EN 1090-3:2008

(Main)Execution of steel structures and aluminium structures - Part 3: Technical requirements for aluminium structures

Execution of steel structures and aluminium structures - Part 3: Technical requirements for aluminium structures

This European Standard specifies requirements for the execution of aluminium structural components and structures made from:

a) rolled sheet, strip and plate;

b) extrusions;

c) cold drawn rod, bar and tube;

d) forgings;

e) castings.

NOTE 1 The execution of structural components is referred to as manufacturing, in accordance with EN 1090-1.

This European Standard specifies requirements independent of the type and shape of the aluminium structure, and this European Standard is applicable to structures under predominantly static loads as well as structures subject to fatigue. It specifies requirements related to the execution classes that are linked with consequence classes.

NOTE 2 Consequence classes are defined in EN 1990.

NOTE 3 Recommendations for selection of execution class in relation to consequence class are given in EN 1999-1-1.

This European Standard covers components made of constituent products with thickness not less than 0,6 mm for welded components not less than 1,5 mm.

This European Standard applies to structures designed according to the relevant parts of EN 1999. If this European Standard is used for structures designed according to other design rules or used for other alloys and tempers not covered by EN 1999, a judgement of the reliability elements in these design rules should be made.

This European Standard specifies requirements for surface preparation prior to application of a protective treatment, and gives guidelines for application for such treatment in an informative annex.

This European Standard gives options for specifying requirements to match project specific requirements.

This European Standard is also applicable to temporary aluminium structures.

Ausführung von Stahltragwerken und Aluminiumtragwerken - Teil 3: Technische Regeln für die Ausführung von Aluminiumtragwerken

Diese Europäische Norm legt Anforderungen bezüglich der Ausführung von tragenden Bauteilen aus Aluminium sowie von Aluminiumtragwerken fest, die aus

a) gewalzten Blechen, Bändern und Platten,

b) Strangpressprofilen,

c) kalt gezogenen Stangen und Rohren,

d) Schmiedeteilen,

e) Gussteilen

hergestellt werden.

ANMERKUNG 1 In Übereinstimmung mit EN 1090-1 wird die Ausführung von Tragwerksteilen als Herstellung bezeichnet.

Diese Europäische Norm legt Anforderungen fest, die unabhängig von Art und Form des Aluminiumtrag¬werks sind. Sie gilt sowohl für Tragwerke unter vorwiegend ruhender Belastung als auch für ermüdungsbeanspruchte Tragwerke. Des Weiteren legt diese Europäische Norm die Anforderungen in Bezug auf die Ausführungsklassen fest, welche ihrerseits von Schadensfolgeklassen abhängig sind.

ANMERKUNG 2 Die Schadensfolgeklassen sind in EN 1990 festgelegt.

ANMERKUNG 3 Empfehlungen für die Wahl der Ausführungsklasse in Verbindung mit der Schadensfolgeklasse siehe EN 1999-1-1.

Diese Europäische Norm gilt für Bauteile, die aus Konstruktionsmaterialien mit Dicken nicht unter 0,6 mm, beziehungsweise geschweißt mit Dicken nicht unter 1,5 mm hergestellt werden.

Diese Europäische Norm gilt für Tragwerke, die nach den maßgebenden Teilen von EN 1999 bemessen wurden. Sofern sie auf Tragwerke, die auf anderen Bemessungsregeln basieren, oder auf andere Legierungen und Werkstoffzustände als die in EN 1999 behandelten angewendet wird, sollten die sicherheitsrelevanten Elemente der betreffenden Bemessungsregeln beurteilt werden.

Diese Europäische Norm legt Anforderungen an die Vorbehandlung von Oberflächen für das Aufbringen von Schutzbeschichtungen fest und enthält Hinweise für deren Ausführung in einem informativen Anhang.

Diese Europäische Norm lässt Wahlmöglichkeiten offen, um Spezifikationen speziellen Projektgegebenheiten anpassen zu können.

Diese Europäische Norm gilt auch für temporäre Bauten aus Aluminium (fliegende Bauten).

Exécution des structures en acier et des structures en aluminium - Partie 3 : Exigences techniques pour l'exécution des structures en aluminium

La présente Norme européenne spécifie les exigences relatives à l'exécution des structures et éléments de structure en aluminium fabriqués à partir de :

a) plaques, bandes et tôles épaisses laminées,

b) produits filés,

c) barres et tubes étirés à froid,

d) pièces forgées,

e) pièces moulées.

