EN 13674-1:2003+A1:2007

(Main)Railway applications - Track - Rail - Part 1: Vignole railway rails 46 kg/m and above

Railway applications - Track - Rail - Part 1: Vignole railway rails 46 kg/m and above

This European Standard specifies Vignole railway rails of 46 kg/m and greater linear mass, for general and high speed railway track usage.

Seven pearlitic steel grades are specified covering a hardness range of 200 to 390 HBW and include non heat treated carbon manganese steels; non heat treated alloy steels; and heat treated carbon manganese and low alloy steels.

There are 21 rail profiles specified in this Standard.

Two classes of rail straightness are specified, differing in requirements for straightness, surface flatness and crown profile. Two classes of profile tolerances are specified.

Bahnanwendungen - Oberbau - Schienen - Teil 1: Vignolschienen ab 46 kg/m

Diese Europäische Norm enthält Festlegungen für Vignolschienen mit einer längenbezogenen Masse ab 46 kg/m für normale und Hochgeschwindigkeitsstrecken im Eisenbahnwesen.

Sieben perlitische Stahlsorten in einem Härtebereich zwischen 200 HBW und 390 HBW sind festgelegt. Die Schienen sind entweder nichtwärmebehandelt und bestehen aus Kohlenstoff-Mangan-Stahl bzw. legiertem Stahl oder sind wärmebehandelt und bestehen aus Kohlenstoff-Mangan-Stahl bzw. niedriglegiertem Stahl.

In dieser Norm sind 21 Schienenprofile festgelegt.

Zwei Schienenklassen sind festgelegt, die sich hinsichtlich der Anforderungen an die Geradheit, die Fahrflächenebenheit und das Kopfprofil unterscheiden. Für die Profiltoleranzen sind drei Klassen festgelegt.

Applications ferroviaires - Voie - Rails - Partie 1: Rails vignole de masse supérieure ou égale à 46 kg/m

La présente partie de la Norme européenne spécifie les rails ferroviaires Vignole symétriques de masse linéaire supérieure ou égale à 46 kg/m, destinés à l'usage des voies classiques et à grande vitesse.

Sept nuances d'acier perlitique sont spécifiées représentant une fourchette de dureté comprise entre 200 HBW et 390 HBW et incluant :

- les aciers non traités thermiquement au carbone manganèse ;

- les aciers alliés non traités thermiquement ;

- les aciers traités thermiquement au carbone manganèse ;

- les aciers faiblement alliés traités thermiquement.

21 profils de rail sont spécifiés dans la présente norme.

Deux classes de rectitudes des rails sont spécifiées, différenciées par les exigences de rectitude, la planéité de la surface et le bombé du champignon. Deux classes de tolérances de profils sont également spécifiées.

Železniške naprave - Zgornji ustroj - Tirnica - 1. del: Vignolove tirnice z maso 46 kg/m in več

General Information

- Status

- Withdrawn

- Publication Date

- 31-Oct-2007

- Withdrawal Date

- 08-Feb-2011

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 1/WG 4 - Rails

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 09-Feb-2011

- Completion Date

- 09-Feb-2011

- Directive

- Not Harmonized93/38/EEC - Procurement procedures of entities operating in the water, energy, transport and telecommunications sectors

Not Harmonized96/48/EC - Interoperability of the trans-European high-speed rail systemOJ Ref: C 97, C 97, C 97, C 97, C 97, C 97, C 97, C 97, C, OJ Date: 16-Apr-2010

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 22-Dec-2008

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 13674-1:2003+A1:2007 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Track - Rail - Part 1: Vignole railway rails 46 kg/m and above". This standard covers: This European Standard specifies Vignole railway rails of 46 kg/m and greater linear mass, for general and high speed railway track usage. Seven pearlitic steel grades are specified covering a hardness range of 200 to 390 HBW and include non heat treated carbon manganese steels; non heat treated alloy steels; and heat treated carbon manganese and low alloy steels. There are 21 rail profiles specified in this Standard. Two classes of rail straightness are specified, differing in requirements for straightness, surface flatness and crown profile. Two classes of profile tolerances are specified.

