prEN 12326-2

(Main)Slate and stone for discontinuous roofing and external cladding - Part 2: Test methods

Slate and stone for discontinuous roofing and external cladding - Part 2: Test methods

This document specifies test methods for slate, carbonate slate, schist and schistose stone for discontinuous roofing and external cladding, as defined in 3.1, 3.2, and 3.3 of EN 12326-1:2014 and 3.1 of prEN 12326-3:2021, used for assembly into discontinuous roofs and external wall cladding. In this sense, when the test describes a slate, it could also be considered as carbonate slate.

Schiefer und Naturstein für überlappende Dachdeckungen und Außenwandbekleidungen - Teil 2: Prüfverfahren für Schiefer und carbonathaltige Schiefer

Ardoises et pierres pour toiture et bardage extérieur pour pose en discontinu - Partie 2 : Méthodes d'essai

Le présent document spécifie les méthodes d’essai pour les ardoises, les ardoises carbonatées, les schistes et les pierres schisteuses pour toiture et bardage extérieur pour pose en discontinu, comme défini en 3.1, 3.2 et 3.3 de l’EN 12326 1:2014 et en 3.1 de la prEN 12326 3:2021, utilisés pour la couverture et le bardage extérieur en discontinu des bâtiments. En ce sens, lorsque l’essai décrit une ardoise, elle peut également être considérée comme une ardoise carbonatée.

Skrilavec in izdelki iz naravnega kamna za polaganje streh in zidov - 2. del: Preskusne metode

General Information

- Status

- Not Published

- Publication Date

- 07-Jul-2025

- Technical Committee

- CEN/TC 128 - Roof covering products for discontinuous laying and products for wall cladding

- Drafting Committee

- CEN/TC 128/SC 8 - Slate and stone products for roofing

- Current Stage

- 4098 - Decision to abandon - Enquiry

- Start Date

- 07-Oct-2025

- Completion Date

- 09-Feb-2026

Relations

- Effective Date

- 29-Mar-2023

Overview

The prEN 12326-2:2024 standard, developed by the European Committee for Standardization (CEN), defines test methods for slate, carbonate slate, schist, and schistose stone used in discontinuous roofing and external cladding systems. As the second part of the EN 12326 series, this document focuses specifically on standardized procedures to evaluate the physical and mechanical properties of natural stone materials employed in roofing and cladding applications. This ensures high-quality, durable, and consistent building materials across the European market.

The standard covers test methods applicable to natural slates and similar stones as described in EN 12326-1 and introduces updated procedures replacing the previous EN 12326-2:2011 edition. It provides detailed guidance on sample preparation, testing apparatus, and data reporting for various physical attributes and durability characteristics of roofing and cladding stone products.

Key Topics

prEN 12326-2:2024 includes comprehensive test methods addressing essential performance parameters of discontinuous roofing and external cladding stones:

Dimensional Accuracy

- Measuring length, width, and thickness of slates

- Assessing deviation from specified dimensions and flatness

- Determining rectangularity and edge straightness

Mechanical Strength

- Determination of modulus of rupture and characteristic modulus of rupture to assess load-bearing capacity

Durability Testing

- Water absorption and freeze-thaw resistance tests to evaluate weather resilience

- Thermal cycling tests and sulfur dioxide exposure to simulate environmental aging and pollutant effects

Chemical Analysis

- Quantification of calcium carbonate and other carbonate content by catalytic thermal decomposition

Petrographic Examination

- Microscopic interpretation of mineral content and stone structure to ensure material suitability and predict performance

Each test method includes detailed steps on apparatus setup, sample preparation, execution, result expression, and required documentation for transparency and reproducibility.

Applications

The prEN 12326-2:2024 standard is essential for stakeholders involved in the natural stone industry and construction sectors emphasizing quality and conformity in discontinuous roofing and external cladding:

Manufacturers of slate and natural stone products can utilize these test methods for quality control and certification, ensuring products meet consistent performance standards.

Architects and engineers rely on standardized test data to select appropriate stone materials that comply with structural safety and durability requirements in building designs.

Construction professionals and contractors benefit from knowing the tested properties of roofing and cladding stones, improving installation outcomes and longevity.

Regulatory bodies and certification organizations use the standard as a benchmark for compliance verification and market approvals.

By adhering to prEN 12326-2:2024, the industry enhances product reliability, supports sustainable construction, and minimizes building maintenance costs.

