EN 1858:2008+A1:2011

(Main + Amendment)Chimneys - Components - Concrete flue blocks

Chimneys - Components - Concrete flue blocks

This European Standard specifies the materials, dimensional and performance requirements for precast concrete flue blocks as defined in Clause 3 for use in chimneys. The flue blocks may be of single wall or multi wall construction. The standard does not apply to flue blocks with back ventilation.

This standard does not cover products designated wet (W) in conjunction with corrosion class 3.

The standard also specifies a type of flue block to dimensionally co-ordinate with masonry unit coursing height, referred to as a type B (Bonding block).

This European Standard also applies to storey-height and flue blocks reinforced for handling.

NOTE Any reference to the term flue blocks implies both flue blocks and their fittings, except where otherwise indicated.

Abgasanlagen - Bauteile - Betonformblöcke

Diese Europäische Norm legt die Anforderungen an die Werkstoffe, die Maße sowie die Leistungs-anforderungen an Formblöcke aus Fertigbeton, wie in Abschnitt 3 festgelegt, zur Verwendung in gestrichener Text"Abgasanlagen fest. Die Formblöcke können einschalig oder mehrschalig sein. Diese Norm gilt nicht für Formblöcke, die hinterlüftet sind. Diese Norm gilt nicht für Produkte, die mit feucht (W) gekennzeichnet sind in Verbindung mit Korrosions-beständigkeitsklasse 3. Diese Norm beschreibt außerdem einen Typ von Formblöcken, der mit der Schichthöhe des Mauerwerkes maßlich abgestimmt ist und als Typ B (Verbundblock) bezeichnet wird. Diese Europäische Norm gilt außerdem für geschosshohe und mit einer Transportbewehrung versehene Formblöcke. ANMERKUNG Sämtliche Verweisungen auf den Begriff Formblöcke bedeuten in dieser Norm immer Formblöcke und ihre Formstücke, außer wenn es anders angegeben ist.

Conduits de fumée - Composants - Conduits de fumée simple et multiparois en béton

La présente Norme européenne spécifie les exigences relatives aux matériaux, aux dimensions et aux

performances applicables aux conduits en béton tels que définis à l’Article 3 et constitutifs !texte supprimé

de conduits de fumée. Les conduits peuvent être à simple paroi ou multiparois. La norme ne s'applique pas aux

conduits ventilés par l’extérieur.

La présente norme ne couvre pas les produits désignés humides (W) associés à la classe de corrosion 3.

La norme spécifie également un type de conduit de dimensions coordonnées à la hauteur d'assise des blocs de

maçonnerie, et désigné par conduit de type B (conduits appareillés).

La présente Norme européenne couvre également les conduits hauteur d'étage et les boisseaux armés pour

la manutention.

NOTE Toute référence au terme conduit de fumée implique l’ensemble des conduits et leurs accessoires, sauf

indication contraire.

Dimniki - Sestavni deli - Betonski bloki za dimnike

Ta evropski standard določa zahteve glede materiala, mer in zmogljivosti za montažne betonske obloge za dimnike, kot je določeno v točki 3 za uporabo pri dimnikih. Bloki za dimnike imajo lahko konstrukcijo iz enega ali več zidov. Standard ne velja za bloke za dimnike z ozadnjim prezračevanjem. Ta standard ne zajema proizvodov, ki so označeni kot mokri (W) v povezavi s korozijskim razredom 3. Standard prav tako določa tip bloka za dimnike, da se dimenzijsko uskladi z višino enote zidakov v steni, v nadaljevanju vrsta B (vezni blok). Ta evropski standard prav tako velja za bloke za dimnike etažne višine in bloke, ojačane za ravnanje z njimi.