This European Standard specifies Vignole railway rails of 46 kg/m and greater linear mass, for general and high speed railway track usage. Seven pearlitic steel grades are specified covering a hardness range of 200 to 390 HBW and include non heat treated carbon manganese steels; non heat treated alloy steels; and heat treated carbon manganese and low alloy steels. There are 21 rail profiles specified in this Standard. Two classes of rail straightness are specified, differing in requirements for straightness, surface flatness and crown profile. Two classes of profile tolerances are specified.

EN 13674-1:2003+A1:2007 is classified under the following ICS (International Classification for Standards) categories: 93.100 - Construction of railways. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13674-1:2003+A1:2007 has the following relationships with other standards: It is inter standard links to EN 13674-1:2003, EN 13674-1:2011, EN 13977:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13674-1:2003+A1:2007 is associated with the following European legislation: EU Directives/Regulations: 93/38/EEC, 96/48/EC; Standardization Mandates: M/024, M/275. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13674-1:2003+A1:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Bahnanwendungen - Oberbau - Schienen - Teil 1: Vignolschienen ab 46 kg/mApplications ferroviaires - Voie - Rails - Partie 1: Rails vignole de masse supérieure ou égale a 46 kg/mRailway applications - Track - Rail - Part 1: Vignole railway rails 46 kg/m and above45.080Rails and railway componentsICS:Ta slovenski standard je istoveten z:EN 13674-1:2003+A1:2007SIST EN 13674-1:2004+A1:2008en,fr,de01-marec-2008SIST EN 13674-1:2004+A1:2008SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13674-1:2003+A1

November 2007 ICS 93.100 Supersedes EN 13674-1:2003 English Version

Railway applications - Track - Rail - Part 1: Vignole railway rails 46 kg/m and above

Applications ferroviaires - Voie - Rails - Partie 1: Rails vignole de masse supérieure ou égale à 46 kg/m

Bahnanwendungen - Oberbau - Schienen - Teil 1: Vignolschienen ab 46 kg/m This European Standard was approved by CEN on 28 February 2003 and includes Amendment 1 approved by CEN on 27 September 2007.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2007 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13674-1:2003+A1:2007: ESIST EN 13674-1:2004+A1:2008

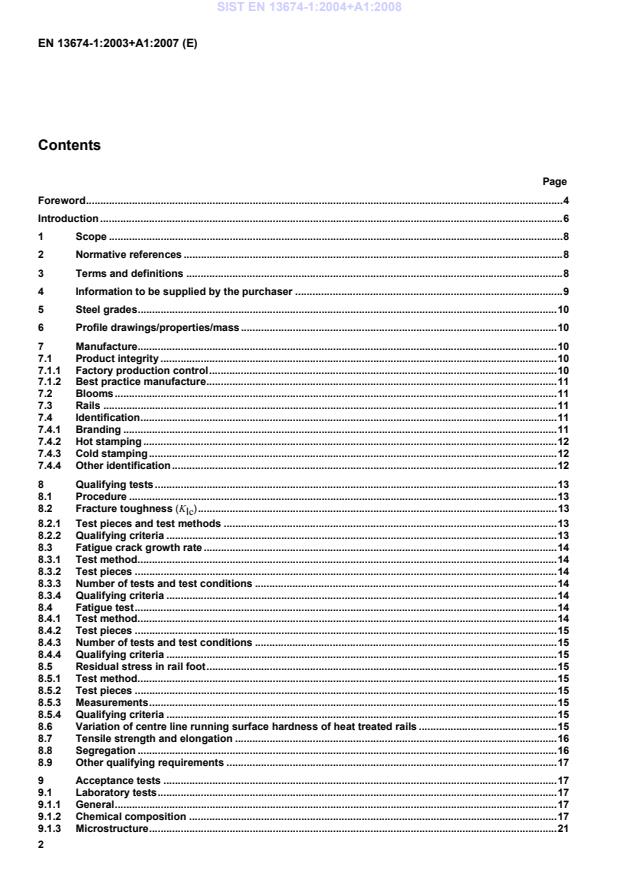

Rail profiles.45 Annex B (normative)

