EN 12331:2003+A2:2010

(Main + Amendment)Food processing machinery - Mincing machines - Safety and hygiene requirements

Food processing machinery - Mincing machines - Safety and hygiene requirements

1.1 This European Standard specifies requirements for the design and manufacture of mincing machines (see Figures 1 and 2) used in a stationary position.

The machines covered by this standard are used for size reduction of fresh or frozen meat, meat products and fish by cutting in a set of cutting tools.

Mincing machines for domestic uses are not included in this standard. Filling mincers are covered by

EN 12463 "Food processing machinery - Filling machines and auxiliary machines - Safety and hygiene requirements".

This standard applies only to machines that are manufactured after the date of issue of this standard.

Mincing machines in connection with using a hold to run foot switch are not covered by this standard.

This European Standard covers:

- mincing machines used in shops and preparation rooms;

- mincing machines used in kitchens where sausages are prepared;

- mincing machines used industrially;

- accessories.

The extent to which hazards are covered, is indicated in this European Standard. For other hazards which are not covered by this European Standard, machinery should comply with EN ISO 12100 where applicable.

This European Standard is not dealing with specific requirements for the control of mincing machines with foot switch.

1.2 This standard covers the following types:

- Mincing machine with tray, feed intake and pusher, diameter < 52 mm on feed intake (see Figure 5)

- Mincing machine with tray, feed intake, restrictor plate and pusher, diameter > 52 mm on feed intake

(see Figure 6)

- Mincing machine with feed intake hopper and cover, screw conveyor, with1) or without mixing screw in feed intake hopper (see Figure 7)

- Mincing machine with feed intake hopper, with or without cover, screw conveyor, with ) or without mixing screw in feed intake hopper, with loading device (continuously or discontinuously)

Mincing machines comprise a machine base, a worm casing with a worm, a feed intake tray or hopper, a screw conveyor (and som

Nahrungsmittelmaschinen - Wölfe - Sicherheits- und Hygieneanforderungen

1.1 Diese Europäische Norm legt Anforderungen an die Konstruktion und Herstellung von Wölfen (siehe Bilder 1 und 2), die stationär betrieben werden, fest.

Die von dieser Norm erfassten Maschinen werden für die Zerkleinerung von frischem oder gefrorenem Fleisch, Fleischprodukten und Fisch durch Zerschneiden in einem Schneidsatz verwendet.

Wölfe für den Hausgebrauch werden von dieser Norm nicht abgedeckt. Füllwölfe werden in prEN 12463 �Nah-rungsmittelmaschinen - Füllmaschinen und Vorsatzmaschinen - Sicherheits- und Hygieneanforderungen" behandelt.

Diese Norm gilt nur für Maschinen, die nach dem Ausgabedatum dieser Norm hergestellt werden.

Wölfe mit einem Fußschalter mit selbstständiger Rückstellung werden in dieser Norm nicht behandelt.

1.2 Diese Norm umfasst folgende Bauarten:

- Wolf mit Schale, Einfüllschacht und Stopfer, Durchmesser £ 52 mm am Einfüllschacht (siehe Bild 5),

- Wolf mit Schale, Einfüllschacht, Schutzplatte und Stopfer, Durchmesser > 52 mm am Einfüllschacht (siehe Bild 6),

- Wolf mit Einfülltrog und Deckel, Transportschnecke, mit ) oder ohne Mengwelle im Einfülltrog (siehe Bild 7),

- Wolf mit Einfülltrog, mit oder ohne Deckel, Transportschnecke, mit1) oder ohne Mengwelle im Einfülltrog, mit Beschickungseinrichtung (kontinuierlich oder diskontinuierlich).

Wölfe bestehen aus einem Maschinenständer, einem Schneckengehäuse mit Arbeitsschnecke, einer Einfüll-schale oder einem Einfülltrog, einer Transportschnecke (und manchmal einer zusätzlichen Mengwelle im

Machines pour les produits alimentaires - Hachoirs - Prescriptions relatives à la sécurité et à l'hygiène

1.1 La présente Norme européenne spécifie les prescriptions relatives à la conception et à la fabrication des hachoirs (voir Figures 1 et 2) utilisés en position fixe.