General Information

- Status

- Published

- Publication Date

- 28-Jun-2011

- Withdrawal Date

- 30-Mar-2013

- Technical Committee

- CEN/TC 166 - Chimneys

- Drafting Committee

- CEN/TC 166/WG 6 - Clay/Ceramic and Concrete chimneys components

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 29-Jun-2011

- Completion Date

- 29-Jun-2011

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 30-Apr-2011

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 16475-7:2016+A1:2020 - Chimneys - Accessories - Part 7: Rain caps - Requirements and test methods - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 16475-7:2016 - Chimneys - Accessories - Part 7: Rain caps - Requirements and test methods - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 1858:2008+A1:2011 is the CEN European Standard that defines requirements for precast concrete flue blocks used in chimneys. It covers materials, dimensional and performance requirements for single‑wall and multi‑wall concrete flue blocks, including a special Type B (bonding) block designed to coordinate with masonry coursing height. The standard excludes flue blocks with back ventilation and products designated wet (W) when used with corrosion class 3. Storey‑height blocks and blocks reinforced for handling are included. Annex ZA links the standard to the EU Construction Products Directive and CE marking requirements.

Key Topics

The standard addresses technical and conformity aspects across product design, manufacture and testing, notably:

- Materials and reaction to fire - concrete quality, constituents and fire behaviour requirements.

- Form, dimensions and tolerances - declared internal dimensions, heights, wall thicknesses, straightness and squareness.

- Reinforcement and handling - requirements for blocks reinforced to aid lifting/installation.

- Surface treatment - provisions for finishes and protective measures.

- Performance requirements and tests (normative Annex A) including:

- heat stress and heat shock resistance

- thermal resistance (calculation method in Annex C)

- gas tightness and condensate resistance

- abrasion and compressive strength

- corrosion resistance and freeze–thaw durability

- bulk density, flexural strength under wind loading, flow resistance and external fire resistance

- Designation, marking and product information - labelling, temperature/pressure classes and resistance classes.

- Evaluation of conformity - initial type testing, further type tests and factory production control; sampling plans (Annex D).

- Informative guidance on testing sequence (Annex E) and relationship to EU directives (Annex ZA).

Applications

EN 1858 is used to specify and verify precast concrete flue blocks for chimneys in buildings and industrial installations. Typical users and stakeholders include:

- Manufacturers of concrete chimney components developing product ranges that meet CEN performance classes.

- Designers and structural engineers selecting flue components based on thermal, mechanical and durability criteria.

- Architects and specifiers coordinating masonry coursing using Type B bonding blocks.

- Installers and contractors ensuring compatible dimensions and handling requirements on site.

- Testing laboratories and certification bodies performing conformity assessment, CE marking and factory production control.

- Regulators and building authorities referencing harmonised product requirements in procurement and compliance checks.

Relevant SEO keywords: EN 1858, concrete flue blocks, chimneys, precast flue blocks, thermal resistance, gas tightness, corrosion resistance, CE marking.

Related Standards

- EN 1443 - Chimneys: general requirements

- EN 1857 - Chimneys: concrete flue liners

- EN 12446 - Chimneys: concrete outer wall elements

(EN 1858 forms part of the coordinated CEN series for concrete chimney products and systems.)

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 1858:2008+A1:2011 is a standard published by the European Committee for Standardization (CEN). Its full title is "Chimneys - Components - Concrete flue blocks". This standard covers: This European Standard specifies the materials, dimensional and performance requirements for precast concrete flue blocks as defined in Clause 3 for use in chimneys. The flue blocks may be of single wall or multi wall construction. The standard does not apply to flue blocks with back ventilation. This standard does not cover products designated wet (W) in conjunction with corrosion class 3. The standard also specifies a type of flue block to dimensionally co-ordinate with masonry unit coursing height, referred to as a type B (Bonding block). This European Standard also applies to storey-height and flue blocks reinforced for handling. NOTE Any reference to the term flue blocks implies both flue blocks and their fittings, except where otherwise indicated.

This European Standard specifies the materials, dimensional and performance requirements for precast concrete flue blocks as defined in Clause 3 for use in chimneys. The flue blocks may be of single wall or multi wall construction. The standard does not apply to flue blocks with back ventilation. This standard does not cover products designated wet (W) in conjunction with corrosion class 3. The standard also specifies a type of flue block to dimensionally co-ordinate with masonry unit coursing height, referred to as a type B (Bonding block). This European Standard also applies to storey-height and flue blocks reinforced for handling. NOTE Any reference to the term flue blocks implies both flue blocks and their fittings, except where otherwise indicated.

