EN 13384-1:2015+A1:2019

(Main)Chimneys - Thermal and fluid dynamic calculation methods - Part 1: Chimneys serving one combustion appliance

Chimneys - Thermal and fluid dynamic calculation methods - Part 1: Chimneys serving one combustion appliance

This European Standard specifies methods for the calculation of the thermal and fluid dynamic characteristics of chimneys serving one heating appliance.

The methods in this part of this European Standard are applicable to negative or positive pressure chimneys with wet or dry operating conditions. It is valid for chimneys with heating appliances for fuels subject to the knowledge of the flue gas characteristics which are needed for the calculation.

The methods in this part of this European Standard are applicable to chimneys with one inlet connected with one appliance. The methods in Part 2 of this European Standard are applicable to chimneys with multiple inlets and one inlet with multiple appliances. Part 3 describes methods for the development of diagrams and tables for chimneys serving one heating appliance.

Abgasanlagen - Wärme- und strömungstechnische Berechnungsverfahren - Teil 1: Abgasanlagen mit einer Verbrennungseinrichtung

Diese Europäische Norm legt wärme- und strömungstechnische Berechnungsverfahren von Abgasanlagen mit einer !Verbrennungseinrichtung" fest.

Diese Europäische Norm gilt sowohl für Unterdruck- als auch für Überdruckanlagen in feuchter und trockener Betriebsweise. Sie gilt für Abgasanlagen von !Verbrennungseinrichtungen" mit Brennstoffen, deren Abgaskennwerte, die für die Berechnung benötigt werden, bekannt sind.

Das Berechnungsverfahren dieser Europäischen Norm gilt für Abgasanlagen mit einem Anschluss für eine Verbrennungseinrichtung. Das Berechnungsverfahren nach Teil 2 dieser Europäischen Norm gilt dagegen für Abgasanlagen mit mehreren Anschlüssen und für einen Anschluss mit mehreren Verbrennungs-einrichtungen. Teil 3 beschreibt Verfahren zur Entwicklung von Diagrammen und Tabellen für Abgasanlagen mit einer !Verbrennungseinrichtung".

Conduits de fumée - Méthodes de calcul thermo-aéraulique - Partie 1: Conduits de fumée ne desservant qu'un seul appareil à combustion

La présente Norme européenne spécifie les méthodes de calcul des caractéristiques thermo-aérauliques des conduits de fumée ne desservant qu'un seul appareil.

Les méthodes données dans la présente partie de cette Norme européenne s'appliquent aux conduits de fumée fonctionnant sous pression négative ou positive, en ambiance humide ou sèche, et desservant des générateurs de chaleur utilisant des combustibles dont les caractéristiques des fumées sont connues pour les calculs.

Les méthodes données dans la présente partie de cette Norme européenne s'appliquent aux conduits de fumée desservant un seul appareil. Les méthodes données dans la partie 2 de la présente Norme européenne concernent les conduits de fumée desservant plusieurs appareils (conduit collectif ou cascade). La partie 3 décrit des méthodes qui permettent d'élaborer des abaques et des tableaux pour les conduits de fumée desservant un seul générateur de chaleur.

Dimniki - Računske metode termodinamike in dinamike fluidov - 1. del: Dimniki za eno ogrevalno napravo

Ta evropski standard določa računske metode termodinamike in dinamike fluidov v dimnikih za eno ogrevalno napravo.

Metode v tem delu tega evropskega standarda se uporabljajo za dimnike z negativnim ali pozitivnim tlakom v vlažnih ali suhih obratovalnih pogojih. Uporablja se za dimnike z grelnimi napravami na goriva, če poznamo značilnosti dinamike fluidov v dimnikih, ki so potrebne za izračun.

Metode v tem delu tega evropskega standarda se uporabljajo za dimnike z enim dovodom, povezanim z eno ogrevalno napravo. Metode v 2. delu tega evropskega standarda se uporabljajo za dimnike z več dovodi in enim dovodom, povezanim z več ogrevalnimi napravami. 3. del opisuje metode za razvoj diagramov in preglednic za dimnike za eno ogrevalno napravo.

General Information

- Status

- Published

- Publication Date

- 02-Jul-2019

- Withdrawal Date

- 30-Jan-2020

- Technical Committee

- CEN/TC 166 - Chimneys

- Current Stage

- 9000 - Start of review/2 Year Review Enquiry - Review Enquiry

- Start Date

- 01-Apr-2020

- Completion Date

- 01-Apr-2020

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 18-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 16475-2:2017 - Chimneys - Accessories - Part 2: Chimney fans - Requirements and test methods - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 14471:2005 - Chimneys - System chimneys with plastic flue liners - Requirements and test methods - Effective Date

- 28-Jan-2026

- Referred By

EN 16497-1:2015 - Chimneys - Concrete System Chimneys - Part 1: Non-balanced flue applications - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 15544:2023 - One off Kachelgrundöfen/Putzgrundöfen (tiled/mortared stoves) - Dimensioning - Effective Date

- 28-Jan-2026

- Referred By

EN 1856-1:2009 - Chimneys - Requirements for metal chimneys - Part 1: System chimney products - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 13384-1:2015+A1:2019 is the European standard that specifies calculation methods for the thermal and fluid-dynamic behaviour of chimneys serving one heating appliance. Applicable to both negative and positive pressure chimneys and to wet or dry operating conditions, the standard provides a consistent engineering approach where the flue gas characteristics of the fuel are known. This Part 1 focuses on chimneys with a single inlet connected to one appliance (see Parts 2 and 3 for multi-inlet or diagram/table development).

