a

low complexity component.

3.2.8

complex component

component in which

– the failure modes are not well-defined; or

– the behaviour under fault conditions cannot be completely defined

3.2.9

functional safety

part of the safety of the machine and the machine control system which depends on the

correct functioning of the SRECS, other technology safety-related systems and external risk

reduction facilities

[IEC 61508-4, 3.1.9 modified]

NOTE 1 This standard only considers the functional safety that depends on the correct functioning of the SRECS

in machinery applications.

NOTE 2 ISO/IEC Guide 51 defines safety as freedom from unacceptable risk.

3.2.10

hazard (from machinery)

potential source of physical injury or damage to health

[ISO 12100-1: 2003, 3.6 modified]

NOTE The term hazard can be qualified in order to define its origin or the nature of the expected harm (e.g.

electric shock hazard, crushing hazard, cutting hazard, toxic hazard, fire hazard).

3.2.11

hazardous situation

circumstance in which a person is exposed to a hazard(s)

[ISO 12100-1:2003, 3.9 modified]

3.2.12

protective measure

measure intended to achieve risk reduction

[ISO 12100-1:2003, 3.18 modified]

– 16 – 62061 © IEC:2005

3.2.13

risk

combination of the probability of occurrence of harm and the severity of that harm

ISO 12100-1:2003, 3.11]

3.2.14

control function

function that evaluates input information or signals and produces output information or

activities

3.2.15

safety function

function of a machine whose failure can result in an immediate increase of the risk(s)

[ISO 12100-1:2003, 3.28]

NOTE This definition differs from the definitions in IEC 61508-4 and ISO 13849-1.

3.2.16

Safety-Related Control Function

SRCF

control function implemented by a SRECS with a specified integrity level that is intended to

maintain the safe condition of the machine or prevent an immediate increase of the risk(s)

3.2.17

SRECS diagnostic function

function intended to detect faults in the SRECS and produce a specified output information or

activity when a fault is detected

NOTE This function is intended to detect faults that could lead to a dangerous failure of a SRCF and initiate a

specified fault reaction function.

3.2.18

SRECS fault reaction function

function that is initiated when a fault within a SRECS is detected by the SRECS diagnostic

function

3.2.19

safety integrity

probability of a SRECS or its subsystem satisfactorily performing the required safety-related

control functions under all stated conditions

[IEC 61508-4, 3.5.2 modified]

NOTE 1 The higher the level of safety integrity of the item, the lower the probability that the item will fail to carry

out the required safety-related control function.

NOTE 2 Safety integrity comprises hardware safety integrity (see 3.2.20) and systematic safety integrity (see

3.2.22).

3.2.20

hardware safety integrity

part of the safety integrity of a SRECS or its subsystems comprising requirements for both the

probability of dangerous random hardware failures and architectural constraints

[IEC 61508-4, 3.5.5 modified]

62061 © IEC:2005 – 17 –

3.2.21

software safety integrity

part of the systematic safety integrity of a SRECS or its subsystems related to the capability

of software in a programmable electronic system performing its safety-related control

functions under all stated conditions during a stated period of time

[IEC 61508-4, 3.5.3 modified ]

NOTE Software safety integrity cannot usually be quantified precisely.

3.2.22

systematic safety integrity

part of the safety integrity of a SRECS or its subsystems relating to its resistance to

systematic failures (see 3.2.45) in a dangerous mode.

[IEC 61508-4, 3.5.4 modified]

NOTE 1 Systematic safety integrity cannot usually be quantified precisely.

NOTE 2 Requirements for systematic safety integrity apply to both hardware and software aspects of a SRECS or

its subsystems.

3.2.23

Safety Integrity Level

SIL

discrete level (one out of a possible three) for specifying the safety integrity requirements of

the safety-related control functions to be allocated to the SRECS, where safety integrity level

three has the highest level of safety integrity and safety integrity level one has the lowest

[IEC 61508-4, 3.5.6 modified]

NOTE SIL 4 is not considered in this standard, as it is not relevant to the risk reduction requirements normally

associated with machinery. For requirements applicable to SIL 4, see IEC 61508-1 and IEC 61508-2.

3.2.24

SIL Claim Limit (for a subsystem)

SILCL

maximum SIL that can be claimed for a SRECS subsystem in relation to architectural

constraints and systematic safety integrity

3.2.25

demand

event that causes the SRECS to perform its SRCF

3.2.26

low demand mode

mode of operation in which the frequency of demands on a SRECS is no greater than one per

year and no greater than twice the proof-test frequency

NOTE Equipment that is only designed in accordance with requirements for the low demand mode of operation

described in IEC 61508-1 and IEC 61508-2 can be unsuitable for use as part of a SRECS in this standard. Low

demand mode of operation is not considered to be relevant for SRECS application

...