EN 1858:2008+A1:2011 is classified under the following ICS (International Classification for Standards) categories: 91.060.40 - Chimneys, shafts, ducts; 91.100.30 - Concrete and concrete products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1858:2008+A1:2011 has the following relationships with other standards: It is inter standard links to EN 1858:2008, EN 1858:2008/FprA1, EN 13384-1:2015+A1:2019, EN 206-1:2000, EN 1443:2019, EN 10088-2:2024, EN 196-1:1994, EN ISO 7500-1:2004, EN 13216-1:2019, EN 14297:2004, EN 16475-7:2016+A1:2020, EN 15287-1:2007+A1:2010, EN 16475-7:2016, EN 15287-2:2008, EN 15287-1:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1858:2008+A1:2011 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/105. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1858:2008+A1:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Dimniki - Sestavni deli - Betonski bloki za dimnikeAbgasanlagen - Bauteile - BetonformblöckeConduits de fumée - Composants - Conduits de fumée simple et multiparois en bétonChimneys - Components - Concrete flue blocks91.100.30Beton in betonski izdelkiConcrete and concrete products91.060.40Dimniki, jaški, kanaliChimneys, shafts, ductsICS:Ta slovenski standard je istoveten z:EN 1858:2008+A1:2011SIST EN 1858:2009+A1:2011en,fr,de01-oktober-2011SIST EN 1858:2009+A1:2011SLOVENSKI

STANDARDSIST EN 1858:20091DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1858:2008+A1

June 2011 ICS 91.060.40; 91.100.30 Supersedes EN 1858:2008English Version

Chimneys - Components - Concrete flue blocks

Conduits de fumée - Composants - Conduits de fumée simple et multiparois en béton

Abgasanlagen - Bauteile - Betonformblöcke This European Standard was approved by CEN on 1 November 2008 and includes Amendment 1 approved by CEN on 14 May 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1858:2008+A1:2011: ESIST EN 1858:2009+A1:2011

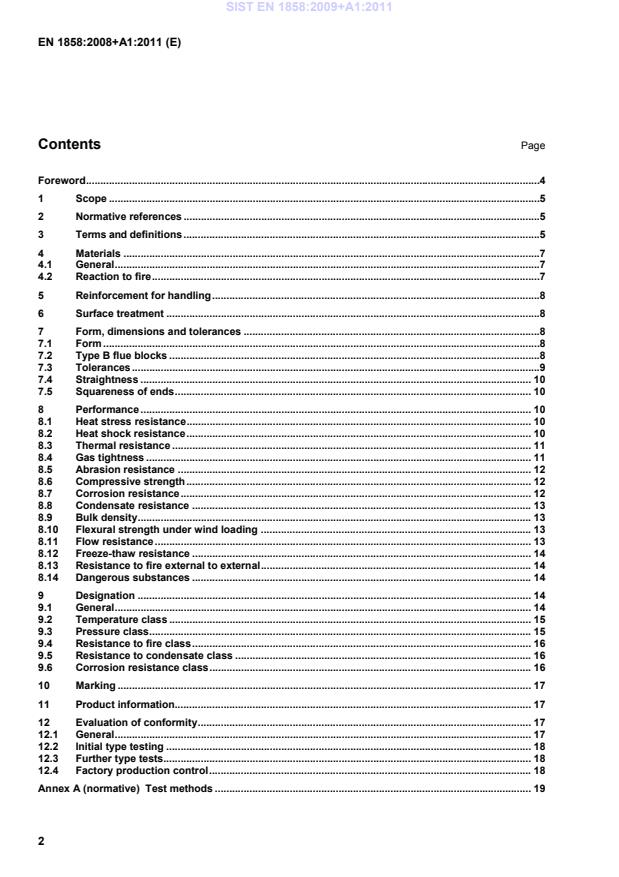

Test methods . 19SIST EN 1858:2009+A1:2011

Examples of concrete flue block shapes . 39B.1Straight flue blocks . 39B.2Flue block fittings - Tee/access/connection unit . 40B.3Examples of Type B flue block shapes . 41Annex C (normative)

