EN 16475-2:2017

(Main)Chimneys - Accessories - Part 2: Chimney fans - Requirements and test methods

Chimneys - Accessories - Part 2: Chimney fans - Requirements and test methods

This European Standard covers electrically operated metal fans for chimneys that are able to create a stable positive or negative pressure for the chimney.

This European Standard covers fans installed inline in the connecting flue pipe (inline fans) or mounted on the chimney outlet (exhaust fans).

This standard excludes chimney cowls (Terminals with aerodynamic characteristics).

Abgasanlagen - Zubehörteile - Teil 2: Abgasventilatoren - Anforderungen und Prüfverfahren

Diese Europäische Norm gilt für elektrisch betriebene Metallventilatoren für Abgasanlagen, die in der Lage sind, einen stabilen Über- oder Unterdruck in der Abgasanlage zu erzeugen.

Diese Europäische Norm gilt nur für Ventilatoren, die innenliegend (inline) in Verbindungsstücken installiert (Einbauventilatoren) oder auf der Abgasanlagenmündung montiert sind (Abgassauger).

Diese Norm gilt nicht für drehbare Abgasanlagenaufsätze (Aufsätze mit aerodynamischen Eigenschaften).

Conduits de fumée - Accessoires - Partie 2: Ventilateurs pour conduit de fumée - Exigences et méthodes d'essai

La présente Norme européenne couvre les ventilateurs métalliques pour conduits de fumée, à fonctionnement électrique, pouvant assurer une pression positive ou négative stable dans le conduit de fumée.

La présente Norme européenne couvre les ventilateurs installés dans un conduit de raccordement des fumées (ventilateurs en ligne) ou montés à la sortie d'un conduit de fumée (ventilateurs d’extraction).

La présente norme exclut de son domaine d’application les terminaux de conduits de fumée (terminaux présentant des caractéristiques aérodynamiques).

Dimovodne naprave - Oprema - 2. del: Ventilatorji za dimovodne naprave - Zahteve in preskusne metode

Ta evropski standard določa zahteve in preskusne metode za izpušne ventilatorje na električni pogon, ki se uporabljajo kot sestavni elementi za pomoč pri odvajanju produktov zgorevanja iz dimnika. Standard zajema izpušne ventilatorje, ki so nameščeni na vrh dimnika, so sestavni del dimnika ali so nameščeni med napravo in dimnik.

General Information

- Status

- Published

- Publication Date

- 07-Mar-2017

- Withdrawal Date

- 30-Dec-2018

- Technical Committee

- CEN/TC 166 - Chimneys

- Drafting Committee

- CEN/TC 166/WG 1 - General requirements

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 15-Nov-2022

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 16475-2:2017 is a European CEN standard that specifies requirements and test methods for electrically operated metal chimney fans able to create a stable positive or negative pressure in chimneys. It applies to both inline fans (installed in the connecting flue pipe) and exhaust fans (mounted on the chimney outlet). The standard explicitly excludes chimney cowls (aerodynamic terminals). EN 16475-2 is part of the EN 16475 series on chimney accessories and supports essential requirements of EU legislation (see informative Annex ZA).

Key topics and technical requirements

The standard defines product characteristics, testing and conformity procedures covering:

- Mechanical resistance and stability

- Dimensional tolerances, wind load resistance and freeze–thaw durability

- Thermal performance

- Reaction to fire, fire resistance (for exhaust fans), temperature class declarations, heat stress and sootfire resistance tests

- Hygiene, health and environment

- Gas tightness, condensate resistance and corrosion durability

- Flow and operational criteria

- Flow characteristics, flow resistance after thermal tests, icing behaviour for exhaust fans

- Safety and maintenance

- Mechanical and electrical safety requirements, cleaning and maintenance access, fan maintenance procedures

- Testing and conformity

- Test methods (wind load, heat stress, sootfire, gas tightness, in-duct flow tests, icing tests), type testing, factory production control (FPC) and Assessment and Verification of Constancy of Performance (AVCP)

- Marking and documentation

- Required marking, manufacturer’s instructions and minimum product data to be provided

Practical applications and users

EN 16475-2 is intended for stakeholders involved in the design, manufacture, testing, installation and certification of chimney fans and related accessories:

- Chimney and flue manufacturers specifying or producing inline fans and exhaust fans

- HVAC and combustion appliance engineers selecting chimney components for heating systems

- Test laboratories performing fan performance, fire and durability testing

- Product certification bodies and conformity assessors implementing AVCP and factory production control

- Installers, specifiers and facilities managers who require compliant chimney fans for safe operation and regulatory compliance

Using EN 16475-2 helps ensure safe thermal performance, mechanical durability, gas tightness, and documented maintenance/marking for chimney fan products.

