EN 15093:2008

(Main)Safety of Machinery - Safety requirements for hot flat rolling mills

Safety of Machinery - Safety requirements for hot flat rolling mills

This European Standard defines the general safety requirements for hot rolling mills for flat products as defined in 3.1.

This European Standard deals with significant hazards, hazardous situations and events relevant to hot rolling mills for flat products. It deals not only with circumstances where the machinery is used as intended, but also includes other conditions foreseen by the manufacturer, such as foreseeable faults, malfunctions or misuse (see Clauses 4 and 5).

This European standard applies to: Machinery and equipment used for the manufacturing of metal hot rolled flat products from the material supply from (1), via the mill stands (2), to the exit (5) (see Figure 1).

The following equipment is outside the scope of this standard:

- furnaces in accordance with EN 746-1, EN 746-2 and EN 746-3;

- continuous casting machines according to EN 14753;

- hook conveyors according to EN 619;

- roll shop equipment;

- storage equipment (e. g., high-bay warehouses);

- cranes, fork lifts, trucks and railway trucks and other vehicles.

This European standard is not applicable to hot rolling mills for flat products, manufactured before the date of publication of this standard by CEN.

Sicherheit von Maschinen - Sicherheitsanforderungen an Warmflachwalzwerke

Diese Europäische Norm spezifiziert die allgemeinen Sicherheitsanforderungen von Warmwalzwerken für

Flachprodukte wie in 3.1. beschrieben.

Diese Europäische Norm behandelt die für Warmflachwalzwerke zutreffenden Gefährdungen, Gefährdungssituationen

und -ereignisse. Sie behandelt nicht nur die Gegebenheiten, bei denen die Maschinen

bestimmungsgemäß genutzt wird, sondern beinhaltet auch andere Bedingungen, die der Hersteller in Betracht

gezogen hat, wie vorhersehbare Fehler, Fehlfunktionen oder fehlerhafte Nutzung (siehe Abschnitte 4 und 5).

Diese Norm umfasst: Maschinen und Ausrüstungen zur Herstellung von warmgewalzten Flacherzeugnissen

aus Metall von der Materialbeschickungsstation (1) über die Walzstationen (2) zum Auslauf (5) (siehe Bild 1).

Sécurité des machines - Prescriptions de sécurité relatives aux laminoirs à chaud pour produits plats

La présente Norme européenne spécifie les prescriptions générales de sécurité pour les laminoirs à chaud

pour produits plats comme défini en 3.1.

La présente Norme européenne traite des phénomènes dangereux significatifs, des situations et événements

dangereux associés aux laminoirs à chaud pour produits plats. Elle ne prend pas seulement en compte les

conditions liées à l’utilisation normale de la machine mais elle inclut aussi d’autres conditions prévues par le

fabricant, comme les défauts, les dysfonctionnements ou le mauvais usage prévisible (voir Articles 4 et 5).

La présente Norme européenne s’applique aux : installations et équipements utilisés pour la fabrication de

produits métalliques plats laminés à chaud depuis le poste d’alimentation en matière (1) jusqu’à la sortie (5)

vers le stockage en passant par les postes de formage (2) (voir Figure 1).

Varnost strojev - Varnostne zahteve za valjarne (vroče valjanje)

General Information

- Status

- Withdrawn

- Publication Date

- 30-Sep-2008

- Withdrawal Date

- 20-Jan-2026

- Drafting Committee

- CEN/TC 322/WG 3 - Rolling mills and finishing line equipment

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 09-Mar-2022

- Completion Date

- 21-Jan-2026

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 06-Feb-2019

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 13850:2006 - Safety of machinery - Emergency stop - Principles for design (ISO 13850:2006) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Frequently Asked Questions

EN 15093:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of Machinery - Safety requirements for hot flat rolling mills". This standard covers: This European Standard defines the general safety requirements for hot rolling mills for flat products as defined in 3.1. This European Standard deals with significant hazards, hazardous situations and events relevant to hot rolling mills for flat products. It deals not only with circumstances where the machinery is used as intended, but also includes other conditions foreseen by the manufacturer, such as foreseeable faults, malfunctions or misuse (see Clauses 4 and 5). This European standard applies to: Machinery and equipment used for the manufacturing of metal hot rolled flat products from the material supply from (1), via the mill stands (2), to the exit (5) (see Figure 1). The following equipment is outside the scope of this standard: - furnaces in accordance with EN 746-1, EN 746-2 and EN 746-3; - continuous casting machines according to EN 14753; - hook conveyors according to EN 619; - roll shop equipment; - storage equipment (e. g., high-bay warehouses); - cranes, fork lifts, trucks and railway trucks and other vehicles. This European standard is not applicable to hot rolling mills for flat products, manufactured before the date of publication of this standard by CEN.