IEC 62061 ®

Edition 1.1 2012-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Safety of machinery – Functional safety of safety-related electrical, electronic

and programmable electronic control systems

Sécurité des machines – Sécurité fonctionnelle des systèmes de commande

électriques, électroniques et électroniques programmables relatifs à la sécurité

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 62061 ®

Edition 1.1 2012-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Safety of machinery – Functional safety of safety-related electrical, electronic

and programmable electronic control systems

Sécurité des machines – Sécurité fonctionnelle des systèmes de commande

électriques, électroniques et électroniques programmables relatifs à la sécurité

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 13.110; 25.040.99; 29.020 ISBN 978-2-8322-0487-0

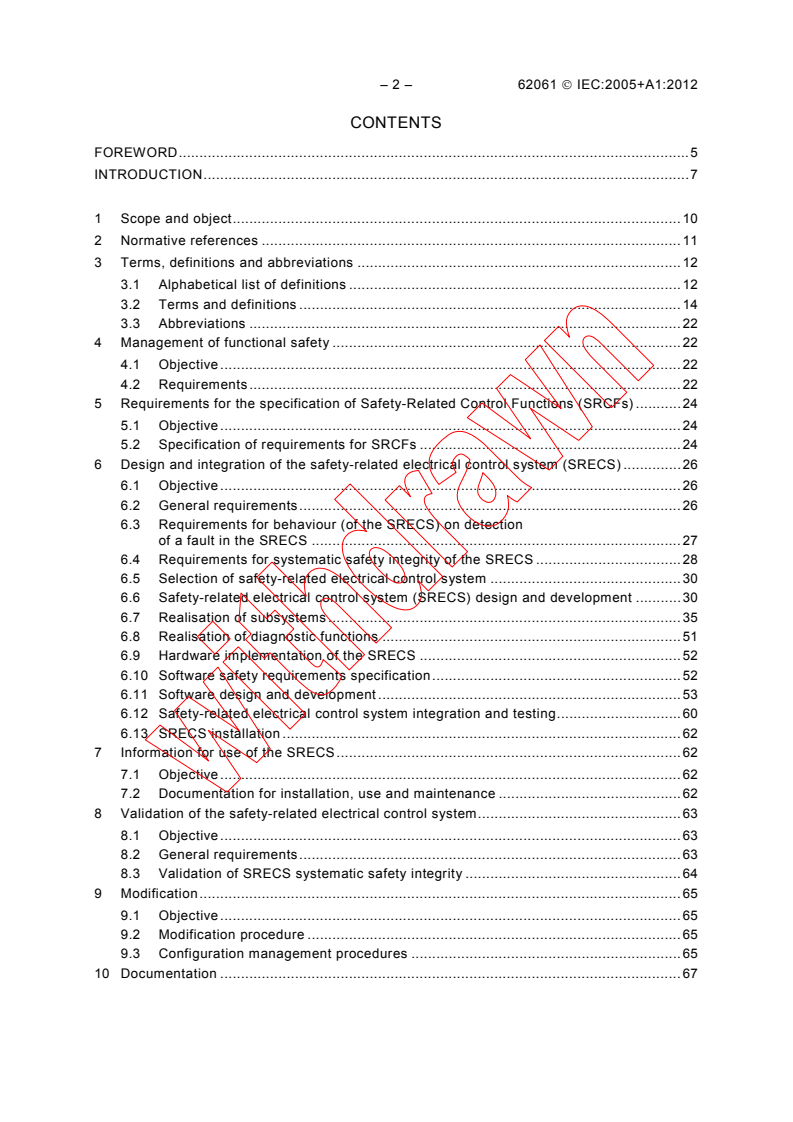

– 2 – 62061 IEC:2005+A1:2012

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope and object . 10

2 Normative references . 11

3 Terms, definitions and abbreviations . 12

3.1 Alphabetical list of definitions . 12

3.2 Terms and definitions . 14

3.3 Abbreviations . 22

4 Management of functional safety . 22

4.1 Objective . 22

4.2 Requirements . 22

5 Requirements for the specification of Safety-Related Control Functions (SRCFs) . 24

5.1 Objective . 24

5.2 Specification of requirements for SRCFs . 24

6 Design and integration of the safety-related electrical control system (SRECS) . 26

6.1 Objective . 26

6.2 General requirements . 26

6.3 Requirements for behaviour (of the SRECS) on detection

of a fault in the SRECS . 27

6.4 Requirements for systematic safety integrity of the SRECS . 28

6.5 Selection of safety-related electrical control system . 30

6.6 Safety-related electrical control system (SRECS) design and development . 30

6.7 Realisation of subsystems . 35

6.8 Realisation of diagnostic functions . 51

6.9 Hardware implementation of the SRECS . 52

6.10 Software safety requirements specification . 52

6.11 Software design and development . 53

6.12 Safety-related electrical control system integration and testing . 60

6.13 SRECS installation . 62

7 Information for use of the SRECS . 62

7.1 Objective . 62

7.2 Documentation for installation, use and maintenance . 62

8 Validation of the safety-related electrical control system . 63

8.1 Objective . 63

8.2 General requirements . 63

8.3 Validation of SRECS systematic safety integrity . 64

9 Modification . 65

9.1 Objective . 65

9.2 Modification procedure . 65

9.3 Configuration management procedures . 65

10 Documentation . 67

62061 IEC:2005+A1:2012 – 3 –

Annex A (informative) SIL assignment . 69

Annex B (informative) Example of safety-related electrical control system (SRECS)

design using concepts and requirements of Clauses 5 and 6 . 77

Annex C (informative) Guide to embedded software design and development . 84

Annex D (informative) Failure modes of electrical/electronic components . 92

Annex E (informative) Electromagnetic (EM) phenomenon and increased immunity

levels for SRECS intended for use in an industrial environment according to

IEC 61000-6-2 . 97

Annex F (informative) Methodology for the estimation of susceptibility to common