Thermal resistance calculation method . 43C.1Thermal resistance of the individual element . 43C.2Thermal resistance of the chimney and of enclosures . 43Annex D (normative)

Requirements of sampling plan according to ISO 2859-1:1999 at an Acceptable Quality Level (AQL) of 10 % and inspection level S2 . 44D.1Acceptability determination . 44D.2Normal inspection . 44D.3Reduced Inspection . 46D.4Reduced to normal inspection . 47D.5Tightened inspection . 47D.6Tightened to normal inspection . 47D.7Discontinuation of inspection . 47Annex E (informative)

Recommended test sequence . 48Annex ZA (informative)

Clauses of this European standard addressing the provisions of the EU Construction Products Directive . 49ZA.1 Relationship between EU Directives and this European Standard . 49ZA.2 Procedure of attestation of conformity of concrete flue blocks . 51ZA.3 CE Marking and labelling . 52Bibliography . 55 SIST EN 1858:2009+A1:2011

1 Scope This European Standard specifies the materials, dimensional and performance requirements for precast concrete flue blocks as defined in Clause 3 for use in !deleted text " chimneys. The flue blocks may be of single wall or multi wall construction. The standard does not apply to flue blocks with back ventilation. This standard does not cover products designated wet (W) in conjunction with corrosion class 3. The standard also specifies a type of flue block to dimensionally co-ordinate with masonry unit coursing height, referred to as a type B (Bonding block). This European Standard also applies to storey-height and flue blocks reinforced for handling. NOTE Any reference to the term flue blocks implies both flue blocks and their fittings, except where otherwise indicated. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 206-1: 2000, Concrete — Part 1: Specification, performance, production and conformity EN 1443, Chimneys — General requirements EN 10088-2, Stainless steel — Part 2: Technical delivery conditions for sheet/plate and strip of corrosion resisting steels for general purposes EN 13216-1, Chimneys — Test methods for system chimneys — Part 1: General test methods EN 13384-1, Chimneys — Thermal and fluid dynamic calculation methods — Part 1: Chimneys serving one appliance EN 14297: 2004, Chimneys — Freeze-thaw resistance test method for chimney products EN ISO 7500-1:2004, Metallic materials — Verification of static uniaxial testing machines — Part 1: Tension/compression testing machines !(ISO 7500-1:2004)" ISO 2859-1:1999, Sampling procedures for inspection by attributes — Part 1: Sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection 3 Terms and definitions For the purposes of this European Standard, the terms and definitions given in EN 1443 and the following apply. 3.1 flue block fitting element fitted to the flue block such as an access opening or offset SIST EN 1858:2009+A1:2011

a) with rebate b) with plain end Key H

internal height Figure 1 — Manufacturer's declared height 3.5 manufacturer's declared structural height maximum constructional height of the flue blocks as declared by the manufacturer 3.6 manufacturer's declared overall wall thickness dimensions at its thinnest point, between the inside face of the flue and the outside face of the flue block, not measured at any joint feature, e.g. spigot/socket end 3.7 multi wall flue block flue block consisting of a flue liner and at least one additional wall 3.8 reinforced flue block flue block having reinforcement to assist handling (not for structural stability) 3.9 solid wall flue block flue block without cavities in the thickness of its walls SIST EN 1858:2009+A1:2011

[EN 206-1:2000] 3.14 precast concrete

concrete that is cast in a place other than its final location of use 3.15 type B flue block type B (Bonding) block bonding block dimensionally co-ordinated with masonry unit coursing height, and having a designation T250, N, D1, O xx (see Clause 9). 4 Materials 4.1 General The wall or walls of flue blocks shall be precast concrete. For multiwall flue blocks the liner and outer wall may be separated by an air space or insulation. Materials used in the manufacture of flue blocks shall be identified for factory production control purposes. When insulation forms part of a flue block, it shall be of bonded material as specified by the manufacturer. If the insulation is supplied as a separate item, it shall be installed in accordance with the flue block manufacturer’s installation instructions.

