EN 16475-4:2020

(Main)Chimneys - Accessories - Part 4: Flue dampers - Requirements and test methods

Chimneys - Accessories - Part 4: Flue dampers - Requirements and test methods

This document specifies the characteristics and test methods for flue dampers that are used as components, carrying flue gas, in order to limit the flow in a chimney or to prevent back flow of soot during cleaning of the chimney or to prevent the backflow of the flue gas e.g. in case of multi-served chimneys.

This document covers only flue dampers incorporated in a housing and installed inside a building.

This document covers only flue dampers with sealings made of elastomeric materials for temperature classes up to T 200 and corrosion class 1 or 2 in accordance with EN 14241-1 or sealing materials for dry applications with a fire reaction class A1 in accordance with EN 13501-1.

This document covers only flue dampers with motor drive, casing and flue damper plate which are interlocked in such a way that they can only be separated by using tools.

This document covers only mechanical flue dampers where any motor is in accordance with EN 60730-2-14 and the cover for electrical components of the flue damper fulfils minimum protection class IP40 according to EN 60529.

This document covers only flue dampers which are designed and installed to ensure that incorrect information about the position of the flue damper flap are absolutely impossible, which are only installed on components that are interlocked to the casing, which are only activated by components that are interlocked to the flue damper flap and where it is ensured that the limit switch opens or the flue damper flap moves to the open position if one of these interlocks fails. This safety target may also be achieved with an equally suitable method (e.g. bracing or welding).

This document covers only flue dampers for biomass boilers ≥ 1 000 kW and industrial applications with limit switches in accordance with EN 61058-1 or EN 50156-1.

This document covers only flue dampers where it is possible to identify the position of the flue damper flap.

This document covers only totally closed, manually driven flue dampers (type 1) which have a facility to adjust the position of the flue damper flap.

This document covers only totally closed, mechanically driven flue dampers (type 2) with only the positions "fully opened" and "fully closed" and where it is not possible to fix the flap in the non-closed position during the flue damper flap stays in closed position while the appliance is not working.

NOTE This applies only to multi-appliance installations with positive pressure conditions.

This document covers only partially closed flue dampers (type 3 to 5) where it is possible to adjust the position of the flue damper flap and where it is ensured that the flue damper flap does not change position by itself.

Flue dampers which are integral parts of system chimney products or other chimney components, e.g. flue liners, connecting flue pipes, are not covered by this document.

This document also specifies the provisions for marking, manufacturers’ instruction, product information, Assessment and Verification of Constancy of Performance (AVCP).

This document does not specify issues for electrical parts.

Abgasanlagen - Zubehörteile - Teil 4: Abgasklappen - Anforderungen und Prüfverfahren

Dieses Dokument legt die Eigenschaften und Prüfverfahren für Abgasklappen fest, die als abgasführende Bauteile genutzt werden, um den Durchfluss in einer Abgasanlage zu begrenzen oder den Rußaustritt während der Reinigung der Abgasanlage oder den Abgasaustritt, etwa im Fall von mehrfach belegten Abgasanlagen, zu verhindern.

Dieses Dokument behandelt nur in ein Gehäuse eingebaute und innerhalb von Gebäuden installierte Abgasklappen.

Dieses Dokument behandelt nur Abgasklappen mit Dichtungen aus Elastomer-Werkstoffen für Temperaturklassen bis T 200 und die Korrosionsklassen 1 oder 2 in Übereinstimmung mit EN 14241 1 oder Dichtungswerkstoffe für trockene Anwendungen mit einer Brandverhaltensklasse A1 in Übereinstimmung mit EN 13501 1.

Dieses Dokument behandelt nur Abgasklappen mit Motorantrieb, Gehäuse und Abgasklappenscheibe, die so verriegelt sind, dass sie nur mithilfe von Werkzeugen auseinandergenommen werden können.

Dieses Dokument behandelt nur mechanische Abgasklappen, deren Motor die Anforderungen nach EN 60730 2 14 erfüllt und bei denen die Abdeckung elektrischer Komponenten mindestens der Schutzklasse IP40 nach EN 60529 entspricht.

Dieses Dokument behandelt nur Abgasklappen, die so gestaltet und installiert sind, dass falsche Informationen über die Position der Abgasklappenscheibe absolut unmöglich sind, die nur an Komponenten installiert werden, die am Gehäuse verriegelt sind, die nur durch an der Abgasklappenscheibe verriegelte Komponenten aktiviert werden und wo sichergestellt wird, dass der Betriebsendschalter sich öffnet oder sich die Abgasklappenscheibe in die offene Position bewegt, falls eine dieser Verriegelungen fehlschlägt. Dieses Sicherheitsziel darf auch durch eine ähnlich geeignete Methode (z. B. Aussteifung oder Schweißen) erreicht werden.

Dieses Dokument behandelt nur Abgasklappen für Biomassekessel ≥ 1 000 kW und Industrieanwendungen mit Betriebsendschaltern in Übereinstimmung mit EN 61058 1 oder EN 50156 1.

Dieses Dokument behandelt nur Abgasklappen, bei denen es möglich ist, die Position der Abgasklappenscheibe zu erkennen.

Dieses Dokument behandelt nur vollständig geschlossene, manuell betriebene Abgasklappen (Typ 1) mit einer Vorrichtung zur Einstellung der Position der Abgasklappenscheibe.

Dieses Dokument behandelt nur vollständig geschlossene, mechanisch angetriebene Abgasklappen (Typ 2) nur mit den Stellungen „vollständig geöffnet“ und „vollständig geschlossen“, bei denen es nicht möglich ist, die Scheibe in der nicht geschlossenen Stellung zu fixieren, wenn die Abgasklappenscheibe außerhalb des Betriebs des Geräts in der geschlossenen Stellung verbleibt.

ANMERKUNG Dies gilt nur für Installationen mit mehreren Verbrennungseinrichtungen und Überdruckbedingungen.