Related standards

Common normative references and related standards include:

- EN 1443 (Chimneys - General requirements)

- EN 1856-1 / EN 1856-2 (metal chimneys, system products and liners)

- EN 13216-1, EN 14297 (test methods)

- EN 60335-1, EN 60335-2-80 (electrical safety for appliances and fans)

- ISO/EN acoustic and fan performance standards (e.g., ISO 5801, ISO 3744, ISO 5136)

Keywords: EN 16475-2, chimney fans standard, chimney fan requirements, chimney fan test methods, inline fans, exhaust fans, CEN standard, chimney safety, fan performance.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 16475-2:2017 is a standard published by the European Committee for Standardization (CEN). Its full title is "Chimneys - Accessories - Part 2: Chimney fans - Requirements and test methods". This standard covers: This European Standard covers electrically operated metal fans for chimneys that are able to create a stable positive or negative pressure for the chimney. This European Standard covers fans installed inline in the connecting flue pipe (inline fans) or mounted on the chimney outlet (exhaust fans). This standard excludes chimney cowls (Terminals with aerodynamic characteristics).

This European Standard covers electrically operated metal fans for chimneys that are able to create a stable positive or negative pressure for the chimney. This European Standard covers fans installed inline in the connecting flue pipe (inline fans) or mounted on the chimney outlet (exhaust fans). This standard excludes chimney cowls (Terminals with aerodynamic characteristics).

EN 16475-2:2017 is classified under the following ICS (International Classification for Standards) categories: 91.060.40 - Chimneys, shafts, ducts. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16475-2:2017 has the following relationships with other standards: It is inter standard links to EN IEC 60335-1:2023, EN IEC 60335-2-80:2024, EN 13216-1:2004, EN ISO 5801:2017, EN 10346:2015, EN 1443:2003, EN 10088-1:2023, EN ISO 5136:2009, EN ISO 3744:2010, EN 14297:2004, EN 15287-1:2007+A1:2010, EN 1856-1:2009, EN 1856-2:2009, EN 13384-2:2015, EN 13384-2:2015+A1:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16475-2:2017 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/105, M/135. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16475-2:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