Key topics and technical requirements

- Pressure and draught calculations - methods to compute minimum and maximum draught, appliance differential pressures, and chimney effect pressures for safe operation.

- Temperature and heat transfer - procedures to determine flue gas and inner wall temperatures, thermal resistance and cooling coefficients for chimney segments.

- Fluid properties - determination of flue gas density, velocity, specific heat and related basic values needed for calculations.

- Balanced and non‑balanced flue systems - separate calculation procedures for non-balanced (single flow) and balanced (combustion air and flue gas ducts) chimneys.

- Secondary air and mixing - rules for inclusion and impact of secondary air in negative pressure systems.

- Condensation effects - how to account for flue gas water vapour condensation and its impact on temperature and thermal performance.

- Chimney fans - guidance for inline and exhaust fan inclusion and their effects on pressure/flow.

- Characteristic data and safety factors - roughness, thermal resistance, flow safety and correction factors required for robust design.

- Informative annexes - additional material such as thermal resistance calculation, tables, and guidance (including considerations for adjacent buildings).

Practical applications and users

This standard is essential for:

- HVAC and chimney designers performing chimney sizing and performance checks

- Boiler and heating appliance manufacturers validating flue connections and draft requirements

- Building services engineers and consultants ensuring compliance with European engineering practice

- Installers and commissioning technicians verifying safe operation and correct fan selection

- Regulatory authorities and certification bodies assessing compliance and safety of chimney systems

Practical outcomes include accurate selection of chimney dimensions, verification of safe draught under varying conditions, prevention of flue gas condensation problems, and correct specification of fans and secondary-air devices.

Related standards

- EN 13384-2 (chimneys with multiple inlets / multiple appliances)

- EN 13384-3 (methods for development of diagrams and tables)

- National adaptations and codes may reference SIST EN 13384-1 for regulatory compliance.

Keywords: EN 13384-1, EN 13384-1:2015+A1:2019, chimney calculation, chimney design standard, flue gas, balanced flue, negative pressure chimney, positive pressure chimney, chimney thermal calculation.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 13384-1:2015+A1:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Chimneys - Thermal and fluid dynamic calculation methods - Part 1: Chimneys serving one combustion appliance". This standard covers: This European Standard specifies methods for the calculation of the thermal and fluid dynamic characteristics of chimneys serving one heating appliance. The methods in this part of this European Standard are applicable to negative or positive pressure chimneys with wet or dry operating conditions. It is valid for chimneys with heating appliances for fuels subject to the knowledge of the flue gas characteristics which are needed for the calculation. The methods in this part of this European Standard are applicable to chimneys with one inlet connected with one appliance. The methods in Part 2 of this European Standard are applicable to chimneys with multiple inlets and one inlet with multiple appliances. Part 3 describes methods for the development of diagrams and tables for chimneys serving one heating appliance.

This European Standard specifies methods for the calculation of the thermal and fluid dynamic characteristics of chimneys serving one heating appliance. The methods in this part of this European Standard are applicable to negative or positive pressure chimneys with wet or dry operating conditions. It is valid for chimneys with heating appliances for fuels subject to the knowledge of the flue gas characteristics which are needed for the calculation. The methods in this part of this European Standard are applicable to chimneys with one inlet connected with one appliance. The methods in Part 2 of this European Standard are applicable to chimneys with multiple inlets and one inlet with multiple appliances. Part 3 describes methods for the development of diagrams and tables for chimneys serving one heating appliance.