Dieses Dokument behandelt nur teilweise geschlossene Abgasklappen (Typ 3 bis 5), bei denen es möglich ist, die Stellung der Abgasklappenscheibe einzustellen und bei denen sichergestellt ist, dass die Abgasklappenscheibe ihre Position nicht selbstständig ändert.

Abgasklappen, die integraler Bestandteil von System-Abgasanlagen oder anderen Bauteilen einer Abgasanlage sind, wie z. B. Innenrohre, Verbindungsstücke, werden nicht von diesem Dokument abgedeckt.

Dieses Dokument legt auch Bestimmungen für Kennzeichnung, Anweisungen des Herstellers, Produktinformationen, Bewertung und Überprüfung der Leistungsbeständigkeit (AVCP) fest.

Dieses Dokument legt keine Aspekte für elektrische Teile fest.

Conduits de fumée - Accessoires - Partie 4 : Clapets de fumées - Exigences et méthodes d’essai

Le présent document spécifie les exigences et les méthodes d’essai pour les clapets de fumées utilisés comme composants, transportant les gaz de fumées, afin de limiter l’écoulement dans un conduit de fumée ou d’empêcher le retour des gaz de fumées, par exemple dans le cas des conduits de fumée collectifs.

Le présent document traite uniquement des clapets de fumées intégrés dans un logement et installés à l’intérieur d’un bâtiment.

Le présent document traite uniquement des clapets de fumées comportant des produits d’étanchéité en matériaux élastomères pour les classes de température allant jusqu’à T 200 et la classe de corrosion 1 ou 2 conformément à l’EN 14241-1 ou des produits d’étanchéité pour les applications sèches de la classe de réaction A1 conformément à l’EN 13501-1.

Le présent document traite uniquement des clapets de fumées dont l’entraînement du moteur, le boîtier et la plaque du clapet de fumées sont fixés ensemble de manière à ne pouvoir être séparés que par des outils.

Le présent document traite uniquement des clapets de fumées mécaniques dont le moteur éventuel est conforme à l’EN 60730-2-14 et dont le capot des composants électriques du clapet de fumées satisfait à la classe de protection minimale IP40 conformément à l’EN 60529.

Le présent document traite uniquement des clapets de fumées qui sont conçus et installés de façon à garantir que des informations incorrectes sur la position du volet du clapet de fumées soient absolument impossibles, qui ne sont installés que sur des éléments qui sont fixés sur le boîtier, qui ne sont activés que par des éléments qui sont fixés sur le volet du clapet de fumées et pour lesquels il est garanti que le contacteur de fin de course s’ouvre ou que le volet du clapet de fumées se déplace dans la position ouverte si l’une de ces fixations fait défaut. Cet objectif de sécurité peut également être atteint au moyen d’un procédé tout aussi adapté (frettage ou soudage, par exemple).

Le présent document traite uniquement des clapets de fumées pour les chaudières à biomasse ≥ 1 000 kW et les applications industrielles contenant des contacteurs de fin de course conformément à l’EN 61058-1 ou à l’EN 50156-1.

Le présent document traite uniquement des clapets de fumées dans lesquels il est possible d’identifier la position du volet du clapet de fumées.

Le présent document traite uniquement des clapets de fumées fermant totalement, à commande manuelle (type 1) qui disposent d’un moyen de régler la position du volet du clapet de fumées.

Le présent document traite uniquement des clapets de fumées totalement fermés, à commande mécanique (type 2) comportant seulement les positions « complètement ouvert » et « complètement fermé » et dans lesquels il n’est pas possible de fixer le volet dans la position non fermée lorsque le volet du clapet de fumées reste dans la position fermée alors que l’appareil ne fonctionne pas.

NOTE Ceci s’applique uniquement aux installations à appareils multiples dans des conditions de pression positive.

Le présent document traite uniquement des clapets de clapet de fumées fermant partiellement (type 3 à 5) dans lesquels il est possible de régler la position du volet du clapet de fumées et dans lesquels il est garanti que le volet du clapet de fumées ne peut pas changer de position de lui-même.

Les clapets de fumées qui font partie intégrante de composants de systèmes de conduits de fumée ou d’autres composants du conduit de fumée, tels que les conduits de tubage ou les éléments de raccordement, ne sont pas couverts par le présent document.

Le présent document spécifie également les dispositions relatives au marquage, aux instructions du fabricant, aux informations sur le produit, à l’évaluation et la vérification de la constance des performances (EVCP).

...

Dimovodne naprave - Oprema - 4. del: Dimovodne lopute - Zahteve in preskusne metode

General Information

- Status

- Published

- Publication Date

- 14-Apr-2020

- Withdrawal Date

- 30-Jan-2022

- Technical Committee

- CEN/TC 166 - Chimneys

- Drafting Committee

- CEN/TC 166/WG 1 - General requirements

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 15-Apr-2020

- Due Date

- 01-Nov-2020

- Completion Date

- 15-Apr-2020

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 16475-4:2020 (CEN) - "Chimneys - Accessories - Part 4: Flue dampers - Requirements and test methods" defines the characteristics, performance requirements and test methods for flue dampers installed inside buildings as chimney components. The standard covers flue dampers incorporated in a housing with motor drive or manual operation, sealing materials and safety interlocks, marking and manufacturer instructions, plus Assessment and Verification of Constancy of Performance (AVCP) and factory production control (FPC).

Keywords: EN 16475-4:2020, flue dampers, chimneys, requirements and test methods, CEN.

Key topics and technical requirements

- Scope and exclusions

- Applies to housed flue dampers installed inside buildings; excludes dampers integral to system chimney products (e.g., liners).

- Electrical parts are not specified in detail.

- Materials and classes

- Seals: elastomeric sealing for temperature classes up to T200 and corrosion classes 1 or 2 (per EN 14241‑1), or dry‑application seals with fire reaction class A1 (EN 13501‑1).

