EN 13216-1:2019

(Main)Chimneys - Test methods for system chimneys - Part 1: General test methods

Chimneys - Test methods for system chimneys - Part 1: General test methods

This document specifies material-independent general test methods for all system chimneys. It can be used for all flue gas carrying products.

NOTE The thermal performance tests for the determination of the distance to combustible material for accessories (draught regulators, access components, etc.) are included in different standards of CEN/TC 166.

Abgasanlagen - Prüfverfahren für System-Abgasanlagen - Teil 1: Allgemeine Prüfverfahren

Dieses Dokument legt werkstoffunabhängige Prüfverfahren für sämtliche System-Abgasanlagen fest.

Die Prüfungen der thermischen Leistungskriterien für die Bestimmung der Entfernung zu brennbaren Stoffen in der vorliegenden Norm beziehen sich ausschließlich auf Abschnitte einer Abgasanlage.

ANMERKUNG Die Prüfungen der thermischen Leistungskriterien für die Bestimmung der Entfernung zu brennbaren Stoffen für Zubehörteile (Nebenluftvorrichtung, Inspektionstüren usw.) werden in anderen Normen von CEN/TC 166 behandelt.

Conduits de fumée - Méthodes d'essai pour les systèmes de conduits de fumée - Partie 1 : Méthodes d'essai générales

Le présent document spécifie des méthodes d'essai générales pour les systèmes de conduits de fumée, indépendamment des matériaux utilisés.

Les essais de performance thermique de la présente norme, destinés à la détermination de la distance à respecter par rapport au matériau combustible, s’appliquent uniquement aux éléments droits de conduit de fumée.

NOTE : Les essais de performance thermique pour la détermination de la distance à respecter entre les matériaux combustibles et les accessoires (régulateurs de tirage, trappes d’inspection, etc.) sont intégrés à différentes normes du CEN/TC 166.

Dimovodne naprave - Preskusne metode za sistemske dimovodne naprave - 1. del: Splošne preskusne metode

Ta dokument določa splošne preskusne metode za vse sistemske dimovodne naprave, ne glede na material.

Toplotni delovni preskus za določanje razdalje do gorljivega materiala v tem standardu se uporabi le za dimovodne sekcije.

OPOMBA: Toplotni delovni preskus za določanje razdalje do gorljivih materialov za dodatke (regulatorji vleka, servisna vrata, itd.) je vključen v druge standarde CEN/TC 166.

General Information

- Status

- Published

- Publication Date

- 16-Apr-2019

- Withdrawal Date

- 30-Oct-2019

- Technical Committee

- CEN/TC 166 - Chimneys

- Drafting Committee

- CEN/TC 166/WG 1 - General requirements

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 13-May-2025

- Completion Date

- 11-Feb-2026

Relations

- Replaces

EN 13216-1:2004 - Chimneys - Test methods for system chimneys - Part 1: General test methods - Effective Date

- 18-Jun-2014

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 16497-1:2015 - Chimneys - Concrete System Chimneys - Part 1: Non-balanced flue applications - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 15035:2006 - Heating boilers - Special requirements for oil fired room sealed units up to 70 kW - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 13216-1:2019 - Chimneys: Test methods for system chimneys - Part 1: General test methods - defines material‑independent, general test methods for system chimneys and for all flue‑gas carrying products. It replaces EN 13216-1:2004 and provides the common test framework used across the EN 13216 series. The standard is intended for laboratory type‑testing, product development, conformity assessment and performance verification of chimney systems and terminals.

Note: thermal performance tests relating to distances to combustible materials for accessories (draught regulators, access components, etc.) are handled in other CEN/TC 166 standards.

Key topics and technical requirements

The standard specifies test environment, instrumentation and a wide range of performance tests, including:

- Test environment and measurement accuracy

- Location, ambient conditions, temperature and pressure measurement requirements.

- Mechanical and durability tests

- Abrasion resistance and relative movement of liners in multi‑wall systems.

- Tightness and condensate behaviour

- Gas tightness; condensate penetration (liquid phase) and condensate resistance (vapour phase).

