EN 14753:2022

(Main)Safety of machinery - Safety requirements for machinery and equipment for continuous casting of steel

Safety of machinery - Safety requirements for machinery and equipment for continuous casting of steel

This document applies for plant (containing machinery and equipment) used in the process of continuous casting of liquid steel (hereafter referred to as continuous casting machine, CCM) as defined in 3.1.

This document deals with all significant hazards, hazardous situations and events relevant to machinery and equipment for the continuous casting of steel, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4).

This document specifies the safety requirements to be met during design, assembly, transport, commissioning, operation, maintenance (as described in Clause 5) and decommissioning of the equipment.

This document assumes that the machinery and equipment of the plant is operated and maintained by adequately trained and competent personnel (see 7.5). Manual intervention for setting, adjustment and maintenance is accepted as part of the intended use of the plant.

This document assumes that the machinery is used with adequate workstation lighting conforming to EN 12464 1.

National regulations regarding lighting should be considered and could differ from requirements of EN 12464 1.

This document applies to:

— CCM for the transformation of molten liquid steel into solid products in sections (e.g. square, rectangular, beam blank, circular);

— CCM's from the point where overhead cranes or other transport systems deposit ladles to CCM (e.g. in a ladle turret, ladle car or ladle stand);

— via casting process and solidification process;

— via cutting and marking equipment;

— thru the run-out-area where the cut product is finished, collected and removed from that area.

This document does not cover safety requirements for:

— horizontal-CCM for steel;

— auxiliary plants (auxiliary plants that are outside of the limits of the CCM);

— ladles and ladle transport;

— cranes;

— winches and hoists;

— conveyors or handling systems;

— workshop equipment (mould and segment shop, tundish workshop);

— gas burners, e.g. as a part of pre-heating stations.

This document can be used in case of modernization for the parts to be modernized.

This document is not applicable to CCM's manufactured before the date of its publication.

Sicherheit von Maschinen - Sicherheitsanforderungen für Maschinen und Einrichtungen zum Stranggießen von Stahl

Dieses Dokument gilt für Anlagen (die Maschinen und Ausrüstung enthalten), die beim Stranggießen von flüssigem Stahl (im Folgenden als Stranggießanlage oder SG-Anlage bezeichnet) wie in 3.1 definiert verwendet werden.

Dieses Dokument behandelt alle wesentlichen Gefährdungen, Gefährdungssituationen und Gefährdungs¬ereignisse mit Bezug zu Maschinen und Anlagen für das Stranggießen von Stahl, wenn sie bestimmungs¬gemäß und unter Bedingungen von durch den Hersteller vernünftigerweise vorhersehbaren Fehl¬anwendungen verwendet werden (siehe Abschnitt 4).

Dieses Dokument legt die sicherheitstechnischen Anforderungen fest, die bei Konstruktion, Montage, Transport, Inbetriebnahme, Betrieb, Instandhaltung (siehe Abschnitt 5) und Außerbetriebnahme der Anlage zu berücksichtigen sind.

Dieses Dokument geht davon aus, dass die Maschinen und Geräte der Anlage von entsprechend geschultem und fachkundigem Personal bedient und gewartet werden (siehe 7.5). Manuelles Eingreifen zum Einstellen, Anpassen und zur Instandhaltung als Teil des bestimmungsgemäßen Gebrauchs der Anlage ist zulässig.

Dieses Dokument setzt voraus, dass die Maschine mit einer geeigneten Beleuchtung des Arbeitsbereichs entsprechend EN 12464 1 betrieben wird.

Es sollten die nationalen Vorschriften für die Beleuchtung beachtet werden, die von den Anforderungen von EN 12464 1 abweichen können.

Dieses Dokument gilt für:

— SG-Anlagen zur Umwandlung von geschmolzenem flüssigem Stahl in feste Produktformen (z. B. quadratisch, rechteckig, Vorblock, rund);

— SG-Anlagen, bei denen Brückenkrane oder andere Transportsysteme Pfannen auf SG-Anlagen absetzen (z. B. in einen Pfannenturm, Pfannenwagen oder Pfannenständer);

— durch Gieß- und Verfestigungsverfahren;

— durch Schneid- und Kennzeichnungseinrichtungen;

— durch den Auslaufbereich, in dem das geschnittene Produkt fertig gestellt, gesammelt und aus diesem Bereich entnommen wird.

Dieses Dokument behandelt keine Sicherheitsanforderungen für:

— horizontale SG-Anlagen für Stahl;

— Hilfsanlagen (Hilfsanlagen, die außerhalb der Grenzen des der SG-Anlagen liegen);

— Pfannen und Pfannentransport;

— Kräne;

— Winden und Hebevorrichtungen;

— Förderer oder Transportanlagen;

— Werkstatt-Anlagen (Form- und Segmentwerkstatt, Verteilerwerkstatt);

— Gasbrenner, z. B. als Teil der Vortemperierstationen.

Dieses Dokument kann im Fall einer Modernisierung für die zu modernisierenden Teile verwendet werden.

Dieses Dokument gilt nicht für SG-Anlagen, die vor dem Datum seiner Veröffentlichung hergestellt wurden.

Sécurité des machines - Prescriptions de sécurité pour les machines et équipements de coulée continue de l'acier

Le présent document s’applique aux installations (contenant des machines et équipements) utilisés dans les procédés de coulée continue d’acier liquide (ci-après référée comme machine de coulée continue, CCM) comme défini au 3.1.

Le présent document traite de tous les phénomènes, situations et évènements dangereux pertinents pour les machines et équipements pour la coulée continue de l’acier, lorsqu’ils sont utilisés comme prévu et dans des conditions de mauvaise utilisation raisonnablement prévisibles par le fabricant (voir Article 4).