- Drive and protection

- Motor drives must comply with EN 60730‑2‑14; electrical covers to at least IP40 (EN 60529).

- Safety and interlocks

- Casing, motor and damper plate must be interlocked; flap position must be identifiable; designs must prevent incorrect position indication and ensure open position or limit‑switch opening on interlock failure (alternative measures like bracing/welding allowed).

- Types and function

- Type 1: totally closed, manually driven (adjustable).

- Type 2: totally closed, mechanically driven (only fully open/closed).

- Types 3–5: partially closed, adjustable positions.

- Special provisions for biomass boilers ≥1 000 kW and industrial applications (limit switches per EN 61058‑1 or EN 50156‑1).

- Testing and performance

- Defined tests include mechanical resistance, free movement/durability, impact resistance, thermal performance/thermal shock, gas tightness (internal and external), condensate resistance, and flow resistance.

- Test sequences, sampling plans, and FPC procedures are specified to support AVCP and product conformity.

- Marking and documentation

- Manufacturer’s instructions, product information and marking requirements are included.

Applications and practical value

- Ensures safe, reliable control of flue gas flow and prevention of backflow or soot ingress during cleaning.

- Relevant for installations in multi‑appliance chimneys, biomass and industrial boilers, and building services projects requiring compliant flue-gas dampers.

- Useful for manufacturers designing dampers, test laboratories performing type tests, specifiers and installers verifying compliance, and certification bodies performing AVCP and FPC assessments.

Who should use this standard

- Chimney and flue damper manufacturers

- HVAC and chimney system designers and installers

- Test laboratories and conformity assessment bodies

- Building services engineers specifying dampers for biomass/industrial systems

Related standards

- EN 16475 series (Parts 1–7) - Accessories for chimneys

- EN 14241‑1 - Corrosion classes for chimney components

- EN 13501‑1 - Reaction to fire classification

- EN 60730‑2‑14, EN 60529, EN 61058‑1, EN 50156‑1 - referenced electrical & protection standards

For product selection and compliance planning, reference EN 16475‑4:2020 to align design, testing and documentation with European requirements for flue dampers.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 16475-4:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Chimneys - Accessories - Part 4: Flue dampers - Requirements and test methods". This standard covers: This document specifies the characteristics and test methods for flue dampers that are used as components, carrying flue gas, in order to limit the flow in a chimney or to prevent back flow of soot during cleaning of the chimney or to prevent the backflow of the flue gas e.g. in case of multi-served chimneys. This document covers only flue dampers incorporated in a housing and installed inside a building. This document covers only flue dampers with sealings made of elastomeric materials for temperature classes up to T 200 and corrosion class 1 or 2 in accordance with EN 14241-1 or sealing materials for dry applications with a fire reaction class A1 in accordance with EN 13501-1. This document covers only flue dampers with motor drive, casing and flue damper plate which are interlocked in such a way that they can only be separated by using tools. This document covers only mechanical flue dampers where any motor is in accordance with EN 60730-2-14 and the cover for electrical components of the flue damper fulfils minimum protection class IP40 according to EN 60529. This document covers only flue dampers which are designed and installed to ensure that incorrect information about the position of the flue damper flap are absolutely impossible, which are only installed on components that are interlocked to the casing, which are only activated by components that are interlocked to the flue damper flap and where it is ensured that the limit switch opens or the flue damper flap moves to the open position if one of these interlocks fails. This safety target may also be achieved with an equally suitable method (e.g. bracing or welding). This document covers only flue dampers for biomass boilers ≥ 1 000 kW and industrial applications with limit switches in accordance with EN 61058-1 or EN 50156-1. This document covers only flue dampers where it is possible to identify the position of the flue damper flap. This document covers only totally closed, manually driven flue dampers (type 1) which have a facility to adjust the position of the flue damper flap. This document covers only totally closed, mechanically driven flue dampers (type 2) with only the positions "fully opened" and "fully closed" and where it is not possible to fix the flap in the non-closed position during the flue damper flap stays in closed position while the appliance is not working. NOTE This applies only to multi-appliance installations with positive pressure conditions. This document covers only partially closed flue dampers (type 3 to 5) where it is possible to adjust the position of the flue damper flap and where it is ensured that the flue damper flap does not change position by itself. Flue dampers which are integral parts of system chimney products or other chimney components, e.g. flue liners, connecting flue pipes, are not covered by this document. This document also specifies the provisions for marking, manufacturers’ instruction, product information, Assessment and Verification of Constancy of Performance (AVCP). This document does not specify issues for electrical parts.

This document specifies the characteristics and test methods for flue dampers that are used as components, carrying flue gas, in order to limit the flow in a chimney or to prevent back flow of soot during cleaning of the chimney or to prevent the backflow of the flue gas e.g. in case of multi-served chimneys. This document covers only flue dampers incorporated in a housing and installed inside a building. This document covers only flue dampers with sealings made of elastomeric materials for temperature classes up to T 200 and corrosion class 1 or 2 in accordance with EN 14241-1 or sealing materials for dry applications with a fire reaction class A1 in accordance with EN 13501-1. This document covers only flue dampers with motor drive, casing and flue damper plate which are interlocked in such a way that they can only be separated by using tools. This document covers only mechanical flue dampers where any motor is in accordance with EN 60730-2-14 and the cover for electrical components of the flue damper fulfils minimum protection class IP40 according to EN 60529. This document covers only flue dampers which are designed and installed to ensure that incorrect information about the position of the flue damper flap are absolutely impossible, which are only installed on components that are interlocked to the casing, which are only activated by components that are interlocked to the flue damper flap and where it is ensured that the limit switch opens or the flue damper flap moves to the open position if one of these interlocks fails. This safety target may also be achieved with an equally suitable method (e.g. bracing or welding). This document covers only flue dampers for biomass boilers ≥ 1 000 kW and industrial applications with limit switches in accordance with EN 61058-1 or EN 50156-1. This document covers only flue dampers where it is possible to identify the position of the flue damper flap. This document covers only totally closed, manually driven flue dampers (type 1) which have a facility to adjust the position of the flue damper flap. This document covers only totally closed, mechanically driven flue dampers (type 2) with only the positions "fully opened" and "fully closed" and where it is not possible to fix the flap in the non-closed position during the flue damper flap stays in closed position while the appliance is not working. NOTE This applies only to multi-appliance installations with positive pressure conditions. This document covers only partially closed flue dampers (type 3 to 5) where it is possible to adjust the position of the flue damper flap and where it is ensured that the flue damper flap does not change position by itself. Flue dampers which are integral parts of system chimney products or other chimney components, e.g. flue liners, connecting flue pipes, are not covered by this document. This document also specifies the provisions for marking, manufacturers’ instruction, product information, Assessment and Verification of Constancy of Performance (AVCP). This document does not specify issues for electrical parts.