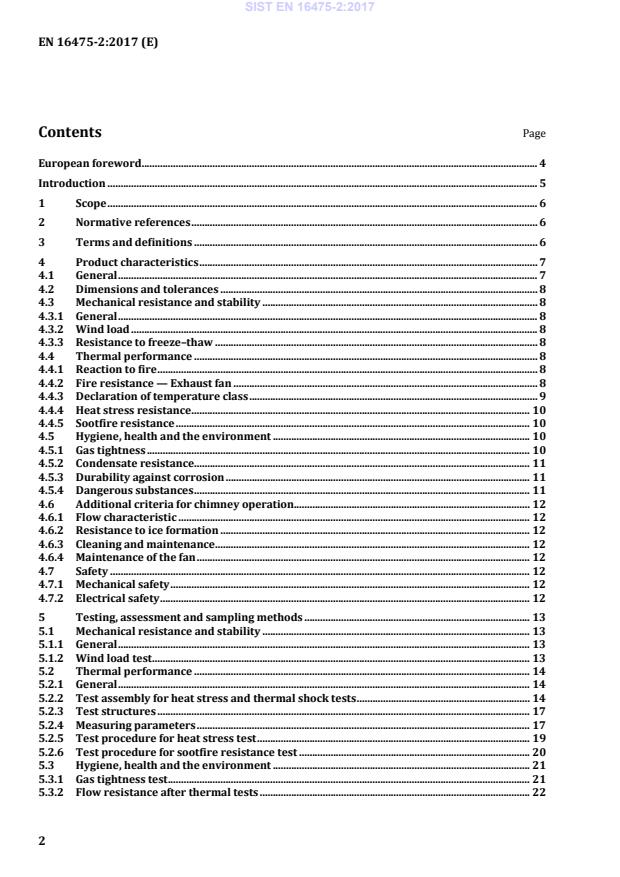

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Dimovodne naprave - Oprema - 2. del: Ventilatorji za dimovodne naprave - Zahteve in preskusne metodeAbgasanlagen - Zubehörteile - Teil 2: Abgasventilatoren - Anforderungen und PrüfmethodenConduits de fumée - Accessoires - Partie 2: Ventilateurs d'extraction - Exigences et méthodes d'essaiChimneys - Accessories - Part 2: Chimney fans - Requirements and test methods91.060.40Dimniki, jaški, kanaliChimneys, shafts, ductsICS:Ta slovenski standard je istoveten z:EN 16475-2:2017SIST EN 16475-2:2017en,fr,de01-maj-2017SIST EN 16475-2:2017SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16475-2

March

t r s y ICS

{ sä r x rä v r English Version

Chimneys æ Accessories æ Part

tã Chimney fans æ Requirements and test methods Conduits de fumée æ Accessoires æ Partie

tã Ventilateurs pour conduit de fumée æ Exigences et méthodes d 5essai Abgasanlagen æ Zubehörteile æ Teil

tã Abgasventilatoren æ Anforderungen und PrüfverfahrenThis European Standard was approved by CEN on

t z November

t r s xä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s y CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s x v y wæ tã t r s y ESIST EN 16475-2:2017

Example of sound chart showing sound levels to surroundings . 38 A.1 Sound levels to external surroundings . 38 Annex B (informative)

Data for calculation programs . 39 Annex C (normative)

Methods for combustible wood surface temperature measurements . 40 Annex D (normative)

Methods for exhaust fan surface temperature measurements . 41 Annex E (normative)

Ambient temperature . 42 Annex ZA (informative)

Relationship of this European Standard with Regulation (EU) No.305/2011 . 43 ZA.1 Scope and relevant characteristics . 43 ZA.2 System of Assessment and Verification of Constancy of Performance (AVCP) . 45 ZA.3 Assignment of AVCP tasks . 45 Bibliography . 48

°C °C T 080

¶

80 100 T 100

¶ 100 120 T 120

¶ 120 150 T 140

¶ 140 170 T 160

¶ 160 190 - - - T 200

¶ 200 250 T 250

¶ 250 300 T 300

¶ 300 350 - - - T 400

¶ 400 500 T 450

¶ 450 550 T 600

¶ 600 700 4.4.3.2 Inline fan 4.4.3.2.1 General The distance to combustible material (as shown in Figure 2) for inline fans shall be: a) O(xx) M stands for “Measured value” as determined by 5.2.5. When related to an ambient temperature of 20 °C, the maximum surface temperature of combustible materials adjacent to the test fan shall not exceed 85 °C at the distance declared (see EN 15287-1:2007+A1:2010, 4.3.2 and EN 1856-2:2009, 6.6.2); b)

As(xx) M, G (xx) M stands for “Measured value” as determined by 5.2.5 and 5.2.6. When related to an ambient temperature of 20 °C, the maximum surface temperature of combustible materials SIST EN 16475-2:2017