Le présent document spécifie les exigences de sécurité à satisfaire pendant la conception, l’assemblage, le transport, la mise en service, le fonctionnement, la maintenance (comme décrit à l’Article 5) et la mise hors service des équipements.

Le présent document suppose que les machines et équipements de l’installation sont utilisées et entretenues par un personnel convenablement formé et compétent (voir 7.5). Les interventions manuelles pour les réglages, ajustements et maintenance font partie de l’utilisation normale de ces machines.

Le présent document suppose que les machines sont utilisées avec un éclairage adapté au poste de travail conformément à l’EN 12464-1.

NOTE Il convient également de considérer les réglementations nationales concernant l’éclairage qui peuvent être différentes des exigences de l’EN 12464-1.

Le présent document s'applique aux :

— machines de coulée continue (CCM) pour la transformation de l’acier en fusion liquide en produits solides profilés (par exemple de forme, carrée, rectangulaire, en faisceaux, circulaire)

— machines de coulée continue aux points où les ponts roulants ou autres systèmes de transport déposent les poches de coulée (par exemples, dans une tourelle porte-poche, un chariot porte-poche ou une base pour poche) ;

— via le procédé de coulée et celui de solidification ;

— via les équipements de coupe et de marquage ;

— à la zone de coulage où les produit découpés sont achevés, collectés et retirés de ladite zone.

Le présent document ne couvre pas les exigences de sécurité pour :

— les CCM horizontales pour l'acier ;

— les installations auxiliaires, les installations auxiliaires qui sont en dehors des limites de la CCM ;

— les poches et le transport des poches ;

— les appareils de levage à charge suspendue ;

— les treuils et palans :

— les convoyeurs ou les systèmes de manutention ;

— les équipements des ateliers (atelier moule/lingotière et segments, atelier des paniers de coulée) ;

— brûleurs à gaz, par exemple dans le cadre de stations de préchauffage

Le présent document peut être utilisé en cas de modernisation pour les pièces devant être modernisées.

Le présent document n'est pas applicable aux CCM fabriqués avant la date de sa publication.

Varnost strojev - Varnostne zahteve za stroje in opremo za zvezno litje jekla

Ta dokument se uporablja za obrat (vključno s stroji in opremo), ki se uporablja v postopku zveznega litja tekočega jekla (v nadaljevanju: »stroj za zvezno litje jekla«), kot je opredeljeno v točki 3.1.

Ta dokument obravnava vsa večja tveganja, nevarne situacije in nevarne dogodke v zvezi s stroji in opremo za zvezno litje jekla, kadar se uporabljajo v skladu s predvidenim namenom in pod pogoji pričakovane nepravilne uporabe, ki jih določa proizvajalec (glej točko 4).

Ta dokument določa varnostne zahteve, ki jih je treba izpolnjevati med načrtovanjem, sestavljanjem, prevozom, usposabljanjem za zagon, obratovanjem, vzdrževanjem (kot je opisano v točki 5) in prenehanjem obratovanja opreme.

Ta dokument predpostavlja, da stroje in opremo v obratu upravlja ter vzdržuje ustrezno usposobljeno in kompetentno osebje (glej točko 7.5). Ročni poseg pri nastavljanju, prilagajanju in vzdrževanju je sprejet kot del predvidene uporabe obrata.

Ta dokument predpostavlja, da se stroji na delovnih postajah uporabljajo ob ustrezni razsvetljavi v skladu s standardom EN 12464-1.

OPOMBA: Priporočljivo je upoštevati nacionalne predpise glede razsvetljave, ki se lahko razlikujejo od zahtev standarda EN 12464-1.

Ta dokument se uporablja za:

– stroje za zvezno litje jekla, ki se uporabljajo za preoblikovanje taljenega tekočega jekla v trdne izdelke v obliki profilov (npr. kvadratne, pravokotne, krožne, surovce):

– stroje za zvezno litje jekla od točke, na kateri mostni žerjavi ali drugi transportni sistemi odložijo livne lonce v stroj za zvezno litje jekla (npr. v livarski obračalnik, livarski voziček ali stojalo za livne lonce);

– prek postopka litja in strjevanja;

– prek opreme za rezanje;

– skozi izstopno območje, kjer se rezani izdelek dokonča, prevzame in nato odstrani iz tega območja.

Ta dokument ne zajema varnostnih zahtev za:

– horizontalne stroje za zvezno litje jekla;

– pomožne obrate (npr. čiščenje vode, ravnanje z ognjevzdržnimi materiali);

– livne lonce;

– žerjave;

– vitle in dvigala;

– transporterje oz. sisteme za ravnanje z materialom;

– delavniško opremo (livarske kalupe in segmente, lijake za taljeno kovino).

OPOMBA: V primeru modernizacije je priporočljivo ta standard uporabiti za dele, ki bodo modernizirani.

General Information

- Status

- Published

- Publication Date

- 08-Mar-2022

- Withdrawal Date

- 29-Sep-2022

- Drafting Committee

- CEN/TC 322/WG 1 - Iron and steel production

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 09-Mar-2022

- Due Date

- 20-Jul-2021

- Completion Date

- 09-Mar-2022

Relations

- Effective Date

- 16-Mar-2022

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN 60825-1:2014 - Safety of laser products - Part 1: Equipment classification and requirements - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 14753:2022 - Safety of machinery: Safety requirements for machinery and equipment for continuous casting of steel (CCM) - is a European type‑C standard that defines essential safety requirements for plants used in the continuous casting of molten steel. The standard covers the lifecycle of CCMs - from design, assembly, transport and commissioning through operation, maintenance and decommissioning - and addresses significant hazards, hazardous situations and foreseeable misuse when equipment is used as intended.

Key points:

- Applies to CCMs transforming molten steel into solid sections (square, rectangular, beam blank, circular) and related casting, cutting/marking and run‑out areas.

- Assumes operation and maintenance by trained, competent personnel and adequate workstation lighting (see EN 12464‑1).