Related Standards

The prEN 12326-2:2024 standard is part of a wider framework covering natural stone materials for roofing and cladding:

EN 12326-1:2014 – Defines product specifications, terminology, and basic requirements for slate and stone products used in discontinuous roofing and cladding.

prEN 12326-3:2021 – Complements Parts 1 and 2 by addressing requirements for slate products used in wall cladding.

EN 12326-2:2011 – The previous edition of test methods that prEN 12326-2:2024 is set to supersede, introducing modernized and clarified procedures.

Other CEN standards related to roofing and construction materials, which ensure harmonized performance and testing across building product categories.

Together, these standards provide a robust framework guaranteeing the quality, safety, and durability of slate and stone materials within European construction practices.

Keywords: prEN 12326-2, slate test methods, discontinuous roofing, external cladding, natural stone testing, carbonate slate, schist testing, roofing stone durability, modulus of rupture, freeze-thaw resistance, water absorption, petrographic examination, CEN standards.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

prEN 12326-2 is a draft published by the European Committee for Standardization (CEN). Its full title is "Slate and stone for discontinuous roofing and external cladding - Part 2: Test methods". This standard covers: This document specifies test methods for slate, carbonate slate, schist and schistose stone for discontinuous roofing and external cladding, as defined in 3.1, 3.2, and 3.3 of EN 12326-1:2014 and 3.1 of prEN 12326-3:2021, used for assembly into discontinuous roofs and external wall cladding. In this sense, when the test describes a slate, it could also be considered as carbonate slate.

This document specifies test methods for slate, carbonate slate, schist and schistose stone for discontinuous roofing and external cladding, as defined in 3.1, 3.2, and 3.3 of EN 12326-1:2014 and 3.1 of prEN 12326-3:2021, used for assembly into discontinuous roofs and external wall cladding. In this sense, when the test describes a slate, it could also be considered as carbonate slate.

prEN 12326-2 is classified under the following ICS (International Classification for Standards) categories: 91.100.15 - Mineral materials and products. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 12326-2 has the following relationships with other standards: It is inter standard links to EN 12326-2:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN 12326-2 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/BC/CEN/87/13. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

prEN 12326-2 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2024

Skrilavec in izdelki iz naravnega kamna za polaganje streh in zidov - 2. del:

Preskusne metode

Slate and stone for discontinuous roofing and external cladding - Part 2: Test methods

Schiefer und Naturstein für überlappende Dachdeckungen und Außenwandbekleidungen

- Teil 2: Prüfverfahren für Schiefer und carbonathaltige Schiefer

Ardoises et pierres pour toiture et bardage extérieur pour pose en discontinu - Partie 2 :

Méthodes d'essai

Ta slovenski standard je istoveten z: prEN 12326-2

ICS:

91.100.15 Mineralni materiali in izdelki Mineral materials and

products

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

February 2024

ICS 91.100.15 Will supersede EN 12326-2:2011

English Version

Slate and stone for discontinuous roofing and external

cladding - Part 2: Test methods

Ardoises et pierres pour toiture et bardage extérieur Schiefer und Naturstein für überlappende

pour pose en discontinu - Partie 2 : Méthodes d'essai Dachdeckungen und Außenwandbekleidungen - Teil 2:

Prüfverfahren für Schiefer und carbonathaltige

Schiefer

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 128.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 12326-2:2024 E

worldwide for CEN national Members.