Les machines couvertes par la présente norme sont utilisées pour hacher de la viande fraîche ou congelée, des produits à base de viande et du poisson, la coupe étant effectuée dans un ensemble de coupe.

Les hachoirs à usage domestique ne sont pas couverts par la présente norme. Les poussoirs sont couverts par l’#EN 12463$ «Machines pour les produits alimentaires — Poussoirs et machines auxiliaires — Prescriptions relatives à la sécurité et à l’hygiène».

La présente norme ne s’applique qu’aux machines fabriquées après sa date de publication.

Les hachoirs utilisant un interrupteur à pied à action maintenue ne sont pas couverts par la présente norme.

#La présente Norme européenne couvre :

- les hachoirs utilisés dans les magasins et les laboratoires ;

- les hachoirs utilisés dans les cuisines pour la préparation des saucissons ;

- les hachoirs industriels ;

- les accessoires.

L'étendue des phénomènes dangereux couverts est indiquée dans la présente Norme européenne. Pour les autres phénomènes dangereux qui ne sont pas couverts par la présente Norme européenne, il convient que les machines soient être conformes à l'EN ISO 12100 lorsqu'elle s'applique.$

1.2 La présente norme couvre les types de machines suivants :

- hachoir avec plateau, goulotte d'alimentation et poussoir, diamètre de la goulotte d'alimentation 52 mm (voir Figure 5) ;

- hachoir avec plateau, goulotte d'alimentation, plaque protectrice et poussoir, diamètre de la goulotte d'alimentation > 52 mm (voir Figure 6) ;

- hachoir avec trémie d'alimentation et couvercle, hélice transporteuse, avec ) ou sans vis mélangeuse dans la trémie d'alimentation (voir Figure 7) ; (...)

Stroji za predelavo hrane - Stroji za mletje mesa - Varnostne in higienske zahteve (vključno z dopolnilom A1)

Ta evropski standard določa zahteve za načrtovanje in izdelavo strojev za mletje mesa, ki se uporabljajo na stalnem mestu. Stroji, ki jih zajema ta standard, se uporabljajo za zmanjševanje velikosti svežega ali zamrznjenega mesa, mesnih izdelkov in rib z rezanjem z garnituro rezalnega orodja. Ta standard ne vključuje strojev za mletje mesa za domačo uporabo. Polnilne stroje za mletje mesa zajema EN 12463$ »Stroji za predelavo hrane – Polnilni stroji in pomožni stroji – Zahteve za varnost in higieno«. Ta standard velja samo za stroje, ki so bili izdelani po datumu izdaje tega standarda. Ta standard ne zajema strojev za mletje mesa v povezavi z uporabo pridržitvenega nožnega stikala. Ta evropski standard zajema: - stroje za mletje mesa, ki se uporabljajo v trgovinah in pripravljalnicah; - stroje za mletje mesa, ki se uporabljajo v kuhinjah, v katerih se pripravljajo klobase in salame; - stroje za mletje mesa za industrijsko uporabo; - pomožne pripomočke. Ta evropski standard navaja obseg kritja nevarnosti. Za druge nevarnosti, ki jih ta evropski standard ne zajema, morajo stroji ustrezati EN ISO 12100, kjer je ustrezno. Ta evropski standard ne obravnava posebnih zahtev za krmiljenje strojev za mletje mesa z nožnim stikalom.

General Information

- Status

- Withdrawn

- Publication Date

- 22-Jun-2010

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 153 - Food processing machinery - Safety and hygiene specifications

- Drafting Committee

- CEN/TC 153/WG 2 - Meat processing machinery

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 09-Sep-2015

- Completion Date

- 09-Feb-2026

- Directive

- 98/37/EC - Machinery

Relations

- Merged From

EN 12331:2003 - Food processing machinery - Mincing machines - Safety and hygiene requirements - Effective Date

- 19-Jan-2023

- Effective Date

- 18-Jan-2023

- Replaced By

EN 12331:2015 - Food processing machinery - Mincing machines - Safety and hygiene requirements - Effective Date