EN 16475-4:2020 is classified under the following ICS (International Classification for Standards) categories: 91.060.40 - Chimneys, shafts, ducts. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16475-4:2020 has the following relationships with other standards: It is inter standard links to EN 13384-1:2015+A1:2019, EN 1443:2019, EN 1563:2018, EN 1561:2023, EN 13501-1:2018, EN 1856-1:2009, EN 1856-2:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16475-4:2020 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/105. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16475-4:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-junij-2020

Dimovodne naprave - Oprema - 4. del: Dimovodne lopute - Zahteve in preskusne

metode

Chimneys - Accessories - Part 4: Flue dampers - Requirements and test methods

Abgasanlagen - Zubehörteile - Teil 4: Abgasklappen - Anforderungen und Prüfverfahren

Conduits de fumée - Accessoires - Partie 4: Clapets de gaz de fumées - Exigences et

méthodes d'essai

Ta slovenski standard je istoveten z: EN 16475-4:2020

ICS:

91.060.40 Dimniki, jaški, kanali Chimneys, shafts, ducts

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 16475-4

EUROPEAN STANDARD

NORME EUROPÉENNE

April 2020

EUROPÄISCHE NORM

ICS 91.060.40

English Version

Chimneys - Accessories - Part 4: Flue dampers -

Requirements and test methods

Conduits de fumée - Accessoires - Partie 4 : Clapets de Abgasanlagen - Zubehörteile - Teil 4: Abgasklappen -

fumées - Exigences et méthodes d'essai Anforderungen und Prüfverfahren

This European Standard was approved by CEN on 24 February 2020.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 16475-4:2020 E

worldwide for CEN national Members.