Pa 12lsm−−⋅⋅ N1 40 < 2,0 P1 200 < 0, 006 P2 200 < 0, 120 H1 200 and 5 000 < 0, 006 H2 200 and 5 000 < 0, 120 4.5.2 Condensate resistance Condensate resistance is only applicable for inline fans. If an inline fan is designated for wet operation (W) in accordance with EN 1443, the inline fan which was exposed to thermal test in 5.2.6, shall be tested in accordance with EN 13216-1:2004, 5.5. During the test period of 4 h there shall be no signs of coloured water outside the inline fan. 4.5.3 Durability against corrosion 4.5.3.1 General The corrosion classes shall be declared in accordance with EN 1443:2003, Table 2. The designation of the corrosion class shall be declared either on the basis of the results of the test method described in EN 1856-1 or shall be declared in accordance with 4.5.3.2 or 4.5.3.3. 4.5.3.2 Dry application Chimney fans of a material as described in 4.1 a), d) or e) are considered to be designated 2 or if the impeller blade is of a material described in 4.1 g) are considered to be designated 3. Chimney fans of a material as described in 4.1 b) are considered to be designated 3. Chimney fans of a material as described in 4.1 c) and f) are considered to be designated 1. 4.5.3.3 Wet application Chimney fans of a material as described in 4.1 b) are considered to be designated 2. Chimney fans of a material as described in 4.1 c) or e) are considered to be designated 1. 4.5.4 Dangerous substances National regulations on dangerous substances may require verification and declaration on release, and sometimes content, when construction products covered by this standard are placed on those markets. In the absence of European harmonized test methods, verification and declaration on release/content should be done taking into account national provisions in the place of use. NOTE An informative database covering European and national provisions on dangerous substances is available at the Construction website on EUROPA accessed through: http://ec.europa.eu/growth/tools-databases/cp-ds_en SIST EN 16475-2:2017

Key 1 chimney fixed to wall 2 chimney fan 3 load Figure 1 — Horizontal wind load test 5.2 Thermal performance 5.2.1 General The chimney fan to be tested shall be mounted in the test assembly and supported according to the manufacturer’s instruction manual. The fan shall be fitted with adapters where appropriate. 5.2.2 Test assembly for heat stress and thermal shock tests 5.2.2.1 General Test rigs for exhaust and inline fans shall be in accordance with Figures 2 and 3. SIST EN 16475-2:2017

Key 1 exhaust fan 2 flue gas temperature 3 hot gas generator D diameter of hot gas connecting pipe Figure 2 — Test rig with insulated chimney for exhaust fan SIST EN 16475-2:2017

Key 1 inline fan 2 thermocouples 3 flue gas temperature 4 hot gas generator D x diameter of the hot gas connecting pipe distance to combustible material Figure 3 — Test rig with insulated chimney for inline fan 5.2.2.2 Test assembly for exhaust fan The test fan shall be the fan representing the manufacturer’s product range. The size shall be the largest size produced up to 200 mm flue diameter. For larger diameters the distance may be calculated from the formula in EN 1856-1:2009, 6.4. The exhaust fan shall be inserted as upper part of a vertical chimney assembly as shown in Figure 2. The diameter of the chimney shall be consistent with the size of the chimney connections of the test fan or to be approximately sized to simulate conditions of radiation to the fan which would be expected in use. A flue gas generator in accordance with EN 13216-1:2004, 5.7.2.4, shall be used to supply flue gases to the vertical chimney assembly. The flue gas generator outlet shall be connected to the inlet of the vertical chimney assembly by means of a tee at the generator. The test chimney shall be insulated to provide a thermal resistance value of not less than that equivalent to 50 mm thickness of material having a thermal conductivity of (0,125 ± 0,005) W/mK at (750 ±

5) °C (see Figure 2). 5.2.2.3 Test assembly for inline fan The test fan is the fan representing the manufacturer’s product range. The size shall be the largest size produced up to 200 mm flue diameter. For larger diameters the distance may be calculated from the formula in EN 1856-1:2009, 6.4. The inline fan shall be inserted as a part of a vertical chimney assembly as shown in Figures 3 and 5 . The diameter of the chimney shall be consistent with the size of the chimney connections of the test fan or to be approximately sized to simulate conditions of radiation to the fan which would be expected in use. SIST EN 16475-2:2017