- Thermal performance

- Thermal performance tests and thermal resistance measurement procedures.

- Aerodynamic and flow tests

- Terminal flow resistance (Types I, II, III), flow resistance of ducts, aerodynamic behaviour under wind and recirculation tests.

- Weather resistance

- Rainwater resistance of chimney sections, rain ingress for terminals (with/without wind), icing behaviour.

- Durability under climatic cycles

- Freeze–thaw resistance tests.

- Annexes and test reporting

- Recommended test sequence, basic test structure, method for measuring hot gas temperature, example test report and terminal characterization.

The standard defines test apparatus, sample preparation, measuring parameters, procedures and criteria for reporting results.

Practical applications

EN 13216-1:2019 is used to:

- Support type testing and CE marking of chimney systems and flue components.

- Provide repeatable methods for R&D and product validation (manufacturers).

- Enable independent test laboratories to produce comparable performance data.

- Inform specifiers, HVAC engineers and installers about expected product behaviour (airflow, condensation, weather resistance).

- Support regulatory and conformity assessment by national authorities and certification bodies.

Who uses this standard?

- Chimney and flue system manufacturers

- Independent testing and certification laboratories

- HVAC and building services engineers

- Product safety and compliance officers

- Regulators and technical assessors

Related standards

- Other parts of the EN 13216 series covering product‑specific tests and accessories

- Standards and documents developed by CEN/TC 166 (chimney and flue systems)

Keywords: EN 13216-1:2019, system chimneys, chimney test methods, flue gas, thermal performance, gas tightness, condensate resistance, terminal flow resistance, rain ingress, aerodynamic behaviour.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 13216-1:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Chimneys - Test methods for system chimneys - Part 1: General test methods". This standard covers: This document specifies material-independent general test methods for all system chimneys. It can be used for all flue gas carrying products. NOTE The thermal performance tests for the determination of the distance to combustible material for accessories (draught regulators, access components, etc.) are included in different standards of CEN/TC 166.

This document specifies material-independent general test methods for all system chimneys. It can be used for all flue gas carrying products. NOTE The thermal performance tests for the determination of the distance to combustible material for accessories (draught regulators, access components, etc.) are included in different standards of CEN/TC 166.

EN 13216-1:2019 is classified under the following ICS (International Classification for Standards) categories: 91.060.40 - Chimneys, shafts, ducts. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13216-1:2019 has the following relationships with other standards: It is inter standard links to EN 13216-1:2004, EN 60529:1991, EN 1443:2019, EN 13384-1:2015, EN 10088-1:2023, EN 16497-1:2015, EN 1857:2010, EN 1366-13:2019, EN 15035:2006, EN 13501-2:2023, EN 1858:2008+A1:2011, EN 15502-2-1:2022, EN 15287-2:2023, EN 13501-2:2016, EN 1443:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13216-1:2019 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/105, M/447. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13216-1:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2019

Nadomešča:

SIST EN 13216-1:2004

Dimovodne naprave - Preskusne metode za sistemske dimovodne naprave - 1. del:

Splošne preskusne metode

Chimneys - Test methods for system chimneys - Part 1: General test methods

Abgasanlagen - Prüfverfahren für System-Abgasanlagen - Teil 1: Allgemeine

Prüfverfahren

Conduits de fumée - Méthodes d'essai pour les systèmes de conduits de fumée - Partie

1 : Méthodes d'essai générales

Ta slovenski standard je istoveten z: EN 13216-1:2019

ICS:

91.060.40 Dimniki, jaški, kanali Chimneys, shafts, ducts

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13216-1

EUROPEAN STANDARD

NORME EUROPÉENNE

April 2019

EUROPÄISCHE NORM

ICS 91.060.40 Supersedes EN 13216-1:2004

English Version

Chimneys - Test methods for system chimneys - Part 1:

General test methods

Conduits de fumée - Méthodes d'essai pour les Abgasanlagen - Prüfverfahren für System-

systèmes de conduits de fumée - Partie 1 : Méthodes Abgasanlagen - Teil 1: Allgemeine Prüfverfahren

d'essai générales

This European Standard was approved by CEN on 12 November 2018.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13216-1:2019 E

worldwide for CEN national Members.

