EN 676:2020

(Main)Forced draught burners for gaseous fuels

Forced draught burners for gaseous fuels

This European Standard specifies the terminology, the general requirements for the construction and operation of forced draught gas burners and also the provision of control and safety devices, and the test procedure for these burners.

This European Standard is applicable to:

- automatic gas burners with a combustion air fan (hereinafter called "burners") and gas line components, intended for use in appliances of different types, and that are operated with gaseous fuels;

- pre mixed burners and nozzle mixed burners;

- single burners with a single combustion chamber;

- single fuel and dual fuel burners when operating only on gas;

- the gas function of dual-fuel burners designed to operate simultaneously on gaseous and liquid fuels, which, for the latter, the requirements of EN 267 also apply.

This European Standard deals with all significant machine hazards, hazardous situations and events relevant to burners, when they are used as intended and under conditions of misuse which are reasonably foreseeable, see Annex J.

This European Standard specifies the requirements to ensure the safety during commissioning, start-up, operation, shut-down and maintenance.

This European Standard does not apply to burners specifically designed for use in industrial processes carried out on industrial premises.

This European Standard deals also with the additional requirements for the burners in the scope with pressurised parts and /or firing pressurised bodies, see Annex K.

This European Standard deals also with forced draught burners intended to be used with biogenous gaseous fuels, mixtures with line-conveyed gas and special gaseous fuels.

This European Standard deals also with burners and their equipment to increase the total appliance efficiency, see Annex M.

Gebläsebrenner für gasförmige Brennstoffe

Dieses Dokument legt die Terminologie für und die allgemeinen Anforderungen an die Konstruktion und den Betrieb von Gasgebläsebrennern und die Ausrüstung mit Steuerungs und Sicherheitseinrichtungen fest sowie das Prüfverfahren für diese Brenner.

Dieses Dokument ist anwendbar auf:

- automatische Gasbrenner mit einem Verbrennungsluftgebläse (im Folgenden als „Brenner“ bezeichnet) und gasseitige Ausrüstungsteile, die für die Verwendung in unterschiedlichen Gerätetypen vorgesehen sind und mit gasförmigen Brennstoffen betrieben werden;

- Vormischbrenner und Düsenbrenner;

- Einzelbrenner mit einem einzigen Feuerraum;

- Brenner und Zweistoffbrenner für den ausschließlichen Betrieb mit Gas;

- den Gasbetrieb von Zweistoffbrennern, die für den gleichzeitigen Betrieb mit gasförmigen und flüssigen Brennstoffen konstruiert sind, wobei in letzterem Fall auch die Anforderungen von EN 267 gelten.

Dieses Dokument behandelt sämtliche signifikanten maschinenbezogenen Gefährdungen, Gefährdungs-situationen und Gefährdungsereignisse im Hinblick auf Brenner, wenn diese zweckentsprechend sowie unter zweckentfremdeten Bedingungen verwendet werden, die vernünftigerweise vorhersehbar sind, siehe Anhang J.

Dieses Dokument legt die Anforderungen fest, die für die Sicherheit während Inbetriebnahme, Anlauf, Betrieb und Abschaltung sowie Wartung erforderlich sind.

Dieses Dokument gilt nicht für Brenner, die speziell für den Einsatz in industriellen Prozessen ausgelegt sind, die in industriellen Anlagen erfolgen.

Dieses Dokument behandelt auch die zusätzlichen Anforderungen für Brenner mit druck¬beaufschlagten Teilen und/oder die Druckgeräte befeuern, siehe Anhang K.

Dieses Dokument behandelt ebenfalls Gebläsebrenner, die für biogene gasförmige Brennstoffe, Mischungen mit leitungsgeführtem Gas und spezielle gasförmige Brennstoffe bestimmt sind.

Dieses Dokument behandelt auch Brenner und deren Ausrüstung für die Steigerung der Gesamt Geräteeffizienz der Anlage; siehe Anhang M.

Brûleurs à air soufflé pour combustibles gazeux

Le présent document définit la terminologie, les exigences générales concernant la construction et le fonctionnement des brûleurs à gaz à air soufflé, leur équipement avec des dispositifs de régulation et de sécurité et les méthodes d’essais pour ces brûleurs.

Le présent document est applicable :

- aux brûleurs automatiques à gaz avec ventilateur d’air de combustion (dénommés ci-après « brûleurs ») et aux composants de la ligne gaz, destinés à être utilisés sur des appareils de différents types et qui fonctionnent avec des combustibles gazeux ;

- aux brûleurs à pré-mélange et aux brûleurs à mélange au nez ;

- aux brûleurs individuels alimentant une seule chambre de combustion ;

- aux brûleurs mono et bicombustibles pour leur fonctionnement exclusif au gaz ;

- au fonctionnement au gaz des brûleurs bicombustibles conçus pour fonctionner simultanément aux combustibles gazeux et liquides, les exigences de l'EN 267 s'appliquant également aux combustibles liquides.