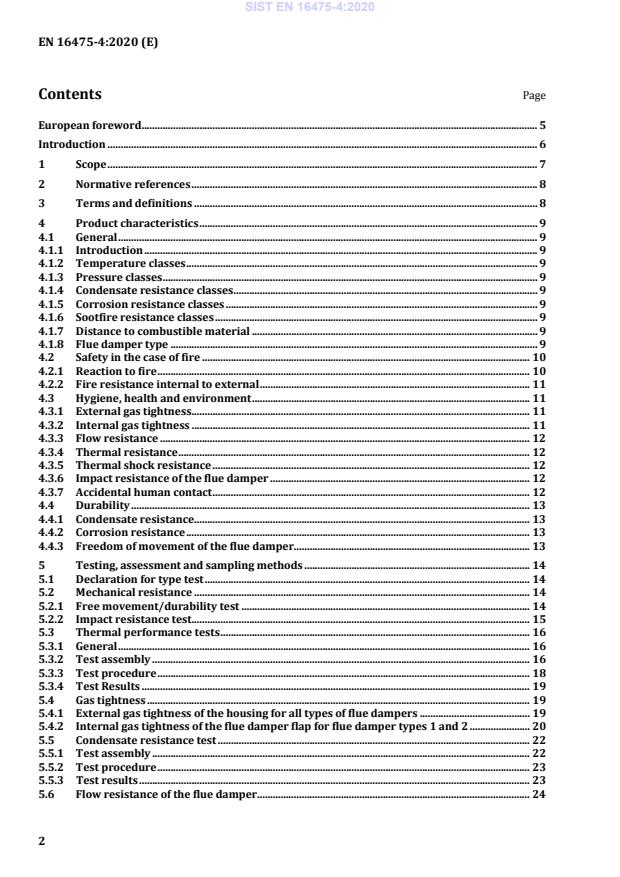

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 7

2 Normative references . 8

3 Terms and definitions . 8

4 Product characteristics . 9

4.1 General . 9

4.1.1 Introduction . 9

4.1.2 Temperature classes . 9

4.1.3 Pressure classes . 9

4.1.4 Condensate resistance classes . 9

4.1.5 Corrosion resistance classes . 9

4.1.6 Sootfire resistance classes . 9

4.1.7 Distance to combustible material . 9

4.1.8 Flue damper type . 9

4.2 Safety in the case of fire . 10

4.2.1 Reaction to fire . 10

4.2.2 Fire resistance internal to external . 11

4.3 Hygiene, health and environment . 11

4.3.1 External gas tightness . 11

4.3.2 Internal gas tightness . 11

4.3.3 Flow resistance . 12

4.3.4 Thermal resistance . 12

4.3.5 Thermal shock resistance . 12

4.3.6 Impact resistance of the flue damper . 12

4.3.7 Accidental human contact . 12

4.4 Durability . 13

4.4.1 Condensate resistance . 13

4.4.2 Corrosion resistance . 13

4.4.3 Freedom of movement of the flue damper . 13

5 Testing, assessment and sampling methods . 14

5.1 Declaration for type test . 14

5.2 Mechanical resistance . 14

5.2.1 Free movement/durability test . 14

5.2.2 Impact resistance test . 15

5.3 Thermal performance tests . 16

5.3.1 General . 16

5.3.2 Test assembly . 16

5.3.3 Test procedure . 18

5.3.4 Test Results . 19

5.4 Gas tightness . 19

5.4.1 External gas tightness of the housing for all types of flue dampers . 19

5.4.2 Internal gas tightness of the flue damper flap for flue damper types 1 and 2 . 20

5.5 Condensate resistance test . 22

5.5.1 Test assembly . 22

5.5.2 Test procedure . 23

5.5.3 Test results . 23

5.6 Flow resistance of the flue damper . 24

5.6.1 Test assembly . 24

5.6.2 Test procedure . 24

5.6.3 Test results. 25

5.7 Test sequence . 25

6 Assessment and verification of constancy of performance — AVCP . 26

6.1 General . 26

6.2 Type testing . 26

6.2.1 General . 26

6.2.2 Test samples, testing and compliance criteria . 27

6.2.3 Test reports . 27

6.3 Factory production control (FPC) . 28

6.3.1 General . 28

6.3.2 Provisions . 28

6.3.3 Product specific provisions . 30

6.3.4 Initial inspection of factory and of FPC . 31

6.3.5 Continuous surveillance of FPC . 31

6.3.6 Procedure for modifications . 31

6.3.7 One-off products, pre-production products (e.g. prototypes) and products produced

in very low quantity . 32

7 Product classification and designation . 32

7.1 Classification . 32

7.2 Designation . 32

8 Marking, labelling and instruction . 33

8.1 Flue damper . 33

8.2 Product information . 33

8.2.1 Manufacturer's instructions . 33

8.2.2 Minimum information to be included in the manufacturer's instructions . 34

Annex A (normative) Sampling for factory production control . 35

A.1 Sampling plans. 35

A.1.1 General . 35

A.1.2 Acceptable quality level (AQL). 35

A.1.3 Normal, tightened or reduced inspection . 35

A.1.4 Single, double, multiple or sequential sampling . 35

A.1.5 Batch quantity . 35

A.2 Inspection levels and procedures . 35

A.2.1 Incoming material . 35

A.2.2 In-process inspection . 36

A.2.3 Finished goods checks . 36

A.3 Electrical inspection . 36

Annex B (informative) Recommended check and test sequence . 37

Annex C (informative) Additional information for the use of a flue damper type 2 and 4 . 39

C.1 Boilers with forced draught burners . 39

C.2 Boilers with burners with fan without air purging . 39

C.3 Boilers with burners with fan with post-purge period . 39

C.4 Gas boilers with burners without fan . 39

C.5 Closing time of the flue damper flap . 39

C.6 Malfunction of the flue damper . 39

Annex D (informative) Examples of different types of flue dampers . 40

Bibliography . 42

European foreword

This document (EN 16475-4:2020) has been prepared by Technical Committee CEN/TC 166 “Chimneys”,

the secretariat of which is held by ASI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by October 2020, and conflicting national standards shall

be withdrawn at the latest by January 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document forms a part of the series of standards EN 16475, Chimneys – Accessories, comprising the

following parts:

— Part 1: Silencers — Requirements and test methods;

— Part 2: Chimney fans — Requirements and test methods;

— Part 3: Draught regulators, standstill opening devices and combined secondary air devices —

Requirements and test methods;

— Part 4: Flue dampers — Requirements and test methods (this part);

— Part 6: Access components — Requirements and test methods;

— Part 7: Rain caps — Requirements and test methods.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

The main purpose of flue dampers is to close or partially close a flue.

Flue dampers can be manually adjusted, sited in connecting flue pipes or chimneys, in order to reduce

the burning rate (solid fuel stoves/fireplaces) or to work as a shut-off slide preventing back flow of soot

during cleaning of the chimney, or mechanically driven for reducing/closing the flue, in order to reduce

the stand-by losses or to prevent the backflow of the flue gas e.g. in case of multi-served chimneys.

1 Scope

This document specifies the characteristics and test methods for flue dampers that are used as

components, carrying flue gas, in order to limit the flow in a chimney or to prevent back flow of soot

during cleaning of the chimney or to prevent the backflow of the flue gas e.g. in case of multi-served

chimneys.

This document covers only flue dampers incorporated in a housing and installed inside a building.

This document covers only flue dampers with sealings made of elastomeric materials for temperature

classes up to T 200 and corrosion class 1 or 2 in accordance with EN 14241-1 or sealing materials for dry

applications with a fire reaction class A1 in accordance with EN 13501-1.

This document covers only flue dampers with motor drive, casing and flue damper plate which are

interlocked in such a way that they can only be separated by using tools.

This document covers only mechanical flue dampers where any motor is in accordance with

EN 60730-2-14 and the cover for electrical components of the flue damper fulfils minimum protection

class IP40 according to EN 60529.

This document covers only flue dampers which are designed and installed to ensure that incorrect

information about the position of the flue damper flap are absolutely impossible, which are only installed

on components that are interlocked to the casing, which are only activated by components that are

interlocked to the flue damper flap and where it is ensured that the limit switch opens or the flue damper

flap moves to the open position if one of these interlocks fails. This safety target may also be achieved

with an equally suitable method (e.g. bracing or welding).

This document covers only flue dampers for biomass boilers ≥ 1 000 kW and industrial applications with

limit switches in accordance with EN 61058-1 or EN 50156-1.

This document covers only flue dampers where it is possible to identify the position of the flue damper

flap.

This document covers only totally closed, manually driven flue dampers (type 1) which have a facility to

adjust the position of the flue damper flap.

This document covers only totally closed, mechanically driven flue dampers (type 2) with only the

positions “fully opened” and “fully closed” and where it is not possible to fix the flap in the non-closed

position during the flue damper flap stays in closed position while the appliance is not working.

NOTE This applies only to multi-appliance installations with positive pressure conditions.

This document covers only partially closed flue dampers (type 3 to 5) where it is possible to adjust the

position of the flue damper flap and where it is ensured that the flue damper flap does not change position

by itself.

Flue dampers which are integral parts of system chimney products or other chimney components, e.g.

flue liners, connecting flue pipes, are not covered by this document.