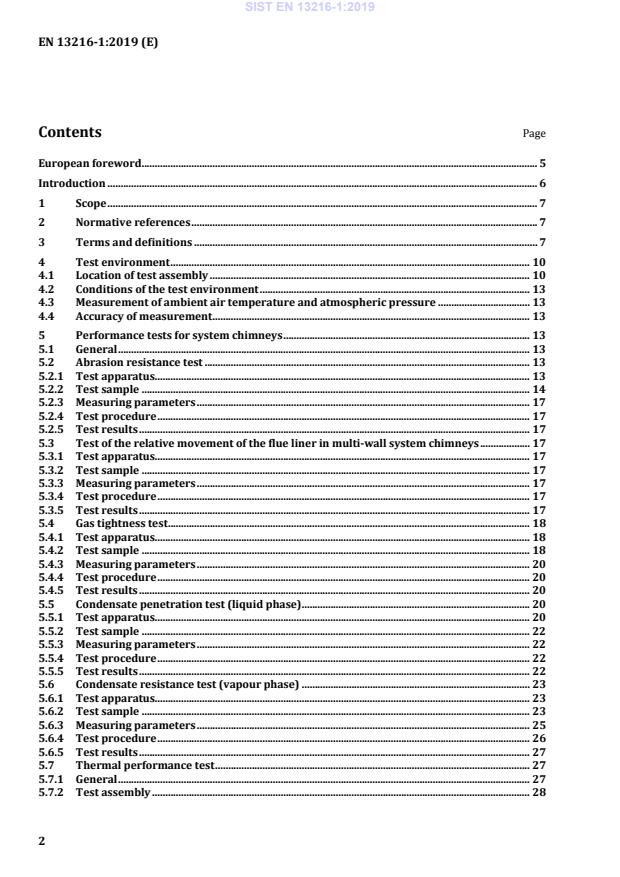

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Test environment . 10

4.1 Location of test assembly . 10

4.2 Conditions of the test environment . 13

4.3 Measurement of ambient air temperature and atmospheric pressure . 13

4.4 Accuracy of measurement . 13

5 Performance tests for system chimneys . 13

5.1 General . 13

5.2 Abrasion resistance test . 13

5.2.1 Test apparatus. 13

5.2.2 Test sample . 14

5.2.3 Measuring parameters . 17

5.2.4 Test procedure . 17

5.2.5 Test results . 17

5.3 Test of the relative movement of the flue liner in multi-wall system chimneys . 17

5.3.1 Test apparatus. 17

5.3.2 Test sample . 17

5.3.3 Measuring parameters . 17

5.3.4 Test procedure . 17

5.3.5 Test results . 17

5.4 Gas tightness test . 18

5.4.1 Test apparatus. 18

5.4.2 Test sample . 18

5.4.3 Measuring parameters . 20

5.4.4 Test procedure . 20

5.4.5 Test results . 20

5.5 Condensate penetration test (liquid phase) . 20

5.5.1 Test apparatus. 20

5.5.2 Test sample . 22

5.5.3 Measuring parameters . 22

5.5.4 Test procedure . 22

5.5.5 Test results . 22

5.6 Condensate resistance test (vapour phase) . 23

5.6.1 Test apparatus. 23

5.6.2 Test sample . 23

5.6.3 Measuring parameters . 25

5.6.4 Test procedure . 26

5.6.5 Test results . 27

5.7 Thermal performance test . 27

5.7.1 General . 27

5.7.2 Test assembly . 28

5.7.3 Test procedure . 38

5.7.4 Test results . 40

5.8 Thermal resistance test . 40

5.8.1 Test apparatus . 40

5.8.2 Test sample . 42

5.8.3 Measuring parameters. 42

5.8.4 Test procedure . 42

5.8.5 Test results . 44

5.9 Terminal flow resistance for terminal Type I, II and III . 44

5.9.1 General . 44

5.9.2 Test apparatus . 44

5.9.3 Test sample . 44

5.9.4 Measurement parameters . 45

5.9.5 Test condition . 45

5.9.6 Test procedure . 45

5.9.7 Test result . 45

5.9.8 Flow resistance in the flue duct for terminals Type I, II and III . 48

5.9.9 Flow resistance in the air duct for terminals Type III . 48

5.10 Aerodynamic behaviour of terminal under wind conditions . 49

5.10.1 For terminal Type II, test method for wind velocity pressure . 49

5.10.2 For a terminal Type III, test method for wind velocity pressure . 51

5.10.3 For terminal Type III, test method for recirculation . 53

5.11 Flow resistance of the test chimney, of fittings or liners . 55

5.11.1 Test apparatus . 55

5.11.2 Test sample . 56

5.11.3 Measuring parameter. 57

5.11.4 Test procedure . 57

5.11.5 Test results . 58

5.12 Rainwater resistance of chimney sections . 59

5.12.1 Test apparatus . 59

5.12.2 Test sample . 60

5.12.3 Measuring parameters. 60

5.12.4 Test procedure . 60

5.12.5 Test results . 60

5.13 Freeze–thaw resistance . 60

5.13.1 Apparatus . 60

5.13.2 Test samples . 61

5.13.3 Test procedure . 61

5.13.4 Test result . 63

5.14 Rainwater ingress for terminals . 63

5.14.1 General . 63

5.14.2 For terminal Type Ib, II and III, test method without wind . 64