NOTE 1 L'exécution des éléments de structure est appelée fabrication, conformément à l'EN 1090-1.

La présente Norme européenne spécifie des exigences indépendamment du type et de la forme de la structure en aluminium, et la présente Norme européenne est applicable aux structures soumises à des charges essentiellement statiques ainsi qu'aux structures soumises à la fatigue. Elle spécifie les exigences en rapport avec les classes d'exécution qui sont liées à des classes de conséquences.

NOTE 2 Les classes de conséquences sont définies dans l'EN 1990.

NOTE 3 L'EN 1999-1-1 donne des recommandations pour le choix d'une classe d'exécution en fonction de la classe de conséquences.

La présente Norme européenne couvre les éléments fabriqués à partir de produits constitutifs dont l'épaisseur n'est pas inférieure à 0,6 mm pour des éléments soudés dont l’épaisseur n’est pas inférieure à 1,5 mm.

La présente Norme européenne s'applique aux structures conçues conformément aux parties pertinentes de l'EN 1999. Lorsque la présente Norme européenne est utilisée pour des structures conçues conformément à d'autres règles de calcul ou pour d'autres alliages et états métallurgiques non couverts par l'EN 1999, il convient de procéder à une évaluation des éléments de fiabilité dans ces règles de calcul.

La présente Norme européenne spécifie les exigences relatives à la préparation de la surface avant l'application d'un traitement de protection et donne des recommandations pour l'application d'un tel traitement dans une annexe informative.

La présente Norme européenne offre des options permettant de spécifier des exigences en adéquation avec les exigences propres à un projet.

Izvedba jeklenih in aluminijastih konstrukcij - 3. del: Tehnične zahteve za aluminijaste konstrukcije

General Information

- Status

- Withdrawn

- Publication Date

- 24-Jun-2008

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 135 - Execution of steel structures

- Drafting Committee

- CEN/TC 135/WG 4 - Erection

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 10-Apr-2019

- Completion Date

- 09-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 11-Feb-2015

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Sponsored listings

Frequently Asked Questions

EN 1090-3:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Execution of steel structures and aluminium structures - Part 3: Technical requirements for aluminium structures". This standard covers: This European Standard specifies requirements for the execution of aluminium structural components and structures made from: a) rolled sheet, strip and plate; b) extrusions; c) cold drawn rod, bar and tube; d) forgings; e) castings. NOTE 1 The execution of structural components is referred to as manufacturing, in accordance with EN 1090-1. This European Standard specifies requirements independent of the type and shape of the aluminium structure, and this European Standard is applicable to structures under predominantly static loads as well as structures subject to fatigue. It specifies requirements related to the execution classes that are linked with consequence classes. NOTE 2 Consequence classes are defined in EN 1990. NOTE 3 Recommendations for selection of execution class in relation to consequence class are given in EN 1999-1-1. This European Standard covers components made of constituent products with thickness not less than 0,6 mm for welded components not less than 1,5 mm. This European Standard applies to structures designed according to the relevant parts of EN 1999. If this European Standard is used for structures designed according to other design rules or used for other alloys and tempers not covered by EN 1999, a judgement of the reliability elements in these design rules should be made. This European Standard specifies requirements for surface preparation prior to application of a protective treatment, and gives guidelines for application for such treatment in an informative annex. This European Standard gives options for specifying requirements to match project specific requirements. This European Standard is also applicable to temporary aluminium structures.

This European Standard specifies requirements for the execution of aluminium structural components and structures made from: a) rolled sheet, strip and plate; b) extrusions; c) cold drawn rod, bar and tube; d) forgings; e) castings. NOTE 1 The execution of structural components is referred to as manufacturing, in accordance with EN 1090-1. This European Standard specifies requirements independent of the type and shape of the aluminium structure, and this European Standard is applicable to structures under predominantly static loads as well as structures subject to fatigue. It specifies requirements related to the execution classes that are linked with consequence classes. NOTE 2 Consequence classes are defined in EN 1990. NOTE 3 Recommendations for selection of execution class in relation to consequence class are given in EN 1999-1-1. This European Standard covers components made of constituent products with thickness not less than 0,6 mm for welded components not less than 1,5 mm. This European Standard applies to structures designed according to the relevant parts of EN 1999. If this European Standard is used for structures designed according to other design rules or used for other alloys and tempers not covered by EN 1999, a judgement of the reliability elements in these design rules should be made. This European Standard specifies requirements for surface preparation prior to application of a protective treatment, and gives guidelines for application for such treatment in an informative annex. This European Standard gives options for specifying requirements to match project specific requirements. This European Standard is also applicable to temporary aluminium structures.