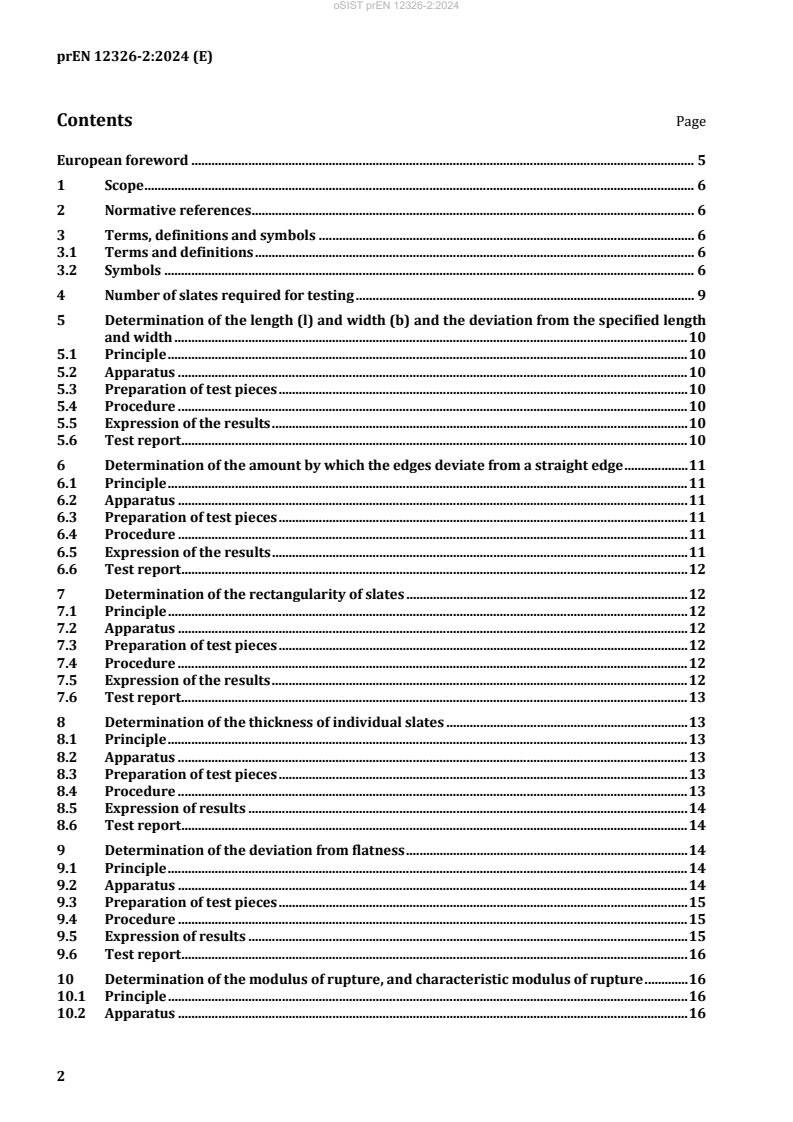

Contents Page

European foreword . 5

1 Scope . 6

2 Normative references . 6

3 Terms, definitions and symbols . 6

3.1 Terms and definitions . 6

3.2 Symbols . 6

4 Number of slates required for testing . 9

5 Determination of the length (l) and width (b) and the deviation from the specified length

and width . 10

5.1 Principle . 10

5.2 Apparatus . 10

5.3 Preparation of test pieces . 10

5.4 Procedure . 10

5.5 Expression of the results . 10

5.6 Test report . 10

6 Determination of the amount by which the edges deviate from a straight edge . 11

6.1 Principle . 11

6.2 Apparatus . 11

6.3 Preparation of test pieces . 11

6.4 Procedure . 11

6.5 Expression of the results . 11

6.6 Test report . 12

7 Determination of the rectangularity of slates . 12

7.1 Principle . 12

7.2 Apparatus . 12

7.3 Preparation of test pieces . 12

7.4 Procedure . 12

7.5 Expression of the results . 12

7.6 Test report . 13

8 Determination of the thickness of individual slates . 13

8.1 Principle . 13

8.2 Apparatus . 13

8.3 Preparation of test pieces . 13

8.4 Procedure . 13

8.5 Expression of results . 14

8.6 Test report . 14

9 Determination of the deviation from flatness . 14

9.1 Principle . 14

9.2 Apparatus . 14

9.3 Preparation of test pieces . 15

9.4 Procedure . 15

9.5 Expression of results . 15

9.6 Test report . 16

10 Determination of the modulus of rupture, and characteristic modulus of rupture . 16

10.1 Principle . 16

10.2 Apparatus . 16

10.3 Preparation of test pieces . 17

10.4 Procedure . 17

10.5 Expression of the results . 18

10.6 Test report . 19

11 Water absorption test . 20

11.1 Principle . 20

11.2 Reagents . 20

11.3 Apparatus . 20

11.4 Preparation of test pieces . 20

11.5 Procedure . 20

11.6 Expression of the results . 21

11.7 Test report . 21

12 Freeze-thaw resistance. 21

12.1 Principle . 21

12.2 Reagent . 21

12.3 Apparatus . 22

12.4 Preparation of Test pieces. 22

12.5 Procedure . 22

12.6 Expression of results and test report . 22

13 Determination of the apparent calcium carbonate and non carbonate carbon content by

catalytic thermal decomposition . 22

13.1 Principle . 23

13.2 Reagents . 23

13.3 Apparatus . 23

13.4 Preparation of powdered test pieces . 23

13.5 Procedure . 23

13.6 Expression of results . 24

13.7 Test report . 24

14 Sulfur dioxide exposure tests . 25

14.1 Sulfur dioxide exposure test for slates with a carbonate content ≤ 20 % (mass %) . 25

14.2 Sulfur dioxide exposure test for slates with a calcium carbonate content > 20 % (mass %)

............................................................................................................................................................................. 26