5.14.3 For terminal Type Ib, II and III, test method with wind . 66

5.15 Icing behaviour, test method for terminal Type II and III . 69

5.15.1 Test apparatus . 69

5.15.2 Test sample . 69

5.15.3 Measuring parameters. 69

5.15.4 Test condition . 69

5.15.5 Test procedure . 70

5.15.6 Test result . 71

Annex A (informative) Recommended test sequence . 72

Annex B (normative) Basic test structure . 73

Annex C (normative) Method of measuring the hot gas temperature . 75

Annex D (informative) Example of a test report . 77

Annex E (informative) Terminals . 79

E.1 Characterization of a terminal . 79

E.1.1 Types of terminals . 79

E.1.1.1 Type I . 79

E.1.1.2 Type II . 79

E.1.1.3 Type III . 79

E.1.2 Wind direction characteristics . 79

E.2 Requirements . 80

E.2.1 General . 80

E.2.2 Flow resistance of terminals Type I, II and III . 80

E.2.3 Aerodynamic properties of terminals Type II and III . 80

E.2.3.1 Terminal Type II . 80

E.2.3.2 Terminal Type III . 80

E.2.4 Rain water ingress . 81

E.2.5 Icing behaviour . 81

Annex F (informative) Type of test structure . 82

European foreword

This document (EN 13216-1:2019) has been prepared by Technical Committee CEN/TC 166

“Chimneys”, the secretariat of which is held by ASI.

This document shall be given the status of a national standard, either by publication of an identical text

or by endorsement, at the latest by month year of October 2019, and conflicting national standards shall

be withdrawn at the latest by January 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document will supersede EN 13216:2004.

System chimneys type tested prior to this revision need not be retested, if historical data covers the

intended configuration for the relevant test.

In comparison to the previous edition the following changes were made:

a) clarification of the scope;

b) revision of terms and definitions;

c) revision of the thermal test assembly and test structure to include options for alternative building

insulation levels;

d) revision of the test procedure;

e) incorporation of terminals;

f) incorporation of test for freeze–thaw resistance;

g) incorporation of testing of concentric balanced flue systems;

h) editorial changes.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

Introduction

CEN/TC 166 intends to publish the test methods for system chimneys as separate parts of a series of

standards.

The first part of the series of EN 13216 includes material-independent test methods for system

chimneys.

Further parts of the multi-part standard include material-specific test methods, each material used for

the inner wall being decisive. The material-specific test methods are based on the general material-

independent test methods. Considering the various characteristics, the material tests can be carried out

on deviating specimens or can include other test procedures that however have correlation to those

given in this document.