The manufacturer shall declare the bulk density of the flue block and when tested to A.10 the density shall be within ± 10 % of the declared value (see 8.9).

4.2 Reaction to fire In accordance with Commission Decision 96/603/EC, as amended, flue blocks to this standard are classified as reaction to fire class A1 without test provided, they contain not more than a mass or volume fraction of 1 % (whichever is the more onerous) of homogeneously distributed organic materials. SIST EN 1858:2009+A1:2011

flue block 3 masonry unit 4 flue block height 5 co-ordinating height 6 coursing height 7 jointing allowance Figure 2 — Type B flue blocks jointing with masonry units 7.2.4 The angle of offset in any Type B flue block shall not exceed 30° (see Clause B.3). 7.2.5 Starter Type B flue blocks shall have internal transverse dimensions not less than 305 mm side × 115 mm deep (see Clause B.3). 7.2.6 When jointed together in accordance with the manufacturer's installation instructions, the flue in adjacent Type B flue blocks shall align to within 3 mm. 7.3 Tolerances Tolerances on manufacturer's declared dimensions, including taper, shall be: a) Declared internal transverse dimensions below 300 mm :

± 3 mm 300 mm and above :

± 1,5 % b) Declared height below 300 mm :

± 5 mm 300 mm to 700 mm :

± 7 mm above 700 mm :

± 10 mm SIST EN 1858:2009+A1:2011

mm 12+− 10 mm to 40 mm :

mm 51,5+− above 40 mm :

% 125+− 7.4 Straightness 7.4.1 When tested as described in A.2, the limit deviation from straightness of a straight concrete flue block of manufacturer's declared height greater than 300 mm and less than 1 000 mm shall not be greater than 1 % of the declared height. 7.4.2 When tested as described in A.2 for flue blocks having a manufactured height equal to or greater than 1 000 mm, the limit deviation shall not be greater than 0,5 % of the manufacturers declared height. 7.5 Squareness of ends When tested in accordance with either procedure described in A.1, the test sample shall not touch the upright for the first procedure and the dimension G shall not be greater than 5 mm for the second procedure. 8 Performance 8.1 Heat stress resistance 8.1.1 When flue blocks and fittings, including those designated soot fire resistant, are tested in accordance with A.3 at the test temperature appropriate to the designation specified in Table 1, the flue block shall subsequently meet the requirements of 8.4. In addition, flue blocks and fittings having a compressive strength less than 10 MPa, or having a temperature designation above T250 and/or designated soot fire resistant, shall meet the requirements of 8.5.

When a flue block is multi-flued with an equal wall thickness, the heat stress test shall be carried out on the flue with the highest designation and temperature. 8.1.2 Flue block bends, made of the same material mix and by the same method of manufacture as the tested straight flue block shall be deemed to comply with the requirement in 8.1.1.

8.1.3 Flue block bends and fittings, made of a different material mix or using a different method of manufacture from those described in 8.1.2, shall be checked for heat stress resistance by testing a special straight test sample in accordance with 8.1.1. This straight test sample shall be made using the same material mix and manufacturing method as the bend or fitting.

8.1.4 The distance to combustible material, xx, shall be declared. The maximum temperature measured on the surface of adjacent combustible materials shall not exceed 85 °C when related to an ambient temperature of 20 °C.