14.3 Test report . 32

15 Thermal cycle . 33

15.1 Principle . 33

15.2 Reagents . 33

15.3 Apparatus . 33

15.4 Preparation of test pieces . 33

15.5 Procedure . 33

15.6 Test report . 34

16 Petrographic examination. 34

16.1 Introduction . 34

16.2 Principle . 34

16.3 Apparatus . 34

16.4 Reagents . 35

16.5 Preparation of test pieces . 35

16.6 Procedure . 36

16.7 Expression of results . 37

16.8 Test report . 37

Annex A (informative) Petrographic interpretation . 39

A.1 Connection between the micas . 39

A.2 Bedding and cleavage, angle of intersection . 39

Annex B (informative) Guidance To interpretate the Codes for the Thermal Cycle test . 41

Bibliography . 47

European foreword

This document (prEN 12326-2:2024) has been prepared by Technical Committee CEN/TC 128 “Roof

covering products for discontinuous laying and products for wall cladding”, the secretariat of which is

held by NBN.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 12326-2:2011.

This document is one of a series of product standards for building materials, which consists of the

following parts:

— Part 1: Specifications for slate and carbonate slate

— Part 2: Test methods

1 Scope

This document specifies test methods for slate, carbonate slate, schist and schistose stone for

discontinuous roofing and external cladding, as defined in 3.1, 3.2, and 3.3 of EN 12326-1:2014 and 3.1

of prEN 12326-3:2021, used for assembly into discontinuous roofs and external wall cladding. In this

sense, when the test describes a slate, it could also be considered as carbonate slate.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 12326-1:2014, Slate and stone for discontinuous roofing and external cladding - Part 1: Specifications

for slate and carbonate slate

3 Terms, definitions and symbols

For the purposes of this document, the following terms, definitions and symbols apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp/

3.1 Terms and definitions

3.1.1

constant mass

mass achieved when two successive weightings taken 24 h apart do not differ by more than 0,005 g or

0,05 % of the mass of the test piece, whichever is greater

3.1.2

modulus of rupture

maximum stress sustained by a slate test piece when a bending moment is applied

Note 1 to entry: In this document, the geometry of the test is three point bending.