EN 13384-1:2015+A1:2019 is classified under the following ICS (International Classification for Standards) categories: 91.060.40 - Chimneys, shafts, ducts. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13384-1:2015+A1:2019 has the following relationships with other standards: It is inter standard links to EN 13384-1:2015, EN 13384-1:2015/prA1, EN 1443:2019, EN 1749:2020, EN 15287-1:2007+A1:2010, EN 16475-2:2017, EN 1859:2009+A1:2013, EN 13502:2002, EN 14471:2005, EN 16497-1:2015, EN 13384-2:2015+A1:2019, EN 15544:2023, EN 1856-1:2009, EN 13063-2:2005+A1:2007, EN ISO 11266:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13384-1:2015+A1:2019 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/105. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13384-1:2015+A1:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2019

Nadomešča:

SIST EN 13384-1:2015

Dimniki - Računske metode termodinamike in dinamike fluidov - 1. del: Dimniki za

eno ogrevalno napravo

Chimneys - Thermal and fluid dynamic calculation methods - Part 1: Chimneys serving

one heating appliance

Abgasanlagen - Wärme- und strömungstechnische Berechnungsverfahren - Teil 1:

Abgasanlagen mit einer Feuerstätte

Conduits de fumée - Méthodes de calcul thermo-aéraulique - Partie 1: Conduits de

fumée ne desservant qu'un seul appareil

Ta slovenski standard je istoveten z: EN 13384-1:2015+A1:2019

ICS:

91.060.40 Dimniki, jaški, kanali Chimneys, shafts, ducts

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13384-1:2015+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

July 2019

EUROPÄISCHE NORM

ICS 91.060.40 Supersedes EN 13384-1:2015

English Version

Chimneys - Thermal and fluid dynamic calculation

methods - Part 1: Chimneys serving one heating appliance

Conduits de fumée - Méthodes de calcul thermo- Abgasanlagen - Wärme- und strömungstechnische

aéraulique - Partie 1: Conduits de fumée ne desservant Berechnungsverfahren - Teil 1: Abgasanlagen mit einer

qu'un seul appareil Feuerstätte

This European Standard was approved by CEN on 24 January 2015 and includes Amendment 1 approved by CEN on 27 April

2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13384-1:2015+A1:2019 E

worldwide for CEN national Members.

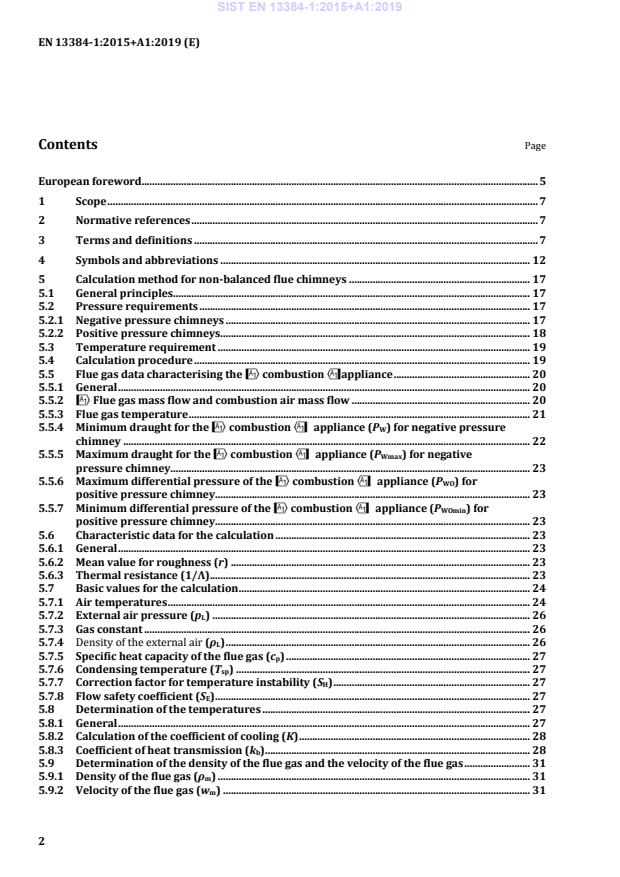

Contents Page

European foreword . 5

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Symbols and abbreviations . 12