It is intended to prepare further parts if further material-specific standards are published.

1 Scope

This document specifies material-independent general test methods for all system chimneys. It can be

used for all flue gas carrying products.

NOTE The thermal performance tests for the determination of the distance to combustible material for

accessories (draught regulators, access components, etc.) are included in different standards of CEN/TC 166.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1443, Chimneys - General requirements

EN 10088-1, Stainless steels - Part 1: List of stainless steels

EN 13384-1:2015, Chimneys - Thermal and fluid dynamic calculation methods - Part 1: Chimneys serving

one heating appliance

EN 60529, Degrees of protection provided by enclosures (IP Code) (IEC 60529)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 1443 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1

test chimney

test sample necessary to enable the system chimney to be assessed for the performance criteria defined

in the relevant product standard

3.2

test assembly

construction of all parts necessary to enable the specific performance criteria to be assessed,

comprising test sample, test structures, and measuring equipment

3.3

test sample

assembly of chimney components necessary to enable the system chimney to be assessed for specific

performance criteria

3.4

test structure

assembly of the additional materials (non-chimney components) to enable the test sample to be

assessed for the specific performance criteria

3.5

thermal performance test

method to assess the temperature characteristics of the system chimney

3.6

heat stress test

method to assess the temperature characteristics of the system chimney under normal operating

conditions

3.7

sootfire resistance test

method to assess the sootfire resistance characteristics of the system chimney (internal to external)

3.8

condensate resistance test (vapour phase)

method to assess the system chimney’s resistance to vapour and condensate

Note 1 to entry: This describes the vapour phase.

3.9

condensate penetration test (liquid phase)

method to assess the components or sub-assemblies of system chimney’s resistance to condensate in

the liquid phase

Note 1 to entry: This describes the liquid phase.

3.10

accuracy

ability of the measuring instruments to give response in the specified range from the true value

3.11

uncertainty of measurement

combination of all parameters to give response in the specified range from the true result

Note 1 to entry: Parameters are e.g. accuracy, human parameter, or environmental parameters.

3.12

tolerance

range in which a parameter has to be met

3.13

distance to combustible material

declared distance to combustible material verified in the thermal performance test

3.14

test apparatus

equipement used to perform a test

3.15

conditioning

stabilisation of the sample in ambient air as specified in product standard

3.16

pit

damage in form of superficial fault consisting of a fraction of material detached from the body of the

test-sample with a mean dimension of over 7 mm

3.17

hair crack

damage which is deemed to be harmless in form of superficial crack having a width of not more than

0,15 mm

3.18

nascent crack

damage which is deemed to be harmless in form of crack formation at the edge, only crack penetrating

slightly into the interior of the test sample

3.19

surface crack

damage caused by crack of more than 0,15 mm width which does not pass through the test sample

3.20

scaling

damage caused by surface raising, nascent chipping or crack, which initiates damage

3.21

peeling

damage characterised by the loss of part of the superficial layer of the test sample

3.22

surface damage

damage caused by breaking off (detachment) a part of the surface of the test sample; the surface area of

the test sample remains unchanged

3.23

flaking

damage characterised by a progressive loss of material affecting the whole, or part of the thickness of

the sample

3.24

structural crack

structural damage consisting of a more or less regular crack running throughout the entire thickness of

the test sample and visible to the naked eye

3.25

break

structural damage consisting of a separation of the test sample into two or more fragments

3.26

delamination

damage in the form of lamellar flaking in a succession of parallel layers

4 Test environment

4.1 Location of test assembly

The distance between the test assembly as shown in Figure 1 a) to 1 c) and other structures (e.g. test

room walls) shall be sufficient to not influence the test results; a distance of at least 1,0 m is deemed to

satisfy this requirement.

a) — Test assembly (schematic)

Dimensions in millimetres

b) — Test assembly (detailed)

Dimensions in millimetres

c) — Example of free standing test assembly

NOTE Figure 1 c) illustrates the principle of test assembly and does not represent any specific test assembly.