- 28-Dec-2011

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

EN 12331:2003+A2:2010 is a standard published by the European Committee for Standardization (CEN). Its full title is "Food processing machinery - Mincing machines - Safety and hygiene requirements". This standard covers: 1.1 This European Standard specifies requirements for the design and manufacture of mincing machines (see Figures 1 and 2) used in a stationary position. The machines covered by this standard are used for size reduction of fresh or frozen meat, meat products and fish by cutting in a set of cutting tools. Mincing machines for domestic uses are not included in this standard. Filling mincers are covered by EN 12463 "Food processing machinery - Filling machines and auxiliary machines - Safety and hygiene requirements". This standard applies only to machines that are manufactured after the date of issue of this standard. Mincing machines in connection with using a hold to run foot switch are not covered by this standard. This European Standard covers: - mincing machines used in shops and preparation rooms; - mincing machines used in kitchens where sausages are prepared; - mincing machines used industrially; - accessories. The extent to which hazards are covered, is indicated in this European Standard. For other hazards which are not covered by this European Standard, machinery should comply with EN ISO 12100 where applicable. This European Standard is not dealing with specific requirements for the control of mincing machines with foot switch. 1.2 This standard covers the following types: - Mincing machine with tray, feed intake and pusher, diameter < 52 mm on feed intake (see Figure 5) - Mincing machine with tray, feed intake, restrictor plate and pusher, diameter > 52 mm on feed intake (see Figure 6) - Mincing machine with feed intake hopper and cover, screw conveyor, with1) or without mixing screw in feed intake hopper (see Figure 7) - Mincing machine with feed intake hopper, with or without cover, screw conveyor, with ) or without mixing screw in feed intake hopper, with loading device (continuously or discontinuously) Mincing machines comprise a machine base, a worm casing with a worm, a feed intake tray or hopper, a screw conveyor (and som

1.1 This European Standard specifies requirements for the design and manufacture of mincing machines (see Figures 1 and 2) used in a stationary position. The machines covered by this standard are used for size reduction of fresh or frozen meat, meat products and fish by cutting in a set of cutting tools. Mincing machines for domestic uses are not included in this standard. Filling mincers are covered by EN 12463 "Food processing machinery - Filling machines and auxiliary machines - Safety and hygiene requirements". This standard applies only to machines that are manufactured after the date of issue of this standard. Mincing machines in connection with using a hold to run foot switch are not covered by this standard. This European Standard covers: - mincing machines used in shops and preparation rooms; - mincing machines used in kitchens where sausages are prepared; - mincing machines used industrially; - accessories. The extent to which hazards are covered, is indicated in this European Standard. For other hazards which are not covered by this European Standard, machinery should comply with EN ISO 12100 where applicable. This European Standard is not dealing with specific requirements for the control of mincing machines with foot switch. 1.2 This standard covers the following types: - Mincing machine with tray, feed intake and pusher, diameter < 52 mm on feed intake (see Figure 5) - Mincing machine with tray, feed intake, restrictor plate and pusher, diameter > 52 mm on feed intake (see Figure 6) - Mincing machine with feed intake hopper and cover, screw conveyor, with1) or without mixing screw in feed intake hopper (see Figure 7) - Mincing machine with feed intake hopper, with or without cover, screw conveyor, with ) or without mixing screw in feed intake hopper, with loading device (continuously or discontinuously) Mincing machines comprise a machine base, a worm casing with a worm, a feed intake tray or hopper, a screw conveyor (and som

EN 12331:2003+A2:2010 is classified under the following ICS (International Classification for Standards) categories: 67.260 - Plants and equipment for the food industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12331:2003+A2:2010 has the following relationships with other standards: It is inter standard links to EN 12331:2003, EN 12331:2003/A1:2005, EN 12331:2015, EN 60529:1991, EN 61496-1:2004, EN ISO 21920-2:2022, EN 1088:1995, EN ISO 12100-2:2003, EN 1005-2:2003+A1:2008, EN ISO 11688-1:2009, EN ISO 4871:2009, EN 1005-1:2001+A1:2008, EN 953:1997, EN 614-1:2006+A1:2009, EN ISO 13854:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12331:2003+A2:2010 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12331:2003+A2:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Nahrungsmittelmaschinen - Wölfe - Sicherheits- und HygieneanforderungenMachines pour les produits alimentaires - Hachoirs - Prescriptions relatives à la sécurité et à l'hygièneFood processing machinery - Mincing machines - Safety and hygiene requirements67.260Tovarne in oprema za živilsko industrijoPlants and equipment for the food industryICS:Ta slovenski standard je istoveten z:EN 12331:2003+A2:2010SIST EN 12331:2004+A2:2010en,fr,de01-oktober-2010SIST EN 12331:2004+A2:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12331:2003+A2

