EN 12977-5:2012

(Main)Thermal solar systems and components - Custom built systems - Part 5: Performance test methods for control equipment

Thermal solar systems and components - Custom built systems - Part 5: Performance test methods for control equipment

This European Standard specifies performance test methods for control equipment. Furthermore, this document contains requirements on accuracy, durability and reliability of control equipment.

The tests described in this document are limited to electrically activated components delivered with or for the system by the final supplier. For the purposes of this document controller and control equipment for solar heating systems and auxiliary heaters, if part of the system, are restricted to the following:

a) Controllers as:

1) system clocks, timers and counters;

2) differential thermostats;

3) multi-function controllers.

b) Sensors as:

1) temperature sensors;

2) irradiance sensors (for short wave radiation);

3) pressure sensors;

4) level sensors;

5) flow meters;

6) heat meters.

c) Actuators as:

1) pumps;

2) solenoid and motor valves;

3) relays.

d) Combinations of controllers, sensors and actuators listed above.

An additional objective of the procedures described in this document is to verify control algorithms and, together with the accuracy of sensors, to determine control parameters. In addition to verifying the functioning of a controller, its equipment and actuators, the determined parameters may be used for numerical system simulations.

Typically, electrical anodes are not part of the control equipment and are not controlled by the control equipment. However, because they are electrical appliances, electrical anodes are included in this document.

This document is valid for control equipment of solar heating systems for the purpose of hot water preparation and/or space heating. If the solar system is connected to or part of a conventional heating system, the validity is extended to the entire system. In combination with the standards EN 12976 1, EN 12976 2 as well as EN 12977 1, EN 12977 2, EN 12977 3 and EN 12977 4, this document is valid for

e) factory made solar heating systems,

f) small custom built solar heating systems,

g) large custom built solar heating systems,

h) auxiliary heater equipment used in connection with e), f) and g).

Thermische Solaranlagen und ihre Bauteile - Kundenspezifisch gefertigte Anlagen - Teil 5: Prüfverfahren für die Regeleinrichtungen

Diese Europäische Norm legt Prüfverfahren für die Beschreibung der Leistung von Regeleinrichtungen fest. Darüber hinaus enthält das vorliegende Dokument Anforderungen an die Genauigkeit, die Dauerhaftigkeit und die Zuverlässigkeit von Regeleinrichtungen.

Die in dem vorliegenden Dokument beschriebenen Prüfungen sind auf die vom Endlieferanten mit der oder für die Anlage gelieferten elektrisch betriebenen Bauteile begrenzt. Für die Anwendung des vorliegenden Doku-ments sind Regler, Reglerzubehör und Regeleinrichtungen für solare Heizungsanlagen und Zusatzheizungen, sofern diese Bestandteil der Anlage sind, auf folgende beschränkt:

a) Regler, wie z. B.:

1) Systemuhren, Zeitgeber und Zähler,

2) Differenzthermostate,

3) Multifunktionsregler;

b) Messfühler, wie z. B.:

1) Temperaturfühler,

2) Bestrahlungsstärkesensoren (für kurzwellige Strahlung),

3) Drucksensoren,

4) Niveausensoren,

5) Durchflussmesser,

6) Wärmemengenzähler;

c) Stellglieder, wie z. B.:

1) Pumpen,

2) Magnet- und Motorventile,

3) Relais;

d) Kombinationen der vorstehend aufgeführten Regler, Messfühler und Stellglieder sind einge¬schlossen.

Ein weiteres Ziel der in diesem Dokument beschriebenen Verfahren besteht darin, die Regelalgorithmen zu verifizieren und in Verbindung mit der Messfühlergenauigkeit die Regelparameter zu bestimmen. Zusätzlich zur Verifizierung der Funktionsweise eines Reglers sowie des dazugehörigen Reglerzubehörs und der Stell-glieder können die ermittelten Kennwerte für numerische Anlagensimulationen verwendet werden.

Elektrische Anoden sind üblicherweise nicht Bestandteil der Regeleinrichtungen und werden von diesen auch nicht geregelt oder gesteuert. Da es sich bei elektrischen Anoden jedoch um elektrische Einrichtungen handelt, werden sie im vorliegenden Dokument mit einbezogen.

