EN 1096-4:2018

(Main)Glass in building - Coated glass - Part 4: Product standard

Glass in building - Coated glass - Part 4: Product standard

This European Standard covers the evaluation of conformity and the factory production control of coated glass for use in buildings.

NOTE For glass products with electrical wiring or connections for, e.g. alarm or heating purposes, other directives, e.g. Low Voltage Directive, may apply.

Glas im Bauwesen - Beschichtetes Glas - Teil 4: Produktnorm

Diese Europäische Norm umfasst die Konformitätsbewertung und die werkseigene Produktionskontrolle von beschichtetem Glas zur Anwendung im Bauwesen.

ANMERKUNG Für Glaserzeugnisse mit elektrischer Verkabelung oder Anschlüssen, wie z. B. Alarm- oder Heizungsanwendungen, können andere Richtlinien, z. B. die Niedrigspannungsrichtlinie, gelten.

Verre dans la construction - Verre à couche - Partie 4: Norme de produit

La présente Norme européenne traite de l’évaluation de la conformité et du contrôle de la production en usine du verre à couche utilisé dans la construction.

NOTE Pour les produits verriers équipés d’un câblage ou de branchements électriques, pour les besoins d’alarme ou de chauffage par exemple, d’autres directives comme la Directive Basse tension peuvent s’appliquer.

Steklo v gradbeništvu - Steklo z nanosi - 4. del: Standard za proizvod

Ta evropski standard zajema vrednotenje skladnosti in kontrolo tovarniške proizvodnje stekla z nanosi, ki se uporablja v stavbah.

OPOMBA: Za steklene izdelke z električno napeljavo ali priključki za npr. alarmne ali grelne namene se lahko uporabljajo druge direktive, npr. direktiva o nizki napetosti.

General Information

- Status

- Published

- Publication Date

- 21-Aug-2018

- Withdrawal Date

- 27-Feb-2019

- Technical Committee

- CEN/TC 129 - Glass in building

- Drafting Committee

- CEN/TC 129/WG 6 - Coated glass for windows

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 03-Mar-2024

- Completion Date

- 03-Mar-2024

- Directive

- Harmonized Standard305/2011 - Regulation (eu) No 305/2011 of the European Parliament and of the Council of 9 march 2011 laying down harmonised conditions for the marketing of construction products and repealing council directive 89/106/eecOJ Ref: L 77/82, L 77/82, L 77/82, L 77/82, L 77/82, L 77/ OJ Date: 20-Mar-2019

Relations

- Effective Date

- 29-Aug-2018

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 410:2011 - Glass in building - Determination of luminous and solar characteristics of glazing - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 1096-4:2018 - “Glass in building - Coated glass - Part 4: Product standard” (CEN) specifies how to assess conformity and operate factory production control (FPC) for coated glass used in buildings. It implements the Assessment and Verification of Constancy of Performance (AVCP) requirements under the EU Construction Products Regulation (Regulation (EU) No 305/2011) and replaces the 2004 edition. The standard defines what manufacturers must document and declare (Declaration of Performance - DoP) for coated glass products.

Key topics and requirements

- Scope and purpose

- Evaluation of conformity and the factory production control (FPC) system for coated glass.

- Notes that other directives (e.g., Low Voltage Directive) may apply when products include wiring or electrical connections.

- Product description

- Manufacturers must prepare and maintain a detailed product description covering coating type (on-line/off-line), deposition method, layer materials and order, glass substrates, and classification.

- Definition of product family and rules for substitution of materials where equivalence is demonstrated.

- Assessment & AVCP

- Procedures for type testing, test reports, and determination of a representative product-type.

- Requirements for initial inspection, routine FPC, and continuous surveillance including sampling and corrective procedures.

- Rules for handling modifications and pre-production prototypes.

- Declared characteristics

- Spectrophotometric and energy characteristics (e.g., light transmittance, reflectance, solar factor (g)) must be declared in the DoP.

- Emissivity tolerances updated - for declared normal emissivity < 0.10 the tolerance is reduced to +0.01.

- Durability/conformity assessment and mechanical resistance (declared as characteristic bending strength of the glass substrate) must be included in the DoP.

- Annexes

- Normative and informative annexes detail FPC procedures, factory tests, type testing, sampling, spectrophotometric measurements and the relationship to the EU CPR (Annex ZA).

Applications and users

EN 1096-4:2018 is intended for:

- Coated glass manufacturers needing to establish FPC and prepare a DoP.