June 2010 ICS 67.260 Supersedes EN 12331:2003English Version

Food processing machinery - Mincing machines - Safety and hygiene requirements

Machines pour les produits alimentaires - Hachoirs - Prescriptions relatives à la sécurité et à l'hygiène

Nahrungsmittelmaschinen - Wölfe - Sicherheits- und Hygieneanforderungen This European Standard was approved by CEN on 1 September 2003 and includes Amendment 1 approved by CEN on 12 December 2004and Amendment 2 approved by CEN on 20 May 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12331:2003+A2:2010: ESIST EN 12331:2004+A2:2010

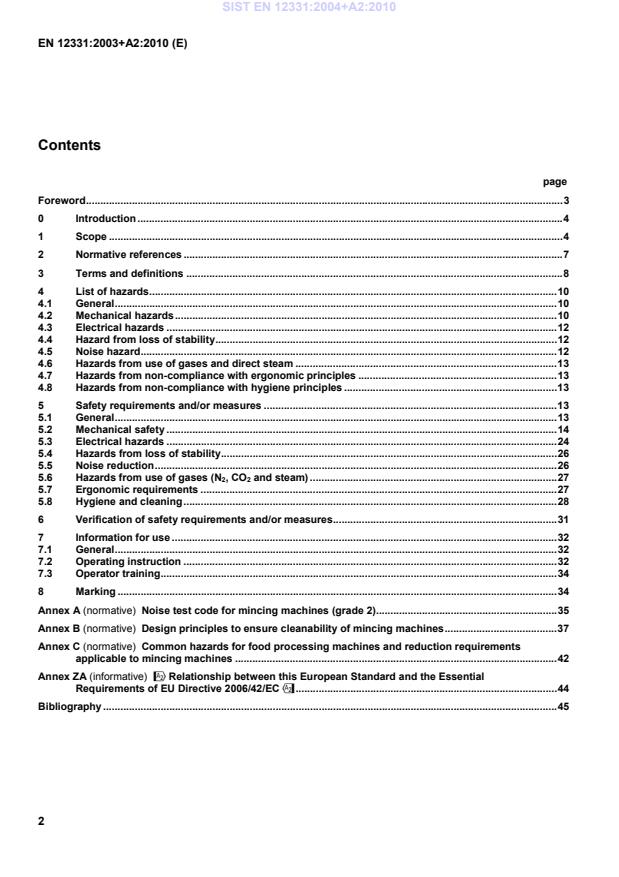

Noise test code for mincing machines (grade 2) . 35Annex B (normative)

Design principles to ensure cleanability of mincing machines . 37Annex C (normative)

Common hazards for food processing machines and reduction requirements applicable to mincing machines . 42Annex ZA (informative)

#Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC$ . 44Bibliography . 45

(see Figures 1 and 2) used in a stationary position. The machines covered by this standard are used for size reduction of fresh or frozen meat, meat products and fish by cutting in a set of cutting tools. Mincing machines for domestic uses are not included in this standard. Filling mincers are covered by

#EN 12463$ "Food processing machinery - Filling machines and auxiliary machines - Safety and hygiene requirements". This standard applies only to machines that are manufactured after the date of issue of this standard. Mincing machines in connection with using a hold to run foot switch are not covered by this standard. #This European Standard covers: mincing machines used in shops and preparation rooms; mincing machines used in kitchens where sausages are prepared; mincing machines used industrially; accessories. The extent to which hazards are covered, is indicated in this European Standard. For other hazards which are not covered by this European Standard, machinery should comply with EN ISO 12100 where applicable. This European Standard is not dealing with specific requirements for the control of mincing machines with foot switch.$ 1.2 This standard covers the following types: Mincing machine with tray, feed intake and pusher, diameter < 52 mm on feed intake (see Figure 5) Mincing machine with tray, feed intake, restrictor plate and pusher, diameter > 52 mm on feed intake (see Figure 6) Mincing machine with feed intake hopper and cover, screw conveyor, with1) or without mixing screw in feed intake hopper (see Figure 7) SIST EN 12331:2004+A2:2010