3.2 Symbols

Symbol Physical quantity Unit

A water absorption %

w

A rate of application of stress in the modulus of rupture test (N/mm )/s

B width mm

C’ apparent mass percentage calcium carbonate in slate %

a

C carbonate carbon content of slate %

c

̄

𝐶𝐶 mean carbonate carbon content of a slate %

𝑐𝑐

C carbon dioxide content of a test piece or standard preparation %

d

C non-carbonate carbon in a slate %

nc

C total carbon in a slate %

T

e to e individual thickness measurements in the SO exposure test mm

1A 4A 2

e Individual thickness measurement of slates or test pieces mm

i

E thickness of a individual slate or a test piece mm

i

mean of 8 individual thickness measurements in the modulus of rupture test mm

e

i8

E maximum deviation of the thickness of a slate from the mean thickness %

d

e mean of three thickness measurements used to determine the rate of mm

mi

application of load in the modulus of rupture test

emax the individual thickness measurement from the four individual thickness mm

measurements with the maximum difference with the mean individual

thickness carried out on one slate or a test piece

e thickness of the softened layer in the SO exposure test mm

s 2

F deviation from flatness of a slate mm

d

λKα wavelength of the α radiation used in the x-ray diffraction analysis nm

l length mm

l distance between the bending supports to base mm

t

m dry mass of a test piece in the water absorption test g

o

m mass of a powdered test piece of slate mg

p

mw wet mass of a test piece in the water absorption test g

n number of slates subject to a test -

P failure load of individual slates in the modulus of rupture test N

i

r individual measurements of the deviation of a slate from a rectangle mm

d

r maximum deviation of a slate from a rectangle mm

dmax

R deviation of a test slate from a rectangle as a percentage of its length %

d

R modulus of rupture of individual test slates N/mm

i

�

𝑅𝑅 sample mean modulus of rupture of test slates N/mm

sample mean modulus of rupture of test slates measured in the longitudinal N/mm

R

l

orientation

sample mean modulus of rupture of test slates measured in the transverse N/mm

R

t

orientation

R characteristic modulus of rupture of test slates N/mm

c

sample mean modulus of rupture of the control test pieces in the freeze- N/mm

R

thaw test

sample mean modulus of rupture of the frost exposed test pieces in the N/mm

R

freeze-thaw test

s sample standard deviation of the modulus of rupture -

s sample standard deviation of the modulus of rupture in the longitudinal -

l

orientation

s sample standard deviation of the modulus of rupture in the transverse -

t

orientation

s sample standard deviation of the modulus of rupture of the control test -

pieces after the freeze-thaw test

s standard deviation of the modulus of rupture of the frost exposed test pieces -

after the freeze-thaw test

s deviation of the edge of a slate from a straight edge mm

d

S deviation of the edge of a slate from a straight edge as a percentage of its %

d

length

v rate of application of the load in the modulus of rupture test N/s

l

o

α deviation of a slate from rectangle

o

θ angle of incidence of the beam in the X-ray diffraction analysis

4 Number of slates required for testing

Table 1 indicates the number of slates required for each test.

In addition, specimens for testing shall be representative of the product and any processes that the stone

is subjected to.

Table 1 — Number of slates required to carry out each test

Test Number of slates required for each test

Length and width 1

Straight edges 1

Rectangularity 1

Individual thickness 1

Curvature 1

Modulus of Rupture 20/40*

Water absorption 5

Freeze thaw 20/40*

Non-carbonate carbon content 3

Carbonate content 3

Sulfur dioxide exposure for less than or equal to 20 % 12

carbonate

Sulfur dioxide exposure for more than 20 % carbonate 6 or 12*

Thermal cycle 6

Where there is a possibility that the slates being tested may contain localized harmful inclusions, such as

calcite veins or oxidizable minerals, the preparation of the test pieces or powdered test pieces should be

modified to ensure sufficient inclusions are contained in the test piece to provide a representative result.

Sampling should preferably be carried out by the recipient or his representative in the presence of the

supplier.

For the tests marked * the number of slates required depends on their size.

The individual tests indicate the size and number of test pieces or powdered test pieces required.

NOTE Because many of the tests do not require whole slates it is possible to carry out a full set of tests with fewer

than the total number of slates listed in this table.

5 Determination of the length (l) and width (b) and the deviation from the

specified length and width

5.1 Principle

The dimensions of slates are measured using a steel rule placed on the midline of the length and the width.

The percentage deviation from the specified dimension is calculated.

5.2 Apparatus

5.2.1 A steel rule capable of reading to 0,5 mm.

5.2.2 Two steel bars longer and thicker than the slates under test. Each bar shall have one edge which

shall not deviate from a straight edge by more than ± 0,1 mm.

5.3 Preparation of test pieces

Whole slates are used and do not need any preparation unless any corners are oversized within 50 mm

of the corner. In this case, remove the oversize corner(s) at an angle of approximately 45° from a point

50 mm from the corner, using a suitable cutting tool.

Figure 1 — Corner oversized within 50 mm of the corner.

5.4 Procedure

Place the slate with the chamfered edge facing down. Align the straight edges of the two steel bars along

the long edges of the slate. Using a steel rule find the midpoints of the length of the slate on each side to

the nearest 1,0 mm at each end and mark the positions on the slate. Place the steel rule across the distance

between the bars at the marked points. Read off and record the width to the nearest 1,0 mm.

Repeat for the length.

5.5 Expression of the results

Calculate the difference of the length from the specified length as a percentage.

Calculate the difference of the width from the specified width as a percentage.

5.6 Test report

Report the length and width in millimetres and the deviation in percentage from the specified length and

width.

The test report shall also include the identification of the product, reference to this method and the

identifier of this document, i.e. prEN 12326-2:2024.

6 Determination of the amount by which the edges deviate from a straight edge

6.1 Principle

The deviation of the long edges of slates from a straight edge is measured using a steel rule. For slates

500 mm long or longer the deviation is calculated as a percentage of the length.