- Supersedes EN 14753:2007 and is not applicable to CCMs manufactured before its publication.

- Excludes horizontal CCMs, off‑site auxiliary plants, ladles, cranes, conveyors, workshop equipment and some gas burner applications.

Key Topics and Technical Requirements

This standard provides structured safety requirements and supporting material, including:

- Risk assessment and planning for CCM layout, interfaces and linked/integrated equipment.

- Safety design measures: guarding, safe access, ergonomics, noise reduction, vibration control, fire and substance hazards.

- Control and safety systems: requirements for safety‑related control systems, performance levels, safety software, remote access, stored energy and electrical safety.

- Access, locking and protective devices: enabling and hold‑to‑run controls, emergency stop and shutdown functions (Annex A), sensitive protective equipment and mechanical restraint devices.

- Verification and validation procedures for safety functions, and guidance on testing (noise test code in Annex B).

- Information for use: marking, instructions, transport and assembly guidance, training requirements and repair/modernization guidance.

- Special annexes: emergency stop, noise testing, asphyxiant gas protection (firefighting), examples of operating modes and hazard listings.

Practical Applications and Who Uses It

EN 14753:2022 is intended for:

- Machine manufacturers and OEMs designing or modernizing continuous casting machinery.

- Plant designers and integrators responsible for safe layout and interfacing of CCM with upstream/downstream systems.

- Safety engineers and risk assessors conducting hazard analyses, specifying safeguards and defining performance levels.

- Maintenance teams, operators and training managers for establishing procedures, training and safe operating instructions.

- Notified bodies and compliance auditors evaluating conformity with European standardization requirements.

Practical uses:

- Developing machine designs that meet recognized safety requirements.

- Preparing technical documentation, verification plans and operator instructions.

- Guiding modernization projects for CCM components to achieve current safety levels.

Related Standards (if applicable)

- EN ISO 12100 (machine safety - general principles of risk assessment and reduction) - referenced as the type‑C framework.

- EN 12464‑1 (lighting for workstations) - cited for workstation lighting requirements.

- Supersedes: EN 14753:2007.

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

EN 14753:2022 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of machinery - Safety requirements for machinery and equipment for continuous casting of steel". This standard covers: This document applies for plant (containing machinery and equipment) used in the process of continuous casting of liquid steel (hereafter referred to as continuous casting machine, CCM) as defined in 3.1. This document deals with all significant hazards, hazardous situations and events relevant to machinery and equipment for the continuous casting of steel, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). This document specifies the safety requirements to be met during design, assembly, transport, commissioning, operation, maintenance (as described in Clause 5) and decommissioning of the equipment. This document assumes that the machinery and equipment of the plant is operated and maintained by adequately trained and competent personnel (see 7.5). Manual intervention for setting, adjustment and maintenance is accepted as part of the intended use of the plant. This document assumes that the machinery is used with adequate workstation lighting conforming to EN 12464 1. National regulations regarding lighting should be considered and could differ from requirements of EN 12464 1. This document applies to: — CCM for the transformation of molten liquid steel into solid products in sections (e.g. square, rectangular, beam blank, circular); — CCM's from the point where overhead cranes or other transport systems deposit ladles to CCM (e.g. in a ladle turret, ladle car or ladle stand); — via casting process and solidification process; — via cutting and marking equipment; — thru the run-out-area where the cut product is finished, collected and removed from that area. This document does not cover safety requirements for: — horizontal-CCM for steel; — auxiliary plants (auxiliary plants that are outside of the limits of the CCM); — ladles and ladle transport; — cranes; — winches and hoists; — conveyors or handling systems; — workshop equipment (mould and segment shop, tundish workshop); — gas burners, e.g. as a part of pre-heating stations. This document can be used in case of modernization for the parts to be modernized. This document is not applicable to CCM's manufactured before the date of its publication.

This document applies for plant (containing machinery and equipment) used in the process of continuous casting of liquid steel (hereafter referred to as continuous casting machine, CCM) as defined in 3.1. This document deals with all significant hazards, hazardous situations and events relevant to machinery and equipment for the continuous casting of steel, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). This document specifies the safety requirements to be met during design, assembly, transport, commissioning, operation, maintenance (as described in Clause 5) and decommissioning of the equipment. This document assumes that the machinery and equipment of the plant is operated and maintained by adequately trained and competent personnel (see 7.5). Manual intervention for setting, adjustment and maintenance is accepted as part of the intended use of the plant. This document assumes that the machinery is used with adequate workstation lighting conforming to EN 12464 1. National regulations regarding lighting should be considered and could differ from requirements of EN 12464 1. This document applies to: — CCM for the transformation of molten liquid steel into solid products in sections (e.g. square, rectangular, beam blank, circular); — CCM's from the point where overhead cranes or other transport systems deposit ladles to CCM (e.g. in a ladle turret, ladle car or ladle stand); — via casting process and solidification process; — via cutting and marking equipment; — thru the run-out-area where the cut product is finished, collected and removed from that area. This document does not cover safety requirements for: — horizontal-CCM for steel; — auxiliary plants (auxiliary plants that are outside of the limits of the CCM); — ladles and ladle transport; — cranes; — winches and hoists; — conveyors or handling systems; — workshop equipment (mould and segment shop, tundish workshop); — gas burners, e.g. as a part of pre-heating stations. This document can be used in case of modernization for the parts to be modernized. This document is not applicable to CCM's manufactured before the date of its publication.