Key 1 2 3-4 5 LOCK NUT HOLE PLATE BLADE WORM WORM CASING

6 7 8 9 10 FEED INTAKE PUSHER RESTRICTOR PLATE TRAY ON/OFF SWITCH PROTECTIVE HOOD 11121314 FEED INTAKE HOPPER SCREW CONVEYOR COVER ON/OFF SWITCH PROTECTIVE HOOD 15161718 LOCK NUT PROTECTIVE HOOD WORM MACHINE RACK Figure 1 — Arrangement of a mincing machine with tray and restrictor plate Figure 2 — Arrangement of a mincing machine with feed intake hopper, cover and screw conveyor Mincing machines may be equipped e.g. with an extraction claw, an ejector or extractor, a protective hood over the discharge outlet, a cover over the inlet opening of the feed intake hopper,

a transport carriage for the lock nut, the set of cutting tools, the worm and the screw conveyor, a lifting device for the lock nut, the set of cutting tools, the worm and the screw conveyor, a loading device.

1) #In this case, EN 13570 should be taken into consideration.$ SIST EN 12331:2004+A2:2010

2 Normative references #The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.$ #EN 349, Safety of machinery — Minimum gaps to avoid crushing of parts of the human body EN 614-1, Safety of machinery — Ergonomic design principles — Part 1: Terminology and general principles EN 953:1997, Safety of machinery — Guards — General requirements for the design and construction of fixed and movable guards EN 1005-1, Safety of machinery — Human physical performance — Part 1: Terms and definitions EN 1005-2, Safety of machinery — Human physical performance — Part 2: Manual handling of machinery and component parts of machinery EN 1005-3, Safety of machinery — Human physical performance — Part 3: Recommended force limits for machinery operation EN 1088:1995, Safety of machinery — Interlocking devices associated with guards — Principles for design and selection EN 1672-2:2005, Food processing machinery — Basic concepts — Part 2: Hygiene requirements EN 60204-1:2006, Safety of machinery — Electrical equipment of machines — Part 1: General requirements

(IEC 60204-1:2005, modified) EN 60529, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989) EN 61496-1:2004, Safety of machinery — Electro-sensitive protective equipment — Part 1: General requirements and tests (IEC 61496-1:2004, modified) EN ISO 4287, Geometrical product specifications (GPS) — Surface texture: Profile method — Terms, definitions and surface texture parameters (ISO 4287:1997) EN ISO 4871, Acoustics — Declaration and verification of noise emission values of machinery and equipment

(ISO 4871:1996) EN ISO 11204:1995, Acoustics — Noise emitted by machinery and equipment — Measurement of emission sound pressure levels at a work station and at other specified positions — Method requiring environmental corrections (ISO 11204:1995) EN ISO 11688-1, Acoustics — Recommended practice for the design of low-noise machinery and equipment — Part 1: Planning (ISO/TR 11688-1:1995) EN ISO 12100-1:2003, Safety of machinery — Basic concepts, general principles for design — Part 1: Basic terminology, methodology (ISO 12100-1:2003) EN ISO 12100-2:2003, Safety of machinery — Basic concepts, general principles for design — Part 2: Technical principles (ISO 12100-2:2003) EN ISO 13849-1:2008, Safety of machinery — Safety-related parts of control systems — Part 1: General principles for design (ISO 13849-1:2006) SIST EN 12331:2004+A2:2010

Zone 1

Rotating screw conveyor at the end of the feed intake (see Figure 3). Hazards of entanglement, shearing or severing of fingers or hand. 4.2.2 Mincing machines with feed intake hopper and screw conveyor/mixing screw Zone 2 Rotating screw conveyor or mixing screw in the feed intake hopper (see Figure 4). Hazards of entanglement, shearing or severing of fingers, hand or forearm. 4.2.3 Discharge outlet on mincing machines Zone 3 Rotating blade behind the hole plate at the discharge outlet (see Figure 4). SIST EN 12331:2004+A2:2010