EN 1090-3:2008 is classified under the following ICS (International Classification for Standards) categories: 77.150.10 - Aluminium products; 91.080.10 - Metal structures; 91.080.13 - Steel structures; 91.080.17 - Aluminium structures. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1090-3:2008 has the following relationships with other standards: It is inter standard links to EN 1090-3:2019, ISO 10509:1992, EN ISO 21920-3:2022, EN 1337-11:1997, EN 14399-2:2015, EN 755-1:2016, EN ISO 663:2001, EN 14399-7:2018, EN 1337-3:2005, EN ISO 7093-1:2000, EN 754-4:2008, EN ISO 15614-2:2025, EN ISO 4762:2004, EN 1999-1-3:2007, EN 1337-4:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1090-3:2008 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/120. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1090-3:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Ausführung von Stahltragwerken und Aluminiumtragwerken - Teil 3: Technische Anforderungen an AluminiumtragwerkeExécution des structures en acier et des structures en aluminium - Partie 3 : Exigences techniques pour l'exécution des structures en aluminiumExecution of steel structures and aluminium structures - Part 3: Technical requirements for aluminium structures91.080.10Kovinske konstrukcijeMetal structures77.150.10Aluminijski izdelkiAluminium productsICS:Ta slovenski standard je istoveten z:EN 1090-3:2008SIST EN 1090-3:2008en,fr,de01-december-2008SIST EN 1090-3:2008SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1090-3

June 2008 ICS 77.150.10; 91.080.10 English Version

Execution of steel structures and aluminium structures - Part 3: Technical requirements for aluminium structures

Exécution des structures en acier et des structures en aluminium - Partie 3 : Exigences techniques pour l'exécution des structures en aluminium

Ausführung von Stahltragwerken und Aluminiumtragwerken - Teil 3: Technische Regeln für die Ausführung von Aluminiumtragwerken This European Standard was approved by CEN on 25 April 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1090-3:2008: ESIST EN 1090-3:2008

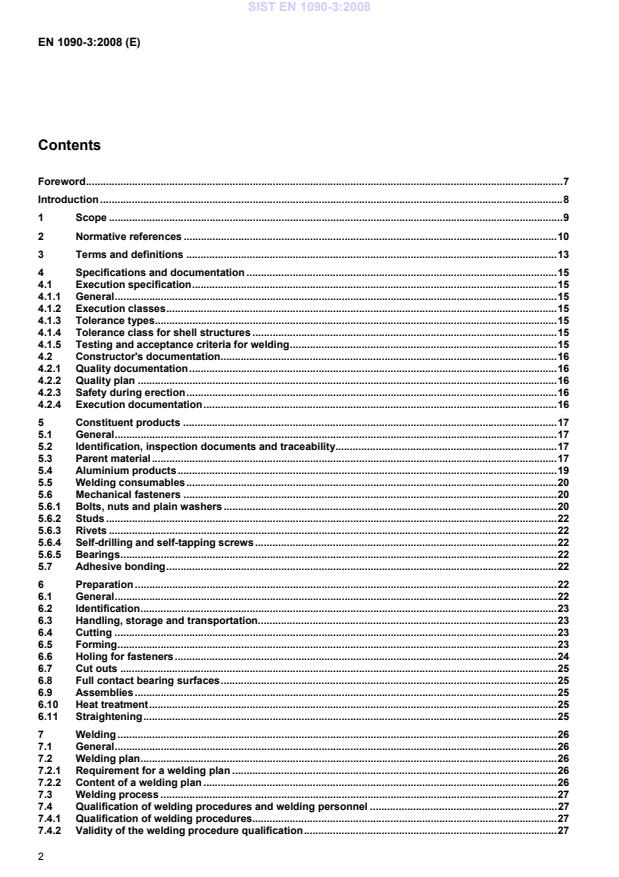

Required additional information, options to be specified and requirements for execution classes.53 A.1 List of required information.53 A.2 List of options to be specified.55 A.3 Requirements related to execution classes.56 Annex B (informative)