6.2 Apparatus

6.2.1 A steel rule capable of reading to 0,5 mm.

6.2.2 A steel bar longer and thicker than the slates under test with one edge which shall not deviate

from a straight edge by more than ± 0,1 mm.

6.3 Preparation of test pieces

Whole slates are used and do not need any preparation unless any corners are oversized within 50 mm

of the corner. In this case, the oversize corner(s) shall be removed at an angle of approximately 45° from

a point 50 mm from the corner, using a suitable cutting tool.

6.4 Procedure

Place the slate with the chamfered edge facing down and position the straight edge of the steel bar

alongside one edge of the slate. Using the steel rule measure the maximum deviation (S ) of the edge of

d1

the slate from the steel bar to the nearest 0,5 mm. Ignore small deviations and flaking resulting from the

dressing of the edges (Figure 1). Repeat and record the deviation for the other edge (S ).

d2

Key

1 deviation from a straight edge

2 acceptable minor deviations and flaking

Figure 2 — Illustration of acceptable small variations and flaking resulting from the dressing of

the edges of slates. The chamfer is shown facing upwards

Measure the length of the slate (l ) by the method given in Clause 5.

s

6.5 Expression of the results

For slates of 500 mm or longer and for each edge calculate the percentage deviation from a straight edge

) using the formula:

(Sd

S .100

dx

S =

d

l

where

S is the deviation for each edge, S and S in millimetres,

dx d1 d2

l is the length of the slate, in millimetres.

6.6 Test report

For slates less than 500 mm long, report for each edge the deviation in mm from a straight edge.

For slates 500 mm long or longer, report for each edge the deviation in mm from a straight edge and the

percentage deviation.

The test report shall also include the identification of the product, reference to this method and the

identifier of this document, i.e. prEN 12326-2:2024.

7 Determination of the rectangularity of slates

7.1 Principle

The deviation from a right angle of the angles enclosing any two sides is measured using a goniometer or

an engineering set square. The deviation is calculated as a percentage of the length.

7.2 Apparatus

7.2.1 A set square with blades longer and thicker than the slates under test calibrated to an angular

deviation of 0,1°.

7.2.2 Alternatively, a goniometer (calibrated adjustable square) with blades longer and thicker than

the slates under test capable of being read to 0,1°.

7.3 Preparation of test pieces

Whole slates are used and do not need any preparation unless any corners are oversized within 50 mm

of the corner. In this case remove the oversize corner(s) at an angle of approximately 45° from a point

50 mm from the corner using a suitable cutting tool.

7.4 Procedure

Place the slate in the set square with one end tightly against the blade so that the long edge of the slate

touches the opposite blade. Using the steel rule measure the maximum deviation (r ) of the long edge

d1

from the opposing blade of the set square to the nearest 0,5 mm.

Repeat for all four corners to obtain the values (R ), (R ) and (R ).

d2 d3 d4

Alternatively, if a goniometer is used read the deviation in degrees to the nearest 0,1°.

Measure the length of the slate (l ) by the method given in Clause 5.

s

7.5 Expression of the results

For each edge calculate the percentage deviation (R ) from a rectangle using the formula:

d

r .100

d max

R =

d

ls

where

r is the maximum value of (r ) to (r ), in millimetres

dmax d1 d4

is the slate length, in millimetres

ls

Alternatively, if a goniometer has been used calculate the percentage deviation using the formula:

R = tan α .100

d

where

α is the maximum angle measured in 7.4.

7.6 Test report

Report the maximum percent deviation.

The test report shall also include the identification of the product, reference to this method and the

identifier of this document, i.e. prEN 12326-2:2024.

8 Determination of the thickness of individual slates

8.1 Principle

The thickness of a slate is measured at four points using a micrometer, or similar equipment.

Four individual readings (ei) shall be taken.

The mean of the four individual readings corresponds with the thickness of that individual slate (E ).

i

8.2 Apparatus

Dial gauge, micrometer or similar equipment capable of measuring thickness to 0,05 mm with a contact

area of 5 mm to 10 mm diameter.

8.3 Preparation of test pieces

Whole slates are used. They do not require any preparation.

8.4 Procedure

Measure the thickness of the slate to 0,1 mm at four points (approximately at the middle of the sides of

the slates, see Figure 2) avoiding all dressed edges and any localized thick or thin areas.

NOTE Figure 3 indicates the approximate points of measurement for various slate shapes.