Key

test apparatus

test structure

test chimney

1 plywood 9 zone C

2 insulation 10 zone B

3 plywood 11 zone A

4 extract provisions x distance to combustible

5 hot gas generator D inner diameter of the test chimney

6 enclosure measuring point for human contact (Figure 1b)

7 test chimney ambient air temperature

8 opening hot gas temperature

ambient air temperature

hot gas temperature

surface temperature, test chimney (Figure 1c)

Figure 1 — Test assemblies

4.2 Conditions of the test environment

The ambient air temperature in the test room shall not vary during the heat stress test by more than 5 K

and shall remain in the temperature range of 15 °C up to 30 °C.

The ambient air temperature in the test room shall not vary during the sootfire resistance test by more

than 15 K and shall remain in the temperature range of 15 °C up to 35 °C.

The test environment shall consist of a ventilated space not subject to air movement greater than

0,5 m/s measured at the ambient thermocouple position. This requirement is deemed fulfilled in a

closed test room.

The humidity shall be controlled between 30 % to 70 % RH.

4.3 Measurement of ambient air temperature and atmospheric pressure

The ambient air temperature shall be measured at a position diagonally from the free corner of the test

assembly (2 ± 0,1) m away from the inside corner of the test rig at the level in the centre of the first

floor (±0,1 m), see Figure 1 b).

Shield a calibrated thermocouple by placing it centrally within a length of aluminium painted metal

tube, (150 ± 2) mm long and 50 mm nominal diameter, open at each end. The metal tube shall be placed

vertically to avoid direct radiation to the thermocouple.

The atmospheric pressure has to be measured.

4.4 Accuracy of measurement

The ambient air temperature shall be measured with an accuracy of ± 1,5 K.

The velocity of the ambient air shall be measured with an accuracy of ± 0,1 m/s.

The atmospheric pressure shall be measured with an accuracy of ± 1 %.

5 Performance tests for system chimneys

5.1 General

Annex A gives a recommended test sequence.

5.2 Abrasion resistance test

5.2.1 Test apparatus

A tight fitting metal sleeve attached to a guide funnel shall be fitted into the top opening of the flue of

the test chimney (see Figure 2). The alternative test sample from chimney sections may be tested as

shown in Figure 3. A tight fitting metal sleeve attached to a plate which has an opening matching the

area of the opening to the flue shall be fitted into the bottom opening of this test sample.

The bottom plate supported directly over a collection box is positioned to collect any material which is

dislodged during the test, and which is sufficiently deep to allow the brush to pass through the complete

length of the test sample.

The brush shall be attached either to a rod or to a sweeping equipment as shown in Figure 4.

Use a sweeping brush having flat spring-steel bristles of stainless steel in accordance with EN 10088-1,

grade X10CrNi18-8, steel number 1.4310, with a cross section of (2,0 ± 0,2) mm x (0,25 ± 0,05) mm

with the ends cut square. The bristles shall be arranged so that there are 5 per 10 mm length of the

perimeter of the plan area of the brush. The brush may be a combination of single brushes.

The over-all dimension of the brush shall be (25 ± 5) mm greater than the internal dimension of a round

flue or the corresponding dimension of a flue with square or rectangular cross section, see Figure 4. The

brush shall be held securely between plates having a plan dimension (100 ± 5) mm less than the

internal dimension of the flue.

The balance to weigh the deposit shall have an accuracy of 1,0 g.

5.2.2 Test sample

The test sample shall be the test chimney used for the thermal performance tests, see Figure 2 or the

alternative test sample, see Figure 3, after thermal performance tests (according to 5.7). The test

sample shall be assembled as specified in the product standards.

Dimensions in millimetres

Key

1 test chimney

2 catchment funnel

Figure 2 — Abrasion resistance – test chimney

Dimensions in millimetres

Key

1 test sample

2 catchment funnel

3 collection box

4 bottom plate

Figure 3 — Abrasion resistance – test sample

Dimensions in millimetres

Key

1 rope

2 striking element

3 brush

4 steel spring bristles

5 chain

6 weight

7 flue liner cross section (round/square/rectangular)

Figure 4 — Abrasion resistance – sweeping test equipment

5.2.3 Measuring parameters

Measure the weight of material dislodged from the inner surface of the test sample after the cycles

specified in the system chimney standards with an accuracy of 1,0 g.