Standard test method for the determination of the plane strain fracture toughness (KIc) of rails.70 Annex C (normative)

Method for the determination of rail foot surface longitudinal residual stresses.76 Annex D (normative)

Limiting sulfur prints.79 Annex E (normative)

Profile and drilling gauges.93 Annex F (informative)

Comparison of steel designations referred to in this standard compared to those in EN 10027-1 and EN 10027-2.105 Annex ZA (informative)

Clauses of this European Standard addressing essential requirements or other provisions of EU Directives.106 Bibliography.107

The standard reflects this change in philosophy from the traditional content of rail standards. A review was undertaken of the most commonly used rail standards of the world. All relevant aspects important to both user and manufacturer were considered with the aim of ensuring that all of the content had specific usefulness and relevance. For example rail grading and much of the standard has been based on hardness rather than tensile strength. Whilst the two are directly related, hardness is very quick and cheap to carry out and provides more relevant guidance to the user particularly where properties vary in different parts of the profile.

Since many rail manufacturers would have not previously carried out proving trials, the standard includes a prerequisite for all manufacturers to prove conformity against a set of qualifying test criteria at the time of tendering. The Qualifying tests include all “normal” acceptance test results plus new "type-casting" features such as fracture toughness, fatigue and residual stress. To provide users with the necessary confidence, acceptance limits have been based on results from rail known to have performed well in demanding track installations.

One aspect of the standard which is a complete break from tradition is the inclusion of quality assurance and inspection clause as part of product integrity. SIST EN 13674-1:2004+A1:2008

The equipment specified is that which gives the best probability of achieving the required product for use in track.

In the future new technology can add to, but preferably will reduce or delete such items. Examples of areas where the technological state of the art renders the standard less than complete include: oxide/oxygen relationships; hydrogen test techniques; roller straightening effects on residual stresses; roller straightening effects on contact scrub; measurement and effect of residual stresses throughout the rail. SIST EN 13674-1:2004+A1:2008

process whereby blooms are held for a period of time at an elevated temperature for diminishing the hydrogen content NOTE 1 For maximum efficiency this is as near to (but below) the pearlite to austenite transformation temperature as is practically possible. NOTE 2 This process is sometimes referred to as sub critical diffusion annealing. 3.8 qualifying tests special tests and criteria which are relevant to some aspects of the service performance of rails. Acceptance tests also form part of the qualifying tests. 3.9 acceptance tests tests carried out as part of the process and product control system, normally on a heat, sequence or tonnage basis 4 Information to be supplied by the purchaser The purchaser shall provide the supplier with the following information at the time of tender or order: a) the rail profile (see annex A); b) the steel grade (see clause 5); c) the profiles class, ‘X’ or ‘Y’ (see 9.2.1); d) the straightness class ‘A’ or ‘B’ of rail as specified in 9.2.2; e) the lengths of rail (see 9.2.3 and Table 10); f) undrilled or drilled rail ends to take fish bolts, and location and dimensions of holes when required (see 9.2.3); g) any special treatments to be applied to bolt holes; h) tolerances for bolt holes to which special processes are to be applied; i) paint code requirements (see 7.4.4). SIST EN 13674-1:2004+A1:2008

Carbon – manganese No branding lines R200 200 to 240 (C-Mn)

Non heat treated

Carbon – manganese _______

R220 220 to 260 (C-Mn)