5 Calculation method for non-balanced flue chimneys . 17

5.1 General principles . 17

5.2 Pressure requirements . 17

5.2.1 Negative pressure chimneys . 17

5.2.2 Positive pressure chimneys. 18

5.3 Temperature requirement . 19

5.4 Calculation procedure . 19

5.5 Flue gas data characterising the !combustion"appliance . 20

5.5.1 General . 20

5.5.2 !Flue gas mass flow and combustion air mass flow . 20

5.5.3 Flue gas temperature . 21

5.5.4 Minimum draught for the !combustion" appliance (PW) for negative pressure

chimney . 22

5.5.5 Maximum draught for the !combustion" appliance (P ) for negative

Wmax

pressure chimney . 23

5.5.6 Maximum differential pressure of the !combustion" appliance (P ) for

WO

positive pressure chimney . 23

5.5.7 Minimum differential pressure of the !combustion" appliance (P ) for

WOmin

positive pressure chimney . 23

5.6 Characteristic data for the calculation . 23

5.6.1 General . 23

5.6.2 Mean value for roughness (r) . 23

5.6.3 Thermal resistance (1/Λ) . 23

5.7 Basic values for the calculation . 24

5.7.1 Air temperatures . 24

5.7.2 External air pressure (p ) . 26

L

5.7.3 Gas constant . 26

5.7.4 Density of the external air (ρ ) . 26

L

5.7.5 Specific heat capacity of the flue gas (c ) . 27

p

5.7.6 Condensing temperature (T ) . 27

sp

5.7.7 Correction factor for temperature instability (S ) . 27

H

5.7.8 Flow safety coefficient (S ) . 27

E

5.8 Determination of the temperatures . 27

5.8.1 General . 27

5.8.2 Calculation of the coefficient of cooling (K) . 28

5.8.3 Coefficient of heat transmission (k ) . 28

b

5.9 Determination of the density of the flue gas and the velocity of the flue gas . 31

5.9.1 Density of the flue gas (ρ ) . 31

m

5.9.2 Velocity of the flue gas (w ) . 31

m

5.10 Determination of the pressures . 31

5.10.1 Pressure at the flue gas inlet into the chimney . 31

5.10.2 Theoretical draught available due to chimney effect (P ) . 32

H

5.10.3 Pressure resistance of the chimney (P ) . 33

R

5.10.4 Wind velocity pressure (P ) . 34

L

5.11 Minimum draught required at the flue gas inlet into the chimney and maximum

allowed draught (P and P ) and maximum and minimum differential pressure

Ze Zemax

at the flue gas inlet into the chimney (P and P ) . 35

ZOe ZOemin

5.11.1 General . 35

5.11.2 Minimum and maximum draught for the !combustion" appliance (P and

W

P ) and maximum and minimum differential pressure of the !combustion"

Wmax

appliance (P and P ) . 36

WO WOmin

5.11.3 Effective pressure resistance of the connecting flue pipe (P ) . 36

FV

5.11.4 Pressure resistance of the air supply (P ) . 37

B

5.12 Calculation of the inner wall temperature at the chimney outlet (T ) . 38

iob

6 Secondary air for negative pressure chimneys . 40

6.1 General . 40

6.2 Calculation method . 40

6.3 Basic values for the calculation of secondary air . 40

6.3.1 General . 40

6.3.2 Mixing calculations . 40

6.4 Pressures . 41

6.4.1 Pressure resistance for the air supply with secondary air (P ) . 41

BNL

6.4.2 Draught required for the secondary air devices (P ) . 43

NL

6.4.3 Pressure resistance for that part of the connecting flue pipe before the secondary air

device (P ) . 44

FV1

6.4.4 Pressure requirement with secondary air . 44

6.5 Temperature requirement with secondary air . 44

7 Calculation method for balanced flue chimneys . 45

7.1 General principles . 45

7.2 Pressure requirements . 46

7.3 Temperature requirements . 46

7.4 Calculation procedure . 46

7.5 Flue gas data characterizing the !combustion" appliance . 47

7.6 Characteristic data for the calculation . 47

7.7 Basic values for the calculation . 47

7.7.1 Air temperatures . 47

7.7.2 Other basic values . 48

7.8 Determination of the temperatures . 48

7.8.1 Non-concentric (separate) ducts. 48

7.8.2 Concentric ducts – calculation based on a correction factor for heat radiation . 49

7.8.3 Concentric ducts – calculation based on calculated heat radiation . 64

7.8.4 Mean temperatures for pressure calculation . 68

7.9 Determination of densities and velocities . 69

7.9.1 Density and velocity of the flue gas . 69

7.9.2 Density and velocity of the !combustion" air . 69

7.10 Determination of pressures . 70

7.10.1 Pressure at the flue gas inlet into the chimney . 70

7.10.2 Theoretical draught due to chimney effect in the chimney segment (P ) . 70

H

7.10.3 Pressure resistance in the chimney segment (P ) . 70

R

7.10.4 Wind velocity pressure (P ) . 70

L

7.11 Minimum draught required at the flue gas inlet into the chimney and maximum

allowed draught (P and P ) and maximum and minimum differential pressure

Ze Zemax

at the flue gas inlet into the chimney (P and P ) . 71

ZOe ZOemin

7.11.1 General . 71

7.11.2 Minimum and maximum draught for the !combustion" appliance (P and

W

P ) and maximum and minimum differential pressure of the !combustion"

Wmax

appliance (P and P ) . 71

WO WOmin

7.11.3 Effective pressure resistance of the connection pipe (P ) . 71

FV

7.11.4 Pressure resistance of the air supply . 71

7.12 Calculation of the inner wall temperature at the chimney outlet (T ) . 74

iob

8 Consideration of the condensation heat of the flue gas water vapour . 75

8.1 General . 75

8.2 Onset of condensation . 75

8.3 Calculation of the flue gas temperature at the outlet of a chimney segment with

condensation (j ≥ NsegK) . 78

9 Consideration of chimney fans . 83

9.1 General . 83

9.2 Inline fans . 84

9.3 Exhaust fans . 85

Annex A (informative) Calculation of thermal resistance . 86

Annex B (informative) Tables . 87

Annex C (informative) Chimney outlet with regard to adjacent buildings . 104

Annex D (informative) Determination of the gas constant R considering the condensation . 105

European foreword

This document (EN 13384-1:2015+A1:2019) has been prepared by Technical Committee CEN/TC 166

“Chimneys”, the secretariat of which is held by ASI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by January 2020, and conflicting national standards shall

be withdrawn at the latest by January 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent

rights.