This European Standard defines the general safety requirements for hot rolling mills for flat products as defined in 3.1. This European Standard deals with significant hazards, hazardous situations and events relevant to hot rolling mills for flat products. It deals not only with circumstances where the machinery is used as intended, but also includes other conditions foreseen by the manufacturer, such as foreseeable faults, malfunctions or misuse (see Clauses 4 and 5). This European standard applies to: Machinery and equipment used for the manufacturing of metal hot rolled flat products from the material supply from (1), via the mill stands (2), to the exit (5) (see Figure 1). The following equipment is outside the scope of this standard: - furnaces in accordance with EN 746-1, EN 746-2 and EN 746-3; - continuous casting machines according to EN 14753; - hook conveyors according to EN 619; - roll shop equipment; - storage equipment (e. g., high-bay warehouses); - cranes, fork lifts, trucks and railway trucks and other vehicles. This European standard is not applicable to hot rolling mills for flat products, manufactured before the date of publication of this standard by CEN.

EN 15093:2008 is classified under the following ICS (International Classification for Standards) categories: 77.180 - Equipment for the metallurgical industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15093:2008 has the following relationships with other standards: It is inter standard links to EN 15093:2022, EN ISO 12100-2:2003, EN ISO 4414:2010, EN 1063:1999, EN 614-1:2006, EN ISO 11202:2010, EN 894-1:1997+A1:2008, EN ISO 11688-1:2009, EN ISO 13850:2006, EN 894-2:1997+A1:2008, EN 14253:2003+A1:2007, EN 15004-1:2024, EN 13861:2011, EN 981:1996+A1:2008, EN 12198-3:2002+A1:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15093:2008 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15093:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sicherheit von Maschinen - Sicherheitsanforderungen an WarmflachwalzwerkeSécurité des Machines - Prescriptions de sécurité relatives aux laminoirs a chaud pour produits platsSafety of Machinery - Safety requirements for hot flat rolling mills25.120.20Rolling, extruding and drawing equipment13.110Varnost strojevSafety of machineryICS:Ta slovenski standard je istoveten z:EN 15093:2008SIST EN 15093:2008en01-december-2008SIST EN 15093:2008SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15093October 2008ICS 77.180 English VersionSafety of Machinery - Safety requirements for hot flat rolling millsSécurité des machines - Prescriptions de sécurité relativesaux laminoirs à chaud pour produits platsSicherheit von Maschinen - Sicherheitsanforderungen anWarmflachwalzwerkeThis European Standard was approved by CEN on 16 August 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15093:2008: ESIST EN 15093:2008