Checklist for the content of a quality plan.58 B.1 Introduction.58 B.2 Content.58 B.2.1 Management.58 B.2.2 Specification review.58 B.2.3 Documentation.58 B.2.4 Inspection and testing procedures.59 Annex C (normative)

Cruciform weld test.60 C.1 Introduction.60 C.2 Test piece.61 C.3 Examination and testing.62 Annex D (normative)

Procedure for determination of slip factor.64 D.1 The purpose of testing.64 D.2 Significant variables.64 D.3 Test specimens.64 D.4 Slip test procedure and evaluation of results.65 D.5 Extended creep test procedure and evaluation.66 D.6 Test results.67 Annex E (informative)

Fastening of cold formed members and sheeting.69 E.1 General.69 E.2 Use of self-tapping and self-drilling screws.69 E.3 Use of blind rivets.70 E.4 Fastening sidelaps.71 Annex F (informative)

Surface treatment.72 F.1 Anodic oxidation.72 SIST EN 1090-3:2008

Geometrical tolerances – Essential tolerances.75 G.1 Manufacturing tolerances.75 G.1.1 General.75 G.1.2 Welded I-sections.75 G.1.3 Welded box sections.77 G.1.4 Webs.77 G.1.5 Components.79 G.1.6 Base plates and end plate connections.79 G.1.7 Column splices.80 G.1.8 Lattice components.81 G.2 Erection tolerances.82 G.2.1 Columns.82 G.2.2 Beams.83 G.2.3 Full contact bearing.84 Annex H (normative)

Geometrical tolerances - Functional tolerances.85 H.1 General.85 H.2 Manufacturing tolerances.85 H.2.1 Box sections.85 H.2.2 Components.86 H.2.3 Stiffeners.87 H.2.4 Fastener holes, notches and edges.89 H.2.5 Lattice components.90 H.3 Erection tolerances.90 H.3.1 Columns.90 H.3.2 Beams, rafters and trusses.92 H.4 Bridges.93 Annex I (normative)

Geometrical tolerances – Shell structures.96 I.1 General.96 I.2 Out-of roundness tolerances.96 I.3 Non-intended eccentricity due to execution.97 I.4 Dent tolerances.98 I.5 Interface flatness tolerances.100 Annex J (informative)

Designation of requirements to welds on drawings.101 J.1 General.101 J.2 Global specification.101 J.3 Specific designations for welds, part of welds, details.102 Annex K (informative)

Recommendations for description of site conditions and erection in the execution specification.103 K.1 Site conditions.103 K.2 Erection method statement.103 Annex L (informative)

Guide for preparation of the execution specification for quality requirements of welds.105 L.1 General.105 L.2 Utilization grades and utilization ranges.105 L.2.1 General.105 L.2.2 Utilization grade for components and structures in service category SC1.106 L.2.3 Utilization grade for components and structures in service category SC2.106 L.3 Extent of additional NDT.106 L.3.1 Extent of NDT (%) for components/structures in service category SC1.106 L.3.2 Extent of additional NDT (%) for components/structures in service category SC2.106 L.4 Acceptance criteria for welds.107 L.4.1 Acceptance criteria for welds in service category SC1.107 SIST EN 1090-3:2008

Guide for specification of quality requirements for components and structures in SC2.109 Annex N (informative)

Chart for development and use of a welding procedure specification (WPS).112 Bibliography.113

Introduction This European Standard specifies requirements for the execution of aluminium structures, in order to ensure adequate levels of mechanical resistance and stability, serviceability and durability. This European Standard specifies requirements for the execution of aluminium structures in particular those that are designed according to EN 1999-1-1, EN 1999-1-2, EN 1999-1-3, EN 1999-1-4 and EN 1999-1-5. This European Standard presupposes that the work is carried out with the necessary skill and adequate equipment and resources to perform the work in accordance with the execution specification and the requirements of this European Standard. SIST EN 1090-3:2008

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...