This document also specifies the provisions for marking, manufacturers’ instruction, product

information, Assessment and Verification of Constancy of Performance (AVCP).

This document does not specify issues for electrical parts.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1443:2019, Chimneys — General requirements

EN 1561, Founding — Grey cast irons

EN 1563, Founding — Spheroidal graphite cast irons

EN 1856-1, Chimneys — Requirements for metal chimneys — Part 1: System chimney products

EN 1856-2:2009, Chimneys — Requirements for metal chimneys — Part 2: Metal flue liners and connecting

flue pipes

EN 13384-1, Chimneys — Thermal and fluid dynamic calculation methods — Part 1: Chimneys serving one

heating appliance

EN 13501-1, Fire classification of construction products and building elements — Part 1: Classification

using data from reaction to fire tests

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 1443, EN 1856-1 and EN 1856-2

and the following apply.

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp/ui

3.1

flue damper

device used to close or partially close the flue, comprising a rotating or sliding flue damper flap, including

fastening elements, in a flue damper housing that may be a section of connecting flue pipe or a section of

chimney (single or multi wall)

Note 1 to entry: Examples given in Annex D.

3.2

shut-off slide

flue damper type 1

flue damper which is intended to prevent the escape of dust out of the chimney during sweeping the

chimney

3.3

internal leakage rate

leakage rate inside the flue caused by the closed flap

3.4

external leakage rate

leakage rate from the inside of the component to the outside atmosphere

Note 1 to entry: Corresponds to the leakage rate of EN 1443:2019, Table 3.

4 Product characteristics

4.1 General

4.1.1 Introduction

In order to identify the characteristics of the flue damper the following product properties shall be

declared:

4.1.2 Temperature classes

The temperature class shall be declared in accordance with EN 1443:2019, Table 1.

4.1.3 Pressure classes

The pressure class shall be in accordance with EN 1443:2019, Table 3.

4.1.4 Condensate resistance classes

The condensate resistance class shall be in accordance with EN 1443:2019, 4.2.3.

4.1.5 Corrosion resistance classes

Corrosion resistance classes shall be in accordance with EN 1443:2019, Table 4.

4.1.6 Sootfire resistance classes

Sootfire resistance class shall be in accordance with EN 1443:2019, 4.2.5.

4.1.7 Distance to combustible material

The minimum allowed distance of the outer wall of the flue damper to walls and floors comprising

combustible material shall be expressed as “xx”, where “xx” is the value in whole millimetres, followed

with a letter “a” to “l” in accordance with EN 1443:2019, 4.2.6.

4.1.8 Flue damper type

The flue damper type shall be in accordance with Table 1.

Table 1 — Flue damper types

Flue Type description Condensate Pressure class Field of application

damper resistance class

type

D W N P/M/H

Totally closed manually Solid fuel manually

1 X — X —

driven fed without fan

All applications

Totally closed except solid fuel

2 X X X X

mechanically driven manually fed

without fan

Partially closed

Solid fuel manually

3 adjustable manually X — X —

fed without fan

a

driven

All applications

Partially closed

except solid fuel

4 adjustable X X X X

manually fed

mechanically driven

without fan

All applications

Partially closed except solid fuel

5 X X X X

fixed manually driven manually fed

without fan

a

opening according to national regulations or manufacturer's instructions or other standards (e.g.

EN 16510-1)

NOTE 'X' means 'applies to this flue damper type'.

4.2 Safety in the case of fire

4.2.1 Reaction to fire

The reaction to fire indicates the degree of contribution of the material to the behaviour of the

construction product in the event of fire. When tested in accordance to the test methods given in

EN 13501-1, relevant for the claimed class, the test results are expressed as a class according to

EN 13501-1.

Whether products covered by this document are made from one or more of the materials that have been

considered, under established conditions, as belonging to the category “No contribution to fire” because

of their low level of combustibility, the reaction to fire class A1 applies to these products without the need

of carrying out reaction to fire tests.

4.2.2 Fire resistance internal to external

Fire resistance internal to external is the capability of the flue damper to prevent a fire at adjacent

combustible materials caused by the chimney operation under:

— normal operating condition for the declared temperature class (see 4.1.2) and pressure class (see

4.1.3), and

— sootfire condition for products declared sootfire-resistant (G) or sootfire safe (As) (see 4.1.6),

taking into account the minimum allowed distance to combustible material (xx) in relation to the test

assembly corresponding to the walls and floors of a variety of building types and the thermal resistance

of their structure (see 4.1.7).

When tested according to the test method described in 5.3.3.2:

— the external gas tightness shall comply with 4.3.1 before and after the test;

— the maximum temperature of adjacent combustible materials shall not exceed 85 °C when related to

an ambient temperature of 20 °C at the distance declared by the manufacturer when tested at the

declared temperature class.

When tested according to the test method described in 5.3.3.3:

— the external gas tightness shall comply with 4.3.1 before and after the test;

— the maximum temperature of adjacent combustible materials shall not exceed 100 °C when related

to an ambient temperature of 20 °C at the distance declared by the manufacturer.

4.3 Hygiene, health and environment

4.3.1 External gas tightness

The external gas tightness is the capability of the flue damper to limit the leakage rate to the room where

flue damper is located appropriate to the designated pressure class (see 4.1.3).

When tested in accordance with the test method described in 5.4.1 the leakage rate in litres/seconds per

square meter of the inner flue surface area of the flue damper before and after any test shall not exceed

the values given in EN 1443:2019, Table 3. The inner flue surface area is calculated with the nominal

diameter of the flue damper. If the joint is a part of elements of the flue damper, the tests are made with

joints.

4.3.2 Internal gas tightness

The internal gas tightness is the capability of the flue damper to limit the leakage rate inside the flue

damper from one side of the flap to the other side.