Le présent document traite des risques significatifs des machines, des situations et événements dangereux liés aux brûleurs lorsqu’ils sont utilisés comme prévu et dans des conditions anormales raisonnablement prévisibles, voir l’Annexe J.

Le présent document spécifie les exigences à satisfaire afin d’assurer la sécurité lors de la réception, de la mise en route, de l’utilisation, de l’arrêt et de l’entretien.

Le présent document ne s’applique pas aux brûleurs spécialement conçus pour une utilisation dans un processus industriel réalisé sur un site industriel.

Le présent document traite également des exigences complémentaires s’appliquant aux brûleurs avec parties sous pression et/ou installés sur des appareils sous pression, voir l’Annexe K.

Le présent document traite également des brûleurs à air soufflé destinés à être utilisés avec des biogaz, des mélanges contenant des gaz distribués et des combustibles gazeux spéciaux.

Le présent document traite également des brûleurs équipés pour augmenter le rendement global de l'appareil, voir l'Annexe M.

Plinski ventilatorski gorilniki

Ta evropski standard določa terminologijo, splošne zahteve za izdelavo in delovanje plinskih ventilatorskih gorilnikov kot tudi zagotavljanje nadzornih in varnostnih naprav ter preskusni postopek za te gorilnike. Ta evropski standard se uporablja za: – samodejne plinske gorilnike z ventilatorjem za zgorevalni zrak (v nadaljevanju: »gorilniki«) in komponente plinovodov, ki so namenjene za uporabo v napravah različnih vrst ter delujejo na plinasta goriva; – gorilnike na predhodno mešanico in gorilnike na mešanico, pripravljeno v šobi; – gorilnike na eno vrsto goriva z eno zgorevalno komoro; – gorilnike na eno vrsto goriva in gorilnike na dve vrsti goriva, kadar delujejo samo na plin; – plinsko delovanje gorilnikov na dve vrsti goriva, zasnovanih za hkratno delovanje na plinska in tekoča goriva, pri čemer se za slednja uporabljajo tudi zahteve iz standarda EN 267. Ta evropski standard obravnava vsa večja tveganja, nevarne situacije in dogodke v zvezi z gorilniki, kadar se uporabljajo v skladu s predvidenim namenom in pod pogoji razumno predvidljive nepravilne uporabe (glej dodatek J).

Ta evropski standard določa zahteve za zagotavljanje varnosti med pripravo na zagon, zagonom, delovanjem, zaustavitvijo delovanja in vzdrževanjem. Ta evropski standard se ne uporablja za gorilnike, ki so posebej namenjeni za industrijsko uporabo v industrijskih prostorih. Ta evropski standard obravnava tudi dodatne zahteve za gorilnike v zvezi z deli pod tlakom in/ali kurilnimi napravami pod tlakom (glej dodatek K). Ta evropski standard poleg tega obravnava gorilnike na prisilni vlek, namenjene za uporabo z biogenimi plinastimi gorivi, mešanicami plinov, ki se dovajajo prek plinovoda, ter posebnimi plinastimi gorivi. Ta evropski standard obravnava tudi gorilnike, opremljene za povečanje skupne učinkovitosti naprav (glej dodatek M).

General Information

- Status

- Published

- Publication Date

- 21-Jan-2020

- Withdrawal Date

- 30-Jan-2023

- Technical Committee

- CEN/TC 131 - Gas burners using fans

- Drafting Committee

- CEN/TC 131 - Gas burners using fans

- Current Stage

- 9092 - Decision on results of review/2YR ENQ - revise - Review Enquiry

- Start Date

- 07-Oct-2025

- Completion Date

- 11-Feb-2026

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 29-Jan-2020

- Effective Date

- 29-Jan-2020

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 676:2020 - Forced draught burners for gaseous fuels is the European standard that defines terminology, construction and operational requirements, safety provisions, control and safety devices, and test procedures for forced draught gas burners. It applies to automatic gas burners equipped with a combustion air fan (forced draught), including pre-mixed and nozzle-mixed designs, single burners with a single combustion chamber, and single- or dual-fuel burners when operating on gas. The standard addresses safe commissioning, start-up, operation, shut-down and maintenance, and includes provisions for burners using biogenous and special gaseous fuels.