The area for the inner surface of the test sample exposed to abrasion shall be calculated.

5.2.4 Test procedure

The brush shall be pushed down and up through the total length of the test sample with a maximum

speed of 2 m/s, and this represents one cycle. The number of cycles shall be specified in the material

dependant system chimney standard.

Record the weight of material dislodged and the dimensions of the inner surface.

5.2.5 Test results

The recorded mass of material abraded from the inner surface of the test sample over the specified

cycles shall be expressed in terms of kilograms per square meter of the total exposed area of the inner

surface of the flue or flue liner.

5.3 Test of the relative movement of the flue liner in multi-wall system chimneys

5.3.1 Test apparatus

Use a test apparatus which allows the measurement of longitudinal change of position between the flue

liner and the outer wall of multi-wall-system chimneys. This is measured at the chimney outlet prior to

and after the thermal performance test.

The accuracy shall be ± 0,001 m.

5.3.2 Test sample

The test sample shall be the test chimney subjected to the thermal performance tests according to the

product designation. The test sample shall be assembled as specified in product standards and the

provisions in 5.7.

5.3.3 Measuring parameters

Measure the surface temperature of the test chimney in accordance with 5.7.2.5.5.

Measure the change in position of the flue liner relative to the outer wall at the top of the test sample

before and after the thermal performance tests.

5.3.4 Test procedure

All measurements shall be made before and after the thermal performance tests appropriate to the

designation.

Record the difference in length between the flue liner and the outer wall when all thermocouples have

reached ambient air temperature within 5 K.

5.3.5 Test results

The results are expressed by the change in position of the flue liner relative to the outer wall after the

test sample has cooled down to room temperature.

5.4 Gas tightness test

5.4.1 Test apparatus

Provide an air supply capable of delivering air at a flow rate sufficient to achieve and maintain the

required test pressure at the leakage rate appropriate to the designation.

Seal the flue inlet and the flue outlet of the test chimney with an air tight seal in a typical manner, see

Figure 5.

For measurement of pressure use:

— for chimneys designated “N”, a device with the pressure to an accuracy of ± 1 Pa;

— for chimneys designated “P”, a device with the pressure to an accuracy of ± 5 Pa;

— for chimneys designated “M”, a device with the pressure to an accuracy of ± 50 Pa;

— for chimneys designated “H”, a device with the pressure to an accuracy of ± 50 Pa.

5.4.2 Test sample

The test sample shall be the test chimney used for the thermal performance tests. The test sample shall

be assembled as specified in system chimney standards and the provisions in 5.7. For the arrangement

of the gas tightness test see Figure 5.

Where the product standard requires additional tightness tests without thermal conditioning, the test

sample (i.e. with an opening where appropriate) shall consist of at least two chimney sections or fittings

with one joint where applicable.

Key

1 test chimney (example)

2 equipment for closing the outlet (plate or bladder)

3 sealing element

4 flowmeter

5 fan (air supply)

6 manometer

Figure 5 — Gas tightness – test chimney

5.4.3 Measuring parameters

Measure and record:

— gas leakage and the pressure maintained during the test in accordance with pressure class

designation as defined in EN 1443;

— dimensions (e.g. inner diameter of the flue liner, length between closing devices) of the test sample.

Calculate the inner surface area.

Record the leakage rate, the pressure and the dimensions (e.g. inner diameter of the flue liner, length

between closing devices) of the test sample.

5.4.4 Test procedure

Deliver air from the air supply to the flue at a rate necessary to achieve and maintain the required test

pressure given in EN 1443 with a tolerance of:

— ± 5 % for chimneys designated “N”;

— ± 5 % for chimneys designated “P”;

— ± 5 % for chimneys designated “M”;

— ± 5 % for chimneys designated “H”.