Non heat treated

Carbon – manganese ____

R260 260 to 300 (C-Mn) _______

Non heat treated

Carbon – manganese _______

R260Mn 260 to 300 (C-Mn) _______

Non heat treated

Alloy (1 %Cr) _______

_______

R320Cr 320 to 360 Non heat treated _______

Carbon – manganese ______

R350HT 350 to 390 b (C-Mn) _______ ________

Heat treated

R350LHT 350 to 390 b Low alloy, heat treated ______

_______ _______

______

a See Table 5 for chemical composition/mechanical properties. b See Table 7 for hardness requirements. 6 Profile drawings/properties/mass Rail profiles, dimensions, properties and linear masses are given in annex A. The tolerances of certain dimensions shall be as given in Table 8. All other quantities are informative only. NOTE Linear masses have been calculated based on the density of steel of 7850 kg/m3. 7 Manufacture 7.1 Product integrity 7.1.1 Factory production control All Vignole rails shall be produced under a comprehensive system of factory production control which shall ensure confidence in the conformity of the finished product. The system shall address this European Standard to ensure that the finished products consistently comply with requirements to achieve the product integrity necessary to provide assurance of product safety in track. Manufacturers shall demonstrate continuing compliance, including documented evidence, with the factory production control system required. SIST EN 13674-1:2004+A1:2008

___

ROLLING MILL _______ 96 60 E 1

(60 E 1 profile rail rolled 1996 and 260 HBW carbon-manganese rail steel grade).

___

ROLLING MILL _______ _______ 96 60 E 1

Figure 1 — Design of letters and numbers on a 10° angle for rail stamps The identification system employed shall be such as to enable the hot stamped marking to be collated with: a) the number of the heat from which the rail has been rolled; b) the number of the strand and position of bloom within the strand; c) the position of the rail in the bloom (A, B . Y). In the event of identification marks having been removed, omitted or requiring alteration, re-identification of such marks shall be made by rotary burr. 7.4.3 Cold stamping Cold stamping shall only be used on the cut face of the rail within the central portion of the head, at the request of the purchaser. 7.4.4 Other identification Rails of straightness class A shall be identified with a green mark and the position of the green mark is to be specified by the purchaser. The steel grade may additionally be identified using paint. The purchaser shall specify the colour and position of the paint application. SIST EN 13674-1:2004+A1:2008

Only a small part of the test piece will be destroyed for the purpose of measuring residual stress; the remainder can be used for other qualifying approval tests. 8.5.3 Measurements Longitudinal residual stress determinations shall be made on the rail foot of each of the 6 test pieces described in 8.5.2. The location of the measurements is shown in Figure C.1. If data are available for straightness class A rails then class B rails of the same profile need not be tested. 8.5.4 Qualifying criteria The maximum longitudinal residual stress in the foot shall be 250 MPa for all steel grades. 8.6 Variation of centre line running surface hardness of heat treated rails This clause only applies to heat treated rails. For the longest length of rail produced by the manufacturer, a one metre length of rail shall be taken from each end and at 20 m intervals from one end of the rail. These shall be hardness tested (HBW) in accordance with EN ISO 6506-1 along their length at 25 mm intervals on the centreline of the running surface after 0,5 mm has been ground away. The hardness results shall be no more than ± 15 HBW from the mean result obtained. SIST EN 13674-1:2004+A1:2008

One per 1000 tonnes or part thereof for grades 260 Mn and 320 Cr One per 100 tonnes of mill heat treated a,c Decarburisation 9.1.4 One per 1000 tonnes or part thereof a,b

One per 500 tonnes of re-heated and mill heat treated a,c Oxide cleanness 9.1.5 One per sequence a,b

One per sequence a,b or c Sulfur print 9.1.6 One per 500 tonnes or part thereof a,b One per 500 tonnes or part thereof a,b or c Hardness 9.1.7 One per heat a,b One per 50 tonnes of re-heated a,c

One per 100 tonnes of mill heat treated a,c Tensile 8.7 & 9.1.8 One calculation per heat/one per 2 000 tonnes a,b One per 1 000 tonnes a,c

a Samples shall be taken at random but only rails from blooms outside the mixing zone between heats when continuously cast in sequence. b Samples shall be cut after rolling. c Samples shall be cut from heat treated rails. SIST EN 13674-1:2004+A1:2008

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...