When flue damper type 1 or 2 tested in accordance with the test method described in 5.4.2 both before

and after the thermal performance tests the internal leakage rate under the specific test pressure shall

not exceed the maximum leakage rate in Table 3.

For flue damper type 2 the leakage rate can be determined according to EN 15502-2-1 at a test pressure

of 100 Pa where the maximum leakage rate is 0,2 m /h for all diameters as additional information.

4.3.3 Flow resistance

The flow resistances due to friction of the flue and due to a directional and/or cross sectional and/or

mass flow change in the flue are the basis for the calculation of the pressure loss in the flue.

The coefficient of flow resistance (ζ) of the mechanically actuated flue damper shall be determined

according to the test method described in 5.6.

Characteristics are to be provided as mean value of roughness for the material of the flue or as coefficient

of flow resistance in accordance with EN 13384-1.

4.3.4 Thermal resistance

The thermal resistance of the chimney is the basis for the thermal and fluid dynamic calculation.

When tested in accordance to EN 1443:2019, 4.3.3, the thermal resistance shall be expressed as levels in

2.

m K/W.

4.3.5 Thermal shock resistance

The thermal shock resistance is the capability of the product to withstand the thermal load under:

— normal operating condition for the declared temperature class (see 4.1.2) and pressure class (see

4.1.3), and

— sootfire condition for products declared sootfire-resistant (G) or sootfire safe (As) (see 4.1.6).

When tested according to the test method described:

— in 5.3.3.2, and

— in 5.3.3.3 for products declared sootfire-resistant or sootfire safe,

the external gas tightness shall comply with 4.3.1 before and after the test.

4.3.6 Impact resistance of the flue damper

When tested according to 5.2.2 the flue damper shall also be able to be opened and closed freely before

and after the thermal tests and the external gas tightness shall comply with 4.3.1.

4.3.7 Accidental human contact

Where accidental human contact is possible, burnings shall be prevented.

When tested in accordance with the test method described in the appropriate clauses of EN 13216-1 the

surface temperature of the flue damper shall not exceed the values in EN 1443:2019, Table 10, or where

accidental human contact is possible, it shall be specified that the chimney shall be protected from

touching.

When the flue damper has a facility to adjust the position of the flue damper flap, e.g. handle, during

operation and where accidental human contact is possible a tool, e.g. glove, shall be used to move the

adjusting facility.

4.4 Durability

4.4.1 Condensate resistance

The condensate resistance is the capability of the product to withstand condensate exposure.

When flue dampers with the declared condensate resistance class (see 4.1.4) W are tested according to

the test method described in 5.5:

— no condensate shall appear on the outer surface of the mechanical flue damper device while the

damper is alternately opening and closing,

— for flue dampers situated in an insulated housing the increase of mass shall not be more than 1 % of

insulation material.

4.4.2 Corrosion resistance

The corrosion resistance is the capability of the product to withstand corrosion exposure.

For flue dampers, this is fulfilled if, depending on the declared condensate resistance class (see 4.1.4) and

the declared corrosion resistance class (see 4.1.5), the materials and minimum thicknesses of both the

flaps and the housings are in accordance with Table 2.

For materials and/or thicknesses not in accordance with Table 2 the durability against corrosion can be

verified by a corrosion test according to EN 1856-1.

Table 2 — Materials for flue damper flaps and housings

Corrosion resistance classes Dry (D) Wet (W)

1 A; B; C; D; E; F; G B; C; D; E

2 A; B; C; F; G C

3 A; B; C; F; G —

where:

A:cast iron, materials according to EN 1561 or EN 1563. - Minimum thickness 4 mm.

B: stainless steel, minimum material number according to EN 10088 of 1.4301 – Minimum thickness 0,8 mm.

C: stainless steel, minimum material number according to EN 10088 of 1.4404, 1.4571 or 1.4539 – Minimum

thickness 0,8 mm.

D: aluminium according to EN 1856-1 – Minimum thickness 1,5 mm.

E: plastic material grades which proved sufficient resistance in a test according to EN 14471 (use for conditions

as designated according to EN 14471).

F: Aluminium coated steel according to EN 10346 (see EN 1856-2). – Minimum Thickness 0,8 mm.

a

G: Black Steel according to EN 10025, S235 JRG 2 – Minimum thickness 1,5 mm.

a

Equivalent for material No. 1.0038 = 1.0330 (material grade DC01).

4.4.3 Freedom of movement of the flue damper

When tested according to 5.2.1.2 the flue damper types 1, 3 and 5 shall be able to move freely when

opened and closed minimum 100 times before and minimum 100 times after the thermal tests, and meet

4.3.1.

When tested according to 5.2.1.3 the flue damper types 2 and 4 shall be able to move freely when opened

and closed and shall comply with 4.3.1 before and after the test.

5 Testing, assessment and sampling methods

5.1 Declaration for type test

The relevant information in 8.1 and 8.2 shall be provided and additionally the following information:

a) drawings including declared nominal dimensions,

b) materials and minimum thicknesses of the materials,

c) method of fixing.

5.2 Mechanical resistance

5.2.1 Free movement/durability test

5.2.1.1 Test assembly for all flue damper types

Mount the flue damper on the test assembly of 5.4 according to the manufacturer’s instructions.

5.2.1.2 Test procedure for flue dampers types 1, 3 and 5 (manually driven)

Subject the flue damper to the external gas tightness test of 5.4.1.

For flue damper type 1 which can be fully closed undertake the internal gas tightness test of 5.4.2.

Move the flue damper flap of types 1, 3 or 5 (manually driven) to the open and closed position 100 times

and record whether the flue damper flap moves freely.

Subject the flue damper to the external gas tightness test of 5.4.1.

For flue damper type 1 which can be fully closed undertake the internal gas tightness test of 5.4.2.

Subject the flue damper to the thermal performance test of 5.3 appropriate to the flue damper

designation.

Move the flue damper flap to the open and closed position 100 times, record whether the flue damper

flap moves freely.

Subject the flue damper to the external gas tightness test of 5.4.1.