cause failures (CCF) . 99

Figure 1 – Relationship of IEC 62061 to other relevant standards . 8

Figure 2 – Workflow of the SRECS design and development process . 32

Figure 3 – Allocation of safety requirements of the function blocks to subsystems

(see 6.6.2.1.1) . 33

Figure 4 – Workflow for subsystem design and development (see box 6B of Figure 2) . 38

Figure 5 – Decomposition of a function block into redundant function block elements

and their associated subsystem elements . 39

Figure 6 – Subsystem A logical representation . 45

Figure 7 – Subsystem B logical representation . 46

Figure 8 – Subsystem C logical representation . 46

Figure 9 – Subsystem D logical representation . 48

Figure A.1 – Workflow of SIL assignment process . 70

Figure A.2 – Parameters used in risk estimation . 71

Figure A.3 – Example proforma for SIL assignment process . 78

Figure B.1 – Terminology used in functional decomposition . 77

Figure B.2 – Example machine . 78

Figure B.3 – Specification of requirements for an SRCF . 78

Figure B.4 – Decomposition to a structure of function blocks . 79

Figure B.5 – Initial concept of an architecture for a SRECS . 80

Figure B.6 – SRECS architecture with diagnostic functions embedded within each

subsystem (SS1 to SS4) . 81

Figure B.7 – SRECS architecture with diagnostic functions embedded within

subsystem SS3 . 82

Figure B.8 – Estimation of PFH for a SRECS. 83

D

Table 1 – Recommended application of IEC 62061 and ISO 13849-1(under revision) . 9

Table 2 – Overview and objectives of IEC 62061 . 11

Table 3 – Safety integrity levels: target failure values for SRCFs . 26

Table 4 – Characteristics of subsystems 1 and 2 used in this example . 35

Table 5 – Architectural constraints on subsystems: maximum SIL that can be claimed

for a SRCF using this subsystem . 41

Table 6 – Architectural constraints: SILCL relating to categories . 41

Table 7 – Probability of dangerous failure . 44

Table 8 – Information and documentation of a SRECS . 68

– 4 – 62061 IEC:2005+A1:2012

Table A.1 – Severity (Se) classification . 72

Table A.2– Frequency and duration of exposure (Fr) classification . 72

Table A.3– Probability (Pr) classification . 73

Table A.4– Probability of avoiding or limiting harm (Av) classification . 74

Table A.5– Parameters used to determine class of probability of harm (Cl) . 74

Table A.6 – SIL assignment matrix . 75

Table D.1 – Examples of the failure mode ratios for electrical/electronic components . 92

Table E.1 – EM phenomenon and increased immunity levels for SRECS . 97

Table E.2 – Selected frequencies for RF field tests . 98

Table E.3 – Selected frequencies for conducted RF tests . 98

Table F.1 – Criteria for estimation of CCF . 99

Table F.2 – Estimation of CCF factor (β) . 100

62061 IEC:2005+A1:2012 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SAFETY OF MACHINERY –

FUNCTIONAL SAFETY OF SAFETY-RELATED ELECTRICAL,

ELECTRONIC AND PROGRAMMABLE ELECTRONIC

CONTROL SYSTEMS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of IEC 62061 consists of the first edition (2005) [documents

44/460/FDIS and 44/470/RVD], its amendment 1 (2012) [documents 44/655/CDV and

44/663/RVC] and its corrigenda of July 2005 and April 2008. It bears the edition

number 1.1.