Key topics and technical requirements

- Scope and applicability: Covers automatic forced draught burners intended for appliances (not burners designed specifically for industrial process plants on industrial premises).

- Terminology and definitions: Comprehensive glossary covering gas types, burner operation modes, test rig and combustion chamber definitions.

- Constructional requirements: Design, materials, mounting, accessibility for maintenance, soundness and connections.

- Equipment requirements: Motors, fans, adjustable air dampers, gas line components, electrical safety and EMC aspects.

- Control and safety devices: Requirements for sequencing, ignition, flame detection, safety times and lock-out/reset behavior.

- Functional and operational tests: Test procedures for start-up, pre‑purge, ignition, heat input determination, flame stability and limits of safe operation.

- Combustion emissions and measurement: Methods and conversions for CO and NOx measurement (Annex A) and test gas specifications (Annex C).

- Special provisions: Additional requirements for pressurised parts and firing pressurised bodies (Annex K), use with biogenous gases, and means to improve appliance efficiency (Annex M).

- Marking, documentation and packaging: Data plate, installation/maintenance instructions and labelling requirements.

Practical applications and who uses this standard

EN 676:2020 is used by:

- Burner and boiler manufacturers to design and certify forced draught gas burners compliant with European safety and performance expectations.

- Test laboratories and certification bodies to perform standardized functional, combustion and safety tests.

- HVAC and mechanical engineers, installers and maintenance technicians for correct installation, commissioning and safe maintenance practices.

- Regulatory authorities and compliance teams verifying conformity with safety, emissions and labelling requirements.

- Product designers working with biogas or mixed gaseous fuels who need guidance on safe burner operation and testing.

Related standards

- EN 267 (referenced for dual-fuel burners when operating on liquid fuels)

- EN 676:2020 supersedes earlier editions (e.g., EN 676:2003+A2:2008)

Keywords: forced draught burners, gaseous fuels, EN 676:2020, gas burners standard, burner safety, combustion emissions, test procedures, premixed burners, nozzle mixed burners.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

EN 676:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Forced draught burners for gaseous fuels". This standard covers: This European Standard specifies the terminology, the general requirements for the construction and operation of forced draught gas burners and also the provision of control and safety devices, and the test procedure for these burners. This European Standard is applicable to: - automatic gas burners with a combustion air fan (hereinafter called "burners") and gas line components, intended for use in appliances of different types, and that are operated with gaseous fuels; - pre mixed burners and nozzle mixed burners; - single burners with a single combustion chamber; - single fuel and dual fuel burners when operating only on gas; - the gas function of dual-fuel burners designed to operate simultaneously on gaseous and liquid fuels, which, for the latter, the requirements of EN 267 also apply. This European Standard deals with all significant machine hazards, hazardous situations and events relevant to burners, when they are used as intended and under conditions of misuse which are reasonably foreseeable, see Annex J. This European Standard specifies the requirements to ensure the safety during commissioning, start-up, operation, shut-down and maintenance. This European Standard does not apply to burners specifically designed for use in industrial processes carried out on industrial premises. This European Standard deals also with the additional requirements for the burners in the scope with pressurised parts and /or firing pressurised bodies, see Annex K. This European Standard deals also with forced draught burners intended to be used with biogenous gaseous fuels, mixtures with line-conveyed gas and special gaseous fuels. This European Standard deals also with burners and their equipment to increase the total appliance efficiency, see Annex M.

This European Standard specifies the terminology, the general requirements for the construction and operation of forced draught gas burners and also the provision of control and safety devices, and the test procedure for these burners. This European Standard is applicable to: - automatic gas burners with a combustion air fan (hereinafter called "burners") and gas line components, intended for use in appliances of different types, and that are operated with gaseous fuels; - pre mixed burners and nozzle mixed burners; - single burners with a single combustion chamber; - single fuel and dual fuel burners when operating only on gas; - the gas function of dual-fuel burners designed to operate simultaneously on gaseous and liquid fuels, which, for the latter, the requirements of EN 267 also apply. This European Standard deals with all significant machine hazards, hazardous situations and events relevant to burners, when they are used as intended and under conditions of misuse which are reasonably foreseeable, see Annex J. This European Standard specifies the requirements to ensure the safety during commissioning, start-up, operation, shut-down and maintenance. This European Standard does not apply to burners specifically designed for use in industrial processes carried out on industrial premises. This European Standard deals also with the additional requirements for the burners in the scope with pressurised parts and /or firing pressurised bodies, see Annex K. This European Standard deals also with forced draught burners intended to be used with biogenous gaseous fuels, mixtures with line-conveyed gas and special gaseous fuels. This European Standard deals also with burners and their equipment to increase the total appliance efficiency, see Annex M.