- Test laboratories performing type tests and spectrophotometric/energy measurements.

- Certification bodies and notified bodies assessing AVCP compliance.

- Architects, façade engineers, specifiers and consultants requiring standardized performance data for coated glazing in building envelopes.

- Regulatory authorities and procurement teams verifying compliance with the CPR.

Related standards

- EN 1096-1, -2, -3, -5 (other parts of the coated glass series)

- EN 410 (luminous and solar characteristics)

- EN 673 (thermal transmittance / U-value)

- Annex ZA of EN 1096-4:2018 explains the link to Regulation (EU) No. 305/2011.

Keywords: EN 1096-4:2018, coated glass, glass in building, factory production control, AVCP, Declaration of Performance, emissivity, solar factor, spectrophotometric characteristics.

Frequently Asked Questions

EN 1096-4:2018 is a standard published by the European Committee for Standardization (CEN). Its full title is "Glass in building - Coated glass - Part 4: Product standard". This standard covers: This European Standard covers the evaluation of conformity and the factory production control of coated glass for use in buildings. NOTE For glass products with electrical wiring or connections for, e.g. alarm or heating purposes, other directives, e.g. Low Voltage Directive, may apply.

This European Standard covers the evaluation of conformity and the factory production control of coated glass for use in buildings. NOTE For glass products with electrical wiring or connections for, e.g. alarm or heating purposes, other directives, e.g. Low Voltage Directive, may apply.

EN 1096-4:2018 is classified under the following ICS (International Classification for Standards) categories: 81.040.20 - Glass in building. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1096-4:2018 has the following relationships with other standards: It is inter standard links to EN 1096-4:2004, EN 1096-5:2016, EN 1063:1999, EN 1096-2:2012, EN 13501-5:2016, EN 13541:2012, EN 673:2024, EN 13501-1:2018, EN 1096-3:2012, EN 356:1999, EN 12898:2019, EN 410:2011, EN 15998:2020, EN 12758:2019+A1:2023, EN 13501-2:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1096-4:2018 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 88/609/EEC; Standardization Mandates: M/135_AM1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1096-4:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Steklo v gradbeništvu - Steklo z nanosi - 4. del: Standard za proizvodGlas im Bauwesen - Beschichtetes Glas - Teil 4: ProduktnormVerre dans la construction - Verre à couche - Partie 4: Norme de produitGlass in building - Coated glass - Part 4: Product standard81.040.20Steklo v gradbeništvuGlass in buildingICS:Ta slovenski standard je istoveten z:EN 1096-4:2018SIST EN 1096-4:2018en,fr,de01-december-2018SIST EN 1096-4:2018SLOVENSKI

STANDARDSIST EN 1096-4:20051DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1096-4

August

t r s z ICS

z sä r v rä t r Supersedes EN

s r { xæ vã t r r vEnglish Version

Glass in building æ Coated glass æ Part

vã Product standardVerre dans la construction æ Verre à couche æ Partie

vã Norme de produit

Glas im Bauwesen æ Beschichtetes Glas æ Teil

vã Produktnorm This European Standard was approved by CEN on

x May

t r s zä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s r { xæ vã t r s z ESIST EN 1096-4:2018