The gas leakage shall be measured at ambient temperature.

5.4.5 Test results

The results are expressed by the leakage rate related to the inner surface area of the test sample.

5.5 Condensate penetration test (liquid phase)

5.5.1 Test apparatus

A test apparatus which allows spraying of water into the flue, in accordance with Figure 6, shall be used.

The balance to weigh components of the test sample shall have an accuracy of ± 1 g up to 10 kg

and ± 2 g for more than 10 kg.

Key

1 tank containing water 4 gate valve 7 spray equipment

2 electric heating 5 air supply 8 test chimney

3 thermometer 6 air tight cap 9 condensate outlet

Figure 6 — Condensate resistance (liquid phase) – test chimney

5.5.2 Test sample

The test sample shall be in accordance with the product standard. It consists of minimum two sections

or fittings subjected to thermal performance tests according to the product designation with at least

one joint.

5.5.3 Measuring parameters

Measure:

— the spray temperature and the spray volume;

— the change in weight of the test sample.

Check the appearance of water on the outside of the test sample of fittings or chimney sections of the

test chimney by visual inspection.

5.5.4 Test procedure

Spray water over the total inner circumference at the outlet of the flue liner:

— with a temperature of (50 ± 5) °C;

— with a spray pressure of a maximum of 3 bar;

3 3

-1 -1 -

— with a water volume related to the inner circumference at 0,040 m ⋅ h ⋅ m ± 0,008 m ⋅ h

1 -1

⋅ m ;

for 4 h or until water appears on the outside of the test sample.

Wipe any surface (inside and outside) water from the test sample. The test sample shall be weighed

immediately afterwards.

Dry and weigh the test sample again.

5.5.5 Test results

Record:

— location of any appearance of water on the outside of any fitting or chimney section of the test

samples; and

— any change in weight of the test sample.

5.6 Condensate resistance test (vapour phase)

5.6.1 Test apparatus

A test apparatus which allows to deliver water vapour saturated air at a temperature of (52 ± 2) °C and

a velocity of (1 ± 0,2) m/s, consisting of a fan, a heater, a vapour steam vessel and a flow rectifier, see

Figure 7.

Use measurement equipment for:

— flue gas temperature with an accuracy of ± 1,5 K,

— layer temperature with an accuracy of ± 0,5 K, and

— humidity with an accuracy of ± 2 % in the range of 0 % to 80 % and of ± 3 % in the range of 80 % to

100 %.

The balance to weigh components of the test sample shall have an accuracy of ± 1 g up to 10 kg

and ± 2 g for more than 10 kg. The balance shall be capable of weighing at least two flue liners or two

chimney sections.

For measurement of chimney draught use a device with an accuracy of ± 1 Pa.

For measurement of flue gas velocity use a device with an accuracy of ± 0,1 m/s.

5.6.2 Test sample

The test sample shall be the test chimney used for the thermal performance tests which was subjected

to the thermal performance tests in accordance with the intended designation. For the arrangement for

the condensate resistance test, see Figure 7.

Dimensions in millimetres

Key

1 fan measuring point

2 electric heating a velocity

3 steam injection b pressure

4 rectifier c temperature

5 insulation surface temperature

6 test chimney humidity

7 flue liner air temperature

8 outer wall

Figure 7 — Condensate resistance test (vapour phase) non-enclosed, measuring points in a

multi-wall chimney

5.6.3 Measuring parameters

5.6.3.1 General

Measure and record the temperatures and relative humidity of:

— the flue gas;

— the specified layers of the test sample;

— the ambient air.

Measure and record any change in weight, where appropriate.

5.6.3.2 Ambient air temperature and humidity

For ambient air temperature, see 4.3. Ambient humidity shall be measured at the same position.

5.6.3.3 Flue gas temperature and humidity

Measure the flue gas temperature with an accuracy of ± 1,5 K at a position (100 ± 2) mm before the inlet

to the test chimney and at a position 500 mm below the exit at the top of the test sample. Measure the

flue gas humidi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...