EN 676:2020 is classified under the following ICS (International Classification for Standards) categories: 27.060.20 - Gas fuel burners. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 676:2020 has the following relationships with other standards: It is inter standard links to EN 676:2003+A2:2008, EN 676:2003+A2:2008/AC:2008, EN 60529:1991/A1:2000, EN 50156-1:2015, EN 61310-1:2008, EN 60529:1991/A2:2013, EN 60204-1:2006, EN 60730-1:2011, EN 60335-2-102:2016, EN 62061:2005, EN 60529:1991, EN ISO 15614-11:2002, EN 13611:2015, EN ISO 13849-1:2015, EN 1092-1:2007+A1:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 676:2020 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 2009/142/EC, 2014/68/EU, 2016/426, 813/2013, 97/23/EC; Standardization Mandates: M/071, M/396, M/535, M/BC/CEN/89/6. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 676:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2020

Nadomešča:

SIST EN 676:2004+A2:2008

SIST EN 676:2004+A2:2008/AC:2009

Plinski ventilatorski gorilniki

Forced draught burners for gaseous fuels

Gebläsebrenner für gasförmige Brennstoffe

Brûleurs à air soufflé pour combustibles gazeux

Ta slovenski standard je istoveten z: EN 676:2020

ICS:

27.060.20 Plinski gorilniki Gas fuel burners

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 676

EUROPEAN STANDARD

NORME EUROPÉENNE

January 2020

EUROPÄISCHE NORM

ICS 27.060.20 Supersedes EN 676:2003+A2:2008

English Version

Forced draught burners for gaseous fuels

Brûleurs à air soufflé pour combustibles gazeux Gebläsebrenner für gasförmige Brennstoffe

This European Standard was approved by CEN on 9 October 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 676:2020 E

worldwide for CEN national Members.