This document supersedes !EN 13384-1:2015".

This document includes Amendment 1 approved by CEN on 26 June 2019.

According to EN 13384-1:2002+A2:2008 and EN 13384-12015+A1:2019 the following fundamental

changes are given:

— editorial mistakes have been corrected;

— mistakes in formulas have been corrected;

— for wood the rise of the dew point to take into account the acid condensation has been deleted;

— table for material characteristics in Table B.5 has been adapted to EN 15287-1 and supplemented

by radiation coefficients;

— in Calculation of thermal resistance according to Annex A are linked to the method of EN 15287-1

for taking into account the temperature dependence has been added;

— for non-concentric ducts the calculation of the mean temperature of the air supply has been

amended;

— for chimney fans a calculation procedure has been added;

— “heating appliance” replaced by “combustion appliance”;

— New calculation for combustion air mass flow introduced;

— “Supply air” replaced by “combustion air".

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association.

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

This European Standard “Chimneys — Thermal and fluid dynamic calculation methods” consists of

three Parts:

— Part 1: Chimneys serving one combustion appliance

— Part 2: Chimneys serving more than one combustion appliance

— Part 3: Methods for the development of diagrams and tables for chimneys serving one heating

appliance

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

1 Scope

This European Standard specifies methods for the calculation of the thermal and fluid dynamic

characteristics of chimneys serving one !combustion" appliance.

The methods in this part of this European Standard are applicable to negative or positive pressure

chimneys with wet or dry operating conditions. It is valid for chimneys with !combustion"

appliances for fuels subject to the knowledge of the flue gas characteristics which are needed for the

calculation.

The methods in this part of this European Standard are applicable to chimneys with one inlet connected

with one appliance. The methods in Part 2 of this European Standard are applicable to chimneys with

multiple inlets and one inlet with multiple appliances. Part 3 describes methods for the development of

diagrams and tables for chimneys serving one !combustion" appliance.

2 Normative references

!The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments)

applies."

EN 1443, Chimneys - General requirements

EN 1856-1, Chimneys - Requirements for metal chimneys - Part 1: System chimney products

EN 1859, Chimneys — Metal chimneys — Test methods

EN 13502, Chimneys - Requirements and test methods for clay/ceramic flue terminals

EN 15287-1:2007+A1:2010, Chimneys - Design, installation and commissioning of chimneys - Part 1:

Chimneys for non-roomsealed heating appliances

prEN 16475-2, Chimneys - Accessories - Part 2: Chimney fans - Requirements and test methods

CEN/TR 1749, European scheme for the classification of gas appliances according to the method of

evacuation of the combustion products (types)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 1443 and the following apply.

!ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp"

3.1

heat output

Q

amount of heat produced by a !combustion"appliance per unit of time

3.1.1

nominal heat output

Q

N

continuous heat output specified by the manufacturer of the !combustion"appliance related to

specified fuels

3.1.2

heat output range

range of output below the nominal heat output specified by the manufacturer over which the appliance

can be used

3.2

heat input

Q

F

amount of heat in unit time which is supplied to the !combustion"appliance by the fuel based on its

net caloric value H

u

3.3

efficiency of the !combustion"appliance

η

W

ratio of the heat output (Q) from the appliance to the heat input (Q )

F

3.4

flue gas mass flow

m

mass of flue gas leaving the !combustion"appliance through the connecting flue pipe per time unit

3.5

effective height of the chimney

H

difference in height between the axis of the flue gas inlet into the chimney and the outlet of the chimney

3.6

effective height of the connecting flue pipe

H

V

difference in height between the axis of the flue gas chimney outlet of the !combustion"appliance

and the axis of the flue gas inlet into the chimney

Note 1 to entry In the case of open fire chimneys, H is the difference in height between the height of the

V

upper frame of the furnace and the axis of the flue gas inlet into the chimney.