Das vorliegende Dokument gilt für Regeleinrichtungen von solaren Heizungsanlagen, die zur Trinkwasser-erwärmung und/oder Raumheizung dienen. Für den Fall, dass die Solaranlage an eine konventionelle Heizungsanlage angeschlossen oder Bestandteil einer solchen ist, wird die Gültigkeit dieses Dokuments auf die gesamte Anlage ausgedehnt. In Verbindung mit den Normen EN 12976 1 und EN 12976 2 sowie mit EN 12977 1, EN 12977 2, EN 12977 3 und EN 12977 4 gilt das vorliegende Dokument für:

e) vorgefertigte solare Heizungsanlagen;

f) kleine kundenspezifisch gefertigte solare Heizungsanlagen;

g) große kundenspezifisch gefertigte solare Heizungsanlagen;

h) Zusatzheizeinrichtungen, die in Verbindung mit e), f) und g) eingesetzt werden.

Installations solaires thermiques et leurs composants - Installations assemblées à façon - Partie 5: Méthodes d'essai de performances des systèmes de régulation

La présente Norme européenne spécifie les méthodes d’essai de performances des systèmes de régulation. Par ailleurs, le présent document comporte des exigences relatives à la précision, à la durabilité et à la fiabilité des systèmes de régulation.

Les essais décrits sont limités aux composants fonctionnant à l’électricité fournis avec ou pour l’installation par le fournisseur final. Pour les besoins du présent document, le régulateur et les systèmes de régulation des installations de chauffage solaire et des appareils de chauffage d’appoint, s’ils sont intégrés à l’installation, se limitent aux éléments suivants :

a) régulateurs tels que :

1) les horloges, temporisateurs et compteurs de l’installation ;

2) les thermostats différentiels ;

3) les régulateurs multifonctionnels.

b) capteurs tels que :

1) les capteurs de température ;

2) les capteurs d’éclairement énergétique (pour le rayonnement à onde courte) ;

3) les capteurs de pression ;

4) les capteurs de niveau ;

5) les débitmètres ; ou

6) les compteurs de chaleur.

c) actionneurs tels que :

1) les pompes ;

2) les électrovannes et vannes motorisées ; ou

3) les relais.

d) les combinaisons des régulateurs, des capteurs et des actionneurs énumérés ci-dessus.

Les modes opératoires décrits dans le présent document ont également pour objet de vérifier les algorithmes de régulation et, avec la précision des capteurs, de déterminer les paramètres de régulation. Outre les résultats de la vérification du fonctionnement d’un régulateur, de ses équipements et actionneurs, les paramètres déterminés peuvent être utilisés pour des simulations numériques de l’installation.

Les anodes électriques types ne font pas partie du système de régulation et ne sont pas contrôlées par le système de régulation. Cependant, du fait qu’elles constituent un appareil électrique, les anodes électriques sont incluses dans le présent document.

Le présent document s’applique aux systèmes de régulation des installations de chauffage solaire destinées à la production d’eau chaude et/ou au chauffage des locaux. Si l’installation solaire est raccordée à ou fait partie d’une installation de chauffage conventionnelle, la validité est élargie à toute l’installation. En combinaison avec les normes EN 12976-1, EN 12976-2 ainsi que les EN 12977 1, EN 12977 2, EN 12977 3 et EN 12977 4, le présent document est valide pour :

e) les installations de chauffage solaire de série ;

f) les petites installations de chauffage solaire assemblées à façon ;

g) les grandes installations de chauffage solaire assemblées à façon ; et

h) les appareils de chauffage d’appoint utilisés en liaison avec e), f) et g).

NOTE Installations de chauffage solaire de série et assemblées à façon.

Toplotni sončni sistemi in sestavni deli - Neserijsko izdelani sistemi - 5. del: Preskusne metode delovanja kontrolnih naprav