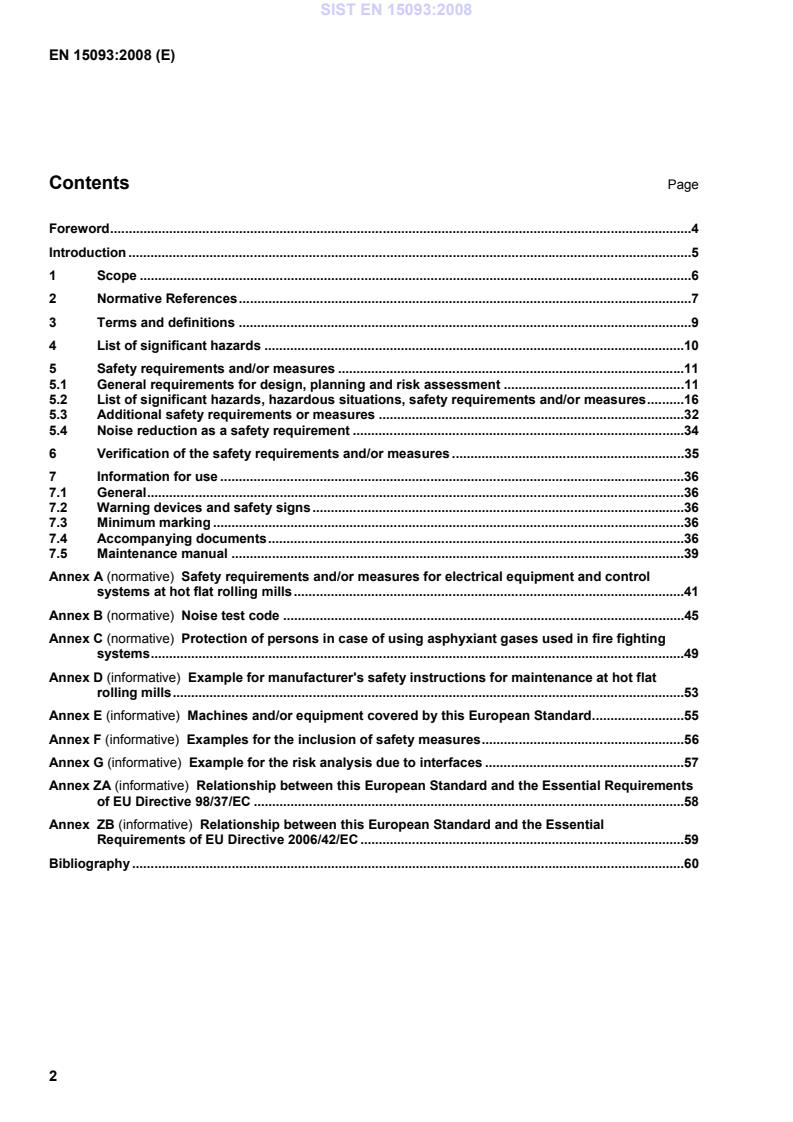

Safety requirements and/or measures for electrical equipment and control systems at hot flat rolling mills.41 Annex B (normative)

Noise test code.45 Annex C (normative)

Protection of persons in case of using asphyxiant gases used in fire fighting systems.49 Annex D (informative)

Example for manufacturer's safety instructions for maintenance at hot flat rolling mills.53 Annex E (informative)

Machines and/or equipment covered by this European Standard.55 Annex F (informative)

Examples for the inclusion of safety measures.56 Annex G (informative)

Example for the risk analysis due to interfaces.57 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC.58 Annex

ZB (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC.59 Bibliography.60

Tables Table 1 — Significant hazards, hazardous situations, safety requirements and/or measures.18 Table 2 — Main noise sources of hot flat rolling mills equipment and exemplary noise reduction measures.35 Table A.1 — Stop functions.43 Table B.1 — Example of declared dual-number noise emission values for work stations and specified measuring points.48

Key 4 coiler/cooling bed 1 e. g., continuous casting machine (according to

EN 14753) or furnace (according to EN 746-1) 5 coil or plate transport 2 mill stands 6 roll changing device 3 roller tables 7 border of the hot rolling mill Figure 1 — Exemplary layout of a hot flat rolling mill The following equipment is outside the scope of this standard: furnaces in accordance with EN 746-1, EN 746-2 and EN 746-3; continuous casting machines according to EN 14753; hook conveyors according to EN 619; roll shop equipment; storage equipment (e. g., high-bay warehouses); cranes, fork lifts, trucks and railway trucks and other vehicles. This European standard is not applicable to hot rolling mills for flat products, manufactured before the date of publication of this standard by CEN. SIST EN 15093:2008

EXAMPLES hot strip, heavy plates.