EN 14753:2022 is classified under the following ICS (International Classification for Standards) categories: 77.180 - Equipment for the metallurgical industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14753:2022 has the following relationships with other standards: It is inter standard links to EN 14753:2007, EN 61310-2:2008, EN IEC 60825-4:2024, EN 61310-1:2008, EN IEC 62061:2021, EN 60825-1:2014, EN 60204-1:2018, ISO 3864-1:2011, EN 62598:2013, ISO 7745:2010, EN 60447:2004, EN 60825-1:1994, EN IEC 61496-1:2020, EN 894-2:1997+A1:2008, EN ISO 13849-1:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14753:2022 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14753:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2022

Nadomešča:

SIST EN 14753:2008

Varnost strojev - Varnostne zahteve za stroje in opremo za zvezno litje jekla

Safety of machinery - Safety requirements for machinery and equipment for continuous

casting of steel

Sicherheit von Maschinen - Sicherheitsanforderungen für Maschinen und Einrichtungen

zum Stranggießen von Stahl

Sécurité des machines - Prescriptions de sécurité pour les machines et équipements de

coulée continue de l'acier

Ta slovenski standard je istoveten z: EN 14753:2022

ICS:

13.110 Varnost strojev Safety of machinery

77.180 Oprema za metalurško Equipment for the

industrijo metallurgical industry

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14753

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2022

EUROPÄISCHE NORM

ICS 77.180; C Supersedes EN 14753:2007

English Version

Safety of machinery - Safety requirements for machinery

and equipment for continuous casting of steel

Sécurité des machines - Prescriptions de sécurité pour Sicherheit von Maschinen - Sicherheitsanforderungen

les machines et équipements de coulée continue de für Maschinen und Einrichtungen zum Stranggießen

l'acier von Stahl

This European Standard was approved by CEN on 12 December 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14753:2022 E

worldwide for CEN national Members.