Key 1 2 3 ZONE 1 ZONE 2 ZONE 3 4 5 6 ZONE 4 ZONE 5 ZONE 6

9 10 ZONE

7 ZONE

8 ZONE

9 ZONE 10 Figure 3 — Mincing machine with feed intake - Danger zones Figure 4 — Mincing machine with feed intake hopper - Danger zones 4.2.4 Installation and removal of worm and set of cutting tools Zone 4 Worm casing with worm and set of cutting tools at discharge outlet (see Figures 3 and 4). Hazard of crushing to hands and feet during installation and removal. 4.2.5 Drive mechanism Zone 5 Drive of worm, screw conveyor and mixing screw (see Figure 4). Hazards of crushing, shearing or entanglement to fingers or hand. 4.2.6 Machine components e.g. cover over hopper edge Zone 6 Unintentional shutting and intentional closing of the cover (see Figure 4). Hazards of crushing to fingers or hand. SIST EN 12331:2004+A2:2010

Physical causes Foreign objects originating from raw materials, machines beings or other sources Hazard of damage to human health of the consumer trough harm 5 Safety requirements and/or measures 5.1 General Machinery shall comply with the safety requirements and/or protective measures of this clause. In addition, the machine shall be designed according to the principles of #EN ISO 12100$ for hazards relevant but not significant, which are not dealt with by this document (e.g. sharp edges). #For hazards which are to be reduced by the application of the type B-standards such as EN 614-1, EN 953,

EN 1005-3, EN 1088, EN 1672-2, EN 60204-1, EN 60529, EN ISO 12100, EN ISO 13849-1 and

EN ISO 13857, the manufacturer shall carry out a risk assessment to establish the requirements of the type

B-standard. This specific risk assessment shall be part of the general risk assessment of the machine.$ Where the means of reducing the risk is by the arrangement or positioning of the installed machine, the manufacturer shall include in the Information for use a reference to the reduction means to be provided, and to any limiting value of the requirement, and, if appropriate, to the means of verification. Where the means of reducing the risk is by a safe system of working the machinery, the manufacturer shall include in the Information of installation, details of the system and of the elements of training required by the operating personnel. SIST EN 12331:2004+A2:2010

Mechanical safety 5.2.1 General The machines shall be designed and constructed in accordance with the conditions mentioned below. The interlocking systems of guards shall comply with 4.2.1 of EN 1088:1995 and the safety-related #parts$ of the control system shall comply with #EN ISO 13849-1$. In addition interlocking systems shall be designed to satisfy all of the following features: to fulfil hygienic requirements, to protect against mechanical damages, to protect against the effects of cleaning and disinfecting materials, to protect against the effects of cleaning fluids (water), to protect against tampering by simple methods be contained in the machine casing and comply with 5.7 of EN 1088:1995. In the instruction handbook, the manufacturer shall indicate the daily verification of the interlocking device. #Fixing systems of fixed guards shall remain attached to these guards or to the machine when the guards are removed.$ 5.2.2 Measures at mincing machines with feed intake and worm Zone 1 Access to the worm in the feed intake shall be protected. This may be achieved e.g. by the following measures (see Figures 5a, 5b, 5c): On the feed intake, the distance L between the upper feed intake edge and the worm shall be

L ≥ 100 mm on mincing machines with intake diameter D ≤ 46 mm L ≥ 120 mm on mincing machines with intake diameter 46 < D ≤ 52 mm (see Figures 5a, 5b, 5c).