Preskusi, opisani v tem dokumentu, so omejeni na električne sestavne dele, ki jih končni dobavitelj dobavi s sistemom ali zanj. Za namene tega dokumenta so krmilniki in kontrolne naprave za sončne ogrevalne sisteme in pomožne grelnike, če so del sistema, omejeni na: a) Krmilnike: 1) sistemske ure, časovniki in števci; 2) diferenčni termostati; 3) večfunkcijski krmilniki. b) Senzorje: 1) temperaturni senzorji; 2) senzorji za obsevanost (za kratkovalovno sevanje); 3) tlačni senzorji; 4) nivojski senzorji; 5) merilniki pretoka; 6) merilniki toplote. c) Aktivatorje: 1) črpalke; 2) elektromagnetni in motorni ventili; 3) releji. d) Kombinacije naštetih krmilnikov, senzorjev in aktivatorjev. Postopki, opisani v tem dokumentu, so namenjeni tudi za preverjanje kontrolnih algoritmov in, skupaj z natančnostjo senzorjev, za določanje kontrolnih parametrov. Določeni parametri se poleg uporabe za preverjanje delovanja krmilnika, njegove opreme in aktivatorjev lahko uporabljajo za numerične simulacije sistema. Električne anode običajno niso del kontrolnih naprav, pri čemer jih te naprave ne upravljajo. Ker pa so anode električne naprave, so vseeno vključene v ta dokument.

General Information

- Status

- Withdrawn

- Publication Date

- 03-Apr-2012

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 312 - Thermal solar systems and components

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 04-Apr-2018

- Completion Date

- 09-Feb-2026

Relations

- Effective Date

- 11-Apr-2012

- Effective Date

- 11-Apr-2018

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

EN 12977-5:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Thermal solar systems and components - Custom built systems - Part 5: Performance test methods for control equipment". This standard covers: This European Standard specifies performance test methods for control equipment. Furthermore, this document contains requirements on accuracy, durability and reliability of control equipment. The tests described in this document are limited to electrically activated components delivered with or for the system by the final supplier. For the purposes of this document controller and control equipment for solar heating systems and auxiliary heaters, if part of the system, are restricted to the following: a) Controllers as: 1) system clocks, timers and counters; 2) differential thermostats; 3) multi-function controllers. b) Sensors as: 1) temperature sensors; 2) irradiance sensors (for short wave radiation); 3) pressure sensors; 4) level sensors; 5) flow meters; 6) heat meters. c) Actuators as: 1) pumps; 2) solenoid and motor valves; 3) relays. d) Combinations of controllers, sensors and actuators listed above. An additional objective of the procedures described in this document is to verify control algorithms and, together with the accuracy of sensors, to determine control parameters. In addition to verifying the functioning of a controller, its equipment and actuators, the determined parameters may be used for numerical system simulations. Typically, electrical anodes are not part of the control equipment and are not controlled by the control equipment. However, because they are electrical appliances, electrical anodes are included in this document. This document is valid for control equipment of solar heating systems for the purpose of hot water preparation and/or space heating. If the solar system is connected to or part of a conventional heating system, the validity is extended to the entire system. In combination with the standards EN 12976 1, EN 12976 2 as well as EN 12977 1, EN 12977 2, EN 12977 3 and EN 12977 4, this document is valid for e) factory made solar heating systems, f) small custom built solar heating systems, g) large custom built solar heating systems, h) auxiliary heater equipment used in connection with e), f) and g).

This European Standard specifies performance test methods for control equipment. Furthermore, this document contains requirements on accuracy, durability and reliability of control equipment. The tests described in this document are limited to electrically activated components delivered with or for the system by the final supplier. For the purposes of this document controller and control equipment for solar heating systems and auxiliary heaters, if part of the system, are restricted to the following: a) Controllers as: 1) system clocks, timers and counters; 2) differential thermostats; 3) multi-function controllers. b) Sensors as: 1) temperature sensors; 2) irradiance sensors (for short wave radiation); 3) pressure sensors; 4) level sensors; 5) flow meters; 6) heat meters. c) Actuators as: 1) pumps; 2) solenoid and motor valves; 3) relays. d) Combinations of controllers, sensors and actuators listed above. An additional objective of the procedures described in this document is to verify control algorithms and, together with the accuracy of sensors, to determine control parameters. In addition to verifying the functioning of a controller, its equipment and actuators, the determined parameters may be used for numerical system simulations. Typically, electrical anodes are not part of the control equipment and are not controlled by the control equipment. However, because they are electrical appliances, electrical anodes are included in this document. This document is valid for control equipment of solar heating systems for the purpose of hot water preparation and/or space heating. If the solar system is connected to or part of a conventional heating system, the validity is extended to the entire system. In combination with the standards EN 12976 1, EN 12976 2 as well as EN 12977 1, EN 12977 2, EN 12977 3 and EN 12977 4, this document is valid for e) factory made solar heating systems, f) small custom built solar heating systems, g) large custom built solar heating systems, h) auxiliary heater equipment used in connection with e), f) and g).