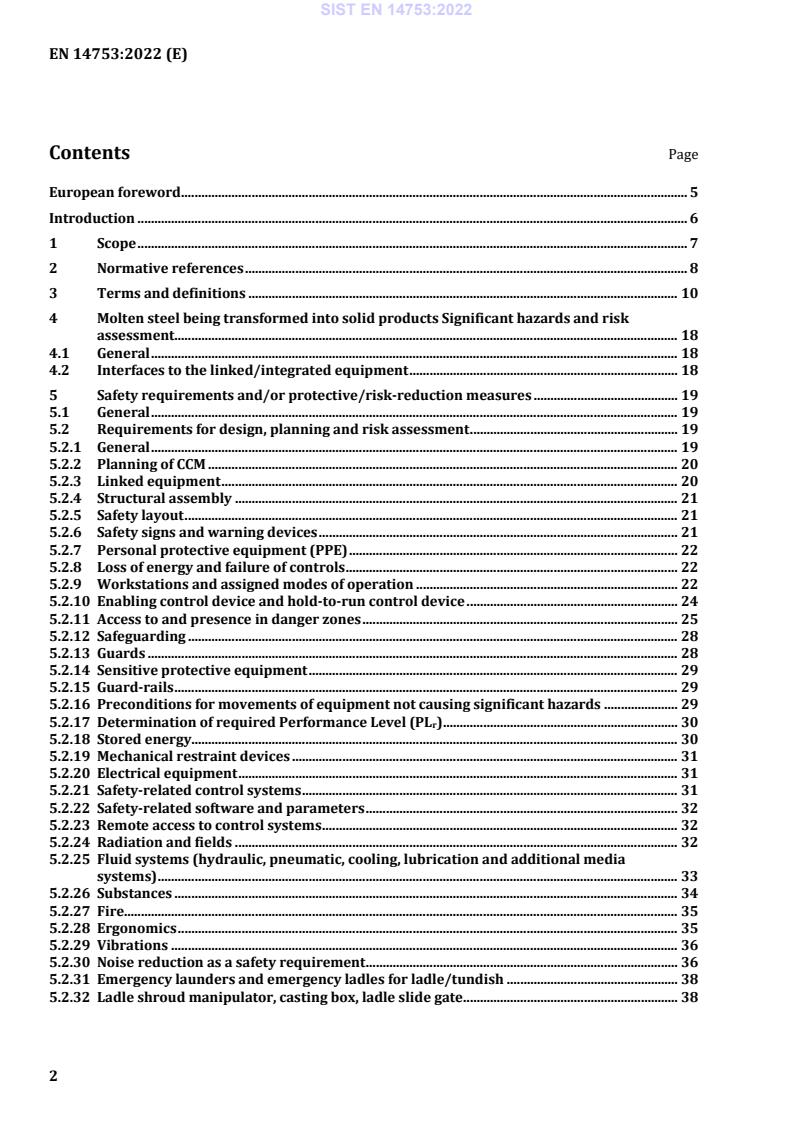

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 7

2 Normative references . 8

3 Terms and definitions . 10

4 Molten steel being transformed into solid products Significant hazards and risk

assessment. 18

4.1 General . 18

4.2 Interfaces to the linked/integrated equipment . 18

5 Safety requirements and/or protective/risk-reduction measures . 19

5.1 General . 19

5.2 Requirements for design, planning and risk assessment . 19

5.2.1 General . 19

5.2.2 Planning of CCM . 20

5.2.3 Linked equipment . 20

5.2.4 Structural assembly . 21

5.2.5 Safety layout . 21

5.2.6 Safety signs and warning devices . 21

5.2.7 Personal protective equipment (PPE) . 22

5.2.8 Loss of energy and failure of controls . 22

5.2.9 Workstations and assigned modes of operation . 22

5.2.10 Enabling control device and hold-to-run control device . 24

5.2.11 Access to and presence in danger zones . 25

5.2.12 Safeguarding . 28

5.2.13 Guards . 28

5.2.14 Sensitive protective equipment . 29

5.2.15 Guard-rails . 29

5.2.16 Preconditions for movements of equipment not causing significant hazards . 29

5.2.17 Determination of required Performance Level (PL ) . 30

r

5.2.18 Stored energy. 30

5.2.19 Mechanical restraint devices . 31

5.2.20 Electrical equipment . 31

5.2.21 Safety-related control systems . 31

5.2.22 Safety-related software and parameters . 32

5.2.23 Remote access to control systems . 32

5.2.24 Radiation and fields . 32

5.2.25 Fluid systems (hydraulic, pneumatic, cooling, lubrication and additional media

systems) . 33

5.2.26 Substances . 34

5.2.27 Fire. 35

5.2.28 Ergonomics . 35

5.2.29 Vibrations . 36

5.2.30 Noise reduction as a safety requirement . 36

5.2.31 Emergency launders and emergency ladles for ladle/tundish . 38

5.2.32 Ladle shroud manipulator, casting box, ladle slide gate . 38

5.3 Significant hazards, hazardous situations, safety requirements and/or

protective/risk-reduction measures . 39

5.3.1 Structure and content of Table 4 . 39

6 Verification/validation of safety requirements/functions and/or protective/risk

reduction measures . 59

6.1 General . 59

6.2 Required verification D . 60

6.3 Required verification V, M and T . 60

7 Information for use . 61

7.1 General . 61

7.2 Warning devices and safety signs . 61

7.3 Minimum marking . 61

7.4 Accompanying documents. 62

7.4.1 Instructions . 62

7.4.2 Instruction for transportation and assembly of the equipment . 64

7.4.3 Information about disabling, disassembly and disposal of the equipment . 64

7.5 Training of personnel. 65

8 Supplementary information regarding repair work . 65

Annex A (normative) Requirements for shut-down, emergency stop and other stop

functions . 66

A.1 General requirements . 66

A.2 Specific requirements . 66

A.3 Selection of stop functions. 67

A.4 Emergency stop areas . 67

A.5 Compilation of applicable shut-down, emergency stop and other stop functions . 67

Annex B (normative) Noise test code . 72

B.1 Introduction. 72

B.2 Determination sound power levels . 72

B.3 Determination of emission sound pressure levels at permanent or temporary work

stations . 72

B.4 Measurement uncertainty . 73

B.5 Installation, mounting and operating conditions . 73

B.6 Information to be recorded and reported . 74

B.7 Declaration and verification of noise emission values . 74

Annex C (normative) Protection of persons in case of using asphyxiant gases used in

firefighting systems . 76

C.1 General . 76

C.2 Warning devices . 76

C.3 Restraint devices . 77

C.4 Preliminary warning time . 77

C.5 Interrupt device for extinguishing gas. 78

C.6 Blocking devices . 78

C.7 Pipes . 78

C.8 Rooms and adjacent areas . 78

C.9 Escape routes . 79

C.10 Doors . 79

C.11 Marking . 79

C.12 Instruction handbook . 79

Annex D (informative) Example for operating modes in relation to segregated areas . 80

Annex E (informative) Examples for limitation of danger zones . 81

Annex F (informative) List of significant hazards . 84

Bibliography . 86

European foreword

This document (EN 14753:2022) has been prepared by Technical Committee CEN/TC 322 “Equipment

for making and shaping of metals - Safety requirements”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by September 2022, and conflicting national standards shall

be withdrawn at the latest by September 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 14753:2007.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document is a type-C standard as stated in EN ISO 12100:2010.

This document is not applicable to continuous casting machines (according to the Scope) manufactured

before the date of its publication.

The machinery concerned and the extent to which hazards, hazardous situations or hazardous events are

covered are indicated in the Scope of this document.

Where for clarity an example of a preventative measure is given, this should not be considered as the only

possible solution. Any other solution leading to the same risk reduction is permissible if an equivalent

level of safety is achieved.

When requirements of this type-C standard are different from those which are stated in type-A or -B

standards, the requirements of this type-C standard take precedence over the requirements of the other

standards for machines that have been designed and built according to the requirements of this type-C

standard.

It is assumed that continuous casting machines are operated and maintained by suitably trained

personnel.

This document is of relevance, in particular, for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine and/or plant manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine and/or plant users/employers (small, medium and large enterprises);

— service providers, e.g. for maintenance (small, medium and large enterprises).

The above-mentioned stakeholder groups have been given the possibility to participate in the drafting

process of this document.

1 Scope

This document applies for plant (containing machinery and equipment) used in the process of continuous

casting of liquid steel (hereafter referred to as continuous casting machine, CCM) as defined in 3.1.

This document deals with all significant hazards, hazardous situations and events relevant to machinery

and equipment for the continuous casting of steel, when they are used as intended and under conditions

of misuse which are reasonably foreseeable by the manufacturer (see Clause 4).

This document specifies the safety requirements to be met during design, assembly, transport,

commissioning, operation, maintenance (as described in Clause 5) and decommissioning of the

equipment.

This document assumes that the machinery and equipment of the plant is operated and maintained by

adequately trained and competent personnel (see 7.5). Manual intervention for setting, adjustment and

maintenance is accepted as part of the intended use of the plant.

This document assumes that the machinery is used with adequate workstation lighting conforming to

EN 12464-1.

National regulations regarding lighting should be considered and could differ from requirements of

EN 12464-1.

This document applies to:

— CCM for the transformation of molten liquid steel into solid products in sections (e.g. square,

rectangular, beam blank, circular);

— CCM's from the point where overhead cranes or other transport systems deposit ladles to CCM (e.g.

in a ladle turret, ladle car or ladle stand);

— via casting process and solidification process;

— via cutting and marking equipment;

— thru the run-out-area where the cut product is finished, collected and removed from that area.

This document does not cover safety requirements for:

— horizontal-CCM for steel;

— auxiliary plants (auxiliary plants that are outside of the limits of the CCM);

— ladles and ladle transport;

— cranes;

— winches and hoists;

— conveyors or handling systems;

— workshop equipment (mould and segment shop, tundish workshop);

— gas burners, e.g. as a part of pre-heating stations.

This document can be used in case of modernization for the parts to be modernized.