Key

perimeter zone of the slate (width 25 mm) excluded from thickness measurements.

point of measurement recommended (25 mm to 30 mm from edge)

Figure 3 — Approximate positions for measurements of individual thickness

8.5 Expression of results

Take four individual thickness readings (e ) and calculate the mean of the four individual measurements

i

(E ).

i

) and the mean value (E), calculate the

Using the largest difference between the individual values (ei i

maximum deviation (E ) from the individual thickness (E ) as a percentage to two significant figures using

d i

the formula:

E = 100 x emax / E

d i

where

e = max |e – E |

max i i

e is from the four individual thickness measurements (e ) the one with the maximum

max i

difference with the thickness of individual slates (Ei), carried out on one slate or a test

piece;

E is the thickness of the individual slate, in millimetres.

i

8.6 Test report

Report the mean thickness and the thickness of individual slates (E ) to 0,1 mm and report the maximum

i

percent deviation from the mean E .

d

The test report shall also include the identification of the product, reference to this method and the

identifier of this document, i.e. prEN 12326-2:2024.

9 Determination of the deviation from flatness

9.1 Principle

The deviation from flatness of individual slates is determined by measuring the difference between the

height of the highest point measured with a dial gauge placed in contact with the convex face of a slate

(h) and the individual thickness of a slate in millimetres, (E ), (Clause 8).

i

9.2 Apparatus

Apparatus comprising a dial gauge or similar device capable of reading deflections of 0,1 mm and with a

contact area of 5 mm to 10 mm diameter arranged above a surface plate as large as the slates to be tested.

The dial gauge shall be capable of being moved to various positions above the slate. A typical apparatus

is shown in Figure 3. Other similar apparatus can be used. At least two wedges will be used to fix slate

position.

Key

1 dial gauge

2 Test slate in position with the highest point (maximum curvature or maximum irregularity) under gauge.

Convex side upwards.

3 wedge

Figure 4 — Typical apparatus for measuring the deviation from flatness

9.3 Preparation of test pieces

Individual slates are used but they do not need any preparation.

9.4 Procedure

Measure the individual thickness of a slate in millimetres, (E ) (Clause 8).

i

Lay the slate convex face uppermost on the surface plate of the test apparatus. If one of the corners of the

slate is not in contact with the surface plate, use two wedges between slate and the surface space to level

the slate piece and avoid undesired movements. The wedges shall be positioned on two diagonally

opposite corners of the slate piece. After placing the wedges, two diagonally opposite corners of the slate

must be in contact with surface plate and the other two must be in contact with the wedges. Move the dial

gauge over the highest point on the slate. Record the height (h) of the highest point of the slate surface in

millimetres.

Figure 5 — Wedge placing

9.5 Expression of results

Calculate the deviation from flatness (F) using the formula:

F = 100 x (h – E )/ E

d i i

9.6 Test report

Report the deviation from flatness (F ) as percentage. The test report shall also include the identification

d

of the product, reference to this method and the identifier of this document, i.e. prEN 12326-2:2024.

) for rectangular slates

Table 4 — Maximum deviation from flatness (Fd

a

Slate flatness Maximum deviation from flatness (F ) as a percentage of E ,

d i

the thickness of the individual slate

Very flat ≤ 40 %

Flat ≤ 60 %

Normal ≤ 70 %

b

Slates for special situations No limit

a As specified by the manufacturer.

b Slates for which there is no limit on the deviation from flatness are only suitable for use in special

situations such as curved slating.

Curved slates shall be manufactured so that the bevelled edges are applied to the convex face of the slate.

10 Determination of the modulus of rupture, and characteristic modulus of

rupture

10.1 Principle

Tests are carried out on prepared test pieces to measure the failure load in bending. From the results the

modulus of rupture and the characteristic modulus of rupture are calculated.

The characteristic modulus of rupture shall be determined for slates with the same reference and the

value will be valid for all nominal thickness. The characteristic modulus of rupture shall be determined

only for one nominal thickness. The same value of the characteristic modulus of rupture is valid for other

slates with different nominal thickness.

10.2 Apparatus

10.2.1 A three point bending test machine, capable of applying a constant rate of loading. The support

bars and load bar shall have a diameter of 20 mm and the load bar and any two of the load and support

bars shall be free to align themselves to the test piece. The load bar shall be parallel to the support bars.

The support bars shall be (180 ± 1,0) mm apart and the load bar shall be central over the span.