5a

Fixed tray

5b

Removable tray

5c

Removable tray Figure 5 — Feed intake without restrictor plate - Safety dimensions SIST EN 12331:2004+A2:2010

EN ISO 13849-1:2008.$ A pusher shall be supplied with the machine (see Figure 1). On mincing machines with a feed intake with diameter > 52 mm, a restrictor plate shall be provided. #Mounting of a fixed restrictor plate shall be in accordance with 3.25.1 of EN ISO 12100-1:2003 (see also 3.2 and 6.4.2 of

EN 953:1997).$ If the restrictor plate is removable, it shall be provided with an interlocking device. Openings in the restrictor plate shall have a diameter ≤ 52 mm. #The interlocking system of the removable restrictor plate shall comply with 5.2.1 and the safety-related parts of the control system shall present at least a Performance Level “d” defined with a MTTFd “high” in accordance with EN ISO 13849-1:2008.$ The dimensions and arrangement of the restrictor plate shall be in accordance with Figures 6a and 6b. When the mincing machine is running empty, the worm shall come to a standstill within 2 s after removal of, in one case the removable tray, or in the other case, the removable restrictor plate. The distance H (tray to lower edge of restrictor plate) shall be ≤ 40 mm based on an assumed metacarpus diameter of 40 mm.

The projection Ü (outer edge of restrictor plate to feed intake edge) shall be ≥ 40 mm (see Figure 6a). The safety distance L1 results from the dimension L = 230 mm (length of hand to wrist) + dimension x. Dimension x results from dimensions Ü (projection), distance H1 (tray to lower edge of restrictor plate) and F ∅ (feed intake diameter) with an assumed forearm and wrist diameter of 40 mm.

Distance H1 (tray to lower edge of restrictor plate) shall be ≤ 120 mm, and projection Ü (outer edge of restrictor plate to feed intake edge) shall be ≥ 40 mm (see Figure 6b). SIST EN 12331:2004+A2:2010

Key

1 2 MIDDLE HAND FINGER 34 FORE ARM HAND H

≤

40 mm

H

=

40 mm L

≥ 120 mm

H1

≤

120 mm Ü

≥

40 mm

L

≥ 230 mm D

≤

52 mm

D

≤

52 mm F

≤ 85 mm

Ü

≥

40 mm

F

≤ 200 mm Figure 6a — Feed intake with restrictor plate - Safety dimensions Figure 6b — Feed intake with restrictor plate - Safety dimensions

5.2.3 Measures at mincing machines with feed intake hopper and screw conveyor 5.2.3.1 General Zone 2 Access to the danger zones at the screw conveyor in the feed intake hopper shall be prevented or made safe. This may be achieved by any of the following measures: Access is prevented by the design (e.g. closed feed intake hoppers) including a closed loading device for products (e.g. feed screw, pipeline with pump) (see 5.2.3.2) or the use of guards (e.g. a cover), see EN 953 (see 5.2.3.3) or # the use of electro-sensitive protective devices (e.g. light barrier), see EN ISO 12100-2:2003 (see 5.2.3.4) or$ SIST EN 12331:2004+A2:2010

the use of adequate safety distances, design and additional measures (see 5.2.3.4.2). 5.2.3.2 Design with closed feed intake hopper The feed intake hopper and the loading device shall be designed to be completely closed (Connection of machines) or the openings shall comply with #EN ISO 13857:2008, Table 4$. The disconnection point shall be protected by an interlocking system. #The interlocking system of the disconnection point shall comply with 5.2.1 and the safety-related parts of the control system shall present at least a Performance Level “c” defined in accordance with

EN ISO 13849-1:2008.$ The manufacturer shall indicate in the instruction handbook that the cover of the hopper opening must not be walked on. 5.2.3.3 Design with cover over feed intake hopper At the feed intake hopper, there shall be a cover. The cover shall be interlocked. If the mincing machine is running empty, the screw conveyor has to come to a standstill within 4 s, after raising the front edge of the cover 50 mm (opening distance). #The interlocking device of the movable cover shall comply with 5.2.1 and the safety-related parts of the control system shall present at least a Performance Level “c” defined in accordance with

EN ISO 13849-1:2008.$ Openings in the cover shall be designed in accordance with #EN ISO 13857:2008, Table 4$.