8.2 Heat shock resistance 8.2.1 Following the heat stress resistance test in 8.1, when a flue block designated as soot fire resistant is tested as described in A.3 at a flue gas temperature of 1 000 °C for a period of 30 min ± 1 min, the block shall subsequently meet the requirements of 8.4. In addition, flue blocks and fittings having a compressive strength SIST EN 1858:2009+A1:2011

Table 1 — Heat stress test temperature Temperature group Temperature of flue gas °C T600 700 500+ T450 550 500+ T400 500 500+ T300 350 350+ T250 300 300+ T200 250 250+ T160 190 190+ T140 170 170+ T120 150 150+ T100 120 120+ T080 100 100+

8.3 Thermal resistance Thermal resistance shall be measured in accordance with the method given in A.4 (reference method) or calculated in accordance with the method given in Annex C and the value obtained declared. 8.4 Gas tightness When tested in accordance with A.5, the gas tightness expressed as a leakage rate of the flue block shall not be greater than the values specified in Table 4 for the relevant gas tightness class before and after the thermal performance tests. SIST EN 1858:2009+A1:2011

8.6 Compressive strength 8.6.1 The manufacturer shall declare the structural height. When tested as described in A.7, straight flue blocks and straight fittings shall withstand an intensity of loading equivalent to four times the manufacturer's declared structural height. NOTE The manufacturer's declared structural height can be derived from the ultimate compressive strength determined by the method in Clause A.11. Type B flue blocks shall be tested as a complete element and shall not be cut. 8.6.2 Flue block bends and fittings, made of the same material mix and by the same method of manufacture as the tested straight flue block, shall be deemed to comply with the requirement in 8.6.1. 8.6.3 Flue block bends and fittings, made of a different material mix or using a different method of manufacture from those described in 8.6.2, shall be checked for compressive strength by testing a special straight test sample in accordance with 8.6.1. The special straight test sample shall be made using the same material mix and manufacturing method as the bend or fitting. 8.7 Corrosion resistance When flue blocks designated condensate resistance class W (suitable for use in wet operating conditions) are tested as described in Clause A.8, flue blocks shall be designated corrosion class 1 or class 2 depending on the test solution used, provided that the mass loss of the test pieces is not greater than 0,1 % of the initial mass. Flue blocks designated condensate resistance class D (dry) and which meet the requirements of 8.1, 8.3, 8.5, and 8.6, may be assigned corrosion resistance class 3. SIST EN 1858:2009+A1:2011

Where national regulations require resistance to fire external to external (see EN 1443) of flue blocks, they shall be evaluated and declared in accordance with those regulations. 8.14 Dangerous substances Materials used in products shall not release any dangerous substances in excess of the maximum permitted levels specified in a relevant European Standard for the material, or permitted in the national regulations of the member state of destination. NOTE

See note 2 in Annex ZA.1. 9 Designation 9.1 General All concrete flue blocks conforming to this standard shall be designated in accordance with 9.2 to 9.6 for temperature, pressure, resistance to soot fire, condensate resistance and corrosion resistance respectively. NOTE An example of a designation system is given in Figure 4. SIST EN 1858:2009+A1:2011

EN 1858T 120N2D3O (20)_ The number of this standard Flue gas temperature class Negative/positive pressure class Resistance to condensate Corrosion resistance Resistance to fire [G(xx) or O(xx)] Figure 4 — Example of a designation system 9.2 Temperature class The temperature class shall be as given in Table 3.

Table 3 — Temperature class Temperature class Nominal working temperature °C T080 ≤ 80 T100 ≤ 100 T120 ≤ 120 T140 ≤ 140 T160 ≤160 T200 ≤ 200 T250 ≤ 250 T300 ≤ 300 T400 ≤ 400 T450 ≤ 450 T600 ≤ 600

9.3 Pressure class The pressure class shall be as follows, with the corresponding test pressure and gas tightness level as given in Table 4: for flue blocks suitable for negative pressure chimneys: N1, N2; SIST EN 1858:2009+A1:2011

≤ 50 mg/m3 natural gas L + H gas natural gas L + H gas natural gas L + H liquid kerosene: sulphur-content ≤ 50 mg/m3 oil: sulphur-content ≤ 0,2 mass % kerosene: sulphur-content > 50 mg/m3 oil: sulphur-content > 0,2 mass % kerosene: sulphur-content > 50 mg/m3 wood

wood in open fire places wood in open fire places wood in closed stoves coal

Coal peat

Peat

e) maximum outer surface temperature; f) thermal resistance; g) manufacturer's declared internal transverse dimensions, height, structural height and overall wall thickness; h) detailed installation instructions including method of jointing and flue identification. NOTE For CE marking requirements for information on the product, Clause ZA.3 applies. 12 Evaluation of conformity 12.1 General The compliance of the concrete flue blocks with the requirements of this standard and with the stated values (including classes) shall be demonstrated by: initial type testing, factory production control by the manufacturer, including product assessment. SIST EN 1858:2009+A1:2011