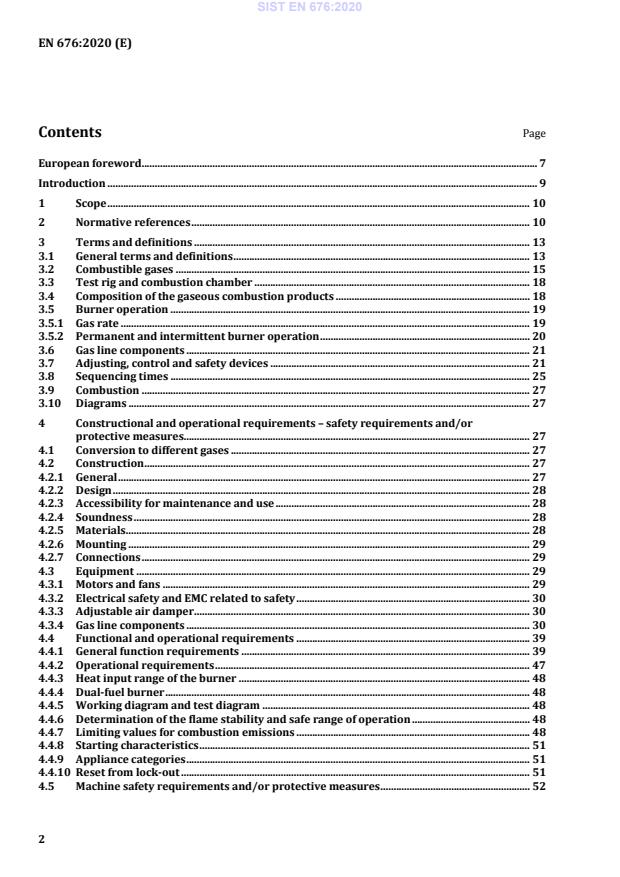

Contents Page

European foreword . 7

Introduction . 9

1 Scope . 10

2 Normative references . 10

3 Terms and definitions . 13

3.1 General terms and definitions . 13

3.2 Combustible gases . 15

3.3 Test rig and combustion chamber . 18

3.4 Composition of the gaseous combustion products . 18

3.5 Burner operation . 19

3.5.1 Gas rate . 19

3.5.2 Permanent and intermittent burner operation . 20

3.6 Gas line components . 21

3.7 Adjusting, control and safety devices . 21

3.8 Sequencing times . 25

3.9 Combustion . 27

3.10 Diagrams . 27

4 Constructional and operational requirements – safety requirements and/or

protective measures. 27

4.1 Conversion to different gases . 27

4.2 Construction . 27

4.2.1 General . 27

4.2.2 Design . 28

4.2.3 Accessibility for maintenance and use . 28

4.2.4 Soundness . 28

4.2.5 Materials . 28

4.2.6 Mounting . 29

4.2.7 Connections . 29

4.3 Equipment . 29

4.3.1 Motors and fans . 29

4.3.2 Electrical safety and EMC related to safety . 30

4.3.3 Adjustable air damper . 30

4.3.4 Gas line components . 30

4.4 Functional and operational requirements . 39

4.4.1 General function requirements . 39

4.4.2 Operational requirements . 47

4.4.3 Heat input range of the burner . 48

4.4.4 Dual-fuel burner . 48

4.4.5 Working diagram and test diagram . 48

4.4.6 Determination of the flame stability and safe range of operation . 48

4.4.7 Limiting values for combustion emissions . 48

4.4.8 Starting characteristics . 51

4.4.9 Appliance categories . 51

4.4.10 Reset from lock-out . 51

4.5 Machine safety requirements and/or protective measures . 52

5 Test methods . 52

5.1 General . 52

5.1.1 Test gases for forced draught burners . 52

5.1.2 Test pressures . 52

5.1.3 Test rig . 53

5.1.4 Types of test . 62

5.2 Functional tests . 62

5.2.1 General . 62

5.2.2 Start-up . 62

5.2.3 Pre-purge . 62

5.2.4 Start-up heat input . 62

5.2.5 Ignition . 62

5.2.6 Safety times . 63

5.3 Operation . 63

5.3.1 External soundness . 63

5.3.2 Resistance of the burner to over-heating . 64

5.3.3 Temperature of the control and safety devices . 64

5.3.4 Ignition — flame stability . 64

5.3.5 Operation — flame stability . 66

5.3.6 Auxiliary electricity consumption (ErP) . 67

5.3.7 Sound power level L (ErP) . 67

WA

5.4 Tests to be carried out on the working and test diagrams . 67

5.4.1 Tests at point 1 . 67

5.4.2 Tests at point Hp1 . 68

5.4.3 Tests at points 2, 5 (single, multi-stage and modulating burners) and 6 (multi-stage

and modulating burners) . 68

5.4.4 Tests at points Hp2 (single, multi-stage and modulating burners) and Hp6 (multi-

stage and modulating burners) . 69

5.4.5 Tests at point 3 . 69

5.4.6 Tests at point 4 . 69

5.4.7 Tests at first stage points or minimum heat input. 70

5.4.8 Summary . 70

5.5 Combustion . 71

5.6 Start-up . 72

5.7 Obtaining the heat input . 72

5.7.1 Determination of heat input at reference conditions . 72

5.7.2 Determination of heat input at ambient conditions . 74

5.8 Electrical safety . 74

5.9 Verification of safety and /or protective measures . 75

6 Marking, labelling and packaging . 75

6.1 General . 75

6.2 Data plate . 75

6.3 Other marking . 76

6.4 Instructions for installation, adjustment, maintenance and operation. 76

6.5 Packaging . 78

6.6 Marking on the packaging . 78

Annex A (normative) Determination of combustion characteristics — Carbon monoxide

and nitrogen oxides, conversion and corrections. 79

A.1 CO content (Q ), calculation from ml/m into mg/kWh . 79

CO

A.2 NO content (Q ), calculation from ml/m into mg/kWh . 80

x NO

X

A.3 Correction for the influence of combustion air temperature and humidity on NO

x

emissions Q . 81

NOx

A.4 NO mean value for evaluating the NO classes . 81

x x

A.5 CO content f . 82

2 CO

3 3

A.6 Other conversion factors for emissions, calculated from ml/m into mg/m at 3 % O

reference flue gas conditions . 82

Annex B (informative) Examples of control box sequencing . 84

Annex C (informative) Test gases . 85

C.1 General . 85

C.2 Conditions for preparation of the test gases . 85

C.3 Practical application of the test gases . 86

Annex D (informative) Gas connections conditions in common use in the various countries . 89

Annex E (informative) Tests . 91

E.1 Supplementary testing . 91

E.2 Drawing review . 91

E.3 Individual test and inspection . 91

E.4 Test report . 92

Annex F (informative) Use of alternative gas lines and test documentation . 93

F.1 Use of alternative gas lines . 93

F.2 Test documentation . 93

Annex G (informative) Void . 94

Annex H (informative) Check of the air proving device . 95

Annex I (informative) Additional recommendations for specific applications . 96

I.1 General . 96

I.2 Pre-heating of the combustion air . 96

I.3 Continuous working of the air ventilator . 96

I.4 Variable excess of combustion air . 96

I.5 Burner with start gas flame . 96

I.6 Air filtering . 97

Annex J (normative) Machine Directive (2006/42/CE) related hazards – safety

)

requirements and/or protective measures . 98

J.1 General . 98

J.2 List of significant hazards . 98

J.3 Safety requirements and /or protective measures . 98

J.4 Verification of machine safety requirements and/or protective measures . 102

J.5 Information for use . 102

Annex K (normative) Additional requirements for burners with pressurized parts and

burners firing pressurized bodies as defined in Pressure Equipment Directive (PED)