Key 1 INTERLOCKED COVER, OPENING DISTANCE

Figure 7 — Mincing machine with feed intake hopper and cover -Safety dimensions

Key 1 2 MECHANICAL TRIP BAR INTERLOCKED STEP

H1

≥

1600 mm H2

≥

1100 mm H3

≥

500 mm with intermediate step H1 + D1 + E

≥

2250 mm H3 + H2 + D1 + E1

≥

2250 mm Figure 8 — Mincing machine with open feed intake hopper, mechanical trip bar, light barrier and interlocked step at the operator side - Safety dimensions

b) Mechanical trip bar/light barrier or movable protective grid at hopper edge, running round all sides At the hopper edge there shall be at all sides a mechanical trip bar, or a light barrier, or a protective grid with a trip function (see Figures 8 and 9). The design dimension from the standing area (floor or fixed step or fixed platform) across the upper edge of the protection equipment at the hopper edge up to the next hazard point in the hopper shall be > 2250 mm. The dangerous equipment in the hopper shall, if the mincing machines is running empty, come to a standstill within 3 s by using hole plates < 160 mm Ø and 4 s by using hole plates ≥ 160 mm Ø. #The interlocking of the mechanical trip bar or the movable protective grid shall comply with 5.2.1 and the safety-related parts of the control system shall present at least a Performance Level “c” defined in accordance with

EN ISO 13849-1:2008.$ The design of the light barrier shall be in accordance with ESPE type 2 of #EN 61496-1:2004$. SIST EN 12331:2004+A2:2010

Key 1 2 LIGHT BARRIER OR MOVABLE PROTECTIVE GRID

PLATFORM FIXED 1 PROTECTIVE HOOD

H1 ≥ 1600 mm L1 ≥

1,8 x D H2 ≥ 1100 mm L2 ≥

1,2 x D H3 ≥

500 mm with intermediate step

U ≤

50 mm H4 ≥ 1600 mm H1 + D + E ≥ 2250 mm H4 + D1 + E1 ≥ 2250 mm Figure 9 — Mincing machine with open feed intake hopper, protective grid and fixed step at the operator side- Safety dimensions Figure 10 — Discharge outlet on mincing machines - Protective hood 5.2.4 Discharge outlet on mincing machines 5.2.4.1 General Zone 3 The access to the danger zone on the blade behind the last plate at the outlet side shall be protected or prevented. This may be achieved by the following measures: a) The access is prevented by the design of the plate (see 5.2.4.2) b) The access will be prevented by using a guard, e.g. protective hood (see 5.2.4.3) 5.2.4.2 Design of the plate The diameter of the holes in the last plate towards the outlet shall be ≤ 8 mm. The thickness of the last plate shall be ≥ 5 mm. SIST EN 12331:2004+A2:2010

EN ISO 13849-1:2008.$ 5.2.5 Installation and removal of worm and set of cutting tools # Zone 4 5.2.5.1 Prevention of starting / functioning during installation and removal of worm and cutting tools Provisions shall be made for preventing starting or functioning of the machine during installation and removal of the worm and / or the set of cutting tools. Acceptable solutions are: A protective hood according to 5.2.4.3. This solution can also be used for machines with plates with holes

< 8 mm. Power interlocking of the end holes plate with the drive of the cutting tools. (Interlocking see 5.2.4.3.) Mechanical interlocking of the end holes plate with the drive of the cutting tools (causing declutching when the end holes plate is removed from its housing). In case one of the last two options is adopted particular attention shall be given to the reliability of the interlocking taking account of possible malfunctioning by the presence of product. 5.2.5.2 Loosening / extraction of the worm and cutting tools set With the exception of machines with a holes plate diameter ≤ 106 mm having a removable worm housing, all mincing machines shall be equipped with means for easy loosening / extraction of the worm and cutting tools set (an ejector or knock-out system, or an extractor system e.g. with lever or screw). The design of this system shall be such that in normal foreseeable conditions of use the forces required for loosening / extracting the worm are within the limits fixed in EN 1005-3. NOTE In case of a machine with a holes plate diameter ≤ 106 mm having a removable worm housing it is considered acceptable to loosen the worm and cutting tools set by knocking without special provisions.$ SIST EN 12331:2004+A2:2010

200 mm, the lowering speed shall not exceed 50 mm/s. 5.2.8 Mincing machines with loading devices 5.2.8.1 General Zones 7 to 10 5.2.8.2 Loading devices Lift-tilt devices of various designs exist, including those with fixed lifting arms for holding the trolley, lifting arms which allow the trolley to swivel in a gondola and thus remain horizontal, a vertical pillar mast with forks for holding trolleys or containers. SIST EN 12331:2004+A2:2010

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...