The technical content is therefore identical to the base edition and its amendment and

has been prepared for user convenience. A vertical line in the margin shows where the

base publication has been modified by amendment 1. Additions and deletions are

displayed in red, with deletions being struck through.

– 6 – 62061 © IEC:2005+A1:2012

International Standard IEC 62061 has been prepared by IEC technical committee 44: Safety

of machinery – Electrotechnical aspects.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of the base publication and its amendments will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the

publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of August 2015 have been included in this copy.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

62061 IEC:2005+A1:2012 – 7 –

INTRODUCTION

As a result of automation, demand for increased production and reduced operator physical

effort, Safety-Related Electrical Control Systems (referred to as SRECS) of machines play an

increasing role in the achievement of overall machine safety. Furthermore, the SRECS

themselves increasingly employ complex electronic technology.

Previously, in the absence of standards, there has been a reluctance to accept SRECS in

safety-related functions for significant machine hazards because of uncertainty regarding the

performance of such technology.

This International Standard is intended for use by machinery designers, control system

manufacturers and integrators, and others involved in the specification, design and validation

of a SRECS. It sets out an approach and provides requirements to achieve the necessary

performance.

This standard is machine sector specific within the framework of IEC 61508. It is intended to

facilitate the specification of the performance of safety-related electrical control systems in

relation to the significant hazards (see 3.8 of ISO 12100-1) of machines.

This standard provides a machine sector specific framework for functional safety of a SRECS

of machines. It only covers those aspects of the safety lifecycle that are related to safety

requirements allocation through to safety validation. Requirements are provided for

information for safe use of SRECS of machines that can also be relevant to later phases of

the life of a SRECS.

There are many situations on machines where SRECS are employed as part of safety

measures that have been provided to achieve risk reduction. A typical case is the use of an

interlocking guard that, when it is opened to allow access to the danger zone, signals the

electrical control system to stop hazardous machine operation. Also in automation, the

electrical control system that is used to achieve correct operation of the machine process

often contributes to safety by mitigating risks associated with hazards arising directly from

control system failures. This standard gives a methodology and requirements to

• assign the required safety integrity level for each safety-related control function to be

implemented by SRECS;

• enable the design of the SRECS appropriate to the assigned safety-related control

function(s);

• integrate safety-related subsystems designed in accordance with ISO 13849 ;

• validate the SRECS.

This standard is intended to be used within the framework of systematic risk reduction

described in ISO 12100-1 and in conjunction with risk assessment according to the principles

described in ISO 14121 (EN 1050). A suggested methodology for safety integrity level (SIL)

assignment is given in informative Annex A.

Measures are given to co-ordinate the performance of the SRECS with the intended risk

reduction taking into account the probabilities and consequences of random or systematic

faults within the electrical control system.

Figure 1 shows the relationship of this standard to other relevant standards.

Table 1 gives recommendations on the recommended application of this standard and the

revision of ISO 13849-1.

– 8 – 62061 IEC:2005+A1:2012

Design and risk asseessment of the machine

ISO 12100, Safety of machinery – Basic concept, general principles

for design

ISO 14121, Safety of machinery – Principles for risk assessement

Design of safety-related electrical, electronic and programmable elecronic control systems

(SRECS) for machinery

Methodology using:

Safety-related control functions

System-based approach

- Quantitative index of safety:

- Index of safety:

Safety integrity level (SIL)

Category/performance level

- SIL assignment methodology for

- Category assigned by

SRECS of machinery

qualitative risk graphing

- Architecture oriented

- Architecture oriented

- Requirements for

avoidance/control of systematic

failures

Design objective for the

SRECS

Relevant standards

Electrical safety aspects of machinery

Design of low complexity

IEC 60204-1, Safety of machinery -

subsystems to categories

Electrical equipment of machinery -

Part 1: General requirements

ISO 13849-1 and 2 Safety of

machinery – Safety related

parts of control systems

(SRPCS)

- Part 1: General princples

for design and Part 2:

Validation

Design of complex subsystems

to SILs

Non-electrical SRPCS

IEC 61508, Functional safety of

(mechanical,

electrical, electronic and

pneumatic, etc.)