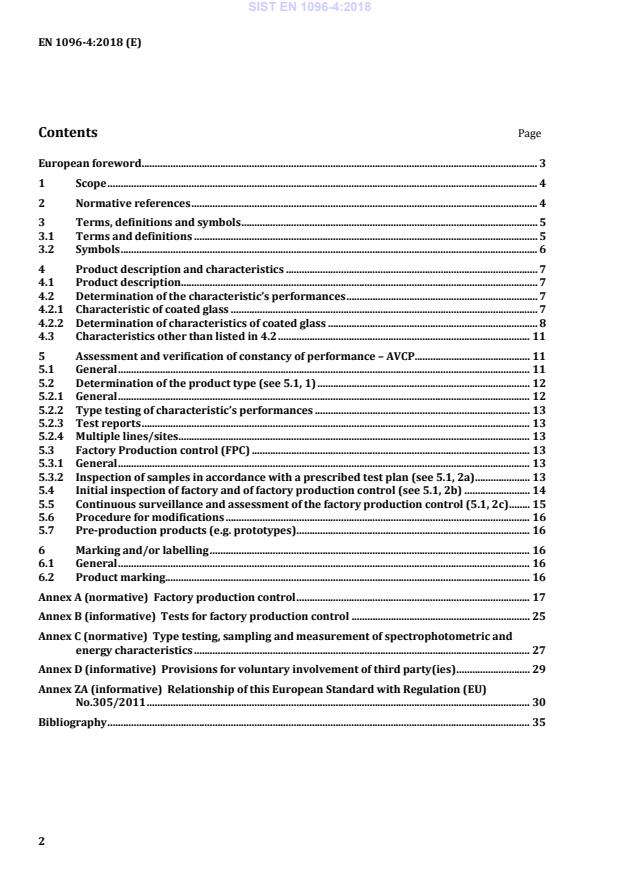

Factory production control . 17 Annex B (informative)

Tests for factory production control . 25 Annex C (normative)

Type testing, sampling and measurement of spectrophotometric and energy characteristics . 27 Annex D (informative)

Provisions for voluntary involvement of third party(ies) . 29 Annex ZA (informative)

Relationship of this European Standard with Regulation (EU) No.305/2011 . 30 Bibliography . 35

IEC Electropedia: available at http://www.electropedia.org/

ISO Online browsing platform: available at http://www.iso.org/obp 3.1.1 factory production control FPC documented, permanent and internal control of production in a factory, in accordance with this standard Note 1 to entry: See also Annexes A and B. [SOURCE: Regulation (EU) No 305/2011] 3.1.2 product-type set of representative performance levels or classes of a construction product, in relation to its essential characteristics, produced using a given combination of raw materials or other elements in a specific production process [SOURCE: Regulation (EU) No 305/2011] 3.1.3 essential characteristic characteristic of the construction product which relate to the basic requirements for construction works Note 1 to entry: Basic requirements for construction work are given in the regulation (EU) No 305/2011, Annex I. [SOURCE: Regulation (EU) No 305/2011] 3.1.4 performance of a construction product performance related to the relevant essential characteristics, expressed by level or class, or in a description [SOURCE: Regulation (EU) No 305/2011] 3.1.5 level result of the assessment of the performance of a construction product in relation to its essential characteristics, expressed as a numerical value [SOURCE: Regulation (EU) No 305/2011] SIST EN 1096-4:2018

and ' normal emissivity of both sides of a coated glass

i emissivity of a test specimen measured during factory production control v light transmittance v and v light reflectance of both sides of a coated glass e energy transmittance e and e energy reflectance of both sides of a coated glass g solar factor d subscript indicating that the value is a declared value m subscript indicating that the value is a determined value obtained by measurement, calculation or other means SIST EN 1096-4:2018

a reference to EN 1096-1, EN 1096-2, EN 1096-3, EN 1096-4 and when relevant EN 1096-5, and all other standards with which the manufacturer claims compliance,

the type of coating, i.e. online, off-line,

the method of coating deposition, e.g. chemical-vapour deposition, sputtering, etc.

the materials making up the layer(s) of the coating,

the order of stacking of the layers,

the glass substrates,

the classification of the coated glass. NOTE The product description can include an identity card (see EN 1096-1:2012, Annex A). The layers may be listed either in full, i.e. chemical composition, or by a manufacturer's code. Product families shall be defined in terms of the above product description taking into account the criteria for demonstrating equivalence of coatings (see EN 1096-2:2012, Annex F and EN 1096-3:2012, Annex B). The substitution of materials and/or components shall maintain the conformity with the product description. The substituting materials and/or components can be added to the product family and also the product description when compliance has been demonstrated. 4.2 Determination of the characteristic’s performances 4.2.1 Characteristic of coated glass 4.2.1.1 General The characteristics of coated glass, listed in Table 1, are in general those of the glass substrate and can be found in the appropriate product standard (see 4.2.1.2). Since they are not changed significantly by the coating process, they shall be used for coated glass. For glass substrates covered by European specifications, generally accepted values, declared values, or calculated values of the characteristics listed in Table 1 shall be used. If glass panes are used which are not covered by harmonized European Specifications (as defined in regulation EU305/2011), it shall be demonstrated that those glasses have a chemical composition and a mechanical stability over time equivalent to the requirements of the relevant standard listed. SIST EN 1096-4:2018

kg/m3 Hardness (Knoop hardness in accordance with ISO 9385) HK 0,1/20 Dimensionless Young's modulus E GPa Poisson's ratio