3.7

draught

positive value of the negative pressure in the flue

3.8

theoretical draught available due to chimney effect

P

H

pressure difference caused by the difference in weight between the column of air equal to the effective

height outside a chimney and the column of flue gas equal to the effective height inside the chimney

3.9

pressure resistance of the chimney

P

R

pressure which is necessary to overcome the resistance of the flue gas mass flow which exists when

carrying the flue gases through the chimney

3.10

wind velocity pressure

P

L

pressure generated on the chimney due to wind

3.11

minimum draught at the flue gas inlet into the chimney

P

Z

difference between the minimum theoretical draught and the sum of the maximum pressure resistance

of the chimney and the wind velocity pressure

3.12

maximum draught at the flue gas inlet into the chimney

P

Zmax

difference between the maximum theoretical draught and the minimum pressure resistance in the

chimney

3.13

minimum draught for the !combustion"appliance

P

W

difference between the static air pressure of the room of installation of the !combustion"appliance

and the static pressure of the flue gas at the chimney outlet of the appliance which is necessary to

maintain the correct operation of the !combustion"appliance

3.14

maximum draught for the !combustion"appliance

P

Wmax

difference between the static air pressure of the room of installation of the !combustion"appliance

and the static pressure of the flue gas at the outlet of the appliance which is the maximum allowed to

maintain the correct operation of the !combustion"appliance

3.15

effective pressure resistance of the connecting flue pipe

P

FV

static pressure difference between the axis of the inlet of the connecting flue pipe and the axis of the

chimney outlet due to the theoretical draught and pressure resistance

3.16

effective pressure resistance of the air supply

P

B

difference between the static pressure in the open air and the static air pressure in the room of

installation of the !combustion"appliance at the same height

3.17

minimum draught required at the flue gas inlet into the chimney

P

Ze

sum of the minimum draught required for the !combustion"appliance and the draught required to

overcome the effective pressure resistance of the connecting flue pipe and the effective pressure

resistance of the air supply

3.18

maximum allowed draught at the flue gas inlet into the chimney

P

Zemax

sum of the maximum draught allowed for the !combustion"appliance and the draught required to

overcome the effective pressure resistance of the connecting flue pipe and the effective pressure

resistance of the air supply

3.19

maximum positive pressure at the flue gas inlet into the chimney

P

ZO

difference of the maximum pressure resistance and the minimum theoretical draught of the chimney

added by the wind velocity pressure

3.20

minimum positive pressure at the flue gas inlet into the chimney

P

ZOmin

difference of the minimum pressure resistance and the maximum theoretical draught of the chimney

3.21

maximum differential pressure of the !combustion"appliance

P

WO

maximum difference between the static pressure of the flue gas at the chimney outlet of the appliance

and the static pressure of the air at the inlet to the !combustion"appliance specified for its correct

operation

3.22

minimum differential pressure of the !combustion"appliance

P

WOmin

minimum difference between the static pressure of the flue gas at the outlet of the appliance and the

static pressure of the air at the inlet to the !combustion"appliance specified for its correct

operation. This can be a negative value.

3.23

maximum differential pressure at the flue gas inlet into the chimney

PZOe

difference between the maximum differential pressure of the !combustion"appliance and the sum

of the effective pressure resistance of the connecting flue pipe and the effective pressure resistance of

the air supply

3.24

secondary air

ambient air added to the flue gas in addition to the nominal flue gas mass flow

3.25

minimum differential pressure at the flue gas inlet into the chimney

P

ZOemin

difference between the minimum differential pressure of the !combustion"appliance and the sum

of the effective pressure resistance of the connecting flue pipe and the effective pressure resistance of

the air supply

3.26

secondary air device

draught regulator or a draught diverter

3.27

draught regulator

component which automatically supplies ambient air to the chimney, the connecting flue pipe or the

!combustion"appliance

3.28

draught diverter

device, placed in the combustion products passage of the !combustion"appliance, that is intended

to maintain the quality of combustion within certain limits and to keep the combustion stable under

certain conditions of up draught and down draught

3.29

temperature limit of the inner wall

T

g

allowed minimum temperature of the inner wall of the chimney outlet

3.30

air-supply duct

component or components parallel to the chimney (separate or concentric) that conveys combustion air

from the outside atmosphere to the inlet of the connecting air supply pipe

3.31

balanced flue chimney

chimney where the point of air entry to the air supply duct is adjacent to the point of discharge of

combustion products from the flue, the inlet and outlet being so positioned that wind effects are

substantially balanced

3.32

chimney segment

calculation part of a chimney

3.33

condensate mass flow

m

D

mass of water vapour of the flue gas condensed in the !combustion"appliance, connecting flue pipe

or the chimney per time unit

3.34

connecting air supply pipe

component or components connecting the air supply duct outlet with the room-sealed

!combustion"appliance combustion air inlet

3.35

condensation factor

f

K

proportion of the theoretical maximum condensation mass flow usable in the calculation

3.36

chimney fan

exhaust fan or inline fan

3.36.1

exhaust fan

fan positioned on the outlet of the chimney

3.36.2

inline fan

fan positioned as a section of the connecting flue

4 Symbols and abbreviations

The symbols given in this clause can be completed by one or more indices to indicate location or

materials if necessary.