programmable electronic safety -

related systems

Electrical SRPCS

IEC 62061

Safety of machinery -

Functional safety of

safety-related electrical,

electronic and programmable

Key:

electronic control systems

Electrical safety aspects

Functional safety aspects

Figure 1 – Relationship of IEC 62061 to other relevant standards

Information on the recommended application of IEC 62061 and ISO 13849-1

(under revision)

62061 IEC:2005+A1:2012 – 9 –

IEC 62061 and ISO 13849-1 (under revision) specify requirements for the design and

implementation of safety-related control systems of machinery. The use of either of these

standards, in accordance with their scopes, can be presumed to fulfil the relevant essential

safety requirements. Table 1 summarises the scopes of IEC 62061 and ISO 13849-1(under

revision). IEC/TR 62061-1 provides guidance on the application of IEC 62061 and ISO 13849-

1 in the design of safety-related control systems for machinery.

NOTE ISO 13849-1 is currently under preparation by ISO TC 199 and CEN TC 114.

Table 1 – Recommended application of IEC 62061 and ISO 13849-1(under revision)

Technology implementing the safety- ISO IEC 62061

related control function(s) 13849-1 (under revision)

A Non electrical, e.g. hydraulics X Not covered

B Electromechanical, e.g. relays, or non Restricted to designated All architectures and up to SIL 3

complex electronics architectures

(see Note 1) and up to PL=e

C Complex electronics, e.g. programmable Restricted to designated All architectures and up to SIL 3

architectures (see Note 1) and up

to PL=d

D A combined with B Restricted to designated X see Note 3

architectures (see Note 1) and up

to PL=e

E C combined with B Restricted to designated All architectures and up to SIL 3

architectures (see Note 1) and up

to PL=d

F C combined with A, or C combined with X see Note 2 X see Note 3

A and B

“X” indicates that this item is dealt with by the standard shown in the column heading.

NOTE 1 Designated architectures are defined in Annex B of EN ISO 13849-1(rev.) to give a simplified approach for

quantification of performance level.

NOTE 2 For complex electronics: Use of designated architectures according to EN ISO 13849-1(rev.) up to PL=d or

any architecture according to IEC 62061.

NOTE 3 For non-electrical technology use parts according to EN ISO 13849-1(rev.) as subsystems.

– 10 – 62061 IEC:2005+A1:2012

SAFETY OF MACHINERY –

FUNCTIONAL SAFETY OF SAFETY-RELATED ELECTRICAL,

ELECTRONIC AND PROGRAMMABLE ELECTRONIC

CONTROL SYSTEMS

1 Scope

This International Standard specifies requirements and makes recommendations for the

design, integration and validation of safety-related electrical, electronic and programmable

electronic control systems (SRECS) for machines (see Notes 1 and 2). It is applicable to

control systems used, either singly or in combination, to carry out safety-related control

functions on machines that are not portable by hand while working, including a group of

machines working together in a co-ordinated manner.

NOTE 1 In this standard, the term “electrical control systems” is used to stand for ”Electrical, Electronic and

Programmable Electronic (E/E/PE) control systems” and “SRECS” is used to stand for “safety-related electrical,

electronic and programmable electronic control systems”.

NOTE 2 In this standard, it is presumed that the design of complex programmable electronic subsystems or

subsystem elements conforms to the relevant requirements of IEC 61508 and uses Route 1 (see

H

IEC 61508-2:2010, 7.4.4.2). It is considered that Route 2 (see IEC 61508-2:2010, 7.4.4.3) is not suitable for

H

general machinery. Therefore, this standard does not deal with Route 2 . This standard provides a methodology for

H

the use, rather than development, of such subsystems and subsystem elements as part of a SRECS.

This standard is an application standard and is not intended to limit or inhibit technological

advancement. It does not cover all the requirements (e.g. guarding, non-electrical interlocking

or non-electrical control) that are needed or required by other standards or regulations in

order to safeguard persons from hazards. Each type of machine has unique requirements to

be satisfied to provide adequate safety.

This standard:

– is concerned only with functional safety requirements intended to reduce the risk of injury

or damage to the health of persons in the immediate vicinity of the machine and those

directly involved in the use of the machine;

– is restricted to risks arising directly from the hazards of the machine itself or from a group

of machines working together in a co-ordinated manner;

NOTE 3 Requirements to mitigate risks arising from other hazards are provided in relevant sector standards.

For example, where a machine(s) is part of a process activity, the machine electrical control system functional

safety requirements should, in addition, satisfy other requirements (e.g. IEC 61511) insofar as safety of the

process is concerned.