NOTE Machines and equipment which are covered by this standard are listed in Annex E. 3.2 material metal being hot rolled 3.3 pulpit enclosed room in which the control desk and monitoring facilities for a machine or equipment are located, used as a permanent work place 3.4 control stand free standing control desk (usually situated adjacent to the machine or equipment), used as a temporary work place 3.5 large machinery/equipment interconnected equipment (size > 15 m) of hot flat rolling mills in which several components of the machinery or forming stages are linked by dedicated transport facilities (e. g., roller conveyors, cross-transfer systems) SIST EN 15093:2008

3.7 trained personnel persons with the knowledge of systems, background, experience and ability to operate and/or maintain the equipment in the intended use and proper operation of the machinery/equipment 3.8 unauthorized person person not permitted to enter certain areas of the hot flat rolling mills, or to perform certain actions in relation with the operation and/or maintenance of the equipment, because of not having the required specific knowledge and skill and not being properly equipped to avoid the related hazards 3.9 maintenance service, inspection and repair 3.10 modes of operation different modes of operation under which machinery and equipment of hot flat rolling mills (single machines or groups of interconnected parts) can function a) manual mode mode in which every single function of the equipment is controlled by an operator by means of a hold-to-run control or equivalent device (see 3.26 of EN ISO 12100-1:2003) b) semi-automatic mode mode of operation of the machinery consisting of a series of automatic sequences (summary of functions) into which the whole working cycle is subdivided and, at the end of each sequence, started by the operator and then controlled by a programmable electronic system (PES), the operation is automatically stopped, and a new command of the operator is needed to initiate the next sequence c) automatic mode process, e. g., a cycle of successive or parallel sequences, once initiated by the operator, which is totally controlled by a PES and in which the repetition of the working cycle of the machinery takes place (as long as the running conditions are met) without any operator intervention required 3.11 safety layout description of line-related equipment with safety functions to ensure safe operation of the hot flat rolling mill avoiding hazards or hazardous situations for, e. g., unauthorized access or having another line-related safety function (see 5.1.3) 4 List of significant hazards This clause contains all significant hazards, hazardous situations and events, as far as they are dealt with in this standard, identified by risk assessment as significant for this type of machinery and which requires action to eliminate or reduce the risk. The risk identification was determined as follows: a) potentially hazardous situations having significant risks; b) the safety requirements and/or measures which shall be incorporated into the machinery/equipment; c) any special instructions which shall be communicated to the user. The significant hazards and hazardous situations identified are listed in columns 1 and 2 of Table 1. In addition it is important for the manufacturer to carry out an individual risk assessment according to EN ISO 14121-1 to identify any other significant hazard of the machine/equipment. Significant hazards identified in this SIST EN 15093:2008

This European Standard assumes that: installations are operated and maintained by adequately trained and competent personnel; manual intervention for setting, adjustment and maintenance is accepted as part of the normal use of the equipment; the machinery is used with adequate workplace lighting conforming to EN 12464-1 or to local regulations. In general, risks and associated hazards are production and plant-related. The main differences arising from the processing of different materials in different qualities and the surroundings (i. e. different combination of machines, different boundary conditions, see Annex G). The resulting variety of "different plants" could not be covered in all details in a European Standard. To deal with this fact, an individual risk assessment of the hot flat rolling mill in question shall be carried out (see 4) considering the safety requirements of this European Standard. Where the means of reducing the risk is by the physical arrangement or positioning of the installed machines, the manufacturer shall include in the information for use a reference to the reduction means to be provided, and to any limiting value of the requirement, and, if appropriate, to the means of verification. Where the means of reducing the risk is by a safe system of working the line, the manufacturer shall include in the Information for use details of the system and of the elements of information required by the operating personnel. This shall include protective measures used according to 4.11.9 and 4.11.10 of EN ISO 12100-2:2003 to run a machine for essential operating reasons or in special mode with safety devices suspended or temporarily modified. The manufacturer shall also include in the information for use all details required for a safe operating process under normal operating condition. He shall also describe the specific safety measures in case of special operating modes, e. g., maintenance and adjustment work. The requirements also apply to under floor areas of the plant. 5.1.1 Planning of hot flat rolling mills Manufacturers of hot flat rolling mills are normally not involved in planning the entire plant (e. g., halls, civil works). But in any case they have to take into account the following aspects in order to ensure good placement and safe operation of the hot flat rolling mill: accessibility; clearance gaps for maintenance and cleaning; escape routes; movement of machinery and material; safe operation; SIST EN 15093:2008