Table 1 — Symbols, terminology and units

Symbol Terminology Unit

A cross section area m

c specific heat capacity J/(kg · K)

c specific heat capacity of flue gas J/(kg · K)

p

d thickness of the section m

D diameter m

D hydraulic diameter

m

h

E heat flux ratio –

g acceleration due to gravity m/s

H effective height of the chimney m

k coefficient for heat transmission W/(m · K)

K coefficient of cooling –

L length m

l proportion of condensation surface –

C

m flue gas mass flow kg/s

flue gas mass flow of !combustion"appliance reduced by

m

kg/s

W

condensed water

condensate mass flow

m

kg/s

D

N Nusselt number –

u

N number of segments –

seg

p static pressure Pa

p external air pressure Pa

L

P effective pressure resistance of the air supply Pa

B

P pressure resistance due to friction and form resistance of the chimney Pa

E

P effective pressure resistance of the connecting flue pipe Pa

FV

difference in pressure caused by change of velocity of flue gas in the

P Pa

G

chimney

P theoretical draught available due to chimney effect Pa

H

theoretical draught available due to chimney effect of the connecting

P Pa

HV

flue pipe

P wind velocity pressure Pa

L

P draught required for secondary air devices Pa

NL

P pressure resistance of the chimney Pa

R

P pressure resistance of the connecting flue pipe Pa

RV

Symbol Terminology Unit

P minimum draught for the !combustion"appliance Pa

W

P maximum draught for the !combustion"appliance Pa

Wmax

P maximum differential pressure of the !combustion"appliance Pa

WO

P minimum differential pressure of the !combustion"appliance Pa

WOmin

P minimum draught at the flue gas inlet into the chimney Pa

Z

P maximum draught at the flue gas inlet into the chimney Pa

Zmax

P minimum draught required at the flue gas inlet into the chimney Pa

Ze

P maximum allowed draught at the flue gas inlet into the chimney Pa

Zemax

P maximum positive pressure at the flue gas inlet into the chimney Pa

ZO

P minimum positive pressure at the flue gas inlet into the chimney Pa

ZOmin

P maximum differential pressure at the flue gas inlet into the chimney Pa

ZOe

P minimum differential pressure at the flue gas inlet into the chimney Pa

ZOemin

P maximum allowed pressure from the designation of the chimney Pa

Zexcess

maximum allowed pressure from the designation of the connecting

P Pa

ZVexcess

flue pipe

Pr Prandtl number –

q heat transfer from the flue to the outer surface W

C

q condensation heat W

K

Q heat output kW

Q heat input kW

F

Q nominal heat output kW

N

r mean value for roughness of the inner wall m

R gas constant of the flue gas J/(kg · K)

R gas constant of the air J/(kg · K)

L

Re Reynolds number –

s cross section m

S flow safety coefficient –

E

S correction factor for temperature instability –

H

S correction factor for radiation –

rad

t temperature °C

T temperature, absolute K

T temperature limit K

g

T inner wall temperature at chimney outlet K

io

inner wall temperature at the chimney outlet at temperature

T K

iob

equilibrium

Symbol Terminology Unit

T flue gas temperature immediately before the additional insulation K

irb

T external air temperature K

L

T mean temperature of the flue gas K

m

T water dew point K

p

T condensing temperature K

sp

T ambient air temperature K

u

T ambient air temperature of the boiler room K

ub

T ambient air temperature for heated areas K

uh

T ambient air temperature for areas external to the building K

ul

T ambient air temperature at the chimney outlet K

uo

is the ambient air temperature immediately before the additional

T K

ur

insulation

T ambient air temperature for unheated areas inside the house K

uu

T flue gas temperature of the appliance K

W

T flue gas temperature of the appliance at nominal heat output K

WN

flue gas temperature of the appliance at the lowest possible heat

T K

Wmin

output

U internal chimney segment parameter m

w mean velocity within a cross section m/s

w mean velocity over a defined length m/s

m

y form value –

z height above sea level m

α coefficient of heat transfer W/(m · K)

β ratio of the combustion air mass flow to the flue gas mass flow –

γ angle between flow directions °

δ wall thickness m

ε proportion of black body radiation emitted by a surface –

coefficient of flow resistance due to a directional and/or

ζ –

cross sectional and/or mass flow change in the flue

dynamic viscosity

η

N ⋅ s/m

η efficiency of the !combustion"appliance –

W

η efficiency of the !combustion"appliance at nominal heat output –

WN

λ coefficient of thermal conductivity W/(m · K)

ρ density kg/m

ρ density of the external air

kg/m

L

Symbol Terminology Unit

mean density of flue gas averaged over a defined length and over the

ρm kg/m

cross section

σ (CO ) volume-concentration of CO %

2 2

σ (H O) volume-concentration of H O (vapour) %

2 2

2 4

σ black body radiation number W/(m · K )