2014/68/EU . 103

K.1 General . 103

K.2 Pressurized parts . 103

K.3 Electrical safety and gas line components . 104

K.4 Gas pressure regulator . 104

K.5 High gas pressure over load protection device. 104

K.6 Automatic safety shut-off valve . 105

K.7 Air proving device . 105

K.8 Automatic burner control system . 105

K.9 Means for draining and venting. 105

K.10 General functions requirements . 106

K.11 External safety limiter . 106

K.12 Design according to Annex L in conjunction with EN 60204-1. 107

K.13 Consideration: safety life cycle . 108

K.14 Tests of pressurized parts . 109

K.15 Other marking . 110

K.16 Instructions for installation, adjustment, maintenance and operation. 110

Annex L (normative) Electrical requirements – modifications to EN 60204-1:2006 . 112

L.1 Scope. 112

L.2 Normative references . 112

L.3 Terms and definitions . 112

L.4 General requirements . 113

L.5 Incoming supply conductor terminations and devices for disconnecting and

switching off . 116

L.6 Protection against electric shock . 116

L.7 Protection of equipment . 116

L.8 Equipotential bonding . 116

L.9 Control circuits and control functions . 116

L.10 Operator interface and machine-mounted control devices . 126

L.11 Electrical equipment (Controlgear: location, mounting, and enclosures) . 126

L.12 Conductors and cables . 127

L.13 Wiring practices . 127

L.14 Electric motors and associated equipment . 127

L.15 Accessories and lighting . 127

L.16 Marking, warning signs and reference designations . 127

L.17 Technical documentation . 127

L.18 Verification . 128

Annex M (informative) Burner equipped to increase the efficiency . 129

Annex N (informative) Electrical interfaces for burners . 130

Annex O (informative) Environmental checklist EN 676 . 135

Annex P (informative) Guide for the applicability of the different standards on electrical

safety . 137

Annex Q (informative) Verification procedures for market surveillance purposes (ErP) . 139

Q.1 General . 139

Q.2 Minimization of the influence of the measurement procedure. 139

Q.3 Verification of the declared parameters . 139

Annex R (informative) Impact of the variations of the gas quality in EU gas grids to gas

burners . 140

Annex S (informative) A-Deviations . 142

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2009/142/EC (GAD) aimed to be covered . 143

Annex ZB (informative) Relationship between this European Standard and the ecodesign

requirements of Commission Regulation (EU) No 813/2013 aimed to be covered . 146

Bibliography . 147

European foreword

This document (EN 676:2020) has been prepared by Technical Committee CEN/TC 131 “Gas burners

using fans”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by July 2020 and conflicting national standards shall be

withdrawn at the latest by January 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document will supersede EN 676:2003+A2:2008.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annexes ZA and ZB, which are an integral part

of this document.

Compared to EN 676:2003 and its amendments A1 and A2 the following fundamental changes have

been made:

a) based on ISO 22967 where different to EN 676 such as:

1) update of definitions;

2) test rig < 2,4 MW and > 2,4 MW;

3) electrical interfaces for burners;

b) modification:

4) replacement of EN 50156-1 by EN 60204-1 to include international available requirements for

the electrical safety of machines; see Annex L with editorial allocation in Annex K;

5) Annex J is adapted to the new EN ISO 12100 which is substituting EN 292 which is currently

referenced to in Table J.1;

6) normative formulation of Annex A 'Combustion characteristics';

c) new functions / requirements:

7) remote reset;

8) environmental aspects (environmental checklist);

9) increase of burner efficiency;

10) terminology for burner load control;

11) implementing new requirements to comply with the 2013/813 (ErP);

12) requiring of a risk assessment as required by EU Directives 2014/35/EU for LVD and EU

Regulation 2016/426 for GAR.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

Introduction

This document is primarily intended for forced draught gas burners having a combustion air fan,

operated with gaseous fuels, and intended to be marketed as a complete assembly.

EN 437 sets out a system of classification of appliances into categories defined according to the gases

and pressures for which they are designed.