EN 12977-5:2012 is classified under the following ICS (International Classification for Standards) categories: 27.160 - Solar energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12977-5:2012 has the following relationships with other standards: It is inter standard links to CEN/TS 12977-5:2010, EN 12977-5:2018, EN IEC 60730-2-14:2025, EN 60255-127:2014, EN IEC 60730-1:2024/A11:2024, EN 60730-2-9:1995/A13:2004, EN 60255-121:2014, EN IEC 60730-2-22:2020, EN 60255-151:2009, EN 60730-2-5:2015, EN 60730-2-5:2015/A1:2019, EN IEC 60730-2-12:2019, EN IEC 60255-27:2025, EN IEC 60730-2-9:2019/A1:2019, EN IEC 60730-2-9:2019/A2:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12977-5:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Thermische Solaranlagen und ihre Bauteile - Kundenspezifisch gefertigte Anlagen - Teil 5: Prüfmethoden für die RegeleinrichtungenInstallations solaires thermiques et leurs composants - Installations assemblées à façon - Partie 5 : Méthodes d'essai pour chauffe-eau solaires et installations solaires combinéesThermal solar systems and components - Custom built systems - Part 5: Performance test methods for control equipment91.140.65Oprema za ogrevanje vodeWater heating equipment91.140.10Sistemi centralnega ogrevanjaCentral heating systems27.160Solar energy engineeringICS:Ta slovenski standard je istoveten z:EN 12977-5:2012SIST EN 12977-5:2012en,fr,de01-julij-2012SIST EN 12977-5:2012SLOVENSKI

STANDARDSIST-TS CEN/TS 12977-5:20101DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12977-5

April 2012 ICS 27.160 Supersedes CEN/TS 12977-5:2010English Version

Thermal solar systems and components - Custom built systems - Part 5: Performance test methods for control equipment

Installations solaires thermiques et leurs composants - Installations assemblées à façon - Partie 5: Méthodes d'essai pour chauffe-eau solaires et installations solaires combinées

Thermische Solaranlagen und ihre Bauteile - Kundenspezifisch gefertigte Anlagen - Teil 5: Prüfverfahren für die Regeleinrichtungen This European Standard was approved by CEN on 19 February 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12977-5:2012: ESIST EN 12977-5:2012