For flue damper type 1 which can be fully closed undertake the internal gas tightness test of 5.4.2.

5.2.1.3 Test procedure for flue dampers types 2 and 4 (mechanically driven)

Subject the flue damper to the internal and external gas tightness test of 5.4 both before and after the

minimum 50 000 switching cycles.

The flue damper is opened and closed continuously, using a time switch, independently from the heating,

whereby the respective closed position shall be at least 10 s. Initially, at least 2 500 switching operations

shall be carried out at nominal working temperature. Subsequently, 45 000 switching operations shall

take place at ambient temperature. After this, another 2 500 switching operations shall take place at

nominal working temperature.

Generate hot gas at the nominal working temperature according to 5.3 for a test assembly according to

Figure 1. The two flue dampers have to open and close alternatingly driven by a control or time switch.

Key

1 test sample flue damper

2 bypass flue damper

3 thermocouple for flue gas temperature

4 hot gas generator

D nominal diameter of the flue of the test sample

Figure 1 — Example of thermal free movement/durability test

5.2.1.4 Test Results

Record if the flue damper moves freely, and the internal and external leakage from the gas tightness tests

before and after the free movement/durability test.

5.2.2 Impact resistance test

5.2.2.1 Test assembly

Construct a test assembly according to Figure 2 with the flue damper installed according to the

manufacturer’s instructions.

Insert a device to load the flue damper without tilting, e.g. two disks connected by a rod or a cylinder with

a flat base, having a cross section > 80 % of the flue damper housing size.

Load the platform for a flue damper plate made of metal with a load F = 100 ( N for a time of at least

%)

+5

10 s.

Load the platform for a flue damper plate made of plastic/combined non-metallic materials with a load

F = 30 ( %) N for a time of at least 3 s.

+5

Key

1 flue damper flap (opened)

2 flue damper housing

3 loading device

F load

Figure 2 — Test assembly for impact resistance test

5.2.2.2 Test procedure

Test the flue damper type 1 in closed position. All other flue damper types shall be tested in open position.

0 0

Load the platform with 30 ( %) N or 100 ( %) N.

+5 +5

Subject the flue damper to the gas tightness test of 5.4.

Check if the free movement of the flue damper is still possible.

5.2.2.3 Test results

Record if the flue damper moves freely, and the internal and external leakage from the gas tightness test

before and after the impact resistance test.

5.3 Thermal performance tests

5.3.1 General

The flue damper to be tested shall be mounted in the test assembly and supported according to the

manufacturer’s instructions.

For the thermal test of the flue damper the test assembly of connecting flue pipes according to EN 1856-2

shall be used.

5.3.2 Test assembly

5.3.2.1 General

The test assembly shall comprise a test structure, a test sample, a hot gas generator and measuring

equipment, see Figures 3 a) and 3 b).

5.3.2.2 Hot gas generator connection

Construct a purpose-made insulated straight flue pipe having an nominal diameter equal to that of the

flue of the test chimney of a length of minimum seven diameters measured from the outlet of the flue gas

generator to the hot gas measuring point, insulated to provide a thermal resistance value of not less than

that equivalent to 50 mm thickness of material having a thermal conductivity of (0,125 ± 0,005) W/mK

at (750 ± 5) °C, see Figures 3 a) and 3 b).

5.3.2.3 Measuring equipment and its location

Measuring equipment shall comply with EN 1856-2:2009, A.7.1.3.

Measuring equipment for distance to combustible material of the flue damper shall be located at the

smallest distance diametrically opposite to the flue damper, sufficient to find the hottest place of the

combustible material. Measurements shall be made in two vertical points and on the ceiling, see Figure 3

a), where appropriate.

5.3.2.4 Test environment

The test room shall comply with EN 1856-2:2009, A.7.1.4.

5.3.2.5 Test structure

The test structure shall comprise the essential wall and ceiling parts of zone A of the thermal test

structure described in EN 1856-2:2009, A.7.2.2, see Figures 3 a) and 3 b).

Figure 3 a) represents the test structure for integrity and confirmation of the declared distance to the

combustible material.

Figure 3 b) represents the test structure for integrity.

The test structure can only be used for flue dampers:

— with temperature classes up to T 160 and a freely ventilated distance to combustible materials of

minimum 50 mm,

— with temperature classes T 200 and more and a freely ventilated distance to combustible materials

of minimum three times the diameter of the connecting flue pipe but not less than 375 mm,

— with a housing of the same material that is already tested according to the relevant product standard,

if the values of distance to combustible materials of the housing are declared also for the flue damper.

NOTE Freely ventilated means that ventilation of the space around the flue damper is not enclosed by e.g. fitting

it in a cupboard.

5.3.2.6 Test samples

Install a connecting flue pipe with a flue damper as shown in Figures 3 a) or 3 b).

a) — Test assembly for measuring the distance to combustible materials

b) — Test assembly for integrity test only (longitudinal section)

Key

1 flue damper

2 hot gas generator

x distance to combustible materials in mm

D nominal diameter of the flue of the test sample

Figure 3 — Test assemblies

5.3.3 Test procedure

5.3.3.1 General

Perform the thermal performance tests according to EN 1856-2:2009, A.7.4.1.

5.3.3.2 Normal operating conditions

The products shall be tested in accordance with EN 1856-2:2009, A.7.4.2 to steady-state at a test

temperature given in EN 1443:2019, Table 2, appropriate to the product characteristics.

Carry out the gas tightness test before and after the heat stress test in accordance with 5.4.

5.3.3.3 Sootfire conditions

The sootfire resistance of flue dampers (G) or sootfire safe flue dampers (As) shall be verified by a test in

accordance with EN 1856-2:2009, A.7.4.3 with a test temperature of 1 000 °C over a period of 30 min and

a hot gas velocity as given in EN 1443:2019, Table 6. The hot gas temperature shall rise gradually to

achieve 1 000 °C in 10 m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...