Rad

ψ coefficient of flow resistance due to friction of the flue –

thermal resistance

m · K/W

Table 2 — Additional subscripts

Subscript Terminology Unit

a outside –

A flue gas –

b equilibrium temperature condition –

B combustion air –

D water vapour –

e entrance –

F open fire place –

G change in velocity –

i inside –

K condensation –

L open air (outside) –

m mean value –

M mixture –

n counting index –

N nominal value –

NL secondary air –

o chimney outlet –

O positive pressure –

tot totalized over all sections (segments) –

u ambient air –

V connecting flue pipe –

W !combustion"appliance –

5 Calculation method for non-balanced flue chimneys

5.1 General principles

The calculation of inside dimensions (cross section) of negative pressure chimneys is based on the

following four criteria:

— the minimum draught at the flue gas inlet into the chimney shall be equal to or greater than the

minimum draught required at the flue gas inlet into the chimney;

— the minimum draught at the flue gas inlet to the chimney shall be equal to or greater than the

effective pressure resistance of the air supply;

— the maximum draught at the flue gas inlet into the chimney shall be equal to or less than the

maximum allowed draught at the flue gas inlet into the chimney;

— the temperature of the inner wall at the outlet of the chimney shall be equal to or greater than the

temperature limit.

The calculation of inside dimensions (cross section) of positive pressure is based on the following four

criteria:

— the maximum positive pressure at the flue gas inlet into the chimney shall be equal or less than the

maximum differential pressure at the flue gas inlet into the chimney;

— the maximum positive pressure in the connecting flue pipe and in the chimney shall not be higher

than the excess pressure for which both are designated;

— the minimum positive pressure at the flue gas inlet into the chimney shall be equal or greater than

the minimum differential pressure at the flue gas inlet into the chimney;

— the temperature of the inner wall at the chimney outlet of the chimney shall be equal to greater

than the temperature limit.

NOTE The pressure requirements for maximum draught or minimum positive pressure are only required if

there is a limit for the maximum draught for the negative pressure !combustion"appliance or a minimum

differential pressure of the positive pressure !combustion"appliance.

In order to verify the criteria two sets of external conditions are used:

— the calculation of the minimum draught and maximum positive pressure is made with conditions

for which the capacity of the chimney is minimal (i.e. high outside temperature); and also

— the calculation of the maximum draught and minimum positive pressure and of the inner wall

temperature with conditions for which the inside temperature of the chimney is minimal (i.e. low

outside temperature.

5.2 Pressure requirements

5.2.1 Negative pressure chimneys

The following relationships shall be verified:

PZ = PH − PR − PL ≥ PW + PFV + PB = PZe, in Pa (1)

P ≥ P , in Pa (2)

Z B

and if appropriate

P = P − P ≤ P + P + P = P , in Pa (2a)

Zmax H R Wmax FV B Zemax

where

P is the effective pressure resistance of air supply (see 5.11.3), in Pa;

B

P is the effective pressure resistance of the connecting flue pipe, in Pa;

FV

P is the theoretical draught available due to chimney effect, in Pa;

H

P is the wind velocity pressure, in Pa;

L

P is the pressure resistance of the chimney, in Pa;

R

P is the minimum draught for the !combustion"appliance, in Pa;

W

P is the maximum draught for the !combustion"appliance, in Pa;

Wmax

P is the minimum draught at the flue gas inlet into the chimney (see 5.10), in Pa;

Z

P is the maximum draught at the flue gas inlet into the chimney (see 5.11), in Pa;

Zmax

PZe is the minimum draught required at the flue gas inlet into the chimney, in Pa;

P is the maximum allowed draught at the flue gas inlet into the chimney, in Pa.

Zemax

NOTE The values of P and P in Formulas (1) and (2a) are normally different because the conditions are

H H

different.

5.2.2 Positive pressure chimneys

The following relationships shall be verified:

P = P - P + P ≤ P - P - P = P , in Pa (3)

ZO R H L WO B FV Zoe

P ≤ P , in Pa (4)

ZO Z excess

P + P ≤ P , in Pa (5)

ZO FV ZV excess

and if appropiate

P = P - P ≥ P - P - P = P , in Pa (5a)

ZOmin R H WOmin B FV Zoemin

where

P is the effective pressure resistance of air supply, in Pa;

B

P is the effective pressure resistance of the connecting flue pipe, in Pa;

FV

P is the theoretical draught available due to chimney effect, in Pa;

H

P is the wind velocity pressure, in Pa;

L

P is the pressure resistance of the chimney, in Pa;

R

P is the maximum differential pressure of the !combustion"appliance, in Pa;

WO

P is the minimum differential pressure of the !combustion"appliance, in Pa;

WOmin

P is the maximum positive pressure at the flue gas inlet into the chimney, in Pa;

ZO

P is the minimum positive pressure at the flue gas inlet into the chimney, in Pa;

ZOmin

P is the maximum differential pressure at the flue gas inlet into the chimney, in Pa;

ZOe

P is the minimum differential pressure at the flue gas inlet into the chimney, in Pa;

ZOemin

P is the maximum allowed pressure from the designation of the chimney, in Pa;

Z excess

P is the maximum allowed pressure from the designation of the connecting flue pipe, in Pa.

ZVexcess

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...