Such a system of classification, when applied to forced draught burners, can lead to difficulties in

defining the precise category to which a particular burner should be allocated. For example many

burners are designed to operate on a wide range of fuel gases with little or no modification other than

adjustment of air supply.

The technical committee responsible for the standard decided that the following appliance categories

for forced draught burners should apply:

— single categories: I for natural gas and I for liquefied petroleum gas;

2R 3R

— dual category: II for natural and liquefied petroleum gas.

2R /3R

All the burners of this standard marked with these categories are commissioned on site and the

measured values are recorded in a commissioning report.

However it should be noted that the Gas Appliance Directive requires the specification of the type of gas

and the supply pressure used as well as the burner category.

Forced draught gas burners according to this document are often used in industrial applications. The

safety principles are the same as for forced draught gas burners used for household/commercial

applications. Industrial forced draught gas burners however should operate safely in their industrial

environment and the risks involved can differ from those for household applications. These industrial

forced draught gas burners can be characterized by the ability to withstand industrial environmental

influences, like moisture, high temperature, electrical and magnetic phenomena, vibrations, etc.

Principal requirements for installation and construction of gas burners used in industrial thermal

processes are covered by EN 746-2 Industrial thermoprocessing equipment — Safety requirements for

combustion and fuel handling systems.

Special requirements for forced draught burners for industrial premises will carry a prefix, “Industrial

application”.

Further information and application limitation for EN 676 forced draught burners which are used for

industrial application are given in informative Annex I.

This document is a type C standard as stated in EN ISO 12100.

The machinery concerned and the extent to which hazards, hazardous situations and hazardous events

are covered are indicated in the scope of this document.

When provisions of this type C standard are different from those which are stated in type A or B

standards, the provisions of this type C standard take precedence over the provisions of the other

standard, for machines that have been designed and built according to the provisions of this type C

standard.

1 Scope

This document specifies the terminology, the general requirements for the construction and operation

of forced draught gas burners and also the provision of control and safety devices, and the test

procedure for these burners.

This document is applicable to:

— automatic gas burners with a combustion air fan (hereinafter called “burners”) and gas line

components, intended for use in appliances of different types, and that are operated with gaseous

fuels;

— pre-mixed burners and nozzle mixed burners;

— single burners with a single combustion chamber;

— single-fuel and dual-fuel burners when operating only on gas;

— the gas function of dual-fuel burners designed to operate simultaneously on gaseous and liquid

fuels, which, for the latter, the requirements of EN 267 also apply.

This document deals with all significant machine hazards, hazardous situations and events relevant to

burners, when they are used as intended and under conditions of misuse which are reasonably

foreseeable, see Annex J.

This document specifies the requirements to ensure the safety during commissioning, start-up,

operation, shut-down and maintenance.

This document does not apply to burners specifically designed for use in industrial processes carried

out on industrial premises.

This document deals also with the additional requirements for the burners in the scope with

pressurized parts and /or firing pressurized bodies, see Annex K.

This document deals also with forced draught burners intended to be used with biogenous gaseous

fuels, mixtures with line-conveyed gas and special gaseous fuels.

This document deals also with burners and their equipment to increase the total appliance efficiency,

see Annex M.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 88-1:2011+A1:2016, Pressure regulators and associated safety devices for gas appliances — Part 1:

Pressure regulators for inlet pressures up to and including 50 kPa

EN 88-2:2007, Pressure regulators and associated safety devices for gas appliances — Part 2: Pressure

regulators for inlet pressures above 500 mbar up to and including 5 bar

EN 126:2012, Multifunctional controls for gas burning appliances

EN 161:2011+A3:2013, Automatic shut-off valves for gas burners and gas appliances

EN 267, Forced draught burners for liquid fuels

EN 298:2012, Automatic burner control systems for burners and appliances burning gaseous or liquid

fuels

EN 334:2005+A1:2009, Gas pressure regulators for inlet pressures up to 100 bar

EN ISO 14120:2015, Safety of machinery — Guards — General requirements for the design and

construction of fixed and movable guards (ISO 14120:2015)

EN 1092-1:2007+A1:2013, Flanges and their joints — Circular flanges for pipes, valves, fittings and

accessories, PN designated — Part 1: Steel flanges

EN 1092-2:1997, Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, PN

designated — Part 2: Cast iron flanges

EN 1092-3:2003, Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, PN

designated — Part 3: Copper alloy flanges

EN 1643:2014, Safety and control devices for gas burners and gas burning appliances — Valve proving

systems for automatic shut-off valves

EN 1854:2010, Pressure sensing devices for gas burners and gas burning appliances