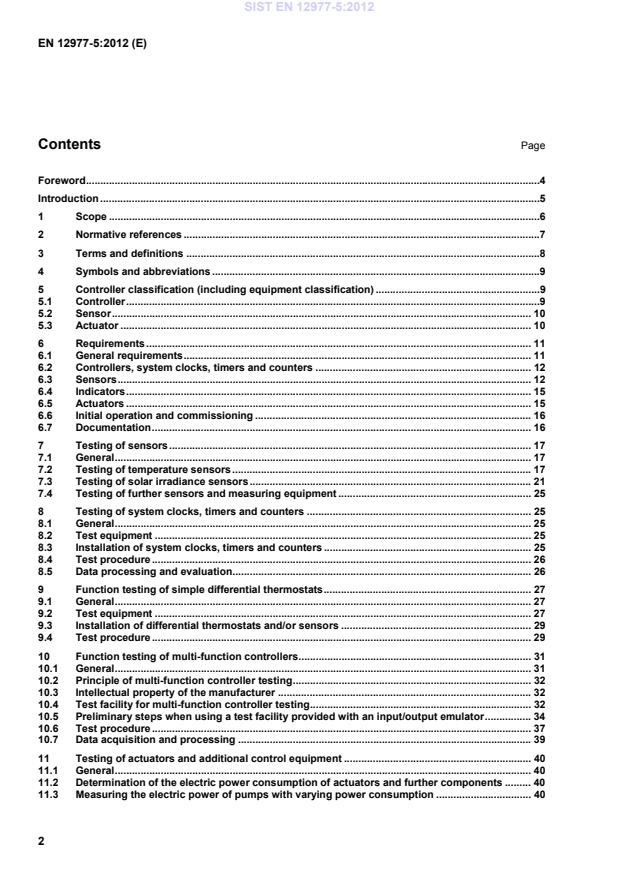

Testing the electrical supply voltage dependence of control equipment . 43A.1General . 43A.2Test equipment . 43A.3Test procedure . 43A.4Data processing . 44Bibliography . 45 Figures Figure 1 — Elevation of an oven-arrangement to test temperature sensor accuracy, high-temperature resistance and differential thermostat functions . 18Figure 2 — Example of a simulation box for testing differential thermostats of solar heating systems . 28Figure 3 — Schematic of a controller test facility including an input/output emulator . 34Figure 4 — Flow chart of steps when using a test facility provided with an input/output emulator according to Figure 3 . 35 Tables Table 1 — Classification of controllers for solar heating systems . 9Table 2 — Common sensors for solar heating systems . 10Table 3 — Most common actuators for solar heating systems . 10Table 4 — Accuracy of system clocks, timers and counters . 12Table 5 — Accuracy requirements of temperature sensors for solar heating systems . 13Table 6 — Requirements of high-temperature resistance of temperature sensors . 13Table 7 — Climate test conditions for solar irradiance sensors capability to resist to high irradiance . 14Table 8 — Climate test conditions for solar irradiance sensors capability to resist to high surrounding temperatures . 14Table 9 — Accuracy requirements for solar irradiance sensors . 14Table 10 — Total maximum electrical power of the pump(s) . 15Table 11 — Temperatures to be used for the accuracy test . 20Table 12 — Minimum climate test conditions for exposure and for external shock test . 23Table 13 — Irradiance levels to test the accuracy of solar irradiance sensors . 24Table 14 — Examples of control algorithms and corresponding test sequences for multi-function controllers . 38 SIST EN 12977-5:2012

In addition, the capability for all sensors to resist extreme operating conditions and to determine any significant drift in accuracy caused by this should be tested. The energy consumption of the controller and the associated control equipment should be documented, e.g. actuators. If the electrical supply is different from the mains supply this should be documented, e.g. PV powered pumps. Performance predictions for the associated system that the control equipment belongs to are considered. For the determination of the component parameters according to the CTSS method, as specified in EN 12977-2, a detailed investigation of all relevant algorithms, features and parameters controlling the system is relevant.

NOTE The most widely used control equipment for solar heating systems is described in EN 12977-5. For control equipment not widely used in solar heating systems or auxiliary heaters, if part of the system, accompanying standards should be applied if available.

In respect of potential adverse effects to human health or life (e.g. drinking water quality) caused by the products covered by EN 12977-5 it should be noted that: this document provides no information as to whether the product may be used without restriction in any of the Member States of the EU or EFTA; while awaiting the adoption of verifiable European criteria, existing national regulations concerning the use and/or the characteristics of this product remain in force. EN 12976-1, EN 12976-2 as well as EN 12977-1, EN 12977-2, EN 12977-3, and EN 12977-4 distinguish two categories of solar heating systems:

1) factory made solar heating systems;

2) custom built solar heating systems.

As defined in EN 12977-1, the classification of a system as factory made or custom built is a choice of the final supplier. Custom built solar heating systems are subdivided into two categories: i) large custom built systems are uniquely designed for a specific situation. ii) small custom built systems offered by a company are described in a so-called assortment file, in which all components and possible system configurations, marketed by the company, are specified; SIST EN 12977-5:2012

ISO/TR 9901, Solar energy — Field pyranometers — Recommended practice for use ISO 15218, Pneumatic fluid power — 3/2 solenoid valves — Mounting interface surfaces SIST EN 12977-5:2012

3.3 controller device to control a solar heating system, sometimes in connection/combination with auxiliary heater(s) Note 1 to entry: For classification, see Table 1. 3.4 pump any device capable of circulating liquid 3.5 reference device/measurement device or measurement which control equipment under test or measured quantities are referred or compared to 3.6 sensor device to measure physical (or chemical) qualities/properties

Note 1 to entry: With respect to solar heating systems, temperature, irradiance, flow/circulation, pressure and level sensors are most common. Note 2 to entry: For classification see Table 2. SIST EN 12977-5:2012

Controller C1 System clock, timer and counter Controlling the operation of one or more actuators by means of real or relative time. Timers and counters might be connected to different kinds of sensors influencing their behaviour by superposition of the commands. Beside time intervals counter might count and sum up events or quantities. C2 Differential thermostat Control of one or more actuators by means of a temperature difference between two temperature sensors. In most cases, a hysteresis between switching ON and OFF is present. Differential controllers are sometimes used with other signals, e.g. solar irradiation, pressure or level sensors. C3 Multi-function controller Controller designed to control one or more actuators based on measured quantities delivered by different kinds of sensors, real time or relative time and/or control concepts including specific control algorithms.