This document is not applicable to CCM's manufactured before the date of its publication.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 298, Automatic burner control systems for burners and appliances burning gaseous or liquid fuels

EN 614-1, Safety of machinery - Ergonomic design principles - Part 1: Terminology and general principles

EN 614-2, Safety of machinery - Ergonomic design principles - Part 2: Interactions between the design of

machinery and work tasks

EN 842, Safety of machinery - Visual danger signals - General requirements, design and testing

EN 894-1, Safety of machinery - Ergonomics requirements for the design of displays and control actuators

— Part 1: General principles for human interactions with displays and control actuators

EN 894-2, Safety of machinery - Ergonomics requirements for the design of displays and control actuators

— Part 2: Displays

EN 894-3, Safety of machinery - Ergonomics requirements for the design of displays and control actuators

— Part 3: Control actuators

EN 981, Safety of machinery - System of auditory and visual danger and information signals

EN 1299, Mechanical vibration and shock - Vibration isolation of machines - Information for the application

of source isolation

EN 1837, Safety of machinery - Integral lighting of machines

EN 12198-3, Safety of machinery - Assessment and reduction of risks arising from radiation emitted by

machinery - Part 3: Reduction of radiation by attenuation or screening

EN 12464-1, Light and lighting - Lighting of work places - Part 1: Indoor work places

EN 12254, Screens for laser working places - Safety requirements and testing

EN 13480-1, Metallic industrial piping - Part 1: General

EN 13480-2, Metallic industrial piping - Part 2: Materials

EN 13480-3, Metallic industrial piping - Part 3: Design and calculation

EN 13480-4, Metallic industrial piping - Part 4: Fabrication and installation

EN 13480-5, Metallic industrial piping - Part 5: Inspection and testing

EN 13861, Safety of machinery - Guidance for the application of ergonomics standards in the design of

machinery

EN 60204-1:2018, Safety of machinery - Electrical equipment of machines - Part 1: General requirements

(IEC 60204-1:2016, modified)

EN 60447, Basic and safety principles for man-machine interface, marking and identification - Actuating

principles (IEC 60447)

EN 60825-1, Safety of laser products - Part 1: Equipment classification and requirements (IEC 60825-1)

EN 60825-4, Safety of laser products - Part 4: Laser guards (IEC 60825-4)

EN 61310-1, Safety of machinery - Indication, marking and actuation - Part 1: Requirements for visual,

acoustic and tactile signals (IEC 61310-1)

EN 61310-2, Safety of machinery - Indication, marking and actuation - Part 2: Requirements for marking

(IEC 61310-2)

EN 61496-1, Safety of machinery - Electro-sensitive protective equipment - Part 1: General requirements

and tests (IEC 61496-1)

EN 62061, Safety of machinery - Functional safety of safety-related electrical, electronic and programmable

electronic control systems (IEC 62061)

EN 62598, Nuclear instrumentation - Constructional requirements and classification of radiometric gauges

(IEC 62598)

EN ISO 4413, Hydraulic fluid power - General rules and safety requirements for systems and their

components (ISO 4413)

EN ISO 4414, Pneumatic fluid power - General rules and safety requirements for systems and their

components (ISO 4414)

EN ISO 4871:2009, Acoustics - Declaration and verification of noise emission values of machinery and

equipment (ISO 4871:1996)

EN ISO 7010, Graphical symbols - Safety colours and safety signs - Registered safety signs (ISO 7010)

EN ISO 7731, Ergonomics - Danger signals for public and work areas - Auditory danger signals (ISO 7731)

EN ISO 11064-1, Ergonomic design of control centres - Part 1: Principles for the design of control centres

(ISO 11064-1)

EN ISO 11202:2010, Acoustics - Noise emitted by machinery and equipment - Determination of emission

sound pressure levels at a work station and at other specified positions applying approximate environmental

corrections (ISO 11202:2010)

EN ISO 11553-1, Safety of machinery - Laser processing machines - Part 1: Laser safety requirements

(ISO 11553-1)

EN ISO 11688-1, Acoustics - Recommended practice for the design of low-noise machinery and equipment -

Part 1: Planning (ISO/TR 11688-1)

EN ISO 12100:2010, Safety of machinery - General principles for design - Risk assessment and risk reduction

(ISO 12100:2010)

EN ISO 13732-1, Ergonomics of the thermal environment - Methods for the assessment of human responses

to contact with surfaces - Part 1: Hot surfaces (ISO 13732-1)

EN ISO 13849-1:2015, Safety of machinery - Safety-related parts of control systems - Part 1: General

principles for design (ISO 13849-1:2015)

EN ISO 13850:2015, Safety of machinery - Emergency stop function - Principles for design (ISO 13850:2015)

EN ISO 13854, Safety of machinery - Minimum gaps to avoid crushing of parts of the human body (ISO

13854)

EN ISO 13855, Safety of machinery - Positioning of safeguards with respect to the approach speeds of parts

of the human body (ISO 13855)

EN ISO 13857, Safety of machinery - Safety distances to prevent hazard zones being reached by upper and

lower limbs (ISO 13857)

EN ISO 14118:2018, Safety of machinery - Prevention of unexpected start-up (ISO 14118:2017)

EN ISO 14119, Safety of machinery - Interlocking devices associated with guards - Principles for design and

selection (ISO 14119)

EN ISO 14120, Safety of machinery - Guards - General requirements for the design and construction of fixed

and movable guards (ISO 14120)

EN ISO 14122 (all parts), Safety of machinery - Permanent means of access to machinery (ISO 14122)

ISO 3864-1, Graphical symbols — Safety colours and safety signs — Part 1: Design principles for safety signs

and safety markings

ISO 7745, Hydraulic fluid power — Fire-resistant (FR) fluids — Requirements and guidelines for use

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010 and the

following apply.