NOTE Where an apparatus capable of applying a constant rate of loading is not available a constant rate of

deflection is acceptable.

10.2.2 Oven, ventilated and capable of maintaining a temperature of (110 ± 10) °C.

10.2.3 Water cooled diamond saw.

10.2.4 Metal rule or similar equipment, capable of measurements to 1 mm.

10.2.5 Micrometer or similar equipment, capable of measuring thickness to 0,05 mm with a contact

area of 5 mm to 10 mm diameter.

10.3 Preparation of test pieces

Determine the number of test pieces required by reference to Clause 4 but using not less than 20 for each

orientation (Figure 6).

Using a water-cooled diamond saw, cut from each slate one test piece parallel (longitudinal) to the long

edge and measuring (125 ± 1,0) mm by the length of the slate (minimum 190 mm), and one test piece

perpendicular (transverse) to the long edge and measuring (125 ± 1,0) mm by the width of the slate

(minimum 190 mm). Make the saw cuts so that they avoid the dressed edges of the slates and trim off the

ends with the saw. If the slates are too small to cut test pieces for each orientation from one slate, two

slates shall be used.

Dry the test pieces in the oven at (110 ± 10) °C for at least 17± 2 h and then allow them to cool to ambient

temperature.

Dimensions in millimetres

Key

1 slate

2 test piece

3 orientation of the load bar in the test

4 perpendicular or transverse orientation

5 parallel or longitudinal orientation

NOTE The description of the test pieces as transverse or longitudinal is the opposite of that used in some

standards for roofing slates.

Figure 6 — Orientations of test pieces in the Modulus of Rupture test

10.4 Procedure

Using the micrometer or similar apparatus measure the thickness of each test piece in three equally

spaced positions across the width. For each test piece calculate the mean (e ) of the three values. Using

mi

a metal ruler measure the width (b) of each test piece to the nearest 1 mm by the method given in

Clause 5.

Calculate the loading rate in N/s for each test piece using the formula:

2 be

mi

va=

l

3 l

t

where

a is the rate of application of stress and is equal to (1,00 ± 0,25) (N/mm )/s;

v is the rate of loading to be used in the test, in N/s;

l

b is the width of the test piece, in millimetres;

e is the mean thickness of the test pieces, in millimetres;

mi

l is the distance between the support bars (normally 180 mm).

t

Place the test piece in the three point bending test machine centrally under the load bar and check that is

(180 ± 1,0) mm. Apply the load at the calculated rate v .

l

NOTE If it is not possible to apply a constant rate of loading, it is acceptable to apply a constant rate of deflection

so that failure occurs in 20 s to 30 s.

Record the failure load in bending in newtons to the nearest 1 N. Using a micrometer or similar

equipment, measure the thickness of the slate (e) to 0,1 mm at four evenly spaced points on each side of

the break at a distance of 25 mm to 30 mm from the rupture line (8 measurements). Repeat for each of

the test pieces.

10.5 Expression of the results

For each orientation, calculate:

a) the modulus of rupture (R ) in N/mm for each test piece using the formula:

i

3.Pl

i t

R =

i

2.be

i8

where

P is the failure load, in newtons;

i

l is 180 mm;

t

b is the test piece width, in millimetres;

is the mean of the 8 individual thickness measurements in mm, taken after testing, at

e

i8

a distance of 25 mm of the rupture line (4 measurements in each side of the rupture

line equally spread).

b) Identify the outliers using the following method:

Order the R values obtained from lower (R ) to higher (R ).

i 1 n

1. First exclude the largest difference between the mean flexion strength and the individual flexion

strength.

2. Calculate with the other results the mean value and the standard deviation (s).

3. If the excluded value lies in the interval of the mean value + or – 3s, the value is not an outlier

and you stop your calculations.

If the value you excluded lies outside the interval of the mean value + 3s or – 3s, the value is an

outlier and should be excluded.

4. Repeat the procedure 1-3 for the second largest difference till all the values are within the

interval of the mean value + 3s or – 3s. Exclude the outliers from the following steps of the

calculation.

c) calculate the mean modulus of rupture ( ) in N/mm , for the total number of slates tested

R

excluding the outliers;

d) calculate the characteristic modulus of rupture (R ), in N/mm , for the total number of slates tested

c

excluding the outliers using the formula:

R=Rk−× s

c s

where

Σ−RR

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...