For the equipment linked to hot flat rolling mills, e. g., exhausting systems, energy supply (e. g., compressed air, gases, steam), auxiliary equipment and systems, respective instructions and safety measures including monitor requirements for the take-over-points shall be given in the information for use. 5.2 List of significant hazards, hazardous situations, safety requirements and/or measures Table 1 is developed to allow the designer and manufacturer of the equipment to apply a logical approach for checking the design against the list of significant hazards with respect to hot flat rolling mills. Table 1 is structured as follows: a) column 1 identifies the significant hazards; b) column 2 describes the hazardous situations; c) column 3 specifies the safety requirements and/or measures to avoid or minimize the hazards and hazardous situations; they are shown as combined measures or as options; d) column 4 makes reference to the relevant clauses or standards defining the measures; all references shown are applicable to each of the measures except where this is otherwise indicated; NOTE 1 When implementing safety requirements and/or measures it has to be considered that different hazards may appear at the same time. NOTE 2 5.3 and 5.4 are containing special safety requirements or measures. e) column 5 identifies the verification methods to be used to demonstrate conformity; the abbreviations V, P, M and D are defined as follows: 1) V: Visual inspection verifies the required features of the components. SIST EN 15093:2008

Table 1 — Significant hazards, hazardous situations, safety requirements and/or measures Column 1 Column 2 Column 3 Column 4 Column 5 Significant hazard Hazardous situation Safety requirements and/or measures Reference Verifi-cation 5.2.1 General 1 Combination of hazards Unexpected movement during maintenance Where equipment has to be held in a defined position and the risk of unexpected movement is given, mechanical restraining devices shall be provided. 5.3.2 D, V

Operating/maintenance instructions 7.4 D

Damage of cables or hoses Provision of protecting devices (e. g., covers, power track, cable winding device, cable-holding trolley) for the cables and hoses supplying energy to the equipment 5.1.11 5.1.12 D, V Exposure to noise Noise reduction at workplaces 5.4 D, M, P 2 Noise

Operating/maintenance instructions 7.4.2 D 3 Vibration Exposure to hand-arm and whole-body vibration Vibration reduction at work stations 5.1.20 D, M, P 5.2.2 Hydraulics, pneumatics, emulsions and other pressurised fluid systems Hose or pipe break due to:

Use of adequately dimensioned hoses, pipes and fittings and 5.1.12 5.1.13 D 1 High pressure fluid ejection which may cause injury to persons inadequate dimensions of hoses, pipes and fittings Selection of component material 5.1.12 5.1.13 D

Vibration reduction at source or 5.1.12 D

Positioning equipment at a distance from vibration sources to eliminate vibration damage or 5.1.13 V, D

Provision of isolation/dampening measures and/or 5.1.13 V, D

vibration Dimensioning taking into account the vibration load and

5.1.12 5.1.13 D

reversed bending stress Selection of material and dimension-ing, taking into account the fatigue strength of pipework and hoses 5.1.12 5.1.13 D

Dimensioning taking into account mechanical stress and kinking pipework and hoses and 5.1.12 5.1.13 D

mechanical stress, kinking, damage Protected location (e. g., by distance) or covering 5.1.13 D

Taking corrosion/chemical reactions into account when selecting materials and fluids and dimensioning wall thickness 5.1.12 D

chemical reaction Use of inhibitors in fluids 5.1.13 D, M

(continued) Column 1 Column 2 Column 3 Column 4 Column 5 Significant hazard Hazardous situation Safety requirements and/or measures Reference Verifi-cation Protected location or 5.1.5.4 D Protection against mechanical damage by covering or

5.1.5.4 V, D

Mechanical damage by cobbling material or during scrap re-moval (e. g., welding or gas cutting) Use of deflectors 5.1.5.4 V, D

Unexpected start-up Automatic pressure reduction in the pressure system (vessels) when the mill is switched off and 5.1.12 EN ISO 13849-1 P, D

Measures to prevent start-up by third parties (e. g., key-operated switch) shall be implemented by providing trapped key interlocking of the pressure system where one of the locks is used to lock the venting system (or isolating device) in its open position and Annex A; A.2 EN 1037 EN 60204-1:2006; 5.4; 5.5; 5.6 P, D

Acoustic and visual warning device for restart 5.1.8 P, D

Dismantling and repair operations Attachment of measuring points with pressure relief facility and 5.1.5 5.1.12 V, D

Hoselines with quick disconnecting couplings which are not automatically shutting-off at both ends shall be di

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...