EN 10204:2004, Metallic products — Types of inspection documents

EN 10216-1:2013, Seamless steel tubes for pressure purposes — Technical delivery conditions — Part 1:

Non-alloy steel tubes with specified room temperature properties

EN 10217-1:2002+A1:2005, Welded steel tubes for pressure purposes — Technical delivery conditions —

Part 1: Non-alloy steel tubes with specified room temperature properties

EN 10220:2002, Seamless and welded steel tubes — Dimensions and masses per unit length

EN 12067-2:2004, Gas/air ratio controls for gas burners and gas burning appliances — Part 2: Electronic

types

EN 12516-3:2002, Valves — Shell design strength — Part 3: Experimental method

EN 13611:2015, Safety and control devices for burners and appliances burning gaseous and/or liquid fuels

— General requirements

EN 15036-1:2006, Heating boilers — Test regulations for airborne noise emissions from heat generators -

Part 1: Airborne noise emissions from heat generators

EN 50156-1:2015, Electrical equipment for furnaces and ancillary equipment — Part 1: Requirements for

application design and installation

EN 60204-1:2006, Safety of machinery — Electrical equipment of machines — Part 1: General

requirements (IEC 60204-1:2005, modified))

EN 60335-2-102:2016, Household and similar electrical appliances — Safety — Part 2-102: Particular

requirements for gas, oil and solid-fuel burning appliances having electrical connections

EN 60529:1991, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989)

EN 60529:1991/A1:2000, Degrees of protection provided by enclosures (IP Code) (IEC 60529/A1:1999)

EN 60529:1991/A2:2013, Degrees of protection provided by enclosures (IP Code) (IEC 60529/A2:2013)

EN 60730-1:2011, Automatic electrical controls for household and similar use — Part 1: General

requirements

EN 61310-1, Safety of machinery — Indication, marking and actuation — Part 1: Requirements for visual,

acoustic and tactile signals

EN 62061:2011, Safety of machinery — Functional safety of safety-related electrical, electronic and

programmable electronic control systems

EN ISO 228-1:2003, Pipe threads where pressure-tight joints are not made on the threads — Part 1:

Dimensions, tolerances and designation (ISO 228-1:2000)

EN ISO 3166-1, Codes for the representation of names of countries and their subdivisions — Part 1:

Country codes (ISO 3166-1:2013)

EN ISO 3183:2012, Petroleum and natural gas industries — Steel pipe for pipeline transportation systems

(ISO 3183:2012)

EN ISO 4871, Acoustics — Declaration and verification of noise emission values of machinery and

equipment (ISO 4871:1996)

EN ISO 9606-1:2013, Qualification testing of welders — Fusion welding — Part 1: Steels (ISO 9606-1:2012

including Cor 1:2012)

EN ISO 9606-2:2004, Qualification test of welders — Fusion welding — Part 2: Aluminium and aluminium

alloys (ISO 9606-2:2004)

EN ISO 9606-3, Approval testing of welders — Fusion welding — Part 3: Copper and copper alloys (ISO

9606-3:1999)

EN ISO 9606-4, Approval testing of welders — Fusion welding — Part 4: Nickel and nickel alloys (ISO

9606-4:1999)

EN ISO 9606-5:2000, Approval testing of welders — Fusion welding — Part 5: Titanium and titanium

alloys, zirconium and zirconium alloys (ISO 9606-5:2000)

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction (ISO 12100:2010)

EN ISO 13849-1:2015, Safety of machinery — Safety-related parts of control systems — Part 1: General

principles for design (ISO 13849-1:2015)

EN ISO 13857, Safety of machinery — Safety distances to prevent hazard zones being reached by upper

and lower limbs (ISO 13857:2008)

EN ISO 14119:2013, Safety of machinery — Interlocking devices associated with guards — Principles for

design and selection (ISO 14119:2013)

EN ISO 15609-1:2004, Specification and qualification of welding procedures for metallic materials -

Welding procedure specification — Part 1: Arc welding (ISO 15609-1:2004)

EN ISO 15609-2:2001, Specification and qualification of welding procedures for metallic materials —

Welding procedure specification — Part 2: Gas welding (ISO 15609-2:2001)

EN ISO 15609-3:2004, Specification and qualification of welding procedures for metallic materials —

Welding procedures specification — Part 3: Electron beam welding (ISO 15609-3:2004)

EN ISO 15609-4:2009, Specification and qualification of welding procedures for metallic materials —

Welding procedure specification — Part 4: Laser beam welding (ISO 15609-4:2009)

EN ISO 15609-5:2011, Specification and qualification of welding procedures for metallic materi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...