With regard to this document multi-function controllers are used to control and operate a solar heating system, and may also control a combination of hot water preparation, space heating, heat distribution or any kind of back-up heating. Multi-function controllers may use more than one differential algorithm in one unit or at least one operation is caused by more than a simple differential algorithm. If a device operates its output(s) depending on more than one (temperature) difference or not simply in an ON/OFF mode, then a controller incorporating such differential algorithm (thermostat) should be treated as a multi-function controller. If this is not the case, the unit shall be treated as a differential thermostat.

Sensor S1 Temperature sensor Sensing of temperatures of different parts in the system. In connection with the electronic layout of a controller or accessory measuring device determination of temperatures, e.g. in degrees Celsius.

S2 Irradiance sensor Instrument measuring the hemispherical solar irradiance in the plane of the radiation sensor within a spectral range of approx. 0,3 µm to 3 µm. To control a (solar) heating system irradiance sensors and accessory control equipment might have special designs to meet the specific requirements to solar energy utilization. With respect to this document both, irradiance sensors with thermoelectric sensor and irradiance sensors based on the photoelectrical effect are included. Supplementary photocells or other devices used to measure the solar irradiance are treated equate to solar irradiance sensor. S3 Flow/circulation sensors Sensing of the flow/circulation of a fluid. In connection with the electronic layout of a controller or accessory measuring device determination of the volume and/or mass flow. S4 Pressure sensor Sensing of absolute or relative pressure. In connection with the electronic layout of a controller or accessory measuring device determination of absolute pressure or pressure differences. S5 Level sensor Sensing of the level of a fluid within a vessel or a store. NOTE 1 The controller or accessory-measuring devices shall enable the conversion of sensor signals to values suitable to serve as control criterion for functioning and supervising of the system. NOTE 2 Values serving as control criterion should be displayed by a control device or, at least, a read back of data should be possible. NOTE 3 If other physical quantities or conditions than listed under S1, S2, S3, S4 or S5 are measured, the use of those sensors and the data processing might be in a similar manner to S1, S2, S3, S4 or S5.

5.3 Actuator Table 3 gives a selection of the most common actuators that can be found in solar heating systems. Table 3 — Most common actuators for solar heating systems

Actuator A1 Pump Device to circulate a heat transfer medium and/or water in a forced-circulation system, e.g. a collector circuit, a circuit for space heating/cooling and/or hot water preparation. A2 Solenoid and motor valve Electric driven device to start and/or to stop flow/circulation as well as to join, divide and/or to divert flow streams. A3 Relay / Contactor Device to connect and/or to switch electrical loads and/or actuators, e.g. when using a low-level signal (voltage and/or current) of a controller to start and stop a high voltage/power pump.

If an upper temperature limit for materials and/or components specified by the manufacturer or final supplier is reached, the control equipment should stop the circulation pump(s) of the collector loop. With regard to restarting the circulation pump(s), the control strategies should be designed in a way to prevent damage to the system, the components and materials. If the control equipment includes algorithms and/or devices for limitation of the flow temperature, e.g. to a floor heating circuit, these algorithms and/or control equipment shall be reliable.

6.1.6 Lightning The control equipment shall meet the requirements given in EN 62305-3. The manufacturer or the final supplier shall specify particular features for lightning protection within the control equipment. SIST EN 12977-5:2012

6.2.3 Accuracy requirements for system clocks, timers and counters The accuracy requirements of system clocks, timers and counters in charge of controlling a solar heating system are listed in Table 4. Table 4 — Accuracy of system clocks, timers and counters Clock / timer / counter Tolerance Real time clock ± 1,0 min per 30 days Timer ± 1,0 min per 30 days operating time Counter ± 1,0 %

In case of solar heating systems installed in regions with a time shift between summer- and wintertime, adjustments have to be specified by the final supplier, where applicable. 6.3 Sensors 6.3.1 Temperature sensors 6.3.1.1 General For all temperature sensors, the location and installation shall ensure a reliable thermal contact with the part for which the temperature shall be measured. Surrounding conditions, when not relevant, shall not influence the measurement. With the exception of ambient air temperature sensors, temperature sensors shall be protected/insulated against external influences. 6.3.1.2 Accuracy requirements The accuracy requirements of temperature sensors in charge of controlling a solar heating system are listed in Table 5. SIST EN 12977-5:2012

if the auxiliary heater is part of a solar heating system Minimum required temperature Maximum temperature declared by the manufacturer or final supplier plus 10 K Time of exposure At least 6 h