12.4 Factory production control To achieve compliance with this standard, the manufacturer shall establish and maintain an effective documented quality system. Factory production control tests are carried out following manufacture to monitor the quality of product (see Table 6). Sampling and testing of any batch shall be completed prior to removal from the works and shall be in accordance with ISO 2859-1:1999 at an AQL of 10 % and inspection level S2. Isolated batches of units shall be assessed in accordance with tightened inspection procedures, with a maximum batch size of 2 500 (see Annex D). Batches rejected under the factory production control procedure may be resubmitted once, after removal of units with previously undetected visible defects, under the tightened inspection procedures, in respect only of the defect that caused initial rejection. NOTE A quality system assessed by a certification body which complies with the requirements of EN ISO/IEC 17021 [1] may be applied to ensure that the requirements of EN ISO 9001 [3] and Clause 12 are complied with.

Test methods NOTE Annex E gives the recommended test sequence. A.1 Squareness of ends test A.1.1 Apparatus The apparatus shall include the following: A.1.1.1 A level test bench with a fixed upright at 90°, see Figure A.1 a); A.1.1.2 A square having one arm 300 mm long and the second arm 400 mm long. SIST EN 1858:2009+A1:2011

Dimensions in millimetres 450 min90º1352 a) First procedure G b) Second procedure Key 1 adjustable 2 adjustable cantilevered straight edge 3 level test surface 5 dimension in mm G dimension in mm Figure A.1 — Apparatus for squareness test A.1.2 First procedure Place the flue block upright on the test bench with the base of the flue block touching the collar. Rotate the flue block through 360°. SIST EN 1858:2009+A1:2011

A.1.4 Second procedure Place the flue block upright on the test bench and apply one arm of the square along its side with the other arm touching the end of the flue block. Rotate the square across the end of the flue block as shown in Figure A.1 b). A.1.5 Test result — second procedure Record any case where the dimension G exceeds 5 mm. A.2 Straightness test A.2.1 Apparatus A straightness measuring device, such as a straight edge, having a height 100 mm less than the nominal height of the flue block under test. A.2.2 Procedure A.2.2.1 Place the measuring device along the line HT as shown in Figure A.2.

A.2.2.2 Measure the maximum distance from the centre of the straight line created by the apparatus in A.2.1 spanning any concave curve on the outside of the flue block surface (DS) as shown in Figure A.2.

DHH

/2sTNTH

/2TH Key HN nominal height of the flue block in mm HT test height in mm DS deviation from straightness in mm HN - HT

= 100 mm ± 5 mm Figure A.2 — Straightness test A.2.3 Test result

Record any case where DS is greater than 1 % or, in the case of flue blocks equal to or greater than 1 000 mm in height, any case where DS is greater than 0,5 % of the declared height.

5 seal ⊗ outer wall temperature

X partition temperature Figure A.3 — Example of test assembly Either: SIST EN 1858:2009+A1:2011

0,002 W/(m·K) at 20 °C ± 10 °C, with a minimum density of 70 kg/m3 ± 10 kg/m3. The walls shall extend 1 200 mm ± 12 mm. Dimensions in millimetres132038101891016411200241238895491099118813202412 a) — Wall Frame C Side 1 Zone Bb)—Wall Frame D Side 2 Zone BFigure A.4 — Wall frames

Test type B gas flue blocks using the test assembly described in Figure 5 where the partition is a 225 mm by 50 mm timber joist extending one masonry wall block length on either side of the flue block. NOTE Type B gas flue blocks differ from standard flue blocks as they are designed to be used within a masonry wall. In this situati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...