Dimensionless Characteristic bending strength ƒg;k MPa Resistance against sudden temperature changes and temperature differentials - K Specific heat capacity c J/(kg.K) Coefficient of linear expansion l K «1 Thermal conductivity

W/(m.K) Mean refractive index to visible radiation n Dimensionless 4.2.1.2 Glass panes used as substrates for the production of coated glass The glass substrates used for the production of coated glass shall be selected according to EN 1096-1:2012, Clause 5. 4.2.2 Determination of characteristics of coated glass 4.2.2.1 General If the coated glass manufacturer wishes to claim that any performance characteristic is independent of the production equipment used, then the factory production control system shall be in accordance with this document including his specific process control conditions. The information supplied with the incoming glass may be used for the characteristics listed in 4.2.2.3 to 4.2.2.11, as the coating process does not alter the values. 4.2.2.2 Safety in the case of fire - Resistance to fire Fire resistance shall be determined in accordance with EN 13501-2. The testing methodology specified in EN 15998 shall be used for glass products that are claiming fire resistance. 4.2.2.3 Safety in the case of fire - Reaction to fire Reaction to fire shall be determined in accordance with EN 13501-1. 4.2.2.4 Safety in the case of fire - External fire performance (for roof coverings only) Where the manufacturer wishes to declare external fire performance (e.g. when subject to regulatory requirements), the product shall be tested and classified in accordance with EN 13501-5. SIST EN 1096-4:2018

shall be the declared normal emissivity of the coating manufacturer. If the information is not available, the normal emissivity shall be determined in accordance with EN 12898 and Annex C of this standard. b) The U-value shall be determined by calculation in accordance with EN 673, with the normal emissivity as defined above and the nominal thickness of the glass panes. 4.2.2.13 Energy conservation and heat retention - Radiation properties: Light transmittance and reflectance The light transmittance and light reflectance shall be determined either: a) in accordance with the following procedure: 1) The light transmittance and light reflectance of one sample of coated glass shall be determined in accordance with EN 410 and Annex C. The exact thicknesses of the glass shall be measured. 2) The light transmittance and the light reflectance of any other thickness shall be calculated according to EN 410. 3) The tool used to calculate the light transmittance and the light reflectance shall be validated. SIST EN 1096-4:2018

the test samples shall be representative of the intended future production and shall be selected by the manufacturer; —

on request of the manufacturer, the results of the assessment of samples of pre-production product may be included in a certificate or in test reports issued by the involved third party, as TT. The manufacturer should ensure the equivalence between pre-production samples and product made on the full production process. 6 Marking and/or labelling 6.1 General All voluntary marking and/or labelling shall comply with D.3. Care shall be taken to ensure that any voluntary marking and/or labelling does not cause confusion with respect to the mandatory requirements. 6.2 Product marking There is no requirement to permanently mark coated glass. However, if they are processed, e.g. thermally toughened, heat strengthened etc., then they have to comply with the appropriate product standard. SIST EN 1096-4:2018

Factory production control A.1 Factory Production Control Requirements A.1.1 General The factory production control system shall consist of procedures, regular inspections and tests and/or assessments and the use of the results to control (raw and other) incoming materials or components, equipment, the production process and the product. NOTE A factory production control system conforming to EN ISO 9001 [1] and made specific to the requirements of this annex is deemed to satisfy the requirements of this annex. A.1.2 Organization A.1.2.1 Responsibility and authority The responsibility, authority and the interrelation of all personnel who manage, perform and verify work affecting conformity shall be defined, particularly for personnel who have the organizational freedom and authority to: a) initiate action to prevent the occurrence of product non-conformity; b) identify and record any product non-conformances. A.1.2.2 Management representative for factory production control The manufacturer shall appoint a management representative who, irrespective of other responsibilities, shall have defined authority and responsibility for ensuring that the requirements of this document are implemented and maintained. A.1.2.3 Management review The production control system shall be reviewed by the manufacturer’s management at appropriate intervals in accordance with the manufacturer’s control system to ensure its continuing suitability and effectiveness. Records of such reviews shall be maintained for a minimum period of 5 years. A.1.3 Control system A.1.3.1 General The manufacturer shall establish and maintain a documented system as a means of ensuring that the product conforms to EN 1096-1. The following requirements shall be fulfilled. A.1.3.2 Personnel The manufacturer shall use appropriately trained personnel for the operation and inspections of all production and inspection equipment. SIST EN 1096-4:2018

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...