3.1

continuous casting machine

CCM

equipment for pouring liquid steel by one or more strands

Note 1 to entry: The CCM can be vertical, bow-shaped or mixed type.

3.2

casting platform

area where liquid steel is poured

3.3

cooling chamber

strand guiding area

closed area located underneath the casting platform from where steam, generated through the casting

process, is exhausted

Note 1 to entry: Within this area, thermal hazards due to liquid steel (e.g. due to breakout of strand) or high

temperature (caused by liquid/solidified steel) and/or steam (caused by water cooling) exist.

3.4

crop and/or sample collecting system

device to collect crops or samples

3.5

cutting equipment

equipment to cut the product to desired length

3.6

run-out-area

cooling bed and product collecting system

area following the cutting system with devices to transport, cool down, finish, mark and/or collect the

products

3.7

dummy bar system

device to start casting

3.8

electromagnetic braking device

EMBR

device to brake liquid steel movement in the mould

3.9

electromagnetic mould stirring device

EMS

device to stir the liquid steel

3.10

electromagnetic strand stirring device

device to stir the liquid steel in the solidification area

3.11

ladle

vessel to collect, transport and discharge molten steel

3.12

emergency launder, emergency ladle

system to convey and collect liquid steel in case of uncontrolled steel flow from ladle

3.13

tundish emergency system

system to stop or convey and collect liquid steel in case of uncontrolled steel flow from tundish

3.14

ladle supporting system

installed on the casting platform to move and/or support the ladles received from the charging area into

casting position

3.15

ladle/tundish shrouding system

movable protection for liquid steel stream between ladle to tundish

3.16

slide gate

stopper rod

system installed on the ladle/tundish to control the liquid steel flow

3.17

deburring system

equipment to remove and collect burrs from the product

3.18

skull

solidified, random shaped piece of steel/slag

3.19

emergency cutting by manual torch

manual cutting by hand with a torch lance during casting process in a defined emergency cutting area

3.20

marking system

equipment to mark the product

3.21

mould

device that solidifies the strand shell

3.22

mould level control system

system to control the steel level in the mould

3.23

oscillating device

device for oscillating movement of the mould

3.24

transfer system

device to transfer the strand product, e.g., roller table

3.25

scale collecting system

device to collect scale

3.26

slag detecting system

system to detect the slag flow from the ladle into the tundish

3.27

strand guide system

device to support the steel product of each strand

3.28

submerged entry nozzle

SEN

device to pour the steel from the tundish into the mould

3.29

tundish

trough to collect the liquid steel poured from the ladle and/or distribute it to the strand(s)

3.30

tundish launder and slag box system

system installed on the casting platform to collect and/or divert liquid steel poured out of the

ladle/tundish in case of failure of the level control system

3.31

tundish supporting system

system, installed on the casting platform, that contains the tundish and carries it between

parking/preheating and casting position

3.32

withdrawal and straightening system

device to withdraw and straighten the strands and transfer them to the cutting machine area

3.33

safety layout

graphical description of plant-related equipment with regard to safety

3.34

safeguard(ing)

guard or protective device

[SOURCE: EN ISO 12100:2010, 3.26]

3.35

route way

provisional, marked and freely accessible paths in the area of the CCM on which also unauthorized

persons (see 3.40) can be present

EXAMPLE Sidewalks or visitor walkways.

3.36

emergency position

position where the ladle and/or tundish is moved in case of an emergency

3.37

protected area

area where persons find protection

3.38

trained person(nel)

skilled person with system knowledge, background knowledge, experience and/or ability to perform a

specific task and are aware of the hazards related to their duties

3.39

authorized person(nel)

trained person who is instructed by the user to perform a specific task on a specific equipment

3.40

unauthorized person

person not permitted to enter certain areas or to perform certain actions in the area of the CCM in relation

with the operation and/or maintenance equipment, because not having the required specific knowledge

and skill, and/or not being properly equipped, in order to avoid the related hazards

3.41

maintenance

combination of service, inspection, reconditioning and functional test of the equipment

Note 1 to entry: The purpose is to preserve the working condition or returning to this condition so that the CCM

is able to perform the required function (including safety requirements).

3.41.1

service

measure to maintain the nominal condition

Note 1 to entry: The nominal condition can be maintained in general without dismantling/disassembling major

parts of the equipment, e.g. cleaning, lubrication of the work equipment as well as addition or replacement of agents

or by replacing tools or operational changing parts.

3.41.2

inspection

measure to observe and assess the current condition as well as fault finding

Note 1 to entry: Measures, e.g. measuring, testing, diagnostics including the determination of the causes of wear

or damage and the derivation of the necessary consequences for the continued use.

3.41.3

reconditioning

measure to return to the nominal condition

Note 1 to entry: Foreseeable measures to replace worn parts or parts having expired the foreseen lifetime (could

require dismantling/disassembling). These parts should meet manufacturers' specification.

3.41.4

functional test

checking the functionality of the exchanged or repaired parts

Note 1 to entry: It is maybe required to carry out adjustment work, e.g. test runs, verifying safety functions.

3.42

repair

non-regular work, not foreseeable, required to re-establish the nominal condition

Note 1 to entry: Measure to replace damaged parts, requires in general dismantling/disassembling.

3.43

pulpit

room in which the control desk and monitoring facilities for a CCM are located

3.44

control stand

free standing control desk (usually situated adjacent to the machine or equipment), used as a temporary

workstation

3.45

portable control device

control unit connected to the control system, e.g., to position equipment more precisely

3.46

enabling control device

additional manually actuated device used in conjunction with a start control which, when continuously

actuated, permits machine function

[SOURCE: EN ISO 12100:2010, 3.28.2]

3.47

hold-to-run control device

control device which initiates and maintains machine functions only as long as the control device is

actuated

[SOURCE: EN ISO 12100:2010, 3.28.3]

3.48

control mode

single machines or groups of linked machines of a CCM can function under different control modes

Note 1 to entry: This document distinguishes between control mode(s) and operating mode(s) because there is

neither a common understanding nor a definition in EN ISO 12100 and EN 60204-1. The operating modes (see 3.49)

corresponds to the “control mode” of EN ISO 12100:2010, 6.2.11.9.