0,005) W/mK at (750 ±

5) °C (see Figure 3). 5.2.3 Test structures 5.2.3.1 Test structure exhaust fan Construct a test structure consisting of two walls at right angles to each other. The test corner extremities shall extend beyond the exhaust fan external dimensions by at least 300 mm, and by at least 500 mm above the topmost surface of the exhaust fan (see Figure 2). The test corner walls shall be constructed with the material dimensions and specifications described in EN 13216-1:2004, 5.7.2.2.2 and 5.7.2.2.3. If the highest temperature is measured at the periphery of the test corner then the test corner walls shall be extended by at least 150 mm beyond the point of the highest temperature. The minimum distance between the test corner and building structures (i.e. walls, etc.) shall be 1,0 m. 5.2.3.2 Test structure inline fan Construct a test structure consisting of a wall and a ceiling at right angles to each other. The test structure extremities shall extend beyond the inline fan external dimensions by at least 500 mm (see Figure 3). The test structure wall and ceiling shall be constructed with the material dimensions and specifications in EN 13216-1:2004, 5.7.2.2.2 and 5.7.2.2.3. If the highest temperature is measured at the periphery of the test structure then the test structure wall and ceiling shall be extended by at least 150 mm beyond the point of the highest temperature. The minimum distance between the test structure and building structures (i.e. walls, etc.) shall be 1,0 m. 5.2.4 Measuring parameters 5.2.4.1 Test environment, test room The test room shall be in accordance with EN 13216-1:2004, 5.7.4.1. This requirement is deemed fulfilled in a closed test room. The velocity of the ambient air shall, if measured, be with an accuracy according to EN 13216-1:2004. 5.2.4.2 Hot gas temperature The hot gas temperature measuring shall be in accordance with EN 13216-1:2004, 5.7.4.2, except for the position of the thermocouple in Figures 2 and 3. The thermocouple used for the measurement shall have a maximum wire diameter of 1,0 mm if unshielded and a maximum total diameter of 1,5 mm if shielded. 5.2.4.3 Hot gas velocity The hot gas velocity measuring shall be in accordance with EN 13216-1:2004, 5.7.4.3. Besides the methods described, an orifice plate is also an acceptable method. 5.2.4.4 Test structure, surface temperatures The maximum surface temperatures of the test corner walls or cealing shall be determined. These temperatures shall be measured using equipment meeting the accuracy requirements specified in EN 13216-1:2004, 5.7.4.4. The position of the measurement points shall be as illustrated in Figures 4 and 5. SIST EN 16475-2:2017

Key 1 thermocouples x distance to combustible Figure 4 — Position of the thermocouples test rig for the exhaust fan SIST EN 16475-2:2017

Key 1 inline fan 2 thermocouples x distance to combustible Figure 5 — Position of the thermocouples test rig for the inline fan 5.2.4.5 Exhaust fan surface temperatures If exhaust fan temperatures shall be measured, this shall be done as described in Annex D. The exhaust fan temperatures shall be measured with an accuracy in accordance with EN 13216-1:2004, 5.7.4.4. 5.2.4.6 Ambient temperature Ambient temperature shall be measured as described in Annex E. Ambient temperatures during the test shall be as described in EN 13216-1:2004, 4.2. The ambient air temperature shall be measured with an accuracy in accordance with EN 13216-1:2004, 5.7.4.5.4. 5.2.5 Test procedure for heat stress test Generate hot gas with a velocity in the test chimney and a test temperature specified in EN 13216-1:2004, Table 1, appropriate to the hot gas velocity for negative and positive pressure chimneys, product designation and diameter. For exhaust fans always use the values for negative pressure chimneys. Regulate the rate of rise of the hot gas temperature to achieve the test temperature defined in EN 1443, with an average increase of 50 K per min. Normal production sizes are limited to a diameter of 200 mm. Hot gas velocities for other sizes are possible by calculating in accordance with EN 13384-1. SIST EN 16475-2:2017

+ 50) °C for a period of 30 min. After 25 min at 1 000 °C, determine the highest temperature on the test corner, using an IR-thermometer. If the position of this temperature is more than 5 cm different from the position found during the heat stress test, terminate the thermal shock test, and move the thermocouple to the new position. Repeat the thermal shock test with a new exhaust fan mounted (if necessary) in exactly the same angular position. After 30 min turn off the hot gas generator. Continue to record the temperatures on the test assembly until the temperatures have reached their maximum. NOTE The relevant product standard may require to run the test with a positive pressure chimney and a high positive pressure chimney for sootfire condition. 5.2.6.2 Test results Record all temperature values as specified in 5.2.4. Record any instance where the maximum temperature exceeds the allowed values. For the purpose of determining temperature rises on the exhaust fan and on enclosures and structures, such temperatures shall be related to the ambient air temperature. Continue to record the temperatures on the test assembly until the temperatures have reached their maximum. SIST EN 16475-2:2017

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...