6.3.1.4 Reduction of temperature sensor accuracy caused by extreme operating conditions All kinds of temperature sensors installed within a solar heating system or auxiliary heater, if the auxiliary heater is part of a solar heating system, shall withstand extreme operating conditions as specified in Table 6, without reduction of the accuracy by more than 1 K. In addition, the accuracy requirements as specified in Table 5 shall be kept. 6.3.2 Irradiance sensors 6.3.2.1 General For control purposes, the solar irradiance sensor shall at least be sensitive to wavelength in the range of approximately 0,4 µm to 0,8 µm. 6.3.2.2 High irradiance resistance The irradiance sensors shall resist any extreme solar irradiance that may occur during operation within the prescribed lifetime or maintenance period specified by the manufacturer or final supplier. The capability requirements of an irradiance sensor to resist extreme irradiance conditions are listed in Table 7. SIST EN 12977-5:2012

6.3.2.3 High temperature resistance The conditions to test solar irradiance sensor's capability to resist to high surrounding temperatures are listed in Table 8. Table 8 — Climate test conditions for solar irradiance sensors capability to resist to high surrounding temperatures Climate parameter Value Hemispherical solar irradiance in the plane of the irradiance sensor, G > 900 W/m² Ambient/Surrounding air temperature for testing sensor's resistance against high temperatures, ϑamb > 30 °C Surrounding air speed, vair < 1 m/s Time the solar irradiance sensor should be exposed to the test conditions, t > 12 h

6.3.2.4 Accuracy requirements The accuracy requirements of solar irradiance sensors in charge of controlling a solar heating system are listed in Table 9: Table 9 — Accuracy requirements for solar irradiance sensors Range of measurement Tolerance 100 W/m² to 300 W/m² ± 15,0 % of the specified solar irradiance > 300 W/m² to 900 W/m² ± 10,0 % of the specified solar irradiance > 900 W/m² ± 15,0 % of the specified solar irradiance

6.3.2.5 Reduction of solar irradiance sensor accuracy caused by extreme operating conditions The irradiance sensor shall withstand extreme operating conditions as specified in Tables 7 and 8 without reduction of the accuracy out of the range given in Table 9. The sensor, gasket(s), cable(s) and all related mounting equipment shall not show decomposition or significant discolouring.

NOTE If not specified in the documentation, the peak power of a collector array shall be calculated by multiplying the aperture area of the whole collector array with 700 W/m² of aperture area. In the case of pumps operated with variable power (e.g. pulse width modulation) or short term alternating operation, the requirements stated in Table 10 applies to the average power.

The maximum pump power stated above excludes the power of pumps in drain-back systems that are only needed to refill the system after draining back (down) of the heat carrier fluid.

Other heat transfer loops within the system should be designed by comparing the parasitic power of their pump(s) to the highest heat power transmitted. The values in Table 10 shall not be exceeded. SIST EN 12977-5:2012

6.7 Documentation The documentation of the control equipment shall be complete and clearly arranged. The documentation shall include all instructions necessary for assembly, installation, operation and maintenance. The instructions shall enable correct installation and operation. The documentation shall at least include: a) all relevant system configurations including related hydraulic, control schemes and specifications to enable the user to understand the operating modes of the system; b) a description of the control strategies and the control system(s) including the location of the control equipment (e.g. sensors, actuators), if relevant for different system designs. All control equipment should be included in the hydraulic scheme(s) of the system; c) a list of all components to be included into the respective system configurations, with full reference to dimension and type. The identification of the listed components shall be clear and unambiguous; d) if relevant, list of combination and dimension options within different system configurations; e) a guideline to adjust all parameters and settings. It is recommended to include a table in which all adjusted parameters and their actual settings are entered by the user; f) maintenance instruction for the control equipment, including start-up and shut-down of the system; g) instructions for function and performance testing; h) intended action(s) in the case of most common failures.

NOTE For a detailed specification of the entire documentation of a solar heating system, see EN 12977-1. SIST EN 12977-5:2012

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...