3.48.1

manual control mode

3.48.1.1

hold-to-run control

every function is initiated by an operator by means of a button or equivalent device according to

EN ISO 12100:2010, 3.28.3

Note 1 to entry: Release of the button/device stops the function (e.g. movement) immediately.

3.48.1.2

single function

functions are started and/or stopped by an operator

3.48.2

semi-automatic control

sequence of functions released once by an operator

Note 1 to entry: The released sequence is automatically stopped at its end. For the initiation of another sequence,

a new command by the operator is required.

3.48.3

automatic control

cycles of successive or parallel sequences, once initiated by the operator

Note 1 to entry: If no interruption takes place by an operator, the sequences are repeated as long as the running

conditions are met.

3.49

operating mode

state of the control system allowing to operate the CCM under defined conditions

Note 1 to entry: Such conditions (modes) are, e.g. production, safe stop, enabling, inching, adjustment, inspection.

Note 2 to entry: The safety level of the operating mode(s) is defined as result of the risk assessment.

3.49.1

special mode

3.49.1.1

enabling (mode)

operating machine functions with an additional enabling control device

Note 1 to entry: See EN ISO 12100:2010, 6.2.11.9 and EN 60204-1.

3.49.1.2

inching (jog) mode

operating machine functions using a hold-to-run control device

3.49.2

safe stop (mode)

movement of the involved equipment is prevented through the control system

Note 1 to entry: The safety level of the safe stop is defined as result of the risk assessment.

Note 2 to entry: Safe stop is not sufficient as a safety measure to perform reconditioning or repair work because

isolation of the equipment from the relevant energy sources is not realized.

Note 3 to entry: Residual risks, e.g. by stored energy must have been secured by other means.

Note 4 to entry: Safe stop mode may also include switching off additional devices, e.g. X-ray.

3.49.3

normal production mode

machine is ready to produce or producing as intended

Note 1 to entry: Production, material handling and activities supporting these processes are covered.

Note 2 to entry: Maintenance according to 3.20 is not covered.

3.50

reduced speed

speed, reduced to minimize the hazardous potential without safety monitoring of speed

Note 1 to entry: In case of failure, an increase in speed may occur.

Note 2 to entry: Applies to linear or rotational speed.

Note 3 to entry: Speed reduced without an enabling device means, that the movement is so slow that the operator

can move away from this dangerous movement in time. Based on a risk assessment, an enabling device may

therefore be required in some cases, even at a reduced speed (e.g. in narrow spaces).

Note 4 to entry: Examples of reduced speeds include speeds of less than 10 mm/s for presses, less than

250 mm/s for robots, less than 250 mm/s for all non-shearing movements and less than 33 mm/s for shearing or

crushing movements.

3.51

safely-limited speed

SLS

exceeding of a predefined speed limit is safety-related prevented according to EN 61800-5-2:2017,

4.2.4.5

Note 1 to entry: Linear or rotational speed.

3.52

unexpected [unintended] start-up

any start-up caused by:

— a start command which is the result of failure in, or an external influence on the control system;

— a start command generated by inopportune action on a start control or other parts of the machine,

as e.g. a sensor or a power control element;

— restoration of the power supply after an interruption;

— external/internal influences (gravity, wind, self-ignition in internal combustion engines, etc.) on

parts of the machine

Note 1 to entry: Automatic machine start-up during operation is not unintended but can be considered to be

unexpected from the point of view of the operator. Prevention of accidents in this case involves the use of

safeguarding.

Note 2 to entry: Definition according to EN ISO 14118:2018, 3.2.

3.53

remote access

access from remote location via interface to control systems of the CCM, e.g. for software update

3.54

casting sequence

continuous casting of multiple heats (ladles) consecutively out of one or more tundish

3.55

ionizing radiation

x-ray radiation or radiation emanating from radioactive sources

3.56

laser radiation

coherent optical radiation

Note 1 to entry: See EN 60825.

3.57

EMF

electromagnetic fields

Note 1 to entry: EMF are static electrical, static magnetic as well as time-varying electrical, magnetic and

electromagnetic fields with frequencies up to 300 GHz.

3.58

casting box

protection casing for liquid steel between ladle and tundish

3.59

trouble shooting

form of problem detection and solving often applied to repair failed products or processes on machines

or systems

4 Molten steel being transformed into solid products Significant hazards and

risk assessment

4.1 General

The hazards, hazardous situations and events identified by risk assessment as significant for CCM's and

which require action to eliminate or reduce the risk are listed in Annex F and in Clause 5.

In general, risks and associated hazards are production and plant related. Due to the design variety of

CCM's, an individual risk assessment shall be carried out in any case, considering the special features of

the CCM in question and considering the safety requirements specified in this document. The relevant

required Performance Levels (PL ) or Safety Integrity Levels (SILr) for control devices covering safety

r

functions shall be selected according to this individual risk assessment.

Machinery shall comply with the safety requirements and/or protective/risk reduction measures of

Clause 5. In addition, the machine shall be designed according to the principles of EN ISO 12100:2010 for

relevant but not significant hazards which are not dealt with by this document.

If combinations of machines and/or machine functions described at different parts of the standard are

located in the same danger zone, the different measures shall be considered together.

4.2 Interfaces to the linked/integrated equipment

The individual risk assessment shall include the interfaces to the linked/integrated equipment (see also

5.2.3). For this equipment respective instructions and safety measures including control requirements

for interfaces shall be given in the information for use.

5 Safety r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...